Patents

Literature

31 results about "Haultain operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

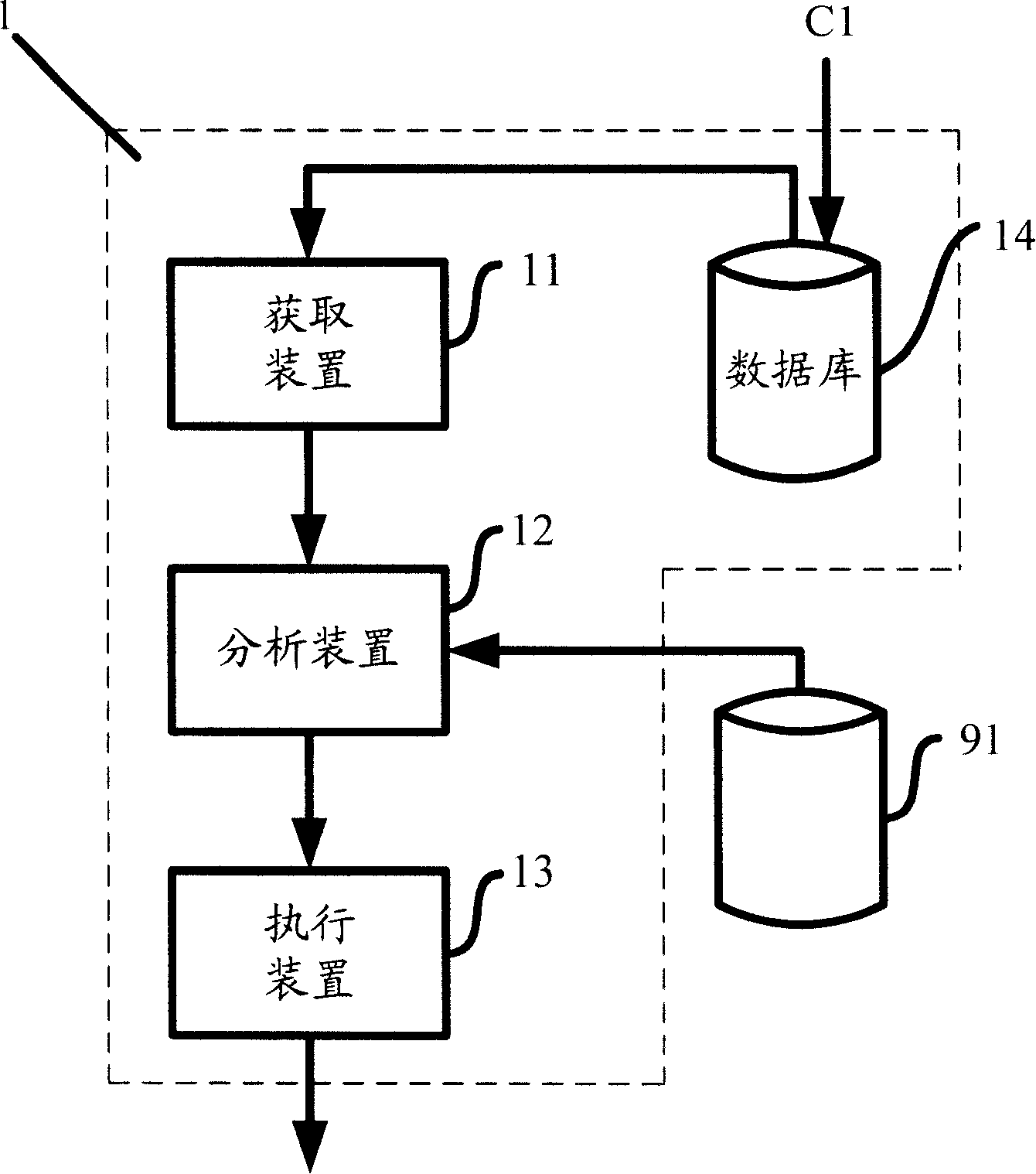

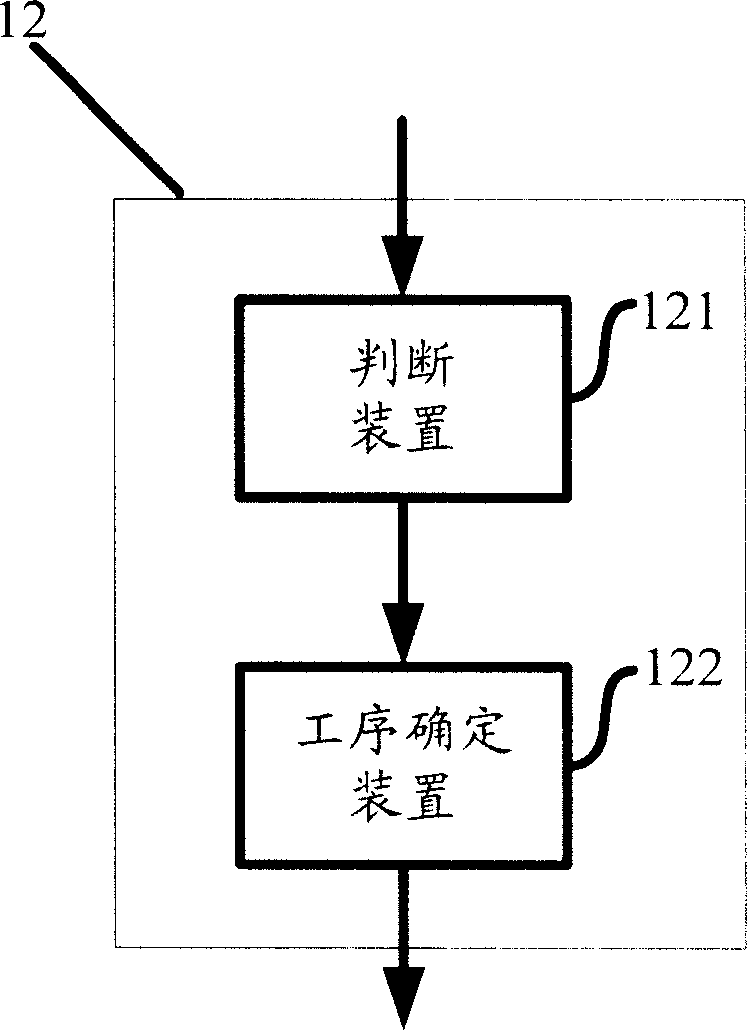

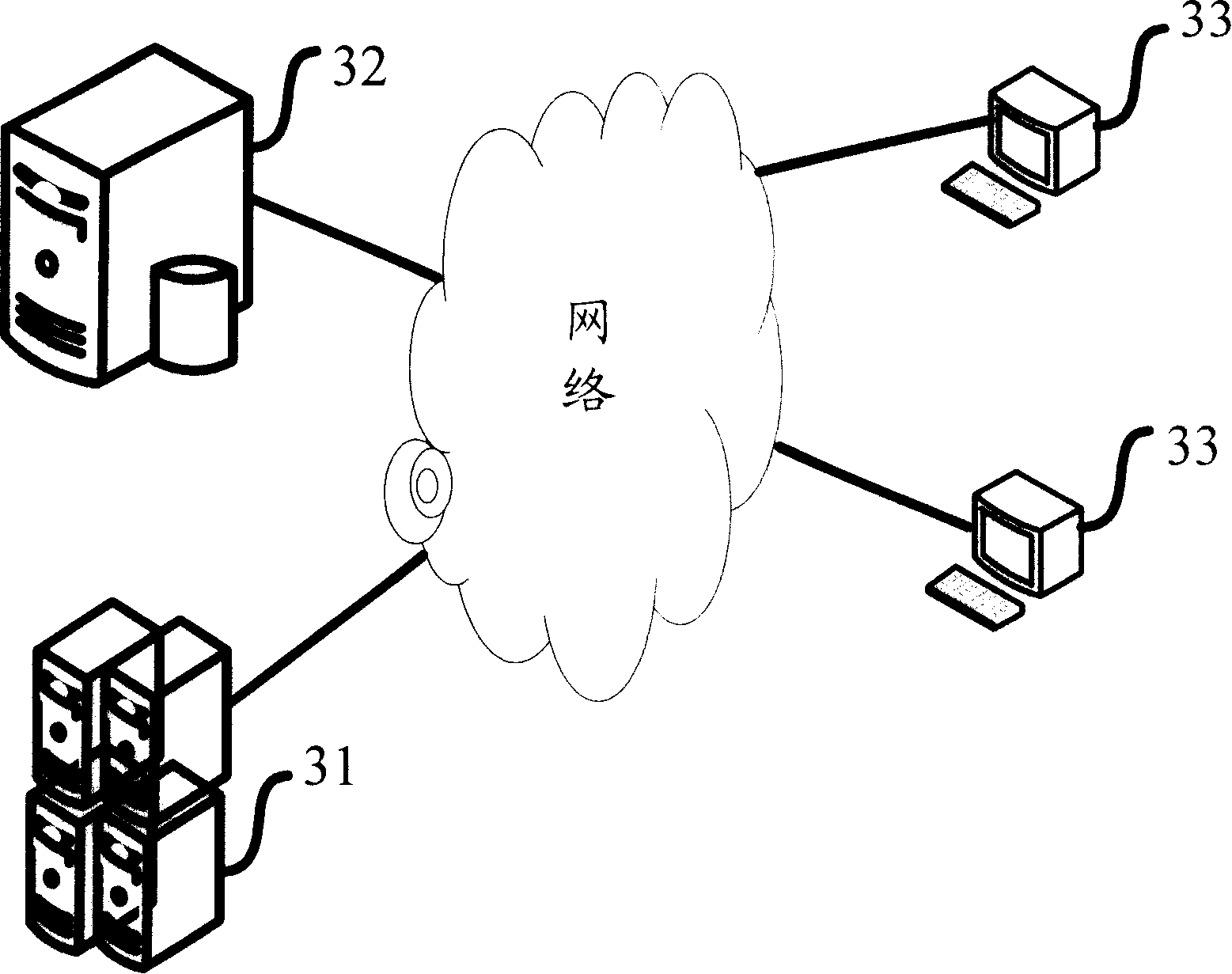

Booking control system for manufacturing executive system and related method

InactiveCN101192049AEasy for production managementIncrease productivityElectric programme controlNon-linear opticsControl systemHaultain operation

The present invention provides a precontract control system used for a manufacturing execution system, which executes precontract control to a current process and the processes after the current process according to precontract control information. The system comprises an acquisition device, an analysis device and an execution device. The analysis device comprises a judging device and a process determining device. The execution device respectively carries out to-be-executed processes through the manufacturing execution system. The precontract control system can also comprise a recording device and a database. The present invention correspondingly provides a precontract control method used for a manufacturing execution system as well. According to the precontract control system and the corresponding method, multiple precontracts can be realized, and a plurality of precontract control tasks can be realized, including the tasks of stopping some process, changing to some process, changing to some production line, changing to some operation device, executing some formula, executing transport operation, executing database input operation, database output operation, etc. The present invention can effectively manage liquid crystal screen production and improve production efficiency.

Owner:SHANGHAI SVA LIQUID CRYSTAL DISPLAY

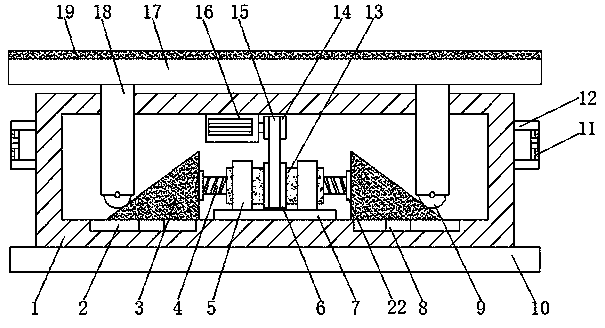

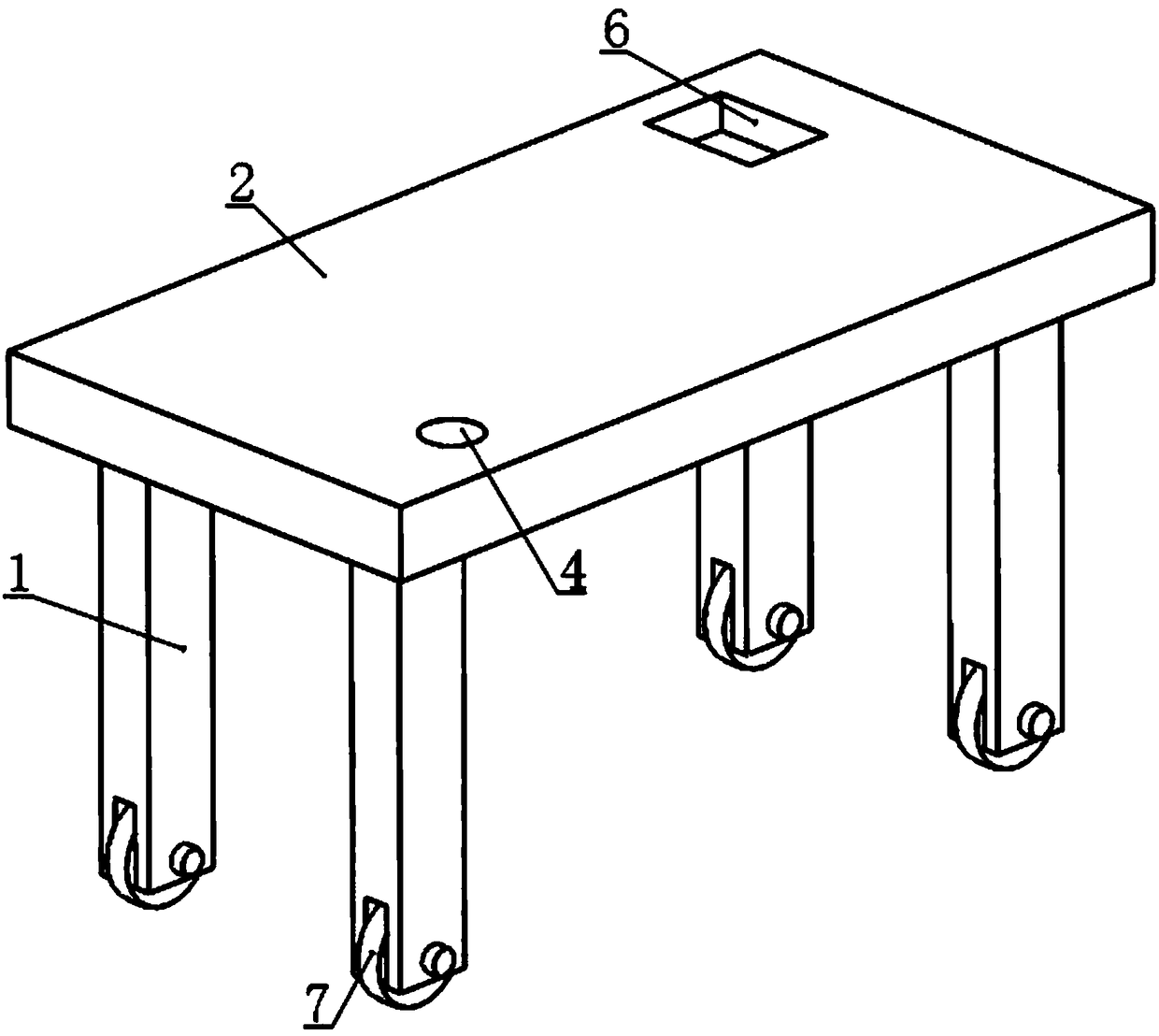

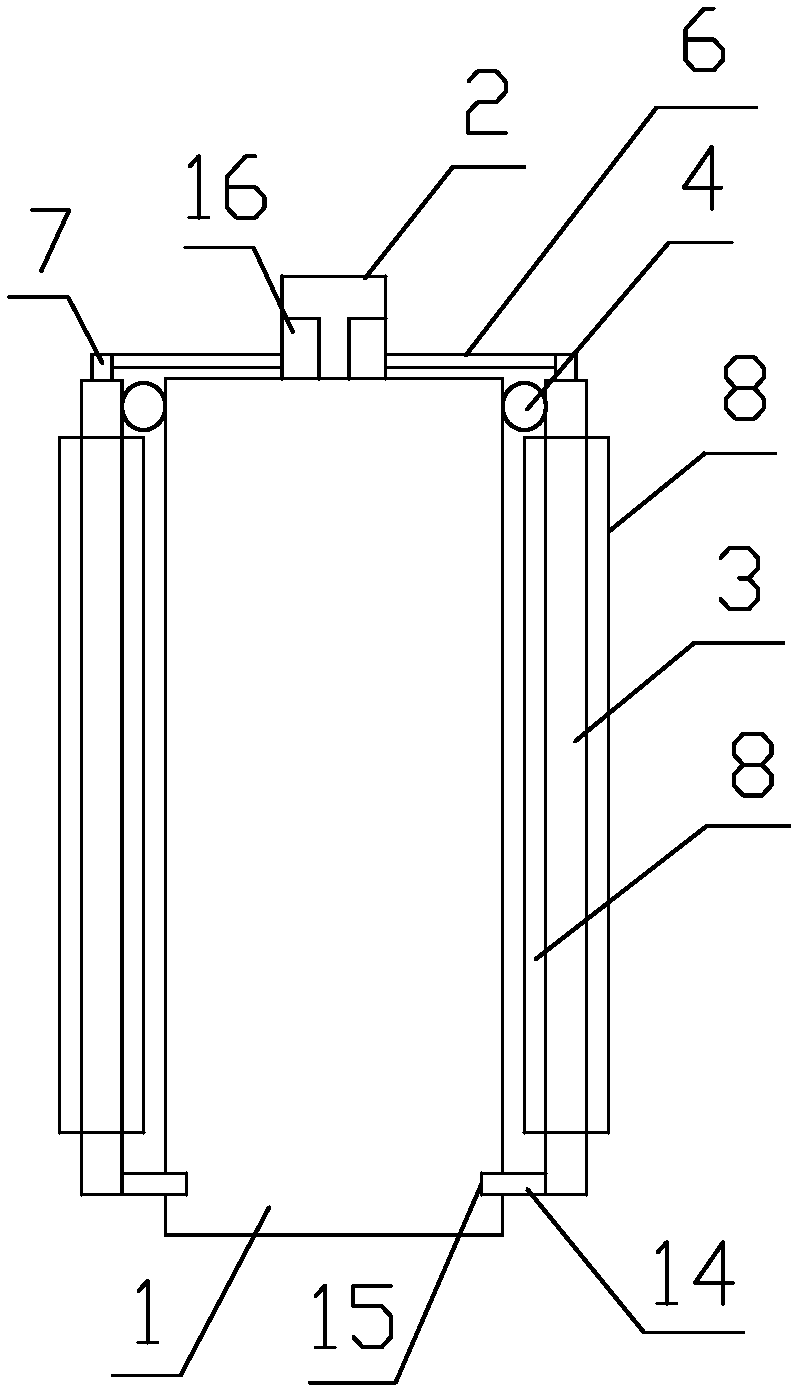

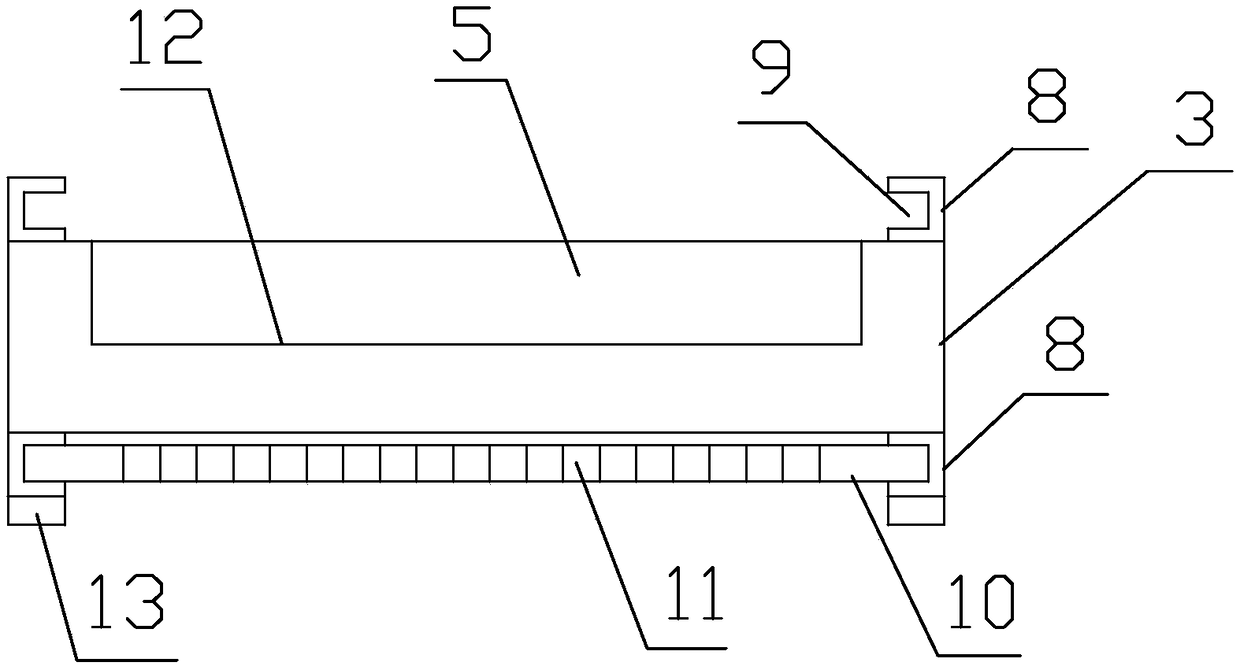

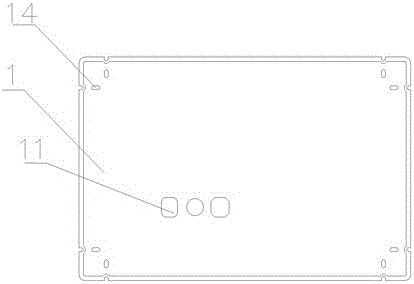

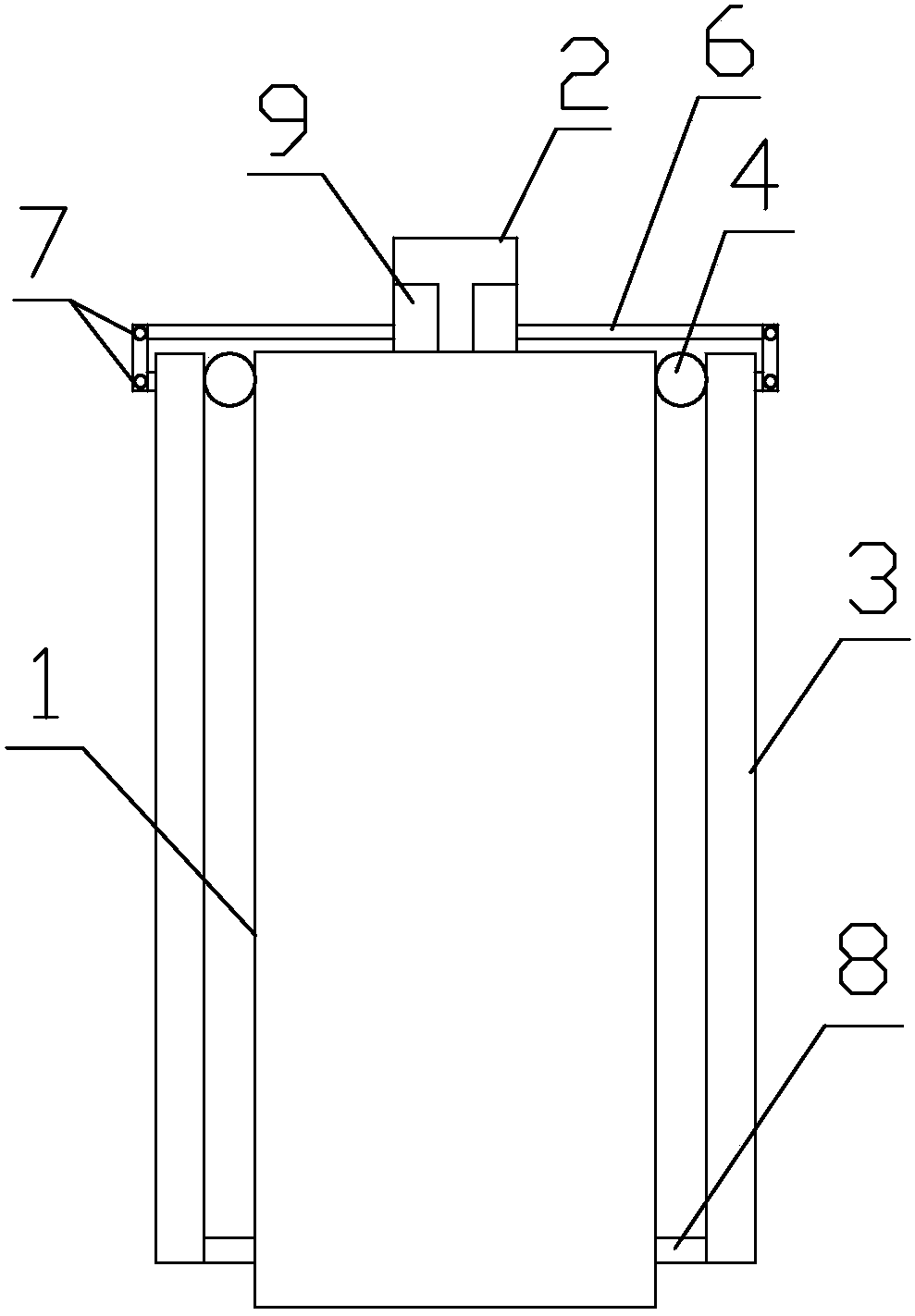

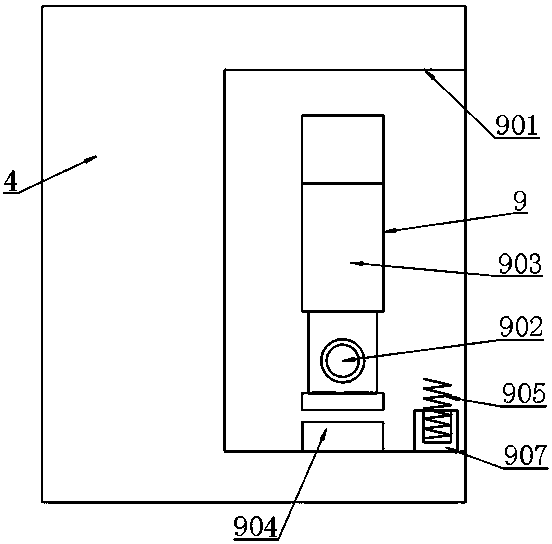

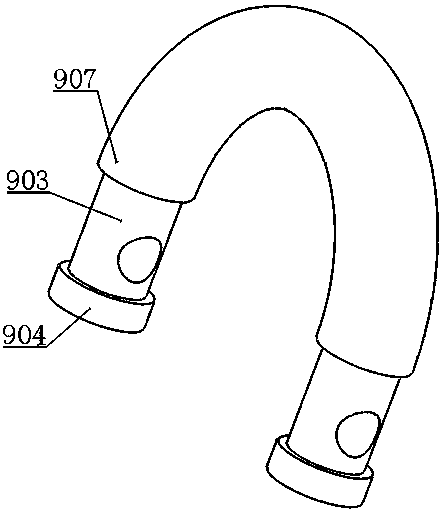

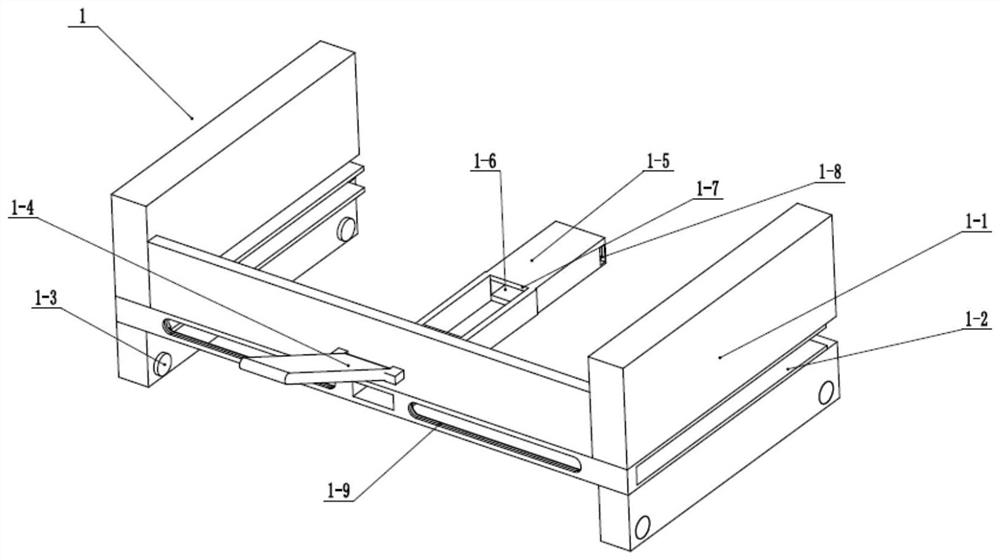

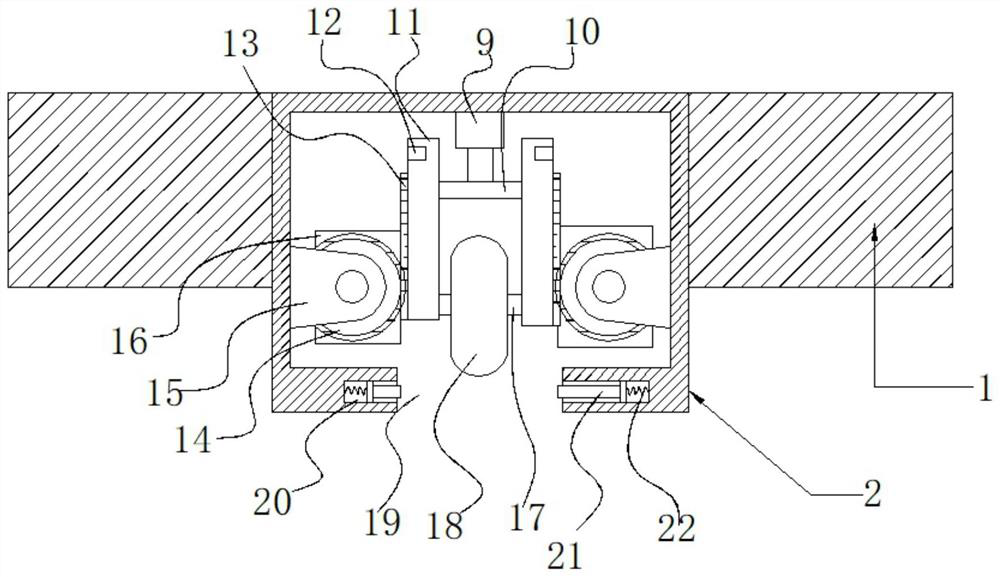

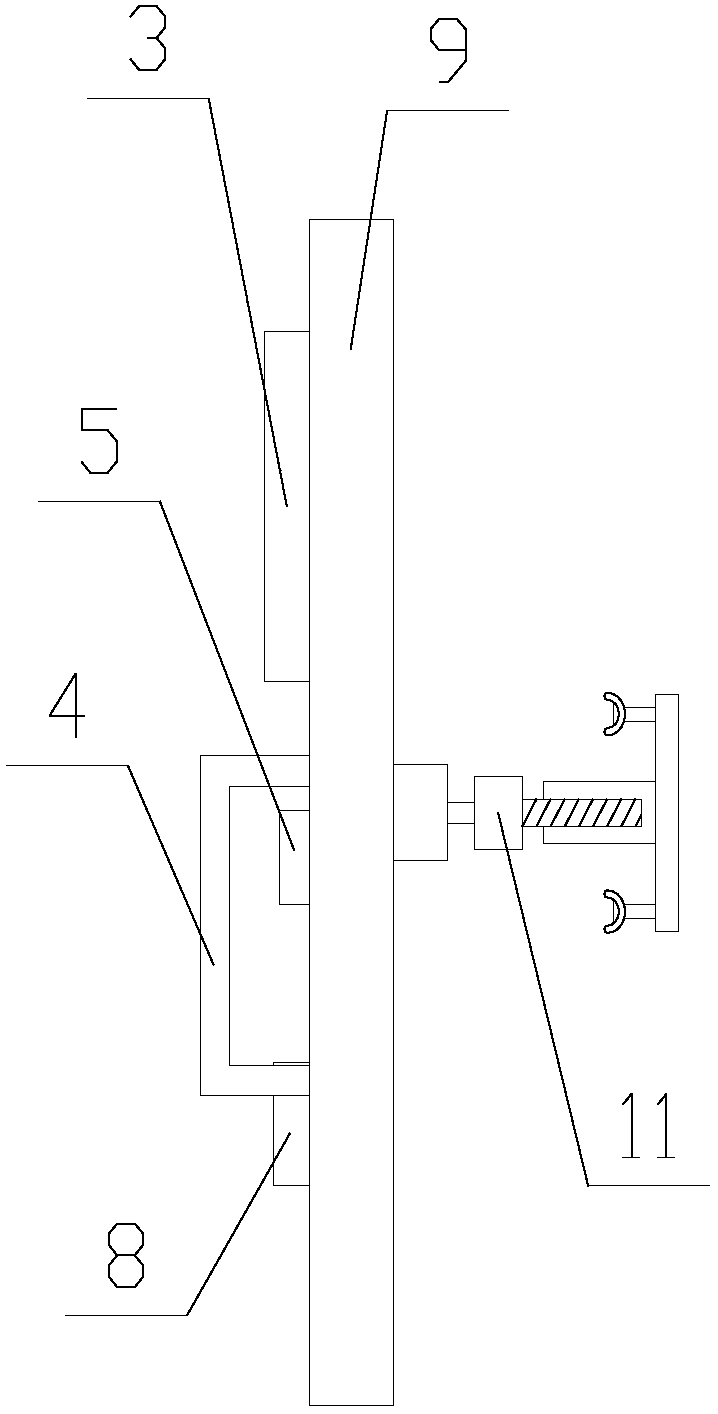

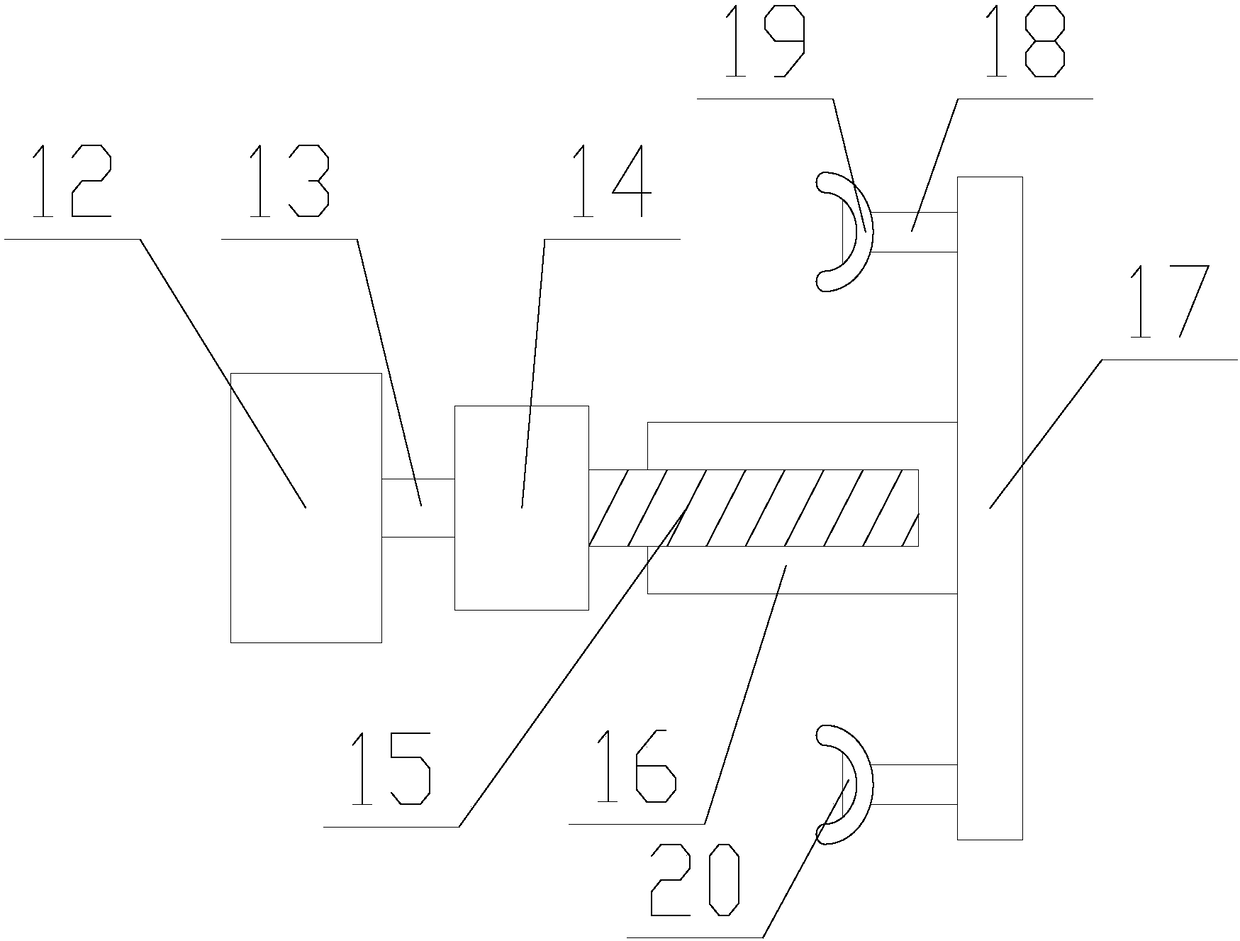

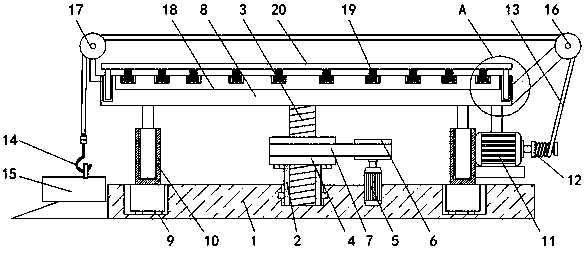

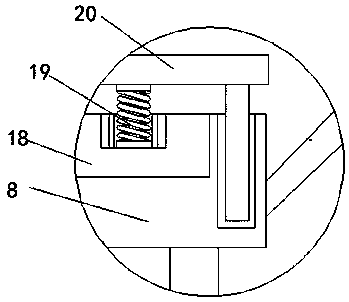

Convenient-to-regulate operation table for battery manufacturing

InactiveCN108336395AEasy to moveImprove stabilityAssembling battery machinesFinal product manufactureHaultain operationWhole body

The invention discloses a convenient-to-regulate operation table for battery manufacturing. The operation table comprises a bottom cabin, wherein the inner bottom wall of the bottom cabin is fixedly connected with a pad plate; two first bearings in symmetrical arrangement are sleeved and arranged on the outer surface of a sleeve arranged inside the bottom cabin; the inner ring of each first bearing is fixedly connected with the outer surface of the sleeve; the outer surface of each first bearing is fixedly connected with the upper surface of the pad plate; a first rotating wheel is sleeved andarranged on the middle of the outer surface of the sleeve; the inner ring of the first rotating wheel is fixedly connected with the outer surface of the sleeve; the inner side wall of the sleeve is fixedly embedded with two symmetrical screw rings; two symmetrical threaded rods are arranged inside the sleeve. The convenient-to-regulate operation table for battery manufacturing has the advantagesthat the whole body can realize the self height regulation according to the body height of workers; the workers can conveniently move the operation table; the friction force between the hand and a handle when the workers carry the operation table can be effectively increased; certain comfort degree is realized; the requirements of enterprises can be met.

Owner:王丽

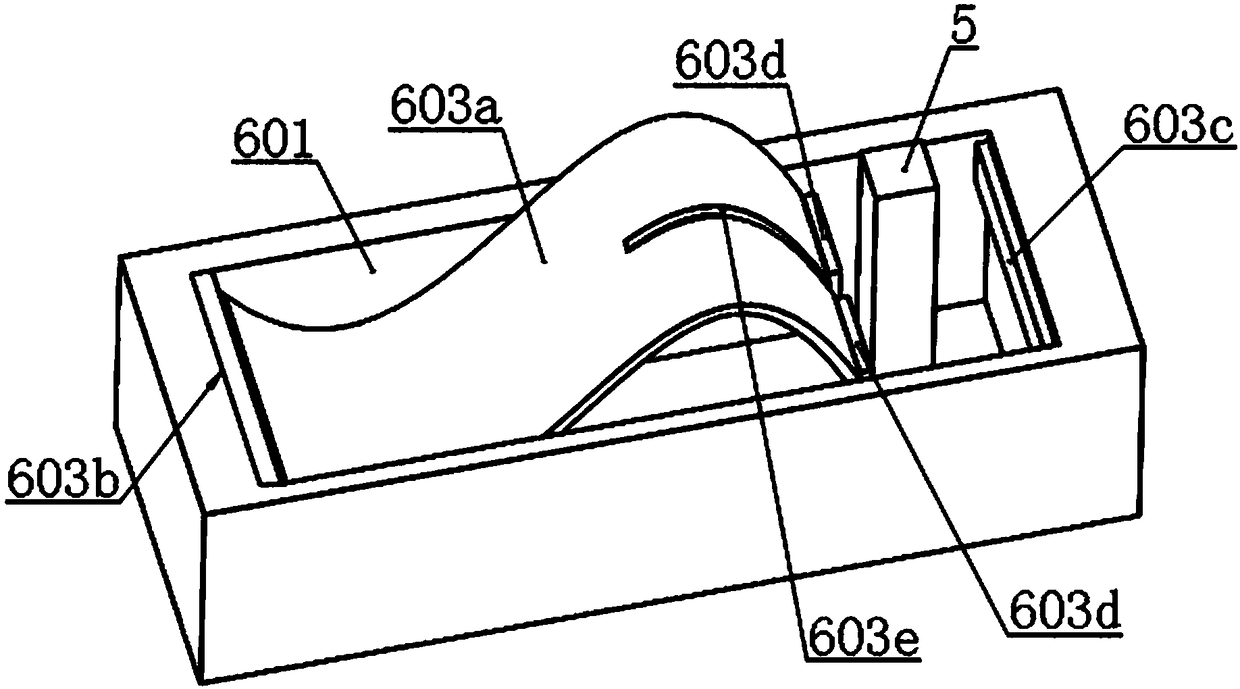

Intelligent desk with flexible transferring function

InactiveCN108354320AEasy to roll and carryEasy to switchCastorsTablesBiochemical engineeringHaultain operation

The invention belongs to the technical field of intelligent desks, and particularly relates to an intelligent desk with a flexible transferring function. The desk comprises desk legs and a desk plate,and further comprises a water cup fixing unit arranged on the desk plate and used for fixing a water cup through inserting and clamping, a desk lamp fixing unit arranged on the desk plate and used for fixing a desk lamp through inserting and bucking, and rolling transferring units arranged at the lower ends of the desk legs. By arranging the water cup fixing unit, the desk lamp fixing unit and the rolling transferring units on the desk plate, the aims of correspondingly fixing the water cup and the desk lamp and facilitating the rolling transferring are realized. The intelligent desk has theadvantages that good water cup fixing and desk lamp fixing multifunctional effects are realized, the fixing structure is intelligent and efficient, the rolling transferring operation is convenient andrapid, and the intelligent desk can be conveniently switched between the transferring state and the fixed state.

Owner:福州市长乐区鑫达家居设计有限公司

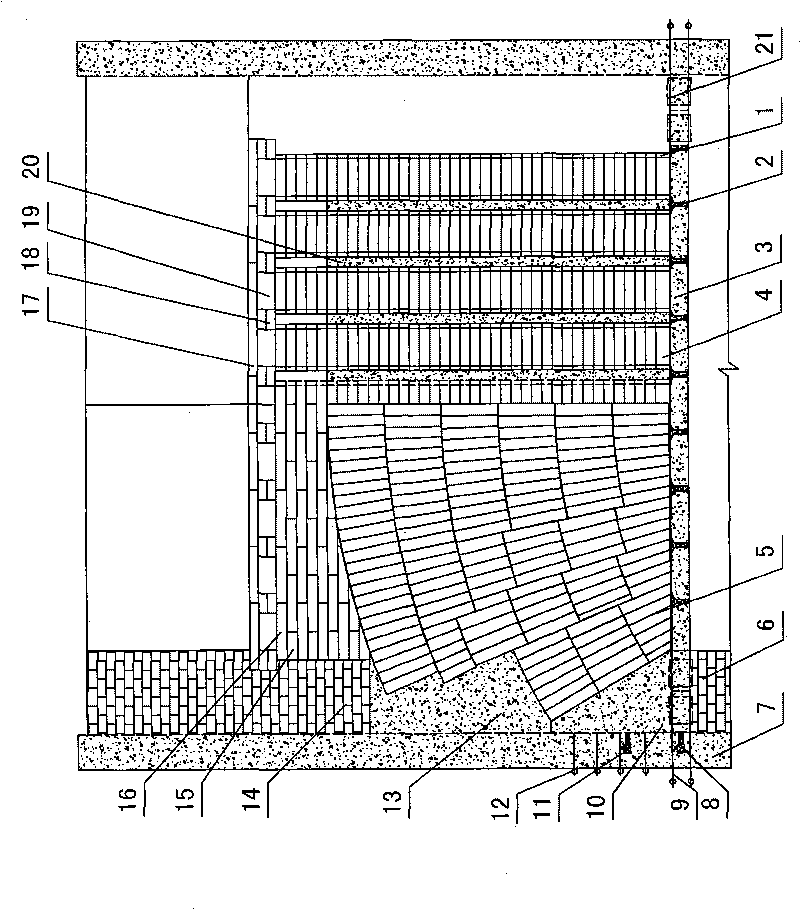

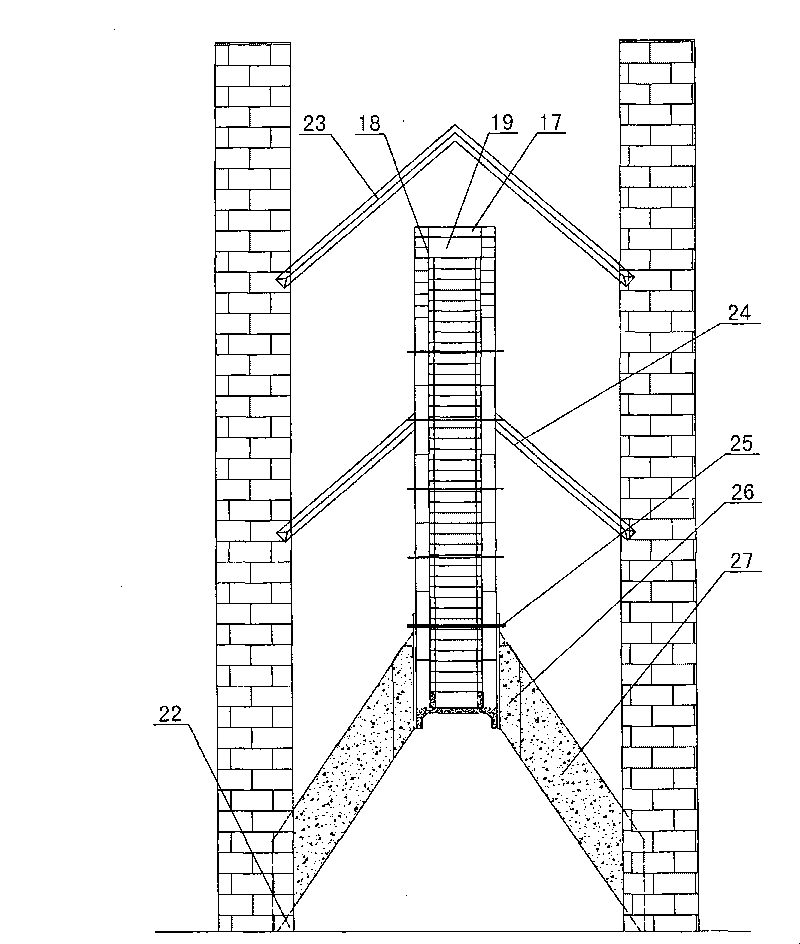

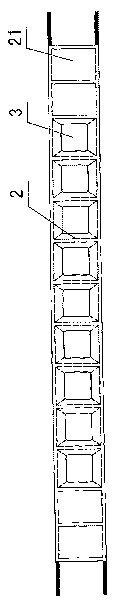

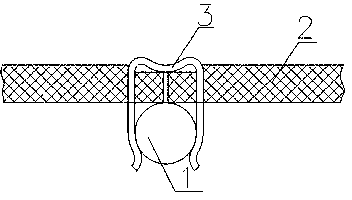

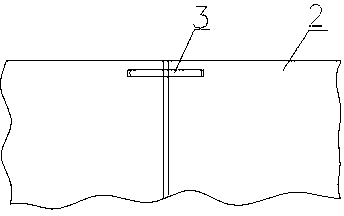

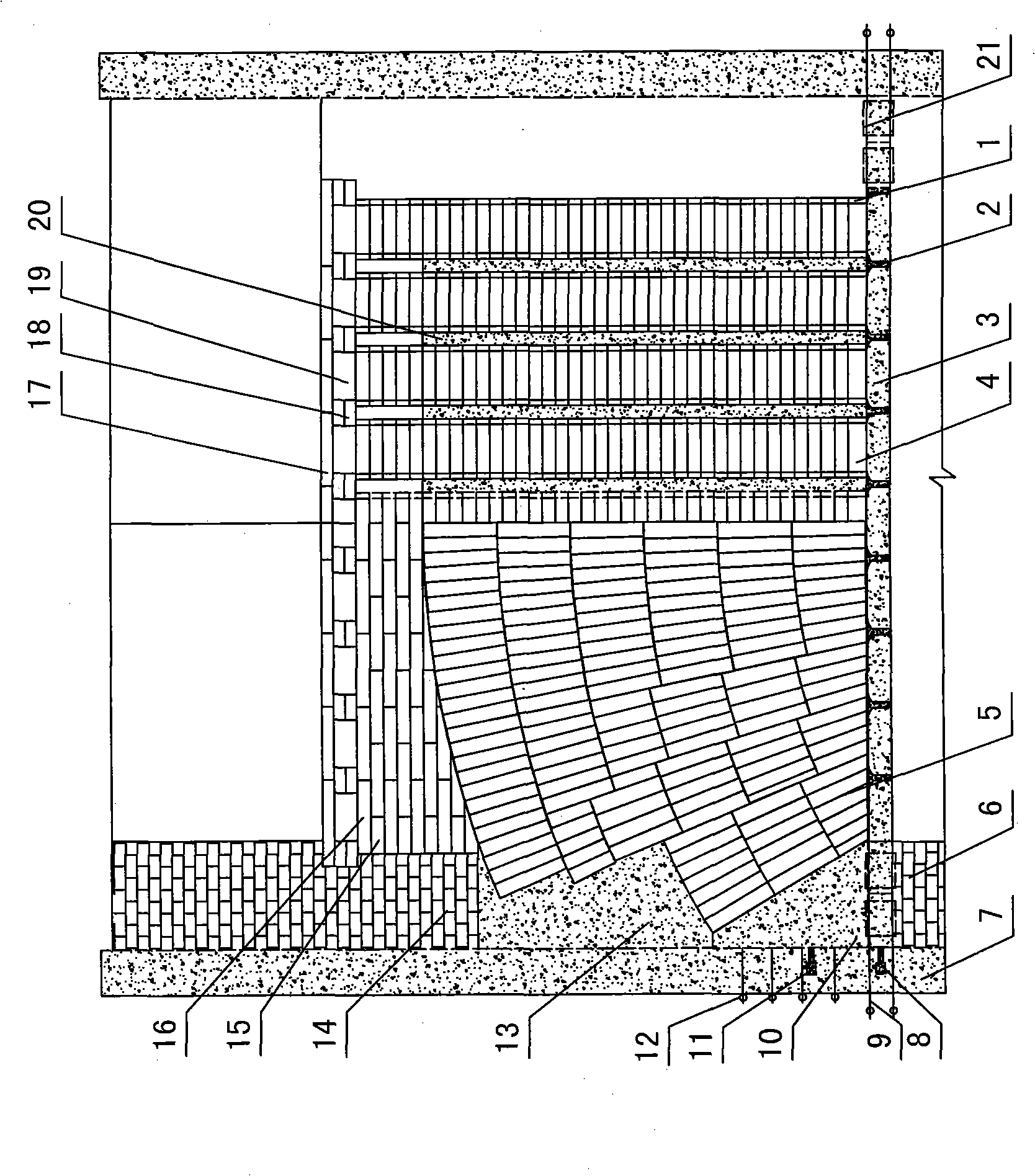

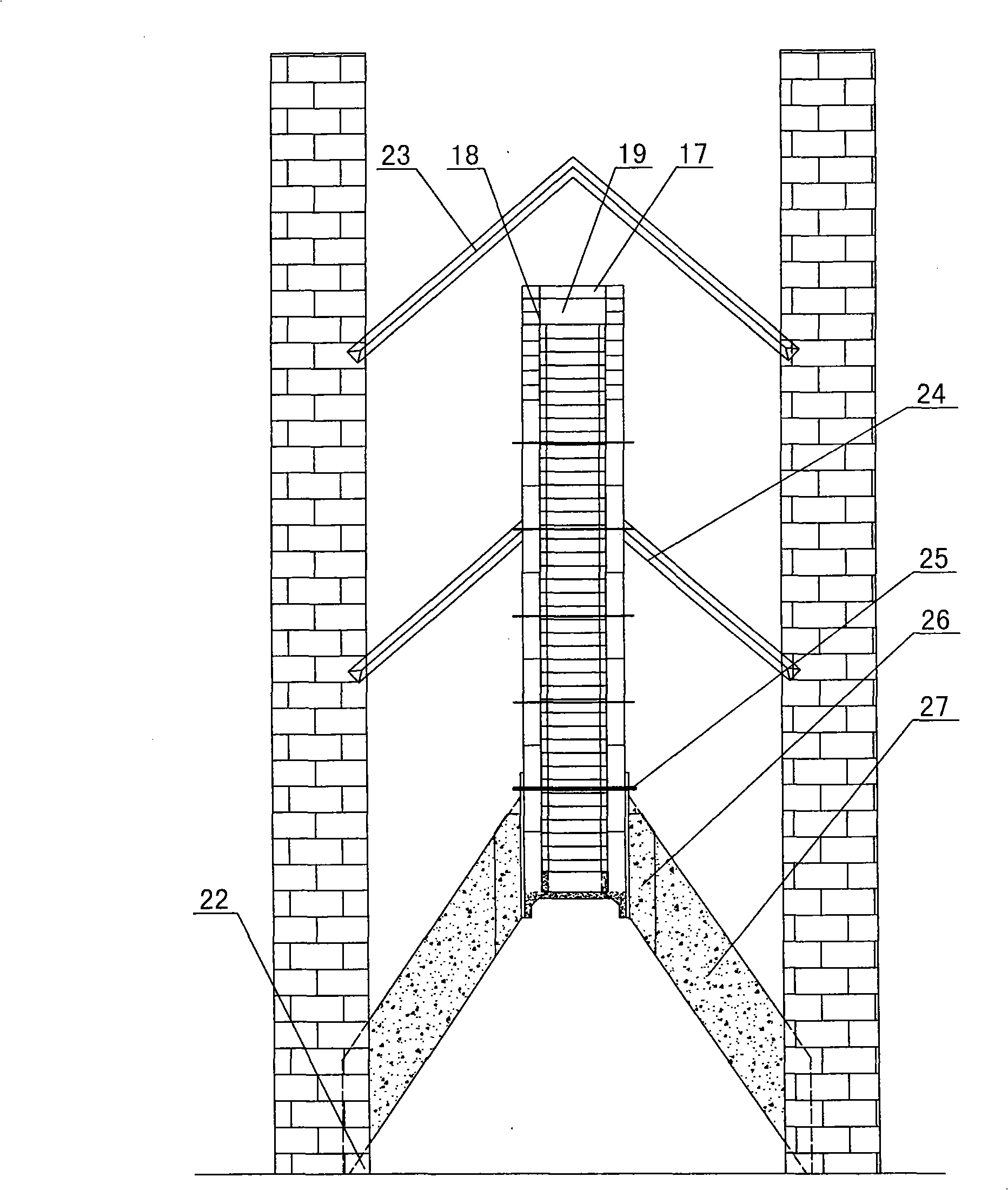

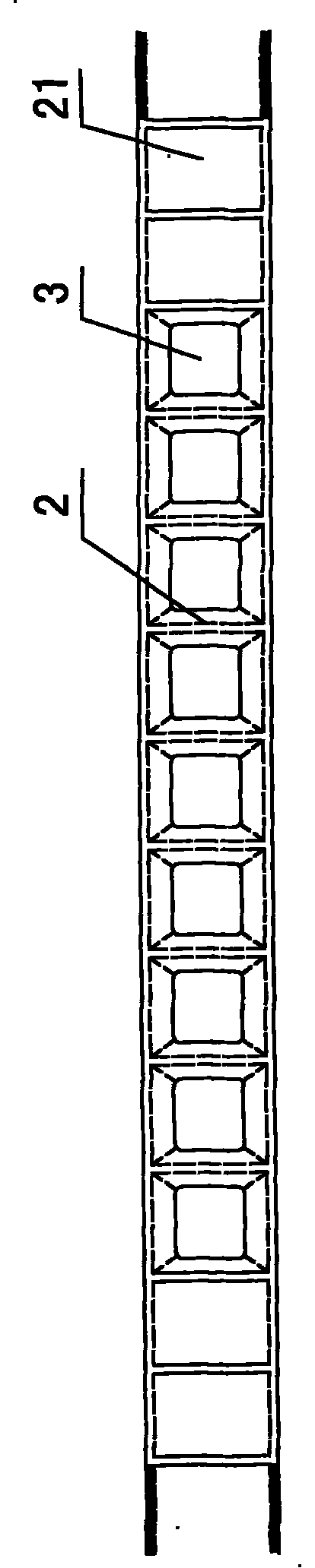

Smelting palletizing shaft furnace air-guiding wall and building method thereof

ActiveCN101738082AReduce airtightnessThe airtightness of the air guide wall is small and the airtightness is excellentFurnace componentsVertical furnacesBrickHaultain operation

The invention relates to a smelting palletizing shaft furnace air-guiding wall and a building method thereof, belonging to the field of smelting palletizing shaft furnaces. The air-guiding wall body is an arch-up flat-down or arch structure; firebricks for building the air-guiding wall body comprise wedge-shaped, T-shaped, L-shaped and reverse I-shaped firebricks as well as lining bricks provided with vent holes in the middle part; the air-guiding wall body is paved and built according to the number of layers and the position; the bottom of the air-guiding wall body is supported by a heat-resistant metal cork base and a support pillar under the cork base; cover plate bricks cover the upper part of the air-guiding wall; and triangular castables are cast on the cover plate brick. In the invention, firebricks with various types are paved and built according to the number of layers and the position by a reasonable method; and because of small clearance, the sealing performance of the air-guiding wall body is superior to similar air-guiding walls; besides, the novel brick is small in volume, light in weight and convenient to carry and operate. The support device is arranged at the lower part of the air-guiding wall, thereby ensuring favorable heat-resistant performance, easy production and installation and large support force.

Owner:唐山市盈心耐火材料有限公司

Architectural engineering aerial work platform

ActiveCN104110126AImprove performanceExtended service lifeScaffold connectionsScaffold accessoriesHaultain operationUltraviolet lights

The invention relates to an architectural engineering aerial work platform which comprises multiple building row hedges, supporting steel tubes and building row hedge connecting pieces. The building row hedges are manufactured through plastic steel, arranged on the supporting steel tubes and provided with connecting holes, and the building row hedges are connected in a clamped mode through the connecting holes. The building row hedges are manufactured through the plastic steel, quality is excellent, the service life is long, practical performance is high, the weight of the building row hedges accounts for two thirds that of an original bamboo hedge, the building row hedges are convenient to install, carry and operate, durable in the open air and capable of defending against sunlight ultraviolet lights, and the service life of the building row hedges can be one time that of moso bamboo. Meanwhile, the building row hedges are connected in the clamping mode, work efficiency of the plastic steel row hedges during installation is more than five times that of original filament bundling, the architectural engineering aerial work platform has the advantages of being quick in installation, fixed in positioning, safe, reliable, easy to disassemble and the like, and work efficiency of the plastic steel row hedges during installation is greatly improved.

Owner:浙江学仕课桌椅制造有限公司

Efficient solar conversion photovoltaic power generation system

InactiveCN108282136AReduce material requirementsRealize detachable connectionPhotovoltaic supportsPV power plantsUniversal jointHaultain operation

The invention discloses an efficient solar conversion photovoltaic power generation system. A mounting shell is arranged at the axial top of a regular polygon fixed column, a mounting plate is correspondingly mounted on each side surface of the fixed column, the lower plate surface of one end of a long-axis direction of each mounting plate is rotatably connected with the side wall of the fixed column close to the top through a rotating shaft, photovoltaic power generation boards are embedded into grooves in the mounting plates, one axial end of each telescopic rod is fixed in the mounting shell, the other end of the telescopic rod is connected with the upper plate surface of one end of the long-axis direction of the corresponding mounting plate through a universal joint, positioning stripsare convexly arranged on two sides of the upper plate surface of each mounting plate along a long-axis direction, clamping grooves are formed in the opposite side walls of the two positioning strips,the system comprises protective plates, and each protective plate is clamped between the clamping grooves in the two positioning strips in a transition fitting manner and used for shielding and protecting the corresponding photovoltaic power generation board. A photovoltaic power generation device is convenient to carry and operate.

Owner:成都亿伏科技有限公司

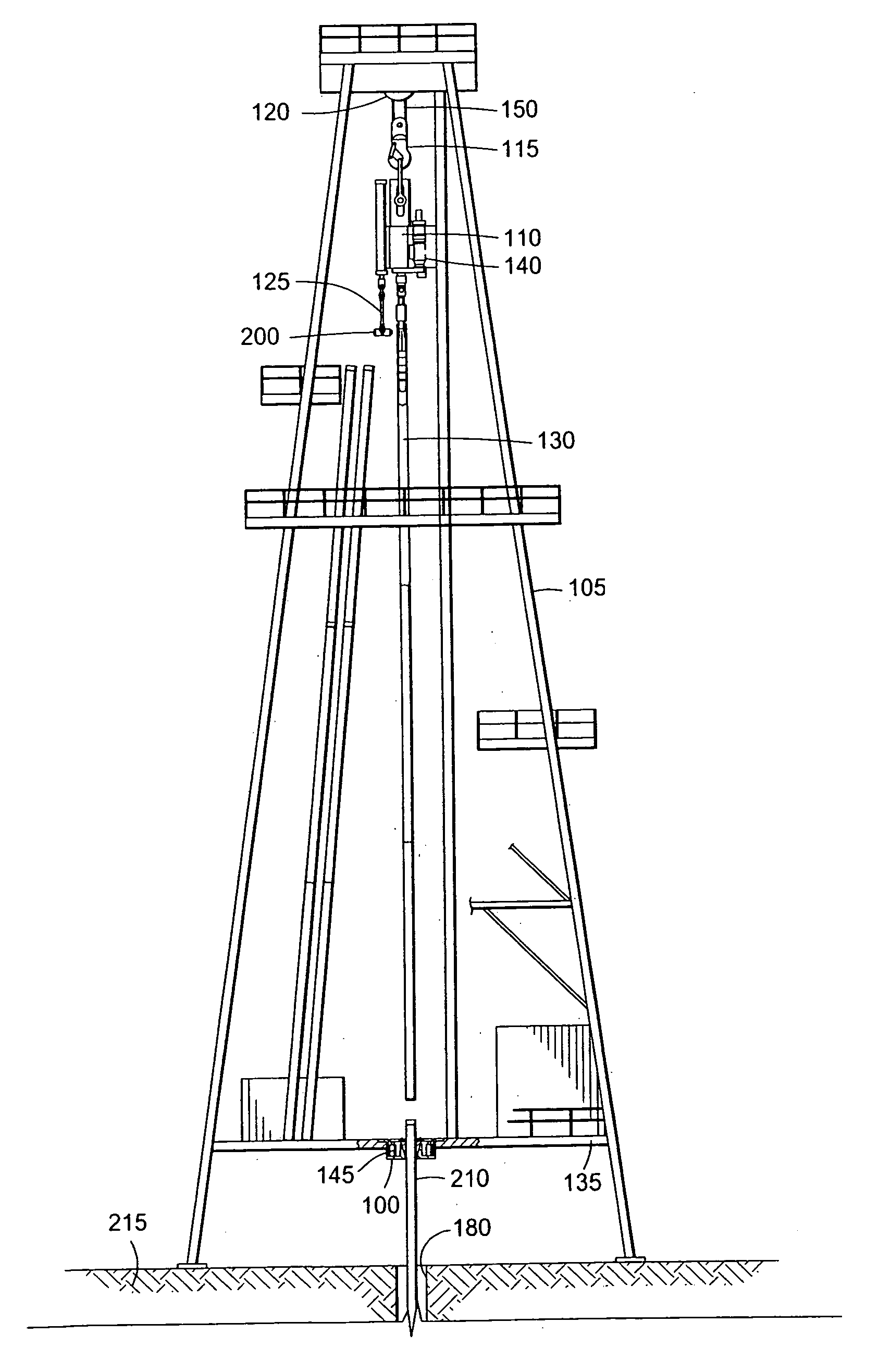

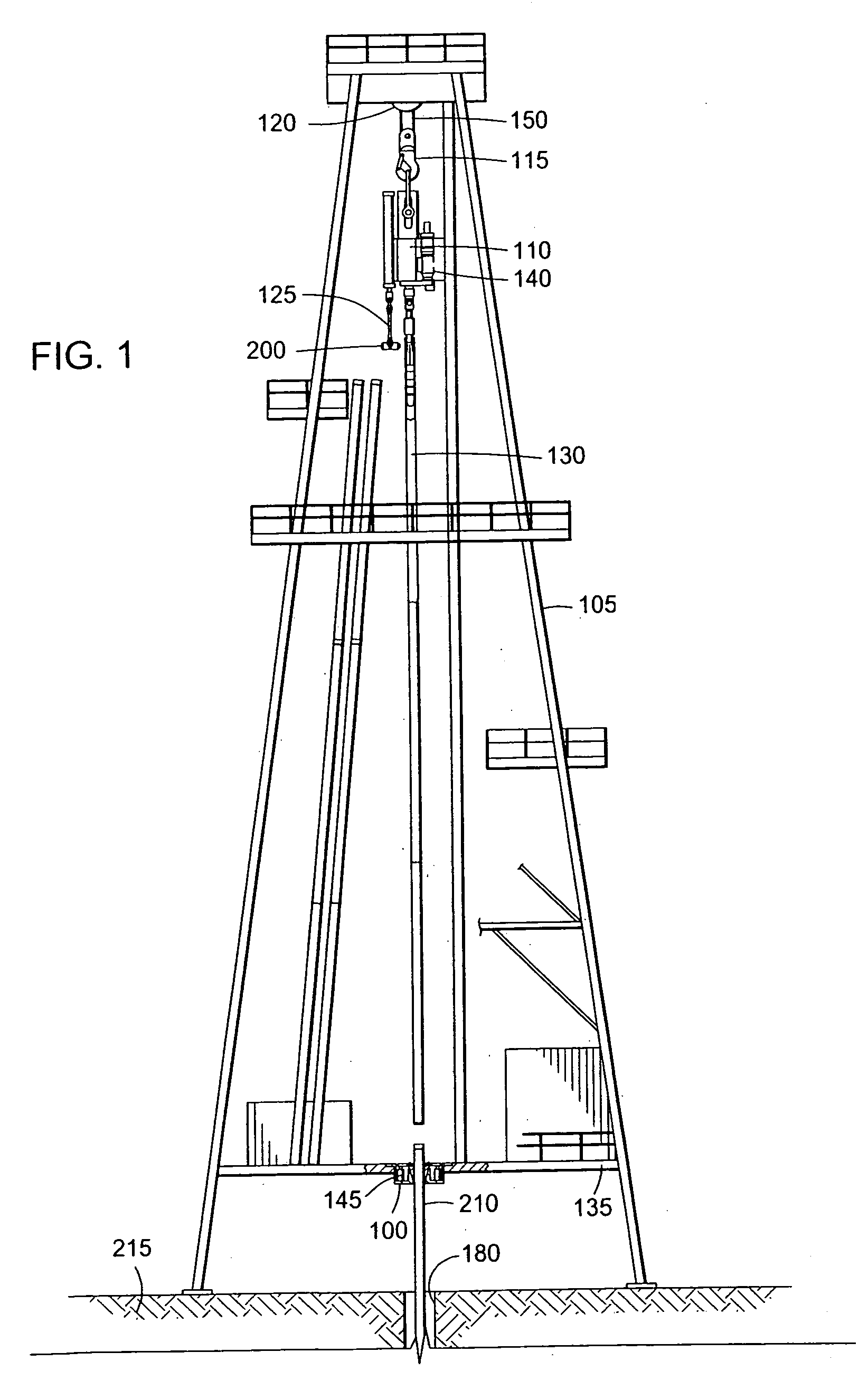

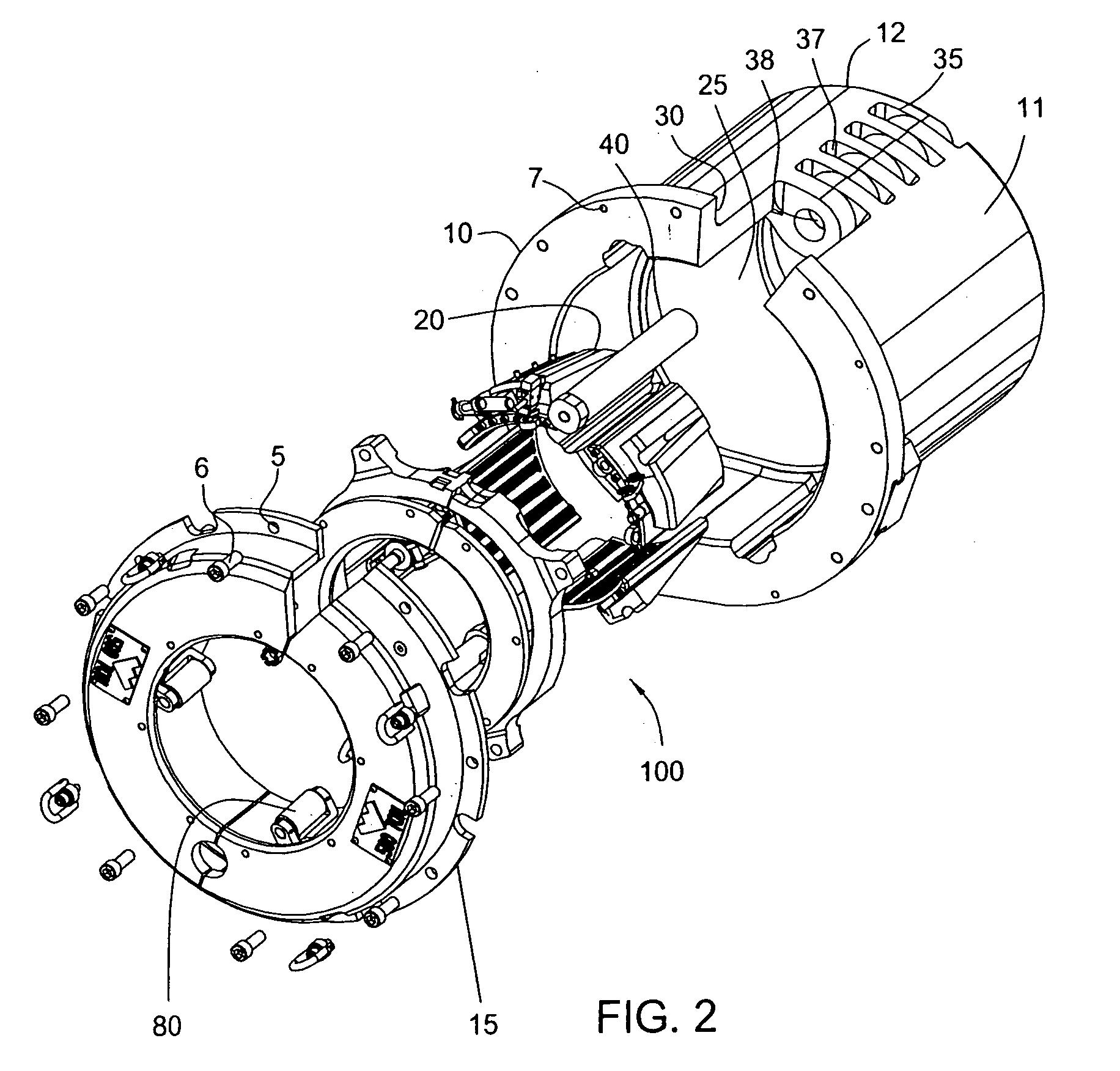

Adjustable rotating guides for spider or elevator

Owner:WEATHERFORD TECH HLDG LLC

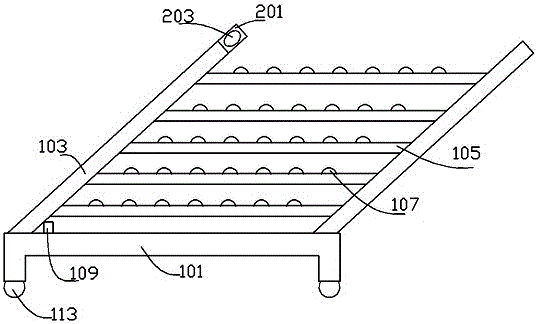

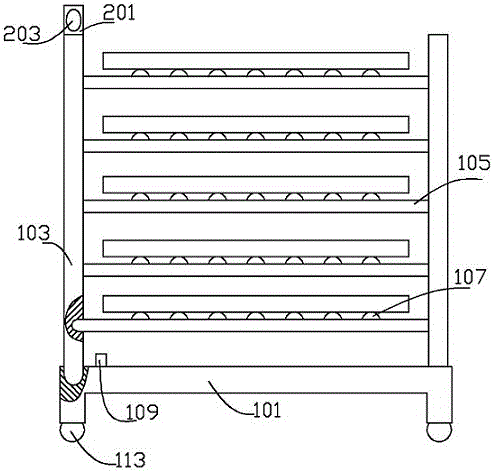

Wood drying frame

InactiveCN105928342ASmall footprintReduce workloadDrying chambers/containersDrying machines with local agitationHaultain operationEngineering

The invention discloses a wood drying frame. The wood drying frame comprises a frame and a support mechanism, wherein the frame includes a support table at the bottom, bracket plates hinged to two sides of the support table, and support plates hinged to the bracket plates; the support mechanism includes connecting blocks, and a driving device for controlling the connecting block to lift; the connecting blocks are arranged at the upper ends of the bracket plates; and connecting holes for connecting with the driving device are formed in the connecting blocks. The wood drying frame solves the problem of strenuous operation of carrying woods into a drying box, and is labor-saved in operation.

Owner:CHONGQING LUWAN WOOD CO LTD

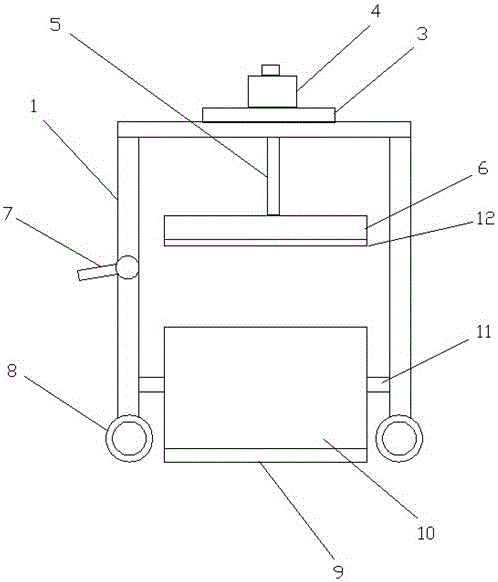

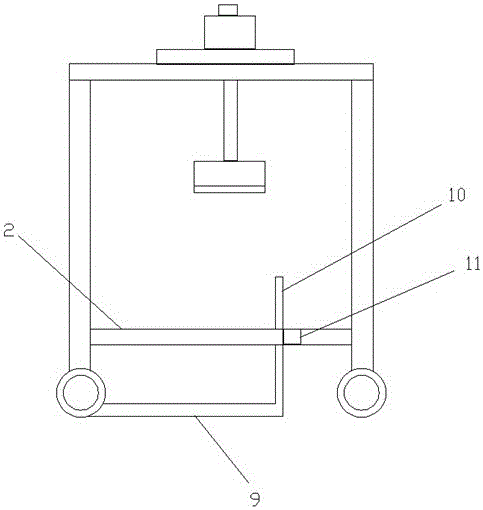

A corrugated paper flattening machine

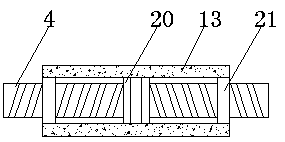

ActiveCN103696316BEasy to operatePrecise positioningCalendersHaultain operationPulp and paper industry

The invention provides a corrugated paper flattening machine. The corrugated paper flattening machine comprises a rack and an independent positioning mechanism, wherein a transverse beam is arranged below the rack; a fixed plate is arranged above the rack; an air cylinder is arranged above the fixed plate; a telescopic rod is arranged on the air cylinder and penetrates through the fixed plate; a flattening plate is arranged at the lower end of the telescopic rod; a flattening switch is arranged on the rack; universal wheels are arranged at the lower end of the rack; the positioning mechanism comprises a corrugated paper placement plate and a positioning baffle plate; the positioning baffle plate is arranged on one side of the corrugated paper placement plate; a connecting rod is arranged on the transverse beam and is positioned at the outer position, right below the flattening plate, on the transverse beam; a protection layer is arranged on the lower end surface of the flattening plate. The corrugated paper flattening machine is convenient to move and easy to position, the transportation operation and the arrangement operation of corrugated paper are eliminated, and the working efficiency and the flattening quality are improved.

Owner:汉川市合兴彩色包装有限公司

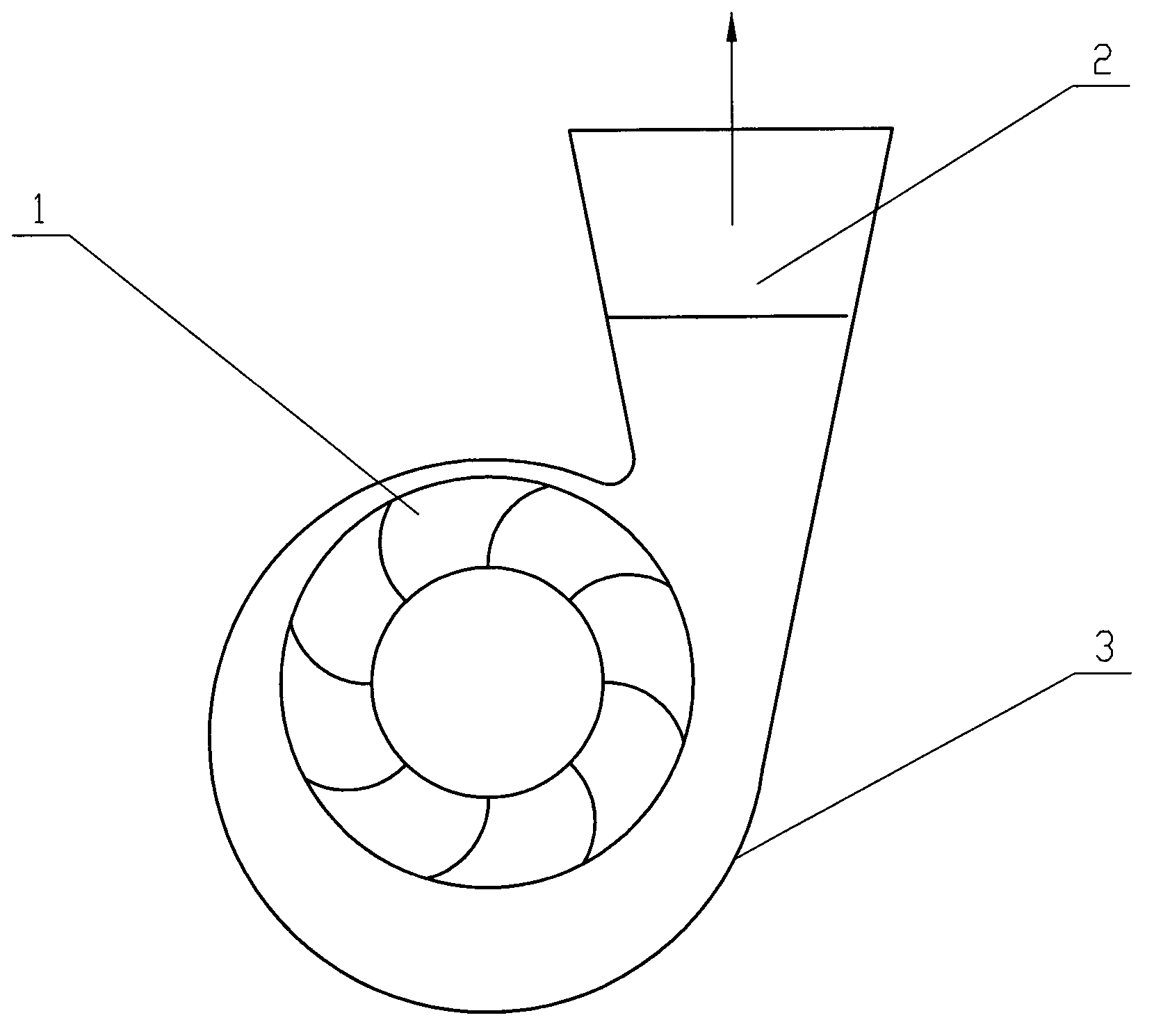

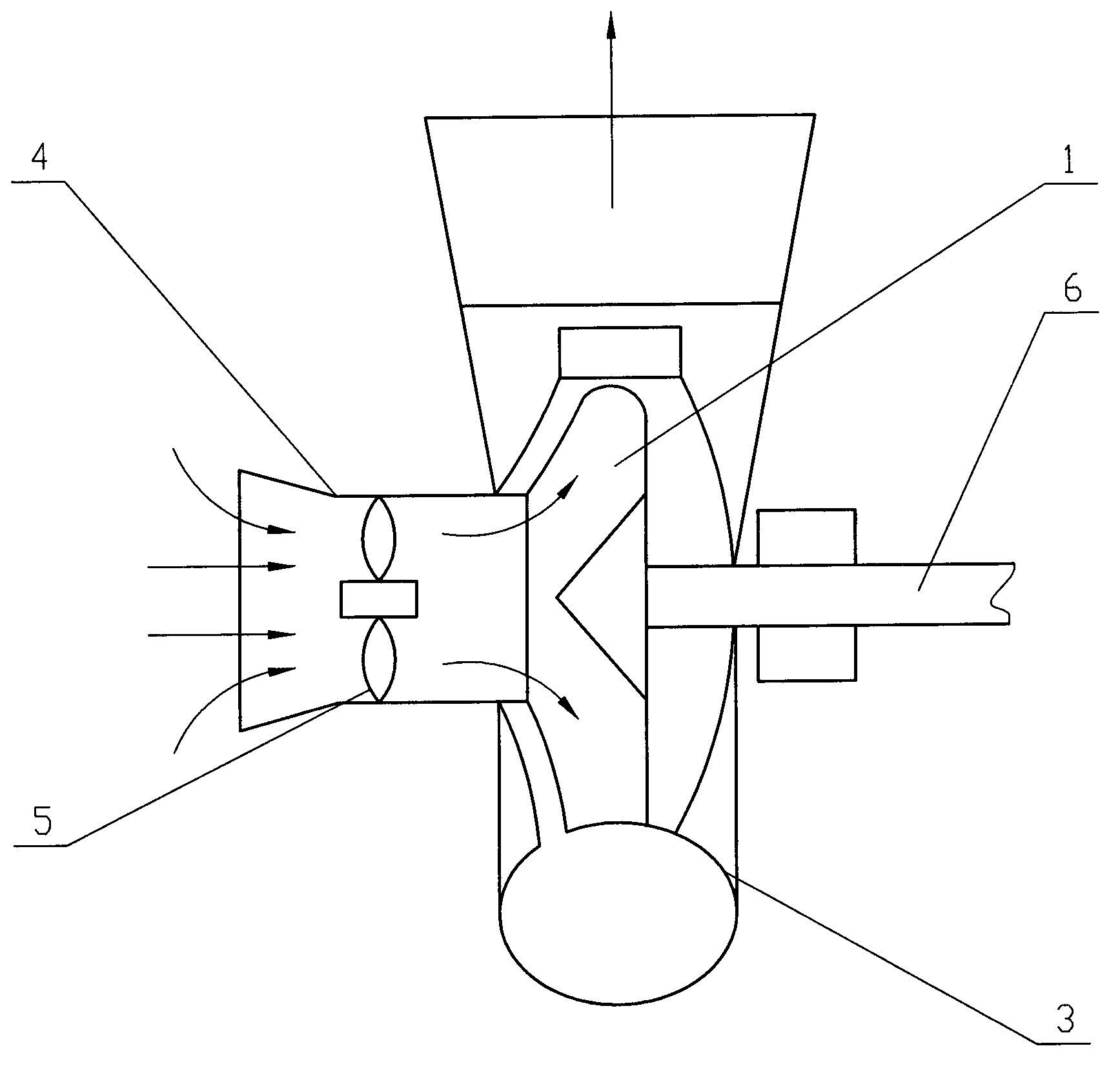

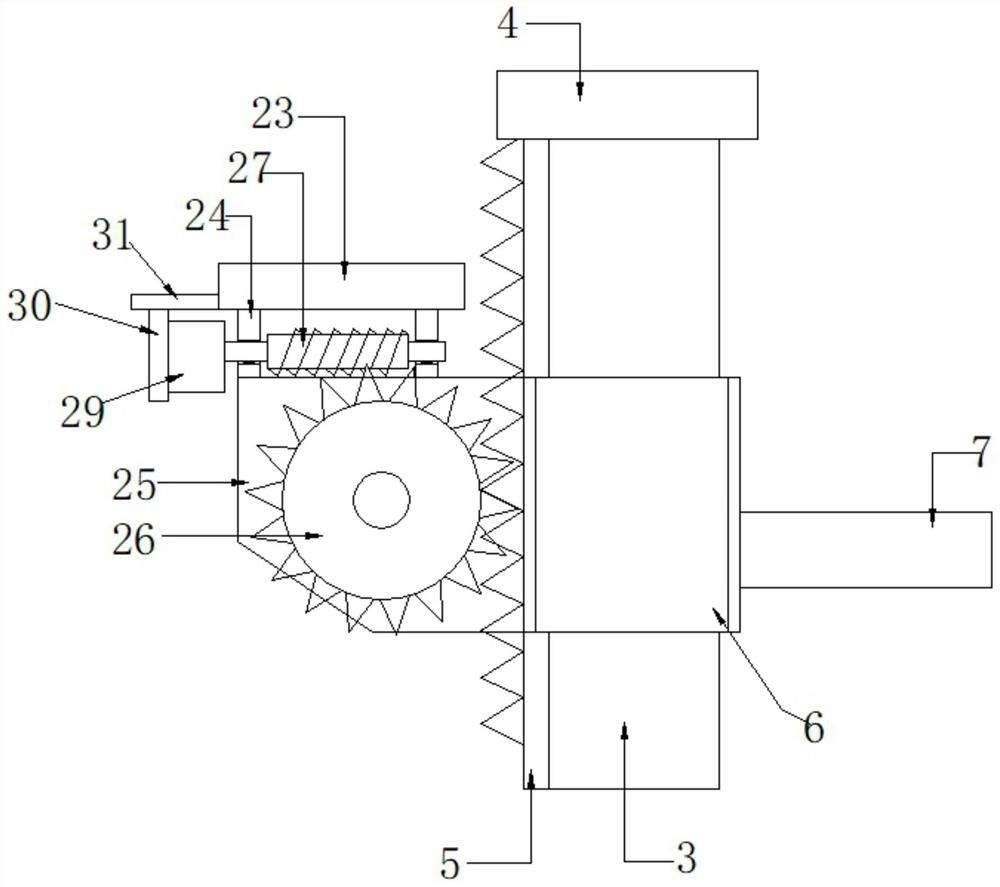

Energy-saving efficient gasoline engine pumping unit

ActiveCN103277280AReduce weightEasy to operatePump installationsPositive-displacement liquid enginesHaultain operationGasoline

The invention provides an energy-saving efficient gasoline engine pumping unit which comprises a gasoline engine and a water pump which are installed on a base. The energy-saving efficient gasoline engine pumping unit is characterized in that a water pressure well type water pressure pump is arranged on a water inlet pipe of the water pump, and the bottom of the water pressure well type water pressure pump is communicated with the water inlet pipe through a communicating port. The energy-saving efficient gasoline engine pumping unit has the advantages of being convenient to carry, durable, capable of saving fuel oil, large in water yield, efficient, environmental friendly and the like. Compared with gasoline, the energy is saved by 20% on a year-to-year basis, and the energy-saving efficient gasoline engine pumping unit is well received by customers.

Owner:东明县天合农业机械有限公司

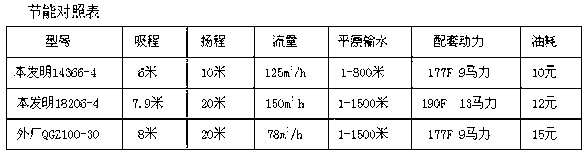

Centrifugal mine ventilator

InactiveCN103835958ASimple structureImprove ventilationPump componentsRadial flow pumpsImpellerHaultain operation

The invention relates to a centrifugal mine ventilator. The centrifugal mine ventilator is characterized by comprising a crankshaft, a case, an air inlet pipe and an air outlet pipe, wherein the air inlet pipe and the air outlet pipe are connected with the case, the crankshaft is fixedly connected with an impeller, the impeller is arranged in the case, the crankshaft is fixedly connected with a front guide device, and the front guide device is arranged on an opening of the air inlet pipe. Compared with a traditional centrifugal mine ventilator device, the centrifugal mine ventilator has the advantages of being simple in structure, good in ventilation effect, low in energy consumption, small in size and convenient to convey and operate.

Owner:WUXI WASHING MACHINERY FACTORY

Method for embedding round pot rare earth material into slabstone for composing patterns and characters

InactiveCN101774228ASecurity guidanceAvoid High Carbon ConsequencesIlluminated signsStone-like material working toolsPunchingHaultain operation

The invention discloses a method for embedding round pot rare earth material into slabstone for composing patterns and characters, which comprises the following steps of: firstly, sticking a template printed with patterns and characters on a ground or wall sheet which needs to be set up with leading marks; then slotting by a punching machine according to the template; sticking round pot rare earth material into hole slots by glass cement; and after the glass cement is dried, comprehensively polishing and regulating. The product manufacture of the method can be carried out after ground stones are installed; circular holes with different specifications are hollowed out on various stones and ground and wall sheets; the combined patterns and the characters of the rare earth luminescent material are embedded; on-site construction solves the working problems of all transport operation; and a large number of tardy tasks are relatively reduced.

Owner:天津光辉现代科技文化艺术发展有限公司

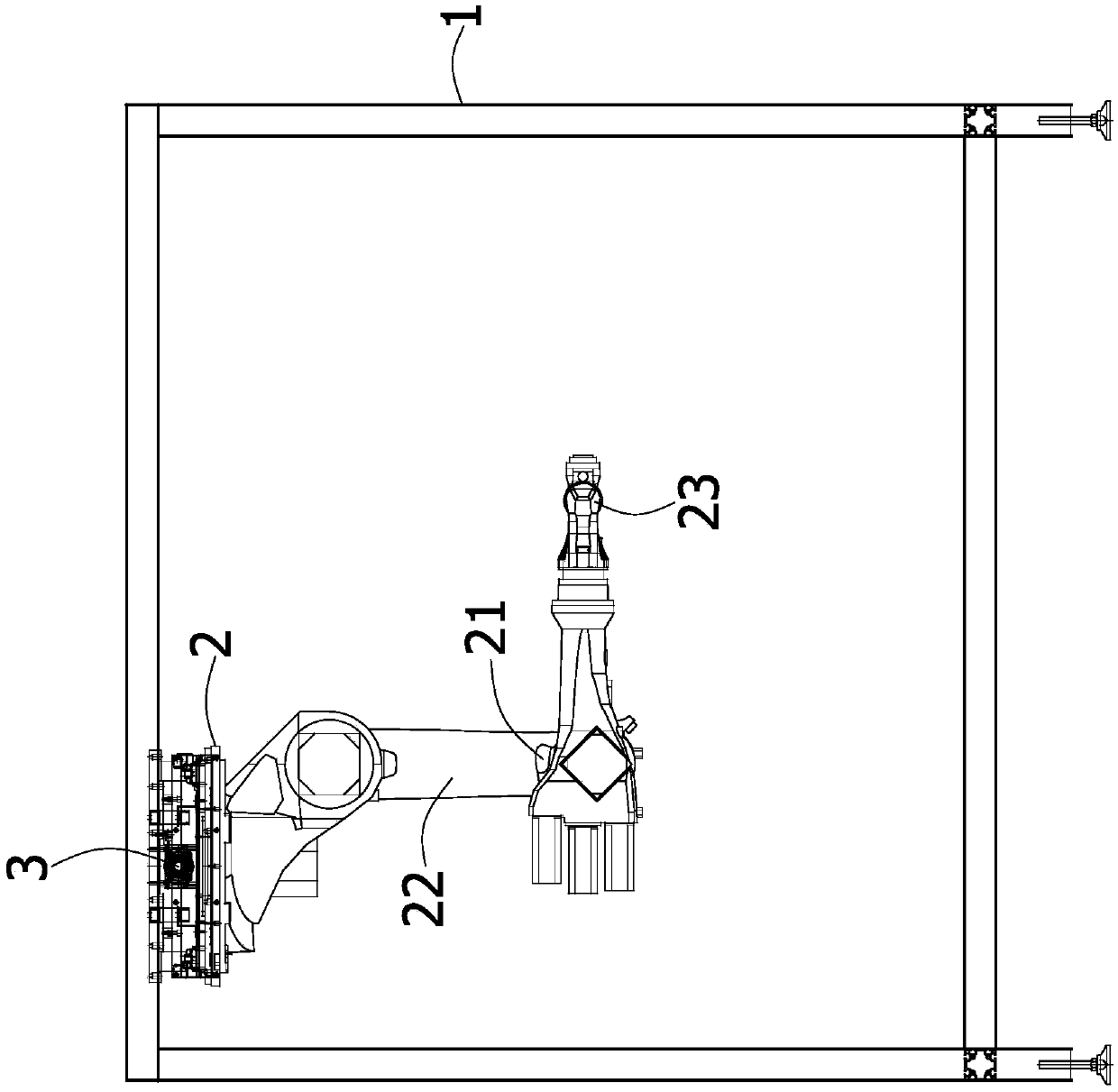

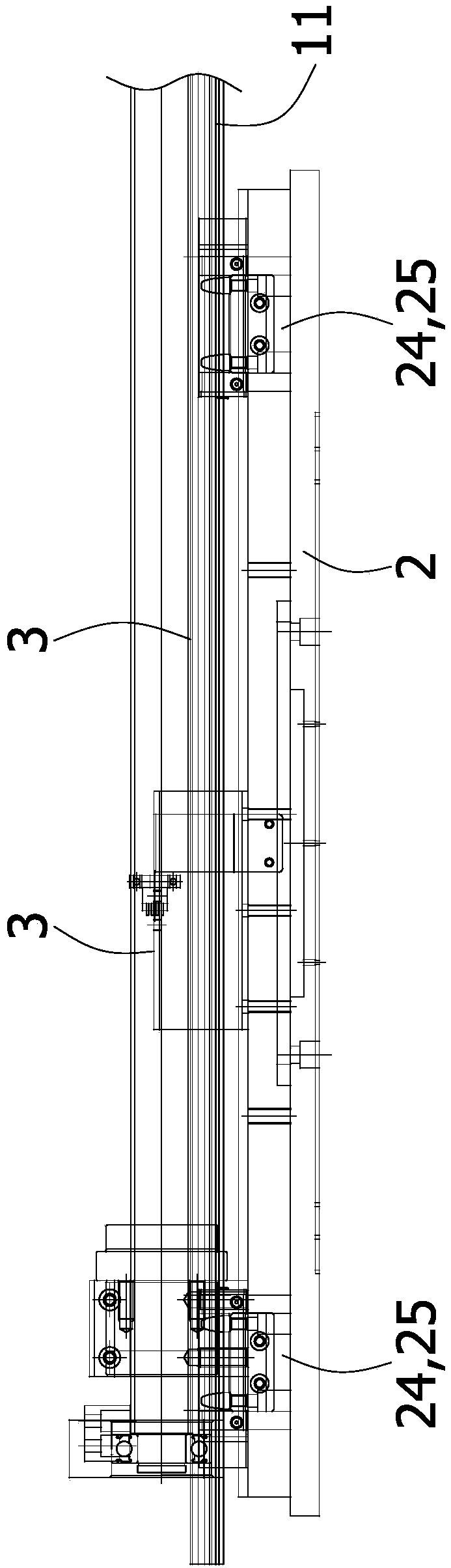

Automatic handling operation system

The present invention provides an automatic handling operation system, which is mainly composed of a frame, a multi-directional sliding device including a sensing element, and a linear unit; the frameis provided with a track on one side thereof; the multi-directional sliding device including the sensing element is disposed on the frame and the track, and supports a multi-degree-of-freedom arm operation mixing action at two supporting positions so as to identify an interface position coordinate and a take-over position coordinate of a barrel cover in a barrel image by using the sensing element; the linear unit is disposed on the frame and provides an accordance coordinate driving the multi-directional sliding device and the multi-degree-of-freedom arm to operate so that the multi-degree-of-freedom arm open and close an interface or a take-over is driven to open and close the interface and then the effect that the take-over is fixed to the interface or separated from the interface is obtained.

Owner:MARKETECH INT

Overturning-type block support used for outdoor badminton

InactiveCN108939476AImprove stabilityBlock loading and unloading is simple and convenientTennisHaultain operationSports facility

The invention relates to the technical field of sports facilities, in particular to an overturning-type block support used for outdoor badminton. The overturning-type block support comprises a longitudinal main support, a telescopic blind hole is formed in the center of the lower surface of the longitudinal main support, a longitudinal telescopic rod is slidingly connected inside the telescopic blind hole, and an external thread connecting rod of an integrated structure is arranged at the position, located below the longitudinal main support, of the lower end of the longitudinal telescopic rod. A fixing bolt is screwed into a lateral inner limiting screw hole through a lateral limiting through hole to fix the longitudinal main support and the longitudinal telescopic rod to fix the whole support in length, a longitudinal overturning supporting plate connected to an outer side connecting rod of the longitudinal telescopic rod is used for being matched with a bottom balancing weight to improve the overall stability of the support, and therefore a block is easy and convenient to install, detach, store and carry.

Owner:安徽禹缤体育科技有限公司

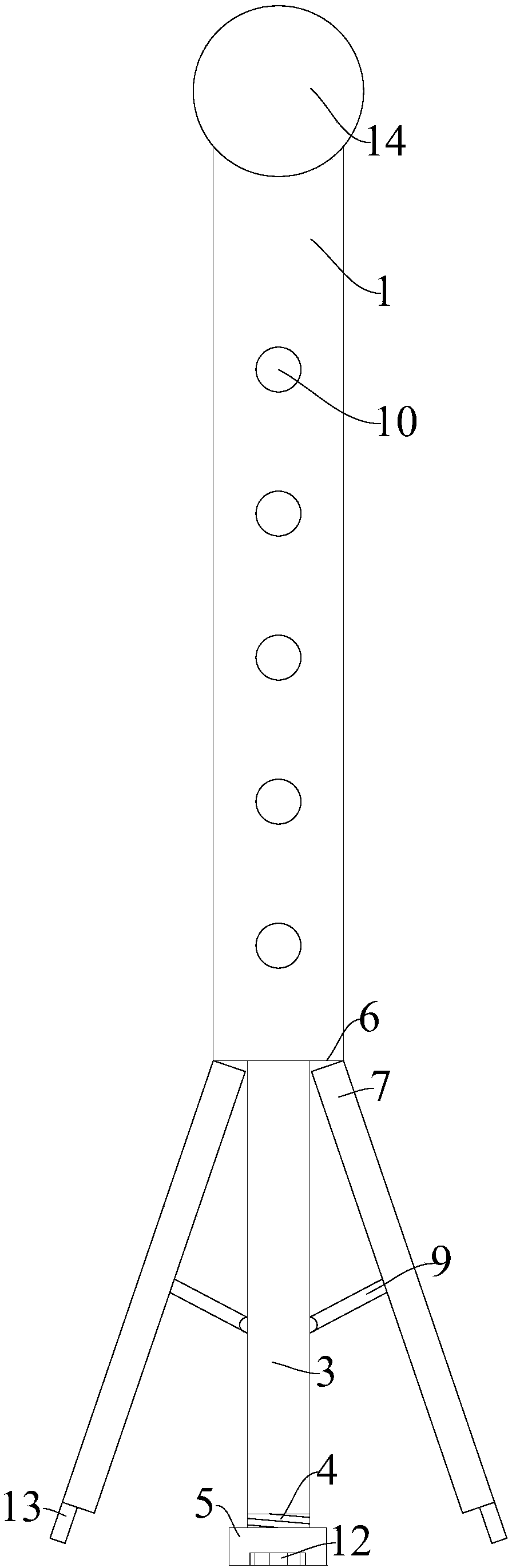

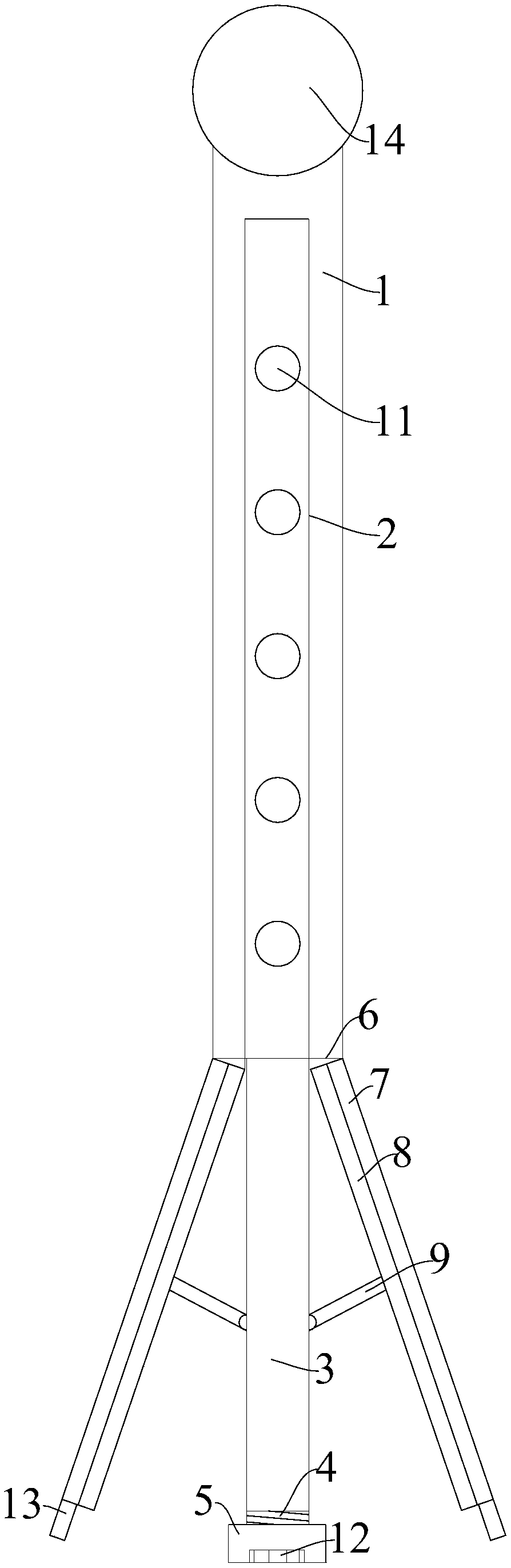

Monitoring device for transformer station foundation settlement monitoring

ActiveCN107702687AEasy to installFirmly connectedHeight/levelling measurementElectricityHaultain operation

The invention discloses a monitoring device for transformer station foundation settlement monitoring, and aims to provide the monitoring device for transformer station foundation settlement monitoringthat is characterized by easy installation of grounding wire, reliable connection, and convenient carrying operation in the process of resettlement to a next measurement station at the end of operation at a previous measurement station. The monitoring device comprises an invar leveling staff and a grounding device, the grounding device consists of an installation sliding sleeve sleeved on the invar leveling staff, an installation sliding sleeve electric connection piece that is disposed on the inner side of the installation sliding sleeve and is electrically connected to the invar leveling staff, a fastening bolt that is disposed on the installation sliding sleeve and is used for fastening the installation sliding sleeve on the invar leveling staff, and a reel rotatably disposed on the installation sliding sleeve and a grounding wire reeled on the reel.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER

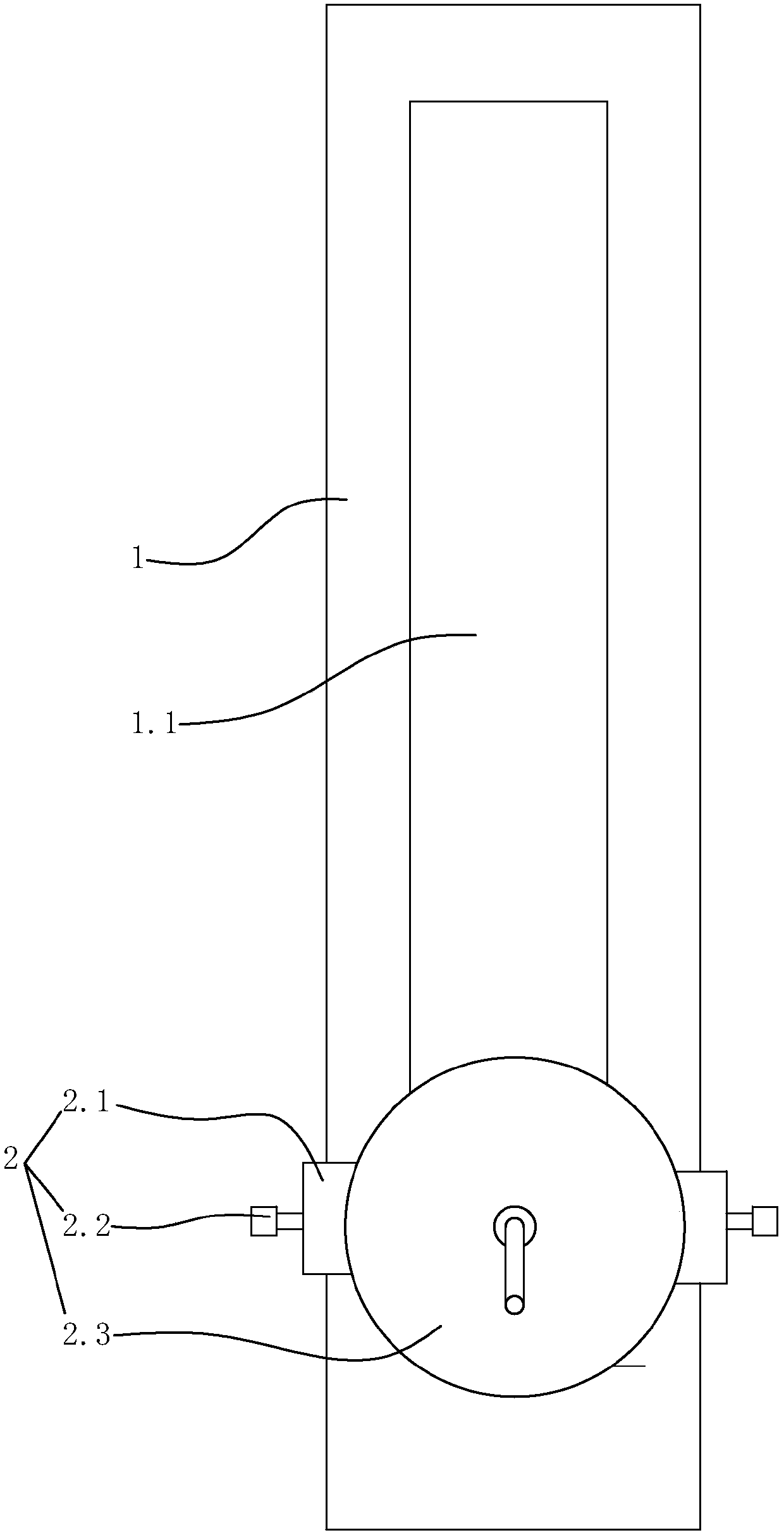

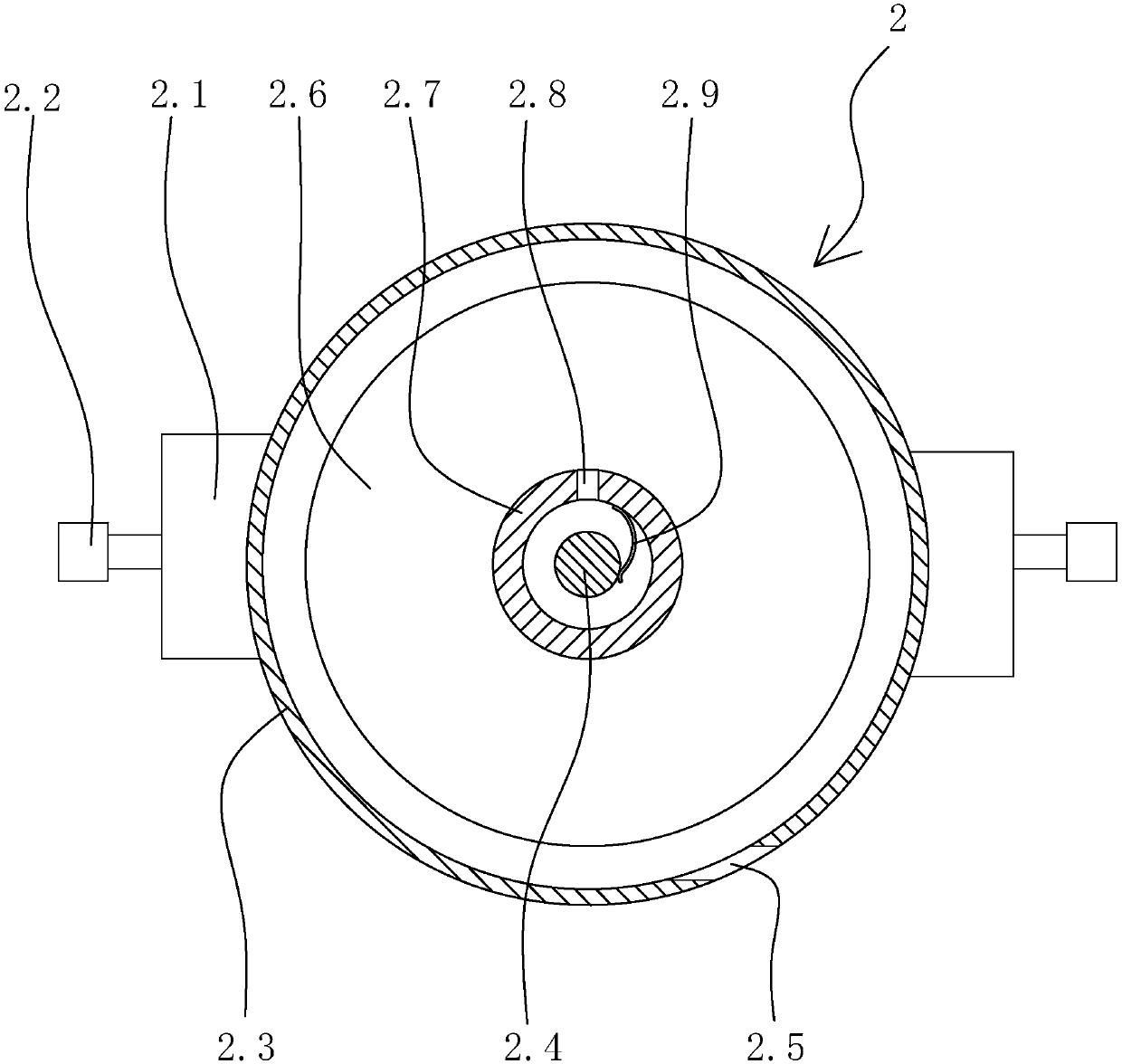

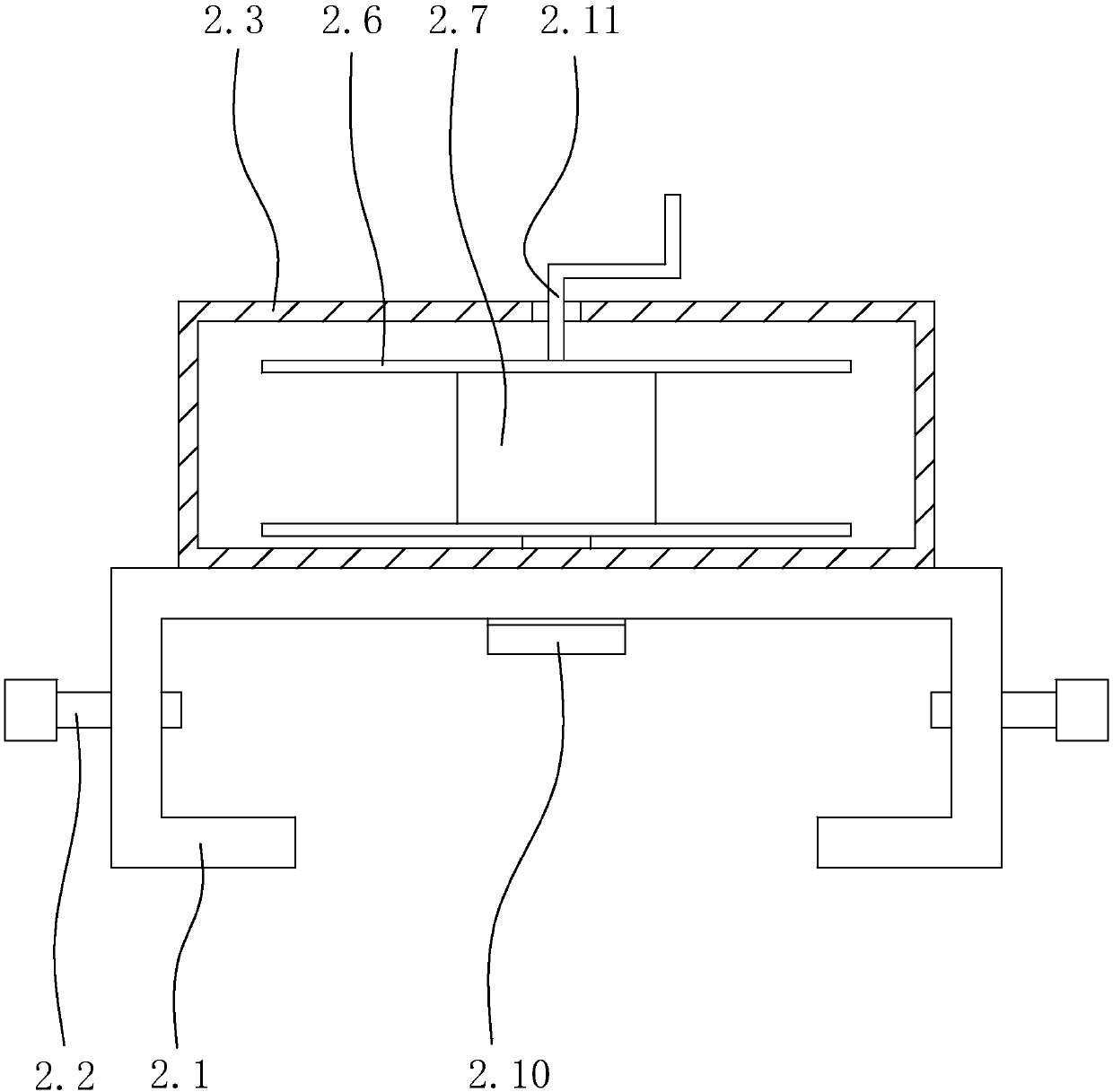

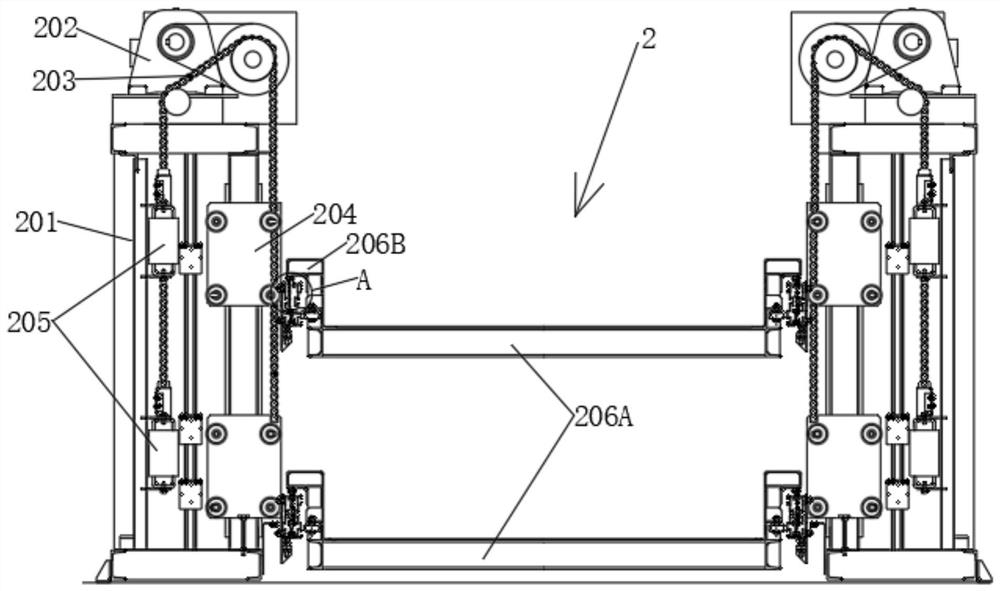

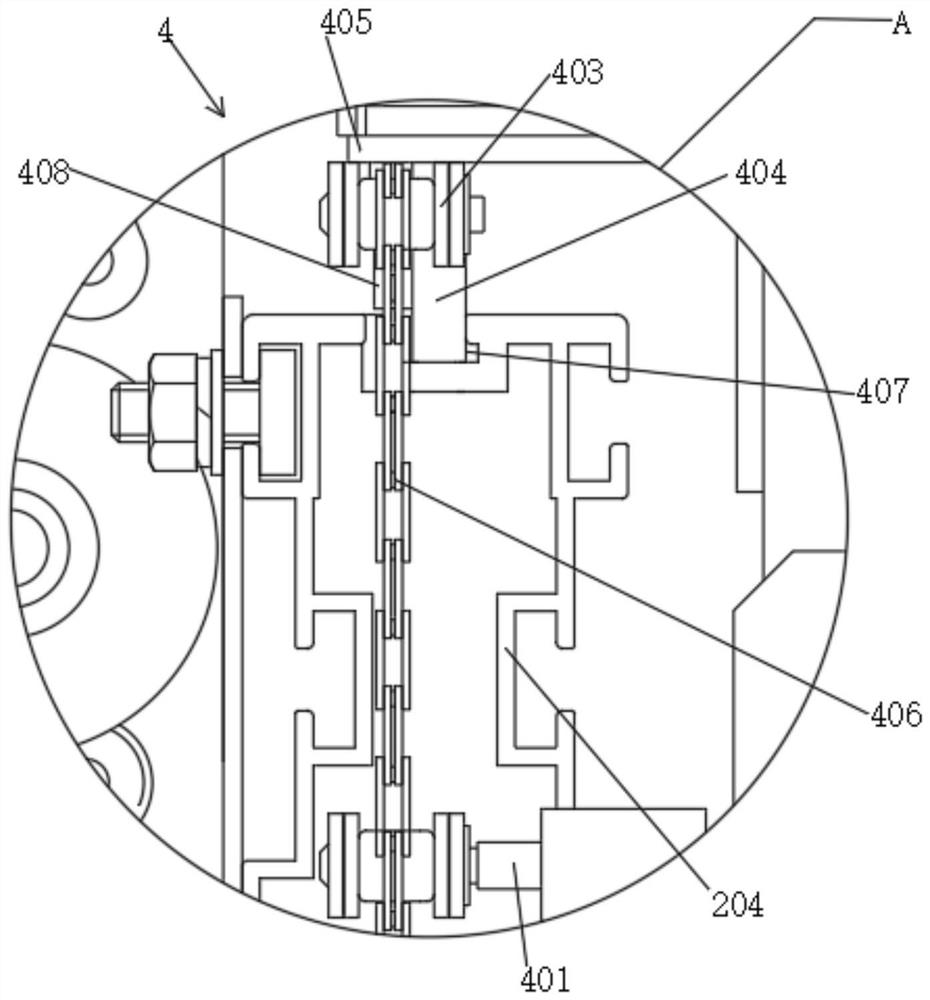

Vertical conveyor with recyclable mother trays

PendingCN114261920AImprove balanceHigh precisionLifting framesRoller-waysLogistics managementHaultain operation

The invention discloses a main tray circulating type vertical conveyor, which belongs to the technical field of logistics carrying equipment and comprises an equipment main body, a connection lifting device, a carrying roller device and a horizontal conveying mechanism, according to the connection lifting device, the special mother tray can be vertically lifted, objects are lifted and conveyed to the carrying roller, the objects are conveyed into the equipment body through the carrying roller, carrying operation is convenient, using is safe, the whole equipment does not comprise special equipment, and operation of professional certificate holding personnel is not needed; the balance device is hung at the other end of the connection lifting chain, so that the accuracy of the balance lifting height of the special mother tray in the lifting process can be improved; by arranging the carrying rollers, the process that goods enter the equipment body from the special mother tray is more stable and saves more labor; a baffle is arranged on the special mother tray, so that articles, especially trucks, can be prevented from falling off from the special mother tray; the baffle is limited to be rotationally connected with the special female tray and provided with a plug pin groove and a plug pin, and the baffle can be laid flat.

Owner:上海玉串自动化科技有限公司

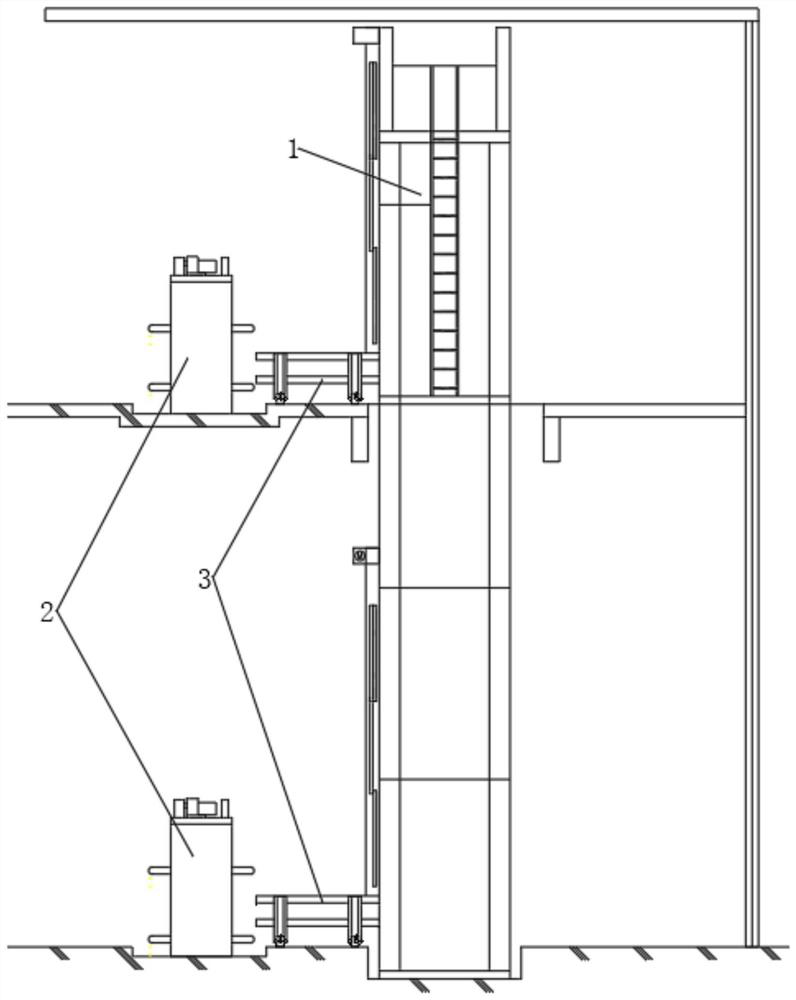

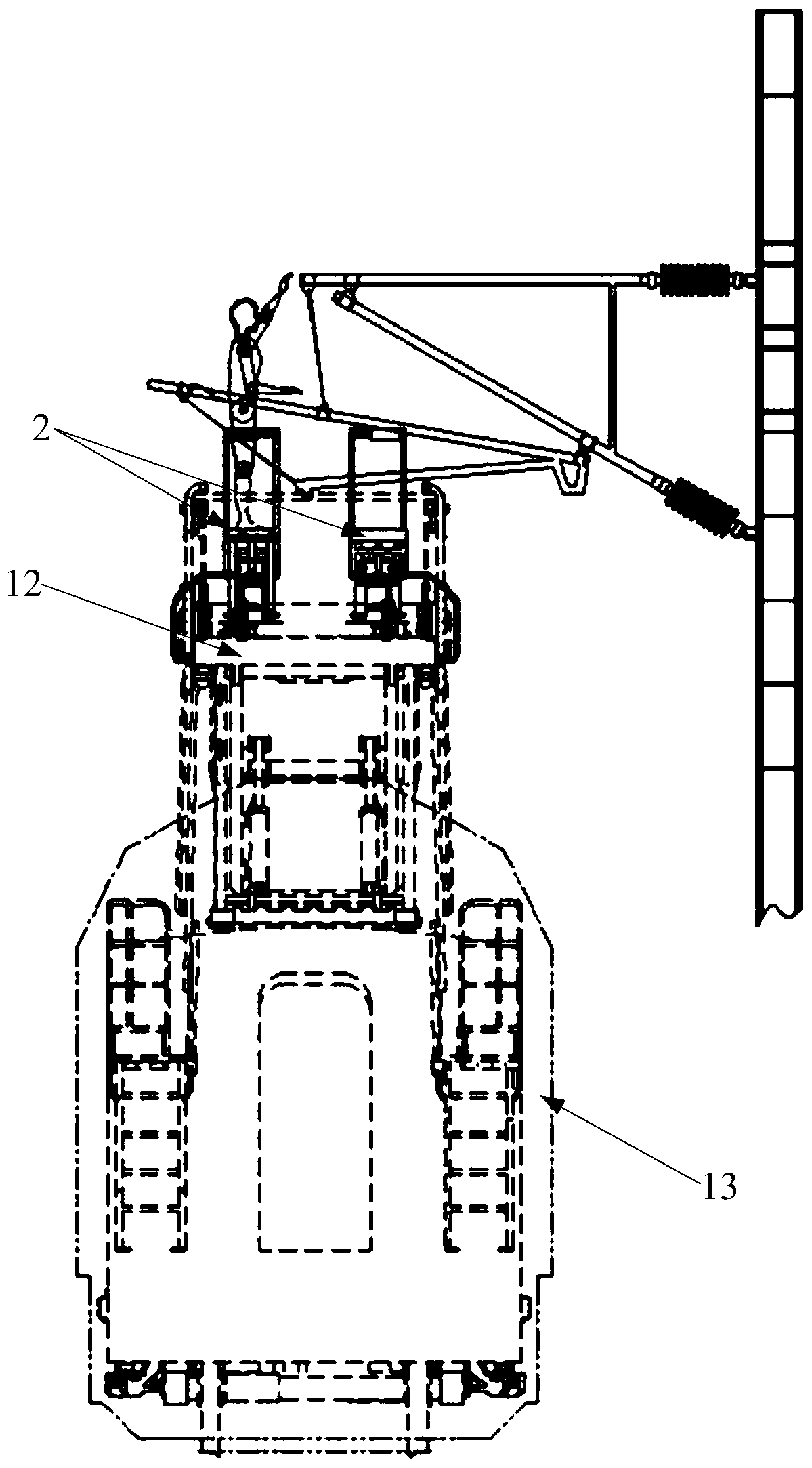

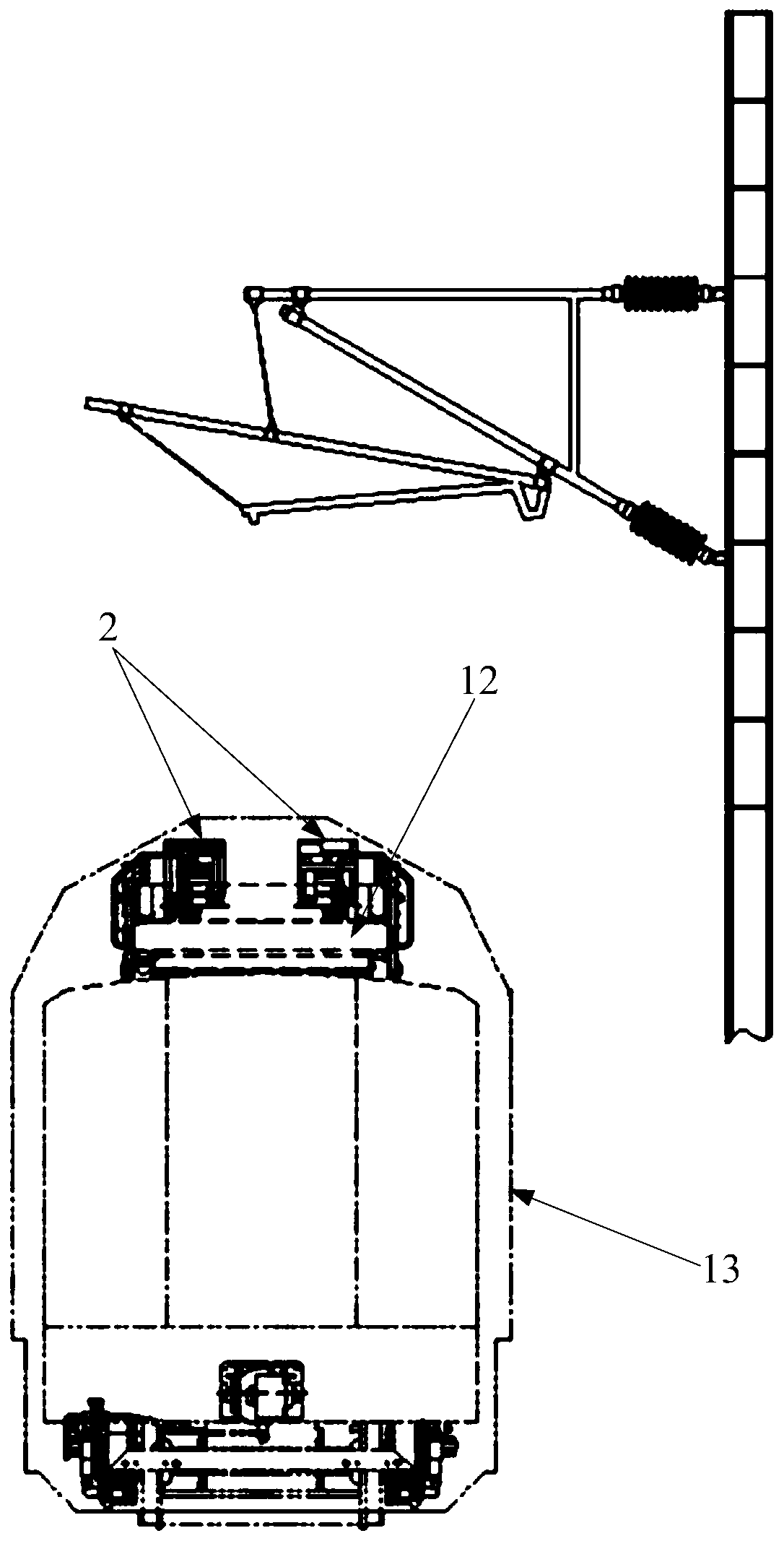

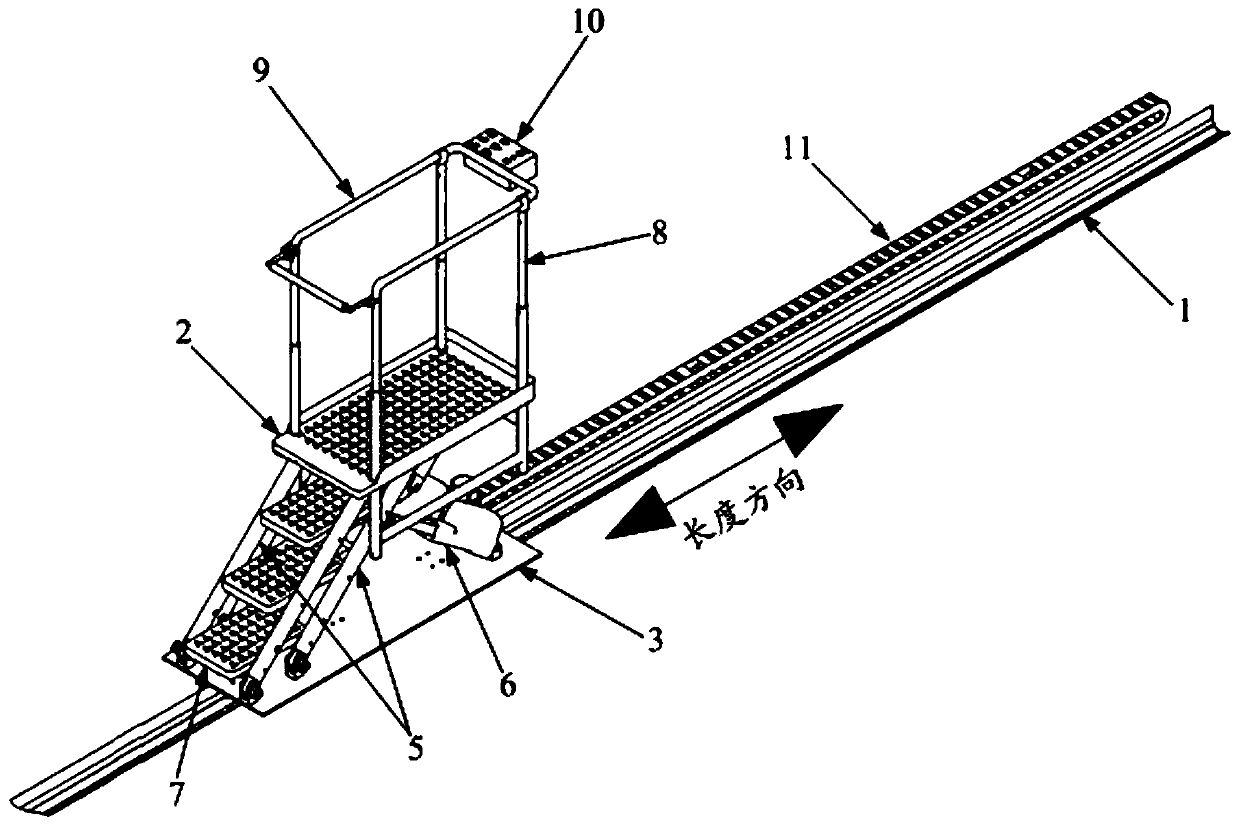

Overhead contact line overhauling operation vehicle and auxiliary device thereof

PendingCN110329287AAchieve transferReduce workloadRailway inspection trolleysTrolley linesHaultain operationContact line

The invention discloses an overhead contact line overhauling operation vehicle and an auxiliary device thereof. The auxiliary device of the overhead contact line overhauling operation vehicle comprises a guide rail and an auxiliary platform, wherein the guide rail is arranged on an operation platform of the overhead contact line overhauling operation vehicle; the guide rail extends in the length direction of the operation platform; the auxiliary platform is arranged on the guide rail; the auxiliary platform can automatically move on the guide rail; and the height of the auxiliary platform is larger than that of the operation platform. As the auxiliary device is provided with the auxiliary platform whose height is larger than the height of the operation platform, the auxiliary device can replace a ladder so that operation personnel can stand on the auxiliary platform to carry out omnibearing sufficient overhauling on higher parts such as an overhead contact line carrier cable; and moreover, the auxiliary platform can also automatically move on the guide rail laid on the operation platform so as to realize transferring of the auxiliary platform between different overhauling positions; and therefore, the conveying operation is avoided, the working burden of operation personnel is reduced, and the overhauling operation efficiency can also be enhanced.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

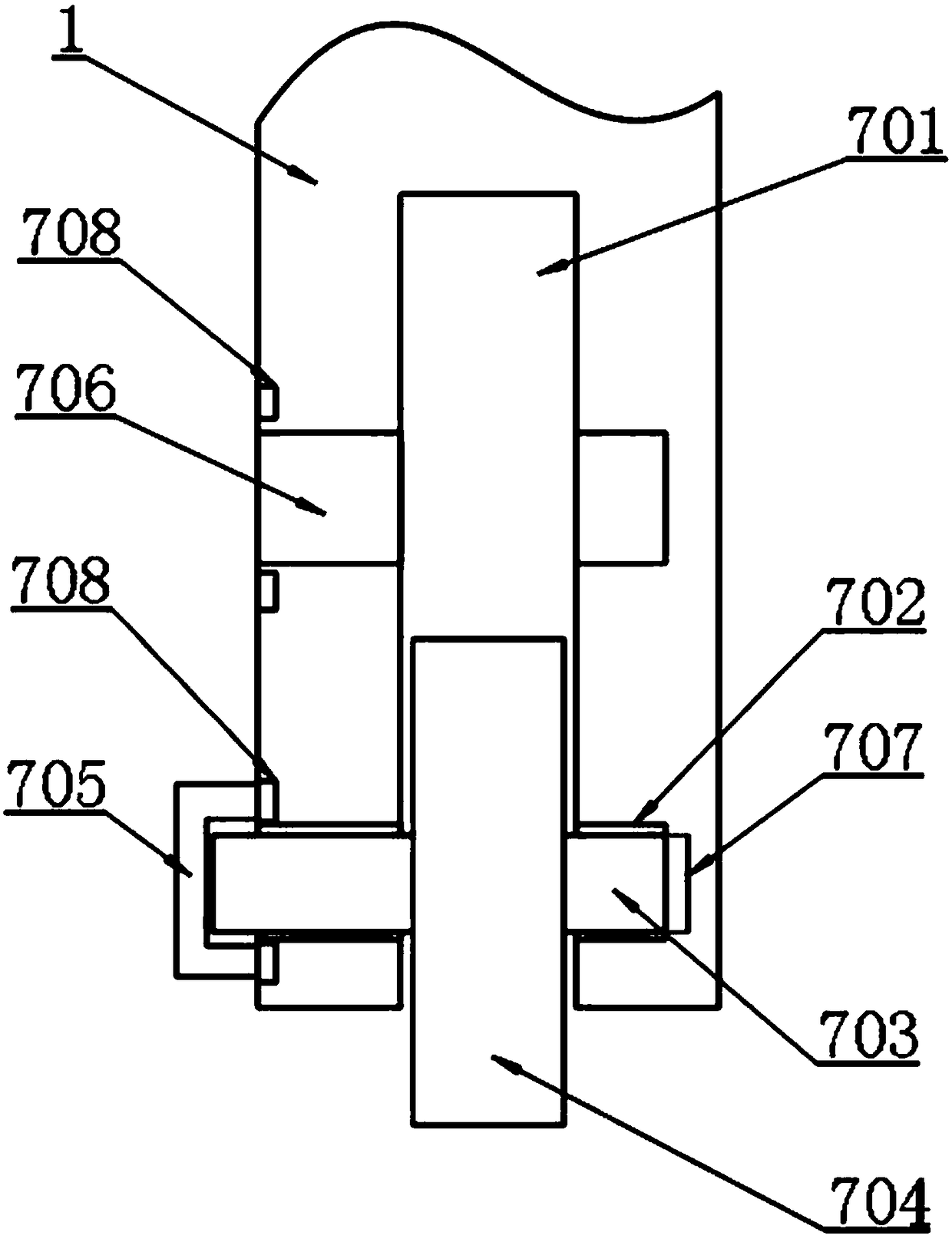

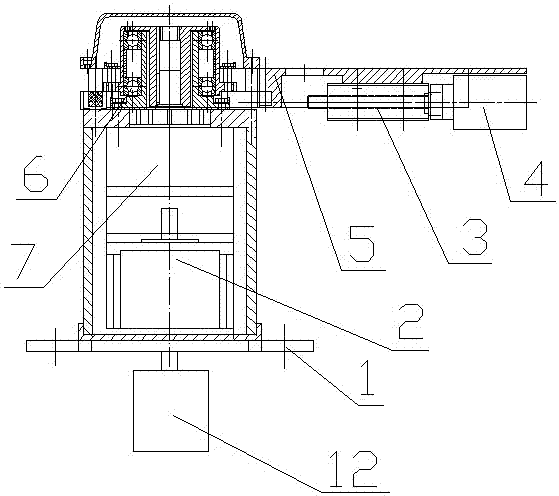

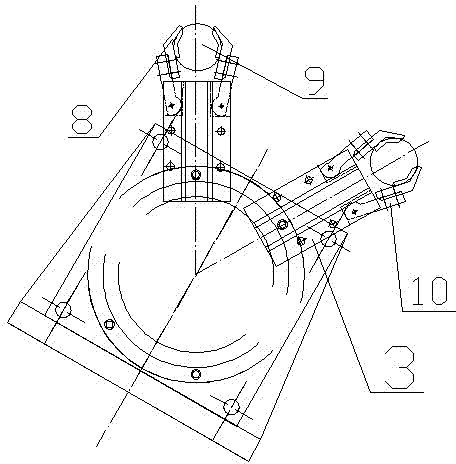

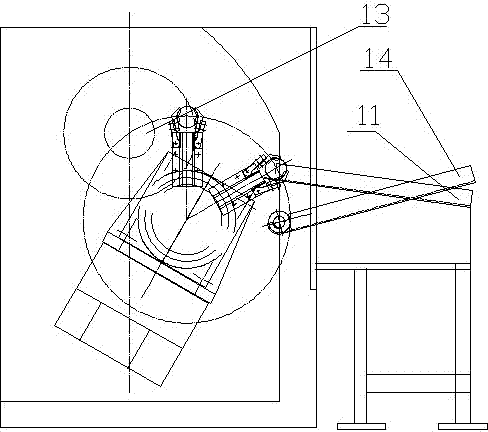

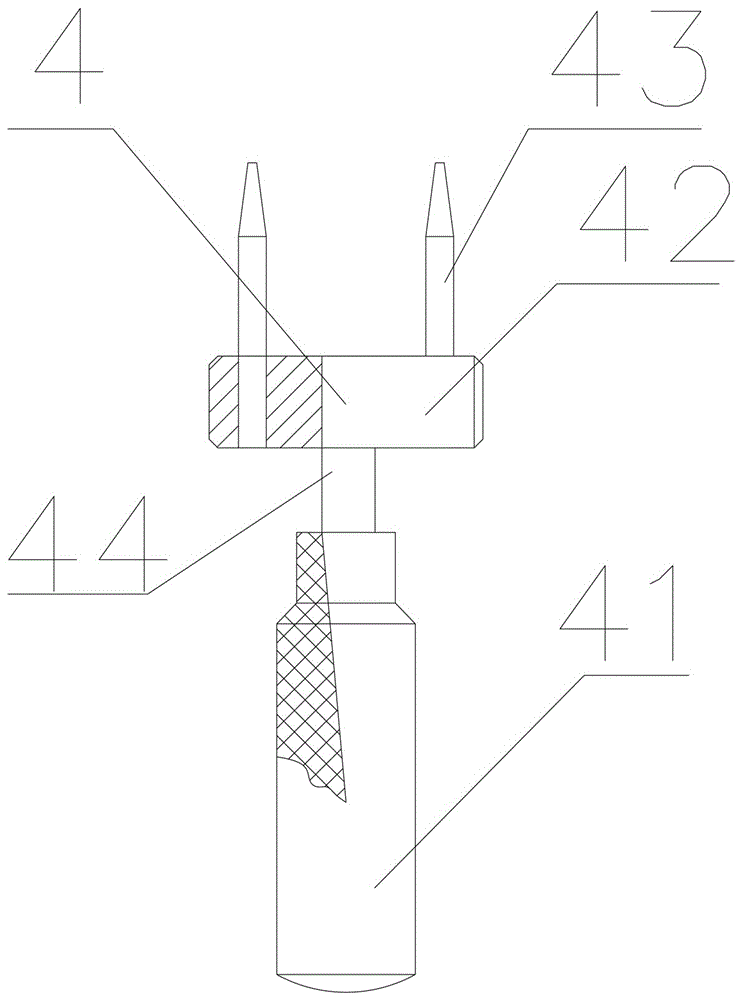

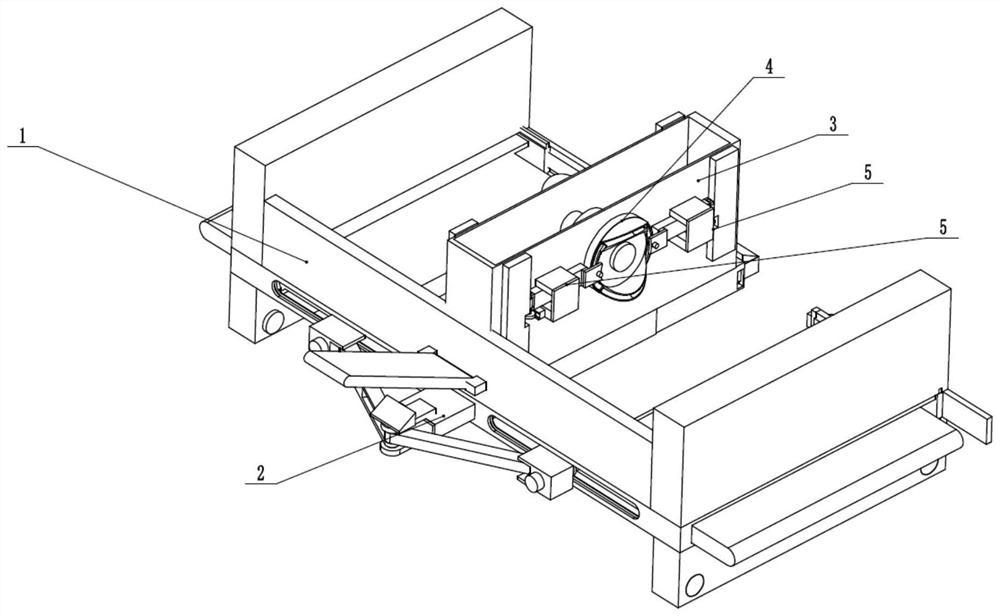

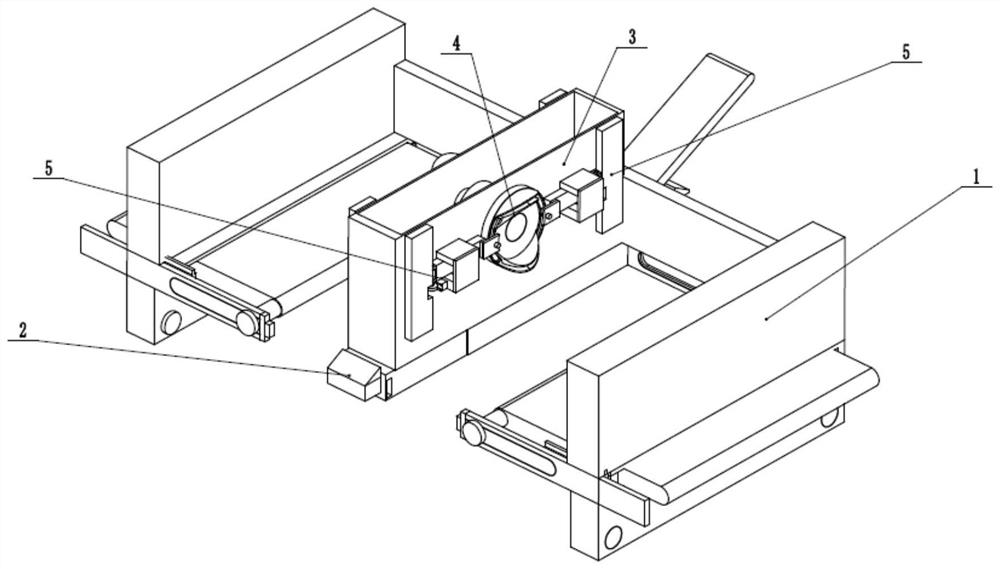

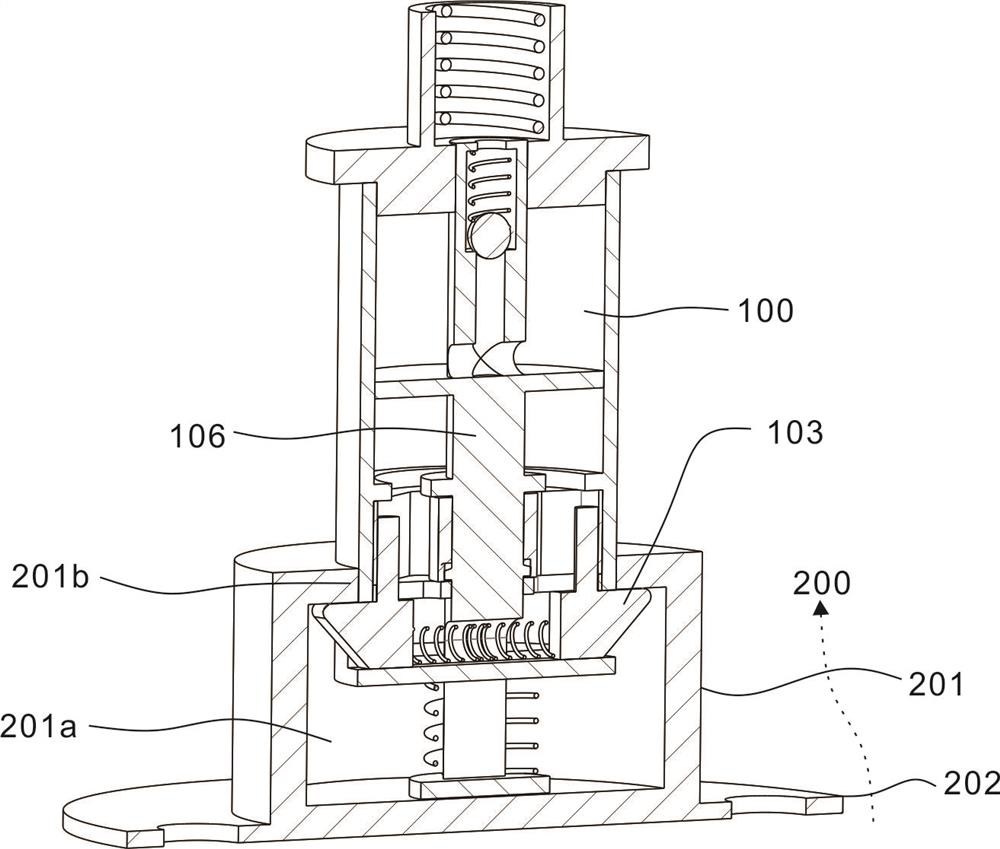

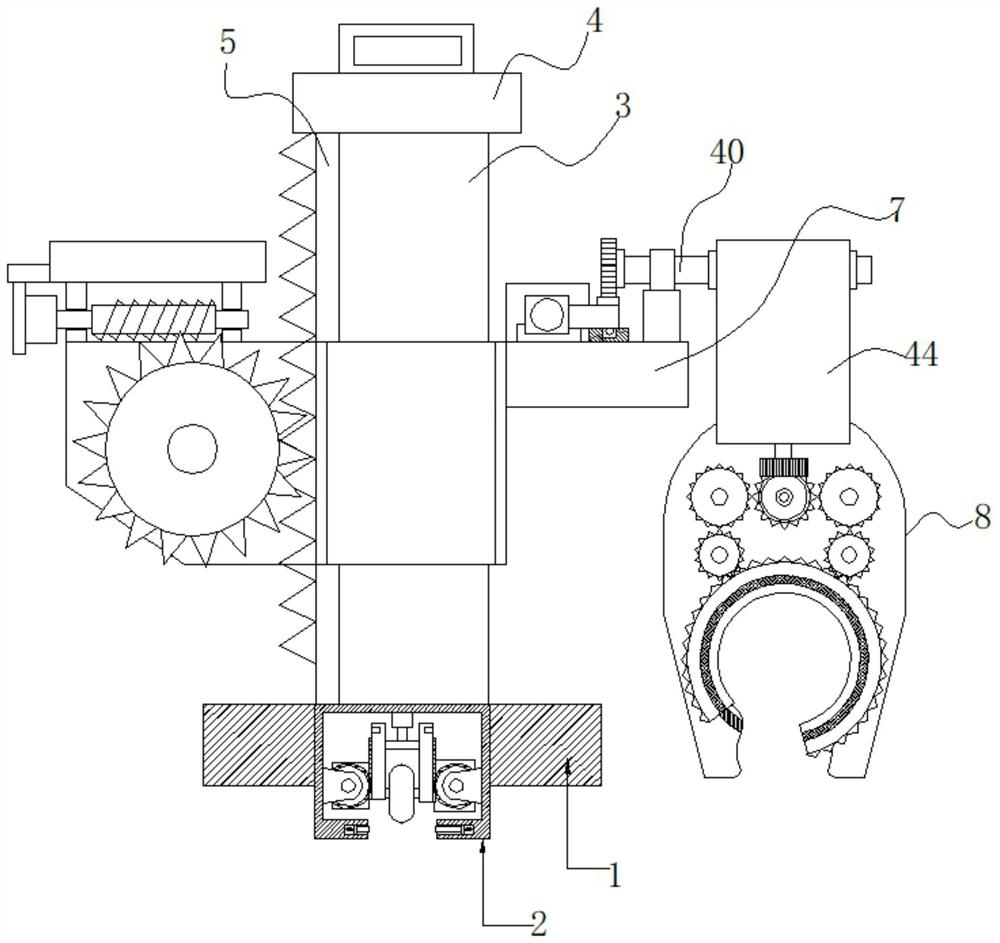

Numerical control lathe mechanical hand suitable for production of disc type parts

InactiveCN102357661BRealize fully automatic handling operationSimple structureProgramme-controlled manipulatorNumerical controlReduction drive

The invention discloses a numerical control lathe mechanical hand suitable for production of disc type parts. The numerical control lathe mechanical hand comprises a base, a servo motor, two paw cylinders, a clamping mechanism, a rotating arm, a speed reducer, clamping paws, clamping arms and a cylinder, wherein a housing is mounted on the base, the servo motor and the speed reducer are sequentially mounted in the housing from bottom to top, and a main shaft of the speed reducer is connected with the rotating arm; one end of the rotating arm is sheathed on the main shaft of the speed reducer,and the two paw cylinders and the clamping mechanism are outwards sequentially mounted at the other end of the rotating arm from the main shaft of the speed reducer; and the two pairs of the clampingpaws in the clamping mechanism are respectively mounted at one end of the each of the respective clamping arms, and the other end of each clamping arm is connected with the respective paw cylinder. The numerical control lathe mechanical hand firstly realizes full-automatic transportation operation of feeding and discharging when a numerical control lathe is used for processing the disc type parts, has the advantages of simple structure, reliability in control, precise positioning and the like, and can further replace two workers for performing clamping and transportation work on the disc-shaped parts during feeding and discharging, greatly reduce the cost and improve the efficiency and the safety.

Owner:ZHEJIANG UNIV

Construction aerial work platform

ActiveCN104110126BDesign material innovationHigh tensile strengthScaffold connectionsScaffold accessoriesPlastic materialsHaultain operation

The invention relates to a construction engineering aerial work platform, which includes a plurality of building fences, supporting steel pipes and building fence connectors, the building fences are made of plastic steel, and the building fences are arranged on the supporting steel pipes. The fence is provided with connecting holes, and the building fences are clamped together through the connecting holes. The invention adopts plastic-steel material to be used on the building fence, which has high quality, long life, high practical performance, two-thirds of the weight of the original bamboo row, convenient installation, transportation and operation, and is durable for resisting sunlight and ultraviolet rays in the open air, and the service life can reach one-half of that of moso bamboo. more than double. At the same time, it is connected through the clamping method, and the work efficiency of installing the plastic steel fence is more than five times that of the original tie wire. It has the advantages of fast installation, fixed positioning, safety and reliability, and easy disassembly. It also greatly improves the work efficiency of the installation of the plastic steel fence.

Owner:浙江学仕课桌椅制造有限公司

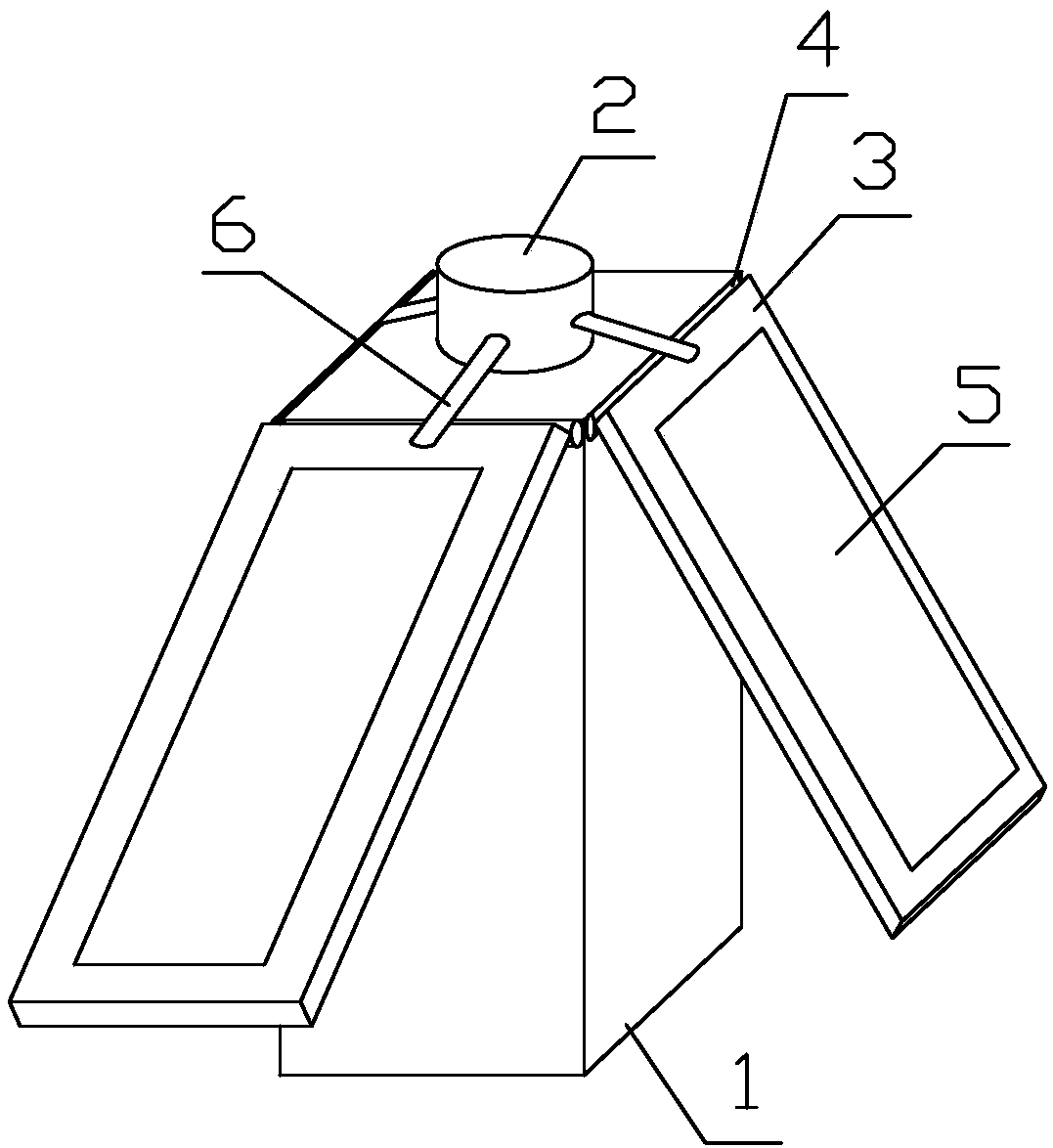

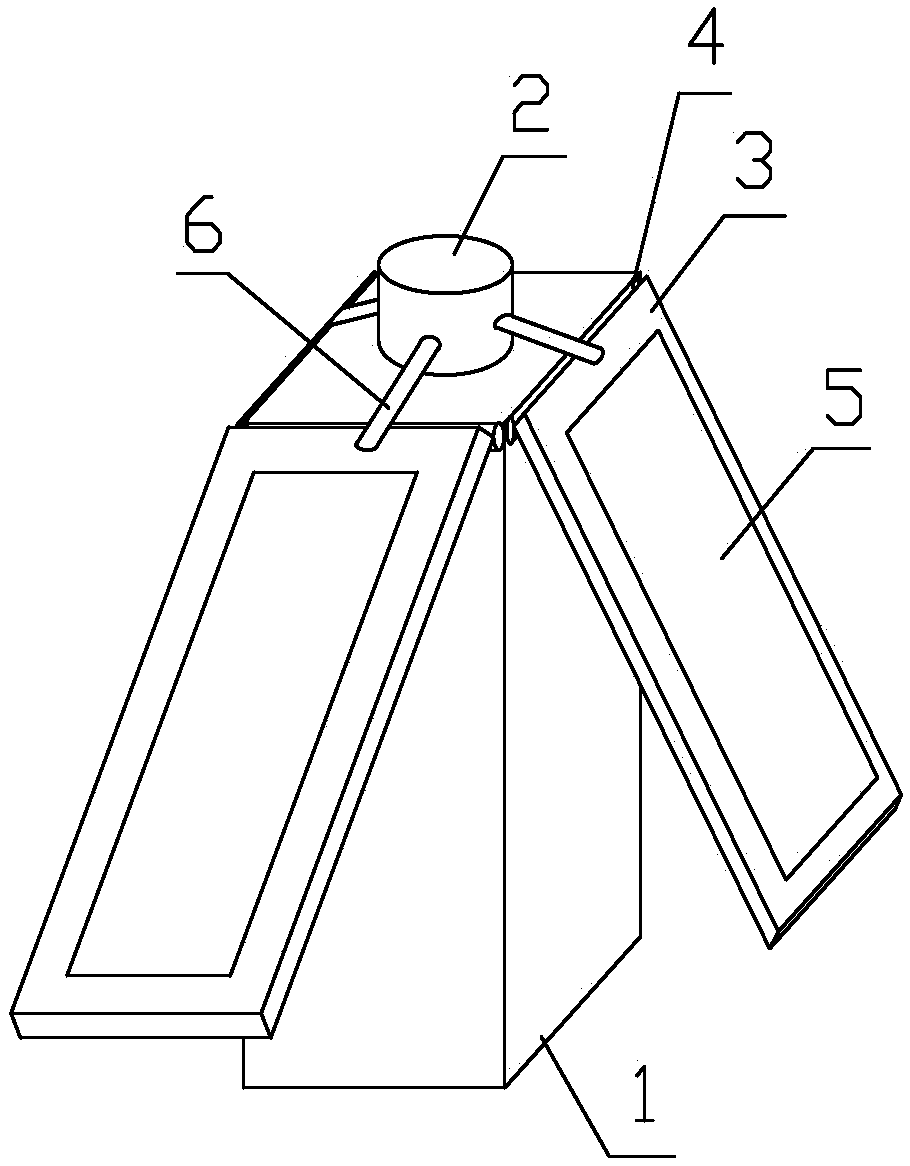

Multi-module type photovoltaic power generation installing support

InactiveCN108173494AReduce material requirementsAlleviate pull drivePhotovoltaic supportsSolar heating energyHaultain operationUniversal joint

The invention discloses a multi-module type photovoltaic power generation installing support. The multi-module type photovoltaic power generation installing support comprises a fixed column, wherein the radial cross section of the fixed column is of a regularly polygonal structure; an installing shell is arranged on the axial top of the fixed column; each side face of the fixed column is correspondingly provided with an installing plate; the lower plate surface, at one end of the long axis direction, of the installing plate is connected with the side wall, close to the top, of the fixed columnthrough a rotating shaft in a rotating manner; the axis direction of the rotating shaft is parallel to the side face of the fixed column; and a photovoltaic power generation panel is arranged on theupper plate surface of the installing plate. The multi-module type photovoltaic power generation installing support also comprises a plurality of telescopic rods, the axial ends of the telescopic rodsare fixed inside the installing shell, and the other ends of the telescopic rods are connected with the upper plate surface, in the long axis direction, of the installing plate through a universal joint. Through the telescoping or stretching movement of the telescopic rods, the installing plate is pulled to rotate upwards by taking the rotating shaft as an axial lead, so that the other end of thelong axis direction leaves away from the side wall of the fixed column or rotates downwards, and the other end of the long axis direction gets close to the side wall of the fixed column. The multi-module type photovoltaic power generation installing support provided by the invention is convenient for carrying operation.

Owner:成都亿伏科技有限公司

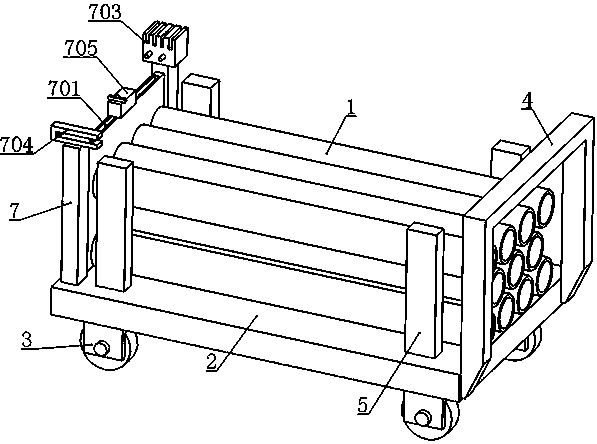

A convenient traction plastic pipe handling equipment

ActiveCN107933660BFlexible and convenient fixed operationHigh handling stabilitySupporting partsTowing devicesMagnetic tension forceMarine engineering

The invention belongs to the technical field of transportation devices and structures and particularly relates to a conveniently-towed plastic pipe transporting device. The conveniently-towed plasticpipe transporting device comprises a bottom plate for placing a plastic pipe, wheels, a push handle, a fixing column set, a clamping unit and an electromagnet unit, wherein the wheels, the push handleand the fixing column set are arranged on the bottom plate; the clamping unit extends into one end of the plastic pipe and is used for fixing the plastic pipe in an open and clamping mode; the electromagnet unit is arranged on one side of the bottom plate, which is away from the push handle, and used for fixing the clamping unit via magnetic attraction; a repulsing magnetic field for jacking andopening the clamping unit to clamp and fix the pipe is formed between the electromagnet unit and the clamping unit; the push handle is provided with a towing connecting unit. The conveniently-towed plastic pipe transporting device is high in transportation and operation stability, flexible and convenient in pipe fixing operation, convenient and rapid in towing operation and capable of greatly increasing the transportation efficiency.

Owner:TAICANG FANSHENG ELECTRONICS TECH CO LTD

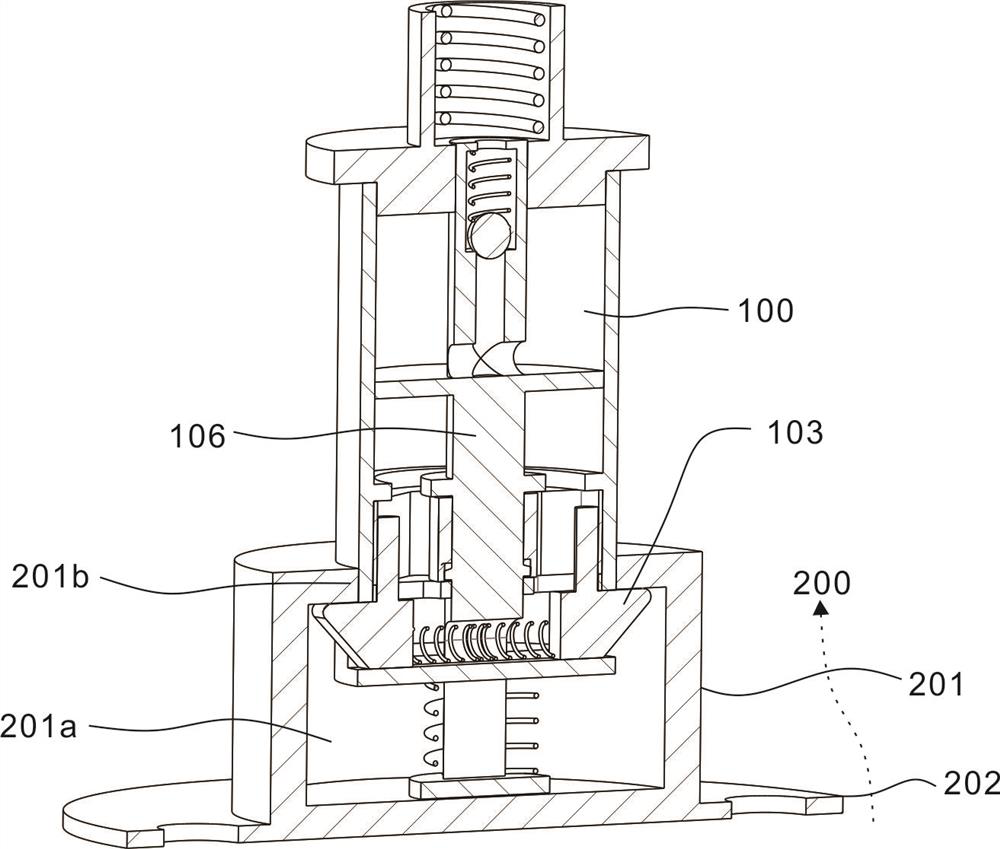

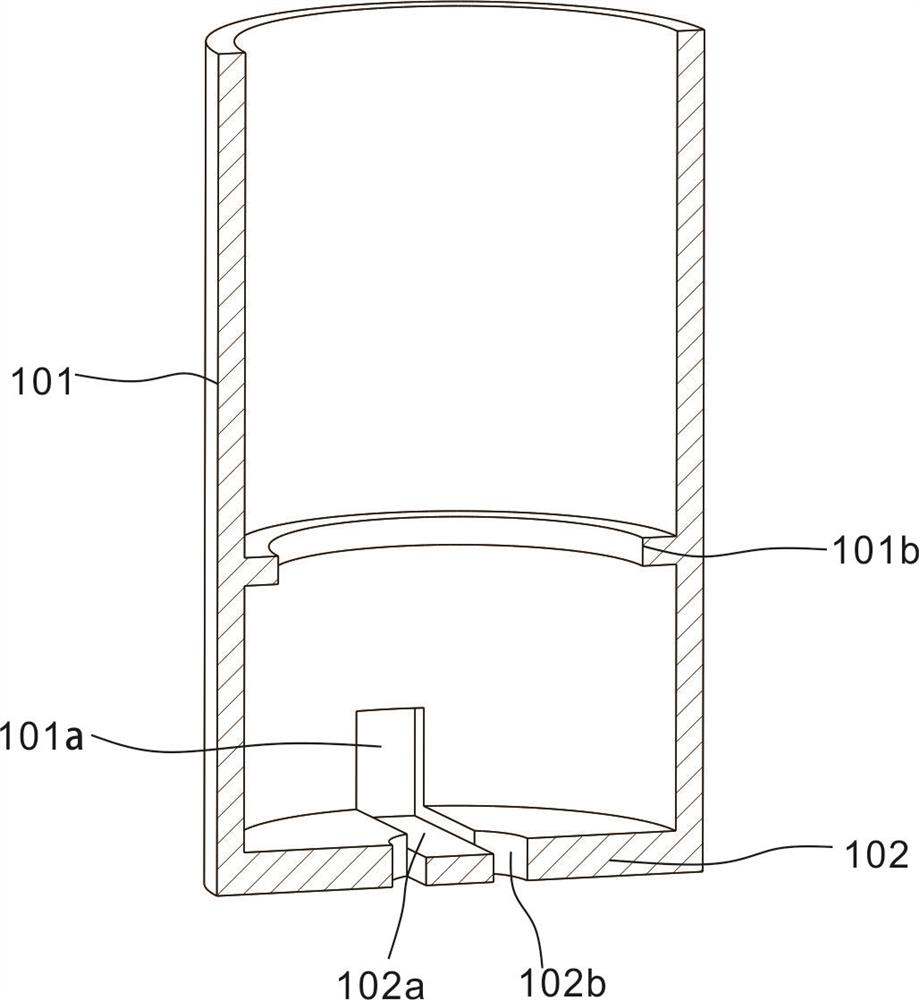

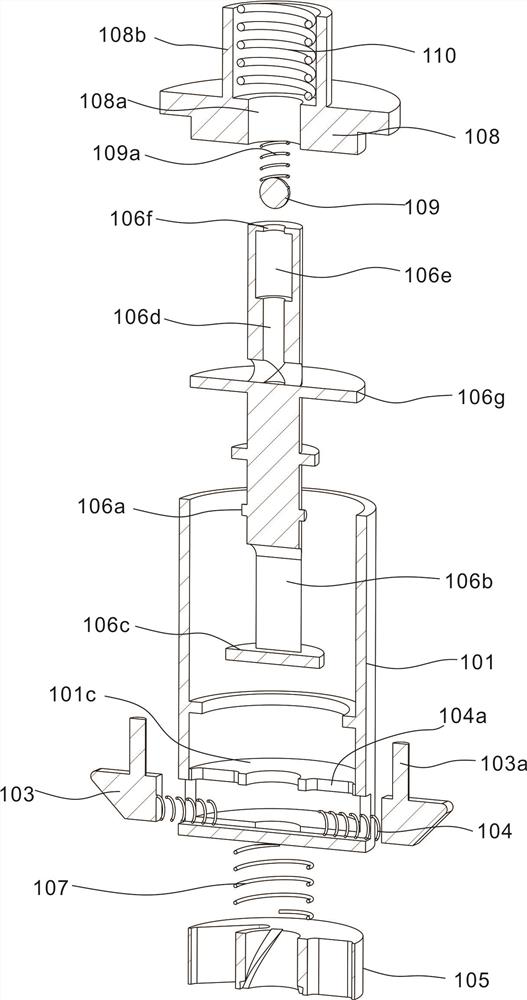

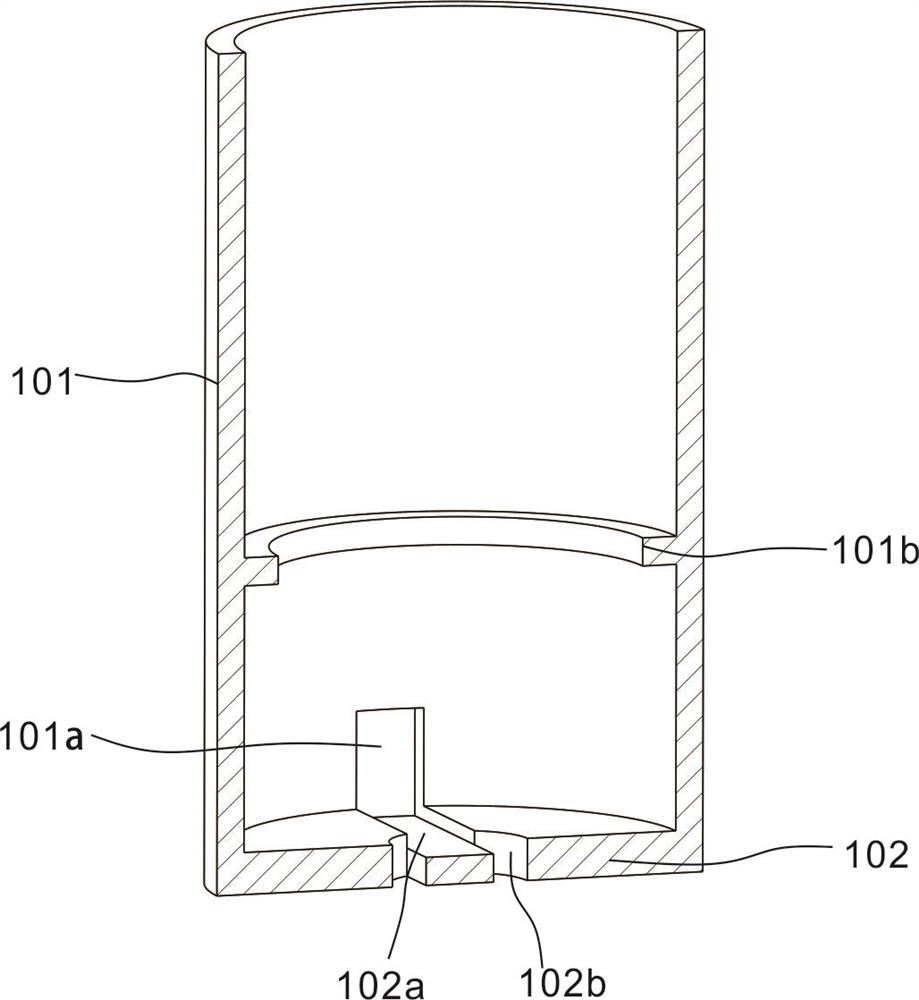

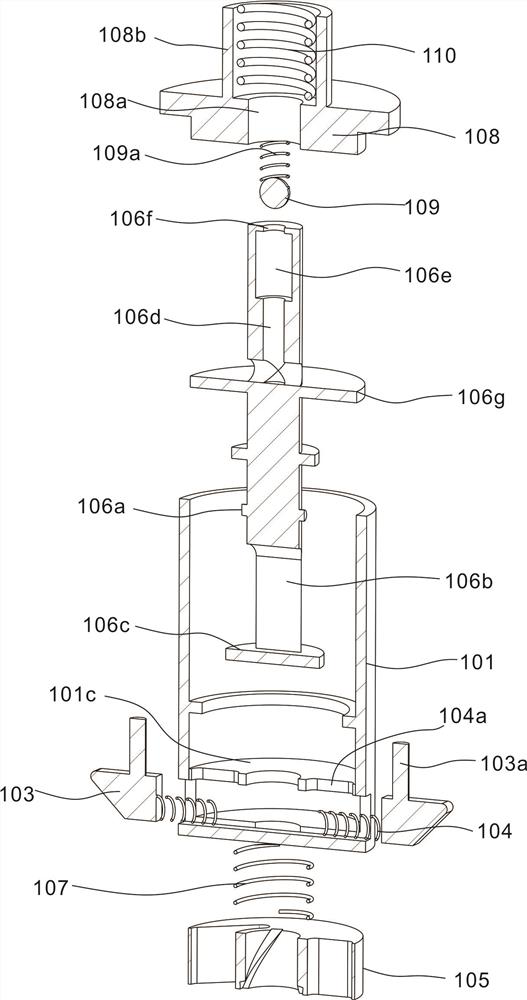

A cargo handling device

The invention discloses a cargo handling device, comprising an extracting unit and a fixing unit; the extracting unit includes an extracting cylinder, the interior of the extracting cylinder is a cavity, the bottom of the extracting cylinder is provided with a bottom plate, and the side of the extracting cylinder is provided with a through groove , a block is arranged in the through groove, and the block moves along a direction perpendicular to the axis of the extraction cylinder; the fixed unit includes a fixed block and a flange connected to the fixed block, and the fixed block is provided with a circular groove , the opening of the circular groove is provided with a boss extending toward the axial direction; the lower end of the extraction cylinder can extend into the circular groove, and the clamping block is in contact with the inner wall of the boss. When transporting goods through the present invention, the goods are directly lifted and transported by operating the extracting cylinder, and after being transported to the designated place, it only needs to operate the extracting cylinder to move down again to complete the shedding, and the operation process is extremely convenient.

Owner:徐州锐尔五金工具制造有限公司

Logistics storage rapid unloading device and method

InactiveCN112607292AEasy to usePrevent shaking and falling offLoading/unloadingStorage devicesLogistics managementHaultain operation

The invention relates to the field of warehousing and transportation, in particular to a logistics storage rapid unloading device and method. The method comprises the steps that goods to be transported and stacked are placed on a transport cart frame and a pedal unloading conveyor and are transported to a designated position by pulling the transport cart frame; while the lower end is blocked by back-treading on the pedal unloading conveyor, a clamping driver and four transport clamping devices are driven to move on a central fixing frame, and then the transported and stacked goods are clamped through the four transport clamping devices to be prevented from falling off in the transporting process; after being conveyed to the designated position, all the stacked cargoes automatically fall to the ground by treading on the pedal unloading conveyor, and meanwhile the clamping devices retract; in the process of transporting the goods to a warehouse, automatic alignment, clamping and protection are achieved, and the situation that the goods fall off due to shaking in the transporting process is prevented; and after arriving at the designated position, the stacked goods can be driven to automatically fall down, and manual carrying is reduced. The device and method are convenient to operate and convenient to use by workers in the actual transporting process.

Owner:哈尔滨铭川运输有限公司

Smelting palletizing shaft furnace air-guiding wall and building method thereof

ActiveCN101738082BReduce airtightnessThe airtightness of the air guide wall is small and the airtightness is excellentFurnace componentsVertical furnacesBrickHaultain operation

The invention relates to a smelting palletizing shaft furnace air-guiding wall and a building method thereof, belonging to the field of smelting palletizing shaft furnaces. The air-guiding wall body is an arch-up flat-down or arch structure; firebricks for building the air-guiding wall body comprise wedge-shaped, T-shaped, L-shaped and reverse I-shaped firebricks as well as lining bricks providedwith vent holes in the middle part; the air-guiding wall body is paved and built according to the number of layers and the position; the bottom of the air-guiding wall body is supported by a heat-resistant metal cork base and a support pillar under the cork base; cover plate bricks cover the upper part of the air-guiding wall; and triangular castables are cast on the cover plate brick. In the invention, firebricks with various types are paved and built according to the number of layers and the position by a reasonable method; and because of small clearance, the sealing performance of the air-guiding wall body is superior to similar air-guiding walls; besides, the novel brick is small in volume, light in weight and convenient to carry and operate. The support device is arranged at the lower part of the air-guiding wall, thereby ensuring favorable heat-resistant performance, easy production and installation and large support force.

Owner:唐山市盈心耐火材料有限公司

Cargo carrying device

The invention discloses a cargo carrying device. The cargo carrying device comprises an extracting unit and a fixing unit, wherein the extracting unit comprises an extraction barrel, the interior of the extraction barrel is a cavity, a bottom plate is arranged at the bottom of the extraction barrel, a through groove is formed in the side face of the extraction barrel, a clamping block is arranged in the through groove, the clamping block moves in the direction perpendicular to the axis of the extraction barrel, the fixing unit comprises a fixing block and a flange plate connected to the fixing block, the fixing block is provided with a circular groove, a boss extending in the axis direction is arranged at the opening position of the circular groove, the lower end of the extraction barrel can stretch into the circular groove, and the clamping blocks make contact with the inner wall of the boss. When cargos are carried through the cargo carrying device, the cargos are directly lifted and carried by operating the extraction barrel, after the cargos are carried to a designated place, falling can be completed only by operating the extraction barrel to move downwards again, and the operation process is extremely convenient and fast.

Owner:徐州锐尔五金工具制造有限公司

Municipal construction pipeline support simulating manual carrying operation

InactiveCN113072005AConvenient card connectionAvoid wear and tearLifting framesLine tubingHaultain operation

Owner:余传洪

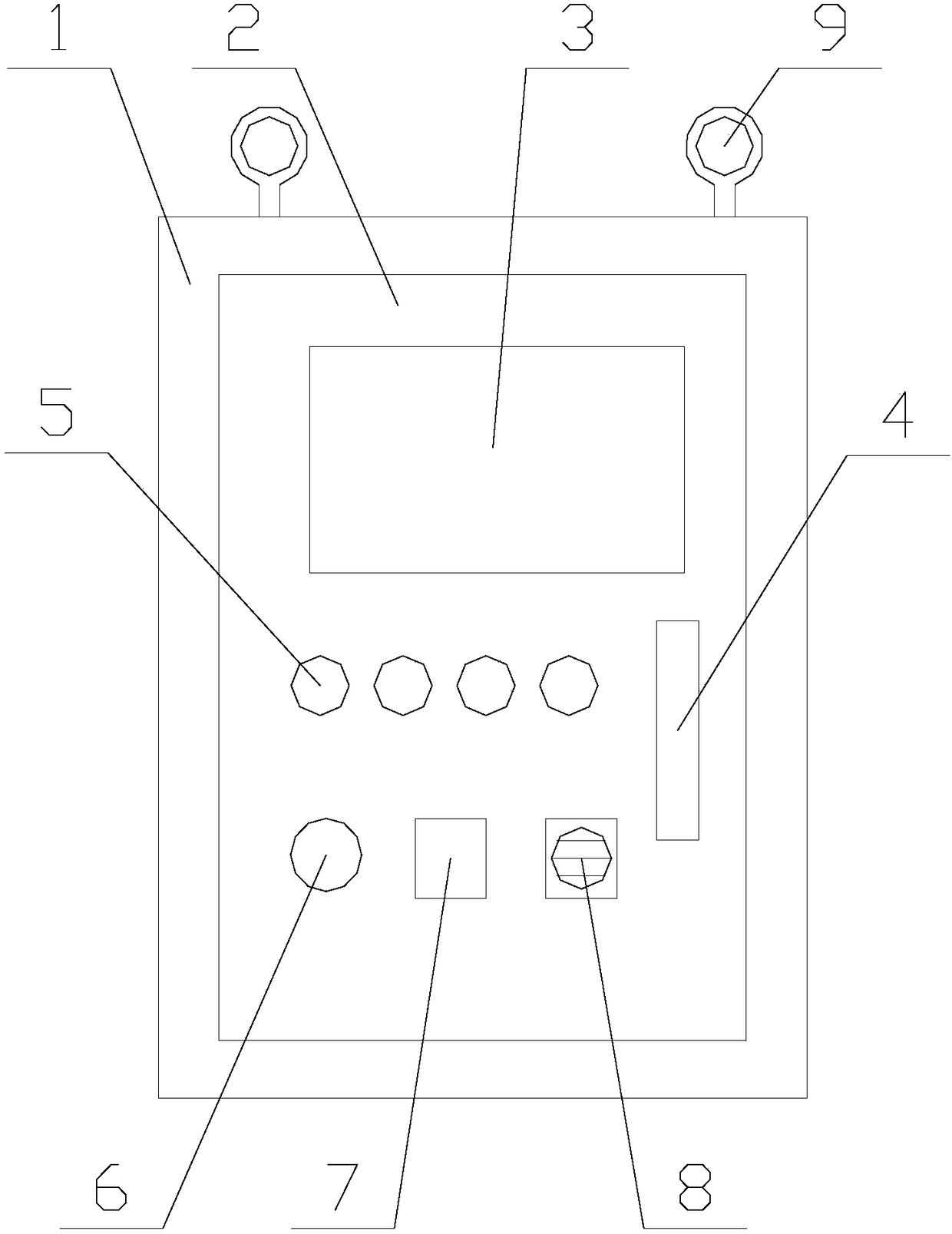

An intelligent power distribution cabinet for power system

ActiveCN106058670BImprove practicalityConvenient lifting and handling operationSubstation/switching arrangement casingsMechanical energy handlingElectric power systemHaultain operation

The invention relates to an intelligent power distribution cabinet for a power system. The intelligent power distribution cabinet comprises a cabinet body and a hoisting mechanism which is arranged above the cabinet body. The cabinet body is provided with a cabinet door. The front surface of the cabinet door is provided with an input / output mechanism and a handle. The back surface of the cabinet door is provided with a fixing mechanism. The cabinet body is internally provided with two horizontally arranged cross bars. The intelligent power distribution cabinet for the power system utilizes a third driving motor in the hoisting unit for making a conveyor belt move, and a moving block is driven to perform displacement, thereby making a suspension ring move in a trough, and facilitating hoisting operation and conveying operation on the suspension ring. Furthermore, a connecting board is horizontally arranged through a first connecting driving motor, thereby facilitating opening of the cabinet door. Through rotation of a second driving motor, a block on the connecting board approaches and clings to cross bar, thereby realizing locking operation on the cabinet door. The fixing mechanism realizes simple operation, high safety and high reliability, so that practicability of the power distribution cabinet is improved.

Owner:LIANYUNGANG GANGSHENG SWITCH MFG

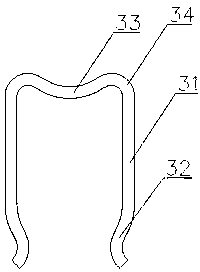

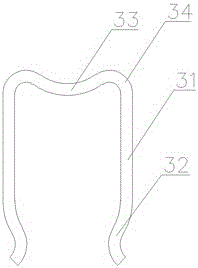

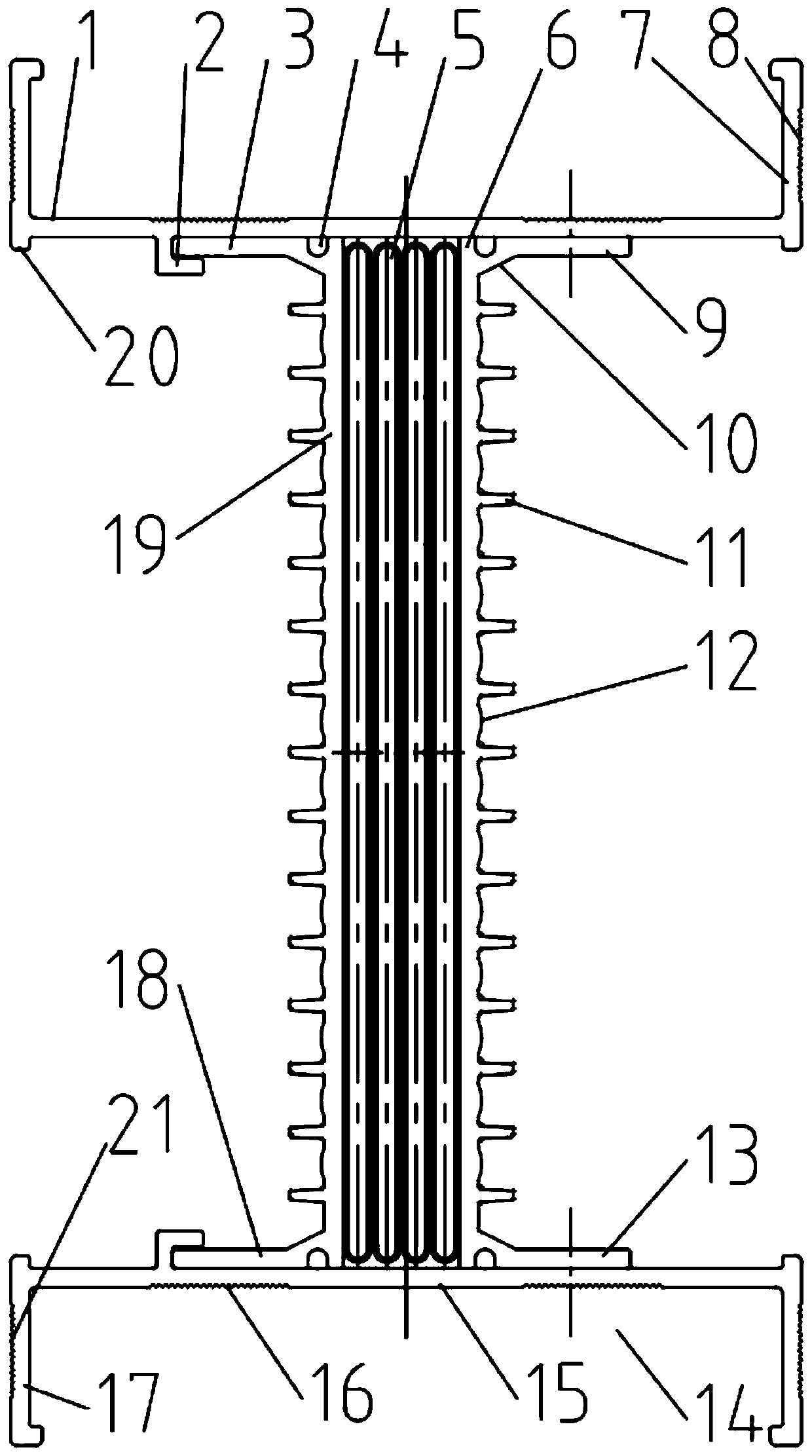

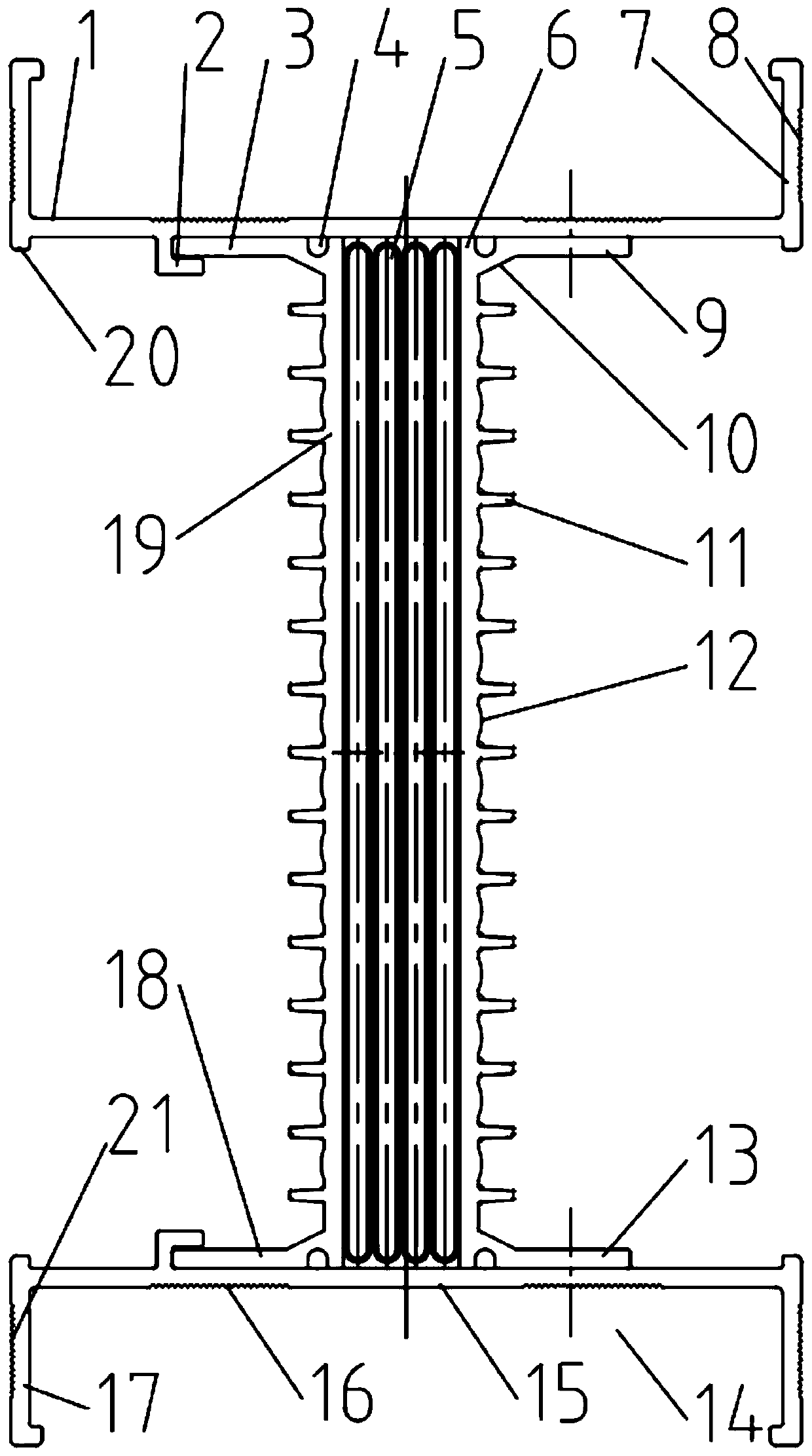

Lightweight dense insulating bus groove

PendingCN109994976AReduce consumptionSmall footprintCooling bus-bar installationsTotally enclosed bus-bar installationsElectrical conductorHaultain operation

The invention relates to a lightweight dense insulating bus groove. A phase line conductor accommodating cavity is formed by the space between a pair of transversely arranged U-shaped left side plateand right side plate which are opposite to each other between an upper cover plate and a lower cover plate. The upper side edge and the lower side edge of the left side plate are respectively limitedand clamped on the upper cover plate and the lower cover plate through limiting grooves. The upper side edge and the lower side edge of the right side plate are respectively riveted and fixedly connected by rivets. The outer side surfaces of the left side plate and the right side plate are provided with multiple reinforcing ribs to increase strength and realize the auxiliary heat radiation function. The heat radiation efficiency is further enhanced by the sawtooth heat radiation grooves. The upper folding edges and the space between the upper folding edges can form a line groove structure fora cable and a signal line, and the space between the lower folding edges can form an auxiliary equipment installation cavity for a lighting lamp, an emergency lamp, a monitoring camera and the like. The outer side surfaces of the upper folding edges and the lower folding edges are provided with anti-slip stripes for convenient handling operation. The structure is simple and compact, the consumption of raw materials is low, the production cost is low, the occupancy area of the workshop is small and the product structure and the production process are all extremely simplified.

Owner:江苏华鹏电力设备股份有限公司

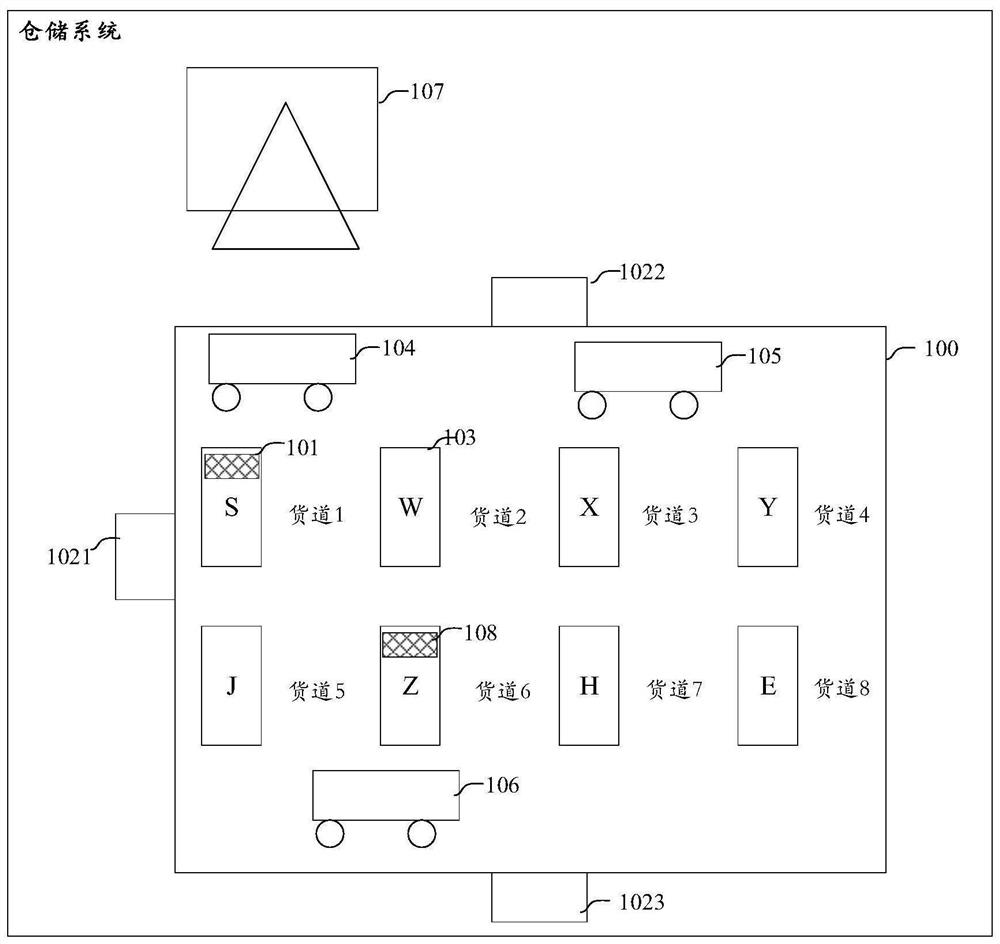

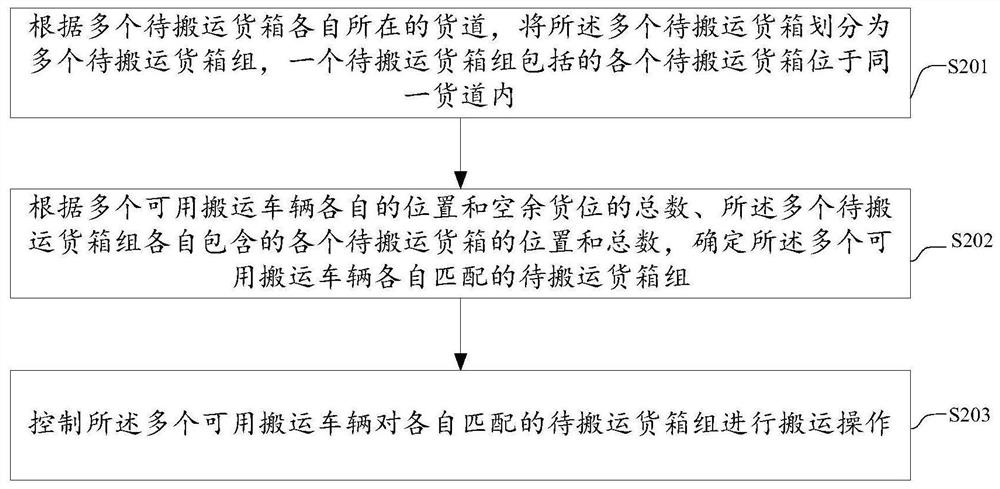

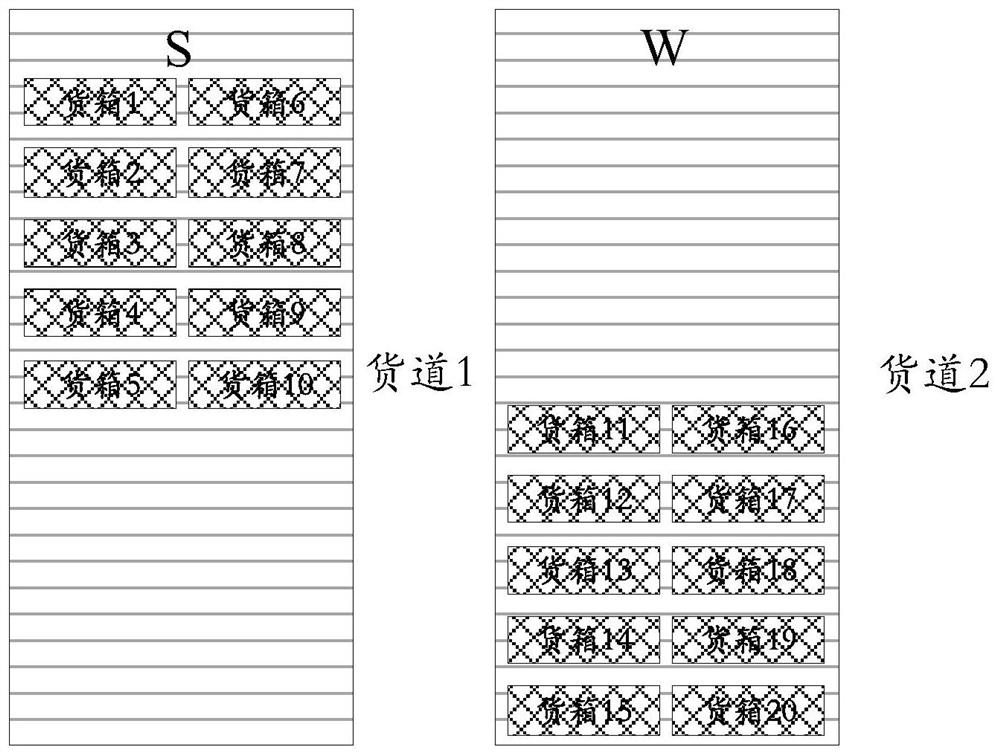

Method, device and system for controlling goods carrying vehicle, equipment and medium

PendingCN111832802AImprove handling efficiencyAvoid congestionForecastingLogisticsHaultain operationTransport engineering

The invention provides a method, device and system for controlling a goods carrying vehicle, and equipment and a storage medium, and the method comprises the steps of dividing a plurality of to-be-carried cargo boxes into a plurality of to-be-carried cargo box groups in the same cargo channel according to the cargo channels where the to-be-carried cargo boxes are located; determining to-be-carriedcontainer groups matched with the plurality of available carrying vehicles according to the respective positions and the total number of the spare goods allocations of the plurality of available carrying vehicles and the respective positions and the total number of the to-be-carried containers contained in the plurality of to-be-carried container groups; and controlling the multiple available carrying vehicles to carry out carrying operation on the to-be-carried container sets matched with the multiple available carrying vehicles. According to the invention, the control end considers the distribution of global tasks on the whole; the cargo boxes to be delivered in the same cargo channel are bound into a plurality of cargo box groups to be delivered, and then the cargo box groups to be delivered are issued to a plurality of available cargo handling vehicles in batches, so that each available cargo handling vehicle executes the task allocated by the available cargo handling vehicle, congestion in the cargo channel can be avoided, and the overall delivery efficiency of a warehouse is improved.

Owner:BEIJING KUANGSHI ROBOTICS TECH CO LTD

Transformer processing table facilitating carrying operation

InactiveCN108263978AEasy to operateEasy to processInductances/transformers/magnets manufactureCranesHaultain operationThreaded pipe

The invention relates to the technical field of transformers and discloses a transformer processing table facilitating carrying operation. The transformer processing table facilitating the carrying operation comprises a mounting base; a threaded pipe is fixedly connected to the top of the mounting base; a threaded rod is in threaded connection with the inner wall of the threaded pipe; the surfaceof the threaded rod is sleeved with a threaded sleeve which is rotationally connected with the threaded pipe; a first motor is fixedly connected to the top of the mounting base; a nylon wheel is fixedly connected to an output shaft of the first motor; the surface of the nylon wheel is sleeved with a belt which is rotationally connected with the threaded sleeve; a processing table body is fixedly connected to the top of the threaded rod; a ring slot is formed in the top of the mounting base; and two lifting devices are connected to the inner wall of the ring slot in a sliding mode. By means ofthe transformer processing table facilitating the carrying operation, a transformer body can be carried out moved more conveniently, waste of manpower and material resources is reduced, and users canuse the processing table conveniently.

Owner:响水澳玛金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com