Automatic handling operation system

An operating system and automatic technology, applied in the field of handling operating systems, can solve the problems of high risk, many special gases, and high process automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

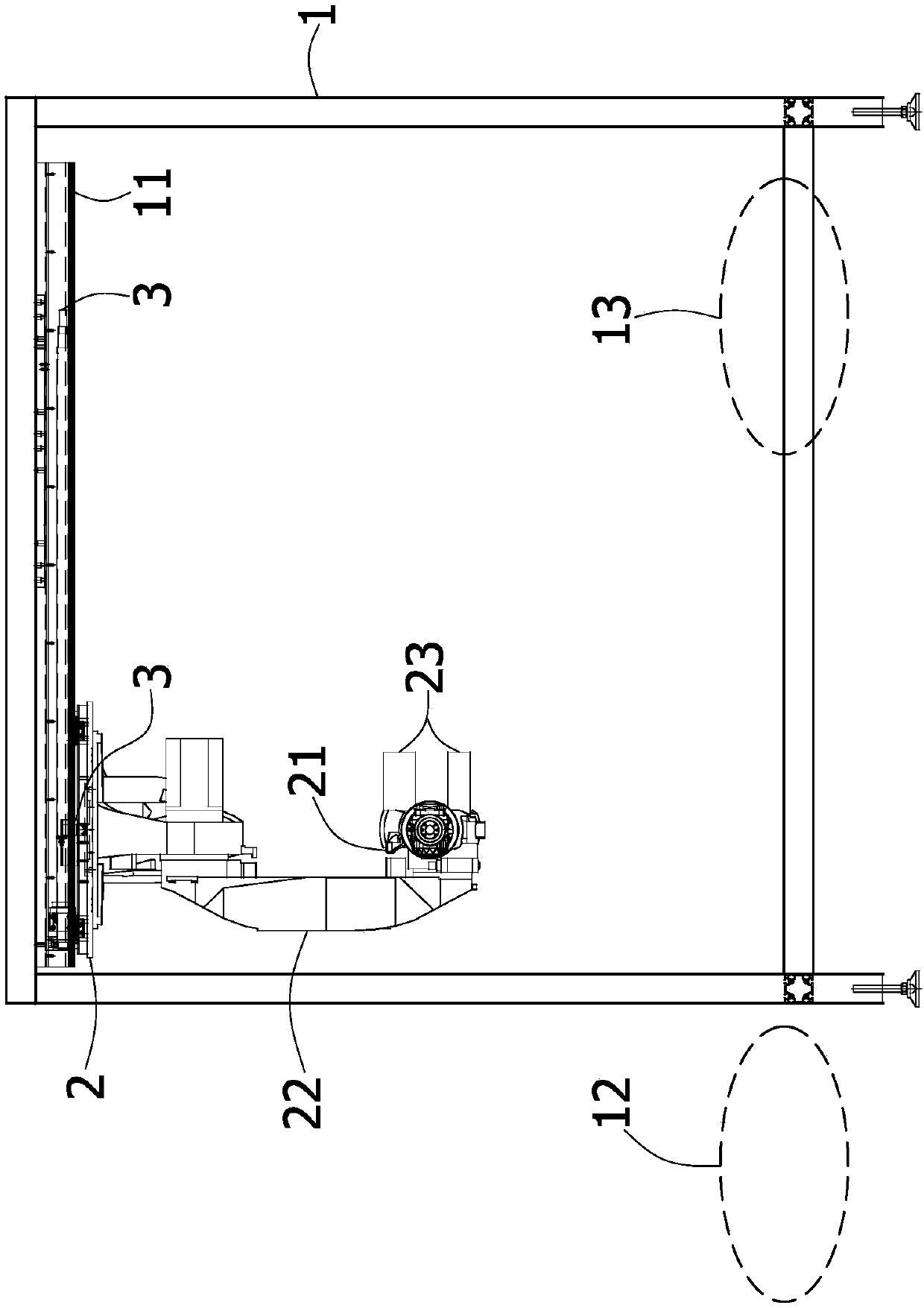

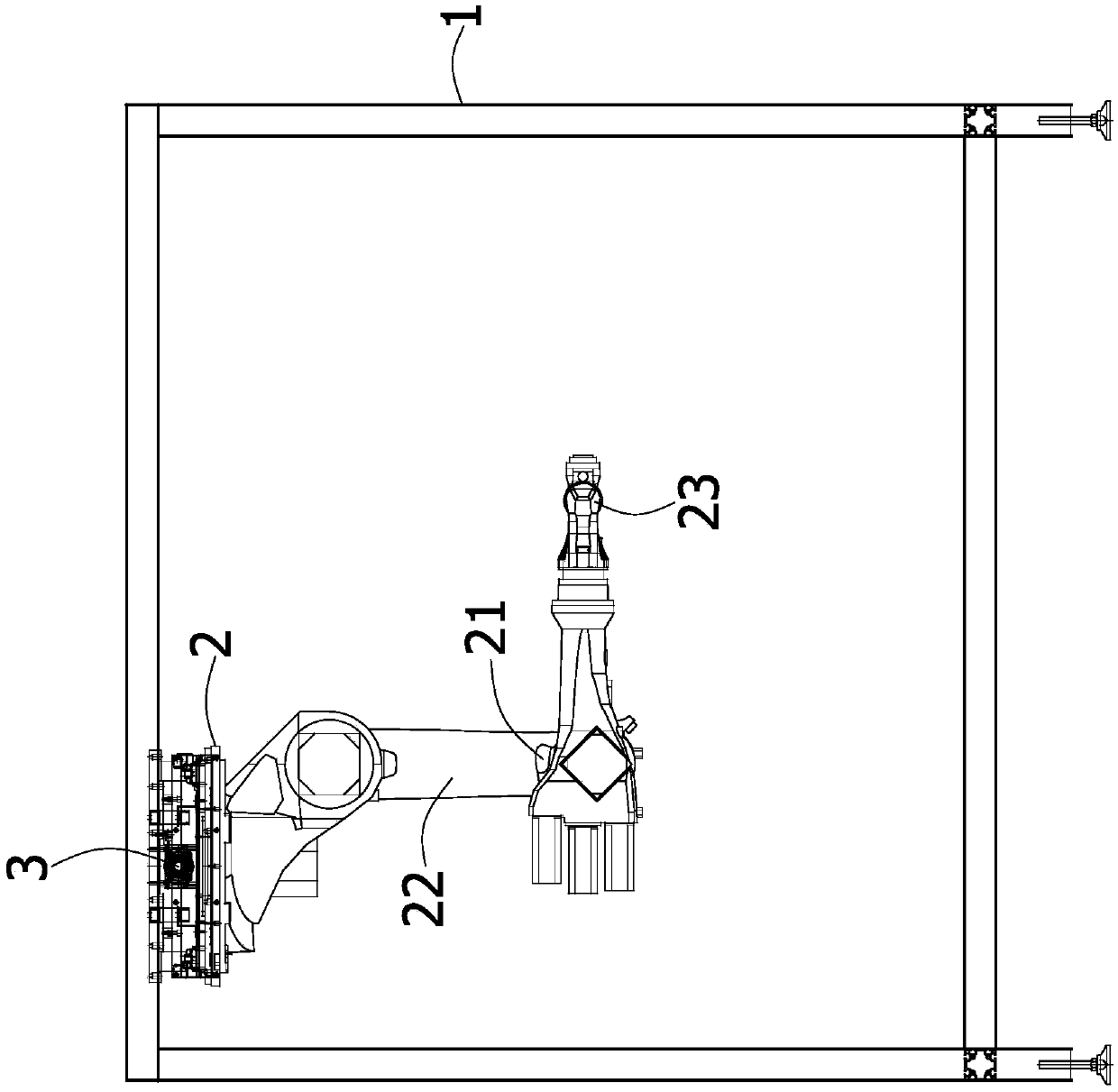

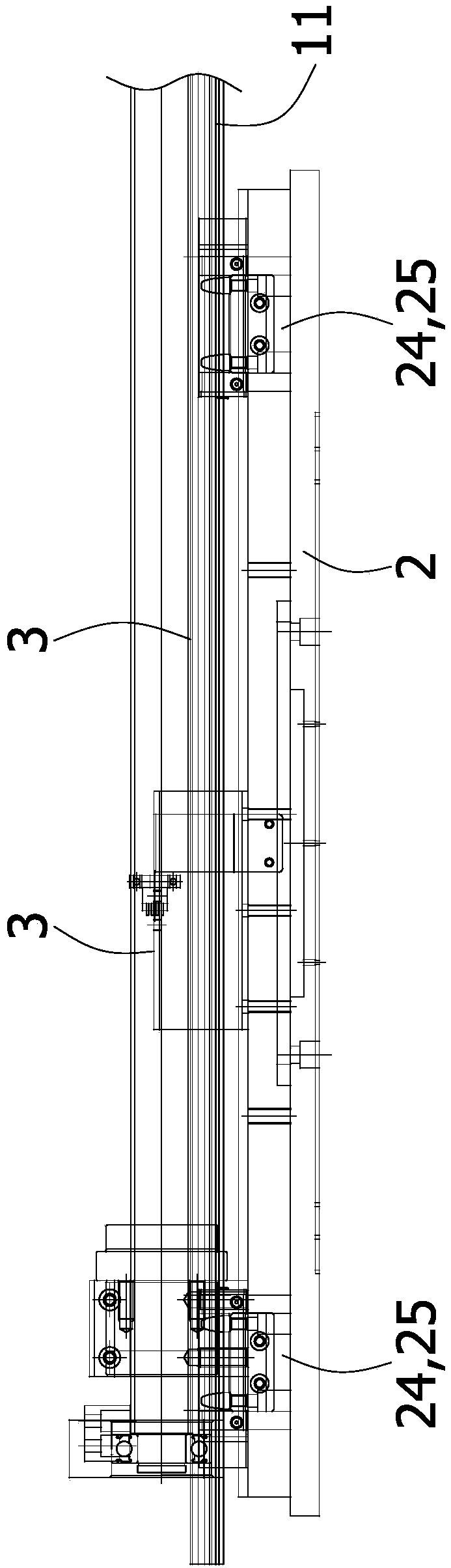

[0018] see Figure 1 to Figure 5 , which shows a schematic front view of the automatic transport operating system of this embodiment, which mainly includes: a frame 1, a multi-directional sliding device 2 containing a sensing element 21 (sensing element) and a linear unit 3.

[0019] One side of the frame 1 is provided with a track 11 , and the bottom surface of the frame 1 is provided with at least one rolling device to provide a barrel 4 (barrel) to move from an entrance 12 to a pick-up area 13 of the frame 1 with low resistance ; An unmanned guided vehicle (Automatic Guided Vehicle) receives a material shortage signal via a wired or wireless connecting line, and the unmanned guided vehicle automatically transports the material from a take-out place in a storage zone (storage zone). barrel material 4 to the entrance 12 of the frame 1;

[0020] In the past, it is known that the storage area of the drum material 4 has a storage space where a drum material 4 is taken out at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com