Energy-saving efficient gasoline engine pumping unit

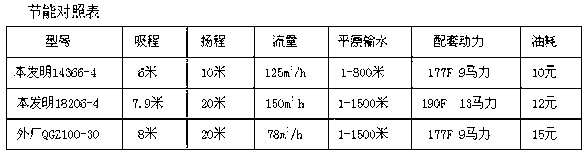

A gasoline engine and water pump technology, which is applied in the direction of machines/engines, pumps, pump devices, etc., can solve the problems of unreasonable ratio, high energy consumption, cumbersome operation, etc., and achieve the effects of convenient handling, fuel saving, and large water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method of the present invention is described in detail below with reference to the accompanying drawings. The accompanying drawing is an energy-saving and high-efficiency gasoline engine water pump unit, which includes a gasoline engine 2 and a water pump 3 installed on a base 1, and is characterized in that: the water inlet pipe 5 of the water pump 3 is provided with a pressure well type water pump 6, and the water pressure well Type pressurized water pump 6 bottoms are communicated with water inlet pipe 5 through communication interface 7. The pressure well type water pump 6 includes a pressure rod 61, a cylinder 62, a piston plate 63 and a non-return pad 64, and a non-return pad 64 is provided on the communication interface 7 at the bottom of the cylinder 62, and the non-return pad 64 It includes a rubber pad 66 and a pressure pad 67 connected to the washer 65 on the communication interface 7 , and the rubber pad 66 and the pressure pad 67 are fixedly connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com