Processing method of hollow stone container

A processing method and technology for empty containers, which are applied in stone processing tools, stone processing equipment, metal processing equipment, etc., can solve the problems of inability to manufacture, cannot be manually operated, and difficult to take holes in the inner cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

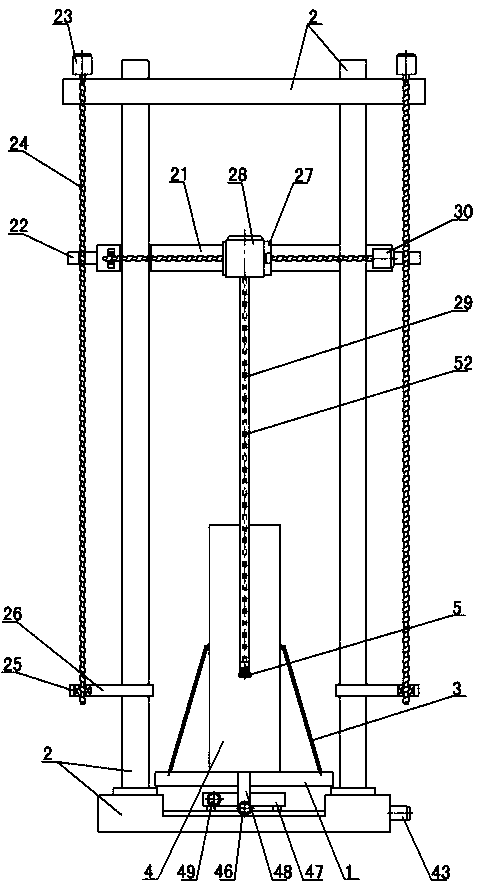

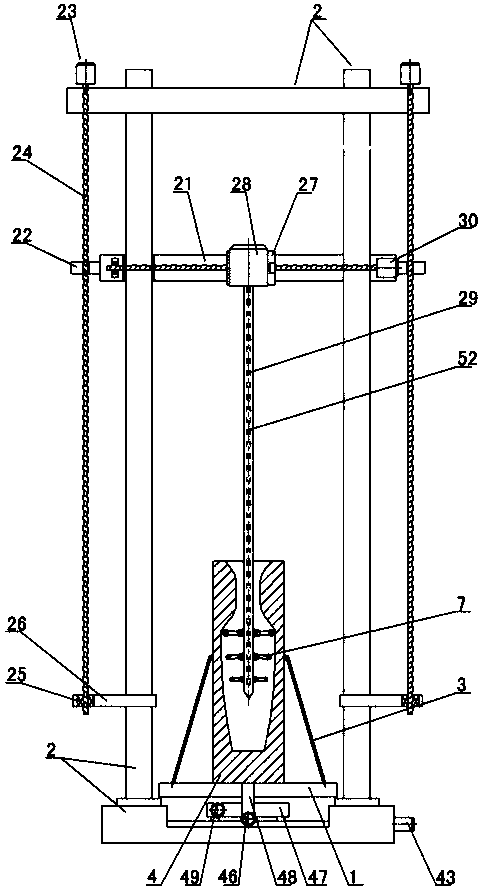

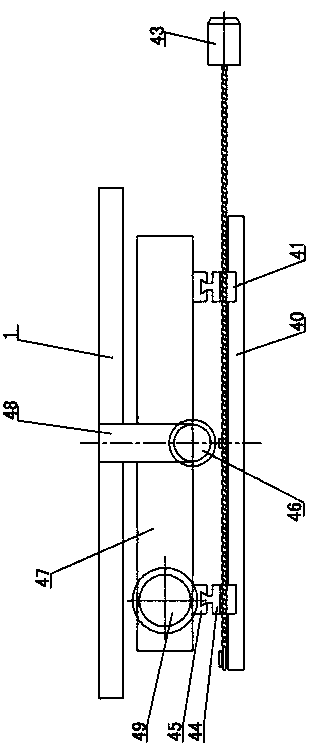

[0022] The invention relates to a processing method of a stone hollow container: figure 1 — Figure 10 as shown,

[0023] (1) Take natural stone, the stone is cuboid or cylinder, the height H is more than 2000mm, the side length L of the cuboid section is more than 1000mm, and the diameter Φ of the cylinder is more than 1200mm, and the stone raw material 4 is obtained;

[0024] (2) Drill holes for the primary stone material, fix the primary stone material on the workbench 1, and the workbench 1 is set in the frame 2. A clamping mechanism 3 is provided to fix the initial stone material with the clamping mechanism. A cross arm 21 is installed on the frame, and a slide seat 27 is installed on the cross arm. The cross arm 21 moves up and down by the lifting mechanism, and the slide seat 27 is moved by sliding The mechanism drives the action to move left and right. The rotating motor 28 is installed on the sliding seat. The rotating motor 28 drives the rotating shaft 29. The rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com