Patents

Literature

111results about How to "Precise entry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

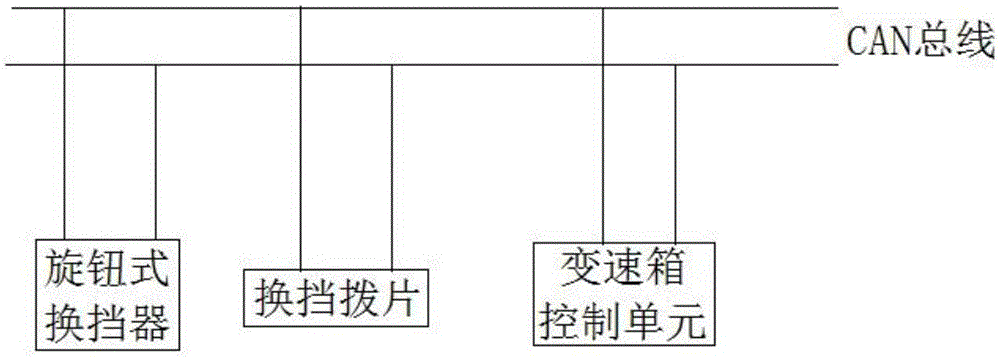

Vehicle gear shifting control method

ActiveCN105650267AGuaranteed uptimePrecise entryControlled membersGearing controlCAN busAutomotive engineering

The invention relates to a vehicle gear shifting control method. A vehicle gear shifting control device comprises a knob type gear shifting machine, a gear shifting poking piece and a transmission control unit, wherein the three are all connected with a CAN bus, and exchange gear data; and the transmission control unit determines a sent gear actuation instruction according to gear request instructions of the knob type gear shifting machine and the gear shifting poking piece and a vehicle speed. Based on the knob type gear shifting machine, a control policy is more accurate, the entrance and the emigration of gears are more precise, and the whole vehicle operation performance is improved.

Owner:NANJING AOLIAN AUTOMOTIVE ELECTRONICS TECH CO LTD

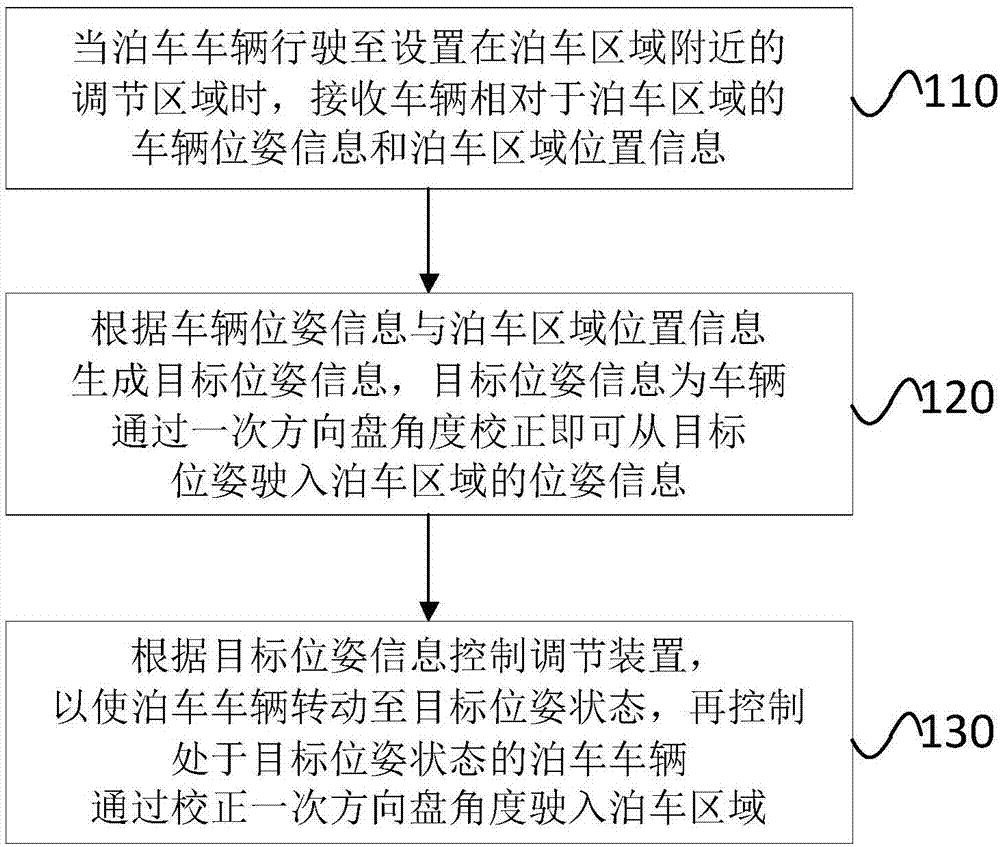

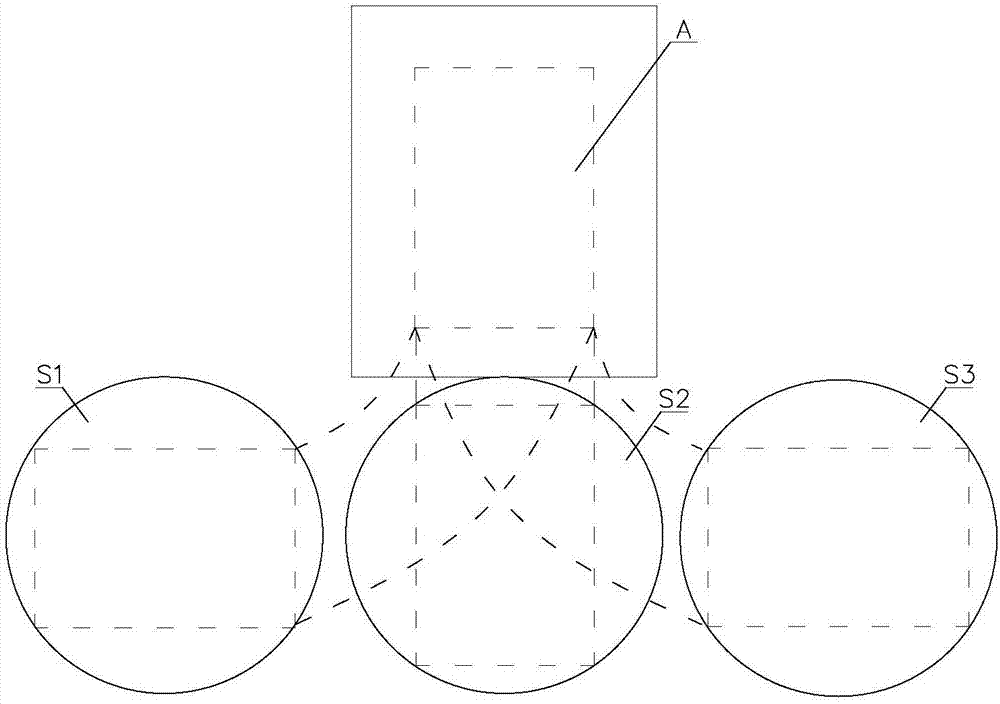

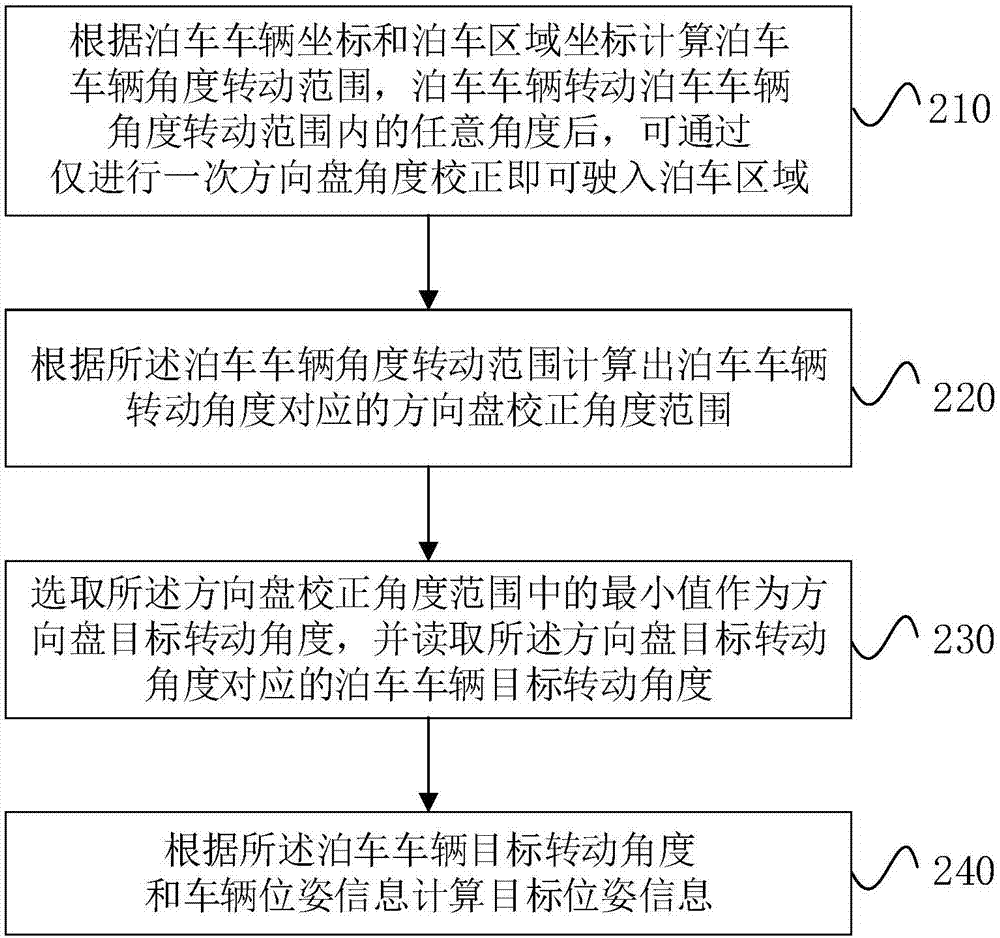

Safe parking method and safe parking device

ActiveCN107399325AImprove reliabilityAccurate parkingElectric/fluid circuitSteering wheelEngineering

The invention relates to a safe parking method and a safe parking device. The safe parking method includes receiving vehicle position and posture information of vehicles relative to parking regions and position information of the parking regions when the to-be-parked vehicles run to adjusting regions nearby the parking regions; generating target position and posture information according to the position and posture information of the vehicles and the position information of the parking regions; controlling and adjusting the safe parking device according to the target position and posture information to allow the to-be-parked vehicles to rotate to be in target position and posture states, and correcting angles of a steering wheel once to drive the corresponding to-be-parked vehicle in the target position and posture state into the corresponding parking region under the control. The safe parking method and the safe parking device in an embodiment of the invention have the advantages that the to-be-parked vehicles are adjusted to be in the target position and posture states before being parked, the angles of each steering wheel are corrected once when the corresponding to-be-parked vehicle is in the target position and posture state, accordingly, the to-be-parked vehicles can be driven into the parking regions under the control, the vehicles can be sequentially quickly parked in the parking regions, the safe parking method and the safe parking device are high in efficiency and are speedy, and the vehicles can be accurately parked without optional blind sections; safety accidents such as collision can be prevented, and accordingly the safe parking method and the safe parking device are high in reliability.

Owner:SHENZHEN SHENGLU IOT COMM TECH CO LTD

Novel antitheft system of smart home

InactiveCN105513234AAccurate detectionPrecise entryBurglar alarmElectric power transmissionNew energy

The invention provides a novel antitheft system of a smart home. The antitheft system is capable of detecting whether doors and windows are closed and whether a theft enters home via an infrared sensor and a human body infrared sensor. Via wireless communication and GPS communication, inner information communication of the antitheft system and alarming with a user cell phone and a security room of a community can be achieved. Via a voice alarming part and a strong light awing part, the actual antitheft objective can be achieved. Evidences can be obtained via real-time tracking and shooting of a rotation motor and a shooting acquisition part. Real-time transmission and storage of theft data can be achieved via real-time transmission between APPs of the cell phone and the network. New energy power supplying can be achieved via a solar energy power supplying part and a power transmission part, thereby greatly saving resources, facilitating achievement of unattended management of the home and improving working efficiency, control precision and safety of household antitheft work.

Owner:QINGDAO AGRI UNIV

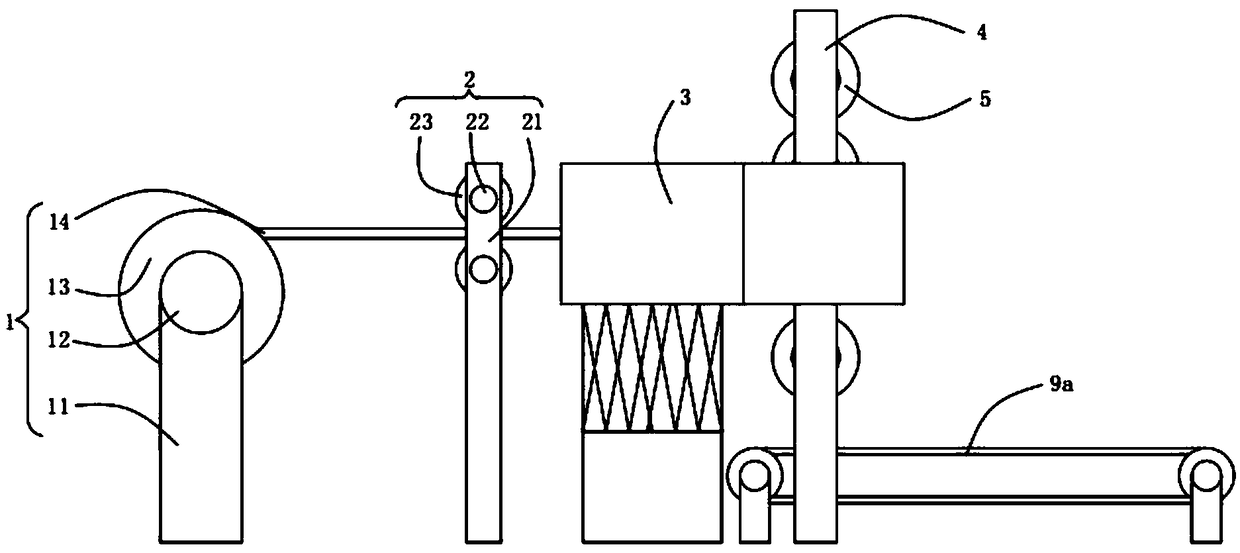

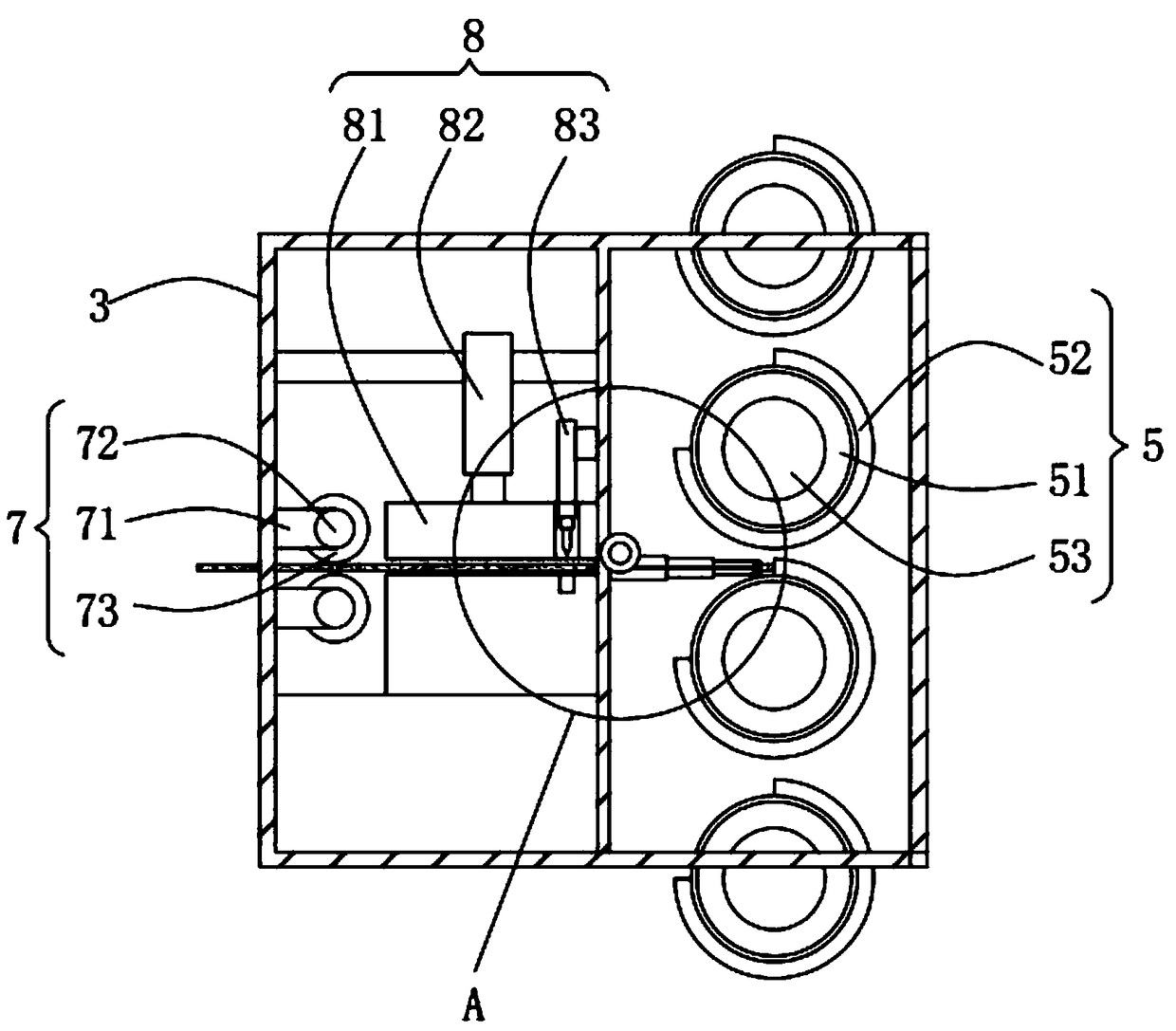

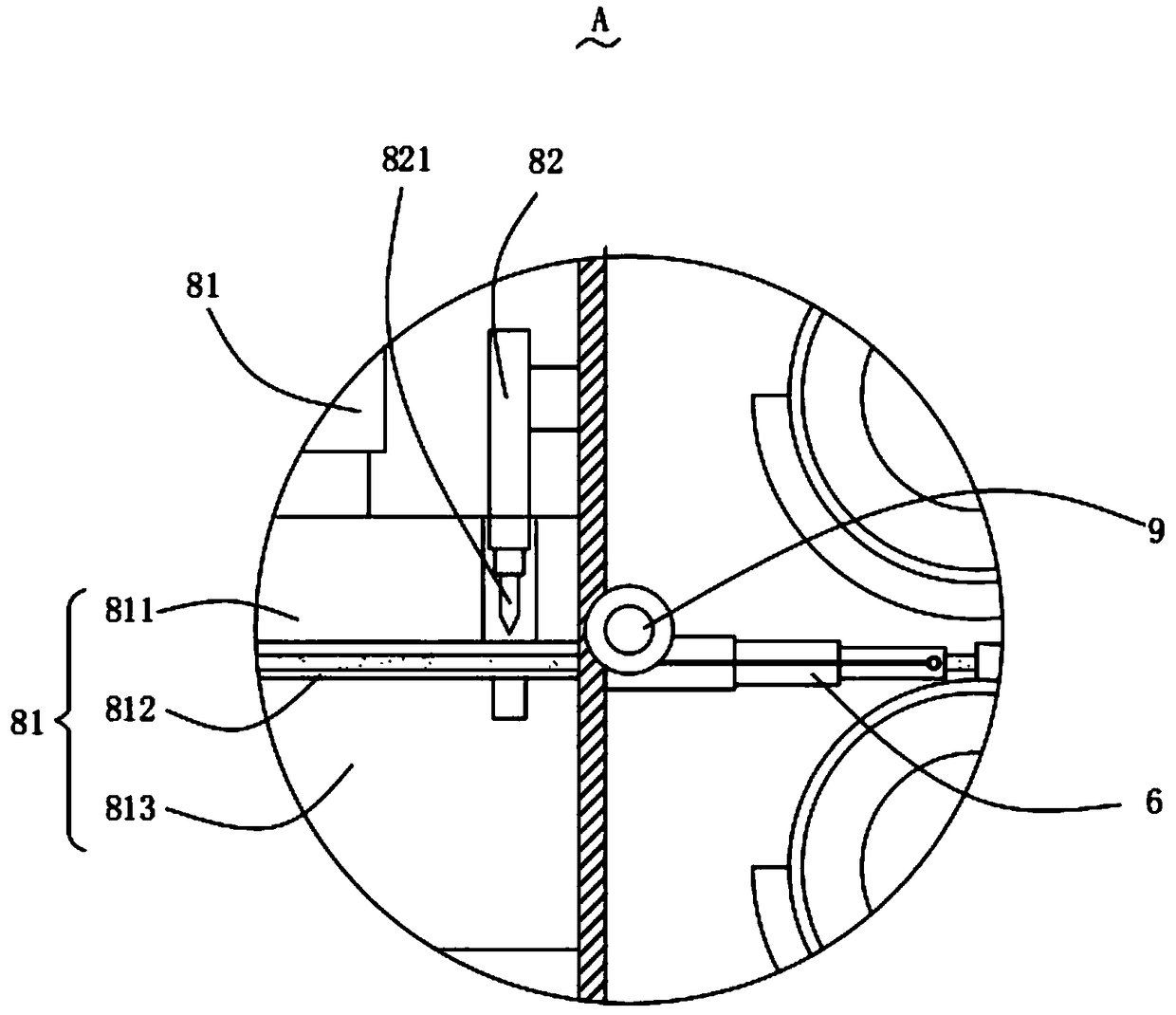

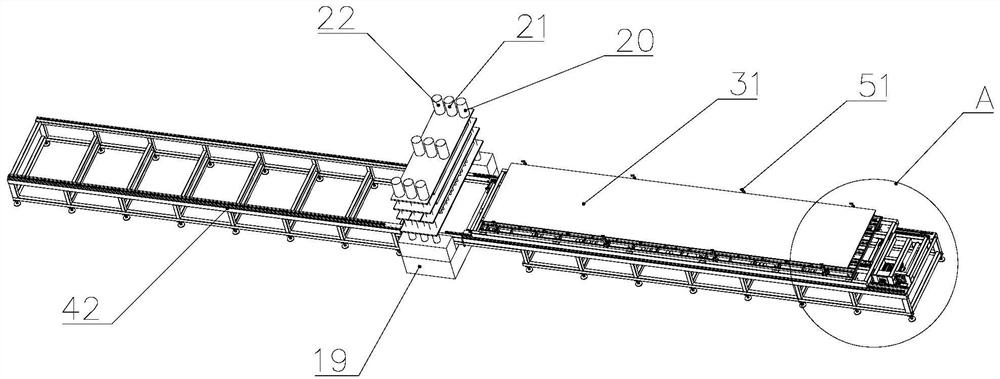

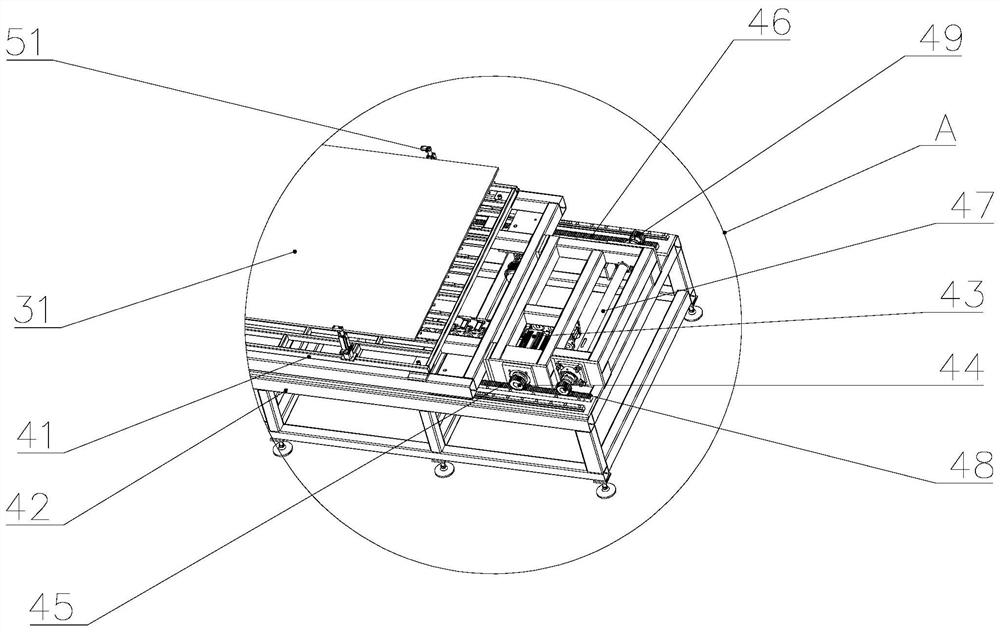

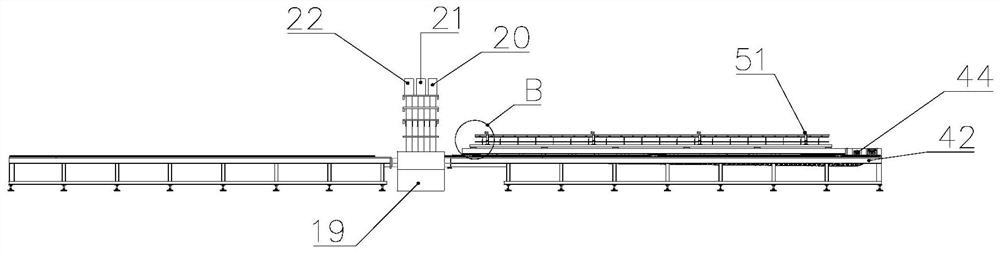

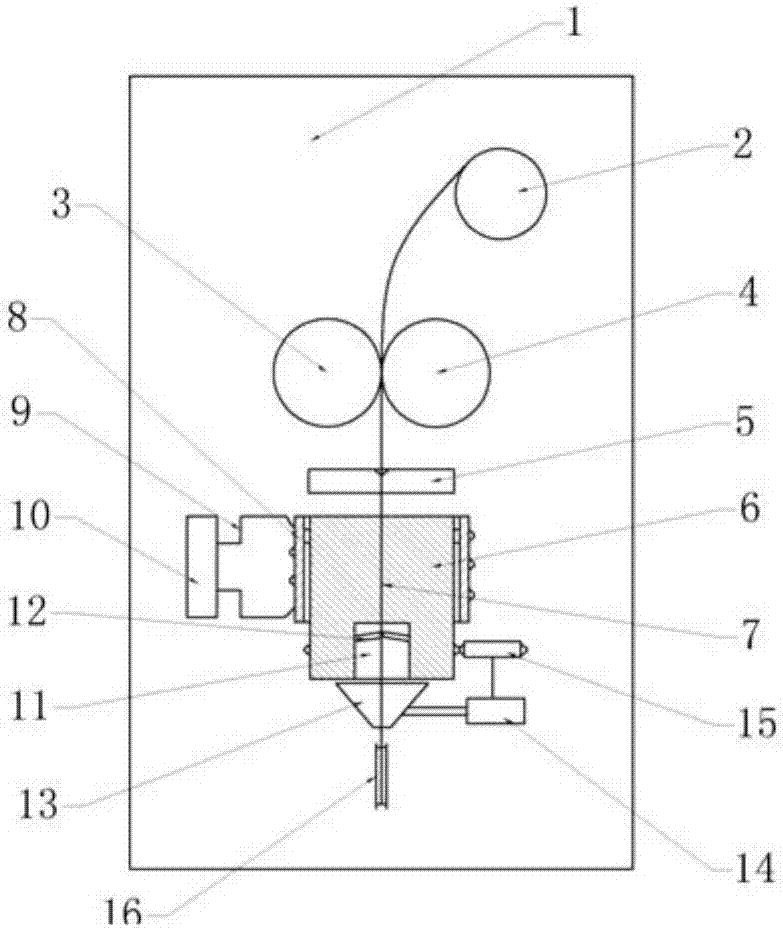

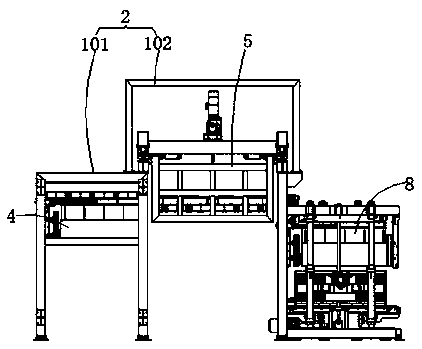

Waterproof coiled material winding and cutting system

The invention relates to the technical field of coiled material processing, in particular to a waterproof coiled material winding and cutting system. The system comprises a storage mechanism, a firstconveying mechanism, a box body, a transposition mechanism, a winding mechanism, a limiting mechanism, a second conveying mechanism, a cutting mechanism, a traction mechanism and a conveying belt. According to the system, the end part of a coiled material can be fixed through clamping of an upper supporting block and a lower supporting block, so that when the next coiled material is wound, the endpart of the coiled material can be directly conveyed, and the processing continuity is guaranteed; the limiting mechanism and sheltering covers of a telescopic mechanism can guide movement of the coiled material, so that the coiled material can enter the corresponding shielding cover accurately, the coiled material can also be wound on a small rolling column partially, so that when the small rolling column rotates, automatic winding can be carried out rapidly, and the coiled material cannot fall off; and electromagnets at the two ends of the winding mechanism can lose magnetism when the winding mechanism moves to the bottommost end, so that the winding mechanism which finishes winding can fall onto the conveying belt.

Owner:江苏中泰绿色建筑科技有限公司

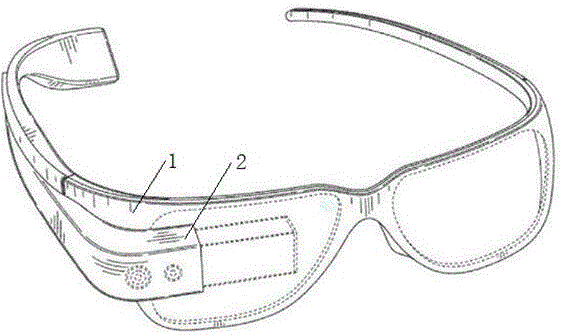

Movable efficient laryngoscope

ActiveCN106419814AImprove inspection efficiencyEasy to observe and operate laryngoscopeBronchoscopesLaryngoscopesWireless dataLaryngoscopes

The invention discloses a movable efficient laryngoscope. The movable efficient laryngoscope comprises a wearing observer, a wireless data transmitter and a movable laryngoscope body, wherein the wearing observer is respectively connected with the movable laryngoscope body and the wireless data transmitter wirelessly; the wireless data transmitter is mounted on a computer and is used for receiving data signals of the wearing observer and transmitting the data signals to the computer; the wearing observer comprises a wearing rack and an observing device which is detachably arranged on the wearing rack; the wearing rack comprises a cross beam and legs; two nose pads are arranged in the middle of the cross beam; the legs are arranged on two sides of the cross beam; and the cross beam and the legs are integrated. The invention aims to provide the laryngoscope which can examine movably, can wirelessly transmit examination data to the computer, and accurately observes laryngoscope detection images through the wearing observer. By the movable laryngoscope with the wearing function, detection time can be greatly shortened, examination of medical workers to patients is facilitated, and a diseased region can be observed clearly.

Owner:成都测迪森生物科技有限公司

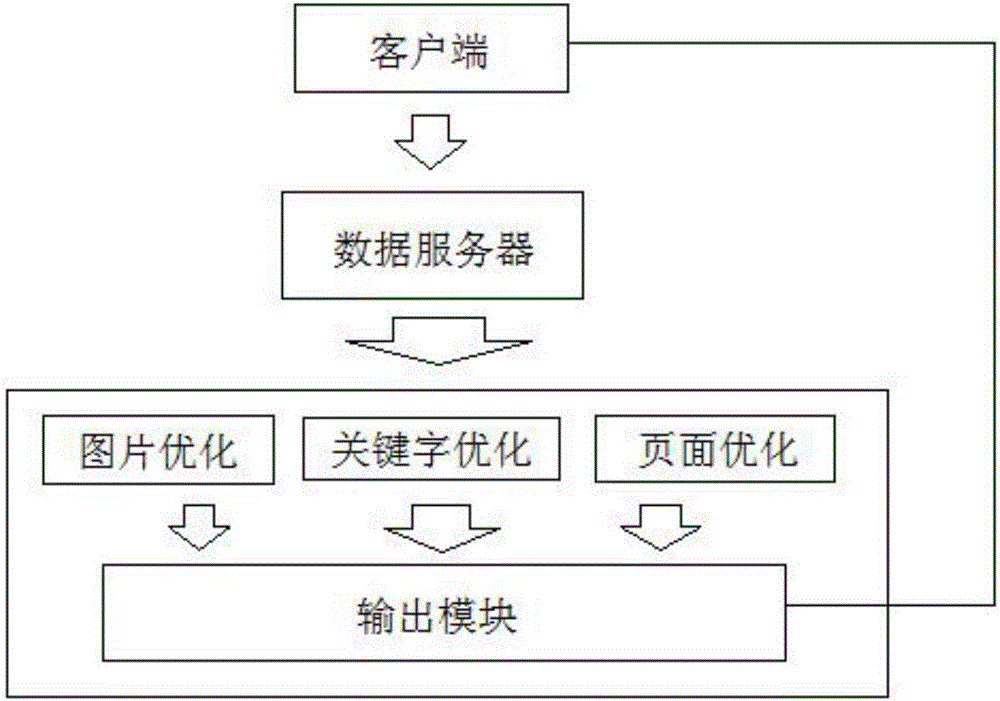

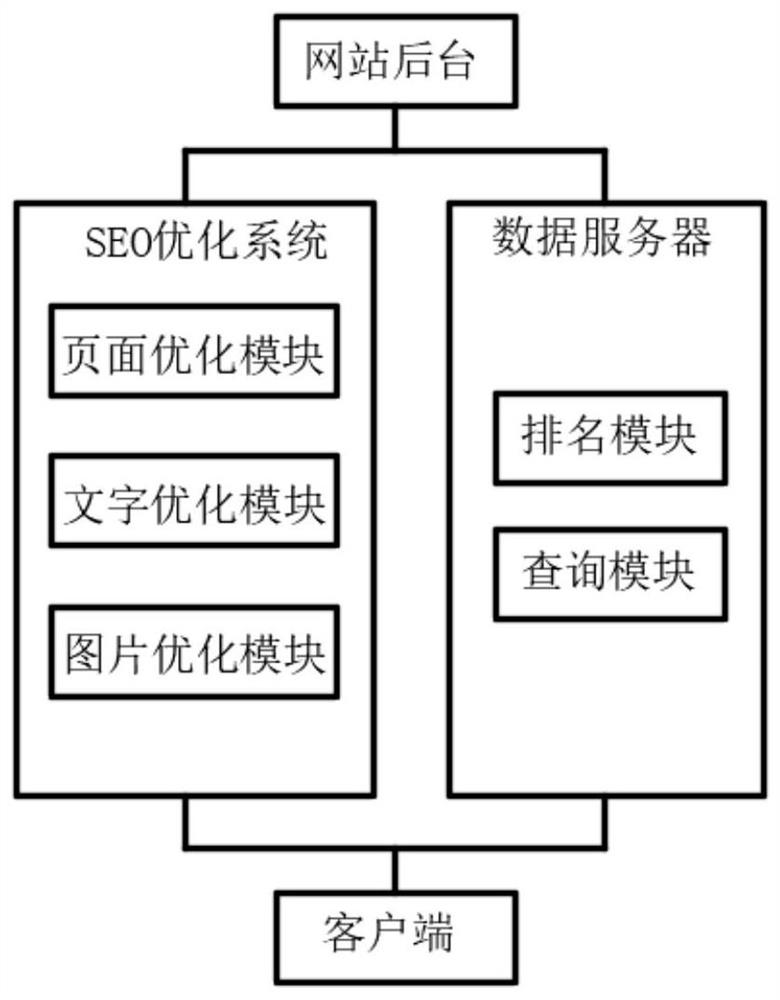

SEO-based intelligent network marking system

The invention discloses an SEO-based intelligent network marking system. The system is characterized by comprising a data server, an optimization module and a client, wherein the data server stores multiple service types, multiple page templates and multiple pieces of website information; the optimization module comprises a keyword optimization module, a picture optimization module, a page optimization module and an output module; the keyword optimization module expands keywords to obtain one or more long tail keywords; the picture optimization module acquires pictures in a webpage and processes the pictures; the page optimization module acquires character content of a webpage and replaces the character content to a corresponding position of a page template; the output module receives the long tail keywords, optimizes the pictures, optimizes a page and performs integration; and the client displays and edits page content. According to the invention, the SEO-based intelligent network marking system enables a user webpage to satisfy the demand of a search engine for ranking recording, improves keyword ranking in the search engine, attracts accurate users to go into the website to obtain free flow and generates a brand promotion effect.

Owner:合肥华贝信息科技有限公司

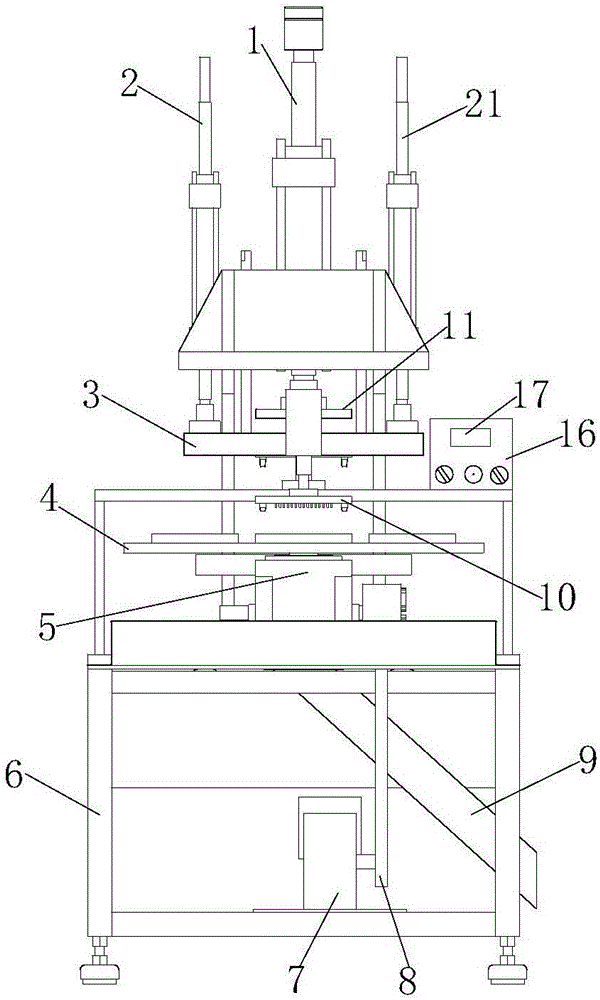

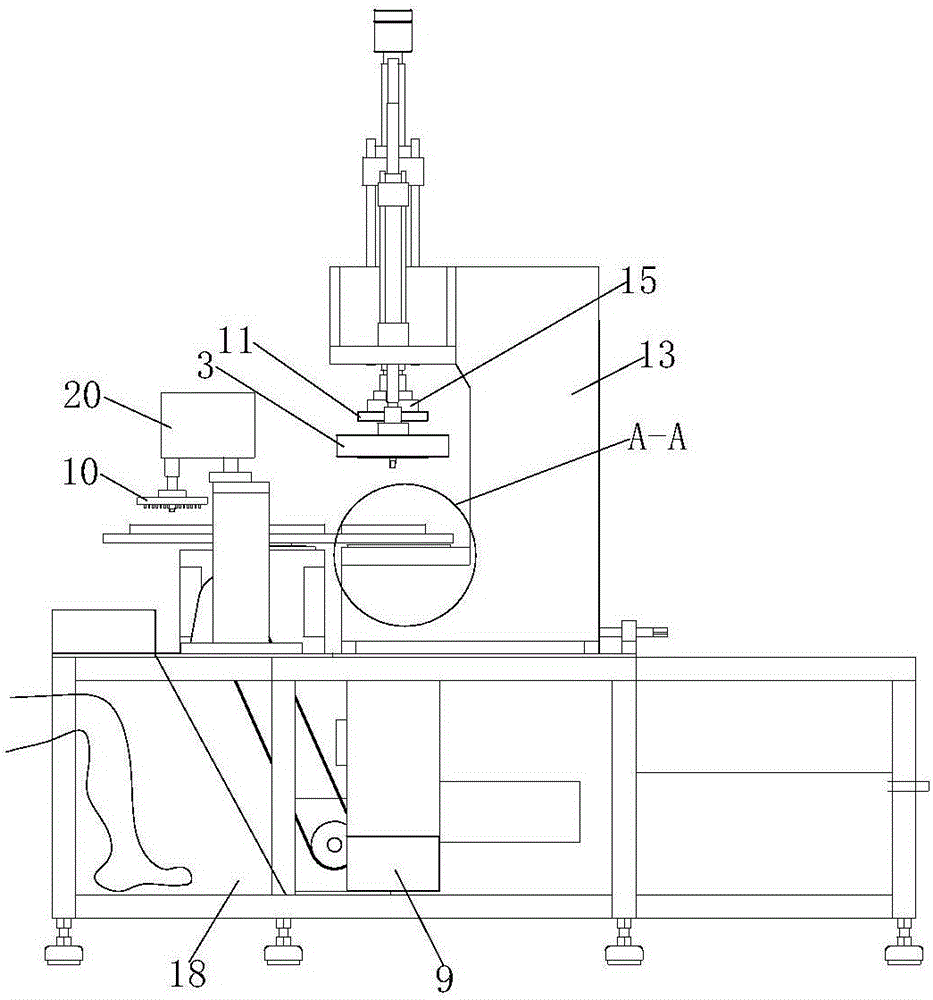

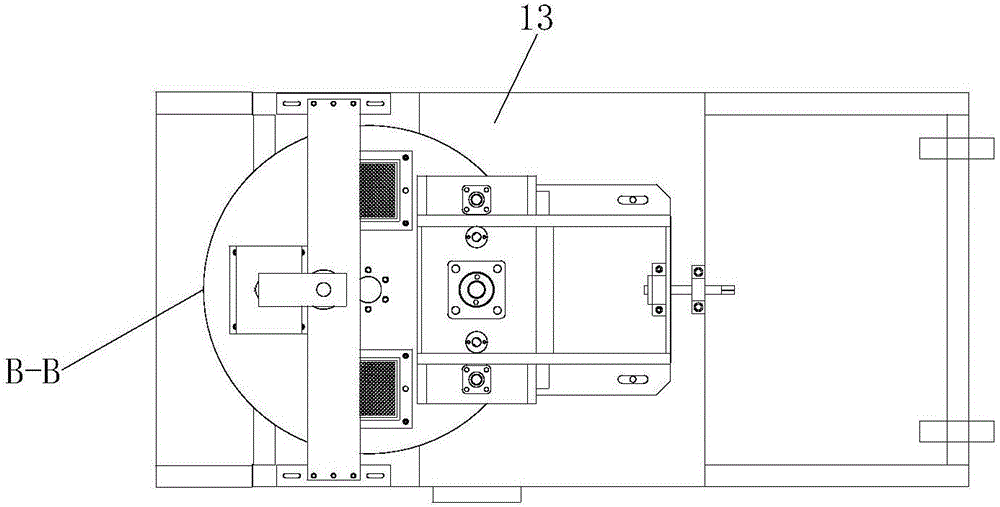

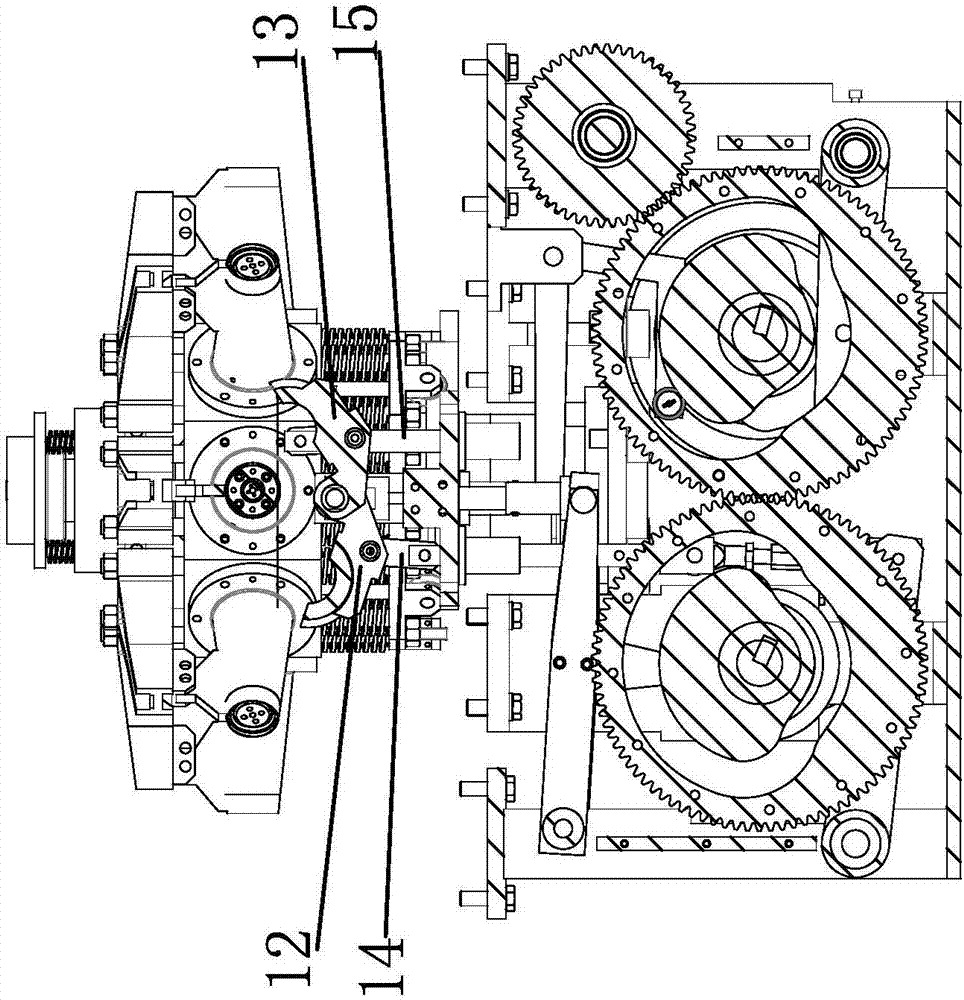

Multi-station rotating disc type force measuring type hydraulic machine

InactiveCN106694671AReduce harmAvoid harmMetal-working feeding devicesShaping safety devicesPunchingEngineering

The invention discloses a multi-station rotating disc type force measuring type hydraulic machine. The multi-station rotating disc type force measuring type hydraulic machine comprises a host body, a large oil cylinder is arranged on the host body, a punching plate is fixedly connected to the bottom of the large oil cylinder, a middle plate is fixedly connected to the bottom of a first small oil cylinder and the bottom of a second small oil cylinder, a worktable rotating disc is arranged below the middle plate, mold products are arranged on the worktable rotating disc, a blanking groove is formed in one side of the worktable rotating disc, and an electric motor is arranged in a rack, and is connected with the worktable rotating disc through a synchronous belt. According to the multi-station rotating disc type force measuring type hydraulic machine, design of the worktable rotating disc can meet multi-station multi-working-procedure requirements, the simultaneous punching working procedure of manual operation and machine punching is flexible and changeable and can adapt to machining of many mold products, precise machining of the mold products can be achieved, the hurt to the person is avoided, and the beneficial effects that cutting and punching are precise, the products automatically enter and are moved out of an operation table, operation is easy, and work efficiency is high are achieved.

Owner:东莞市金拓机械有限公司

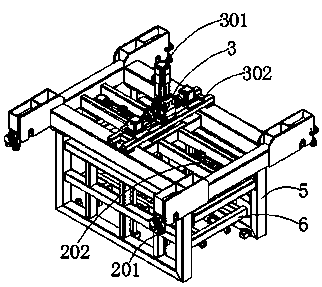

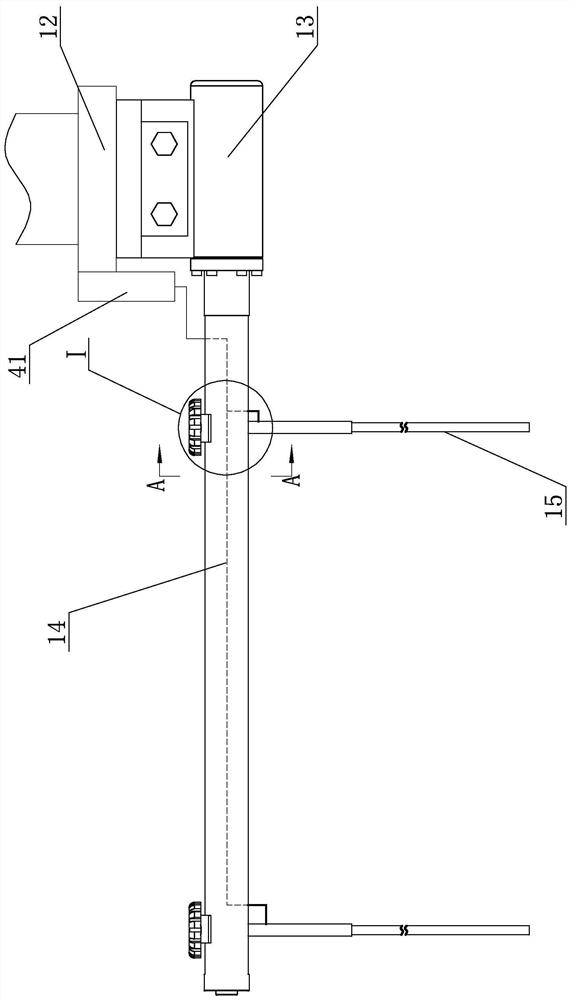

Truss 3D floor plate perforating machine

ActiveCN113020653AReduce damageReduce the breakage rateMetal working apparatusStone-like material working toolsFloor levelFloor plate

The invention discloses a truss 3D floor plate perforating machine, and belongs to the field of floor plate production equipment. The perforating machine comprises a screw feeding mechanism, wherein the screw feeding mechanism comprises a first perforating assembly, a second perforating assembly and a screw feeding assembly, the first perforating assembly comprises a plurality of first perforating drill bits, and the first perforating drill bits are used for perforating a first workpiece; the second perforating assembly comprises a plurality of second perforating drill bits, and the second perforating drill bits are used for perforating a second workpiece; the screw feeding assembly comprises a plurality of screw feeding heads, and the screw feeding heads are used for fastening the first workpiece and the second workpiece; and under the action of a conveying mechanism, the first perforating assembly is used for perforating the first workpiece to form a first hole, the second perforating assembly is used for continuously perforating the second workpiece along the first hole to form a second hole, and then the second workpiece is conveyed to the screw feeding assembly to connect the first hole with the second hole.

Owner:山东七星绿色建筑科技有限公司

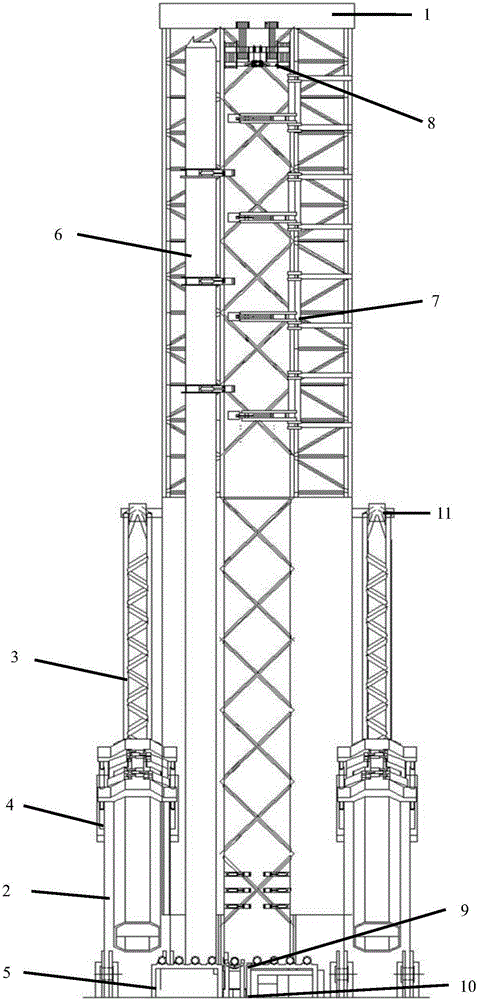

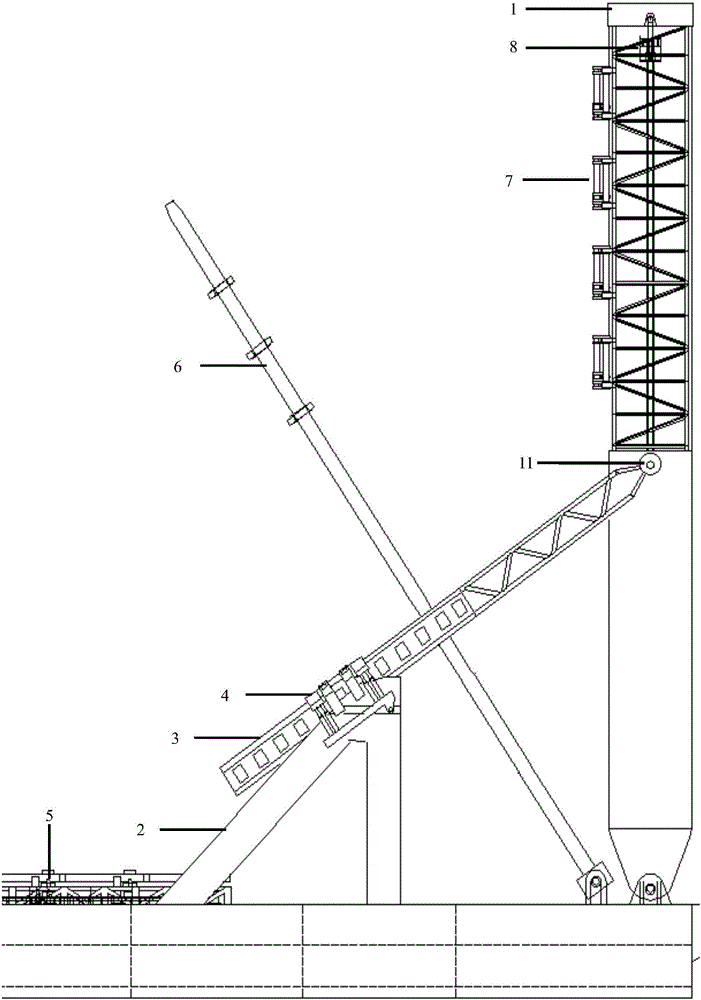

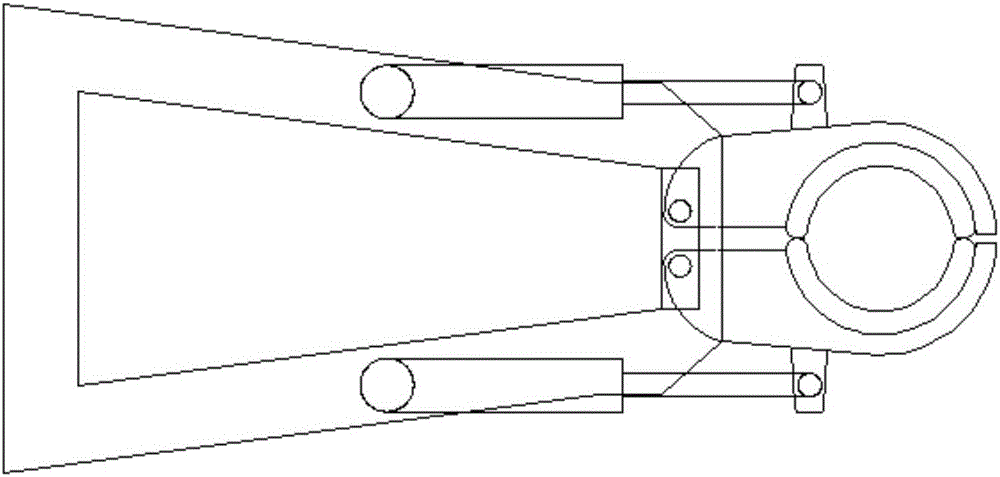

Deep-water quick J-type laying system

ActiveCN105757340ALaying speed is fastImprove efficiencyPipe laying and repairHydraulic cylinderLoading arm

The invention provides a deep-water quick J-type laying system, comprising a laying column, a laying column angle adjusting system, a J-type laying segment conveying system, and J-type laying related equipment. The laying column angle adjusting system mainly comprises an A-shaped frame, an angle adjuster and a hydraulic cylinder, the J-type laying segment conveying system comprises a horizontal conveying system, a loading arm, a rotating arm and an elevator; the J-type laying related equipment generally comprises a centering unit, a welding station and a moving platform. It is possible to provide a 1*4 node (one 4-node segment is laid on the laying tower, and each 4-node segment is 48.8 m in length) laying mode at the premise of controlled height of the laying tower, and by optimizing equipment structure and layout, the laying speed is 80.2% higher than typical J-lay speed of 1.5 km / d and laying cost is reduced.

Owner:哈尔滨航沣科技开发有限公司

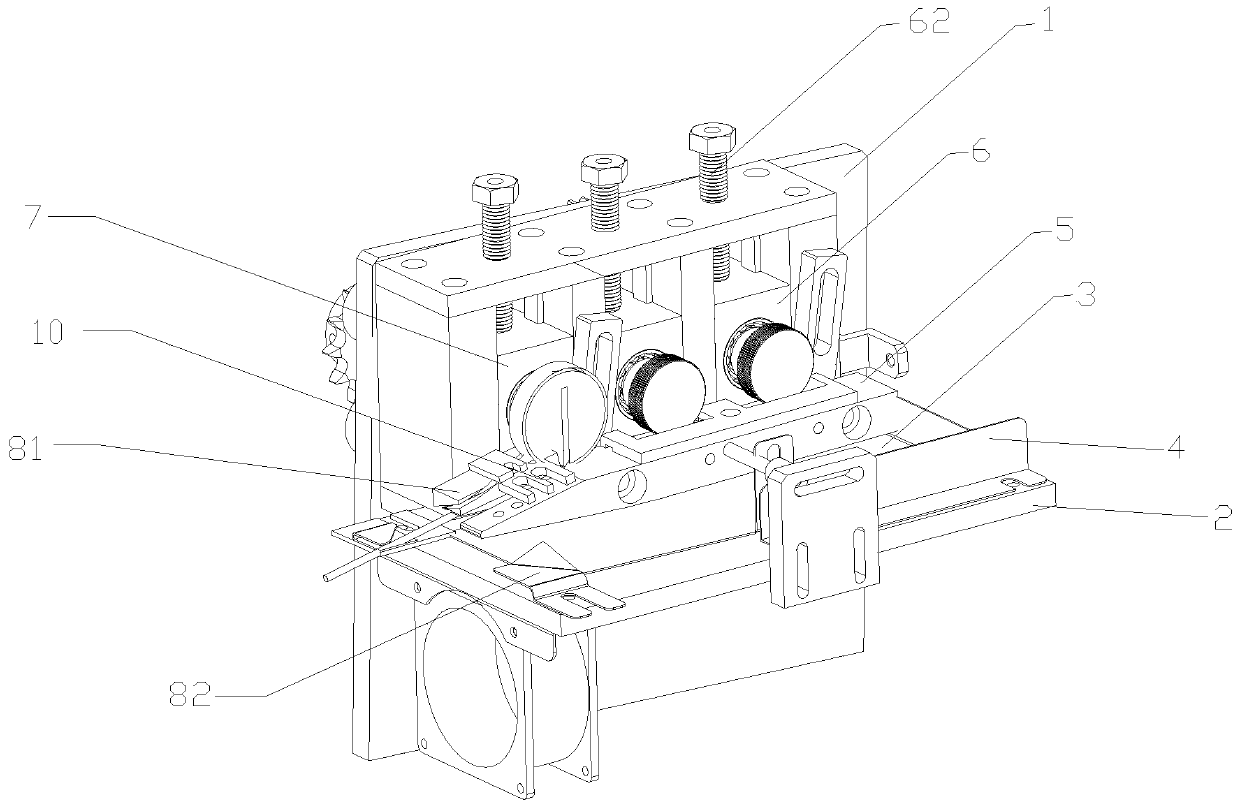

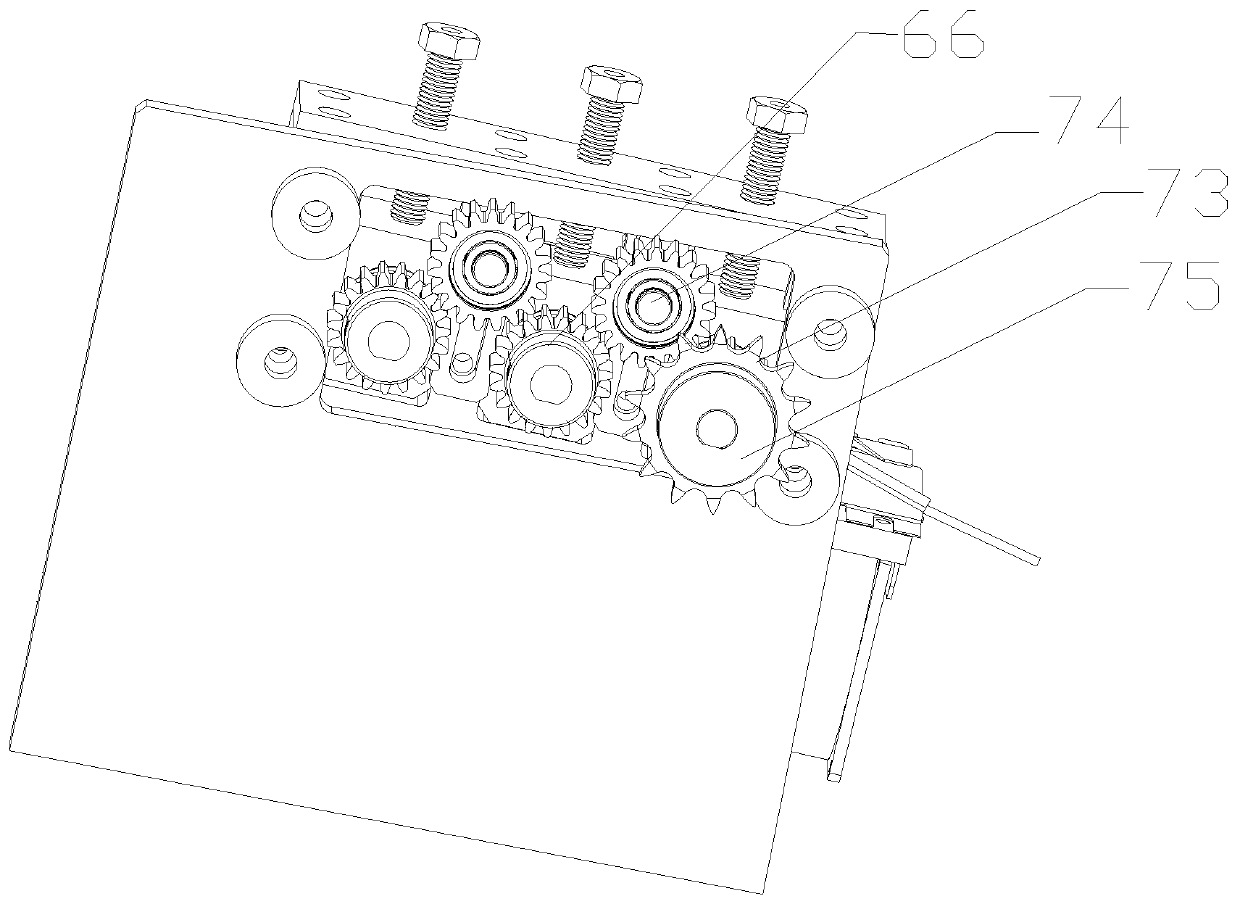

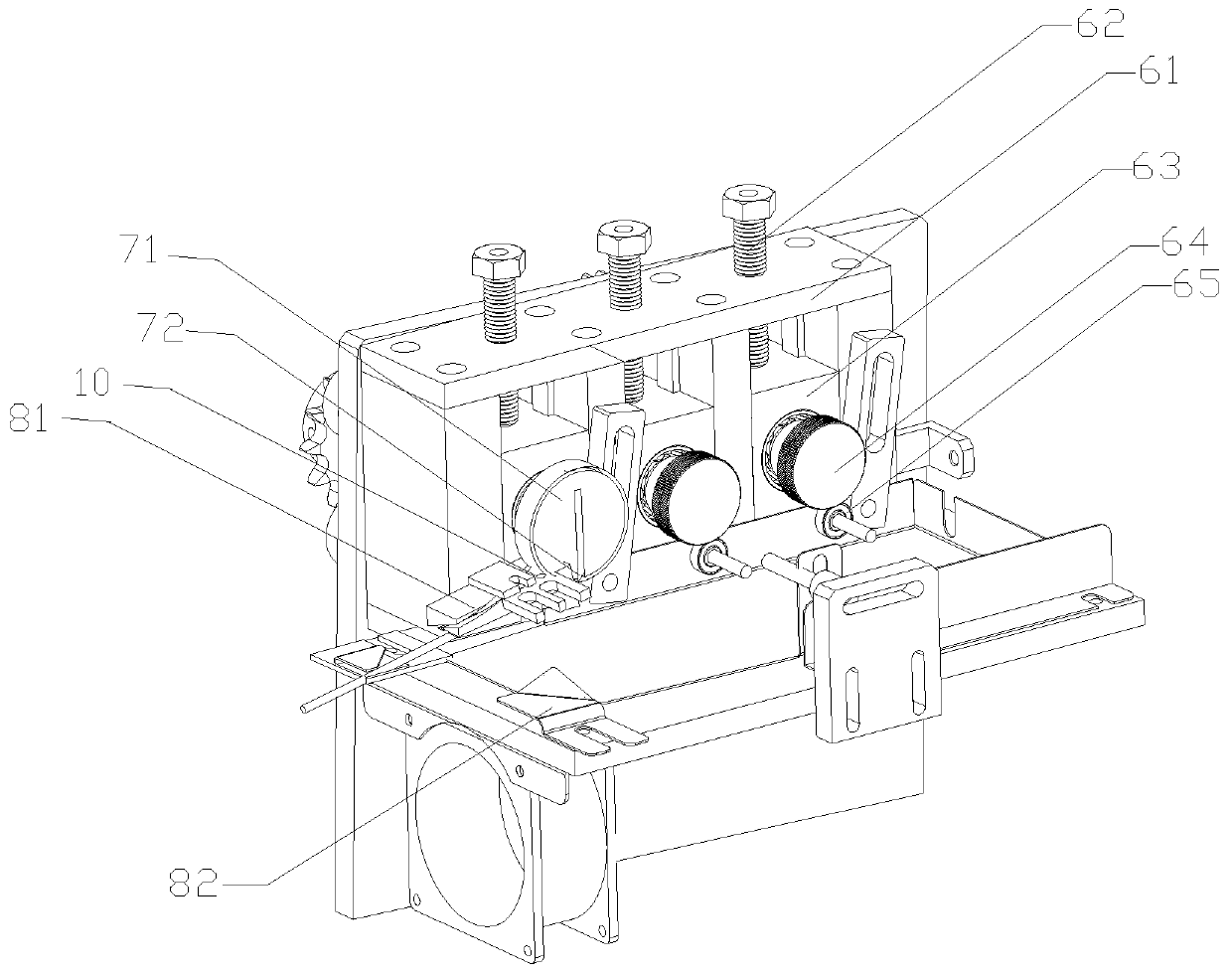

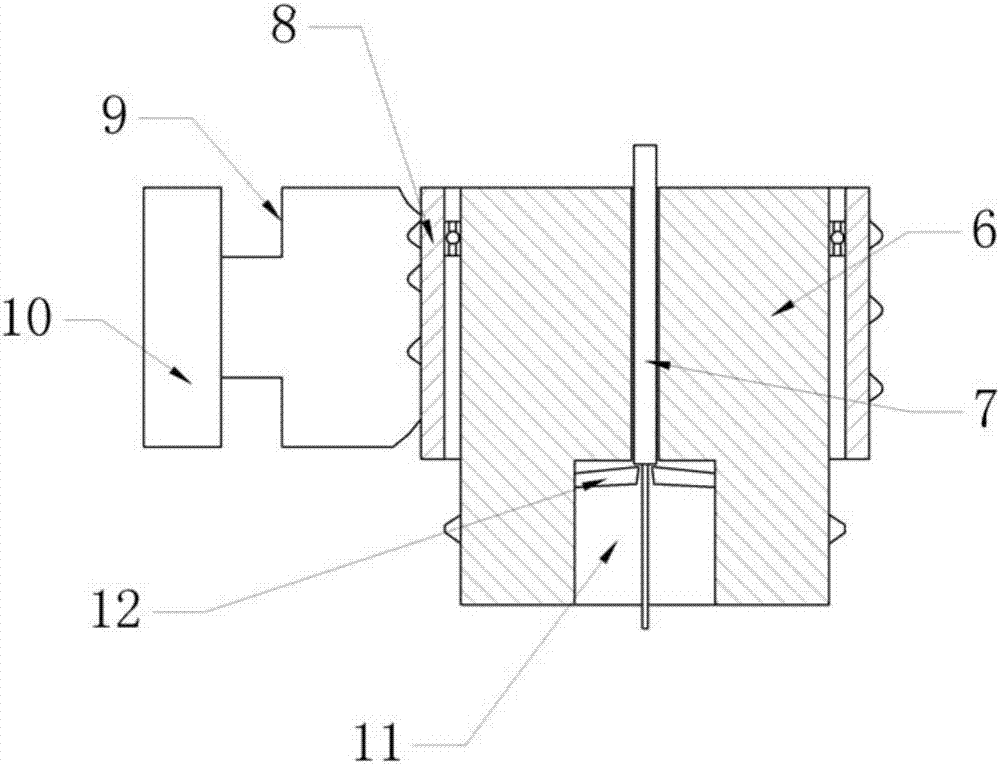

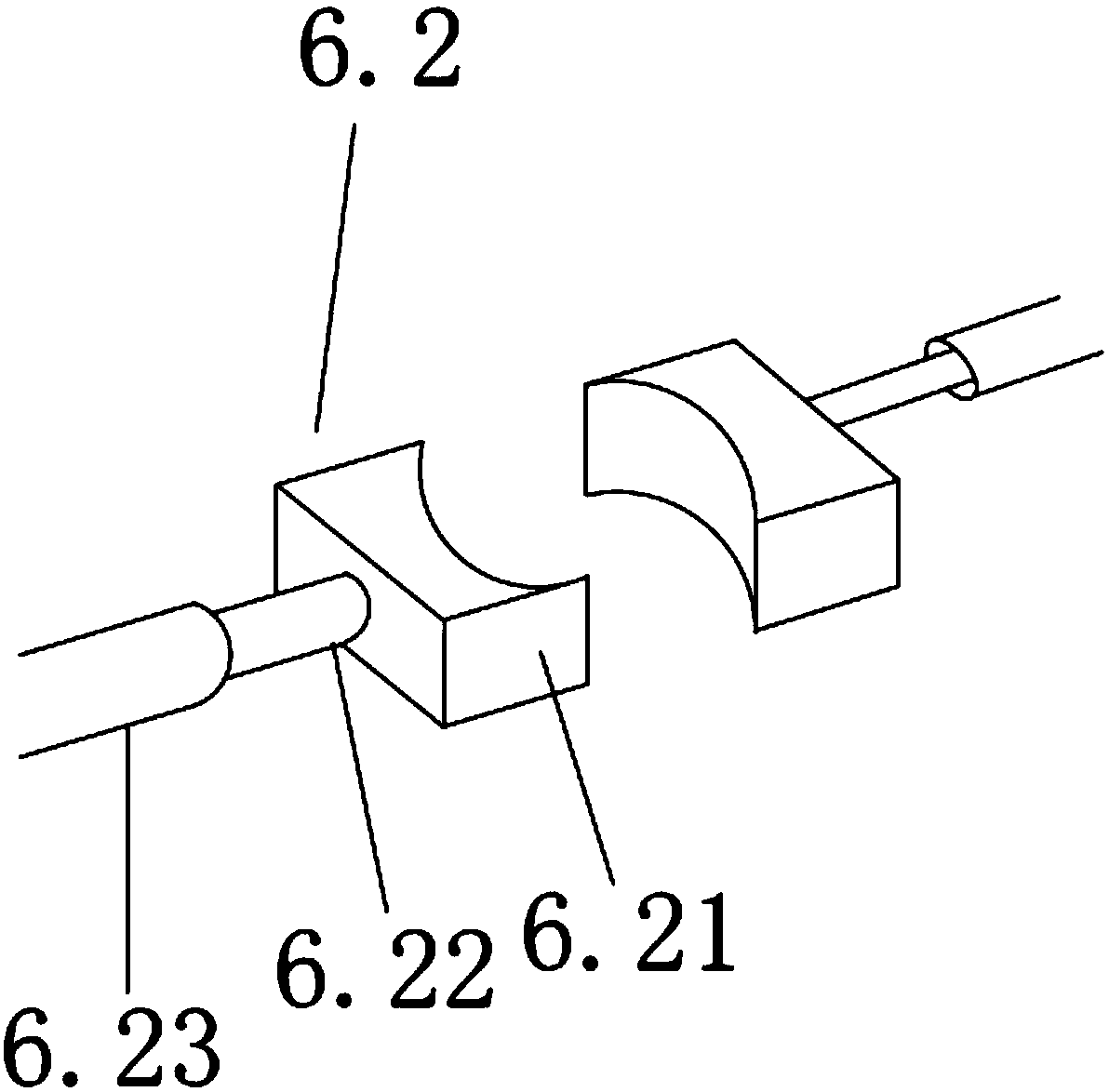

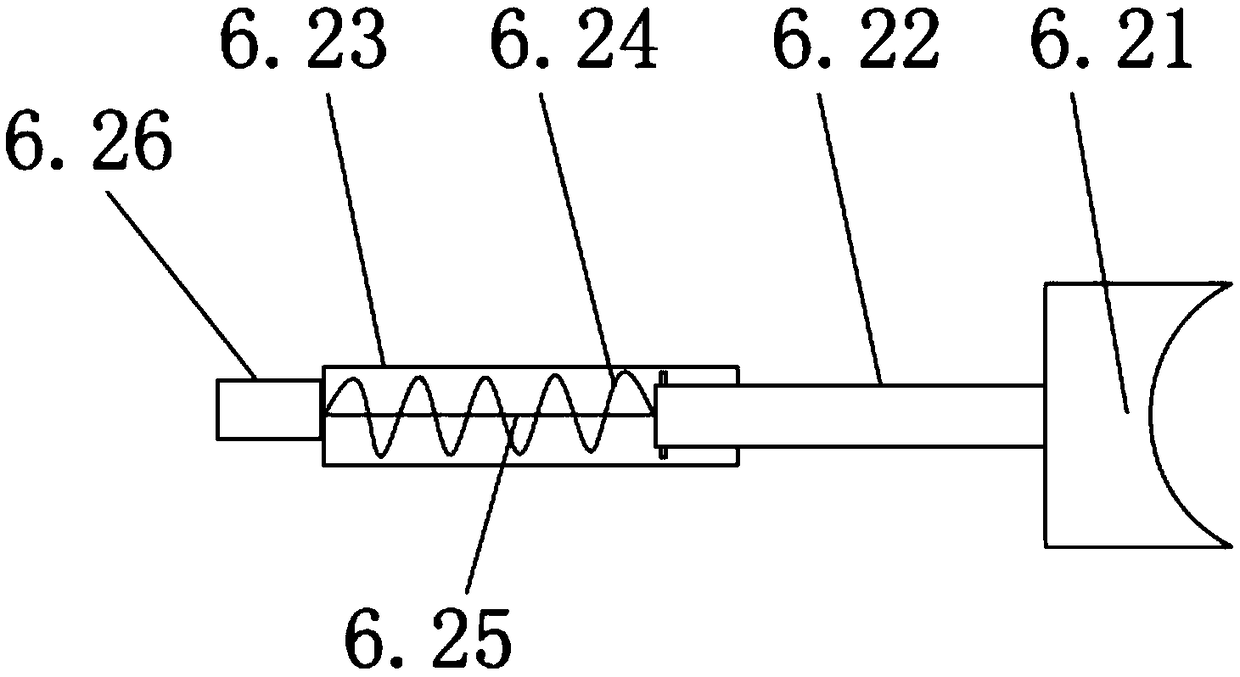

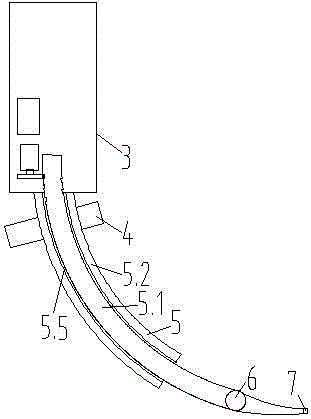

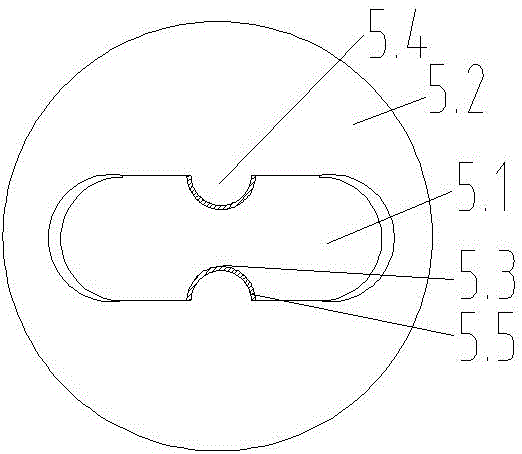

Mechanism for nose bridge strip cutting-off and mask flanging

PendingCN111418923ATurn over smoothlyReduce defective rateProtective garmentStructural engineeringMechanical engineering

The invention discloses a mechanism for nose bridge strip cutting-off and mask flanging. The mechanism comprises a mounting plate, a bottom plate is arranged on the mounting plate, a mask guide plateis arranged on the upper part of the bottom plate, a gap allowing a mask to pass through is formed between the bottom plate and the mask guide plate, vertical plates for driving two sides of the maskto be erected are arranged on two sides of the bottom plate, and a pressing and folding mechanism for driving the two sides of the mask to be pressed and folded immediately after being erected is disposed at the tail end of the bottom plate; a nose bridge strip conveying plate is further arranged above the mask guide plate, a nose bridge strip conveying mechanism for driving the nose bridge stripto move on the nose bridge strip conveying plate and a nose bridge strip cutting-off mechanism for cutting off the nose bridge strip are sequentially arranged on the mounting plate in the movement direction of the nose bridge strip, the tail end of the nose bridge strip conveying plate is equipped with a guide conveying mechanism for driving the nose bridge strip to move to the inside of mask flanging. According to the invention, by arranging the pressing and folding mechanism, smooth folding of two sides of the mask is guaranteed, and meanwhile the cut-off nose bridge strip can precisely enter the inner side of the folded edge through the arrangement of the guide conveying mechanism.

Owner:苏州德尔富自动化科技有限公司

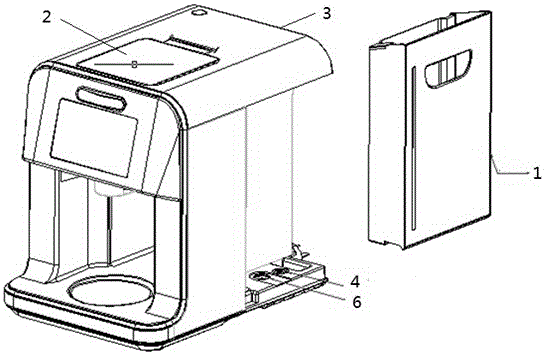

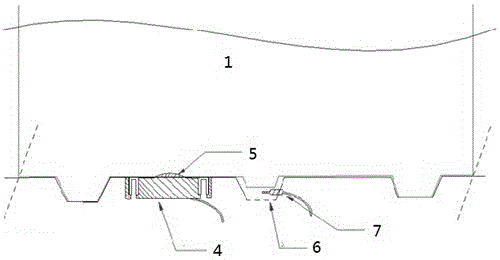

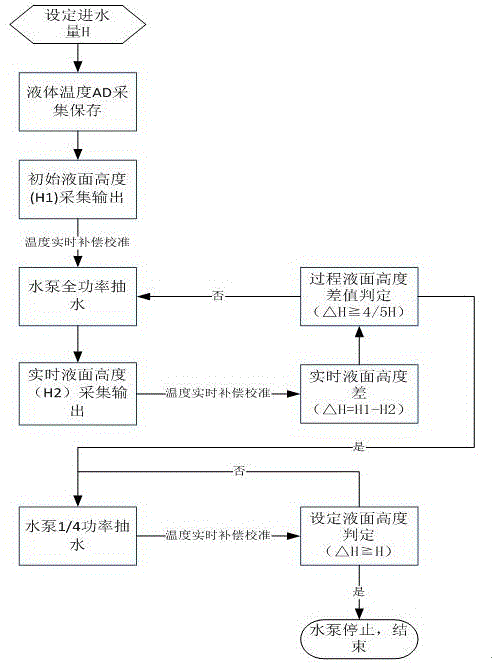

Control method of food processing machine

InactiveCN105759858APrecise entryIntelligent processingLevel controlUltrasonic sensorPulp and paper industry

The invention discloses a control method of a food processing machine. The food processing machine includes a water tank, and a processing chamber for food processing. An ultrasonic sensor for detecting the water level of the water tank is disposed on the food processing machine. A temperature detection device for detecting the water temperature in the water tank is further disposed on the food processing machine. The food processing machine adjusts a water level value detected by the ultrasonic sensor according to the water temperature. Continuous water level detection can be achieved by detecting the water level of the water tank using the ultrasonic sensor, so as to accurately control the water entering the processing chamber, and in this way, the food processing machine is allowed to intelligently control the material entry. Meanwhile, the temperature sensor is disposed at a water inlet / outlet between the water tank and a base, the water temperature of the water tank can be monitored in real time, so that the water level value monitored by the ultrasonic sensor can be corrected to enable more accurate water level monitoring, and thus, the food processing machine is allowed to process food more intelligently.

Owner:HONGYANG HOME APPLIANCES

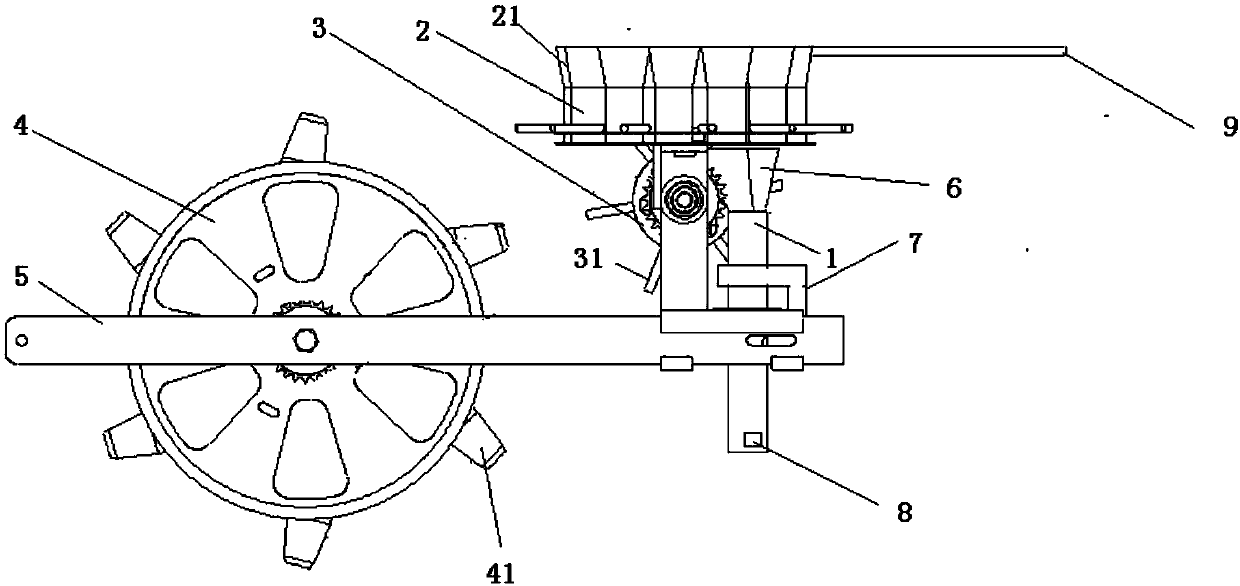

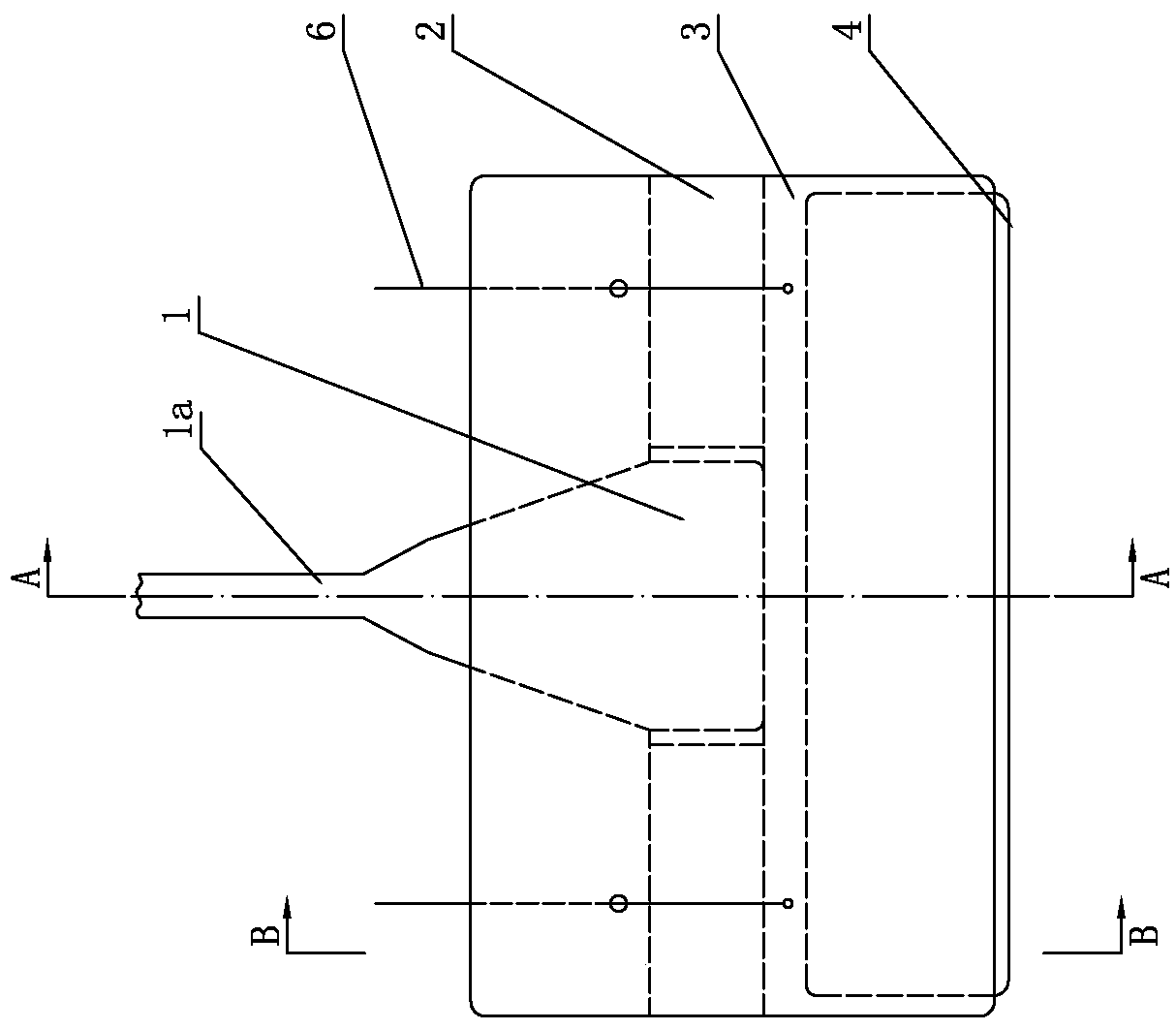

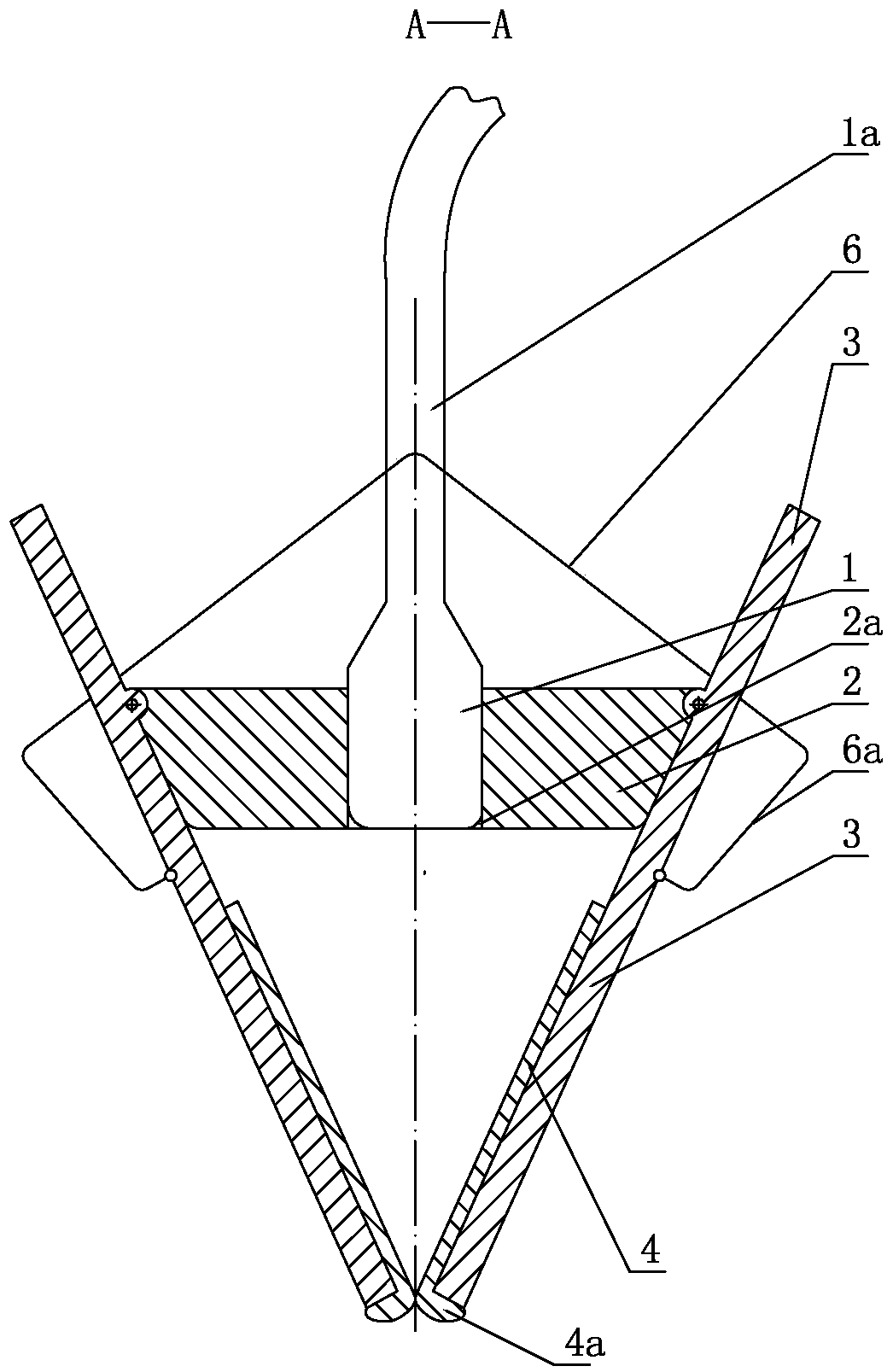

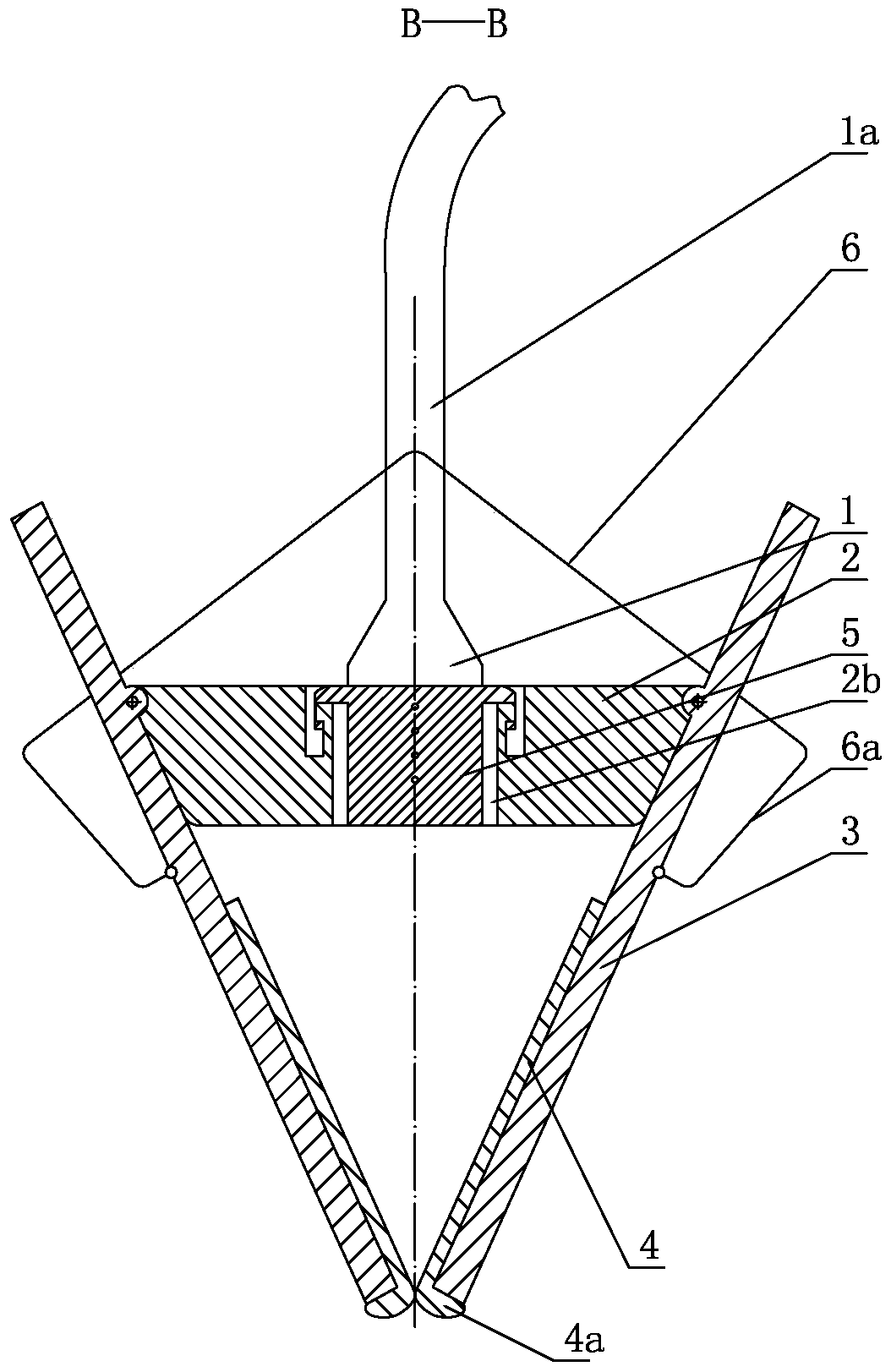

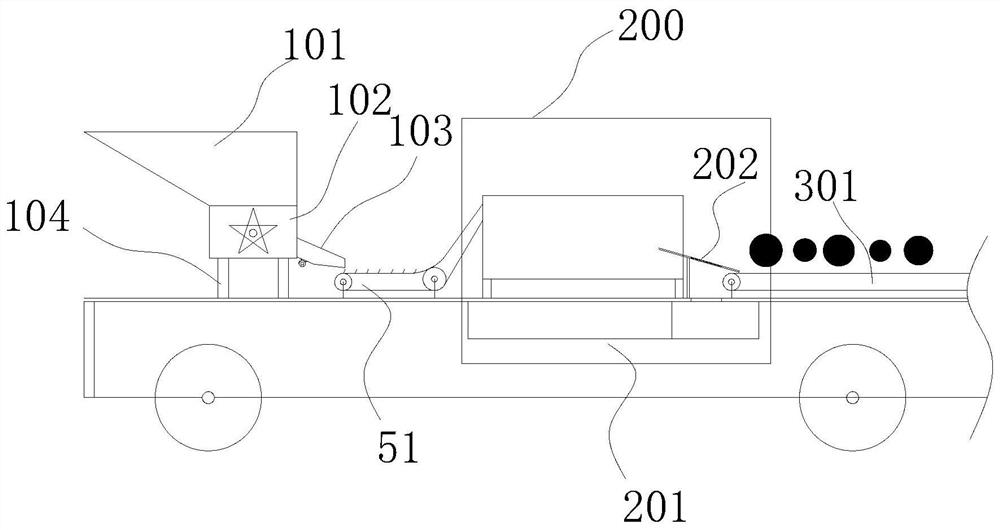

Solar transplanting machine

InactiveCN107593058ASolve the problem of precise seedling injectionPrecise entryRenewable energy machinesTransplantingEngineeringTractor

The invention provides a solar transplanting machine. The solar transplanting machine is dragged by a tractor and a holing device is driven to rotate; a holing pile is in contact with the ground so that a planting hole is obtained; an intermittent mechanism drives an intermittent seedling launching rotary table to realize intermittent rotation; when a seedling planting pipe is aligned to the planting hole, an induction sensor is used for firstly detecting whether the seedling planting pipe is aligned to the planting hole or not; if so, the induction sensor feeds a signal back to a controller and the controller sends out the signal to control a seedling launching stirring wheel to stir a transplanted seedling to be led out from the seedling planting pipe; if not, the induction sensor feedsthe signal back to the controller and the controller sends out the signal to a strengthening device of the seedling planting pipe to strengthen the seedling planting pipe and align the seedling planting pipe to the planting hole; the strengthening device is arranged and the transplanted seedling accurately enters the seedling planting hole, so that the seedling planting action is finished. The solar transplanting machine provided by the invention is a full-automatic transplanting machine and the problem of accurately launching the seedling by the transplanting machine is solved.

Owner:赵东顺

Conveying mechanism of paper cup machine

InactiveCN107472945AImprove efficiencyQuality assurancePaper/cardboard wound articlesArticle feedersEngineeringPaper cup

The invention provides a conveying mechanism of a paper cup machine and belongs to the technical field of paper cup machines. By means of the conveying mechanism, the problem that in the prior art, conveying efficiency is low is solved. The conveying mechanism of the paper cup machine comprises a workbench. A conveying disc is arranged on the workbench. A driving mechanism is arranged below the conveying disc, wherein by means of the driving mechanism, the conveying disc can be driven to rotate. The conveying disc is provided with an inlet end and an outlet end. A paper pushing mechanism is arranged at the position, located at the inlet end of the conveying disc, on the workbench, wherein by means of the paper pushing mechanism, paper pieces can be conveyed into the conveying disc. The conveying disc is provided with a paper clamping mechanism, wherein the paper clamping mechanism is used for clamping the paper pieces. The workbench is further provided with a primary heating mechanism and a secondary heating mechanism, wherein by means of the primary heating mechanism and the secondary heating mechanism, the paper pieces can be heated. An output mechanism is arranged at the position, located at the outlet end of the conveying disc, on the workbench, wherein by means of the output mechanism, the paper pieces can be output from the conveying disc. The conveying mechanism has the beneficial effect of being high in conveying efficiency.

Owner:海宁诚达机械有限公司

Environment-protective recovery device

ActiveCN107979029AReduce wearDoes not require frequent disassemblyBasic electric elementsApparatus for removing/armouring cablesEddy current effectEngineering

The invention relates to the field of recovery devices, and especially to an environment-protective recovery device. The environment-protective recovery device comprises a pedestal, a feeding wheel, acutting portion, an inner core recovery wheel and a motor; the cutting portion comprises a cutting wheel and a blade, a preheating hole is formed in the top end of the cutting wheel, a cutting hole is formed in the bottom of the cutting wheel, and the preheating hole is communicated with the cutting hole; a sleeve is arranged outside the preheating hole of the cutting wheel, a lead is arranged outside the sleeve and wound around the sleeve, and the two ends of the lead are connected with an AC power supply; the blade in arranged on the sidewall of the cutting hole in an inclined way, and theouter wall of the cutting wheel under the sleeve is provided with teeth; a gear is arranged outside the cutting wheel and engaged with the teeth of the cutting wheel; and an aggregating casing and anaggregating tube communicated with the aggregating casing are arranged under the cutting wheel, the aggregating tube is connected with a negative-pressure blower fan, and the motor is connected with the feeding wheel and the inner core recovery wheel. According to schemes of the invention, an eddy current effect is used to heat a waste wire, so that a rubber sheath of the waste wire is softened and thus can be cut easily; and the blade replacement frequency is reduced, the cost is saved and the working efficiency is improved.

Owner:宁波江北清纬环保科技有限公司

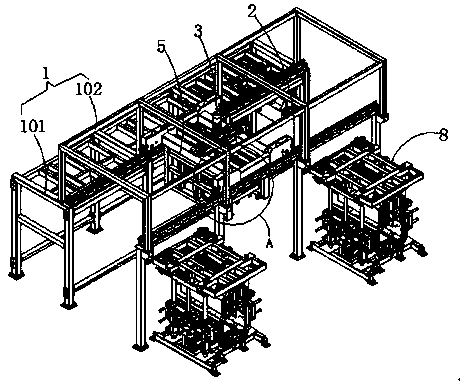

Translation type automatic mold replacement mechanism

The invention provides a translation type automatic mold replacement mechanism, and relates to the technical field of box foaming equipment mold replacement. The translation type automatic mold replacement mechanism comprises a supporting frame, a translation transmission mechanism and a vertical transmission mechanism; the supporting frame comprises a left side frame and a right side frame; the interior of the left side frame is provided with foaming equipment, and the interior of the right side fame is movably provided with a mold replacement trolley through the translation transmission mechanism; a mold storeroom is arranged on the side, away from the left side frame, of the right side frame; and the top end of the inner side of a mold trough and the top of the mold storeroom are both provided with mold conveying mechanisms which are the same with a mold conveying mechanism on the foaming equipment. According to the translation type automatic mold replacement mechanism, by arrangingthe translation transmission mechanism and the vertical transmission mechanism, moving of a mold in the horizontal and vertical directions during replacing is achieved; by arranging a servo motor, the whole conveying process is accurate; and through the invention, an original turnover mold replacement mode is changed, the mold replacement position is precise, the mold replacement speed is high, aproduction line does not need to be stopped during mold replacement, the production efficiency is improved, safety and effectiveness are achieved, and the practicability is high.

Owner:滁州信达自动化设备制造有限公司

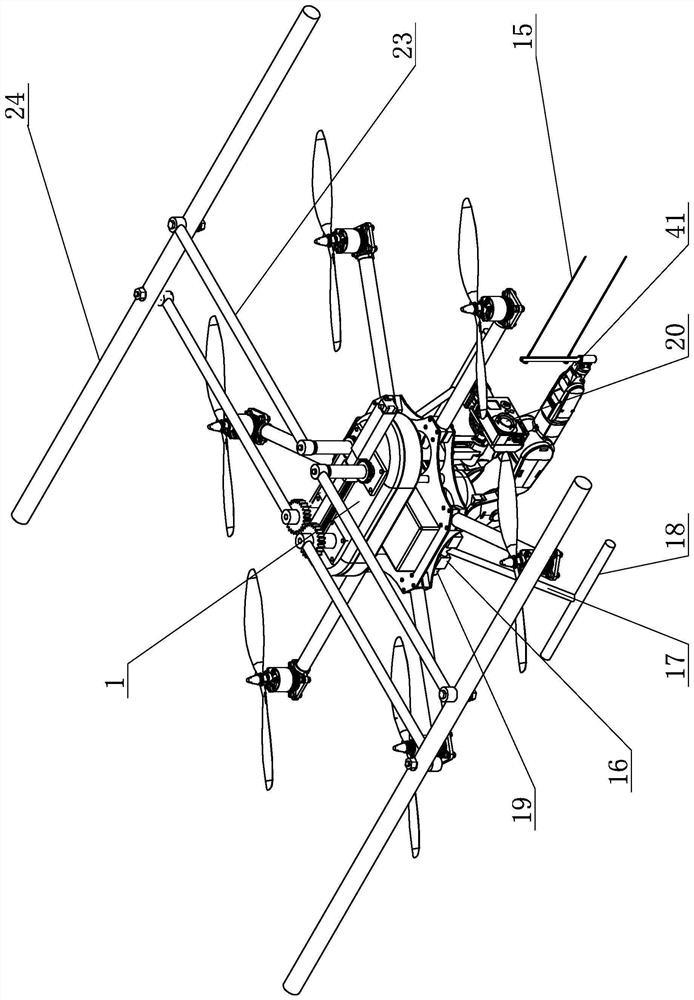

Unmanned aerial vehicle zero detection device for strain tower porcelain insulator of ultra-high voltage power transmission line

ActiveCN113872100AEasy to serial check zero operationPrecise entryApparatus for overhead lines/cablesUncrewed vehicleRotor (electric)

An unmanned aerial vehicle zero detection device for a strain tower porcelain insulator of an ultra-high voltage power transmission line is characterized in that an insulator detector is carried by an unmanned aerial vehicle to collect the distribution condition of an electric field around the strain porcelain insulator, whether a degraded insulator or a zero-value insulator exists in an insulator string is compared, analyzed and judged according to the detected data, and the detection operation of the insulator is completed instead of manual work. Through the real-time monitoring of the pan-tilt camera and the flexible adjustment of the mechanical arm assembly, the detection needle can accurately enter the space between the insulators to be detected, so that the labor intensity of workers is reduced, the operation difficulty is reduced, the efficiency and quality of detection operation are greatly improved, and the influence on the personal safety of operators is avoided. The upper part of the unmanned aerial vehicle is also provided with a rotor wing protection device, and the arrangement of the rotor wing protection device can ensure that the unmanned aerial vehicle can avoid the influence of a power transmission line on a rotor wing in the rising process, so that the detection needle is smoothly moved to the position of an insulator chain needing to be detected, and the subsequent zero detection operation of the insulator chain is facilitated.

Owner:STATE GRID CORP OF CHINA +1

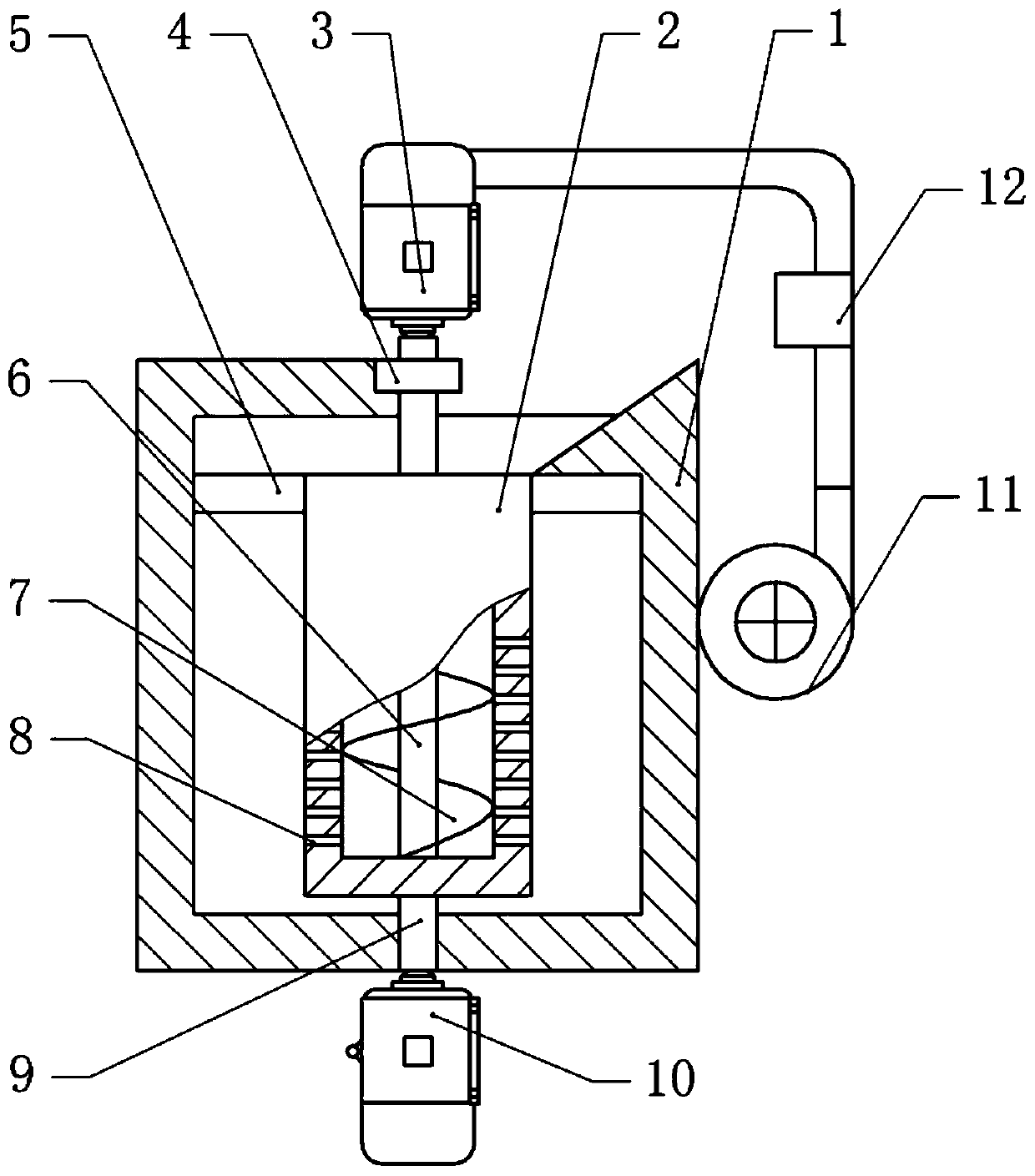

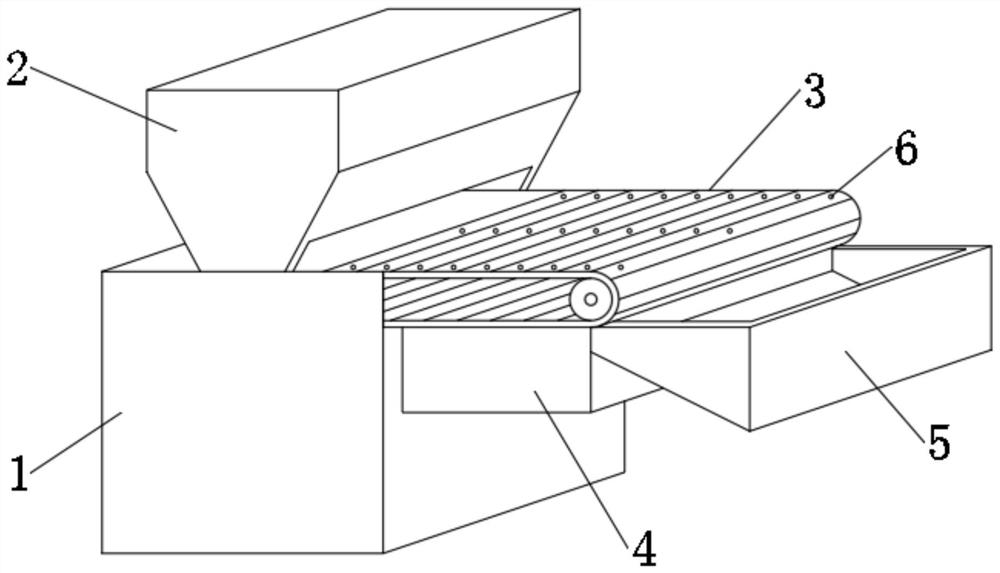

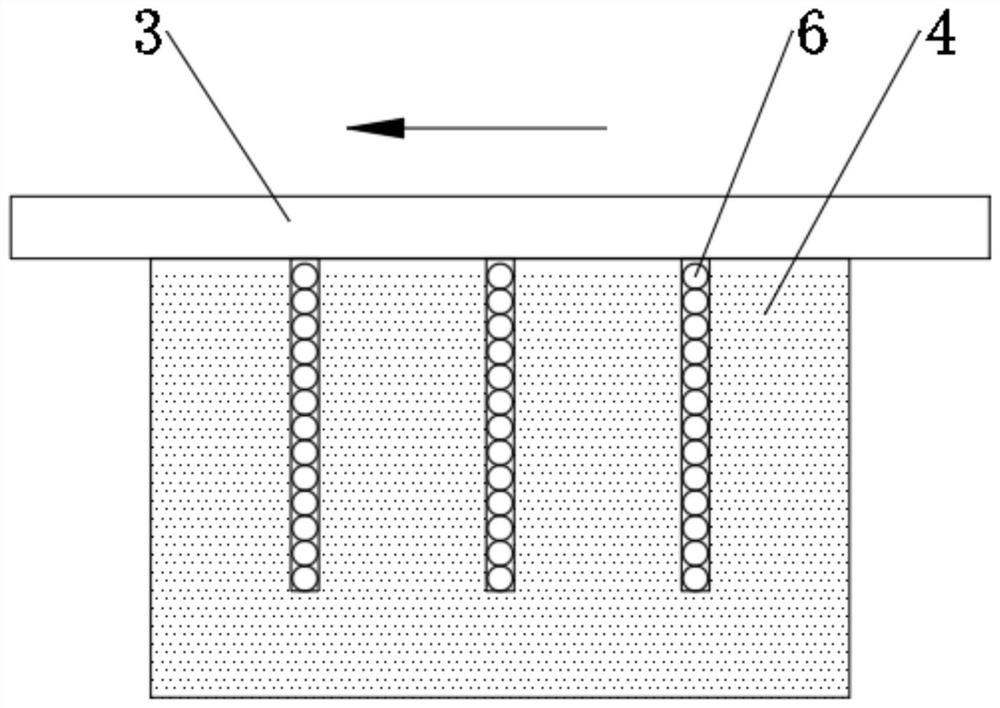

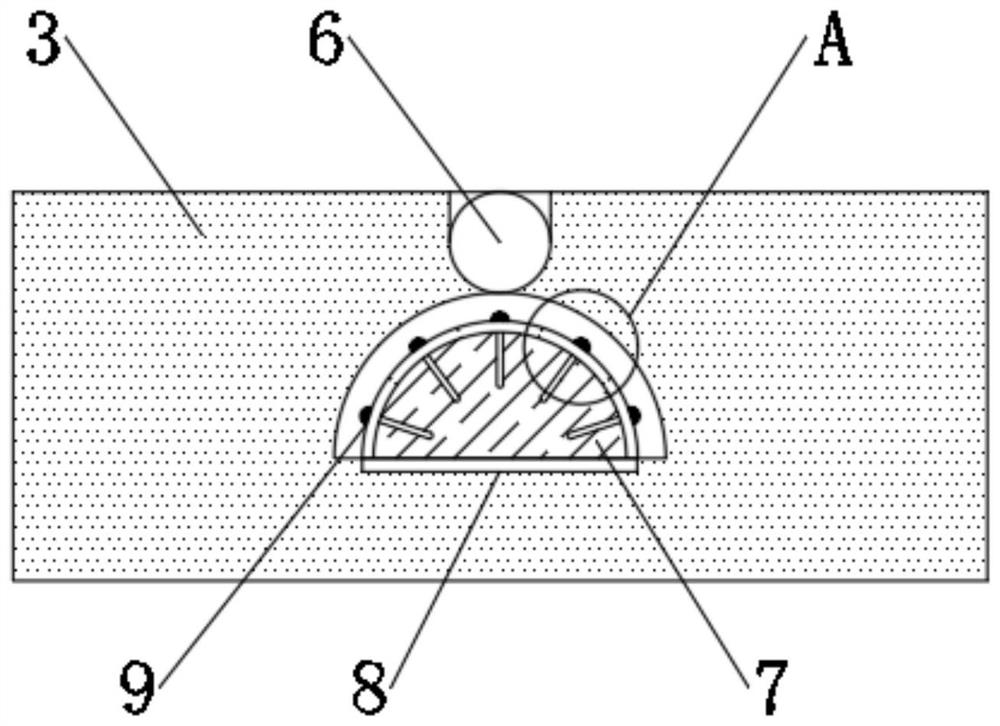

Specific-gravity stoner for rice

The invention relates to the technical field of separating device assembly of separating solid by screening or sieving or using gas flow, and discloses a specific-gravity stoner for rice. The specific-gravity stoner for rice comprises a collecting box and a separating barrel, and further comprises a fan, wherein a separating hole is formed in the side wall of the separating barrel; a pneumatic motor is fixedly arranged above the collecting box; a drive part is fixedly arranged below the collecting box; the separating barrel is fixedly connected to the output shaft of the drive part; a separating shaft is rotatably connected in the separating barrel; the separating barrel is fixedly connected to the output shaft of the pneumatic motor; the periphery of the separating shaft is fixedly equipped with a packing auger; the blade of the packing auger is gradually reduced from bottom to top; a negative-pressure section and a dust-removal section which communicates with the negative-pressure section are arranged in the separating shaft; a gas hole which communicates with the negative-pressure section is formed in the side wall of the separating shaft; a gas outlet of the pneumatic motor communicates with the negative-pressure section; the dust-removal section communicates with outside air; and a gas outlet of the dust-removal section is positioned above the gas inlet of the negative-pressure section. According to the scheme adopted by the invention, the specific-gravity stoner is simple in structure, and conveniently removes gravels and sediments in grains.

Owner:重庆诚阳农业发展有限公司

Mammary gland puncture fixing device and use method thereof

PendingCN109498069AAvoid displacementAvoid blockingSurgical needlesVaccination/ovulation diagnosticsElastic compressionPuncture Biopsy

The invention discloses a mammary gland puncture fixing device and a use method thereof in the field of puncture biopsy medical instruments. The mammary gland puncture fixing device comprises an ultrasonic high-frequency probe, a probe cable and an ultrasonic diagnostic apparatus, the ultrasonic high-frequency probe is placed in a positioning groove in the middle of a probe support, positioning splints are hinged to the front side and the rear side of the probe support, an elastic compression mechanism is arranged between the two positioning splints, an elastic protective pad is arranged at the bottom of one side of each positioning splint, the left side and the right side of the probe support are detachably connected with puncture guide modules, and at least four puncture needle guide grooves are formed in the puncture guide modules. The method includes the steps: disinfecting a mammary gland; fixing the mammary gland and the ultrasonic high-frequency probe by the positioning splints;finding out a puncture guide path after analysis of the ultrasonic diagnostic apparatus. The positional relationship of the ultrasonic high-frequency probe and a mammary gland mass can be positioned,stability of the probe is improved, and puncture needle inserting paths are more accurately selected.

Owner:YANGZHOU FIRST PEOPLES HOSPITAL

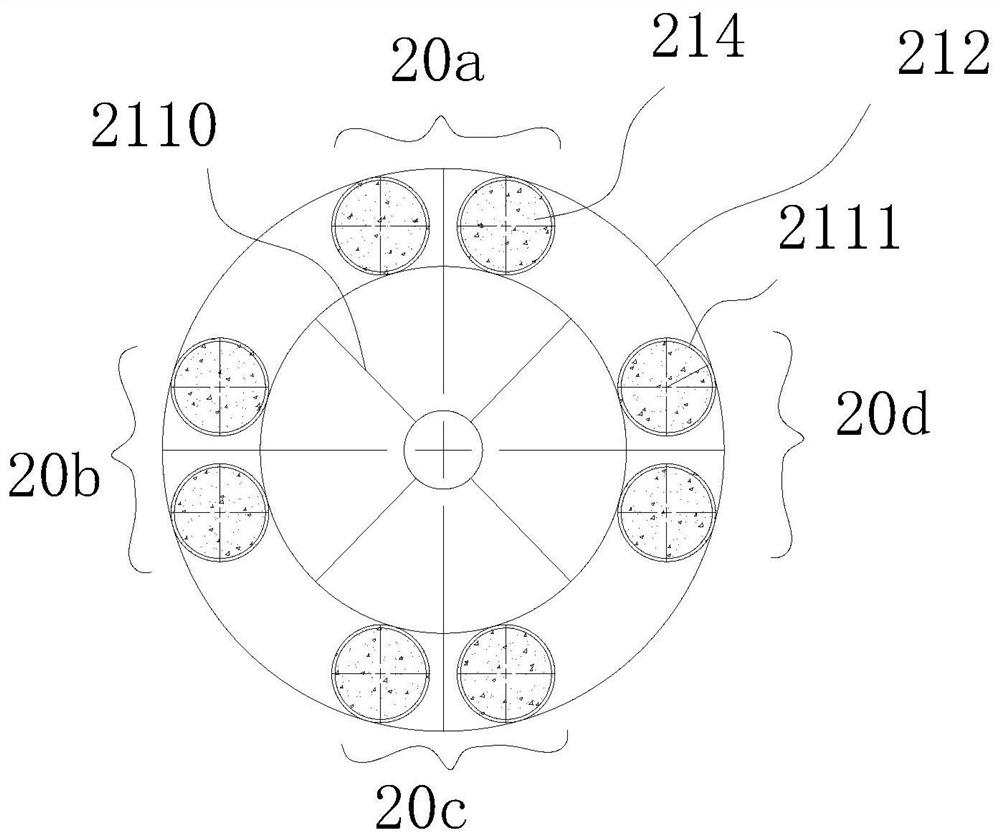

Drink filling bottle circularly rotating and continuously and precisely sterilizing and drying device

InactiveCN108981358APrecise entryAvoid damageHollow article cleaningDrying gas arrangementsSpray nozzleEngineering

The invention provides a drink filling bottle circularly rotating and continuously and precisely sterilizing and drying device and belongs to the field of filling bottle sterilizing and drying. The drink filling bottle circularly rotating and continuously and precisely sterilizing and drying device comprises an inlet conveying belt, a bottle guiding frame, a conveying turntable, a bottle clampinggroove, a rotating column, a sterilizing and drying turntable, an extending gripper air cylinder, a fixing ripper, a bottle discharging limiting bar, an outlet conveying belt, a control panel, a spraynozzle, an air cylinder, a hose and a sterilizing and drying module. The drink filling bottle circularly rotating and continuously and precisely sterilizing and drying device comprises the extendinggripper air cylinder and the fixing ripper, so that before the spray nozzle moves downwards for steam spray sterilizing and drying, the extending gripper air cylinder moves downwards and the fixing gripper fixes a drink filling bottle, and the spray nozzle can avoid deviation during downward movement; the extending gripper air cylinder and the fixing gripper can achieve guiding effects on the spray nozzle, the spray nozzle can precisely enter the filling bottle, so that damage to the filling bottle due to inaccurate entering of the spray nozzle into the filling bottle can be reduced as well asinfluence on normal drink filling production and production efficiency can be avoided.

Owner:刘业倩

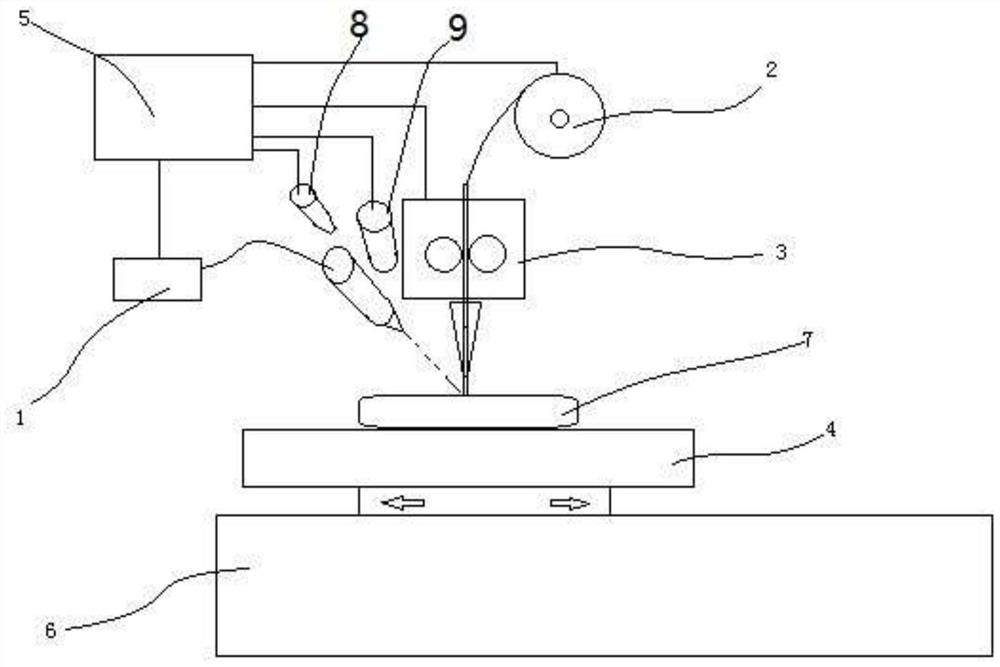

Laser joule composite heat source metal filament additive manufacturing device and method

PendingCN112643205AEfficient use ofReduce laser powerAdditive manufacturing apparatusLaser beam welding apparatusMetal filamentLaser assisted

The invention discloses a laser joule composite heat source metal filament additive manufacturing device and method. A laser device, a filament feeding mechanism, a joule heating device, a forming base plate and a controller are utilized to form the laser joule composite additive manufacturing device, and a joule heating device is arranged at the upper end of the forming base plate. A filament feeding port of the filament feeding mechanism is aligned with a filament inlet of the joule heating device, filaments are fed into the joule heating device through the filament feeding mechanism to be heated and then reach the forming base plate, and filaments discharged from a heating point of the laser device and a wire outlet of the joule heating device are both located on to-be-formed points. After the filaments are electrified with current, the filaments are heated to the temperature close to the melting point under the action of joule heat, part of heat is provided through laser assistance to melt the filaments, a molten pool is formed in the surface of the base plate or the surface of the previous layer, metallurgical bonding is formed, the electric energy can be effectively utilized, the power of needed lasers is reduced, and the overall energy utilization rate is increased.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

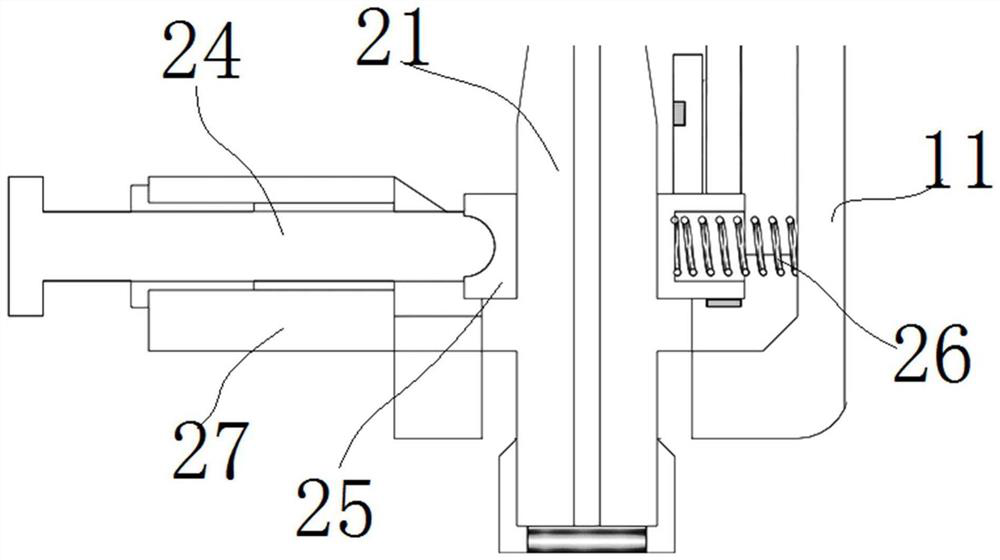

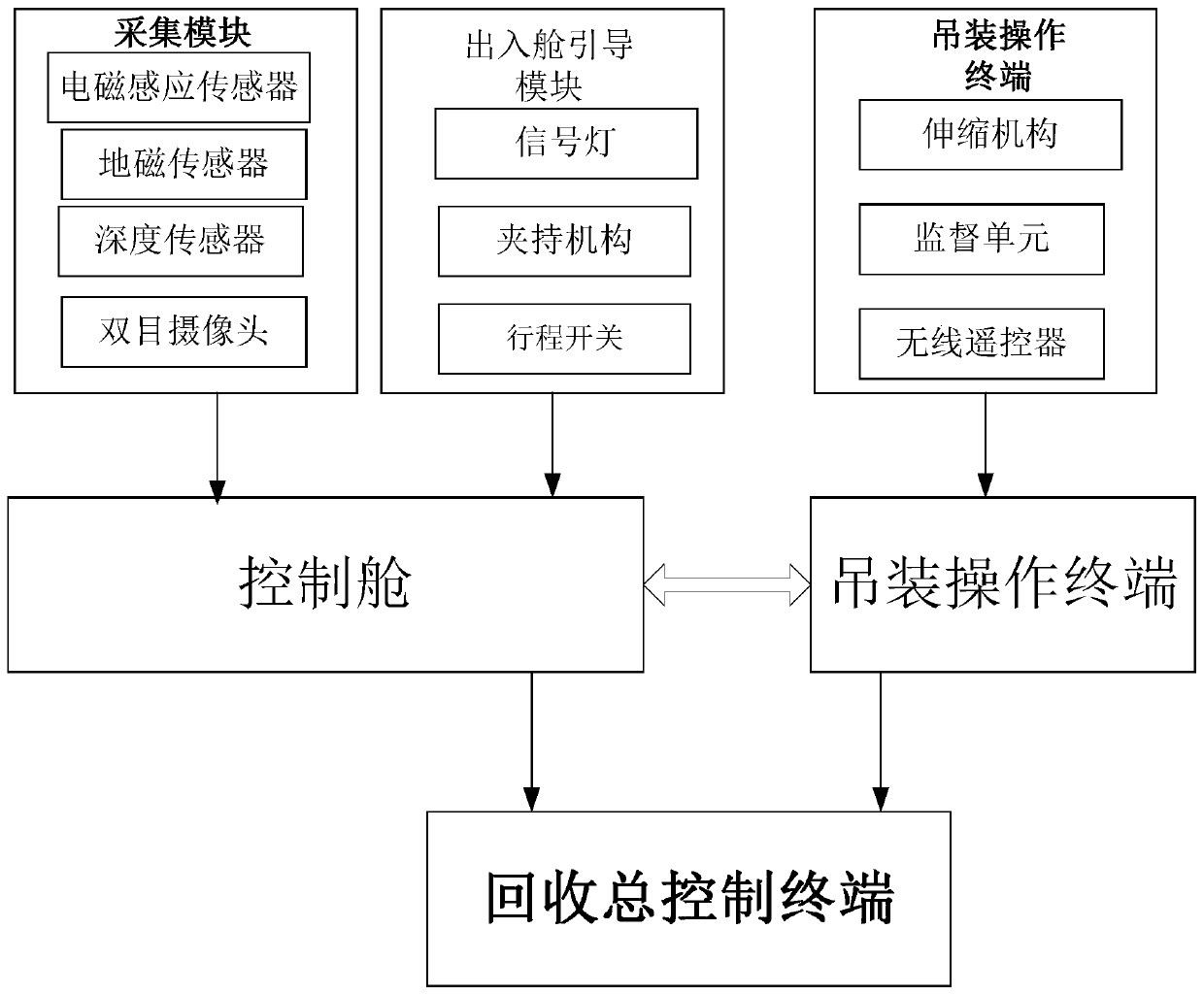

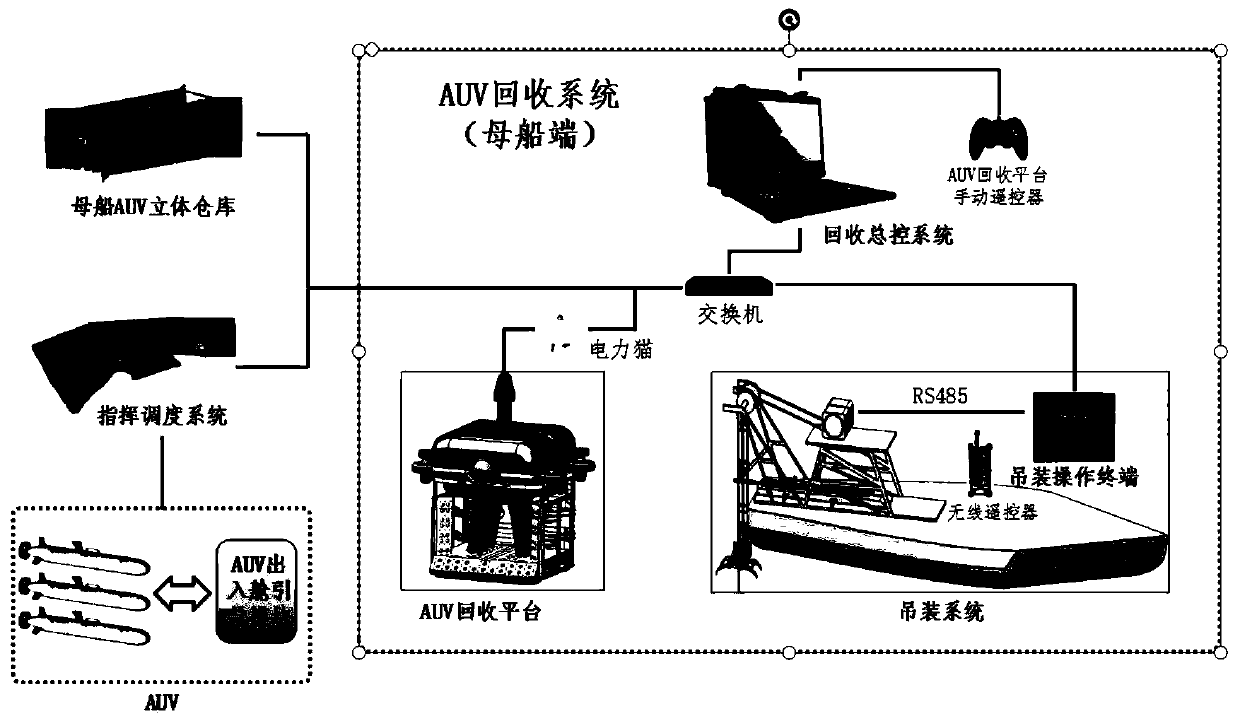

AUV recovery platform for monitoring recovery and hoisting processes of AUV in real time

ActiveCN111601089AEliminate distractionsEnergy savingTransmission systemsClosed circuit television systemsMarine engineeringData messages

The invention discloses an AUV recovery platform for monitoring the recovery and hoisting processes of an AUV in real time. The AUV recovery platform comprises: an acquisition module that is arrangedon an AUV recovery device and is used for monitoring motion direction information of the AUV in real time; the in-out cabin guide module that is arranged in the AUV recovery device and is used for guiding the AUV to stably enter the AUV recovery device by adopting an acoustic guide principle and an optical guide principle; the control cabin that is used for receiving the data information transmitted by the acquisition module and the in-out cabin guide module, is arranged in the AUV recovery device and is used for controlling the motion state of the AUV recovery device and the recovery processof the AUV; the hoisting operation terminal that is arranged in the hoisting system and used for hoisting and lowering the AUV recovery device and monitoring the AUV recovery process in real time, andthe control cabin is in data communication with the hoisting operation terminal; and the recovery master control terminal that is used for receiving the hoisting process data information transmittedby the hoisting operation terminal and the control cabin.

Owner:DALIAN MARITIME UNIVERSITY +1

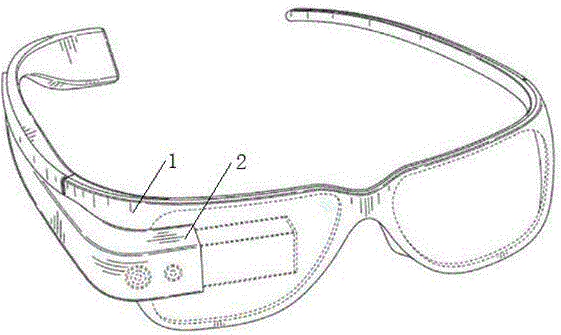

Mobile laryngoscope having wearable function

ActiveCN106419815AEasy to operateEasy to observeBronchoscopesLaryngoscopesObservation unitData signal

The invention discloses a mobile laryngoscope having a wearable function. The mobile laryngoscope comprises a wearable observer, a wireless data transmission device and a mobile laryngoscope body. The wearable observer is connected with the mobile laryngoscope body and the wireless data transmission device wirelessly. The wireless data transmission device installed on a computer is used for receiving a data signal of the wearable observer and transmitting the signal to the computer. The wearable observer consists of a wearing frame and an observation unit arranged on the wearing rack detachably; and the wearing frame includes a cross beam with two nose pads arranged at the middle part and glasses legs arranged at the two sides of the cross beam, wherein the cross beam and the glasses legs are integrated into one. The invention aims at providing a laryngoscope through which mobile checking can be carried out, checking data can be transmitted to the computer wirelessly and a laryngoscope detection image can be observed accurately by using the wearable observer. When the mobile laryngoscope having the wearable function is in use, the detection time is reduced substantially; the medical staff can check patients conveniently; and a diseased part can be observed clearly.

Owner:成都测迪森生物科技有限公司

Ship segmented hoisting and positioning device

ActiveCN111746752AAccurateShorten the lifting timeWaterborne vesselsStructural engineeringMarine engineering

The invention discloses a ship segmented hoisting and positioning device. The device comprises an assembly workpiece and an auxiliary workpiece which are matched and corresponding, the assembly workpiece and the auxiliary workpiece are coaxial, the assembly workpiece comprises a horizontally-arranged guiding piece, a limiting unit arranged in the middle of the guiding piece and adjusting units arranged on the periphery of the guiding piece. The auxiliary workpiece comprises a horizontally-arranged limiting plate, a supporting plate fixed to one side of the limiting plate and a limiting hole formed in the limiting plate and corresponding to the limiting unit. According to the ship segmented hoisting and positioning device, through cooperation of the adjusting unit, the guide seat and the limiting unit, the relative positions of the auxiliary workpiece and the assembly workpiece do not need to be observed in real time, ship segments are accurately positioned in place, the ship segments do not need to be adjusted subsequently through an external traction device, and the hoisting time is saved; the adjusting unit, the guiding piece and the limiting unit can be independently arranged and can be rapidly disassembled, assembled and repeatedly used, cost is saved, and storage is convenient.

Owner:CHENGXI SHIPYARD

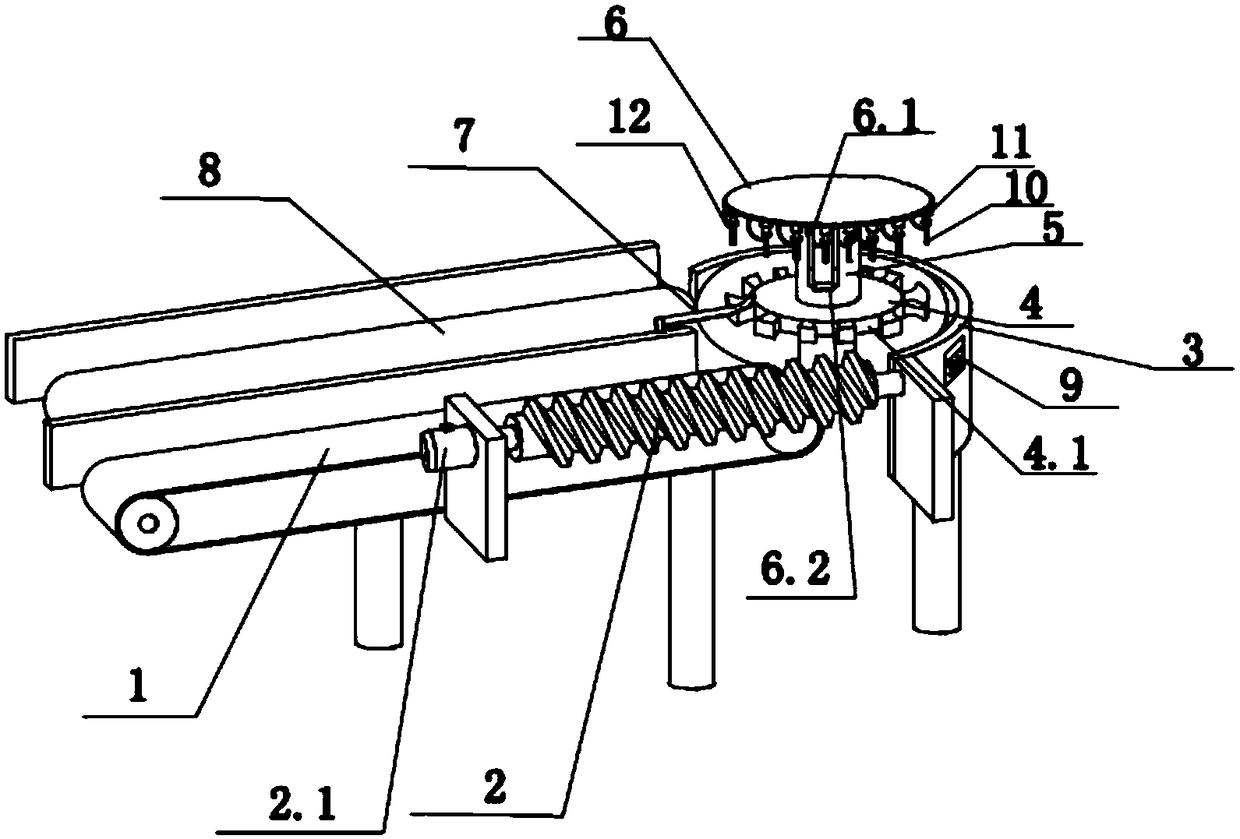

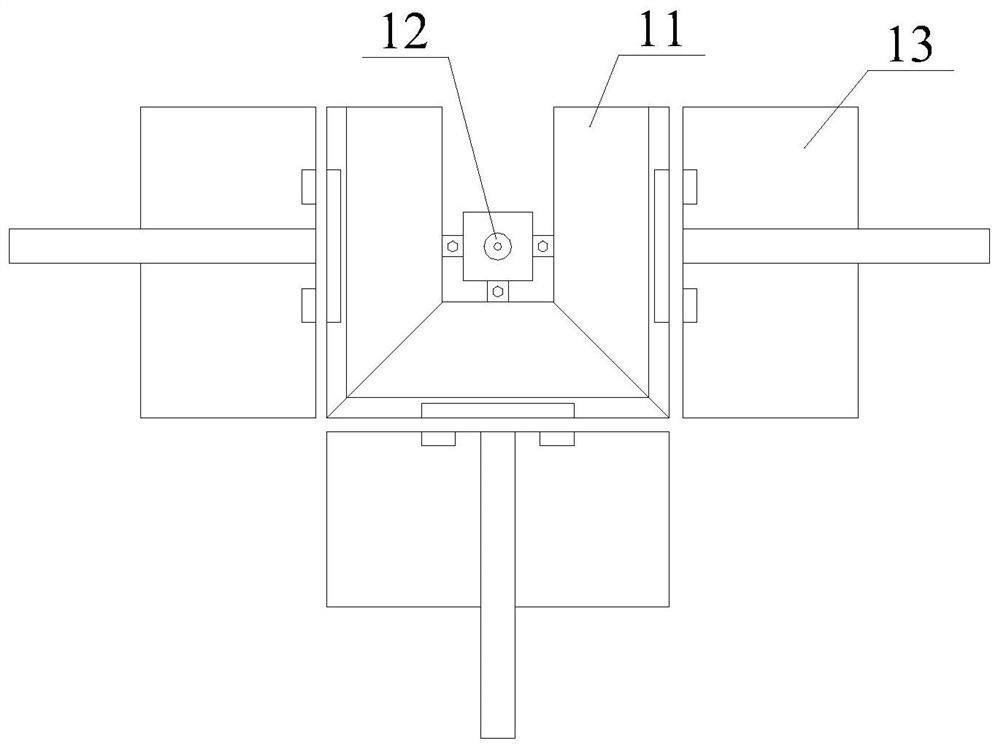

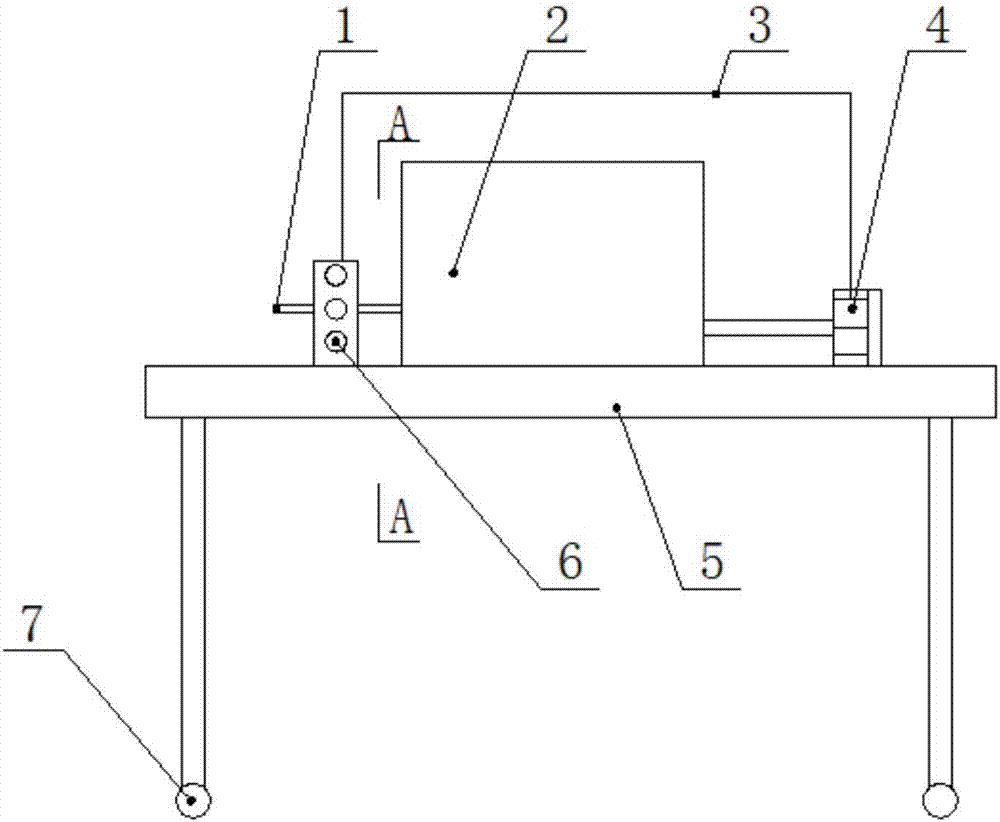

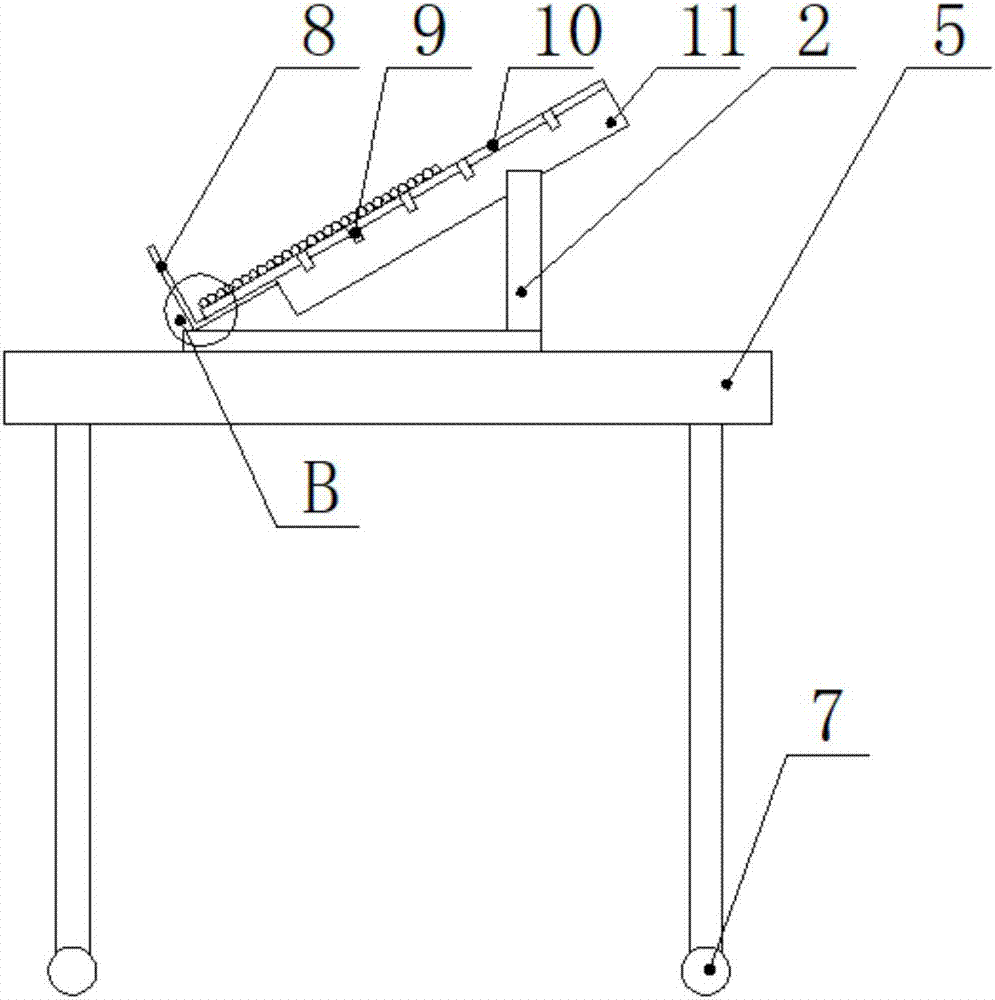

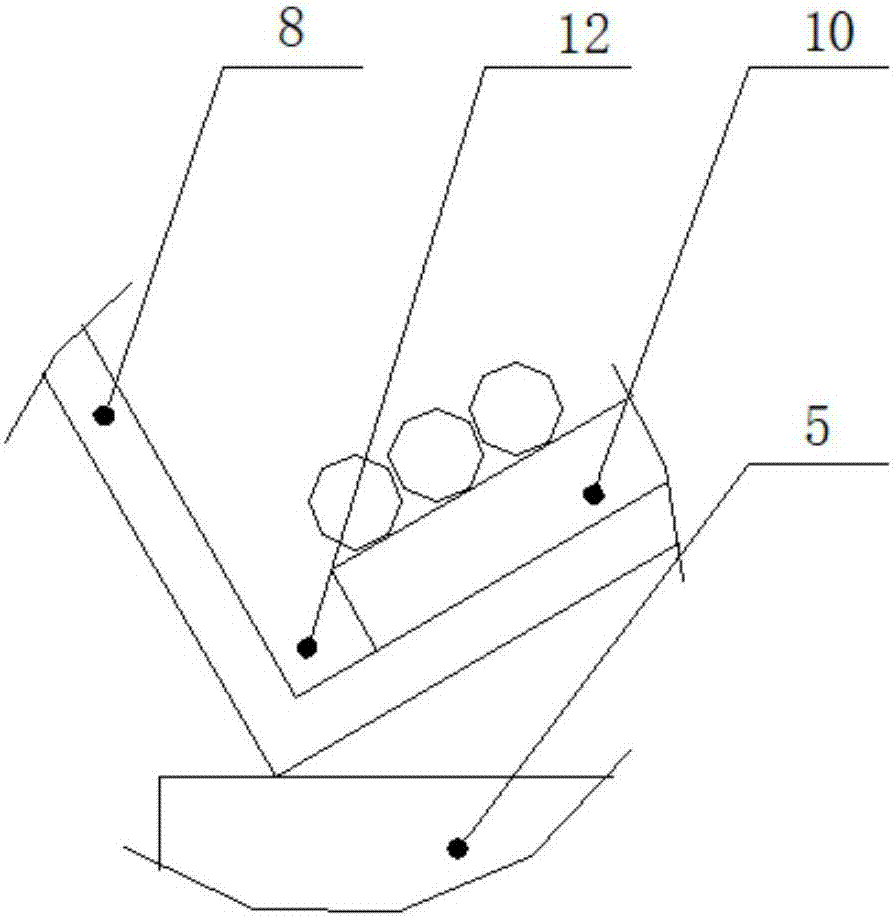

Multi-specification motor shaft feeding device

The invention relates to a multi-specification motor shaft feeding device. The multi-specification motor shaft feeding device is characterized by comprising a support, a feeding support and a pushingair cylinder, the feeding support and the pushing air cylinder are fixedly installed on the support, the feeding support comprises an L-shaped supporting plate, an inclined support plate, a storing plate and an L-shaped stopping plate, the inclined support plate is fixedly installed on the L-shaped supporting plate, a plurality of snap joints are arranged on the side wall of the inclined support plate, a plurality of clamping holes are formed in the upper surface of the storing plate, the storing plate is detachably clamped to the inclined support plate, the L-shaped stopping plate is fixed tothe L-shaped supporting plate, the L-shaped stopping plate is matched with the storing plate to form a material bayonet, and the pushing air cylinder corresponds to the material bayonet. The multi-specification motor shaft feeding device is scientific and reasonable in structural design, stable and continuous feeding of motor shaft materials can be guaranteed, the motor shaft quality can be guaranteed, motor shaft deformation is effectively prevented, the multi-specification motor shaft feeding device can be suitable for feeding motor shaft cutting machines in different machining sizes, the application scope is wide, manpower is saved, and the feeding efficiency is improved.

Owner:天津超金精密电子有限公司

Automatic material collecting device for film cutting machine

PendingCN113213235AReduce frictional resistanceReduce wearMetal working apparatusArticle deliveryThin membraneEngineering

The invention discloses an automatic material collecting device for a film cutting machine, and belongs to the technical field of film cutting machines. The automatic material collecting device can automatically discharge materials through a transmission crawler belt, a plurality of uniformly distributed transfer balls are attracted from the lower side by virtue of the magnetic attraction effect of magnetic control bags, the magnetic attraction force of the magnetic control bags is automatically lost after the transmission crawler belt rotates to the upper side, the transfer balls are in contact with a thin film and then are adhered to the thin film, the thin film normally slides down when reaching an inclined collecting box, the transmission crawler belt always attracts the transfer balls in a reciprocating manner and then enables the transfer balls to be adhered to the thin film, the thin film can realize automatic collecting under the action of gravity, and meanwhile, due to the existence of the transfer balls, frictional resistance of the thin film during sliding down can be greatly reduced, and possibly appearing wear between thin films can be reduced. Compared with the prior art, the device has the advantages that the thin films can be automatically collected, arranged and stacked by means of the transfer balls, the collecting efficiency is greatly improved, and the device is suitable for large-scale production of products.

Owner:深圳市质立科技有限公司

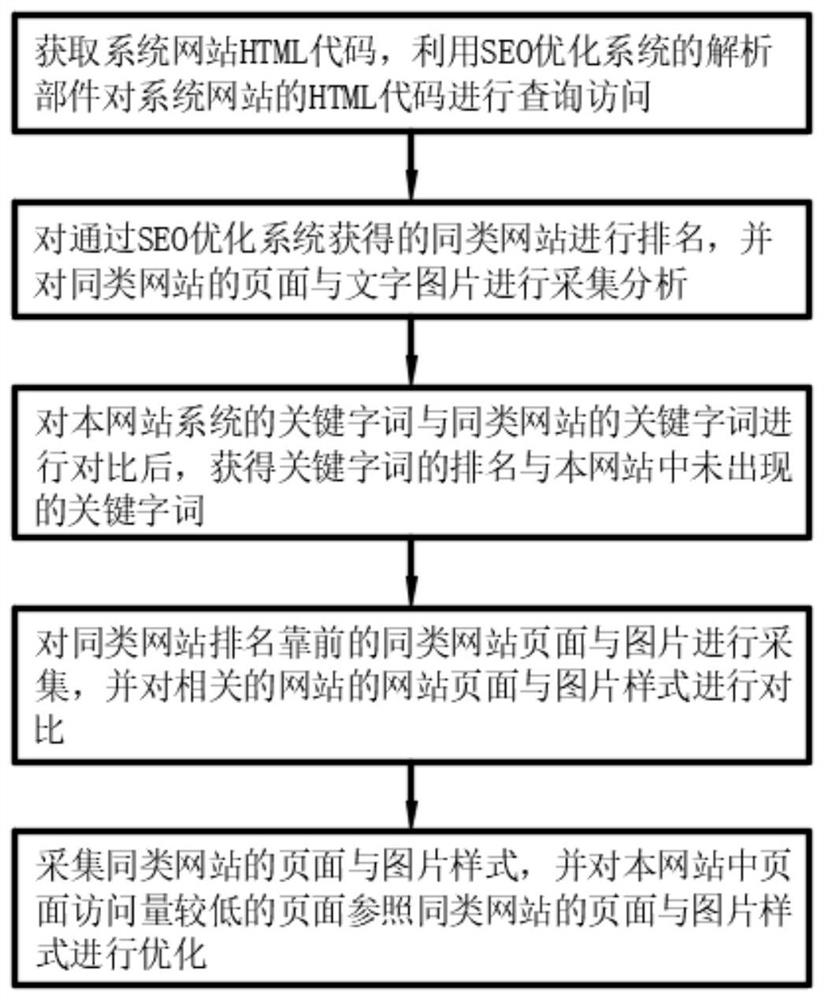

SEO intelligent optimization ranking and query algorithm

PendingCN112434240APrecise entryAccurately draw inWebsite content managementSpecial data processing applicationsEngineeringAlgorithm

The invention discloses an SEO intelligent optimization ranking and query algorithm. An SEO optimization system of a system website, a website speed optimization system, a data server, a website background, and a client are included, wherein the SEO optimization system is used for optimizing a website system so as to facilitate ranking and querying, the website speed optimization system is used for increasing the webpage access speed, the data server is used as a carrier according to ranking and querying functions, the website background is used for operating the SEO optimization system and the data server, and a client is used for displaying operation results of the SEO optimization system and the data server. According to the algorithm provided by the invention, the website system is optimized through the website speed optimization system and the SEO optimization system according to keywords, pictures and characters of similar websites, so that client webpages which can be seen by auser meet the requirement of a search engine for recording and ranking, the ranking of the keywords, the pictures and the pages is improved in the search engine, and the user experience is improved. Therefore, the user is accurately attracted to enter the website, free flow is obtained, and advertisements in the website can be popularized.

Owner:苏州工业园区晨光科技有限公司

Coal and gangue separation device

ActiveCN112536241AReduce control difficultyHigh control precisionSievingScreeningSpray nozzleEnvironmental geology

The invention provides a coal and gangue separation device. The coal and gangue separation device comprises a first supporting seat, a guide part and a plurality of stock bins, wherein the guide partis hinged to the first supporting seat and rotates in the vertical direction; and inlets of the plurality of stock bins are sequentially distributed on the rotating track of the movable end of the guide part. The coal and gangue separation device has the advantages that high-pressure airflow of high-pressure spray nozzles acts on a screen bar driving mechanism instead of directly acting on materials; the screen bar driving mechanism drives cantilever screen bars to rotate; directional discharging of mineral aggregates is achieved, so that gangue can accurately enter a gangue collecting box; and clean coal can accurately enter a clean coal collecting box.

Owner:ANHUI UNIV OF SCI & TECH

AR (augmented reality) auxiliary fork insertion calibrating method under remote manipulation environment and matched forklift

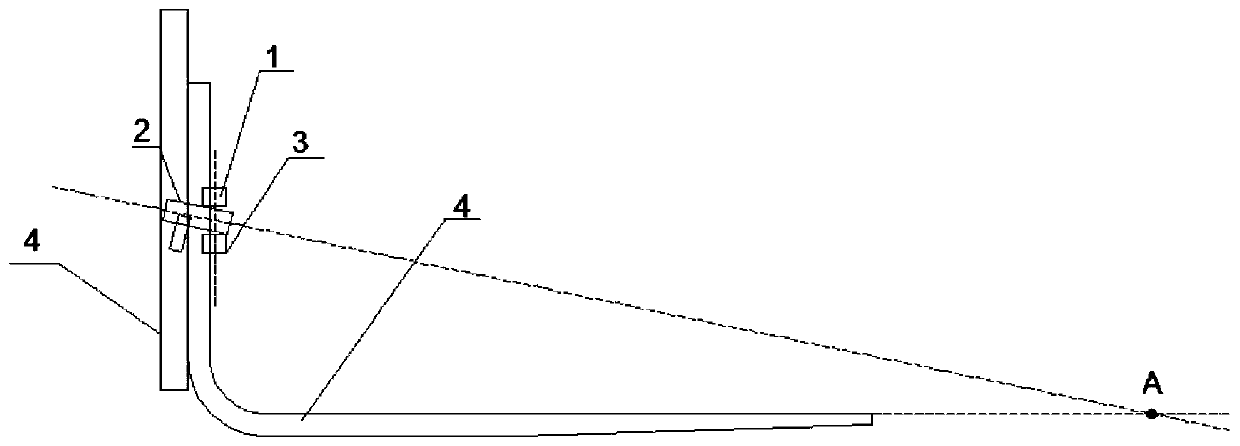

ActiveCN110217727APrecise entryReduce the difficulty of operationLifting devicesEngineeringDistance sensors

The invention relates to industrial vehicles, in particular to an operation transport vehicle, and more particularly relates to an AR (augmented reality) auxiliary fork insertion calibrating method under a remote manipulation environment and a matched forklift. By using a camera and a range sensor, a fork insertion auxiliary line and peak position information of a pallet fork are superposed on animage obtained by the camera through AR technology, and therefore an accurate aiming line, on a material place, of a pallet fork extension line, is obtained when the pallet fork is inserted, and thenoperation difficulty of operating personnel is greatly reduced, material security is guaranteed, and simultaneously achievement of remote manipulation is facilitated.

Owner:JIANGSU ELECTRIC POWER CO +1

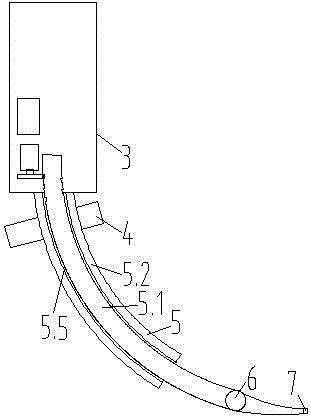

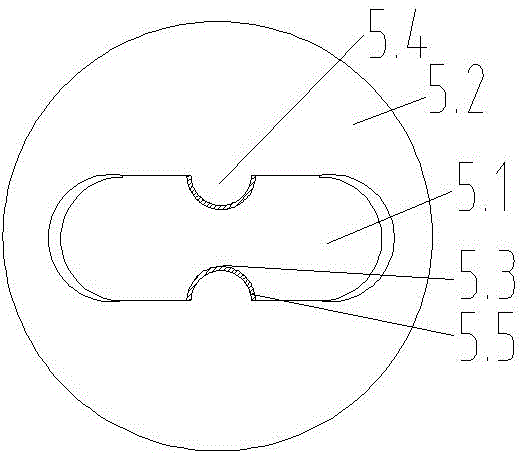

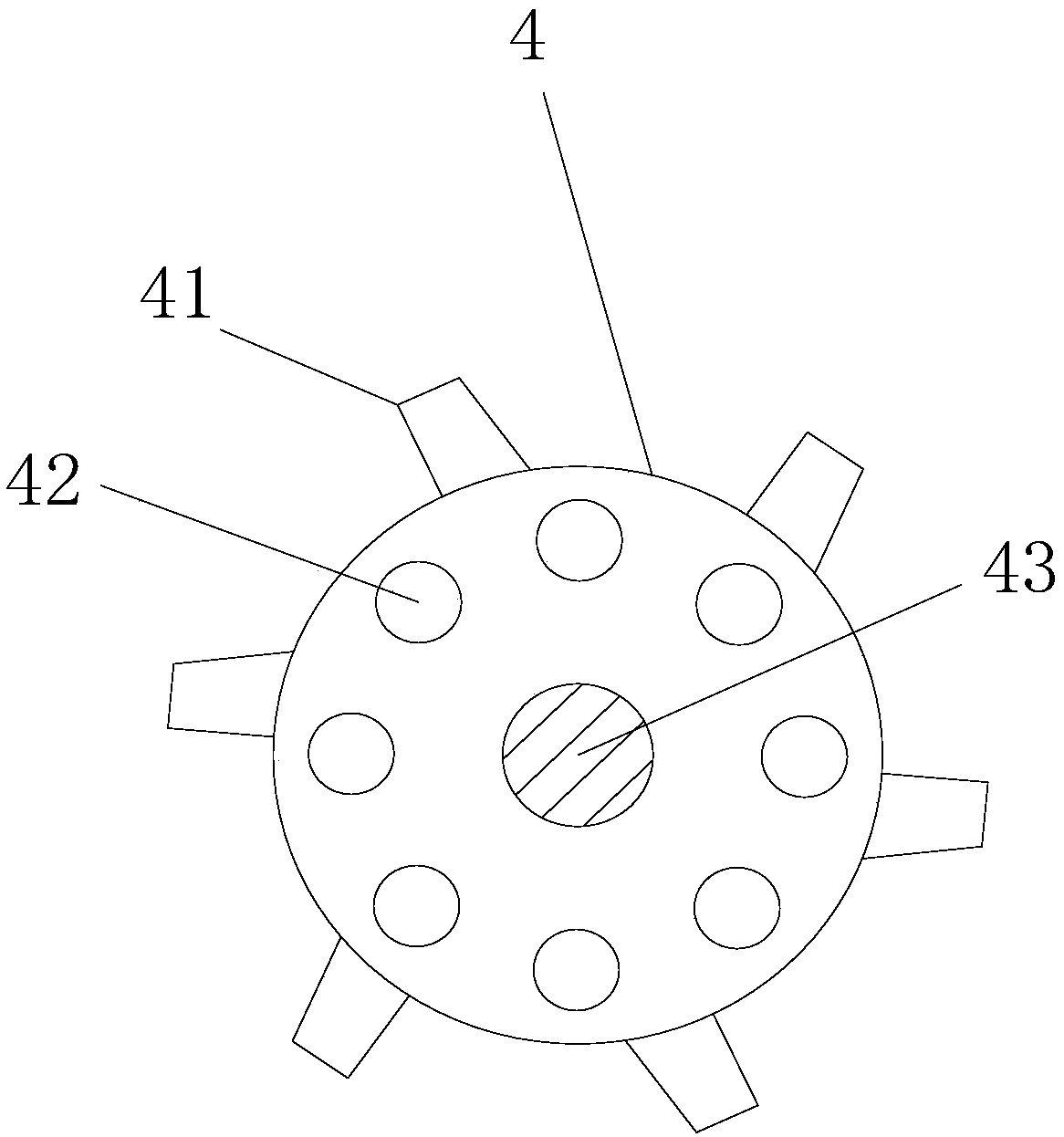

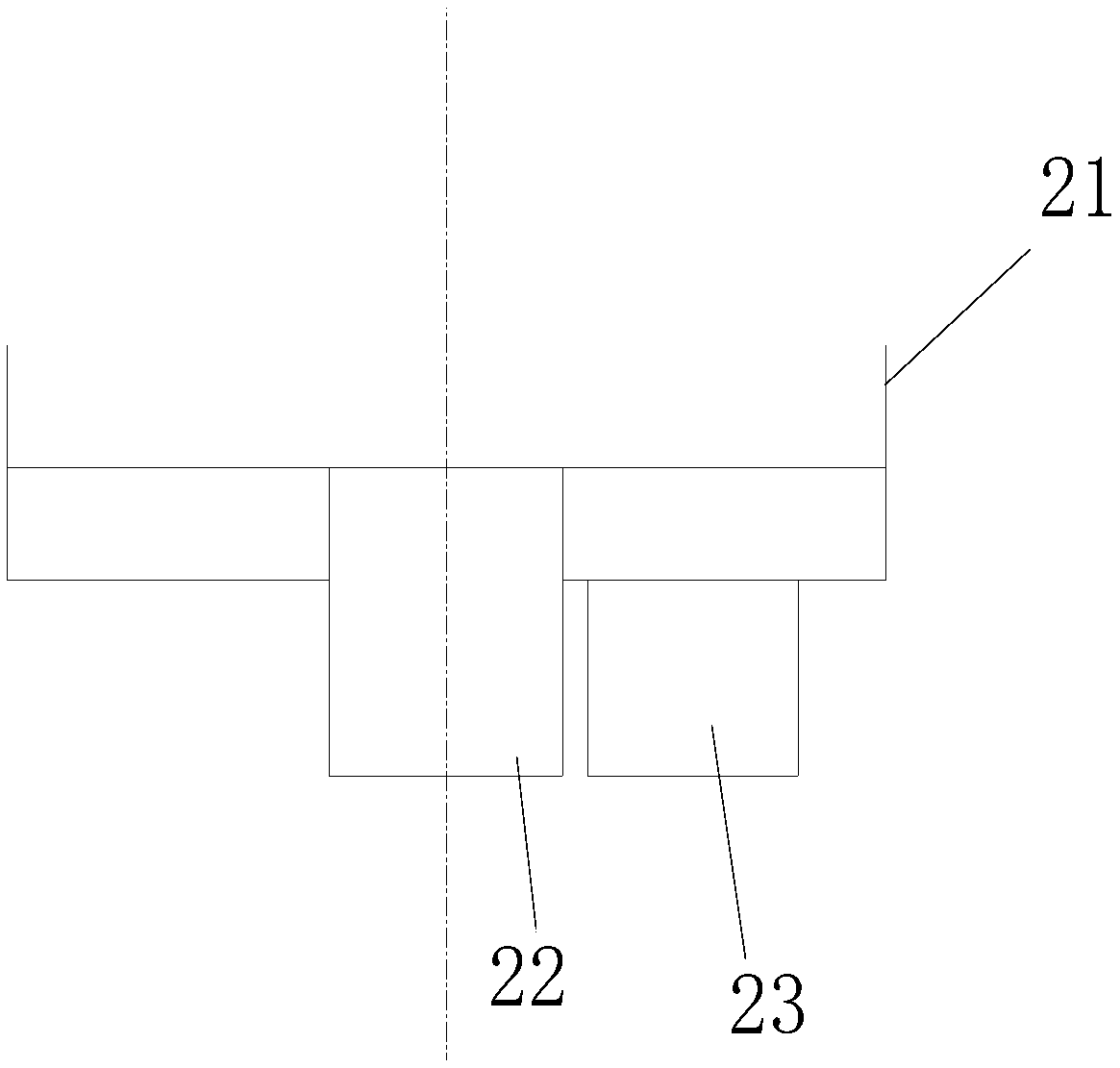

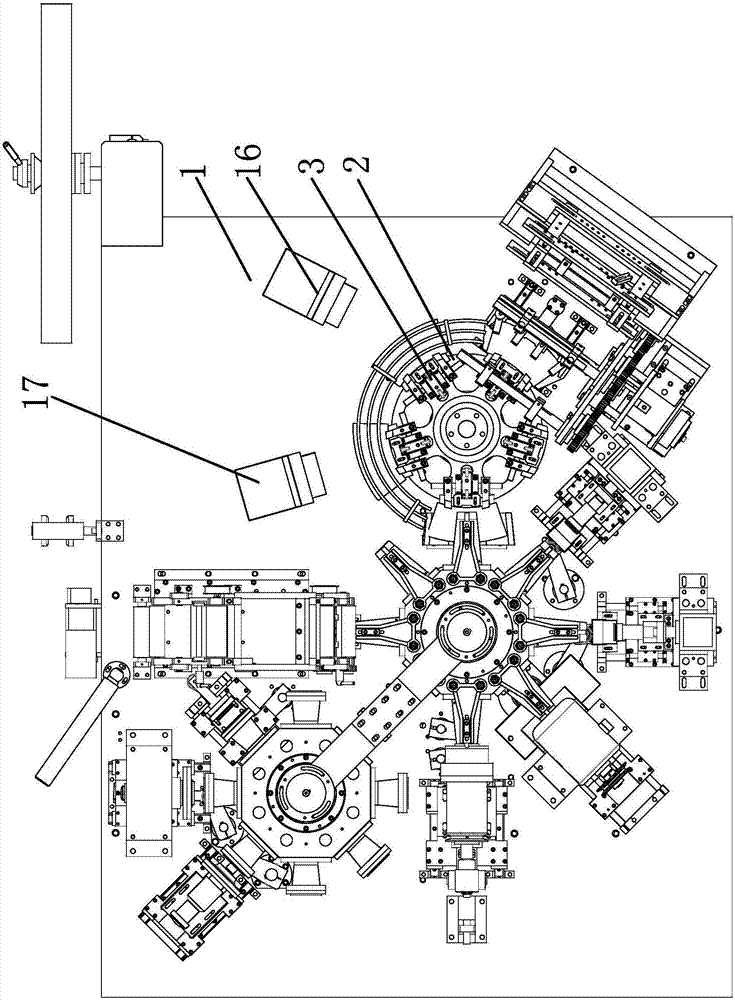

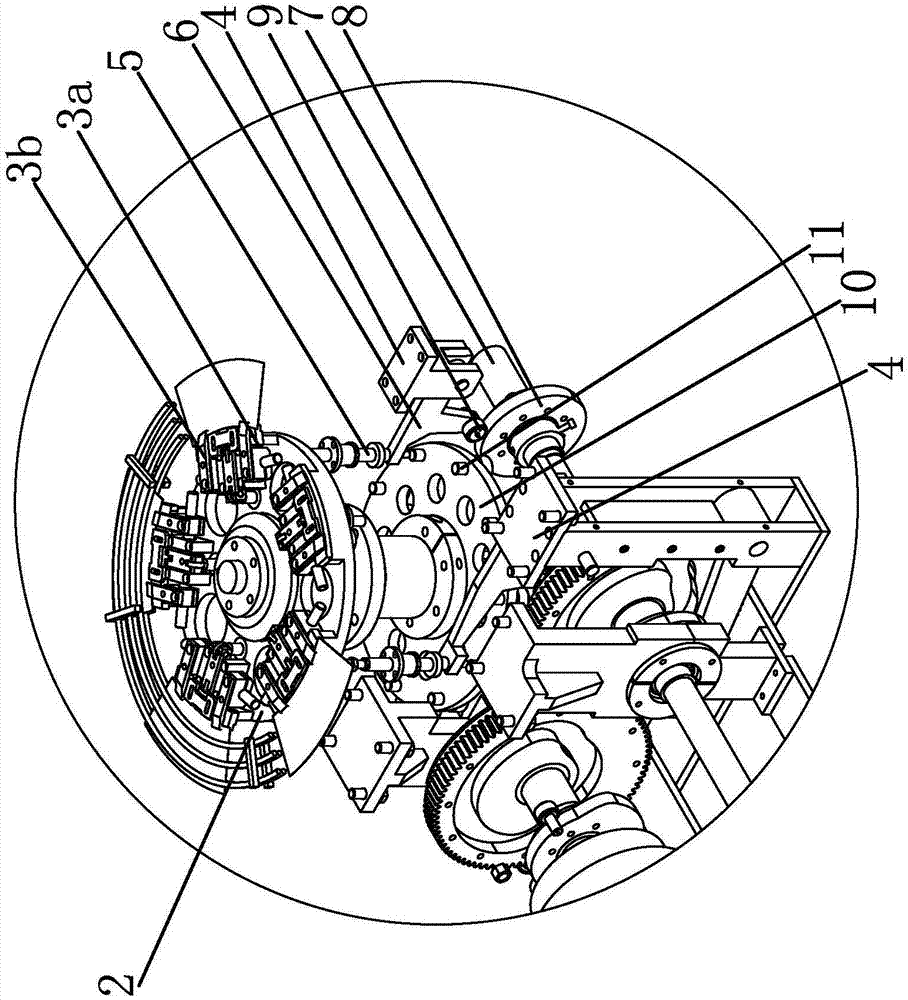

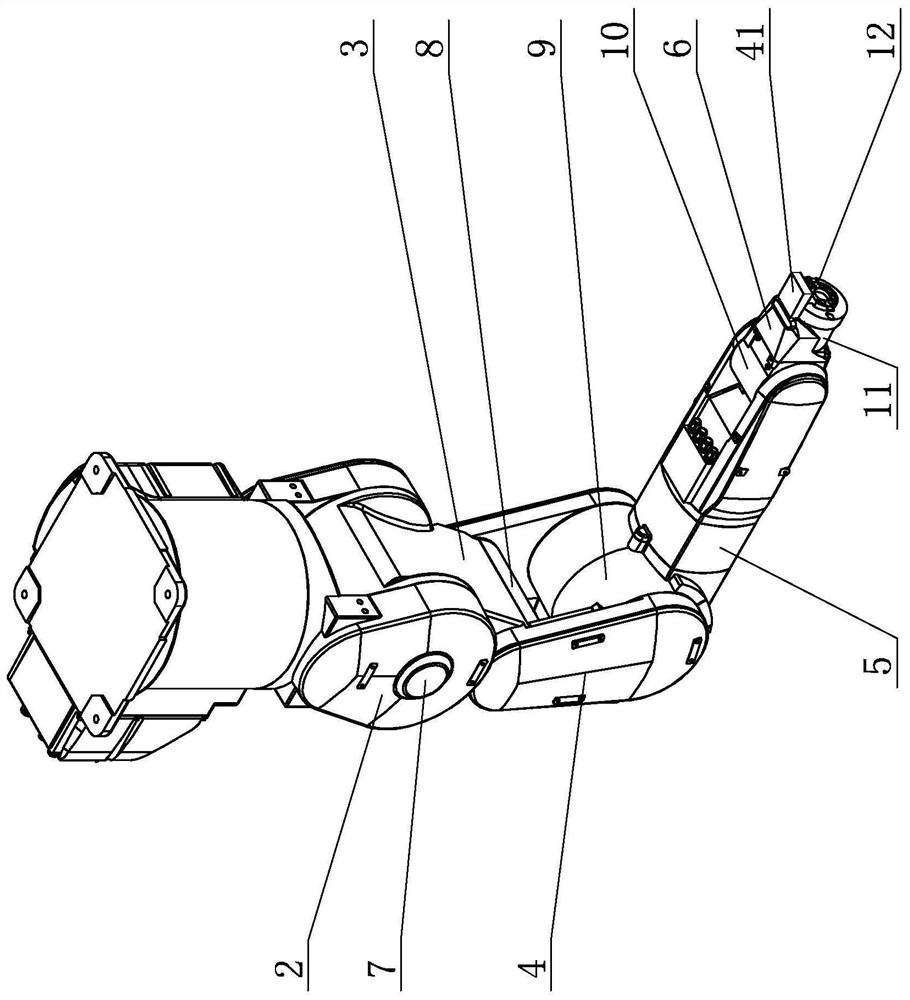

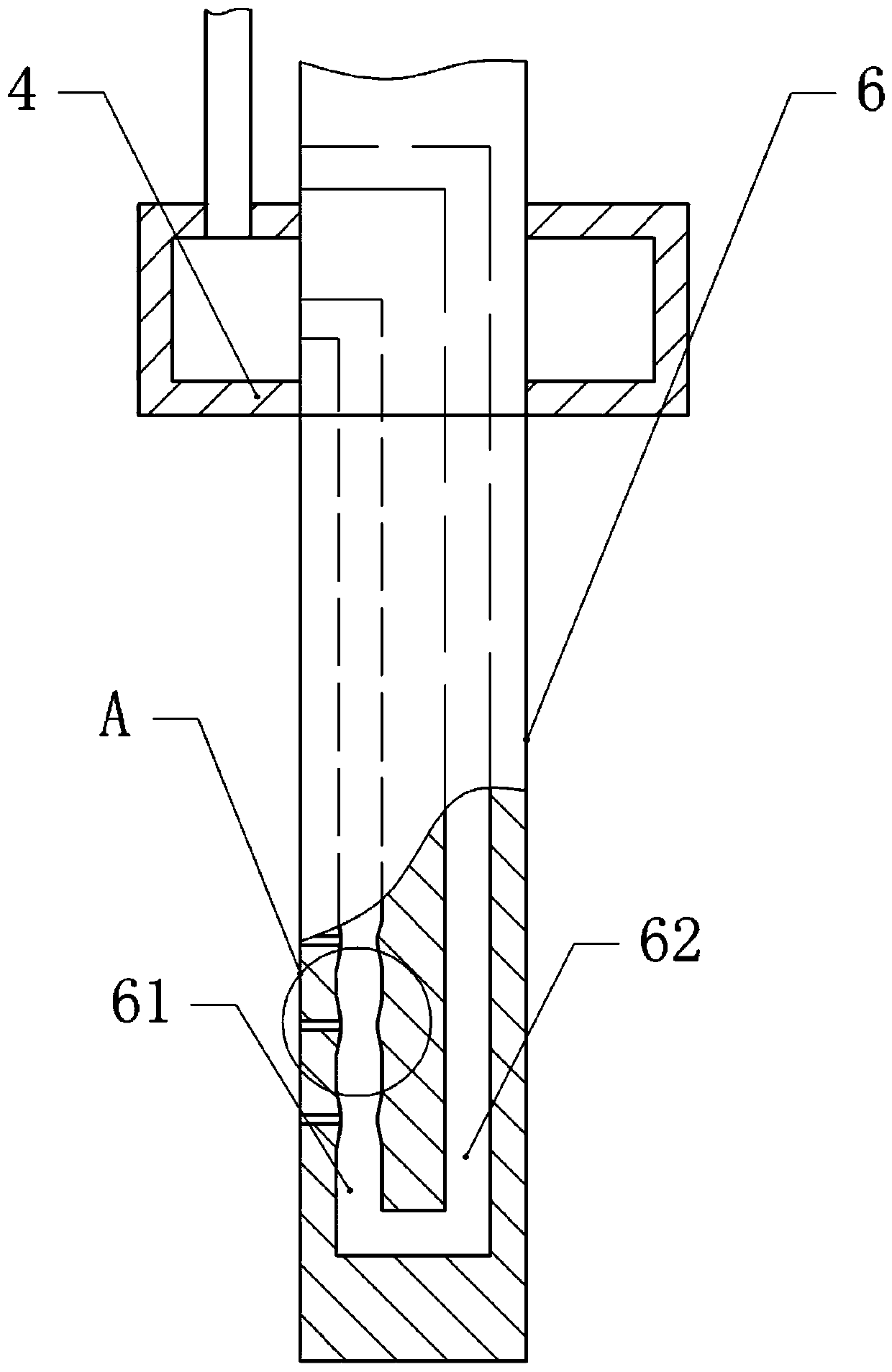

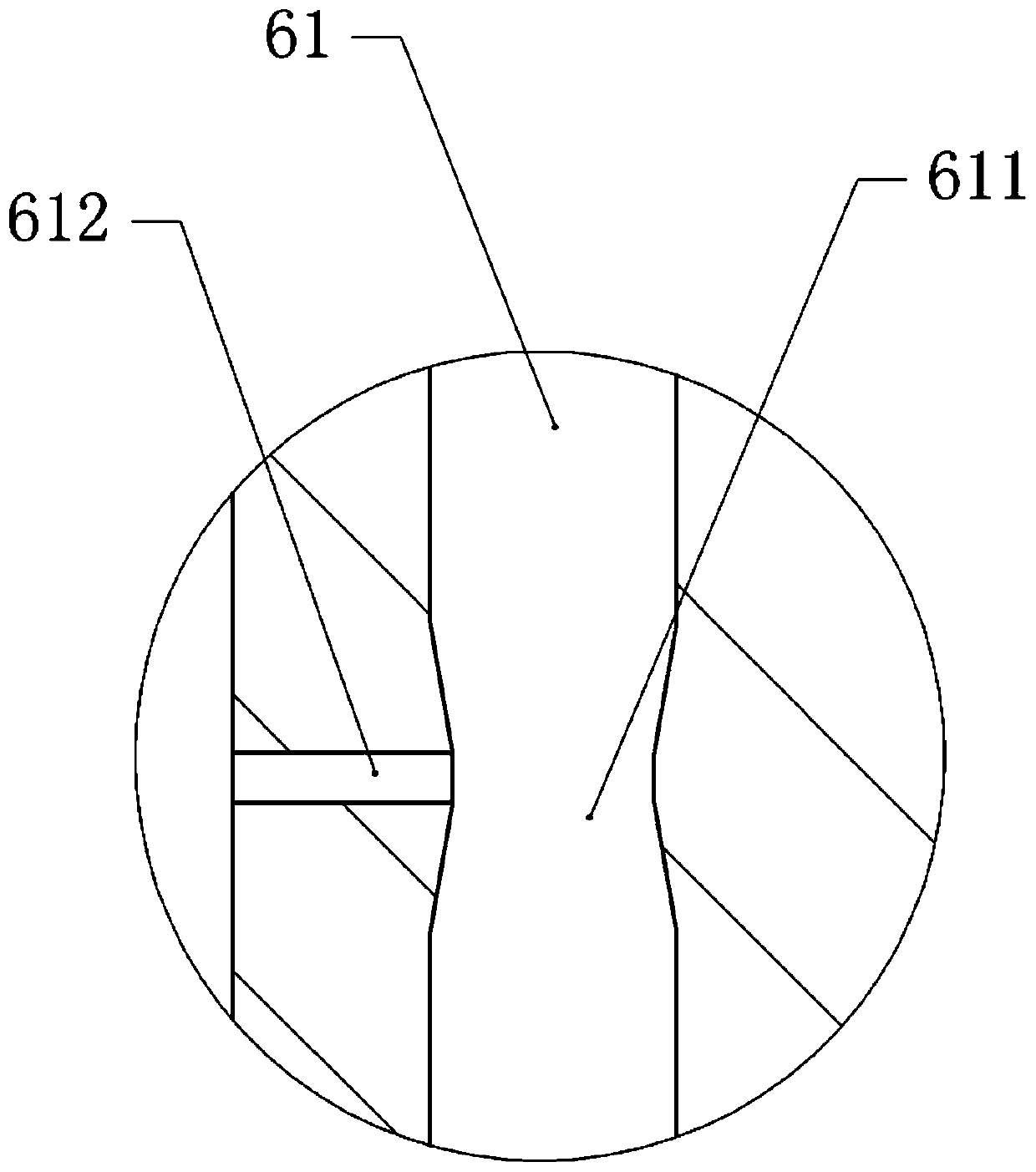

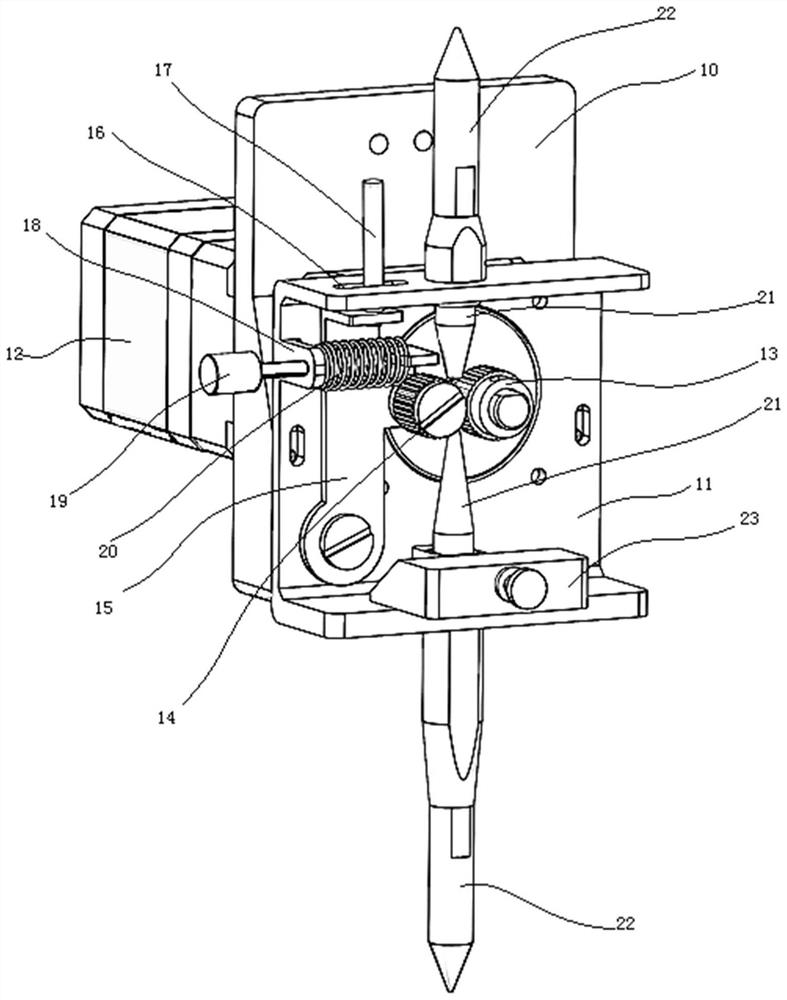

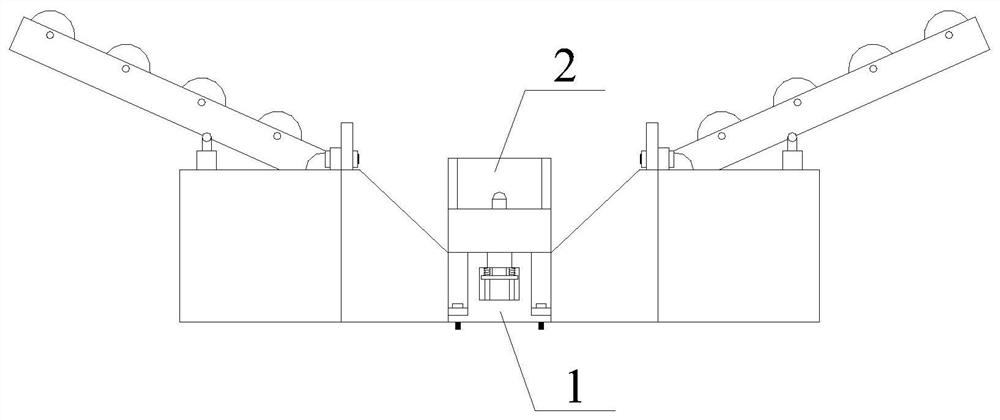

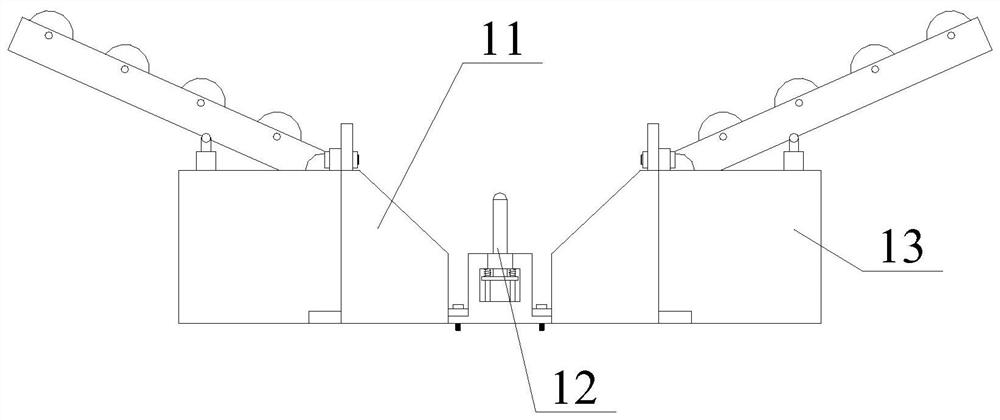

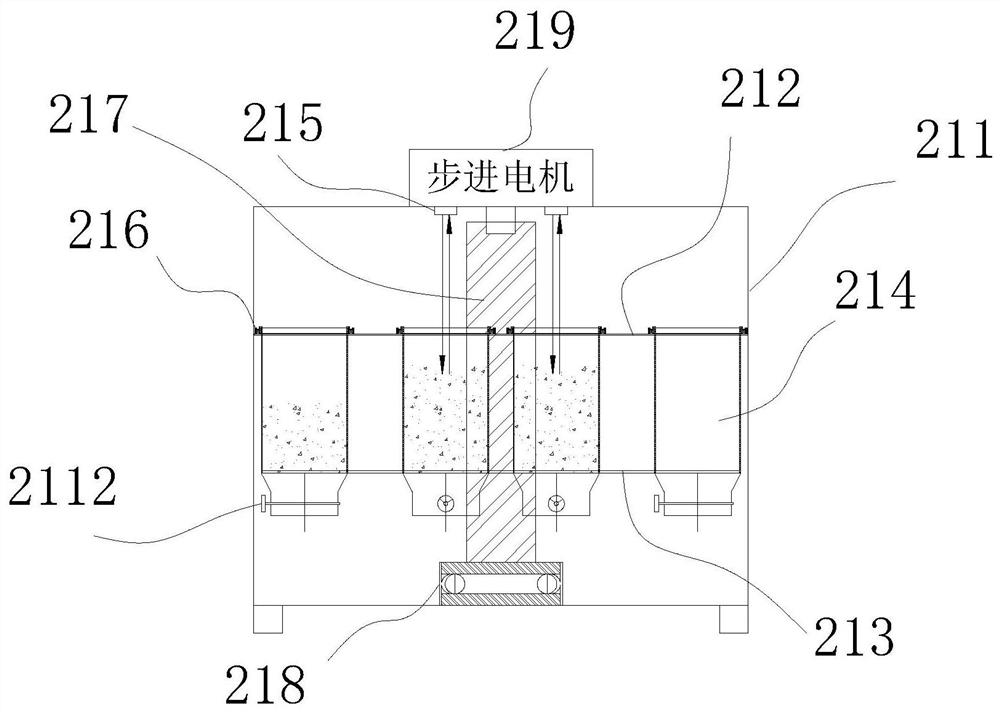

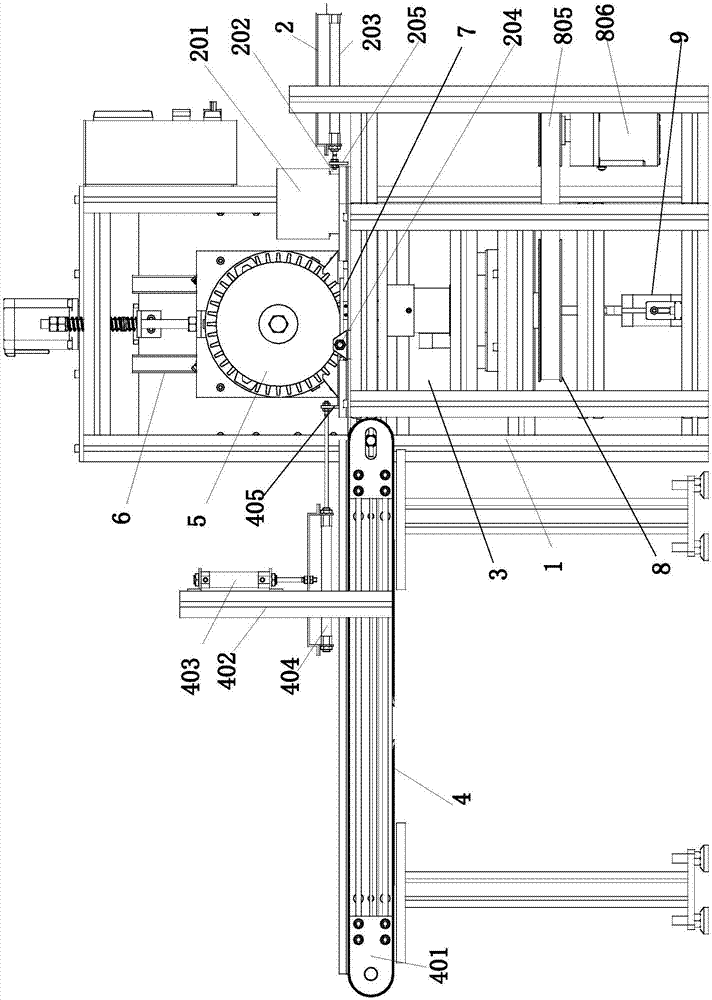

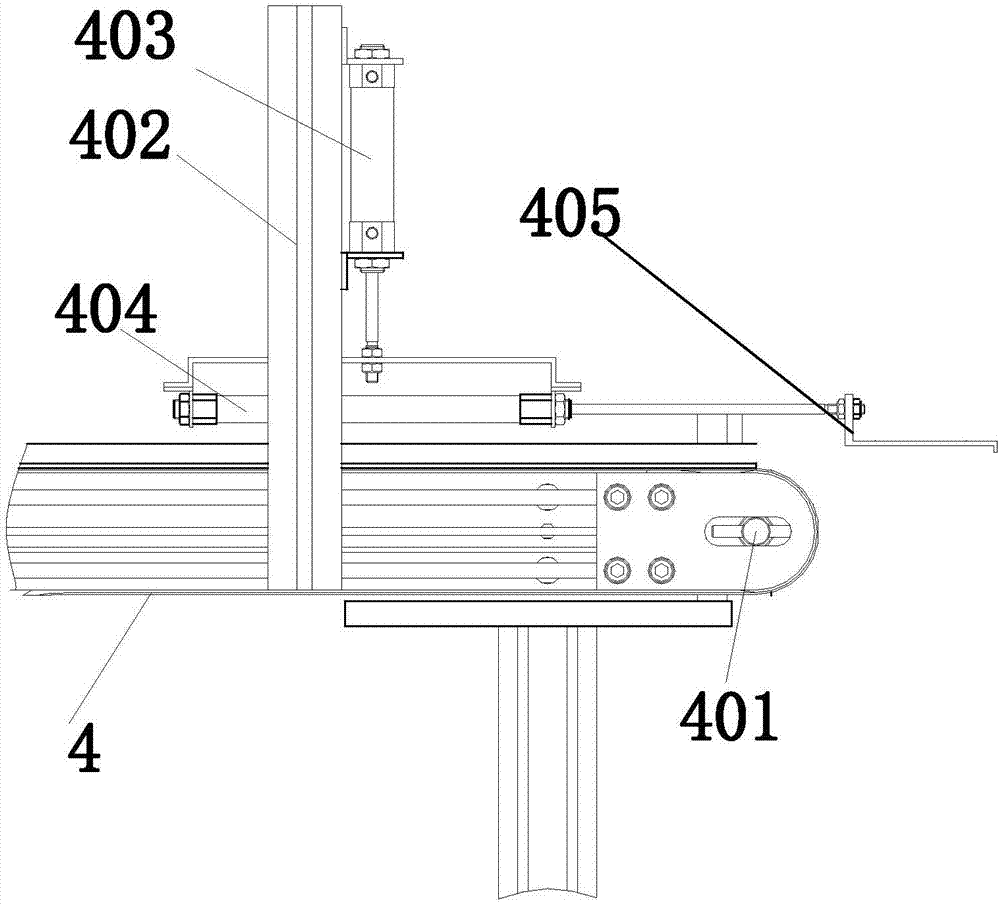

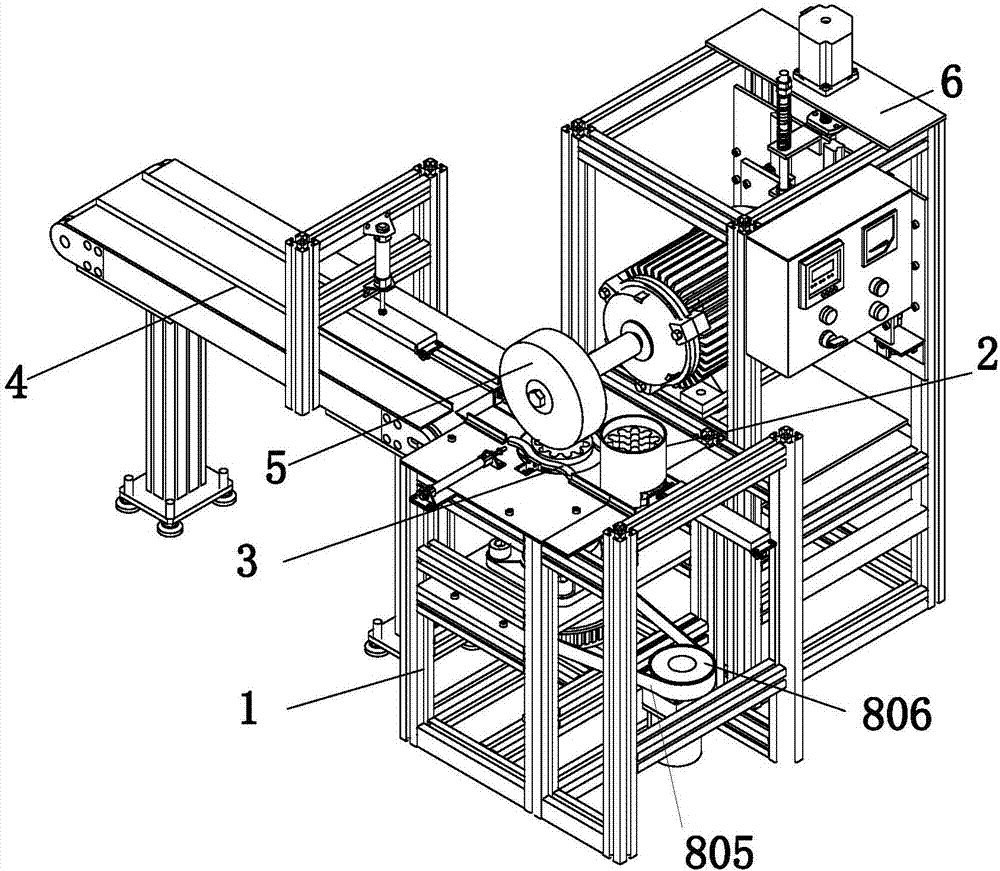

Oil pump rotor deburring device

ActiveCN108000278APrecise entryHigh positioning accuracyEdge grinding machinesGrinding feedersBiochemical engineering

The invention discloses an oil pump rotor deburring device which comprises a rack (1); a charging component (2), a clamping component (3) and a discharging component (4) are sequentially arranged on the rack (1); a grinding head (5) is arranged above the clamping component (3), and is connected with a grinding head component (6) located on the side surface of the clamping component (3); the charging component (2) comprises a charging bin (201) arranged at one end of the rack (1); a push-in port (202) is formed in the lower part of the charging bin (201); a push-in air cylinder (203) and a limiting air cylinder (204) are arranged on the two sides of the charging bin (201) correspondingly; a push plate (205) corresponding to the push-in port (202) is arranged at the protruding end of the push-in air cylinder (203); a limiting rod (206) is arranged at the protruding end of the limiting air cylinder (204); and the limiting rod (206) is located at the discharging end of the clamping component (3). The oil pump rotor deburring device has the characteristics that the burr treatment efficiency can be improved and the deburring effect can be improved.

Owner:ZHEJIANG UNIV CITY COLLEGE

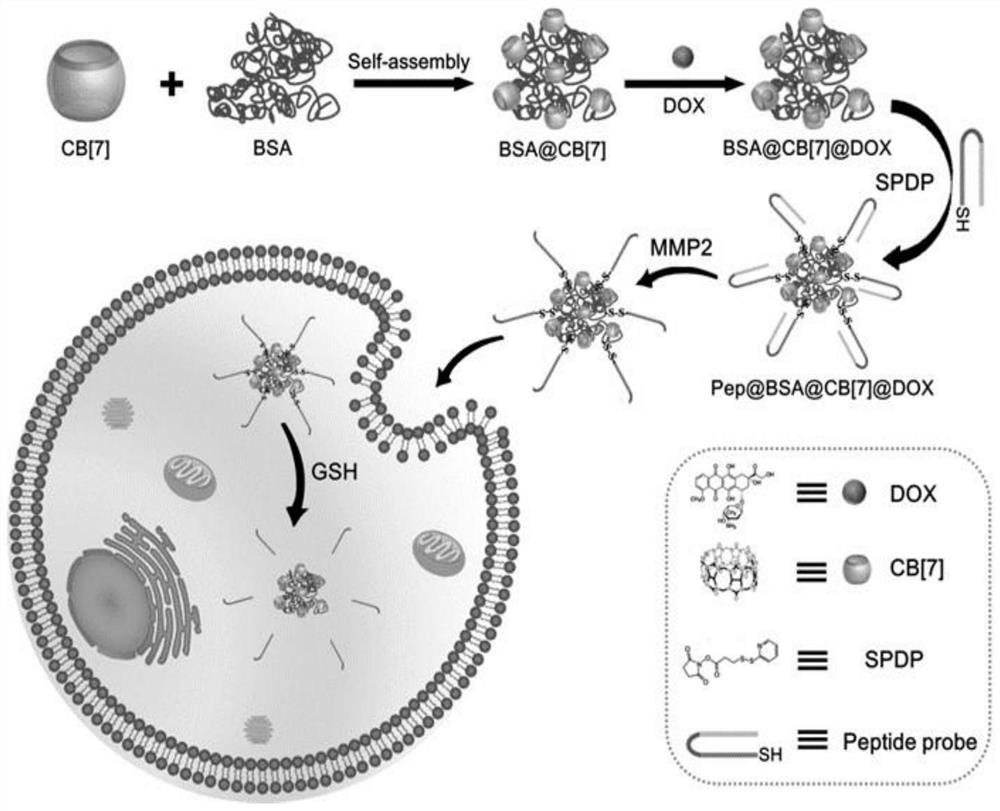

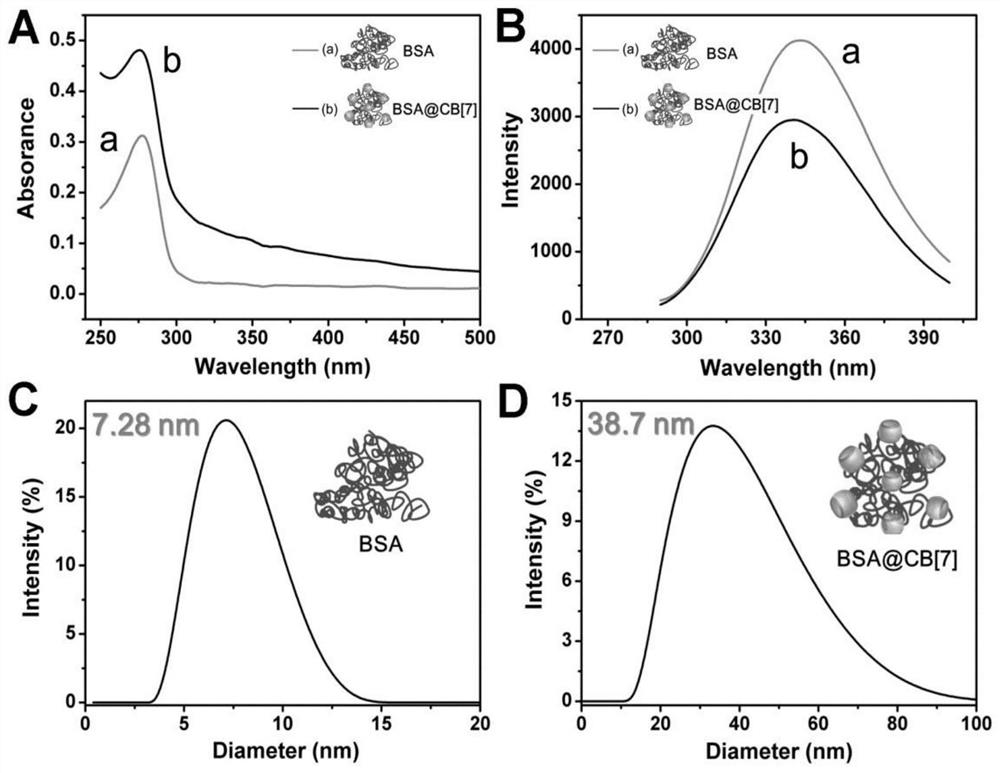

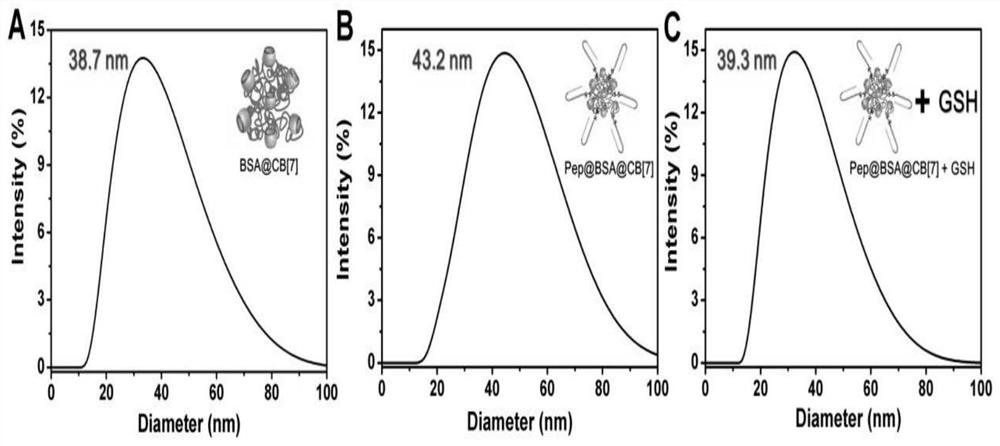

Tumor-targeting drug carrier as well as preparation method and application thereof

ActiveCN111789963AGood water solubilityExtended half-lifeOrganic active ingredientsMacromolecular non-active ingredientsDrug carrierBovine serum albumin

The invention discloses a tumor-targeting drug carrier, a preparation method and application of the tumor-targeting drug carrier to preparation of an antitumor drug. The antitumor targeting drug carrier is synthesized from cell penetrating peptide, bovine serum albumin and cucurbit[n]uril. The cell penetrating peptide has a cell penetrating functional zone and a shielding zone after modification,the cell penetrating functional zone is activated in a special microenvironment of tumor cell tissue, and the drug carrier is mediated to carry the drug to enter tumor cells and play an antitumor effect. Compared with exclusively used antitumor chemotherapy drugs, the drug carrier combined with the antitumor drug has good tumor cell specificity and safety and has good application prospects.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com