Specific-gravity stoner for rice

A stone removal machine and specific gravity technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problems of inability to remove sediment particles and affect grain quality, and achieve the goal of improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

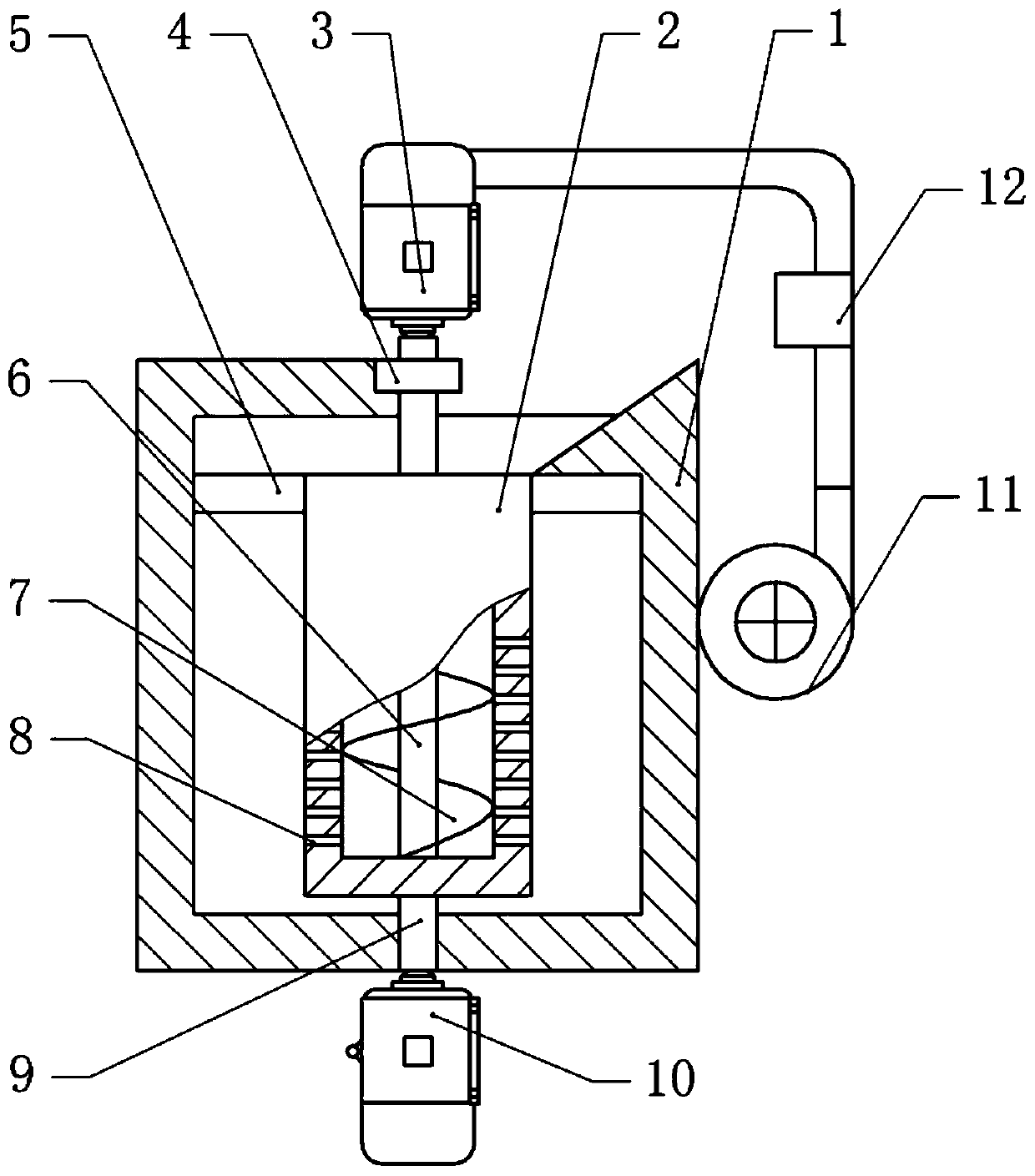

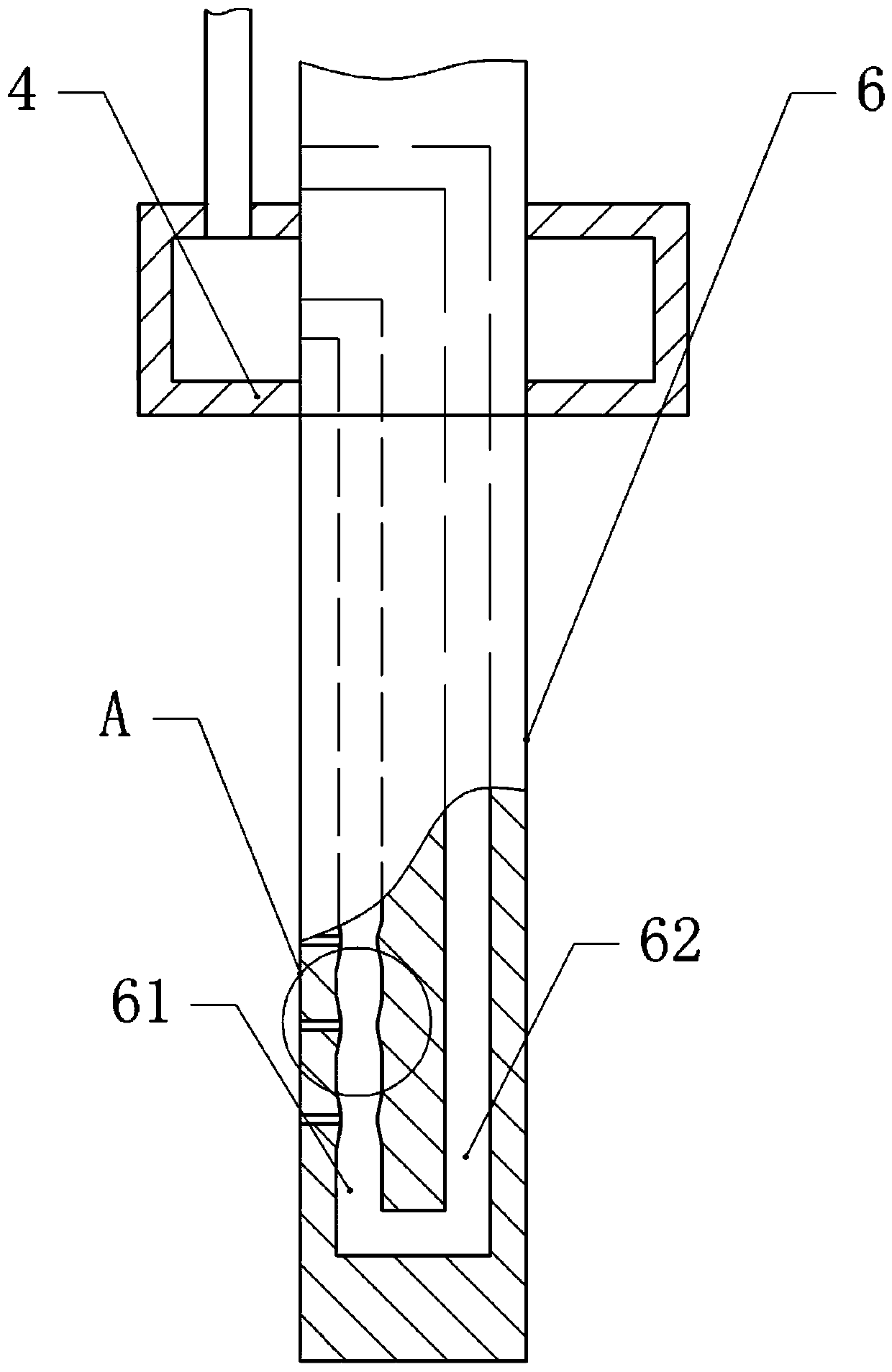

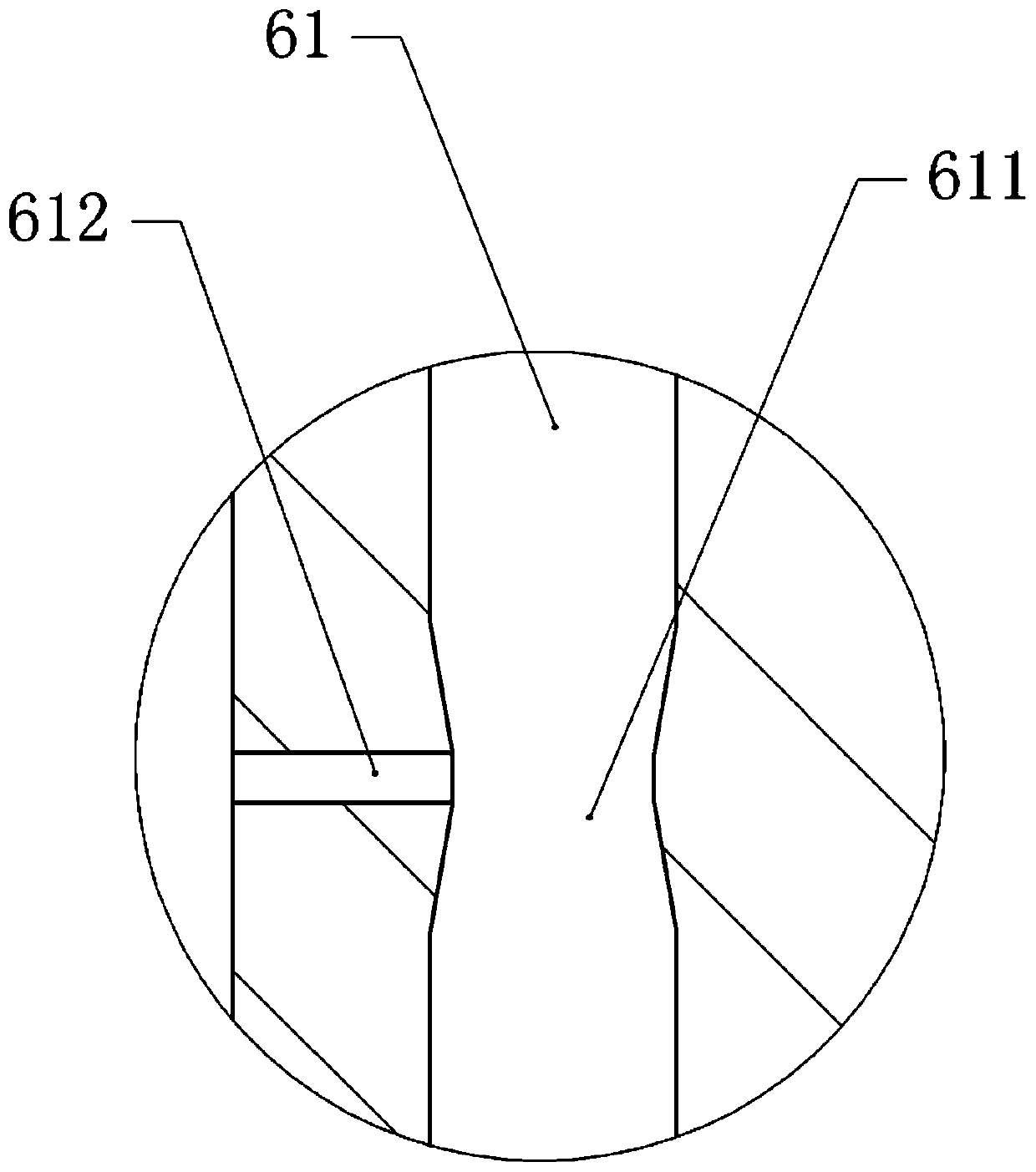

[0025] A specific gravity stoner for rice, basically as attached figure 1 , attached figure 2 And attached image 3 Shown, comprise collection box 1 and be positioned at the separating barrel 2 in collecting box 1, be provided with annular groove on the outer wall of the top of separating barrel 2, be provided with guide rod 5 in collecting box 1, guide rod 5 is two . One end of the guide rod 5 is fixed on the collection box 1, and the other end of the guide rod 5 extends into the groove and is slidably connected with the groove, so that the collection box 1 and the separation bucket 2 can rotate relatively, and the side of the separation bucket 2 Separation holes 8 are provided on the wall. When the separation barrel 2 rotates, the guide rod 5 limits the separation barrel 2 to prevent the separation barrel 2 from shifting under the action of centrifugal force when the separation barrel 2 rotates.

[0026] An air motor 3 is arranged above the collecting box 1 , and a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com