Translation type automatic mold replacement mechanism

An automatic mold change, translation technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of low device tightness, difficulty in ensuring accurate mold replacement, high precision, etc., to achieve accurate transfer process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

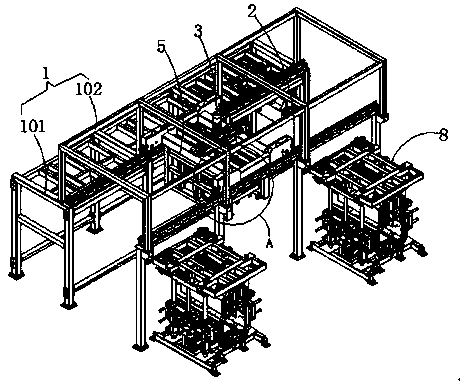

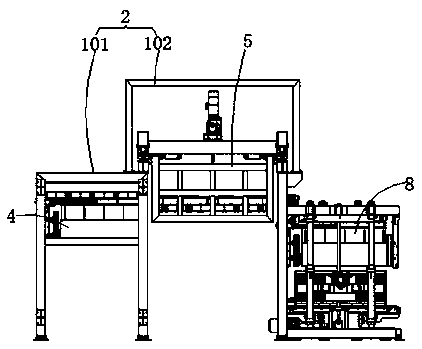

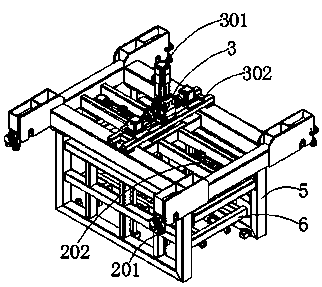

[0029] like Figure 1-5 As shown, a translational automatic mold change mechanism includes a support frame 1, a translation transmission mechanism 2, and a vertical transmission mechanism 3. The support frame 1 includes a left frame 101 and a right frame 102, and the inside of the left frame 101 is installed with Foaming equipment 4, the inside of the right frame 102 is movable and installed with a mold changing trolley 5 through the translation transmission mechanism 2, and the inside of the mold changing trolley 5 is provided with a mold groove 6, and a mold 7 is slidably installed inside the mold groove 6, and the right frame 102 is provided with a mold library 8 on the side away from the left frame 101. The translation transmission mechanism 2 includes translation rollers 201 installed on the left and right sides of the mold changing trolley 5. A translation motor 202 is installed inside the mold changing trolley 5, and the translation motor 202 The output end of the outpu...

Embodiment 2

[0036] Such as Figure 1-9 As shown, a translational automatic mold change mechanism includes a support frame 1, a translation transmission mechanism 2, and a vertical transmission mechanism 3. The support frame 1 includes a left frame 101 and a right frame 102, and the inside of the left frame 101 is installed with Foaming equipment 4, the inside of the right frame 102 is movable and installed with a mold changing trolley 5 through the translation transmission mechanism 2, and the inside of the mold changing trolley 5 is provided with a mold groove 6, and a mold 7 is slidably installed inside the mold groove 6, and the right frame 102 is provided with a mold library 8 on the side away from the left frame 101. The translation transmission mechanism 2 includes translation rollers 201 installed on the left and right sides of the mold changing trolley 5. A translation motor 202 is installed inside the mold changing trolley 5, and the translation motor 202 The output end of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com