Patents

Literature

60results about How to "Avoid production delays" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

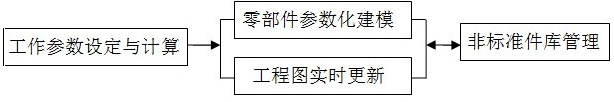

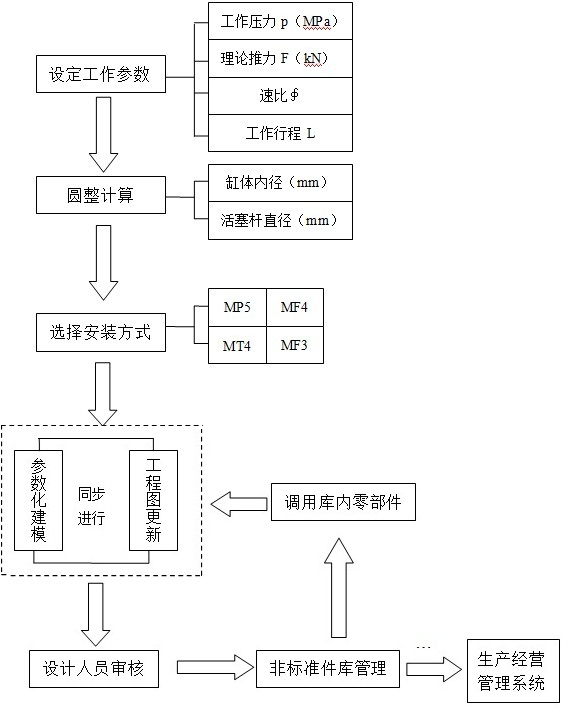

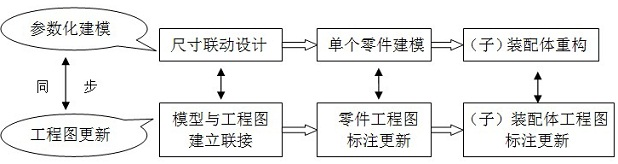

Parameterization designing system for non-standard parts of hydraulic cylinders and method thereof

InactiveCN102567593AShorten the timeReduce excess spaceSpecial data processing applicationsHydraulic cylinderData information

The invention discloses a parameterization designing system for non-standard parts of hydraulic cylinders and a method thereof. The parameterization designing system for non-standard parts of the hydraulic cylinders comprises a work parameter setting and computing module, a part parameterization modeling module, an engineering drawing linkage updating module and a non-standard part warehouse management module. The method includes steps of creating a part model in a parameterization manner according to the set work parameters and conditions of the hydraulic cylinder and assembling integrally, and meanwhile updating two-dimensional engineering drawings automatically, and finally, realizing database management of developed non-standard parts so as to transfer, optimize and produce the non-standard parts conveniently. The parameterization designing system and the method thereof have the advantages of accuracy and high efficiency in design and convenience and reliability in management, cost for time and space of optimization of production process of the hydraulic cylinder is reduced, and the parameterization designing system can exchange data information with an operation management system of production enterprises and realize paperless working from development and production of non-standard parts.

Owner:HOHAI UNIV CHANGZHOU

Method for forging flat steel by using universal hammerhead

ActiveCN102581187AAvoid reheatingReduce impact on production scheduleMetal-working apparatusHeating furnaceForging

A method for forging flat steel by using universal hammerheads comprises feeding red steels to a chamber heating furnace, quickly heating to 1170+ / -50 DEG C, holding for 2h, performing cogging at a single-edge reduction amount of 40-45mm and a frequency of 180 times / min, forging billet material into an intermediate billet with a diameter of 440mm after three-pass forging, forging from a machine A to a machine B at a reduced frequency of 90 times / min, a single-edge reduction amount of the R group of hammerheads of 30-40mm, a forging force of the R group of hammerheads of 800-900t, a single-edge reduction amount of the L group of hammerheads of 3-5mm and a forging force of the L group of hammerheads of 150-200t, forging from the machine B to the machine A at the reduced frequency of 90 times / min, a single-edge reduction amount of the L group of hammerheads of 30-40mm, a forging force of the L group of hammerheads of 800-900t, a single-edge reduction amount of the R group of hammerheads of 3-5mm and a forging force of the R group of hammerheads of 150-200t, performing final-pass forging at a single-edge reduction amount of 2-5mm, a forging force of 100-150t and a finish forging temperature not lower than 850 DEG C, and shaping four edges of the forging. The once-heating of flat steel forging is effectively controlled, the once qualified rate of the method through test is 100%, the production efficiency is improved, and at the same time the cost is lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

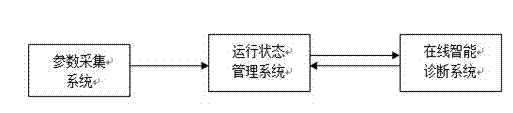

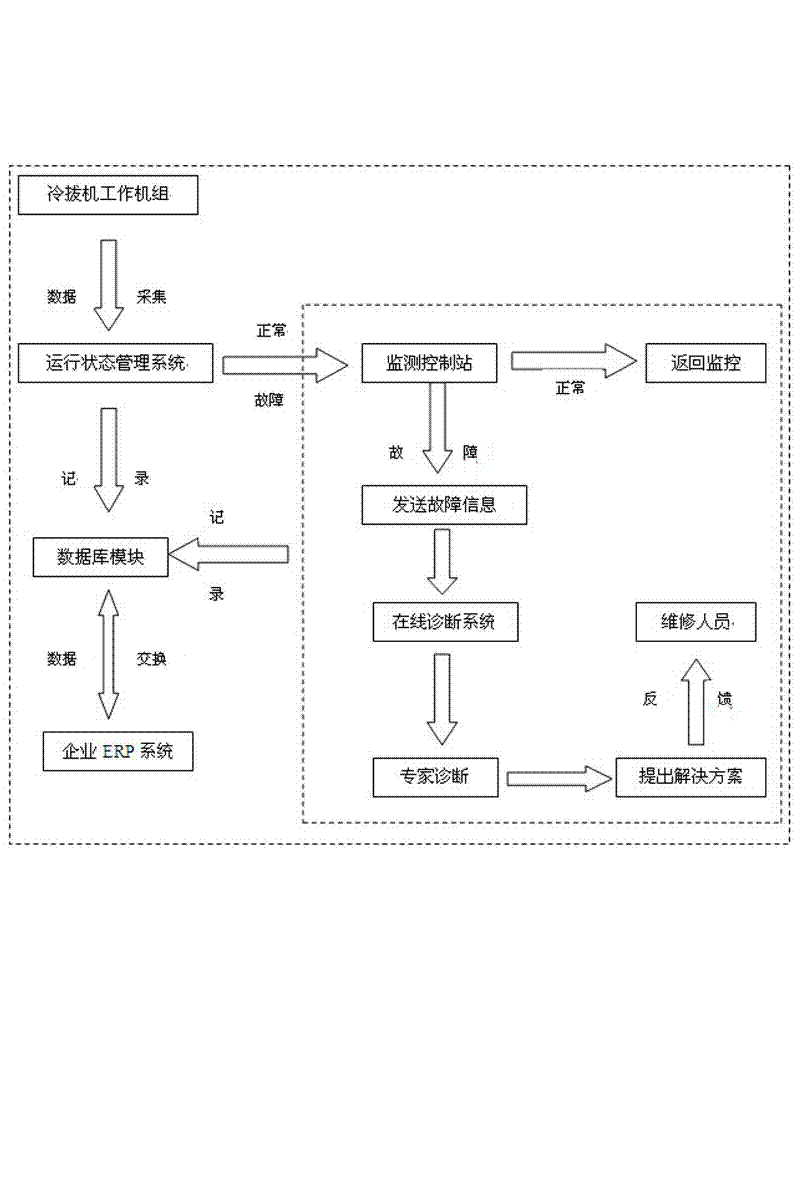

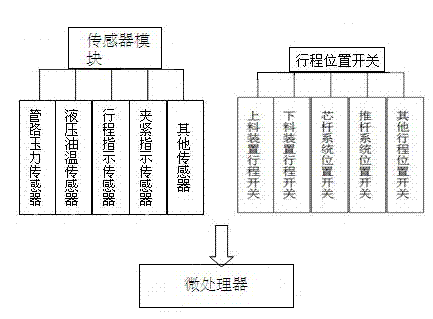

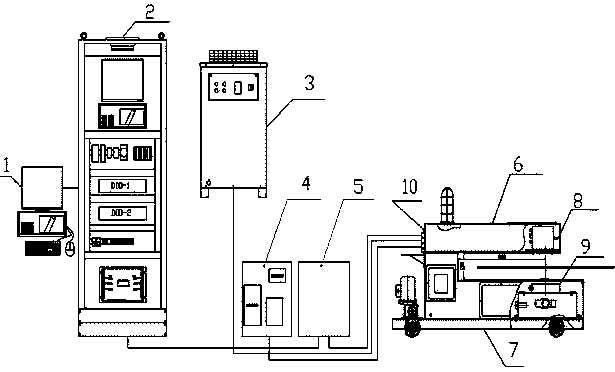

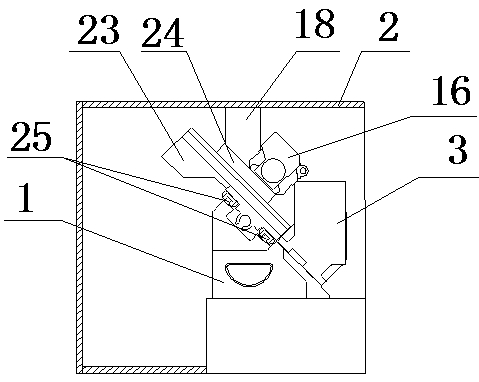

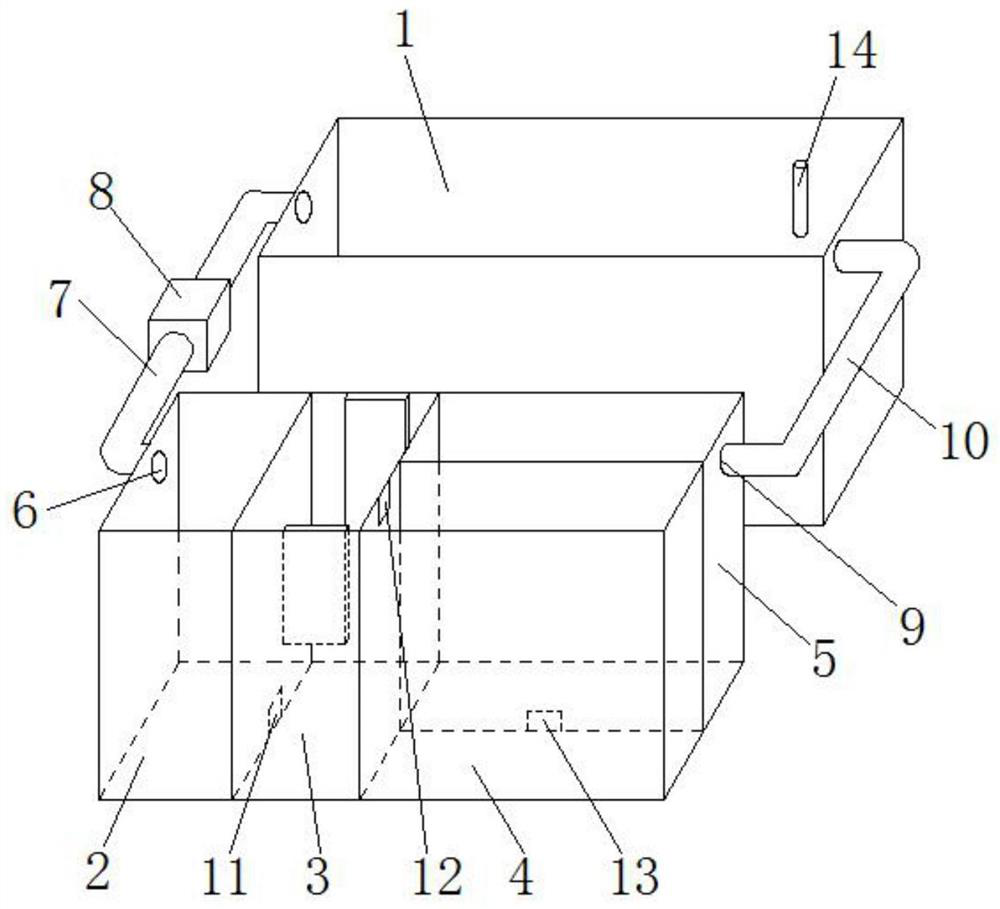

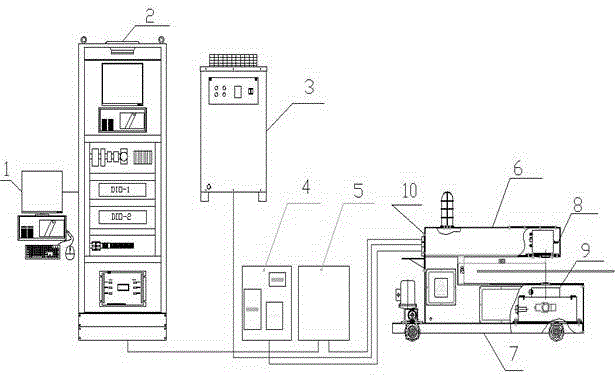

Online real-time diagnosis service system and method for hydraulic cold-drawing machine

InactiveCN102339030AAvoid Equipment DamageProduction delayProgramme controlComputer controlService systemResource planning

The invention discloses an online real-time diagnosis service system and an online real-time diagnosis service method for a hydraulic cold-drawing machine. The online real-time diagnosis service system for the hydraulic cold-drawing machine comprises a parameter acquisition system, a running state management system and an online diagnosis system, wherein by using an online monitoring mode, running management and fault maintenance of the hydraulic cold-drawing machine can be realized, and the online real-time diagnosis service system has the advantages of convenience for management, reliability and timeliness and high efficiency in maintenance; furthermore, a production delay phenomenon caused by equipment fault can be avoided effectively, historical data can be supplied to an optimized cold-drawing processing technology, and traceability and the like of the data can be realized; and data information exchange with an entrise resource planning (ERP) system of an enterprise can be realized, so online diagnosis service can be realized.

Owner:HOHAI UNIV CHANGZHOU

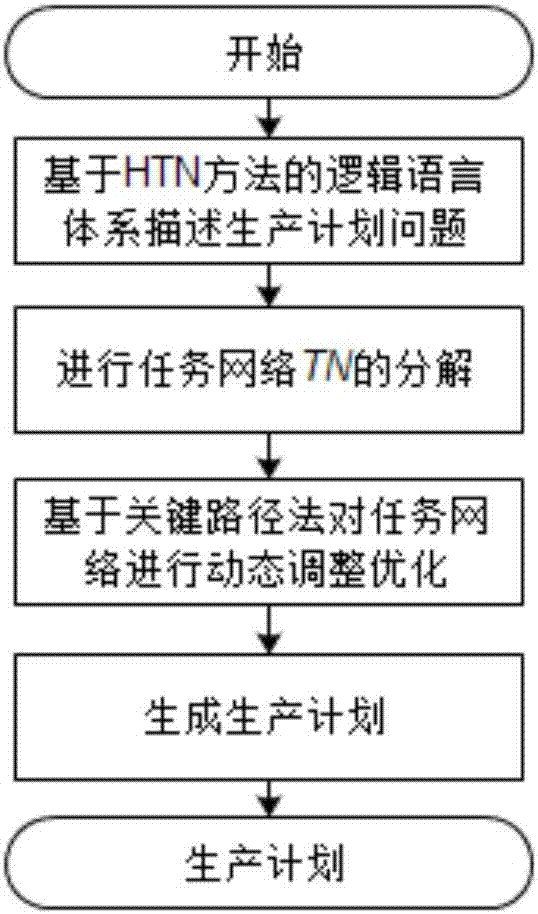

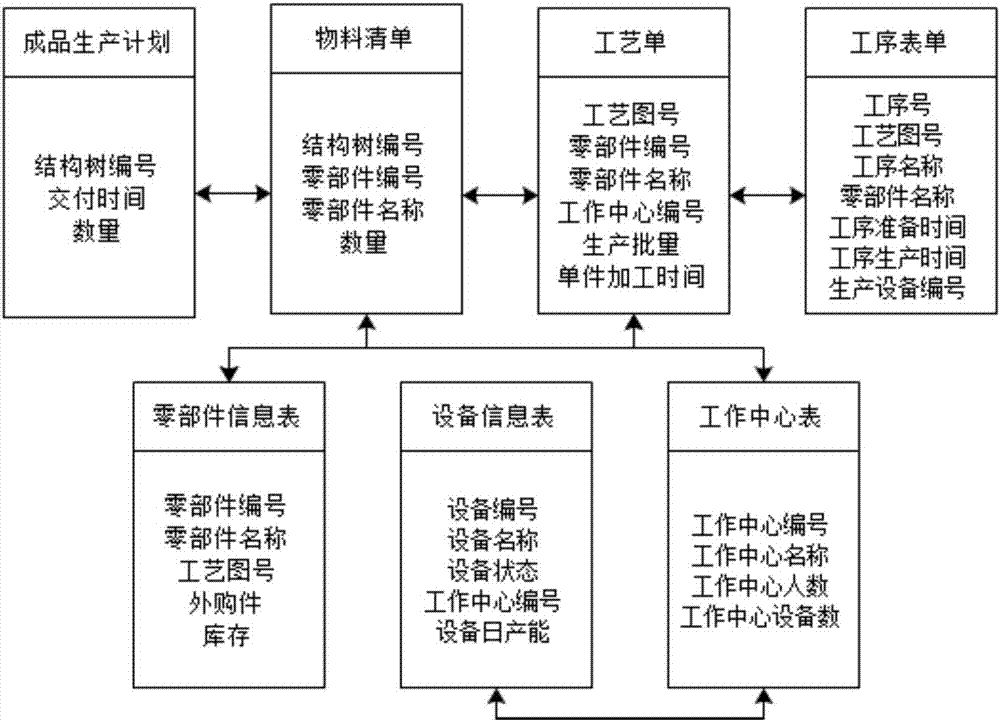

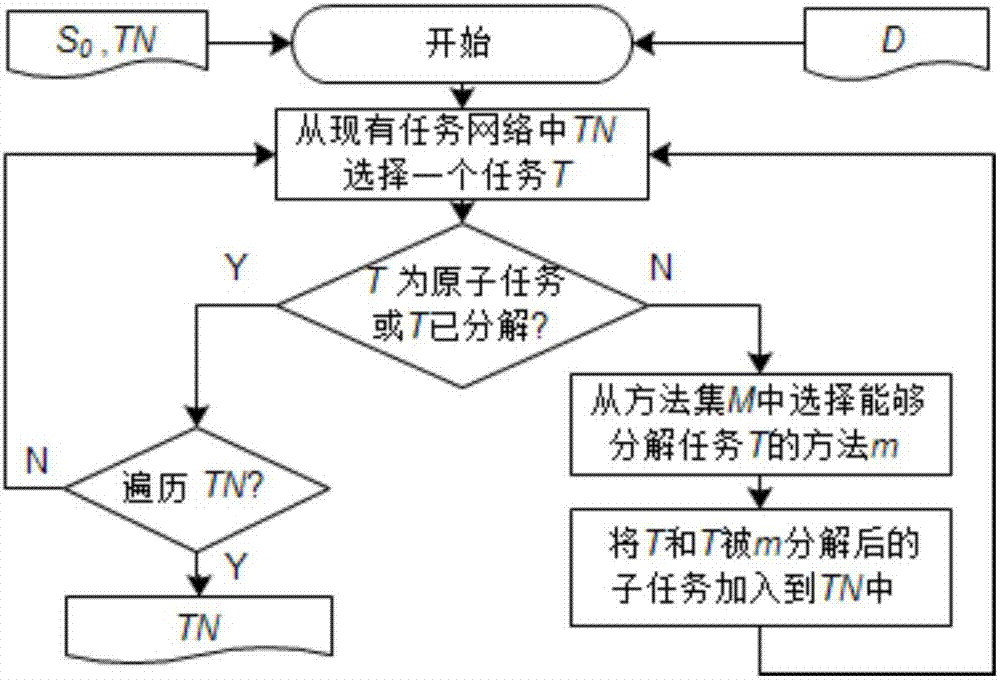

Hierarchical task network and key path method-based task optimization method

InactiveCN107341596AAvoid production conflictsAvoid production delaysResourcesTask networkProgram planning

The invention discloses a hierarchical task network and key path method-based task optimization method. The method comprises the steps of building a workshop production plan problem quadruple model through an HTN planning method-based logic language system and decomposing a task network; then performing dynamic adjustment optimization on the task network based on a key path method; and finally generating a production plan according to the optimized task network TN. According to the method, a production plan problem model is described by an HTN-based logic language, so that the problem that an actual production plan problem is difficultly modeled and is difficultly described by using a formalized language is solved; production capacity and duration are considered, so that production conflicts and excess tasks in production execution and production tardiness can be avoided; and better guidance and executability are achieved.

Owner:SHANGHAI JIAO TONG UNIV +1

Numerical control machine tool

ActiveCN111113067AFirmly connectedEasy inspection and maintenanceBatteries circuit arrangementsMeasurement/indication equipmentsNumerical controlEngineering

The invention provides a numerical control machine tool. A main plate, an auxiliary plate and a balance control box are included. The left side and the right side of the top surface of the main plateare provided with a left guide rail and a right guide rail correspondingly. A front wall and a rear wall are arranged on the top surfaces of a front movable base and a rear movable base correspondingly. A motor is arranged on the rear side face of the front wall, the power output end of the motor is provided with a power shaft, a front chuck is fixed to the rear end portion of the power shaft, a rear chuck is arranged at the front end portion of a connecting column, and the front chuck and the rear chuck are matched to achieve fixing of a to-be-machined workpiece. An upper connecting rod is arranged on the left side of the lower surface of the upper connecting plate, a numerical control tool is connected to the bottom of a tool base, and a collecting chamber for receiving iron scraps generated in the production process is arranged below the numerical control tool. The disclosed technical scheme effectively solves the technical problems that in the prior art, the capability of power recycling for storage battery power supply, intelligent deceleration braking, automatic horizontal state adjusting and the like is not achieved, and popularization and application of the device are facilitated.

Owner:泰州尚诚数控科技有限公司

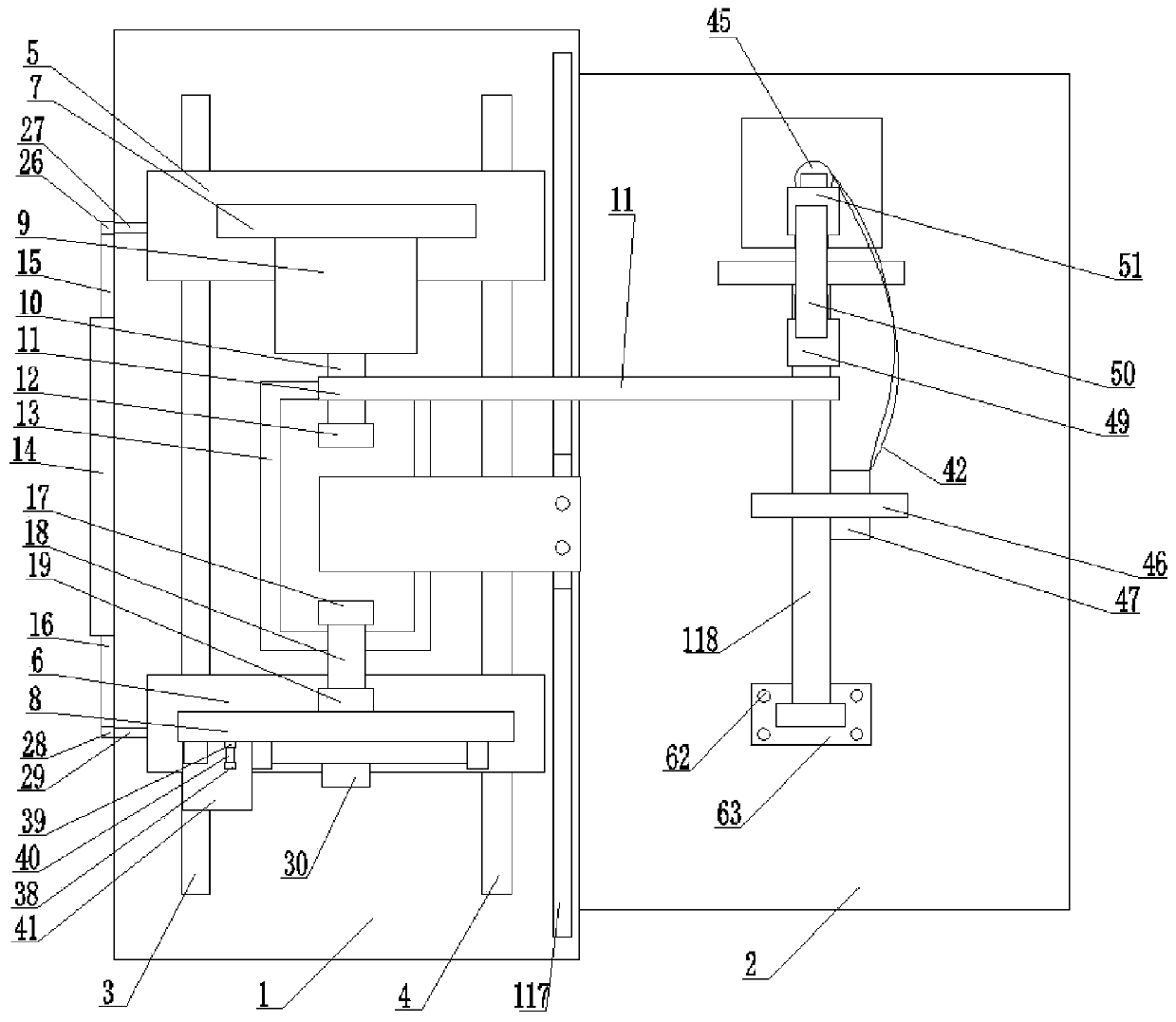

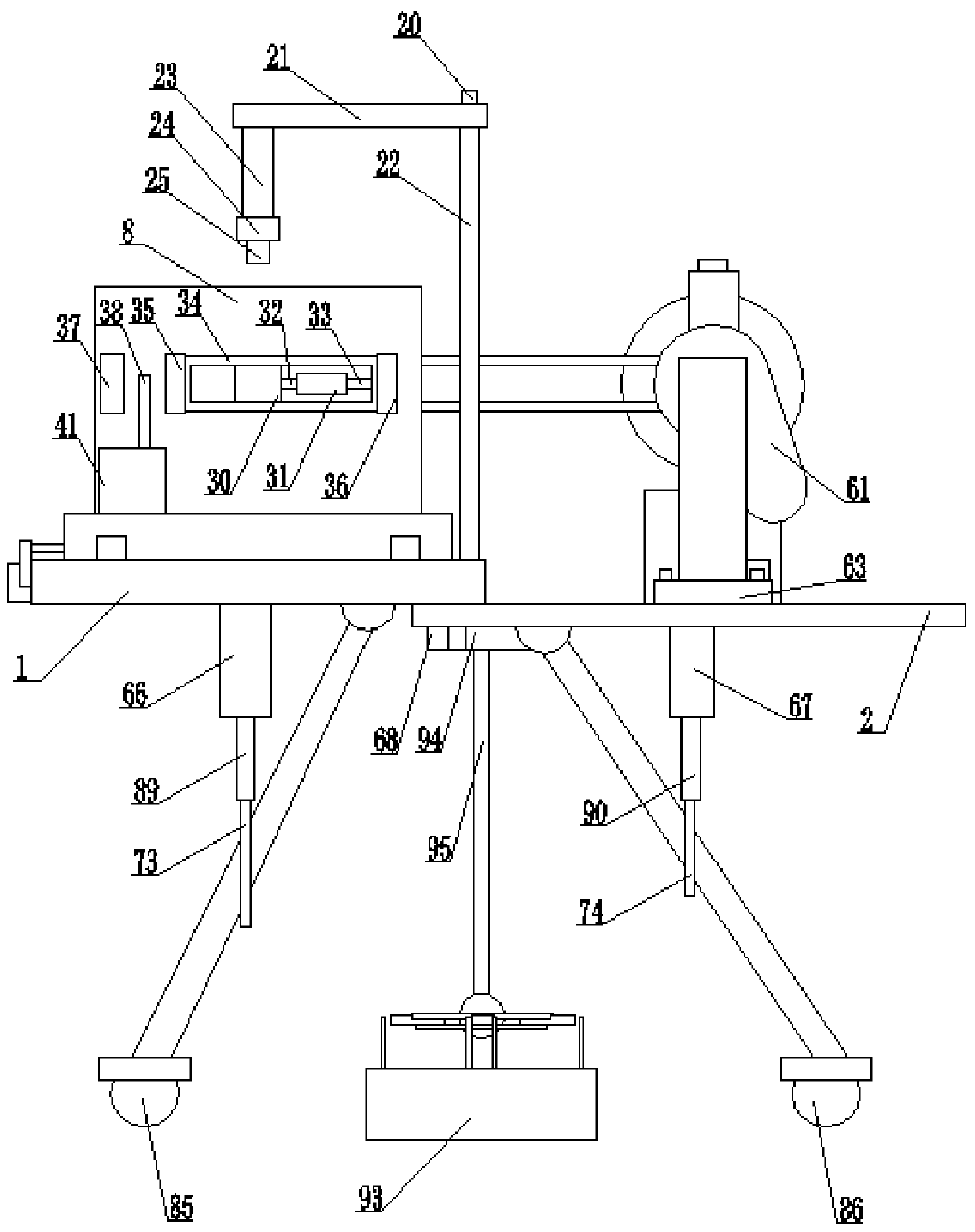

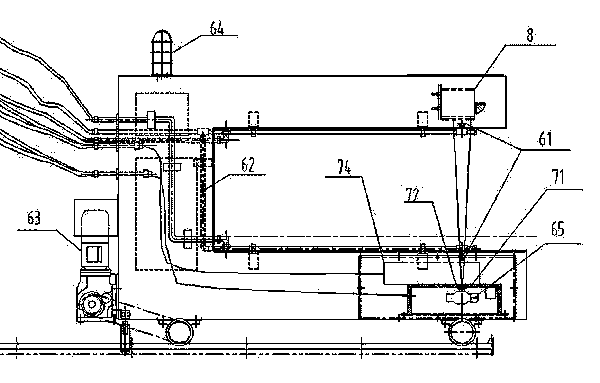

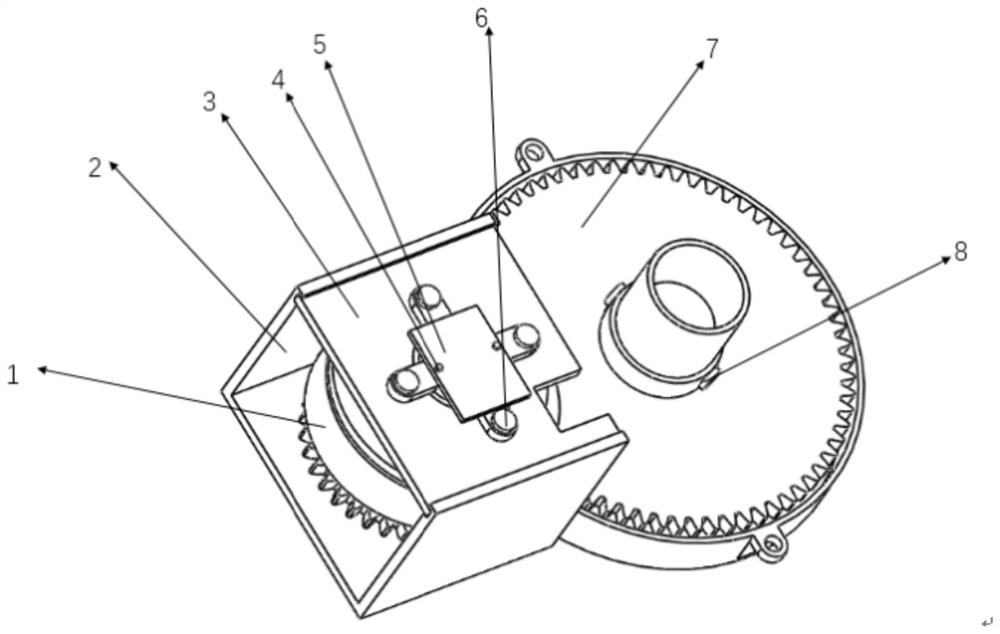

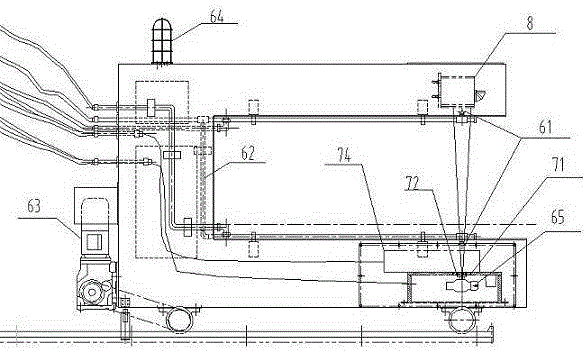

Thickness gauge and using and overhauling methods thereof

ActiveCN103968785AFlexible movementSo as not to damageUsing wave/particle radiation meansEngineeringDrive motor

The invention discloses a thickness gauge and using and overhauling methods thereof, and relates to the field of measuring equipment. The thickness gauge comprises a control terminal, a main electric cabinet and a water-cooling tank, and the control terminal is connected with the main electric cabinet. A C-frame comprises an upper cantilever and a lower cantilever, and the upper cantilever and the lower cantilever are both arranged horizontally and connected with each other through a supporting arm perpendicular to the two cantilevers. Each of the upper cantilever and the lower cantilever of the C-frame is provided with an air temperature detector. A C-type traveling drive device matched with the C-frame is arranged on the inner wall of the C-frame, and a drive motor is arranged on the outer wall of the C-frame and connected with the C-type traveling drive device. The junction box, the main electric cabinet and the water-cooling tank are all connected with the C-frame. A signal detector is arranged at one end, farther away from the supporting arm, of the upper cantilever, and a radiation source is arranged at one end, farther away from the supporting arm, of the lower cantilever. The thickness gauge is accurate in measurement.

Owner:MAANSHAN HENGRUI MEASURE EQUIP

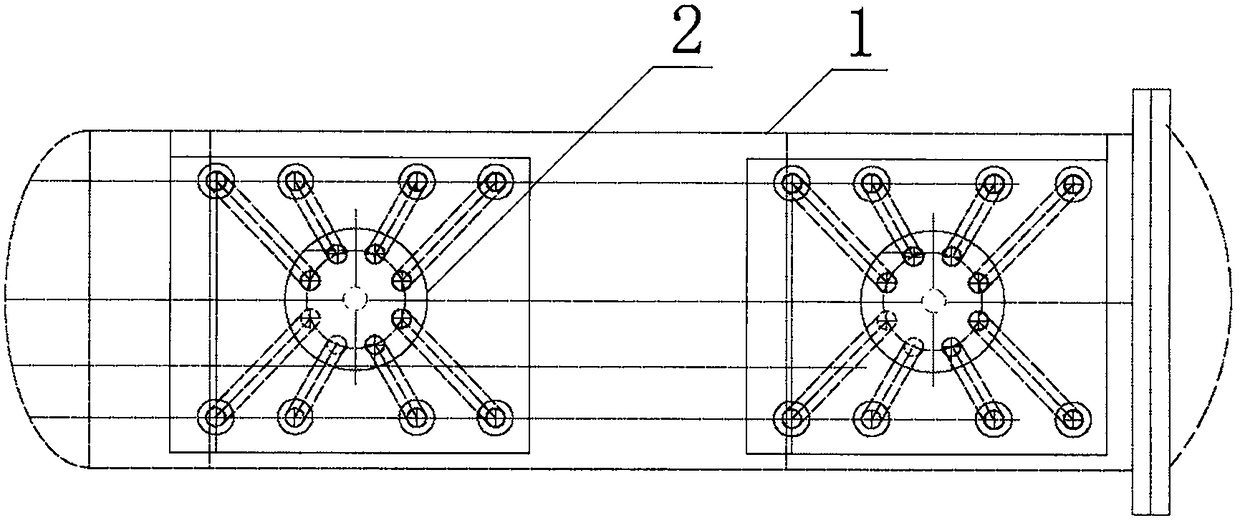

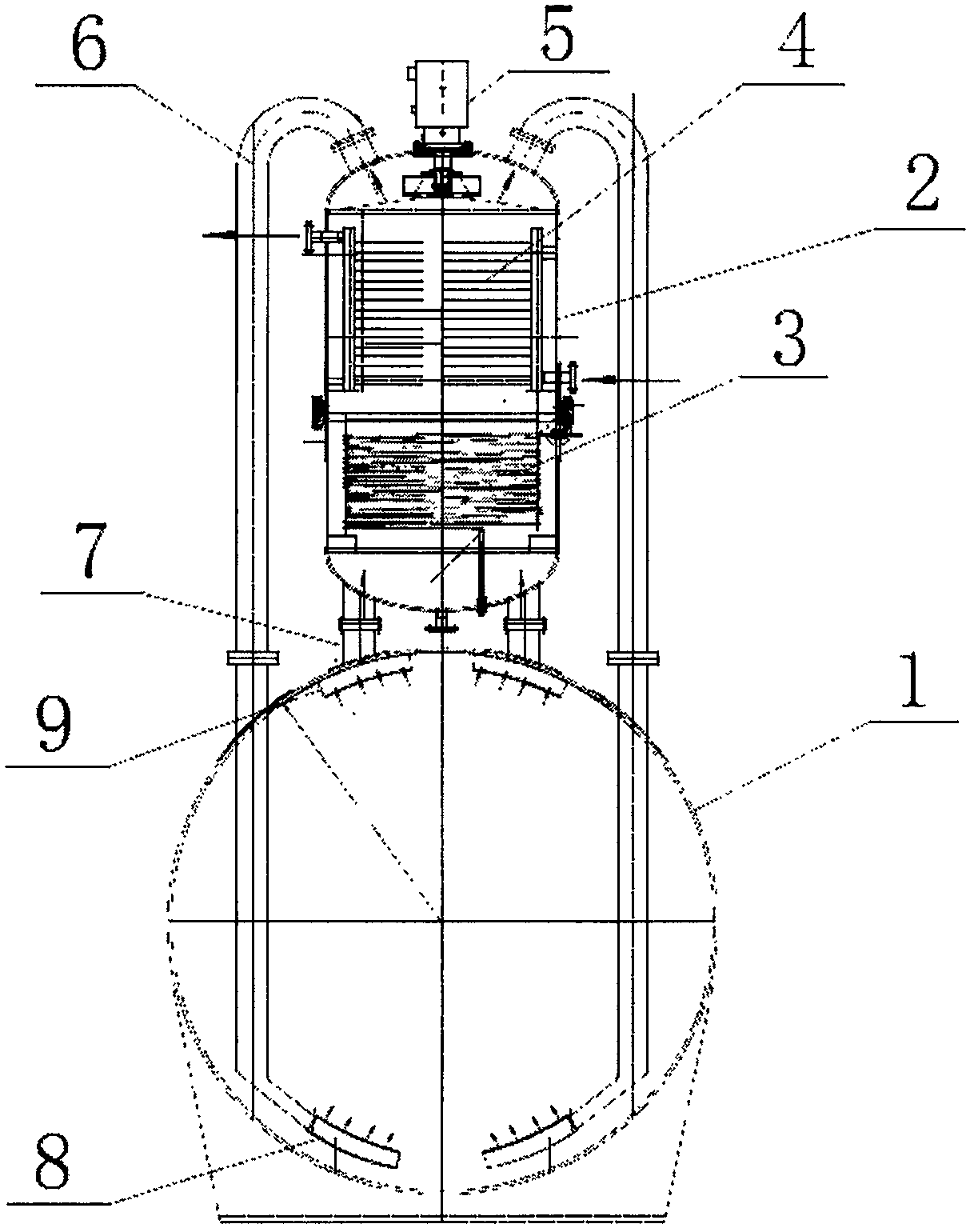

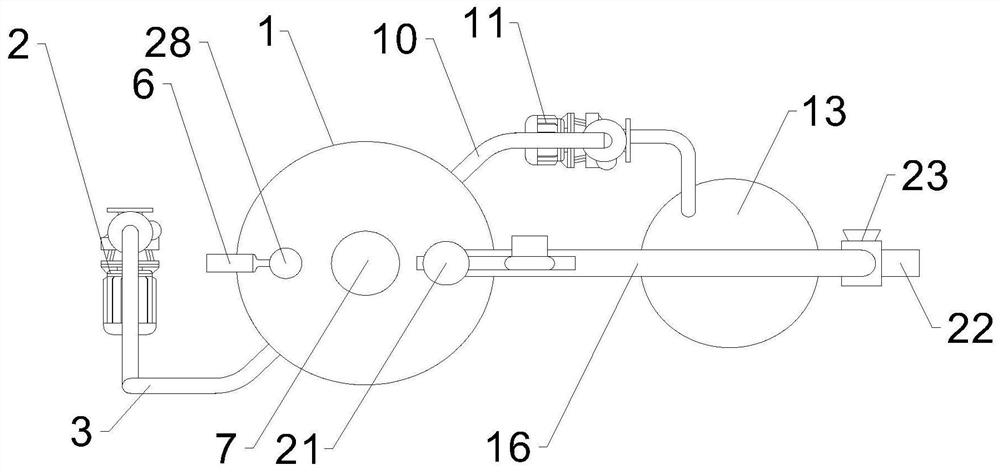

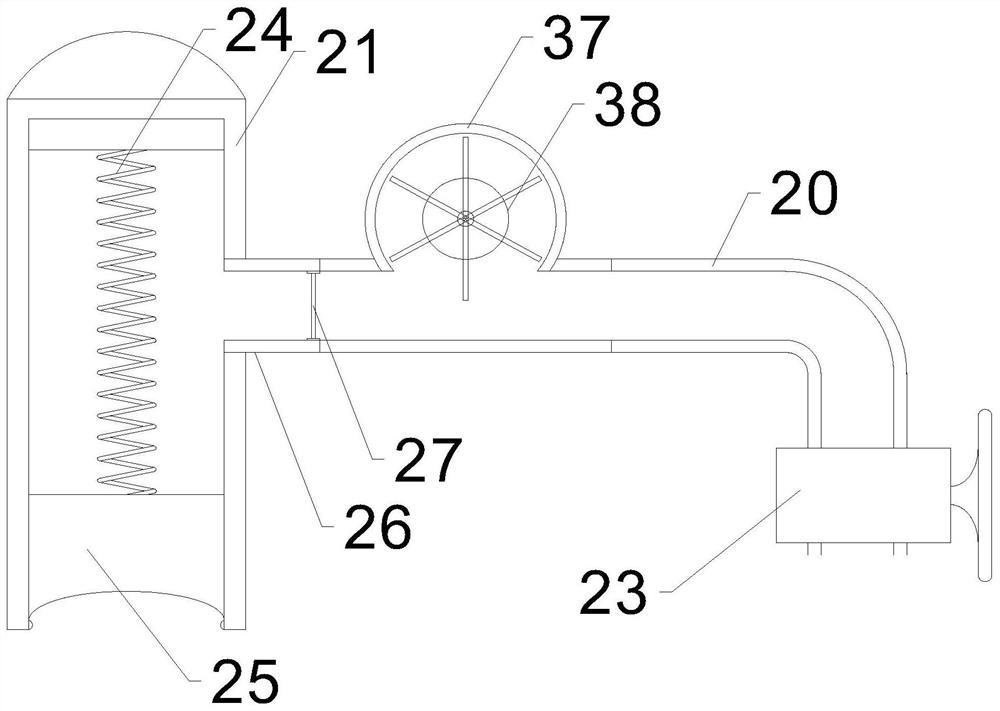

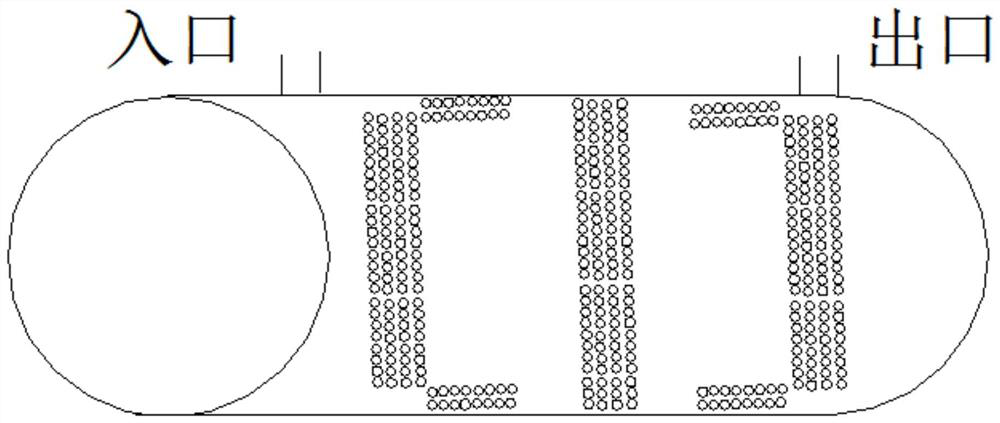

Longitudinal-circulation autoclave provided with external thermal-cold cycling device

PendingCN108297525AUniform temperature distributionEasy to replace and maintainLaminationLamination apparatusEngineeringTemperature difference

The invention relates to a longitudinal-circulation autoclave provided with an external thermal-cold cycling device. The longitudinal-circulation autoclave comprises a main tank body, air suction connection pipelines, air blowing connection pipelines and the thermal-cold cycling device, wherein the main tank body is connected with airflow distributors through the air suction connection pipelines and the air blowing connection pipelines respectively; the thermal-cold cycling device is located outside the main tank body. According to the autoclave with the structure, the complicated heating, cooling and circulating device is moved out of the main tank body, and loading rate is remarkably increased; the circulation path is shortened by means of a new longitudinal-circulation mode, and under cooperation with the airflow distributors, the temperature distribution in the tank is uniform, vertical temperature difference is reduced, and front and back temperature difference is almost zero; with adoption of an electromagnetic heating mode with higher efficiency, not only is energy saved, but also efficiency is remarkably improved; the external thermal-cold cycling device can be wholly replaced and dismounted for maintenance due to presence of spare parts, and the condition of production delay caused by equipment failure maintenance is avoided.

Owner:王新志

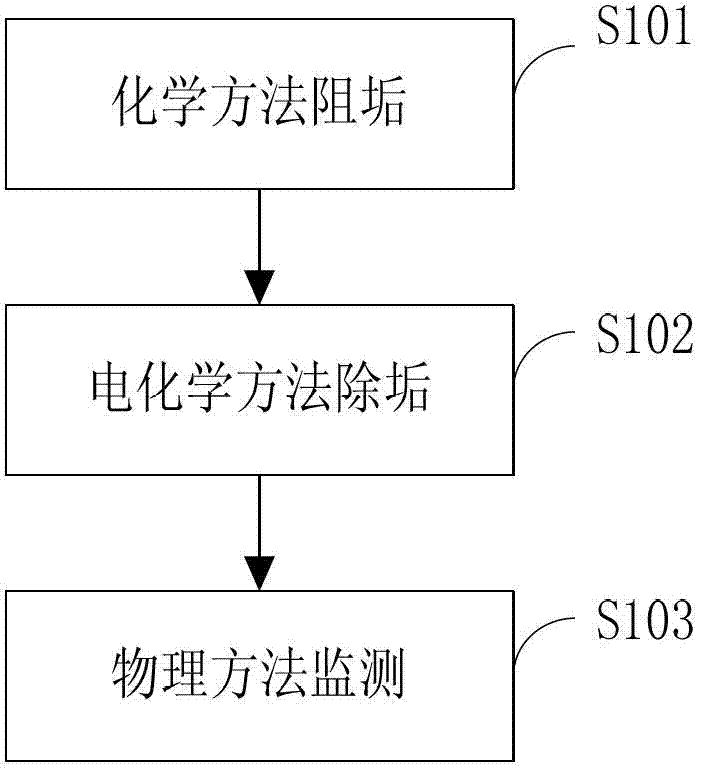

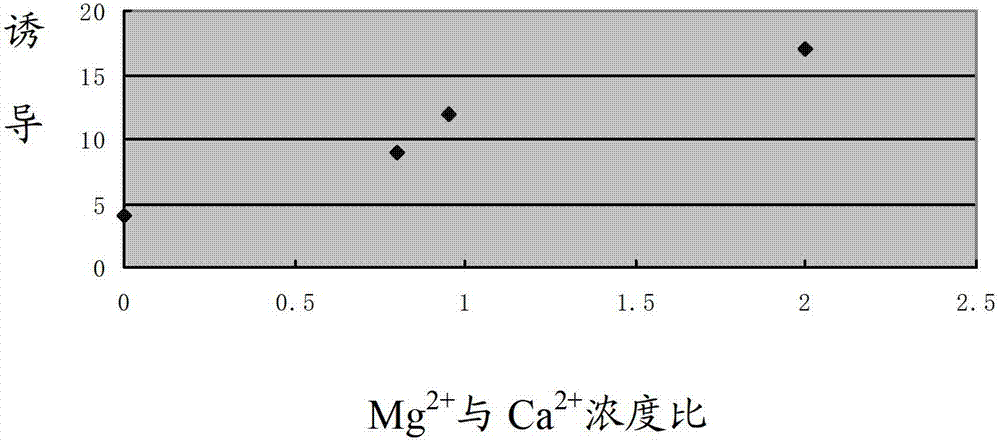

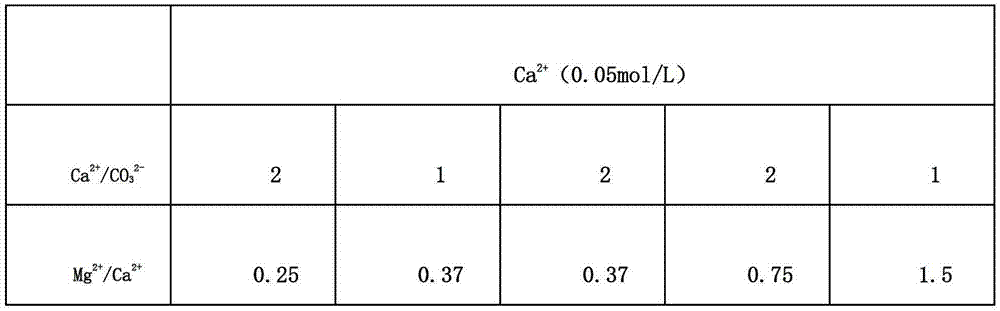

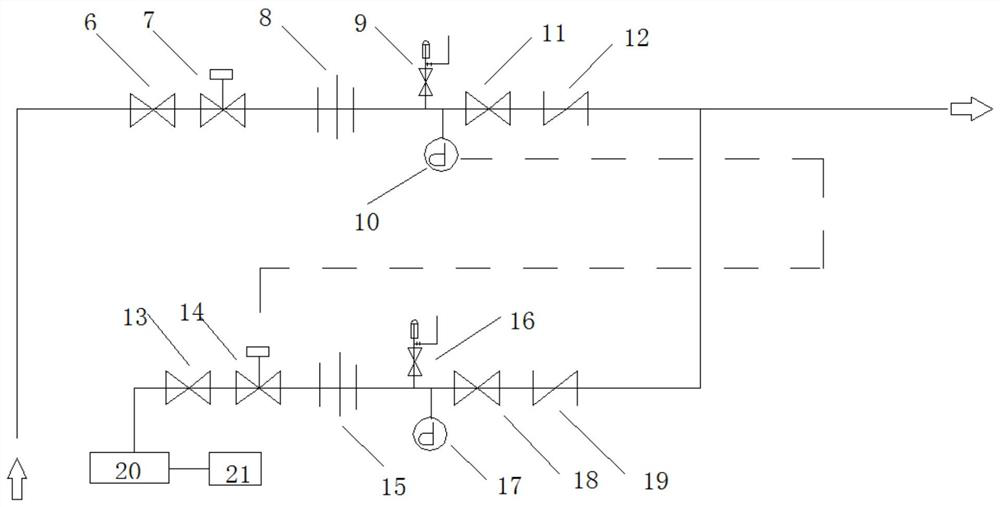

Method for handling inner scaling problem of offshore production platform pipeline device

InactiveCN103111446AAvoid production delaysReduce manpower expenditureHollow article cleaningScale effectsCorrosion

The invention discloses a method for handling an inner scaling problem of an offshore production platform pipeline device. The method for handling the inner scaling problem of the offshore production platform pipeline device comprises scale inhibition by a chemical method, scale removal by an electrochemical method and monitoring by a physical method. The method for handling the inner scaling problem of the offshore production platform pipeline device methodically handles the scaling problem of the offshore production platform pipeline device in a thought of scale inhibition, scale removal and scale monitoring, organically combines antisepsis and scaling removal into one by using the electrochemical method, overcomes the defect that scale inhibitor can not effectively decrease thickness of formed scale layers, avoids pipeline corrosion caused by acid cleaning and production delay due to acid cleaning and pipe replacing, and reduces manpower expenses; meanwhile, the method for handling the inner scaling problem of the offshore production platform pipeline device monitors scaling effect and water quality scaling trend by using the physical method, and excellently solves the problems that construction period is long and cleaning efficiency is low in an existing method for handling the inner scaling problem of the offshore production platform pipeline device. Besides, the method for handling the inner scaling problem of the offshore production platform pipeline device is convenient to operate, outstanding in using effect, and has excellent application value.

Owner:E TECH ENERGY TECH DEV CORP

Fully enclosed telescopic safety protection device of transloading machine

ActiveCN102352772AEnsure safetyEasy to operateEarth drilling and miningUnderground transportAutomatic controlSlide plate

The invention relates to a mining device and particularly relates to a fully enclosed telescopic safety protection device of a transloading machine. The fully enclosed telescopic safety protection device comprises a fully enclosed sliding plate which can slide forward and backward, wherein the cross section of the fully enclosed sliding plate is in the shape of L which is rotated 180 degrees, thehorizontal part of the fully enclosed sliding plate is slidably mounted between an upper sealing cover plate and a lower sealing cover plate, the vertical part of the fully enclosed sliding plate is positioned on the outer side of a coal blocking plate of the transloading machine, and a driving device of the fully enclosed sliding plate is mounted on the lower sealing cover plate. The fully enclosed telescopic safety protection device has the beneficial effects that the openings of the noses of a front scraper conveyor and a rear scraper conveyor are fully sealed, and operation staff can enter into the place above the upper sealing cover plate of the transloading machine for working during the normal operation process of the transloading machine and be prevented from falling into the transloading machine, thereby providing a working platform for working staff, not only being convenient to operate, but also ensuring the safety of the operation staff. The device adopts a hydraulic control advanced technology for performing automatic control. The device can play a role in indirect reduction of secondary coal dust.

Owner:YANKUANG GRP CO LTD

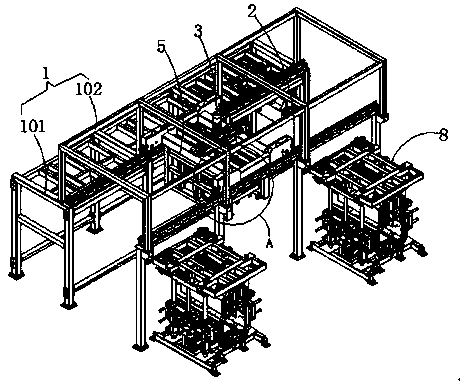

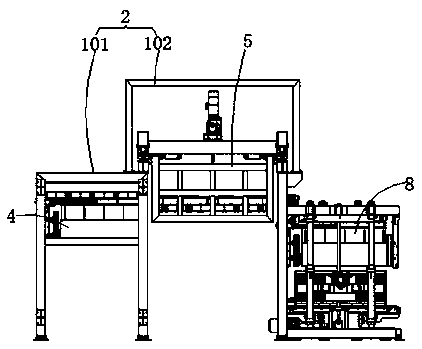

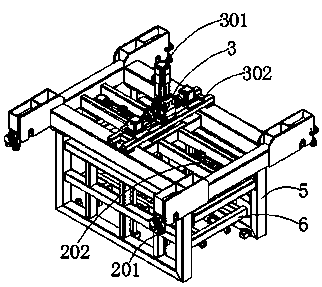

Translation type automatic mold replacement mechanism

The invention provides a translation type automatic mold replacement mechanism, and relates to the technical field of box foaming equipment mold replacement. The translation type automatic mold replacement mechanism comprises a supporting frame, a translation transmission mechanism and a vertical transmission mechanism; the supporting frame comprises a left side frame and a right side frame; the interior of the left side frame is provided with foaming equipment, and the interior of the right side fame is movably provided with a mold replacement trolley through the translation transmission mechanism; a mold storeroom is arranged on the side, away from the left side frame, of the right side frame; and the top end of the inner side of a mold trough and the top of the mold storeroom are both provided with mold conveying mechanisms which are the same with a mold conveying mechanism on the foaming equipment. According to the translation type automatic mold replacement mechanism, by arrangingthe translation transmission mechanism and the vertical transmission mechanism, moving of a mold in the horizontal and vertical directions during replacing is achieved; by arranging a servo motor, the whole conveying process is accurate; and through the invention, an original turnover mold replacement mode is changed, the mold replacement position is precise, the mold replacement speed is high, aproduction line does not need to be stopped during mold replacement, the production efficiency is improved, safety and effectiveness are achieved, and the practicability is high.

Owner:滁州信达自动化设备制造有限公司

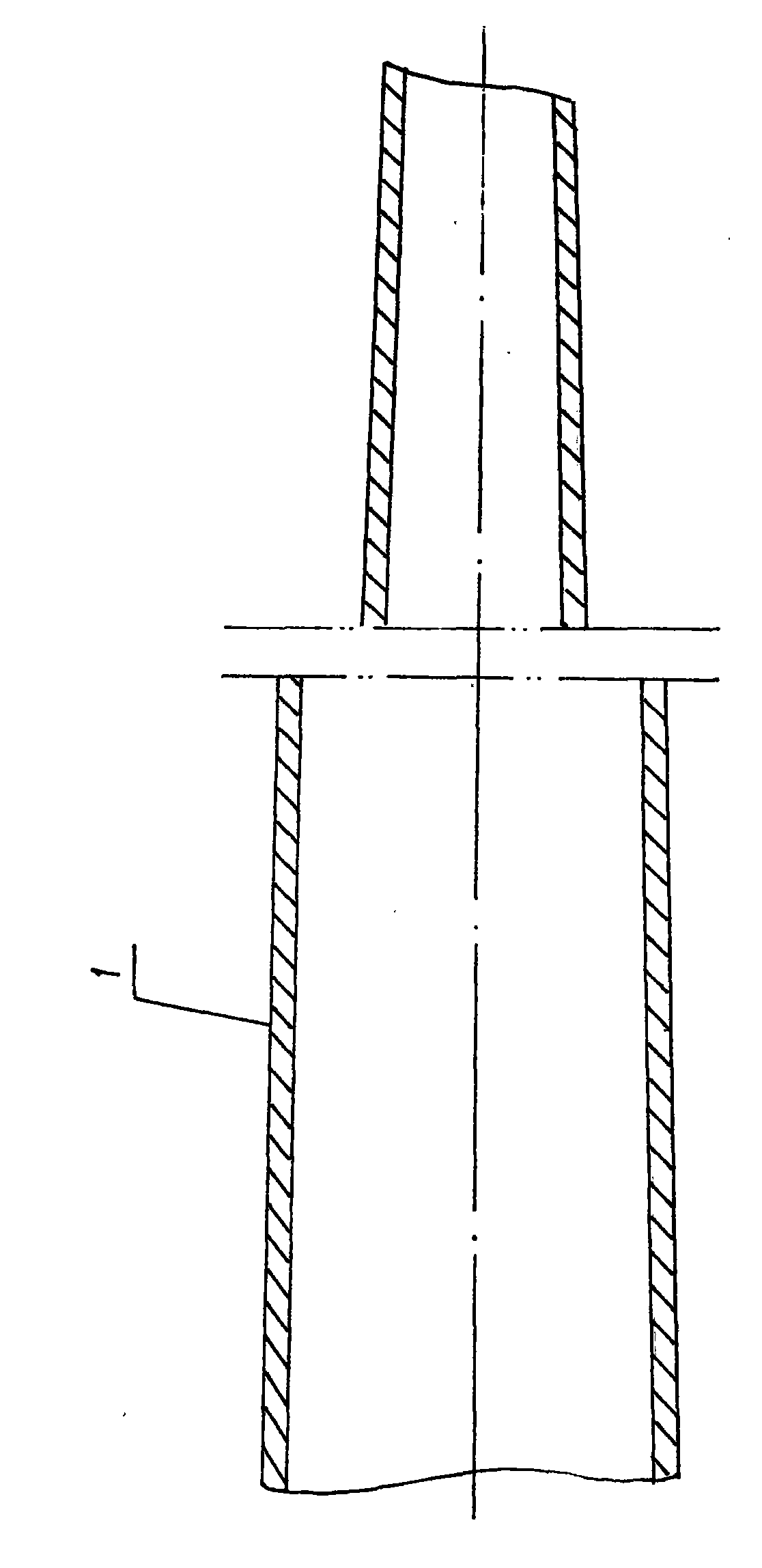

Integrated welding seam-free taper pipe

ActiveCN101551041AReasonable designSimple structureManufacturing convertersRigid pipesSteelmakingPhysical hard work

The invention relates to an integrated welding seam-free taper pipe which is characterized in that: the taper of the pipe is 0 degree to 30 degrees; the length is 1.5 meters to 20 meters; the diameter Phi is 89mm to 2000mm, and the wall thickness is 0.5 to 60mm. The manufacturing of the integrated welding seam-free taper pipe comprises the following steps of: (1) adopting a steel pipe with the diameter corresponding to that of the integrated welding seam-free taper pipe as raw material for hot expanding; (2) pre-manufacturing one or a group of moulds being the same to the welding seam-free taper pipe; (3) carrying out heating in an inductance coil of a hot expanding machine; and (4) carrying out surface finishing. The pipe has the characteristics of reasonable design, simple structure and convenient installation and maintenance. By adopting the integrated welding seam-free taper pipe to manufacture a taper oxygen lance used for converter steelmaking, the problems of production delay caused by adhesive slag on the lance body of the lance, heavy physical labor to workers and adverse effect to production are avoided, the service life of the blow oxygen lance is improved, the energy consumption thereof is reduced and the safe production is ensured.

Owner:陶斌

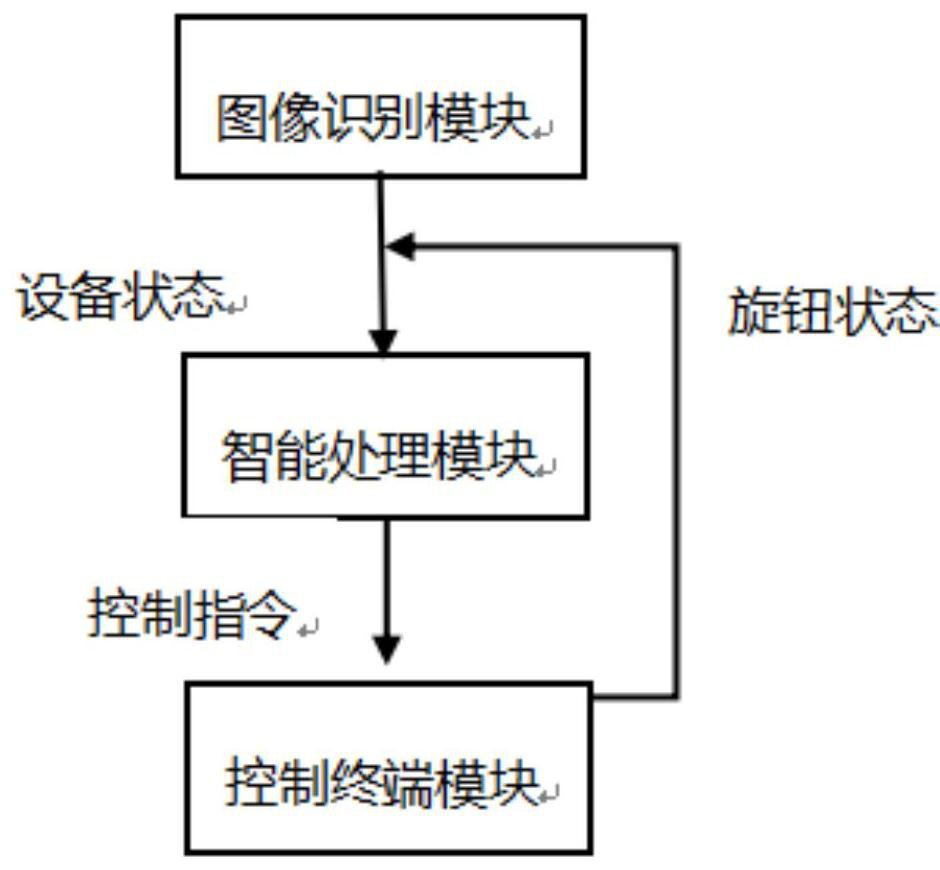

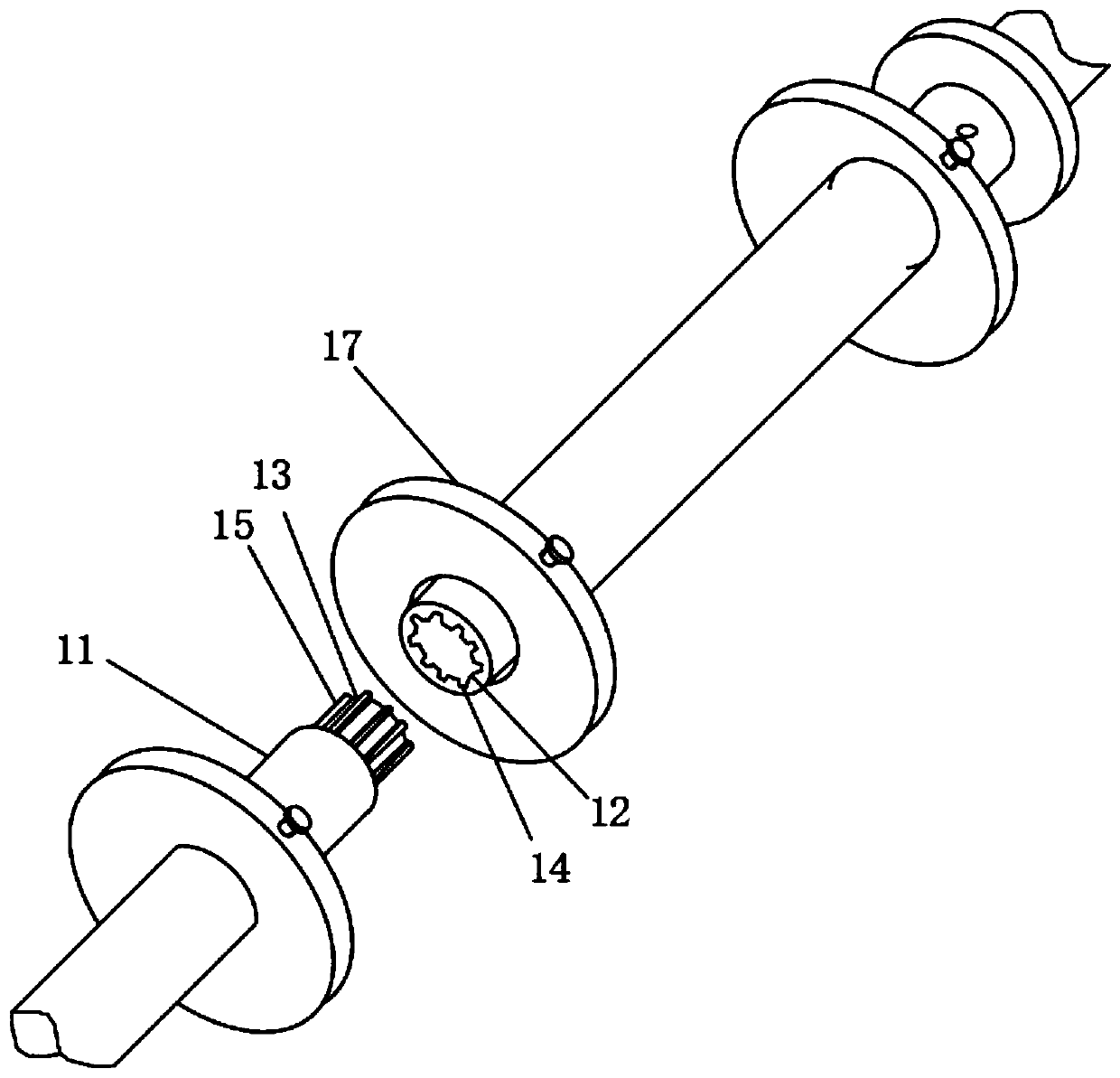

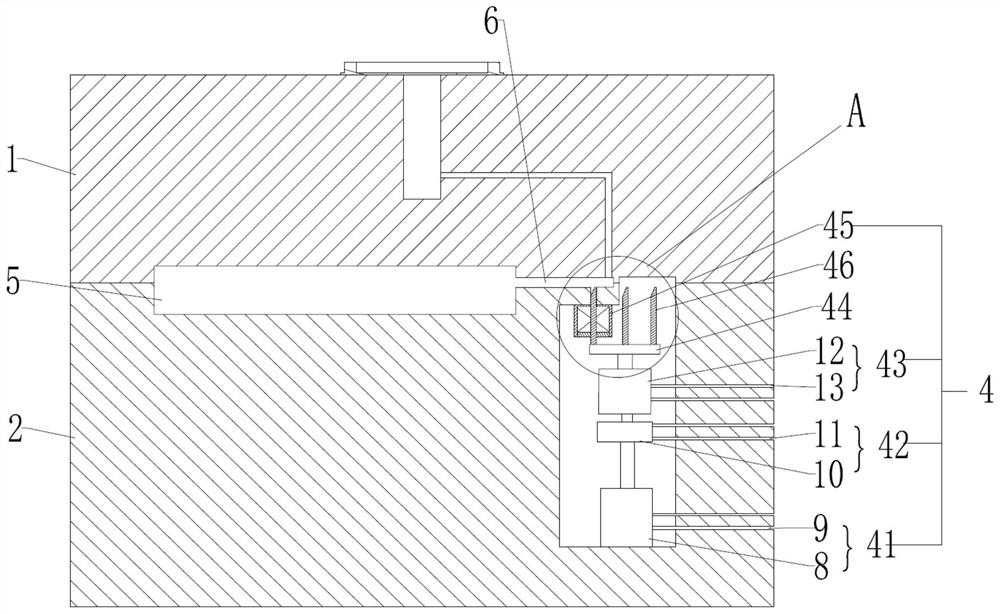

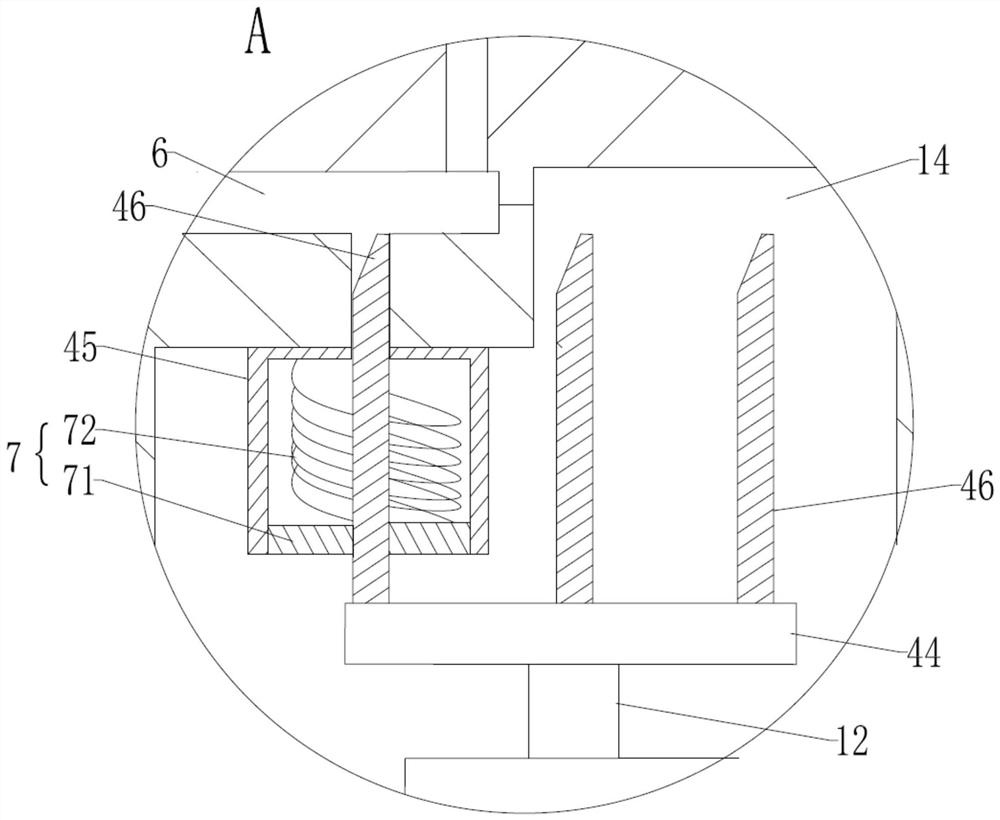

Lossless intelligent transformation device for control knob

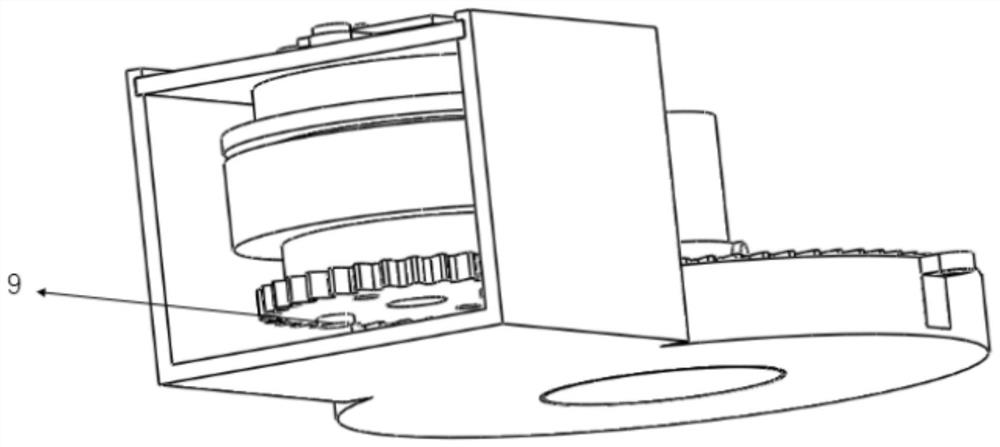

PendingCN113672028ARealize intelligent controlLow costControlling membersGear wheelControl engineering

The invention relates to a lossless intelligent transformation device for a control knob. The device comprises an image recognition module used for recognizing the real-time state of equipment, an intelligent processing module and a control terminal module; the control terminal module comprises a driving circuit and a transmission device, and the transmission device comprises an angle sensor, a gear, a motor and a shell; and the equipment control knob is sleeved with the transmission device, the transmission device is fixed to a console through double faced adhesive tape, and a screw penetrates through a knob gear screw hole and is screwed tightly, so that the equipment control knob is fixedly connected with the knob gear. A rotation instruction of the knob is converted into voltage and frequency for controlling rotation of the motor through the driving circuit, so that the motor rotates, and the knob is driven to rotate by a target angle through the gear; and the angle sensor collects the rotation angle of the motor in real time and sends the rotation angle to the intelligent processing module, the rotation angle is converted into the real-time angle of the knob, and the intelligent processing module takes the equipment state and the knob state parameter as input information.

Owner:CSCEC STRAIT CONSTR & DEV

Group control method for deviation rectification of conveyor belt and detection and correction system thereof

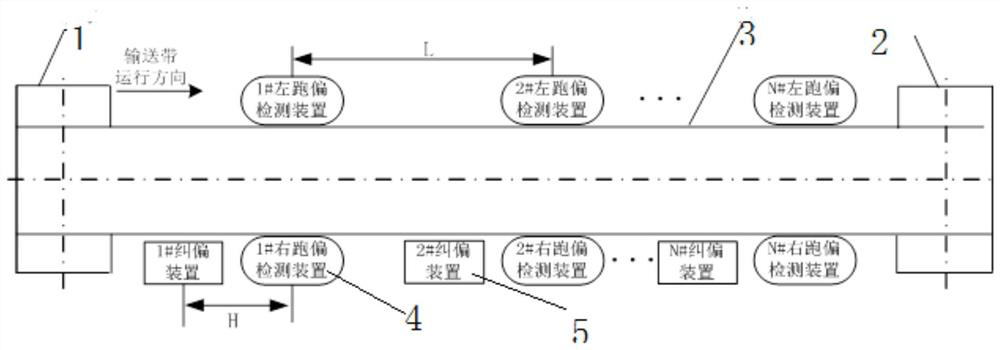

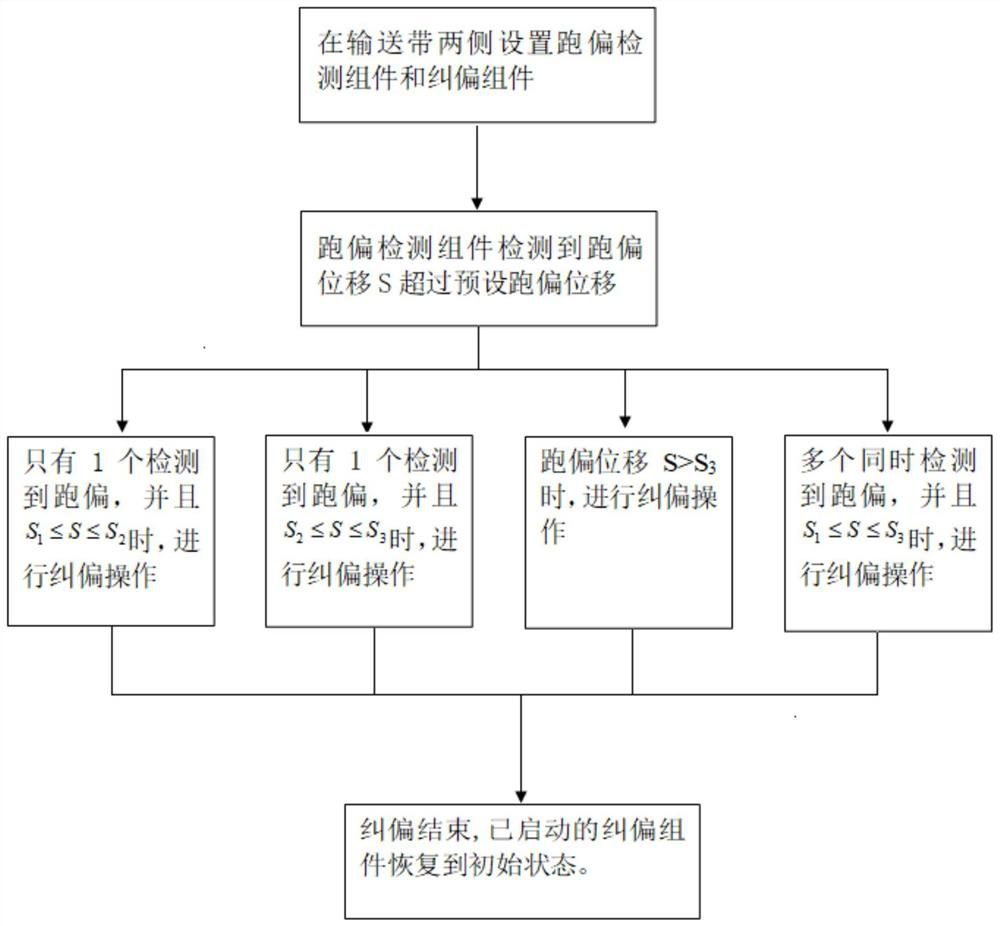

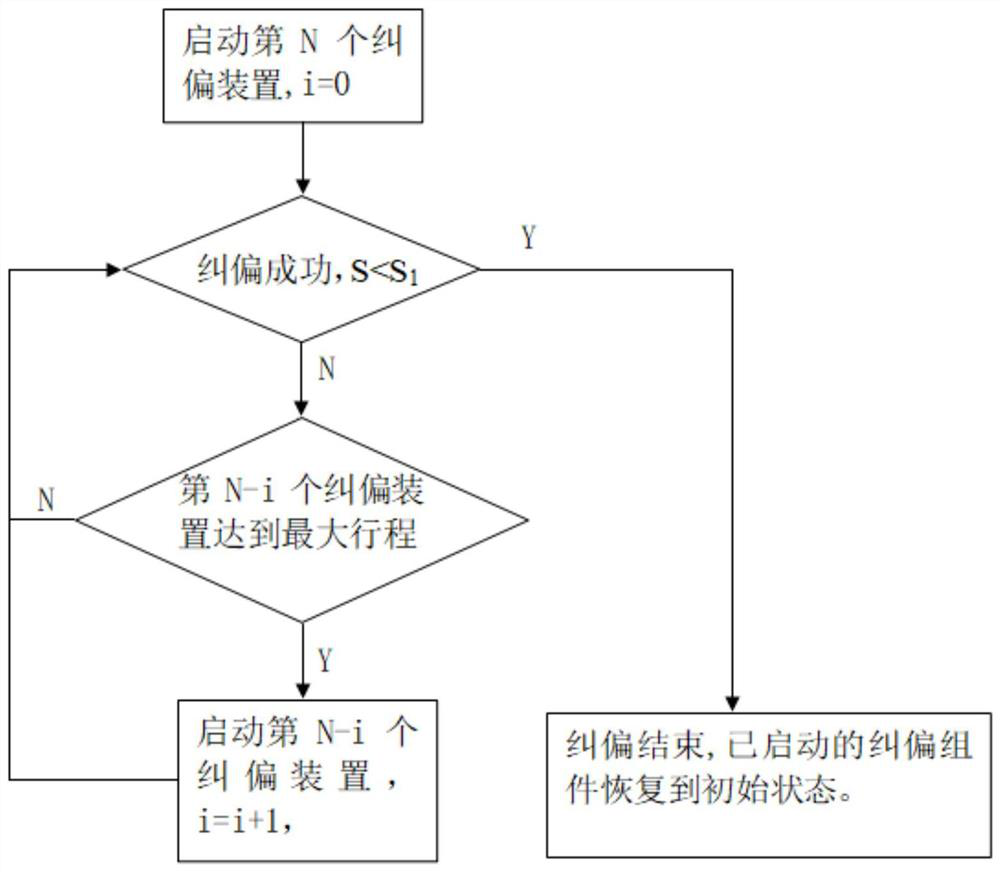

ActiveCN112407780AImprove the correction effectAvoid pollutionConveyorsControl devices for conveyorsLoop controlCoupling

The invention provides a group control method for deviation rectification of a conveyor belt. The method comprises the specific steps: firstly, arranging multiple sets of deviation detection assemblies according to the length and the deviation position of the conveyor belt, and arranging corresponding deviation rectification assemblies at the upstream distance H of the conveyor belt; when the deviation detecting assembly detects that the deviation displacement S of the position exceeds the set deviation displacement S1, sending, by the control assembly, an instruction to control an actuator ofthe corresponding deviation correcting assembly to act to the preset position, and when an angle sensor in the deviation correcting assembly detects the rotating angle of a carrier roller set in thecurrent deviation correcting assembly, correcting, by the deviation correcting assembly, the deviation of the carrier roller set. and feeding back, by the deviation rectifying assembly, the information to the control assembly and comparing, by the deviation rectifying assembly, the information with a set value, and controlling the actuator to conduct corresponding actions, so as to complete coupling closed-loop control over the deviation rectifying assembly. The invention further provides a detection and correction system applied to the group control method for deviation rectification of the conveyor belt, the conveyor belt can be rapidly and automatically corrected when deviating at any position of one or more positions through group control, and the deviation correction effect on the conveyor belt during transportation under complex working conditions is improved.

Owner:HEBEI PORT GRP PORT MACHINERY

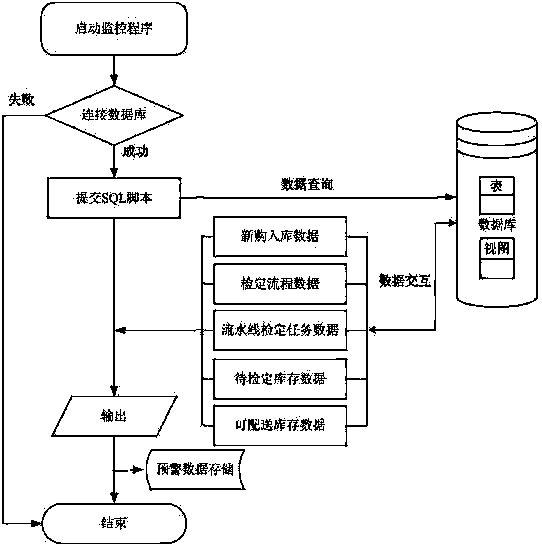

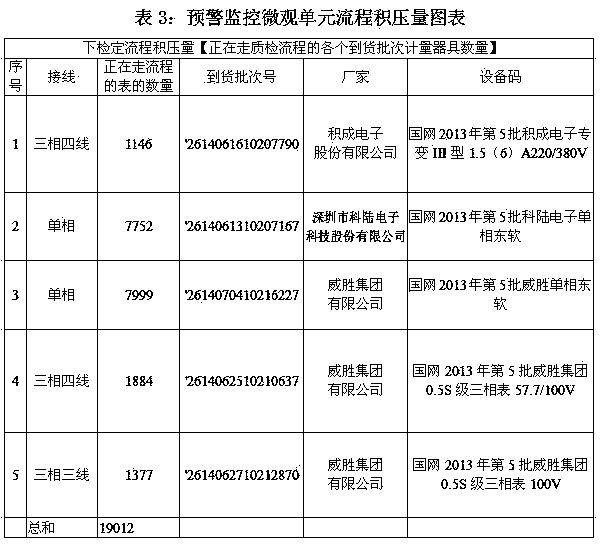

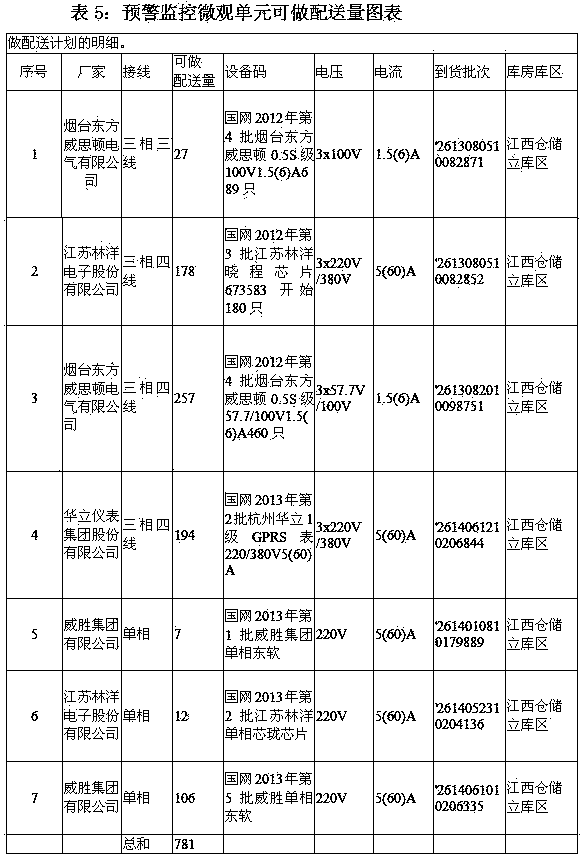

Provincial electric power measurement center production early-warning and monitoring method

InactiveCN104111837AOvercome abstractionSolving Dispersion ProblemsSpecific program execution arrangementsDatasheetMeasuring instrument

The invention discloses a provincial electric power measurement center production early-warning and monitoring method. The method includes the steps that firstly, a production early-warning and monitoring program of a monitoring server has access to an Oracle database of an MDS through ADODB and establishes trust connection with an MDS server database; secondly, sql scripts are submitted to the MDS database, the sql scripts are executed at an MDS server side, data tables and view related fields of the arrival new-purchase warehouse-in operation, the verification process, the assembly line verification task and the distribution link related to production are read, and operational instructions of data inquiry, external connection and operation are finished; finally, visual early-warning information data are sent back to the monitoring server, and connection is closed. According to the provincial electric power measurement center production early-warning and monitoring method, the quantitative relation of measuring instruments corresponding to all links of service circulation of a production dispatching platform can be monitored, the provincial electric power measurement center production early-warning and monitoring method are suitable for improving the monitoring efficiency and the accuracy of monitoring dispatching data in production early warning, the intensity of monitoring work is effectively lowered, and monitoring work efficiency can be practically improved.

Owner:STATE GRID CORP OF CHINA +1

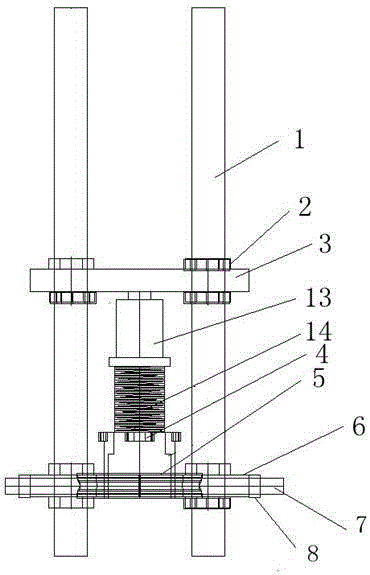

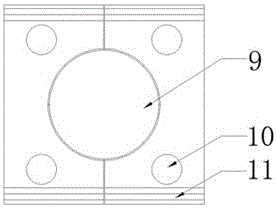

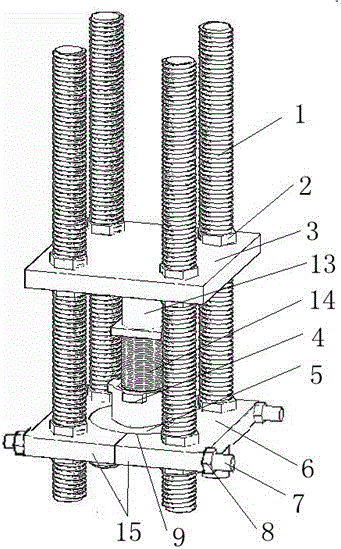

Emergency tool for facilitating dismounting roller ring on line

InactiveCN106180205AIngenious structural designPracticalMetal rolling stand detailsMetal rolling arrangementsSupport pointIndustrial engineering

The invention discloses an emergency tool for facilitating dismounting a roller ring on line. The emergency tool comprises a working plate, a supporting plate, traction screws, a regulating screw and a jack; four locating through holes are formed in each of the working plate and the supporting plate which are connected into a whole through the four traction screws; the working plate is arranged below the supporting plate; a roller ring fixing hole is formed in the center of the working plate; the working plate is composed of two locating plates with the same size; and the bottom of the supporting plate is provided with the jack mounted right above the roller ring fixing hole. Two parts of the working plate is directly fixed together with the roller ring, and then, a working surface for fixing the roller ring is pulled out by supporting the jack by taking a roller shaft of a rolling mill and the supporting plate as supporting points, so that the roller ring which cannot be directly pulled out can be rapidly pulled out, and the emergency tool is labor-saving and efficient.

Owner:JIANGSU YONGGANG GROUP CO LTD

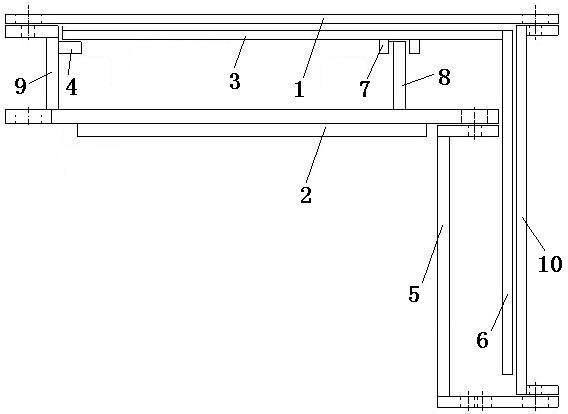

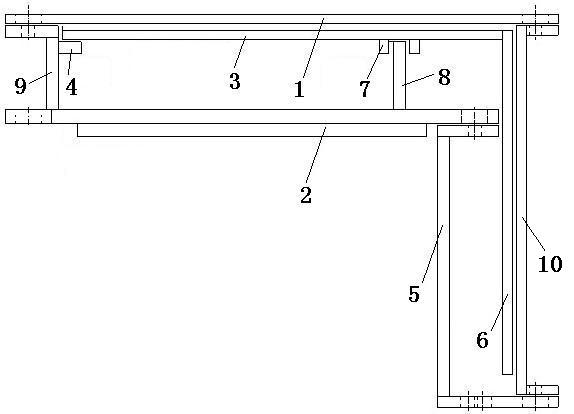

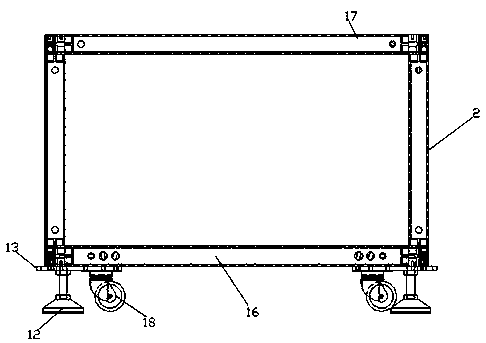

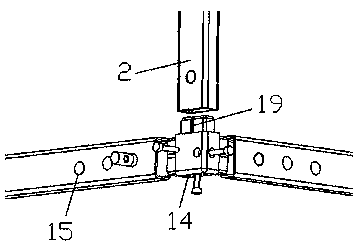

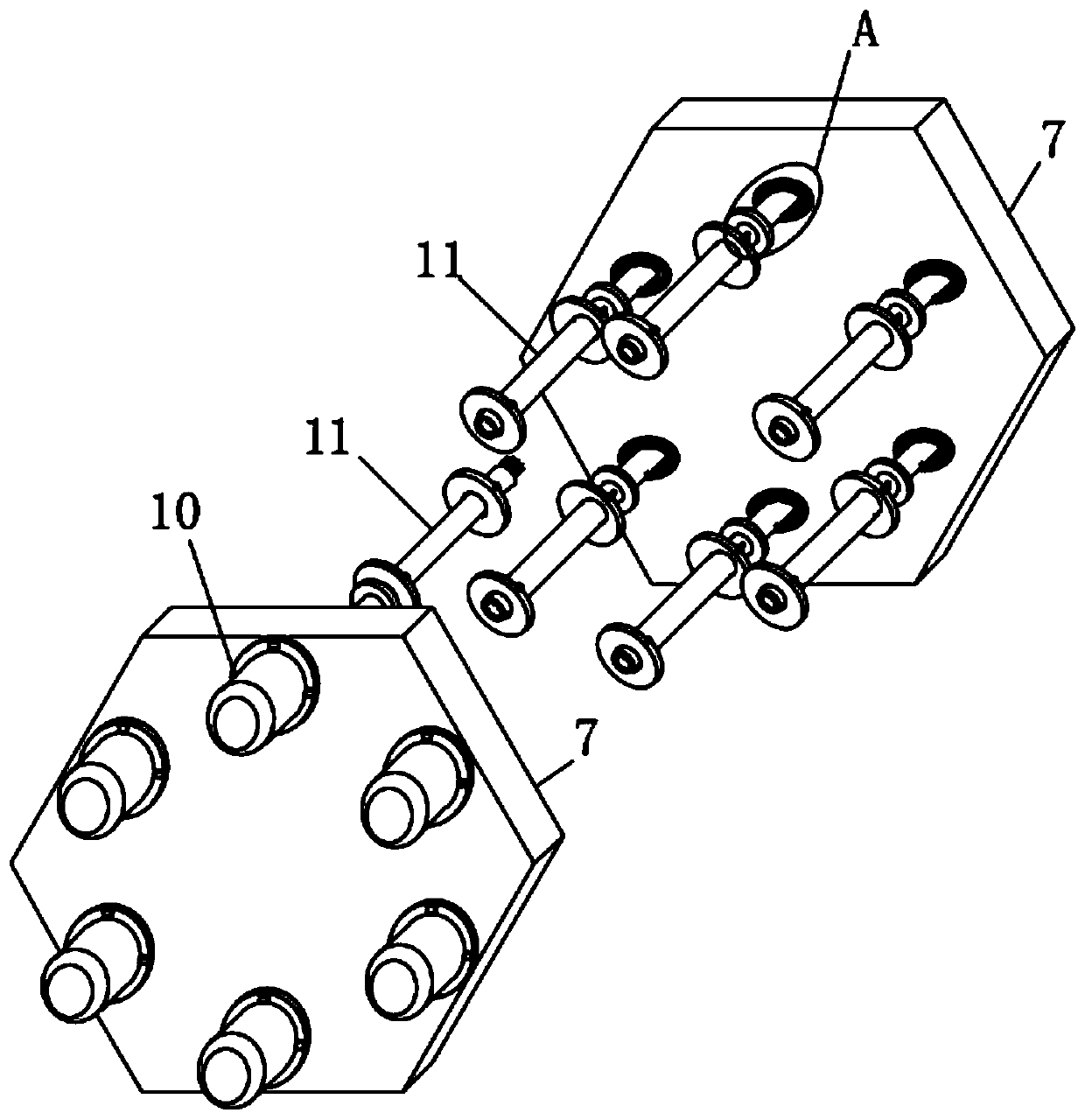

Splicing load carrying rack

PendingCN108869954ATransportation does not interfere with each otherSmall footprintPortable framesRod connectionsEngineeringCounterbore

The invention discloses a splicing load carrying rack, comprising an upper box, a lower box and Z-axis connecting pipes, wherein each of the upper box and the lower box comprises four pipe joints, twoX-axis connecting pipes and two Y-axis connecting pipes, Z-axis connecting pipes are vertically arranged between the corresponding pipe joints of the upper and lower boxes, the pipe joints are provided with inserting blocks extending into the X-axis connecting pipes, the Y-axis connecting pipes and the Z-axis connecting pipes correspondingly, each pipe joint is provided with three cylindrical counterbores extending along the length directions of the X-axis connecting pipes, the Y-axis connecting pipes and the Z-axis connecting pipes into the corresponding inserting blocks, and the cylindricalcounterbores are internally provided with screws connected to the corresponding connecting members. In the manner, the splicing load carrying rack has a stable structure and flexible adjustment, minimizes processing steps, reduces requirements on assembly technology, and is convenient for storage and transportation.

Owner:JIANGSU COWAIN AUTOMATION TECH

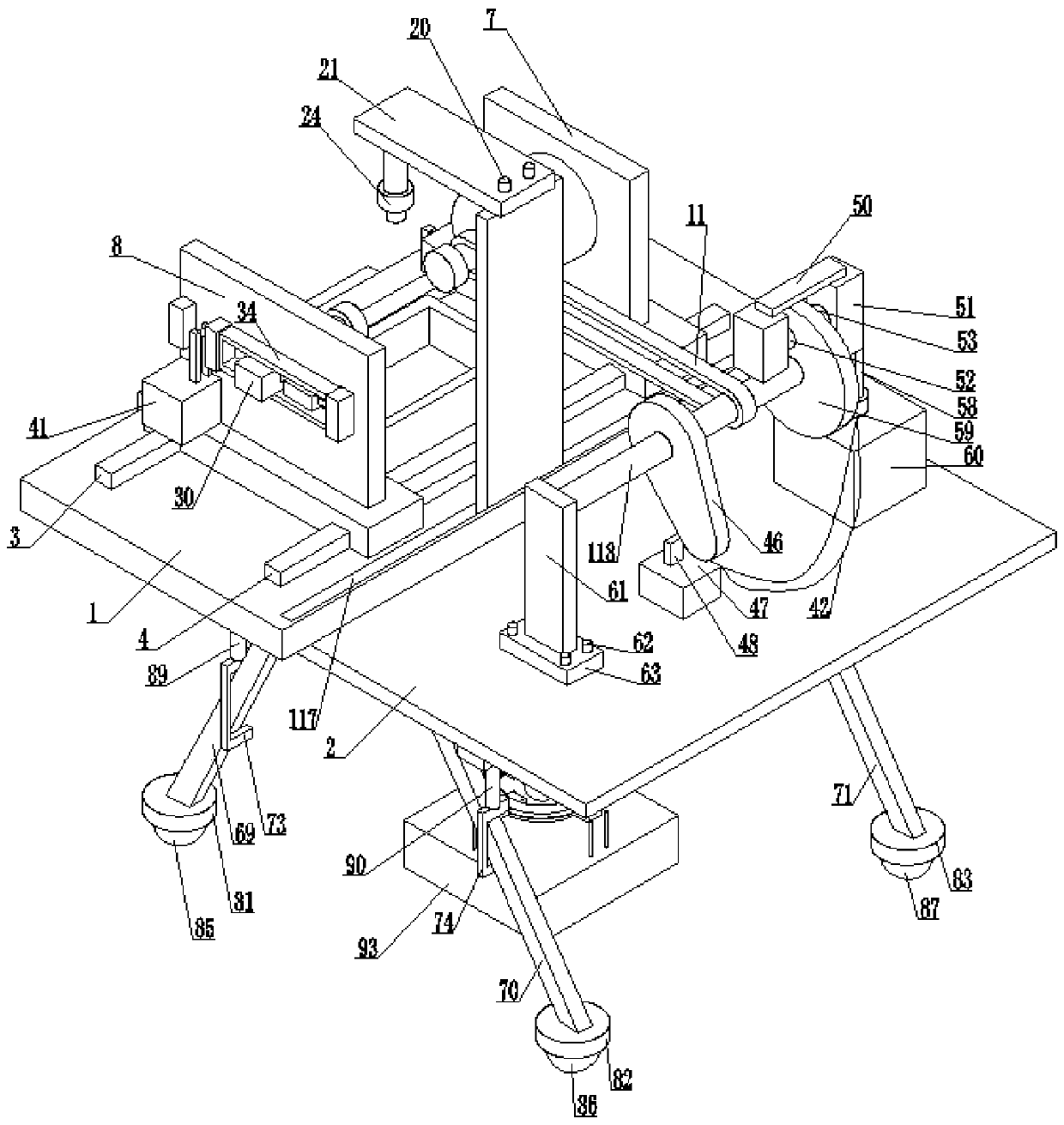

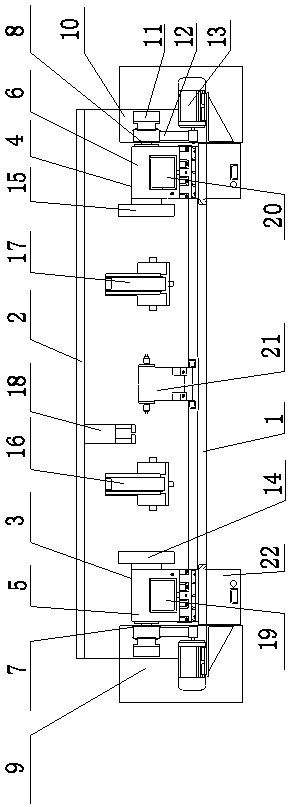

Coupling numerical control machining machine tool

InactiveCN111036943AImprove efficiencyShorten the timeAutomatic control devicesAuxillary equipmentNumerical controlEngineering

The invention relates to a coupling numerical control machining machine tool. The machine tool comprises a body and a shell. A first main spindle box, a tailstock, a second main spindle box and a saddle are arranged on the body. The first main spindle body and the second main spindle box are provided with a first main spindle box body and a second main spindle box body correspondingly. A first main spindle and a second main spindle are mounted on the first main spindle box body and the second main spindle box body correspondingly. A first hollow hydraulic chuck and a second hollow hydraulic chuck are mounted at the front ends of the first main spindle and the second main spindle correspondingly. The tailstock is arranged between the first main spindle box and the second main spindle box. The saddle is arranged on one side of the body. A first tool holder and a second tool holder are fixed to the saddle. The first tool holder is arranged between the first main spindle box and the tailstock. The second tool holder is arranged between the second main spindle box and the tailstock. Supporting legs are arranged on the body. All coupling machining procedures can be completed without needing to change tools, the efficiency is improved, the time is saved, and the cost is lowered.

Owner:江苏泰源数控机床有限公司

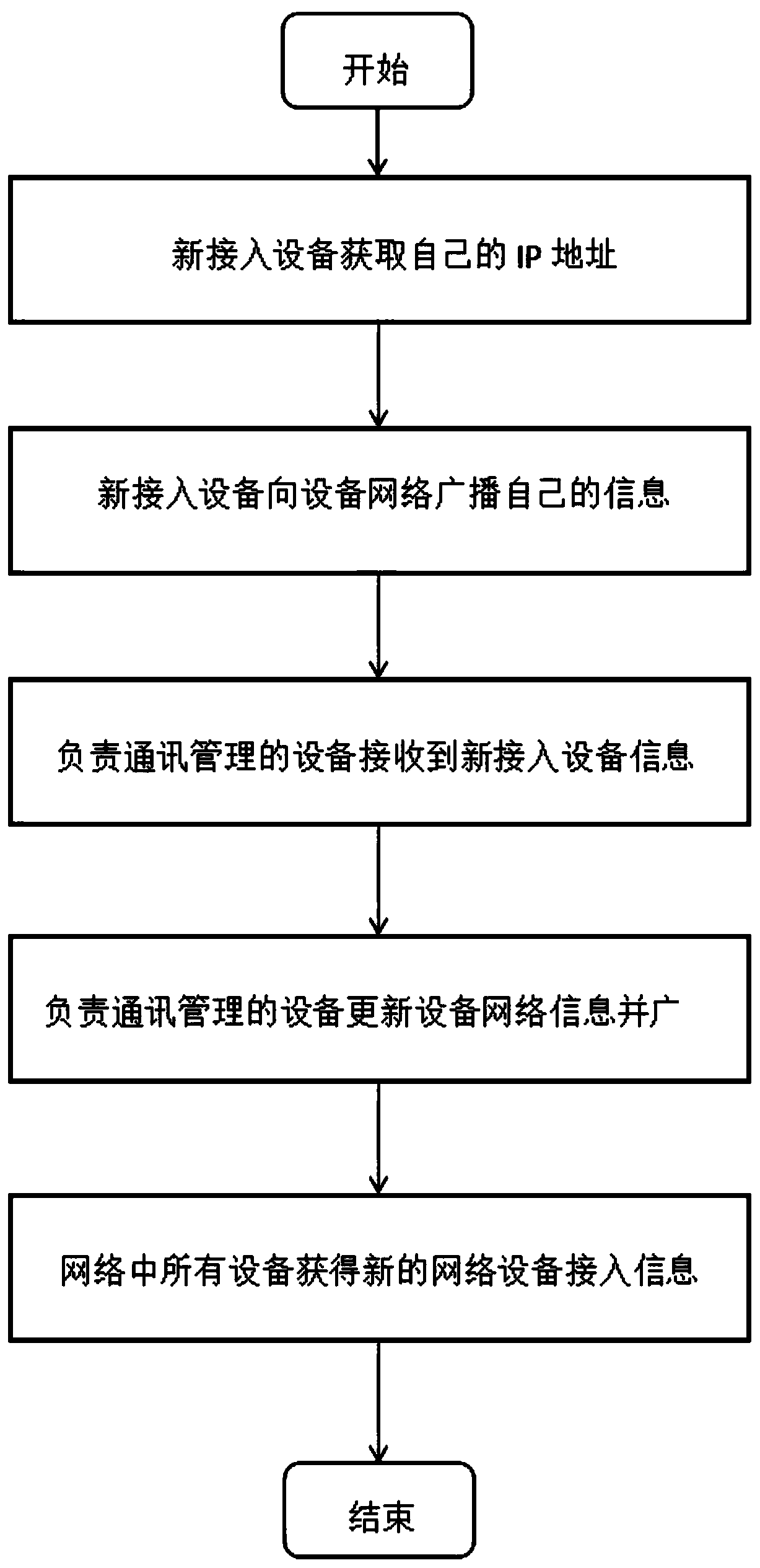

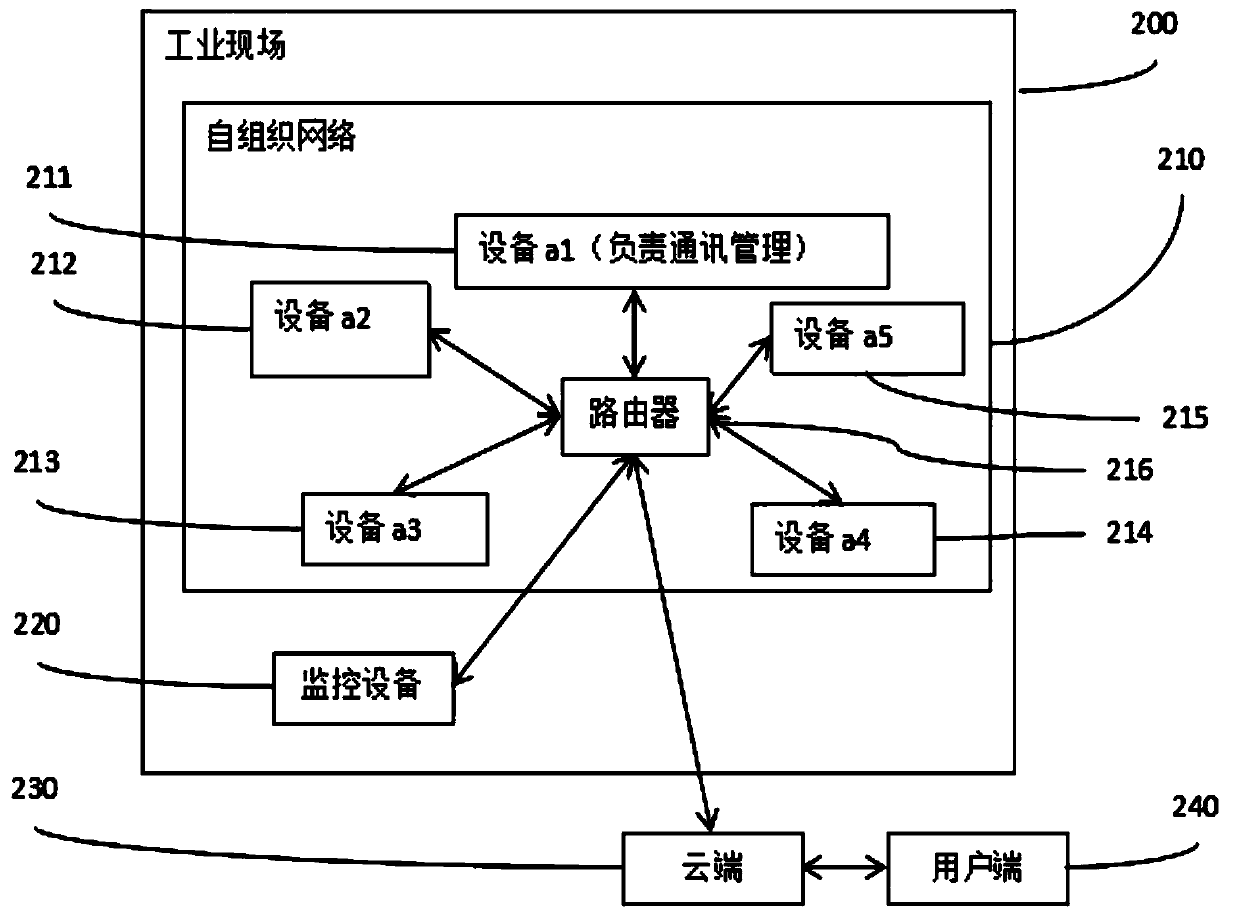

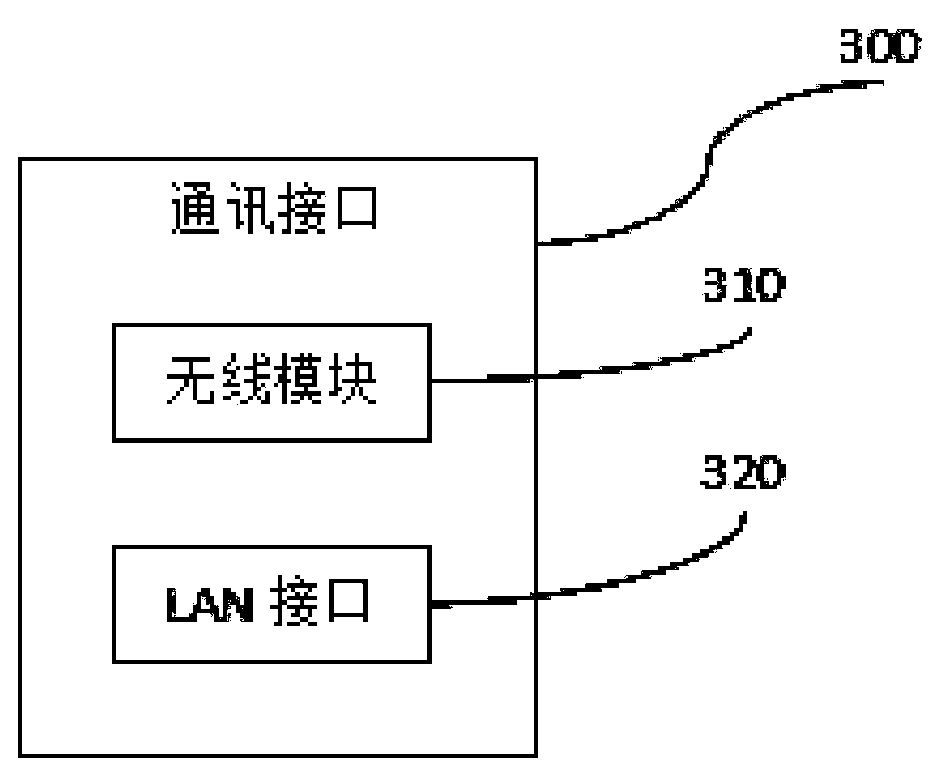

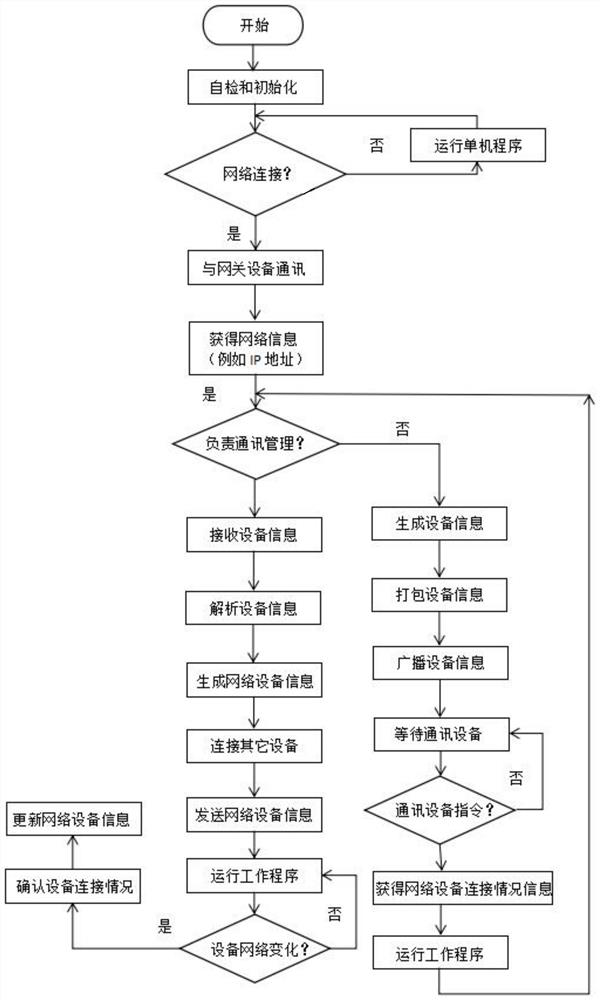

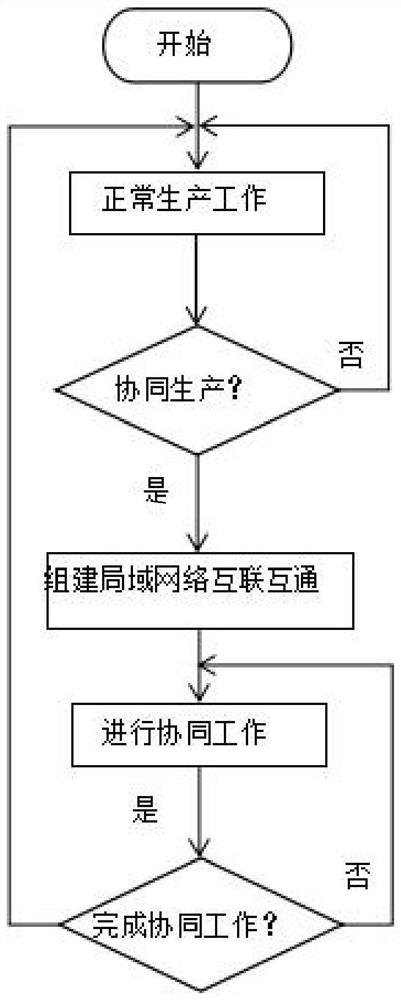

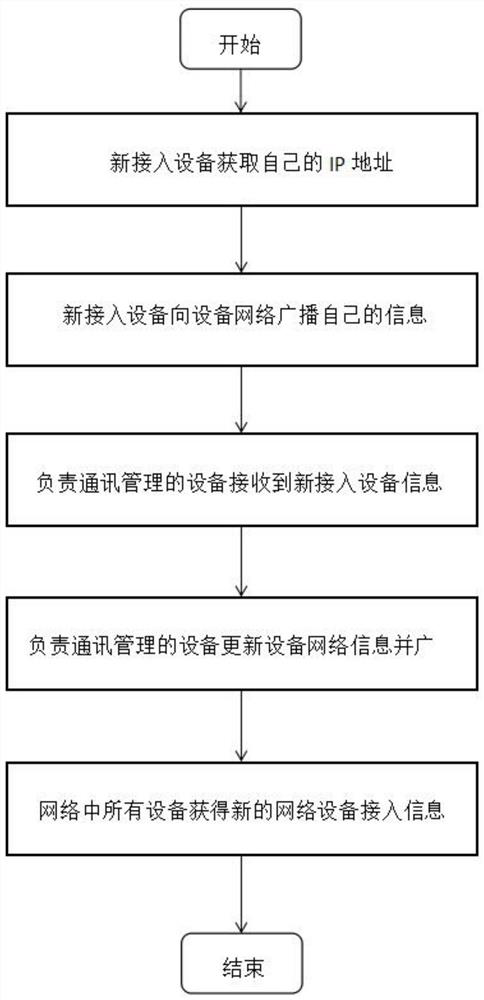

Self-organizing machine interconnection method

ActiveCN111586198AEasy to manageFlexible and open networkTransmissionIp addressSelf-organizing network

The invention provides a self-organizing machine interconnection method. According to the method, devices accessed to the same device network are interconnected and intercommunicated in a self-organized mode, the devices newly added into the network broadcast IP addresses and main device information to all IP addresses in the network, all the devices in the network can know the devices in the network and the IP addresses of the devices, and the devices can communicate with one another. The equipment responsible for communication management in the network receives broadcast addresses and conditions of other equipment, the access condition of the equipment in the network is obtained, the equipment is communicated with other equipment through the TCP to stop broadcasting, the network communication condition is managed by the communication equipment, the communication condition of the other equipment is recorded by the communication equipment, and a self-organizing network is formed amongthe equipment.

Owner:江苏科瑞德智控自动化科技有限公司 +1

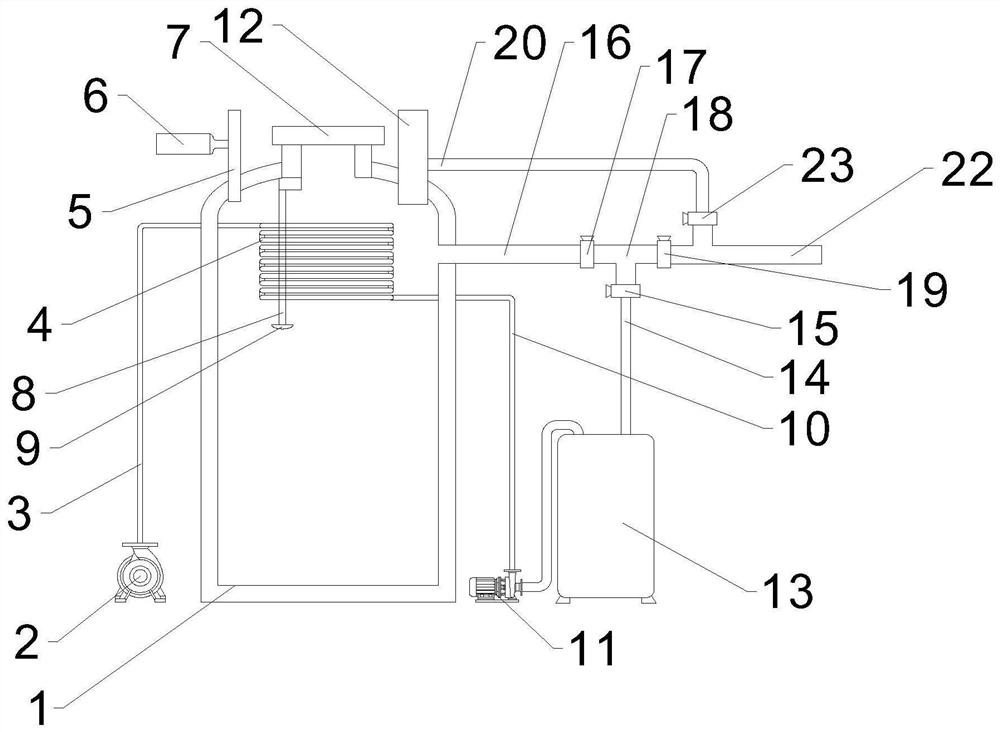

Explosion-proof device for biomass gas production

ActiveCN112646608APrevent explosion accidentsAvoid production delaysGasifier mechanical detailsGasification processes detailsProcess engineeringFlash light

The invention discloses an explosion-proof device for biomass gas production, wherein the explosion-proof device for biomass gas production comprises a gasification furnace, an injection water pump, a water inlet pipe, an evaporation pipe and a whistling alarm device; a first valve is arranged at the communication part of a steam outlet pipe and a three-way connecting pipe, and a second valve is arranged at the communication part of a main gas outlet pipe and the three-way connecting pipe; a flashing light alarm device comprises a first installation cylinder, a first spring, a first sliding stop block, a first safety pipe and a first membrane; the whistling alarm device comprises a second installation cylinder, a second spring, a second sliding stop block, a second safety pipe and a second membrane; and a whistle comprises a whistle base, a reed base, a reed and an air outlet cavity pipe. A temperature sensor detects the temperature of biomass gas produced in the gasification furnace, high-pressure steam of a high-pressure steam storage tank is used for removing blockages in the main gas outlet pipe, the blockages are removed, faults are simply and rapidly removed, and thus workers are safely and orderly arranged for overhaul and maintenance.

Owner:安徽香杨新能源科技发展股份有限公司

Continuous plating solution purification device

The invention discloses a continuous plating solution purification device which comprises a plating solution storage tank, a dosing tank, an electrolytic tank, a primary activated carbon adsorption tank and a secondary activated carbon adsorption tank, wherein a first liquid inlet is formed in the side wall of the dosing tank, the first liquid inlet communicates to the plating solution storage tank through a flowing-in pipeline, and a filtering device is arranged on the flowing-in pipeline; an electrode group for electrolytic impurity removal is arranged in the electrolytic tank; and a first overflow port is formed in the side wall of the secondary activated carbon adsorption tank and communicates to the plating solution storage tank through an outflow pipeline. According to the invention,the purity of the plating solution is improved effectively, and production delay caused by stopping an electroplating process during purification of the plating solution is avoided, so that the production efficiency is improved.

Owner:JIANGSU JIUTIAN PHOTOELECTRIC TECH CO LTD

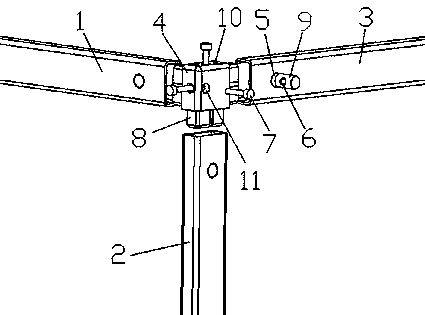

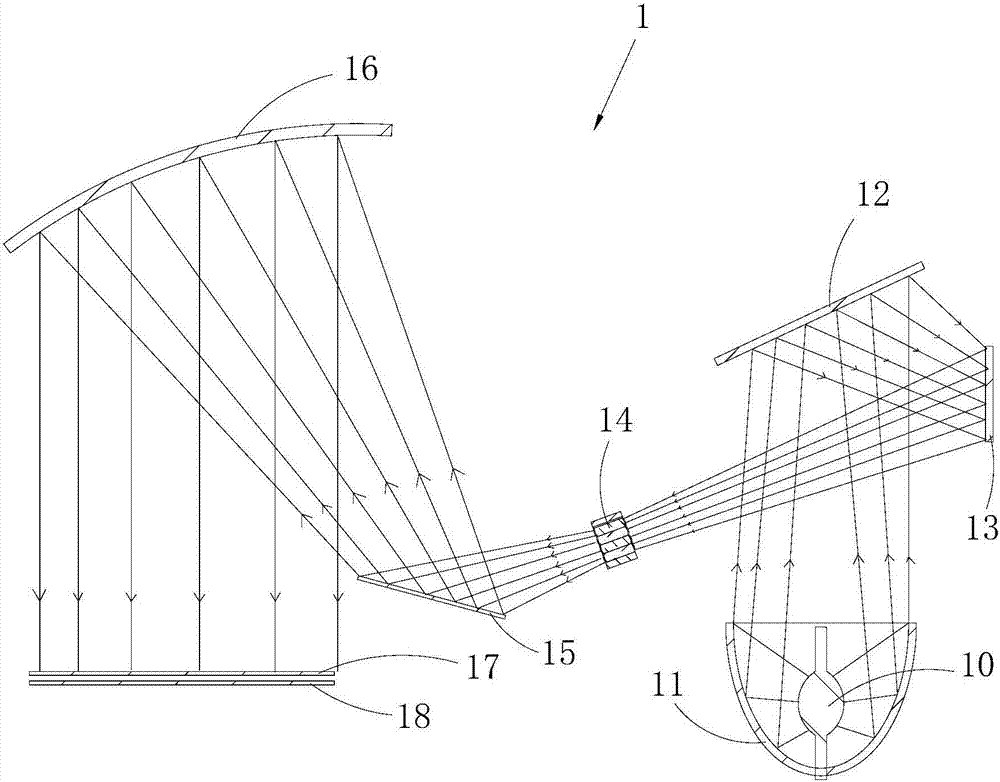

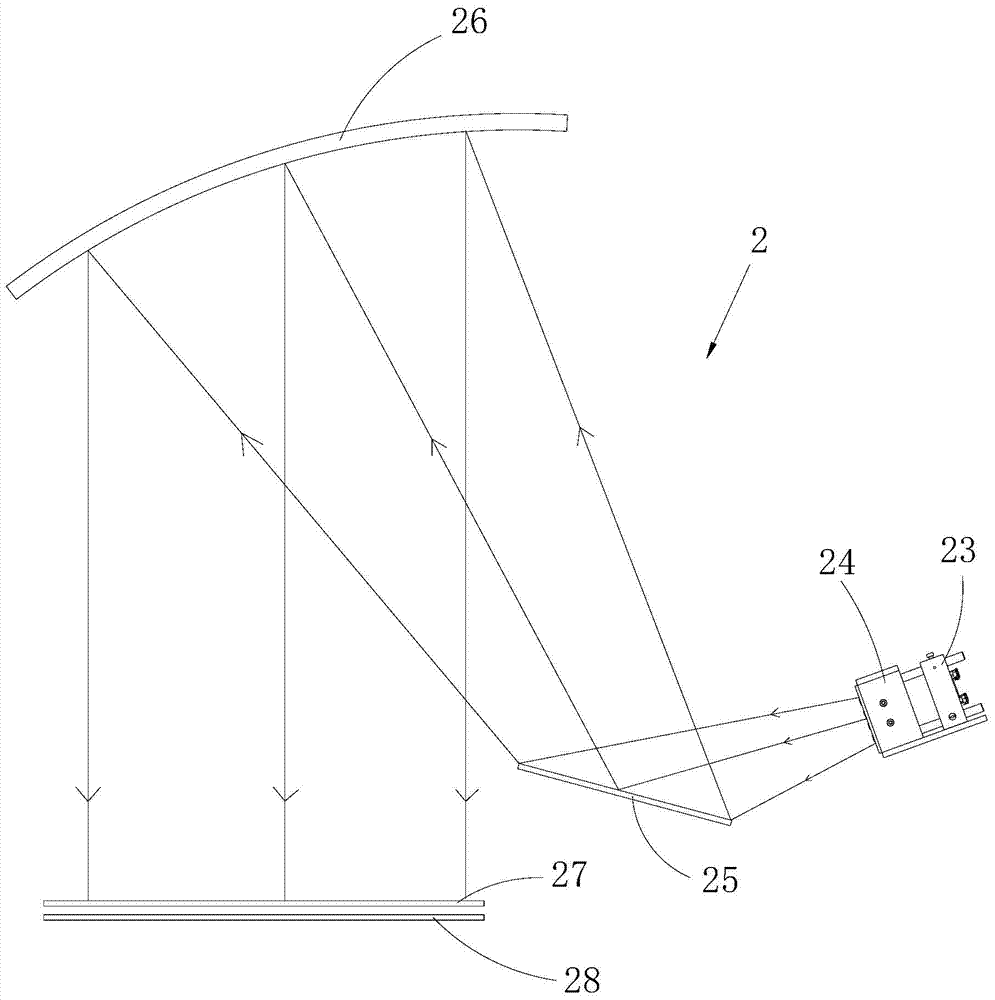

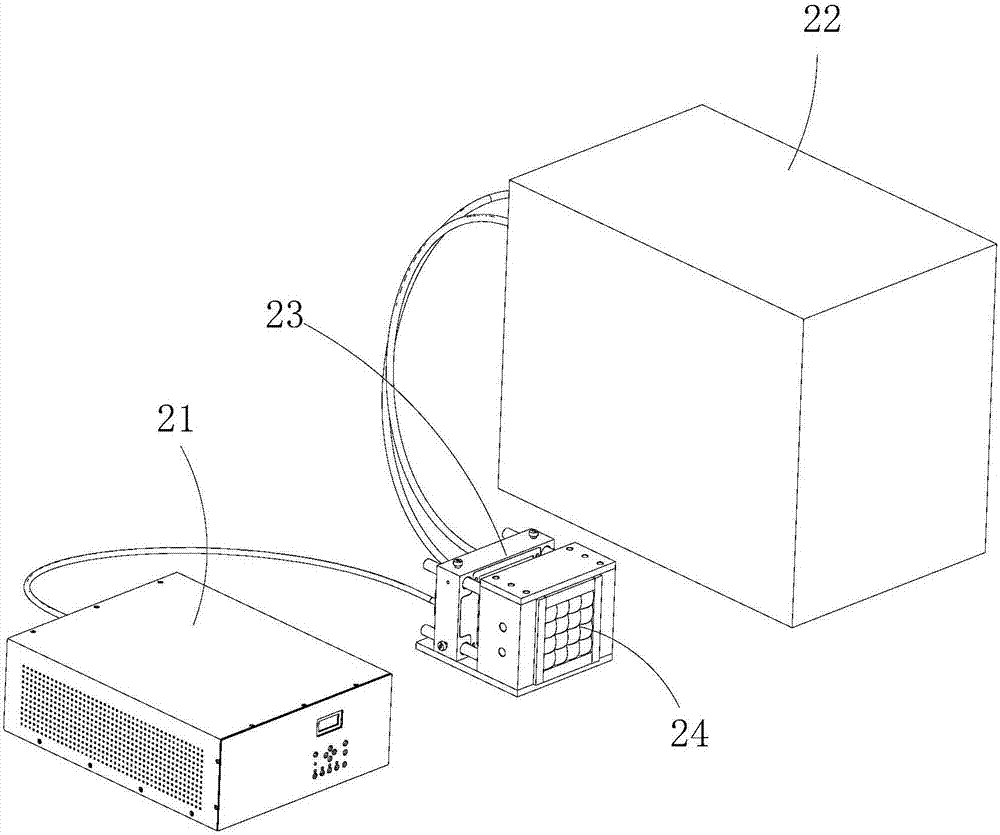

uv LED light source structure and parallel light exposure machine

ActiveCN105301910BSimple optical structureIncrease heatPhotomechanical exposure apparatusMicrolithography exposure apparatusPlane mirrorEngineering

The invention relates to the technical field of exposure machines, and discloses a UV LED light source structure and a parallel light exposure machine, including a UV LED lamp head, a fly-eye lens module, a plane mirror and a spherical mirror, along the light path direction of the UV LED light source structure, a UV LED lamp head, and a fly-eye lens. The module, plane mirror and spherical mirror are arranged in sequence; UV LED lamp beads are arranged in the UV LED, and the UV LED lamp head and the fly-eye lens module are arranged in parallel adjacent to each other. The distance adjustment mechanism is connected. The UV LED lamp head is placed in front of the fly-eye lens module, and the parallel light for exposure is formed by using the fly-eye lens module, plane mirror and spherical mirror; the UV LED light source structure is used in the existing parallel light exposure machine without the need for customers Renewing equipment does not require large-scale modification of equipment, and at the least cost, you can obtain a low-temperature, energy-saving, environmentally friendly, and safe exposure machine with UV LED light source structure, avoiding delays in production, and greatly reducing costs.

Owner:张河生

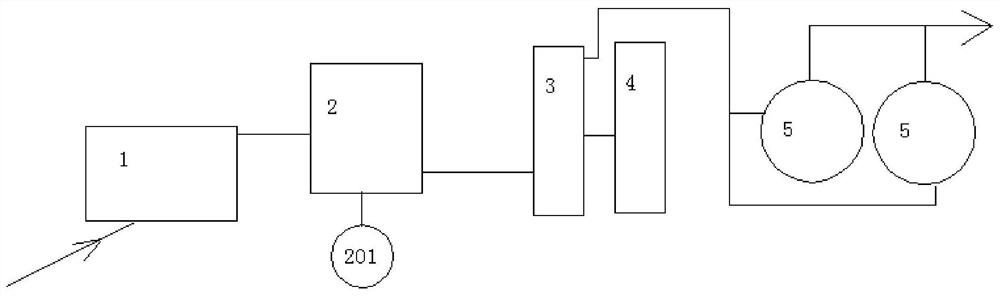

Centrifugal air compressor system for large-scale air separation

InactiveCN111947395AReduce energy consumptionTo achieve the goal of reducing emissionsSolidificationLiquefactionMolecular sieveCooling tower

The invention provides a centrifugal air compressor system for large-scale air separation. The system comprises a self-cleaning filter. The input end of the self-cleaning filter is communicated with an air inlet, and the output end of the self-cleaning filter is communicated with a centrifugal air compressor. The centrifugal air compressor is communicated with an air cooling tower. The air coolingtower is respectively communicated with a water cooling tower and a molecular sieve. The molecular sieve is communicated with an air outlet. According to the centrifugal air compressor system for thelarge-scale air separation, after a series of improvements such as equipment upsizing, an automatic emergency production protection system, a resistance-free drying system and the like, the economicbenefit is considerable, and the production is not influenced under special conditions. Zero emission is achieved by reducing technological process resistance, recycling waste nitrogen or recycling; the purposes of energy conservation and emission reduction are achieved by arranging an automatic yield-keeping emergency system; and the benefit is considerable.

Owner:RIZHAO STEEL HLDG GROUP

Method for forging flat steel by using universal hammerhead

ActiveCN102581187BGuaranteed surface qualityAvoid production delaysMetal-working apparatusHeating furnaceForging

A method for forging flat steel by using universal hammerheads comprises feeding red steels to a chamber heating furnace, quickly heating to 1170+ / -50 DEG C, holding for 2h, performing cogging at a single-edge reduction amount of 40-45mm and a frequency of 180 times / min, forging billet material into an intermediate billet with a diameter of 440mm after three-pass forging, forging from a machine A to a machine B at a reduced frequency of 90 times / min, a single-edge reduction amount of the R group of hammerheads of 30-40mm, a forging force of the R group of hammerheads of 800-900t, a single-edge reduction amount of the L group of hammerheads of 3-5mm and a forging force of the L group of hammerheads of 150-200t, forging from the machine B to the machine A at the reduced frequency of 90 times / min, a single-edge reduction amount of the L group of hammerheads of 30-40mm, a forging force of the L group of hammerheads of 800-900t, a single-edge reduction amount of the R group of hammerheads of 3-5mm and a forging force of the R group of hammerheads of 150-200t, performing final-pass forging at a single-edge reduction amount of 2-5mm, a forging force of 100-150t and a finish forging temperature not lower than 850 DEG C, and shaping four edges of the forging. The once-heating of flat steel forging is effectively controlled, the once qualified rate of the method through test is 100%, the production efficiency is improved, and at the same time the cost is lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

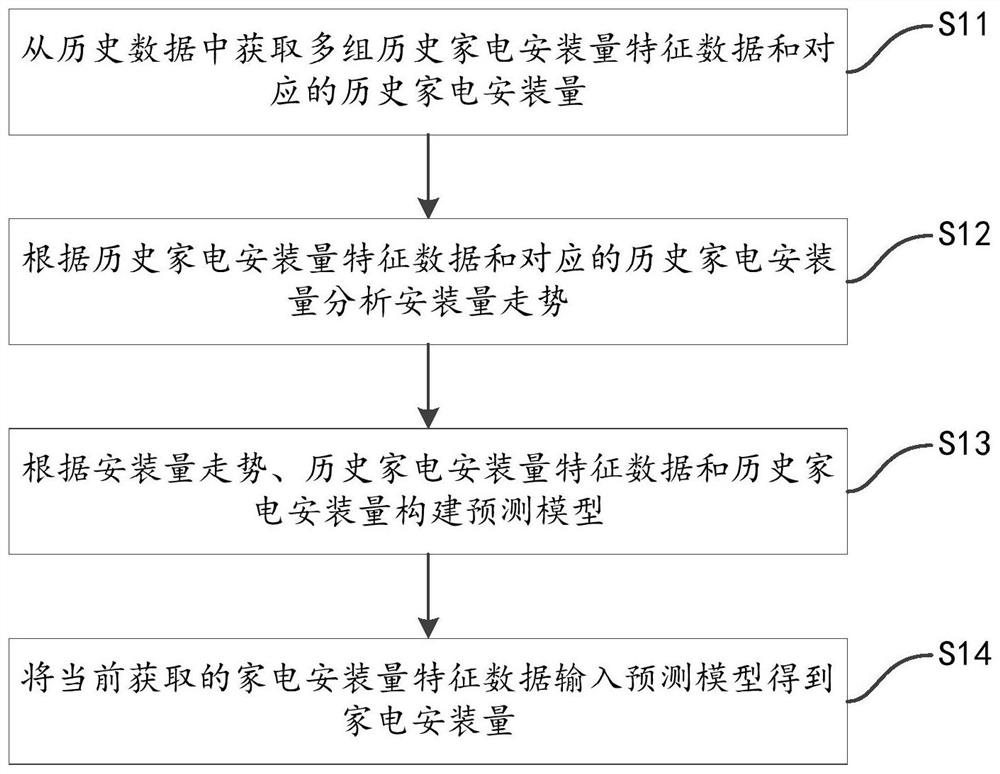

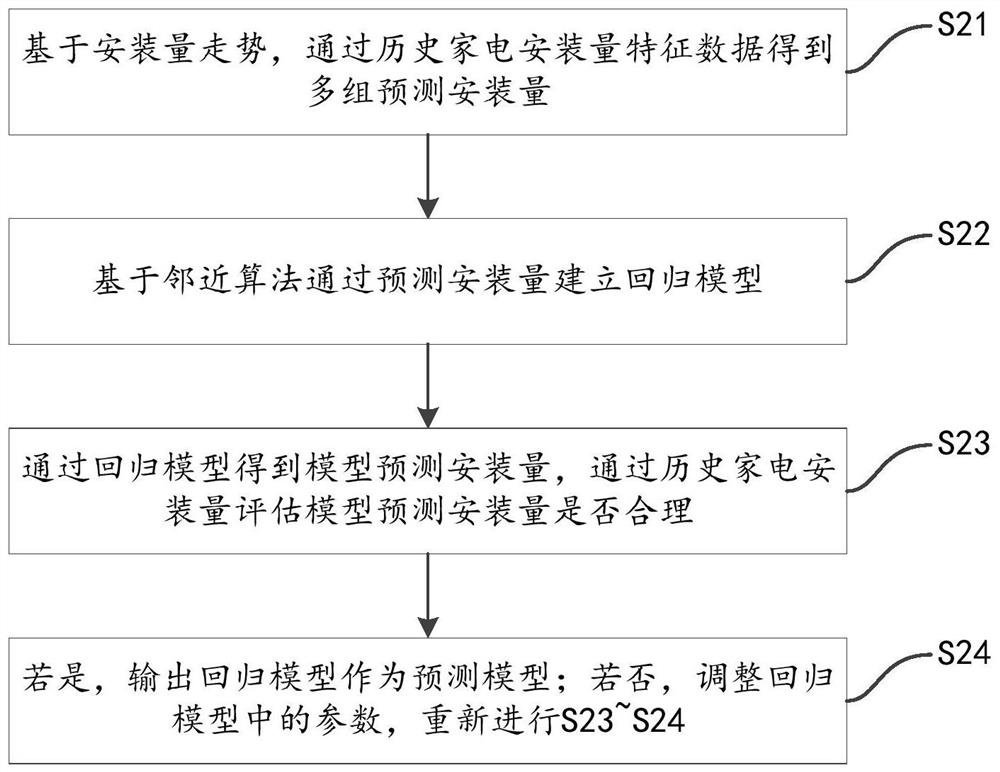

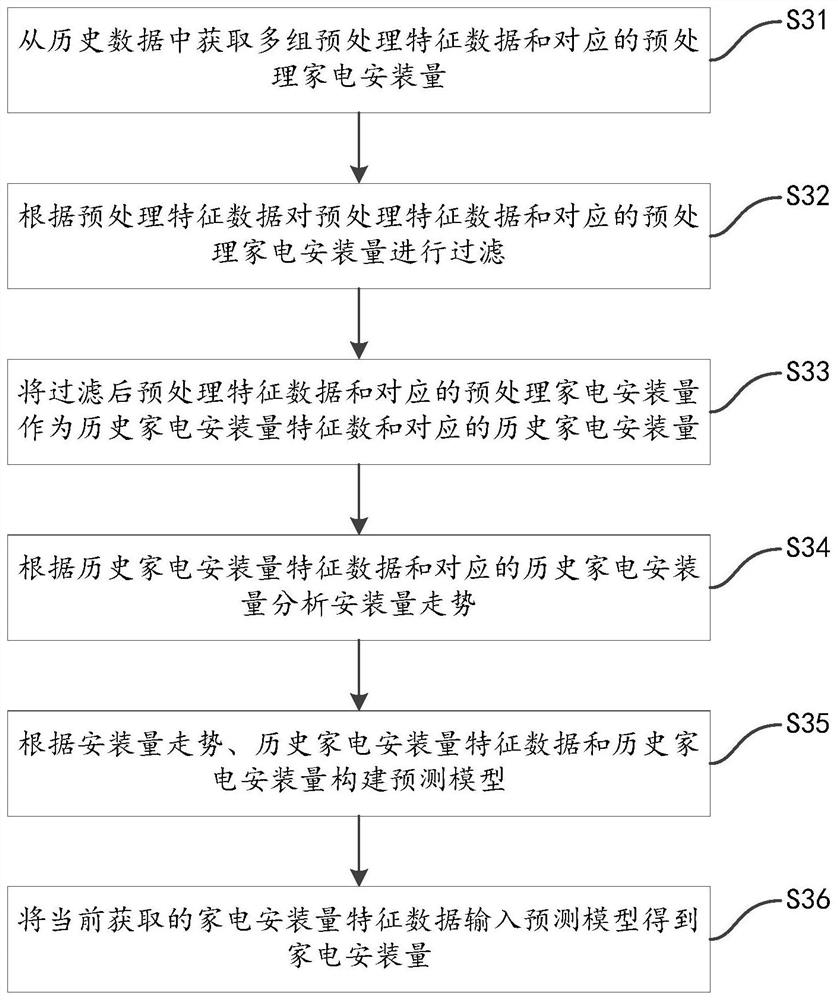

A method, system, and storage medium for predicting installed quantity of home appliances

ActiveCN111382890BReduce waiting timeSlow down periodForecastingMarketingMaterials preparationLogistics management

The invention relates to a method, a system and a storage medium for predicting the installed quantity of home appliances. The prediction method includes: analyzing the trend of installation volume according to the characteristic data of historical home appliance installation volume and the corresponding historical home appliance installation volume; The feature data is input into the prediction model to obtain the installed quantity of home appliances. Enterprises can prepare materials in a planned manner according to the forecast results, which can effectively avoid out-of-stock phenomena and production delays caused by insufficient material preparations, thereby reducing the waiting time for air-conditioning production; combined with the forecast results, it can reduce the safety stock and organize the supply of goods reasonably , to reduce logistics costs; by considering the controllable factors, uncontrollable factors and changes in air-conditioning installation data of the enterprise, comparing the predicted value with the real value, and analyzing the fluctuation of the installation data, so as to start the controllable factors of the enterprise in a planned and organized manner, Do positive interference.

Owner:GREE ELECTRIC APPLIANCES INC

Efficient textile machine with reserve reels

ActiveCN111498609AAvoid production delaysEasy to removeFilament handlingClassical mechanicsElectric machinery

The invention relates to the technical field of textile machines, in particular to an efficient textile machine with reserve reels. The efficient textile machine comprises a textile machine body, twobase plates are arranged in front of the textile machine body, a connecting plate is arranged on the surface of each base plate, a connecting screw is arranged on the surface of each connecting plate,a vertical plate is arranged on the surface of each base plate, a first driving motor is arranged on the surface of each vertical plate, a shaft body of each first driving motor penetrates through the corresponding vertical plate, a rotating disc is arranged at the end of the shaft body of each first driving motor, mounting grooves are formed in the surface of one rotating disc, and bearings arearranged in the mounting grooves. The efficient textile machine with the reserve reels has the beneficial effects that the reels are arranged on rotating rods in a sleeving mode, the rotating rods arefixed to the rotating discs, and the multiple sets of rotating rods are arranged on the rotating discs and used for loading the reels, after one set of reels is used, the first driving motor drives the rotating discs to rotate by 60 degrees so that the reels loaded on the other set rotating rods can be switched for workers to use, and production delay caused by reel loading and unloading is avoided.

Owner:安徽凯炫来纺织科技有限公司

A self-organized machine interconnection method

The present invention proposes a self-organized machine interconnection method, which allows devices connected to the same device network to self-organize interconnection and intercommunication, and a device newly added to the network broadcasts its own IP address and device information to all IP addresses in the network. Main information, so that all devices in the network can know the device in the network and the IP address of the device, and the devices can communicate with each other. The equipment responsible for communication management in the network receives the broadcast address and status of other equipment, obtains the access status of the equipment in the network, and communicates with other equipment through TCP. Other equipment stops broadcasting, and the communication equipment manages the network communication. The communication situation will be recorded by the communication equipment, and the self-organizing network is formed between the equipment.

Owner:江苏科瑞德智控自动化科技有限公司 +1

Display shell injection mold with drainage opening material cutting-away function

PendingCN113619028AAvoid delays in productionEasy replacementDomestic articlesEngineeringDisplay device

The invention discloses a display shell injection mold with a drainage opening material cutting-away function, and belongs to the technical field of injection molds. The display shell injection mold comprises a front mold, a rear mold, an outer sprue and a drainage opening cutting mechanism; the front mold is clamped on the rear mold; the outer sprue is arranged on the front mold; the outer sprue is communicated with a cavity in the rear mold and the front mold; the drainage opening cutting mechanism is arranged in the rear mold; and the drainage opening cutting mechanism is pressed against a drainage opening communicated with the cavity. According to the invention, a first oil way controls a first lifting oil cylinder to descend and pulls cutters out of a guide sleeve, a second oil way controls a rotating oil cylinder to rotate and drive a cutter head to rotate, the cutter head rotates to send different cutters to the position below the guide sleeve, and the first oil way controls the first lifting oil cylinder to ascend and insert the cutters into the guide sleeve, so that replacement of the cutters can be completed; the injection mold does not need to be disassembled, the situation that production is delayed due to machine stagnation is avoided, the replacement operation process is simple and convenient, and the labor cost and the working time cost are saved.

Owner:苏州冬宝光电科技有限公司

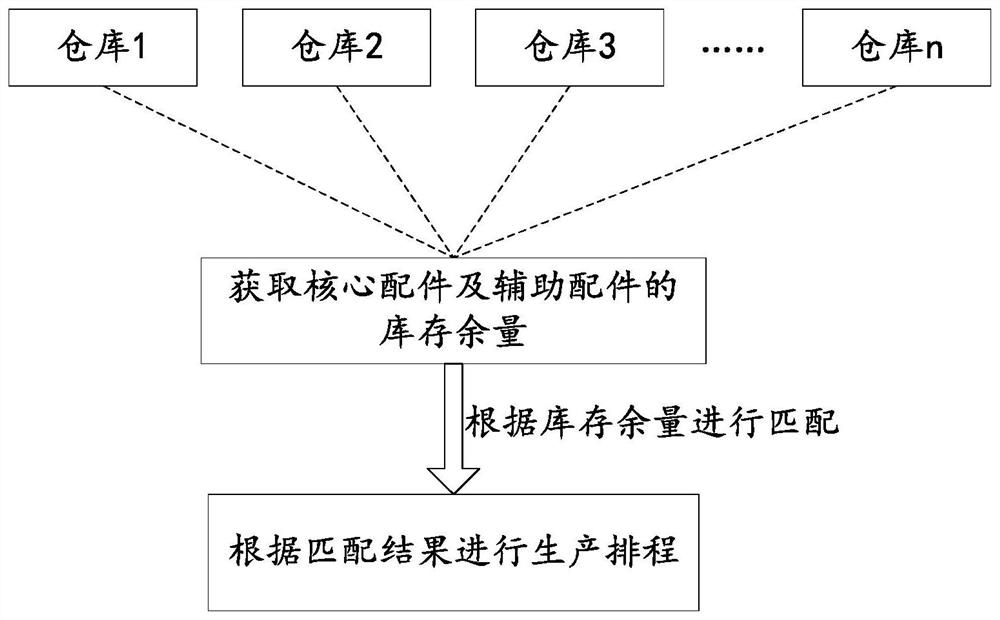

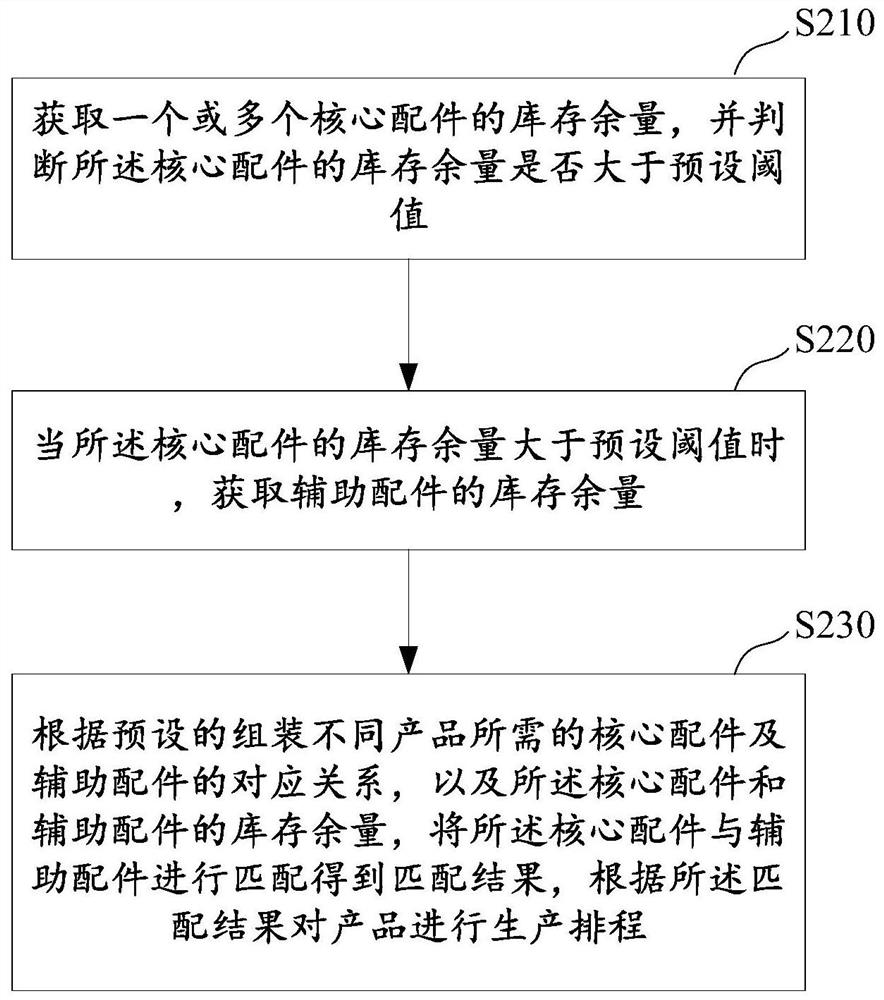

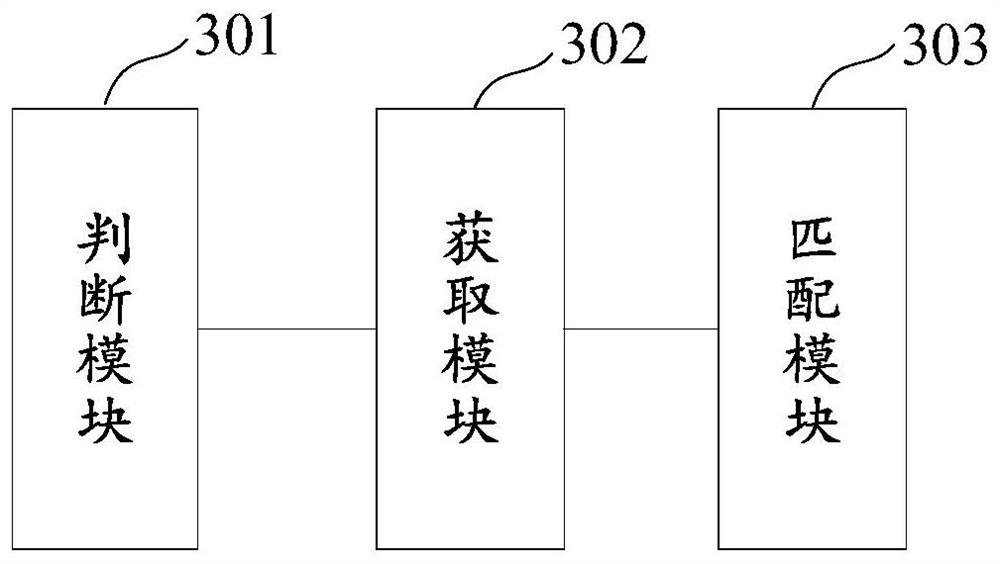

Production scheduling method, device and storage medium based on spare parts inventory

The present disclosure provides a production scheduling method, device and storage medium based on spare parts inventory. The production scheduling method based on spare parts inventory includes: obtaining the inventory balance of one or more core parts, and judging whether the inventory balance of the core parts is greater than a preset threshold; When the amount is greater than the preset threshold, obtain the inventory balance of auxiliary accessories; The core parts and the auxiliary parts are matched to obtain a matching result, and the production schedule of the product is carried out according to the matching result. Based on the technical scheme of the present invention, warehouse resources can be saved, production costs can be reduced, the efficiency and accuracy of production scheduling can be improved, and the results of production scheduling can be made more scientific and reasonable.

Owner:GREE ELECTRIC APPLIANCES INC +1

Thickness gauge and its use and maintenance method

ActiveCN103968785BFlexible movementSo as not to damageUsing wave/particle radiation meansDrive motorEngineering

The invention discloses a thickness gauge and using and overhauling methods thereof, and relates to the field of measuring equipment. The thickness gauge comprises a control terminal, a main electric cabinet and a water-cooling tank, and the control terminal is connected with the main electric cabinet. A C-frame comprises an upper cantilever and a lower cantilever, and the upper cantilever and the lower cantilever are both arranged horizontally and connected with each other through a supporting arm perpendicular to the two cantilevers. Each of the upper cantilever and the lower cantilever of the C-frame is provided with an air temperature detector. A C-type traveling drive device matched with the C-frame is arranged on the inner wall of the C-frame, and a drive motor is arranged on the outer wall of the C-frame and connected with the C-type traveling drive device. The junction box, the main electric cabinet and the water-cooling tank are all connected with the C-frame. A signal detector is arranged at one end, farther away from the supporting arm, of the upper cantilever, and a radiation source is arranged at one end, farther away from the supporting arm, of the lower cantilever. The thickness gauge is accurate in measurement.

Owner:MAANSHAN HENGRUI MEASURE EQUIP

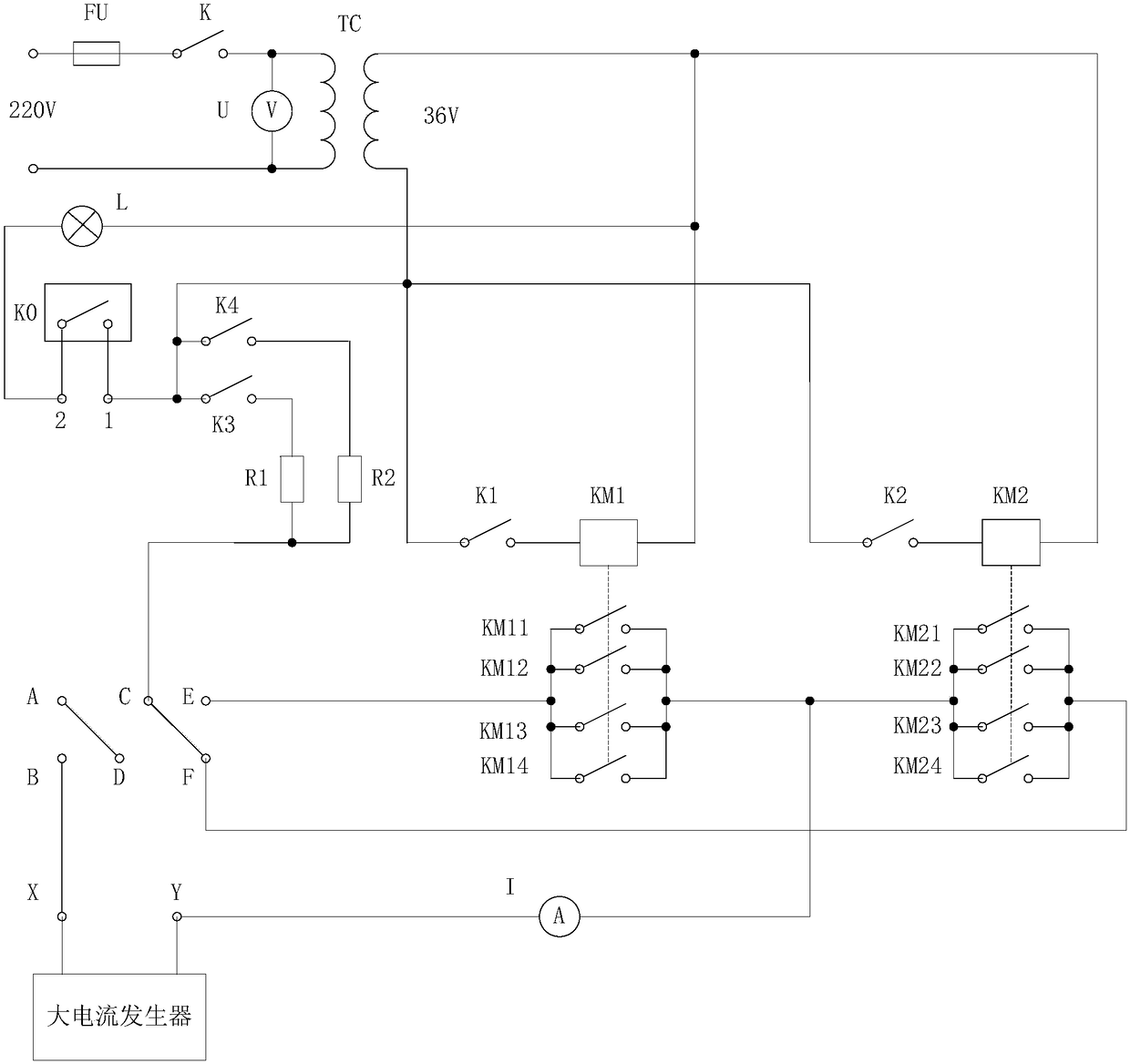

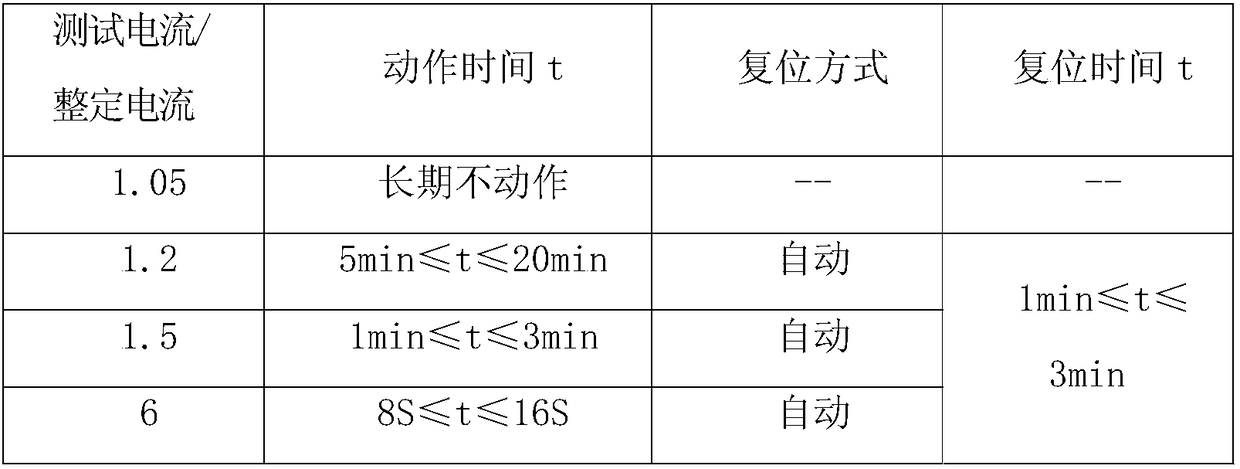

Motor comprehensive protector tester

PendingCN108594053AImprove fault detection efficiencyAvoid production delaysElectrical testingPolyphase network asymmetry measurementsTester deviceEngineering

The invention relates to the motor comprehensive protector testing technology. According to the invention, an existing motor comprehensive protector cannot be normally used due to the unqualified state or the long-distance transportation turbulence condition of the existing motor comprehensive protector. Meanwhile, whether the normal usage of the existing motor comprehensive protector is enabled or not cannot be detected in time, so that the production is delayed. The invention provides a motor comprehensive protector tester. The technical scheme of the motor comprehensive protector tester canbe summarized as follows: a corresponding leakage test circuit, a corresponding overload test circuit and a corresponding phase loss test circuit are integrally arranged in the tester. As a result, whether the electric leakage condition, the overload condition and the phase loss condition of the motor comprehensive protector exist or not can be tested before the usage of the motor comprehensive protector. The fault detection efficiency is greatly improved. The condition that the motor comprehensive protector cannot be used normally due to electric leakage, overload and phase loss conditions so as to delay the production can be avoided. The tester is suitable for motor comprehensive protectors.

Owner:SICHUAN CHUANMEI HUARONG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com