Longitudinal-circulation autoclave provided with external thermal-cold cycling device

A technology of cold and heat cycle and autoclave, applied in the direction of lamination device, lamination, layered products, etc., can solve the problems of affecting product process, large temperature difference, temperature difference between front and back, etc., to increase the surface area of radiator, temperature The effect of uniform distribution and reduced temperature difference between upper and lower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

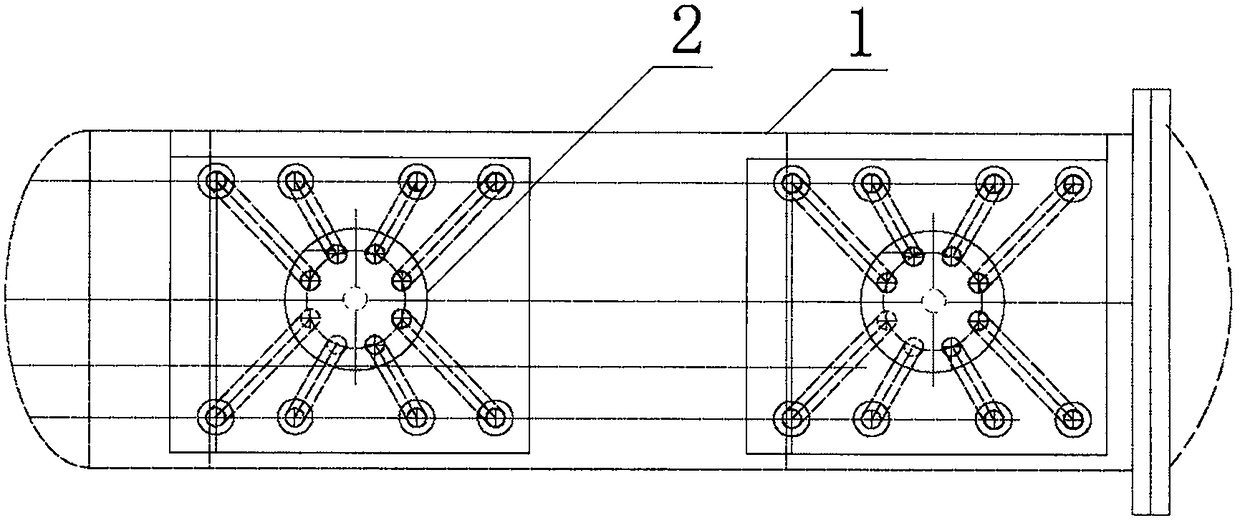

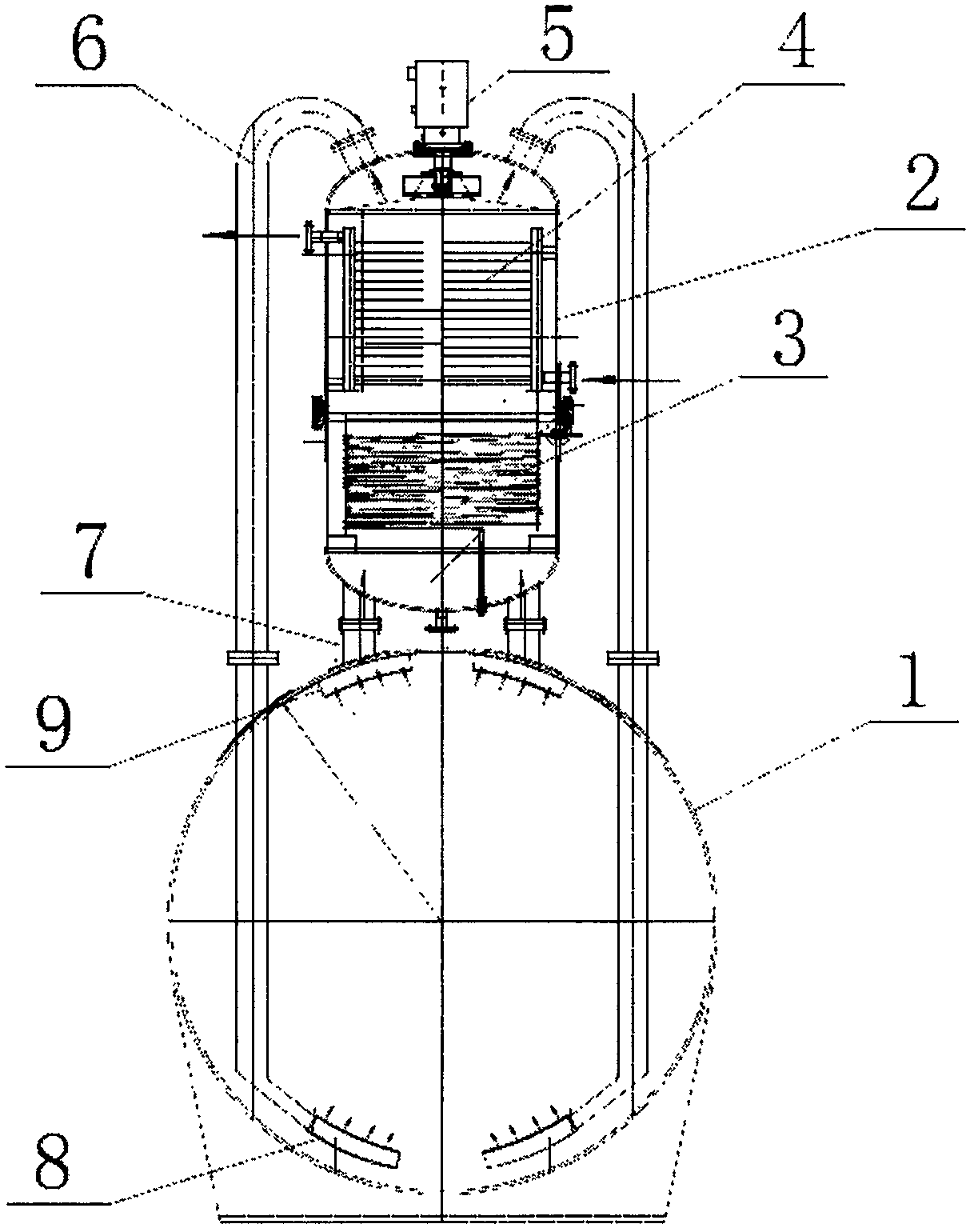

[0020] combine figure 1 , figure 2 , the present invention is a longitudinal circulation autoclave with an external cooling and heating cycle device. The embodiment includes a main tank body 1, a cooling and heating cycle device 2, a blowing connecting pipe 6 and a suction connecting pipe 7. The cooling and heating cycle device 2 is installed outside the main tank body 1, and the cooling and heating cycle device 2 includes a circulation fan 5, a cooler 4 and a heater 3 arranged from top to bottom. One end of the blowing connecting pipe 6 is connected above the cooler 4, and the other end is connected to the bottom end inside the main tank body 1; one end of the described air suction connecting pipe 7 is connected below the heater 3, and the other end is connected to the The top inside the main tank body 1. Circulation fan 5 provides the power of circulation for the gas in blowing connecting pipe 6, suction connecting pipe 7, cooling and heating circulation device 2 and main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com