Patents

Literature

69results about How to "Reduce the temperature difference between upper and lower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

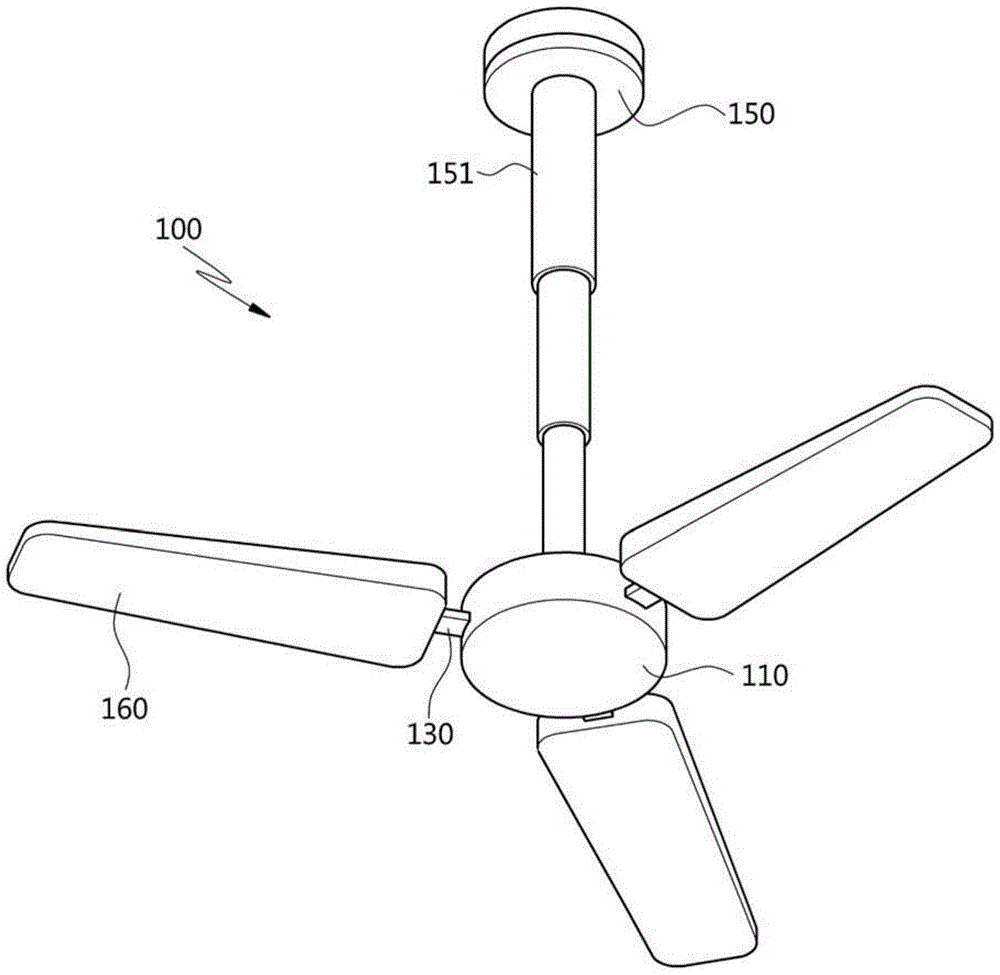

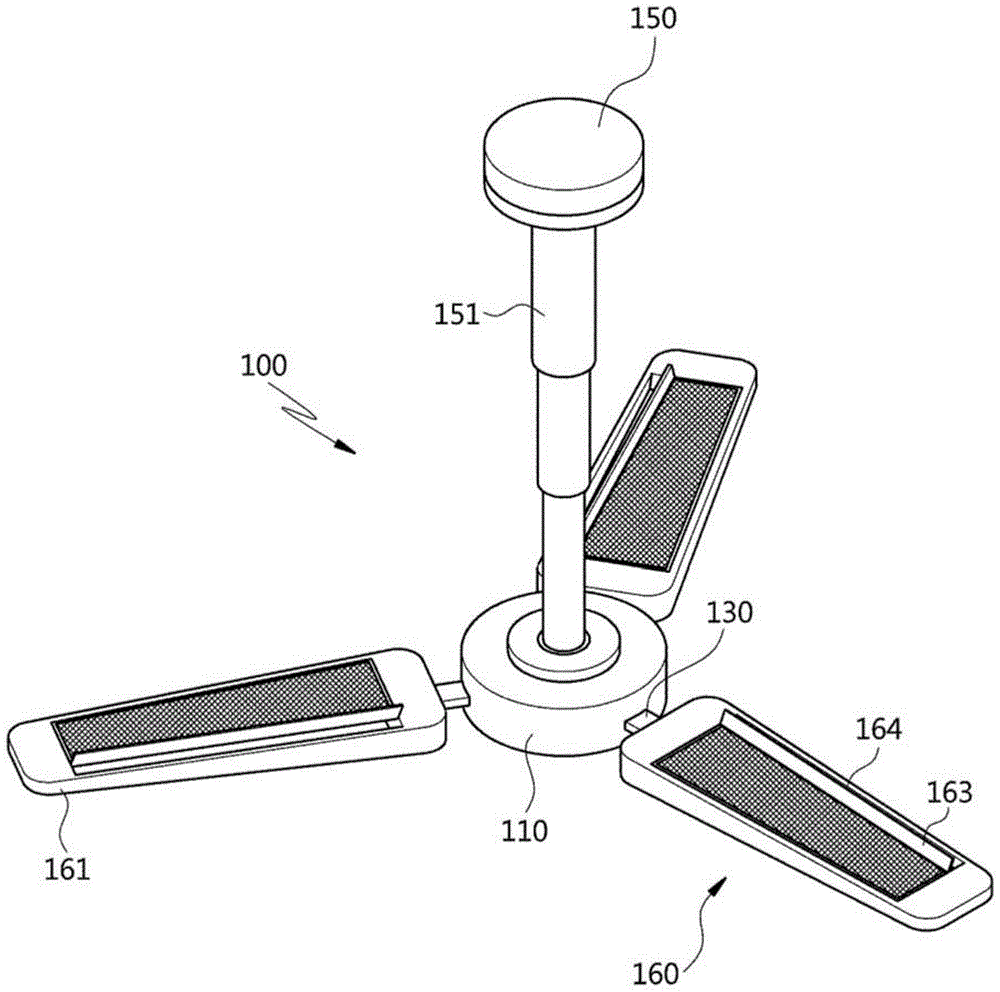

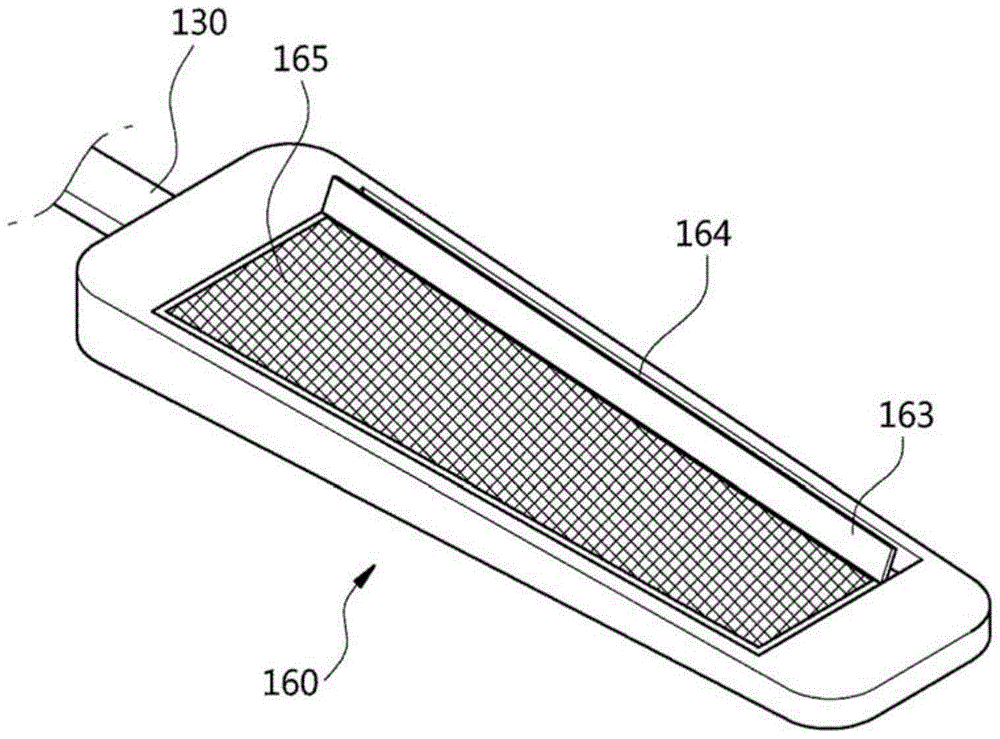

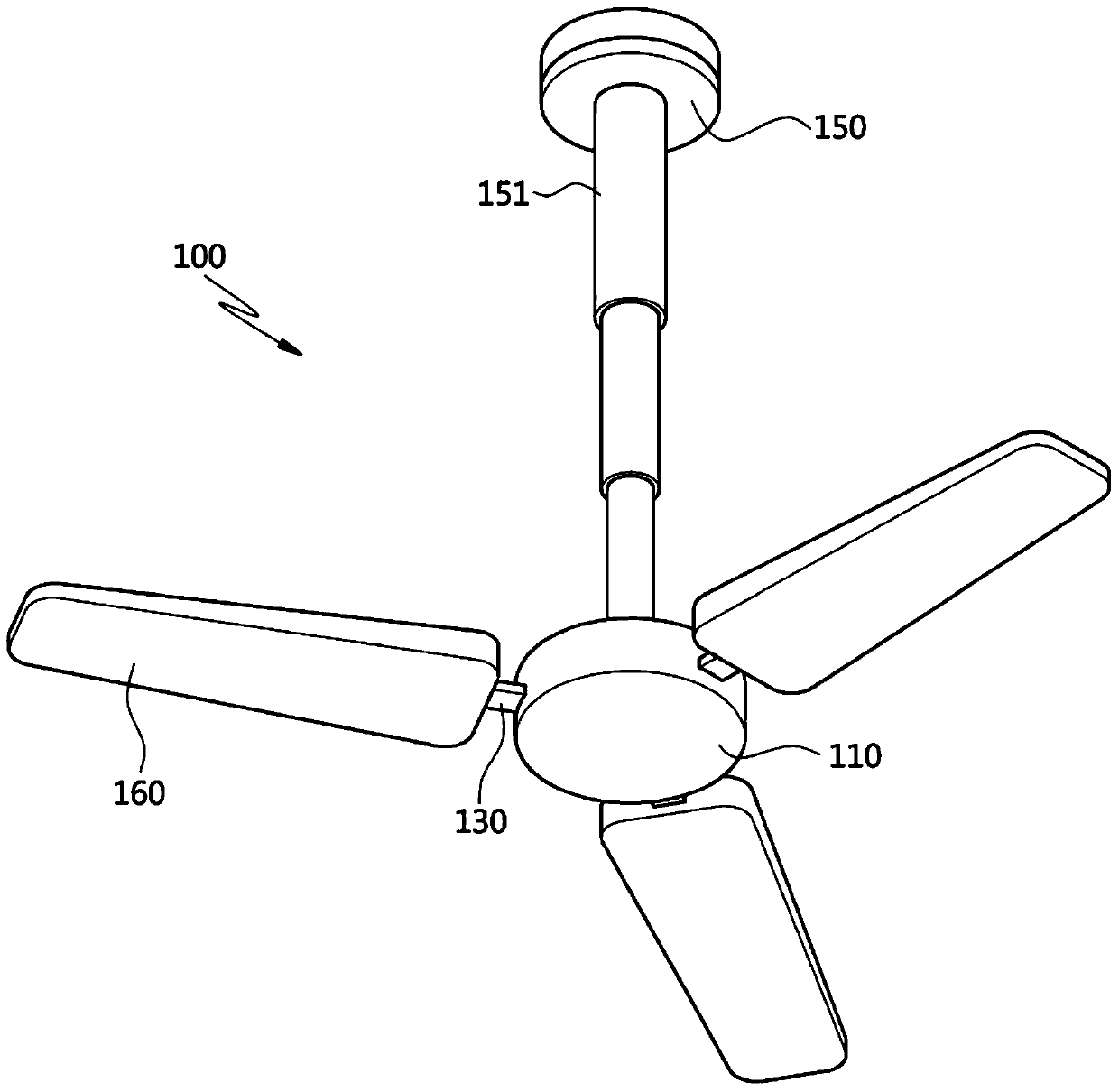

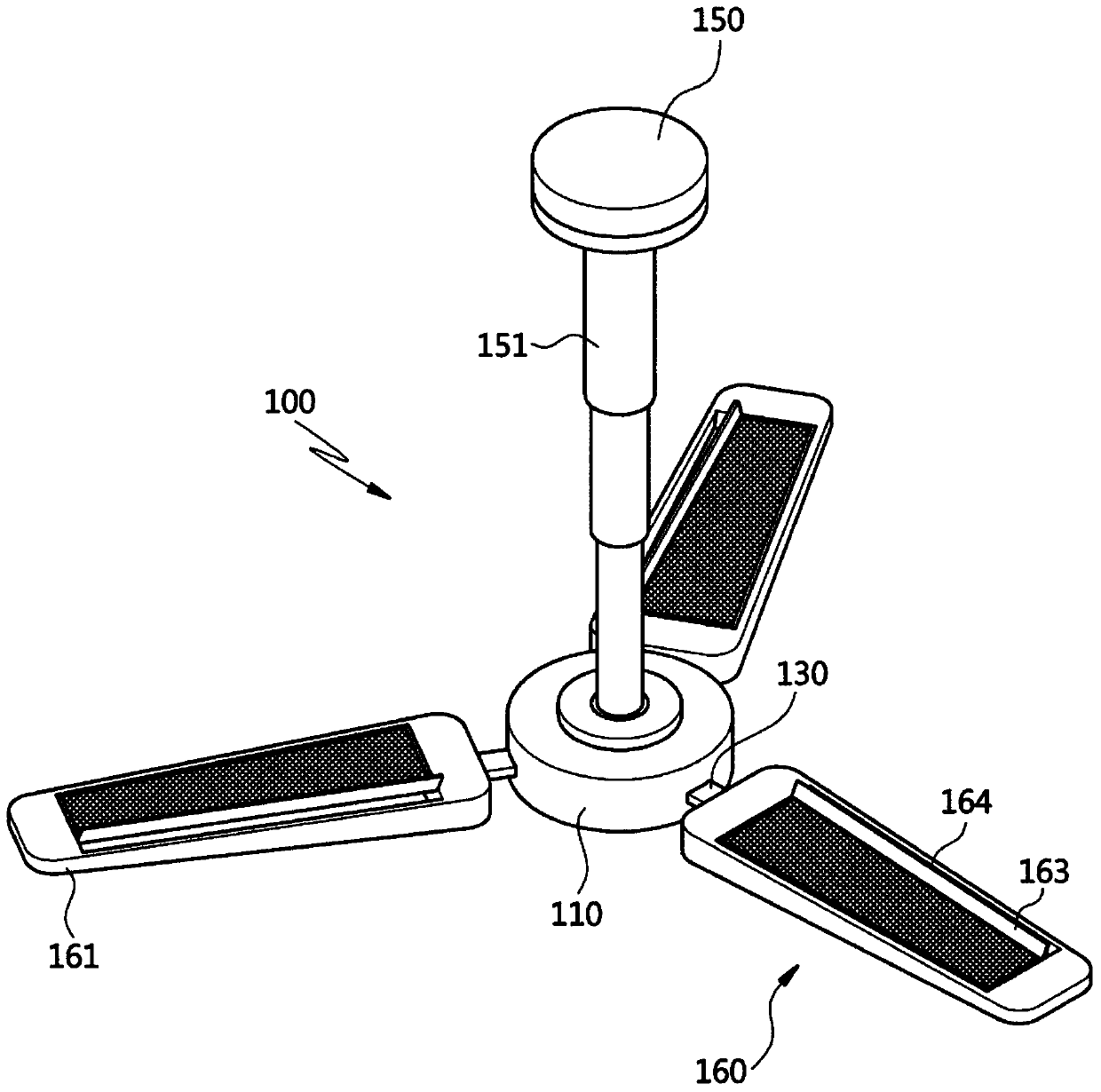

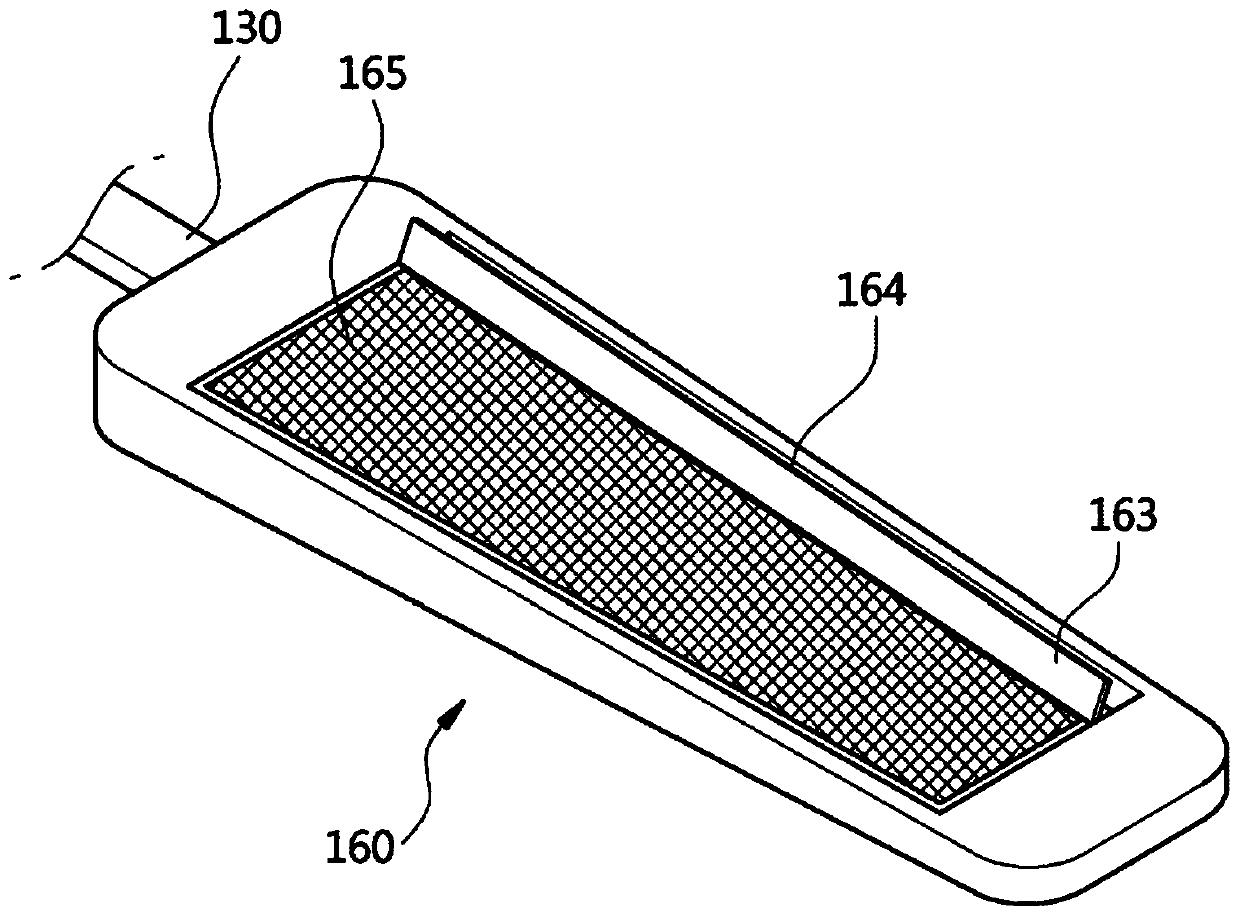

Ceiling-mounted multifunctional fan comprising polluted air sterilization and purification member

InactiveCN106247443ASmooth circulation airflowEnhance cooling/heating efficiencyPump componentsDispersed particle filtrationCeiling fanComposite function

The invention relates to a ceiling-mounted multifunctional fan comprising a polluted air sterilization and purification member. The fan is simply attached to the ceiling of the interior of a building so as to generate wind and circulate indoor air, and thus the fan circulates the stagnant indoor air and makes the interior pleasant in the spring and the autumn. When the fan is used together with a cooler in the summer, the fan lowers the indoor temperature by enabling the cool air to diffuse by means of air circulation of normal rotation (blowing the wind downwards), thereby enhancing the cooling efficiency by enabling the set temperature of the cooler to be increased and excessive air conditioner operation time to be reduced. In the winter, when the fan is used together with a heater, the fan compensates for the difference between a higher indoor temperature and a lower indoor temperature by enabling the hot air at the ceiling to flow to the floor surface by means of reverse rotation (pulling the wind upwards), thereby enhancing the heating efficiency by enabling unnecessary heater operation time to be reduced. By means of one apparatus, the fan can perform multiple functions of an air circulation ceiling fan, a contaminated air sterilizing and deodorizing apparatus, a drying apparatus, an insect extermination apparatus, an anion generation apparatus, and an aesthetically excellent interior ornament.

Owner:丘冀升

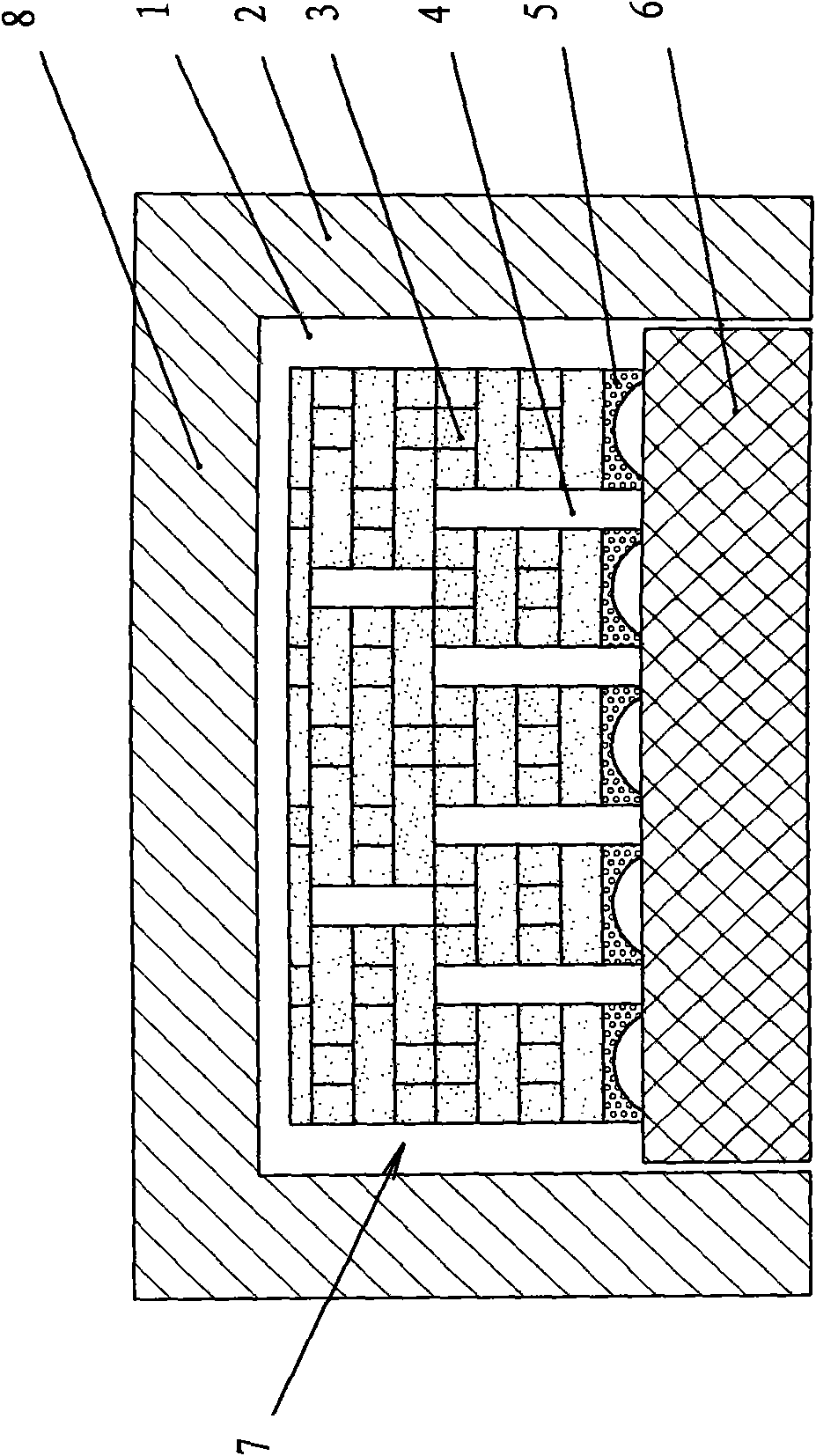

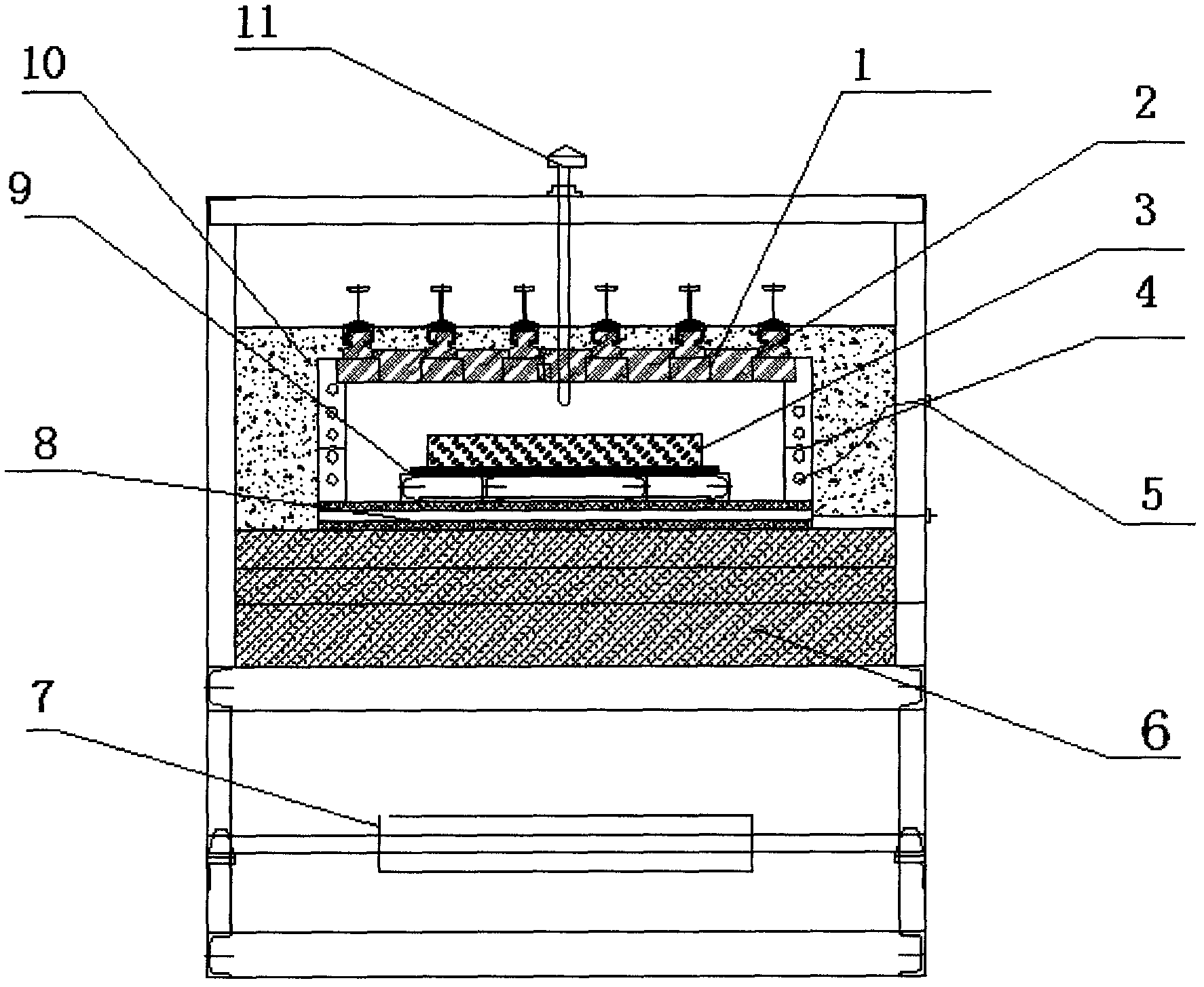

Manufacturing method for burning light burning magnesite powder by tunnel kiln

A Manufacturing method for burning light burning magnesite powder by a tunnel kiln comprises following steps: a. optionally selecting one of magnesite flotation ore concentrate, magnesite flotation tailings, magnesite ore crushing or magnesite shaft kiln dust removing powder, producing into briquette; b. drying the briquette obtained in step a in a drier; c. the sum of the longitudinal passage sectional area between the piled bricks conforming that: (1) the ratio of the sum of the longitudinal passage sectional area between the piled bricks and the sectional area of the kiln chamber is 30-40:100; (2) the ratio of the sum of the sectional area of the external passage formed by a piled brick, a kiln wall and a kiln top and the sum of the sectional area of the longitudinal interior passage between piled bricks is 1.1-1.4; d. pushing the kiln car loading briquettes into the tunnel kiln, wherein the kiln inlet temperature is 100-200 DEG C, holding for 30-60 minutes at 850-900 DEG C and the kiln outlet temperature is 40-200 DEG C; e, after kiln discharge, smashing the briquette obtained in step d into particles with the diameter less than 0.074mm.

Owner:海城华宇耐火材料有限公司

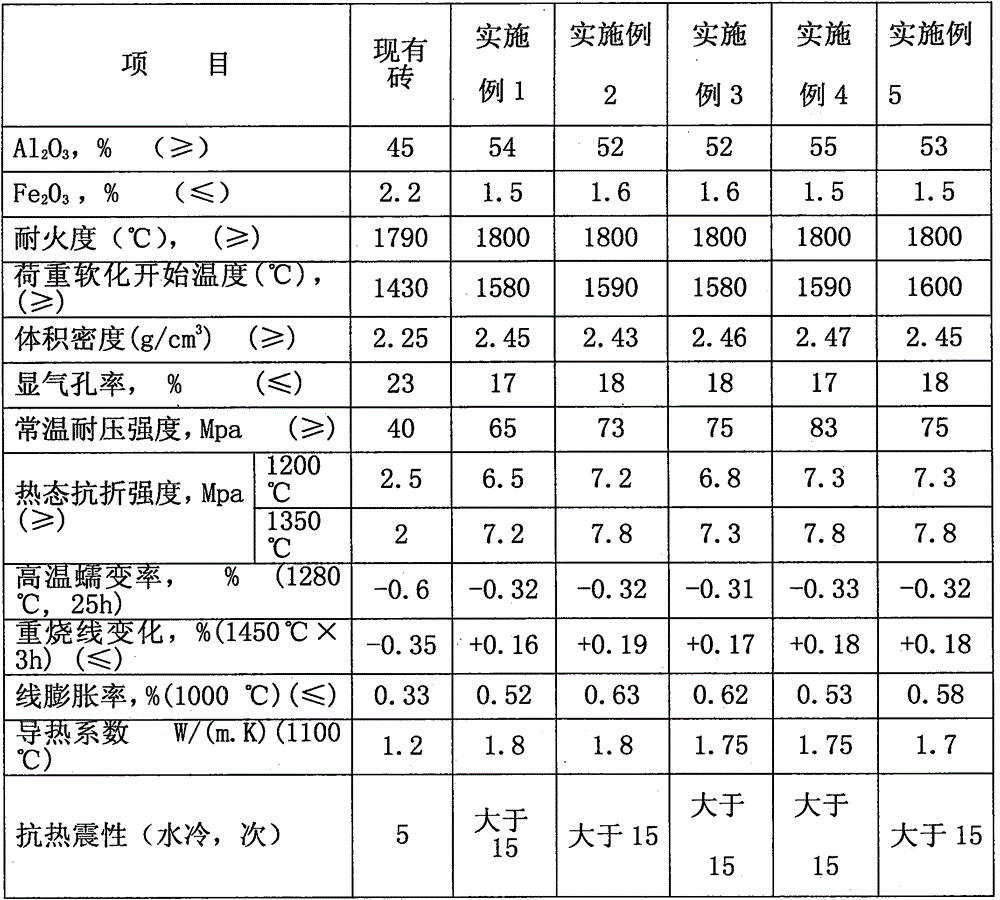

Heat-conductive and energy-saving refractory brick used for fire path wall in carbon roasting furnace and preparation method thereof

InactiveCN105418098AImproved thermal shock stabilityLow creep rate at high temperatureAluminium oxideConstruction aggregate

The invention discloses a heat-conductive and energy-saving refractory brick used for a fire path wall in a carbon roasting furnace and a preparation method thereof. The heat-conductive and energy-saving refractory brick is composed of an aggregate, a mixed fine powder and an additive according to the mass ratio of 30:30-35:5-10. The aggregate is prepared by mixing three or more components of mullite, andalusite, silicon carbide, three-grade high-aluminum bauxite and high-aluminum corundum granules and is 0.1-5 mm in granular size; the mixed fine powder is prepared by mixing four or more components of special-grade high-aluminum bauxite, sillimanite, silicon carbide, brown fused alumina, aluminum oxide, andalusite, high-quality combined clay and metal silicon fine powder and is less than 0.088 mm in granular size; and the additive is calcium lignosulphonate powder. The heat-conductive and energy-saving refractory brick is high in thermal shock stability and low in high-temperature creep rate, is high in refractoriness under load and is high in high-temperature bending strength.

Owner:董建军

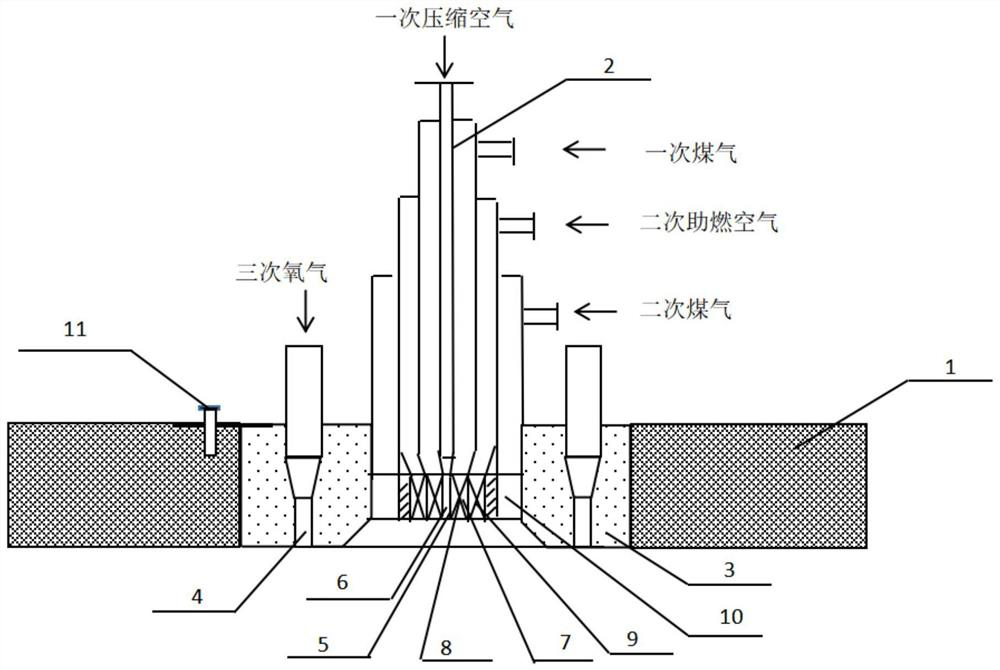

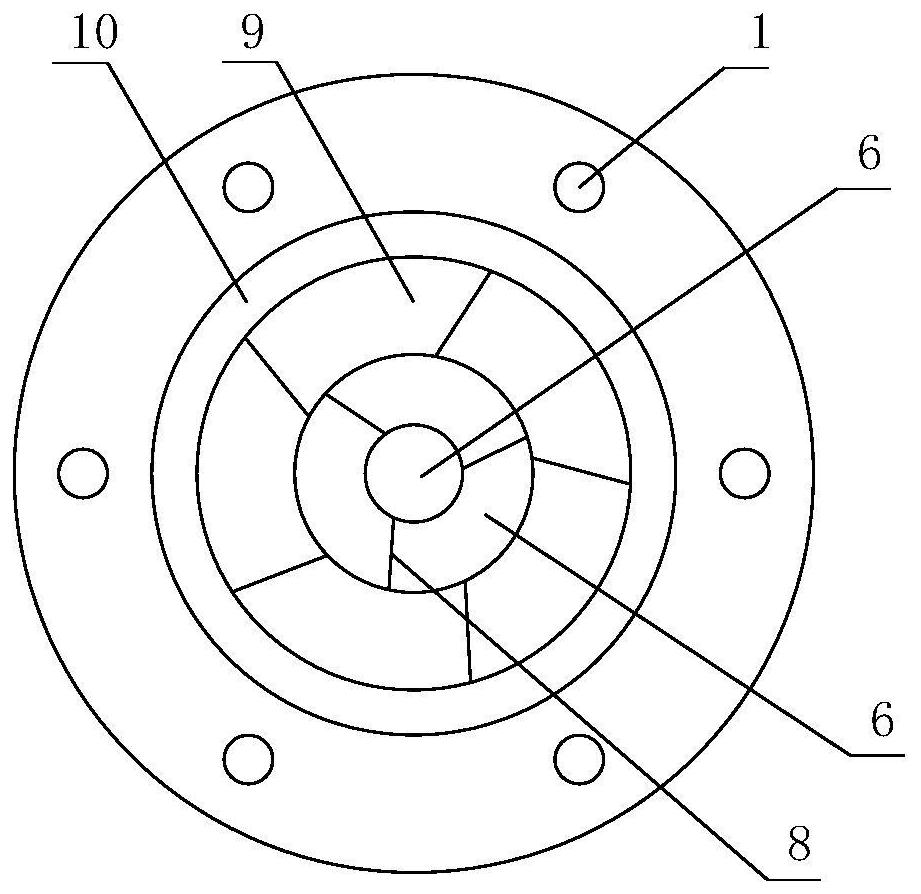

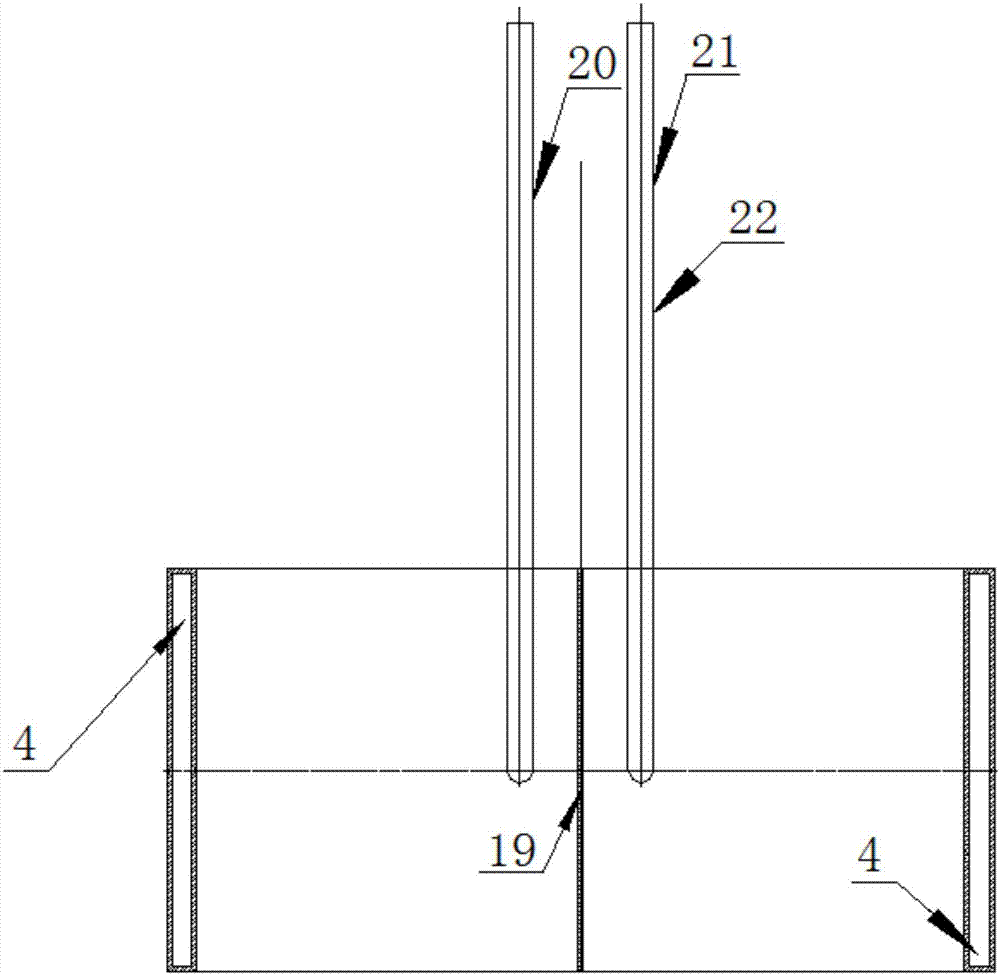

Oxygen jet multi-stage dispersion combustion roaster

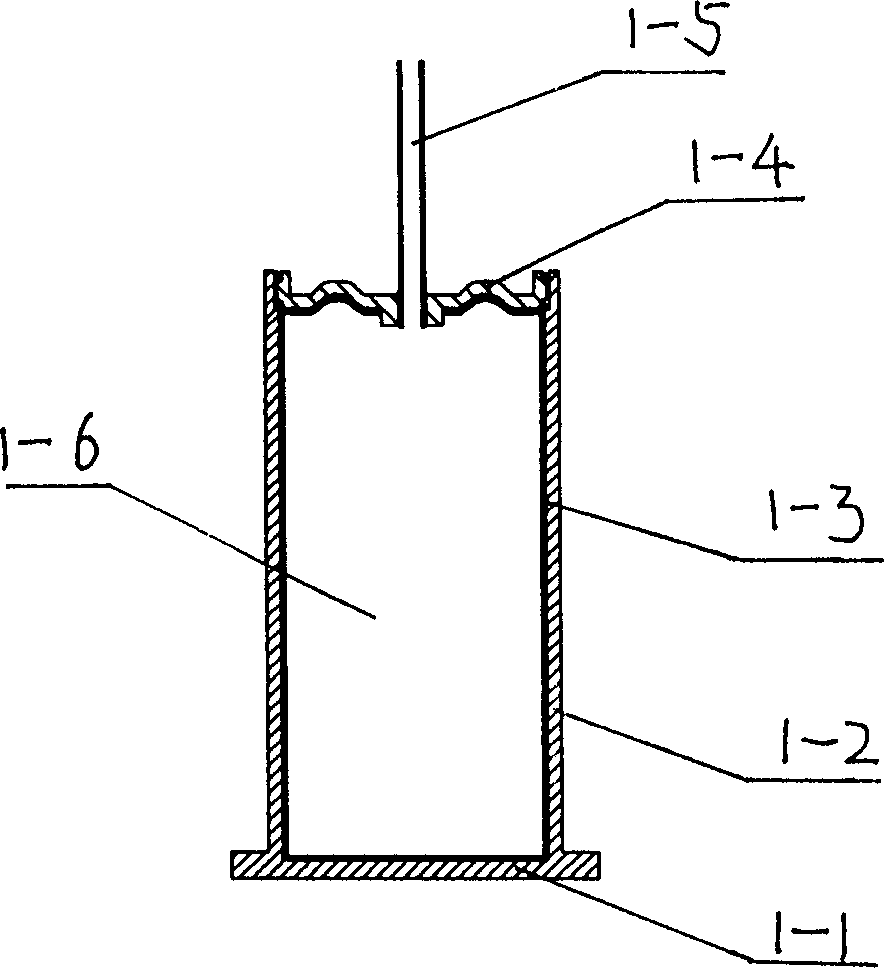

PendingCN112944344AReduce the temperature difference between upper and lowerReduce productionMelt-holding vesselsIndirect carbon-dioxide mitigationThermodynamicsCombustion

The invention relates to an oxygen jet multi-stage dispersion combustion roaster which comprises a metal structure burner and a refractory burner brick; the metal structure burner is arranged in the center of a ladle cover; the metal structure burner is of a four-layer sleeve structure; a first-stage compressed air channel is arranged in the center; a first-stage gas channel, a second-stage combustion-supporting air channel and a second-stage gas channel are sequentially arranged outside the first-stage compressed air channel; a compressed air nozzle is of a contracted conical structure and is arranged at the bottom of the first-stage compressed air channel; a first-stage gas circular seam is arranged at the bottom of the first-stage gas channel; a second-stage air circular seam is arranged at the bottom of the second-stage combustion-supporting air channel; a second-stage gas circular seam is arranged at the bottom of the second-stage gas channel; an oxygen jet orifice is fixed outside the metal structure burner; and a whole burner nozzle is fixed in the burner brick. The oxygen jet multi-stage dispersion combustion roaster has the advantages that oxygen high-speed jet is utilized to strengthen steel ladle bottom heating, upper and lower temperature difference of a steel ladle is reduced, and a local high-temperature area formed by high oxygen concentration is avoided.

Owner:ANGANG STEEL CO LTD

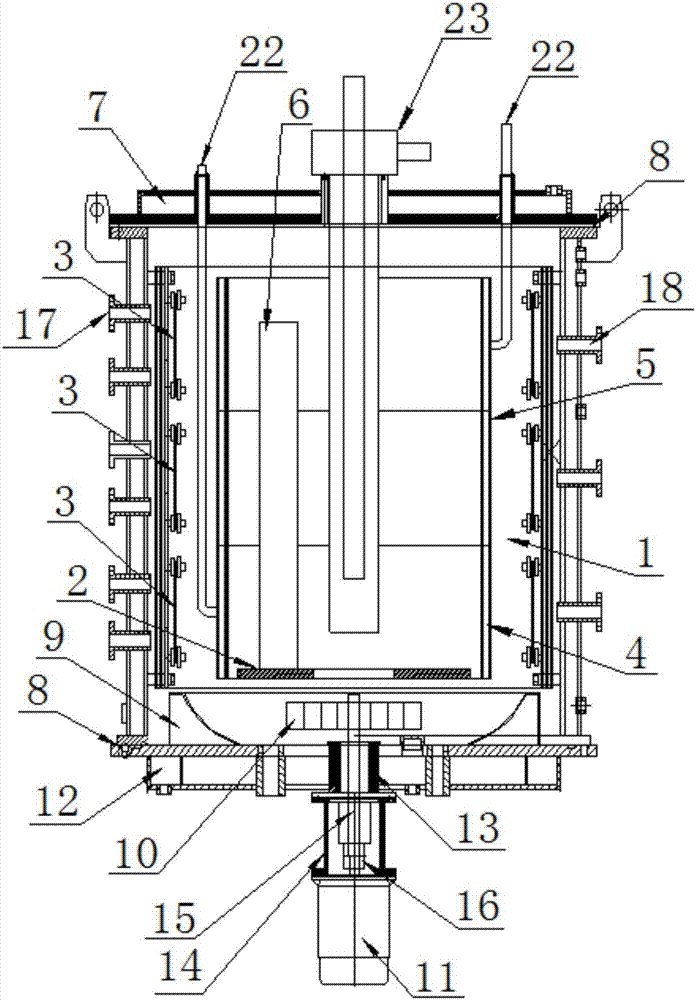

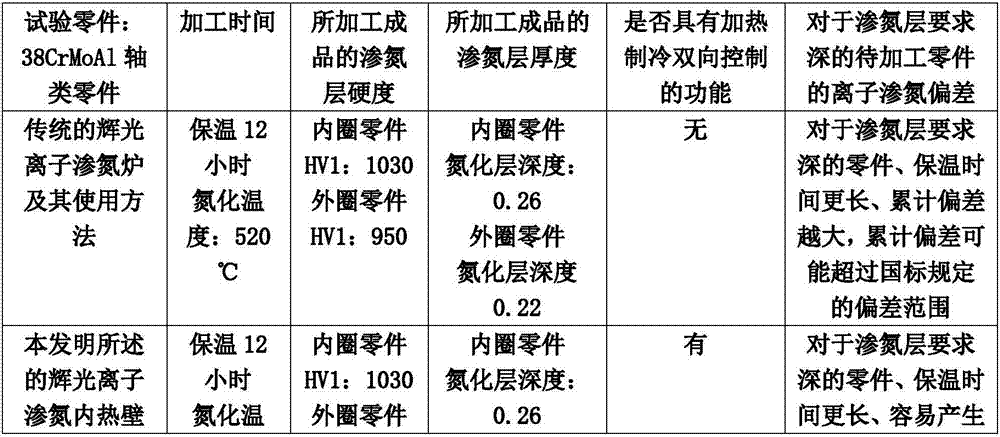

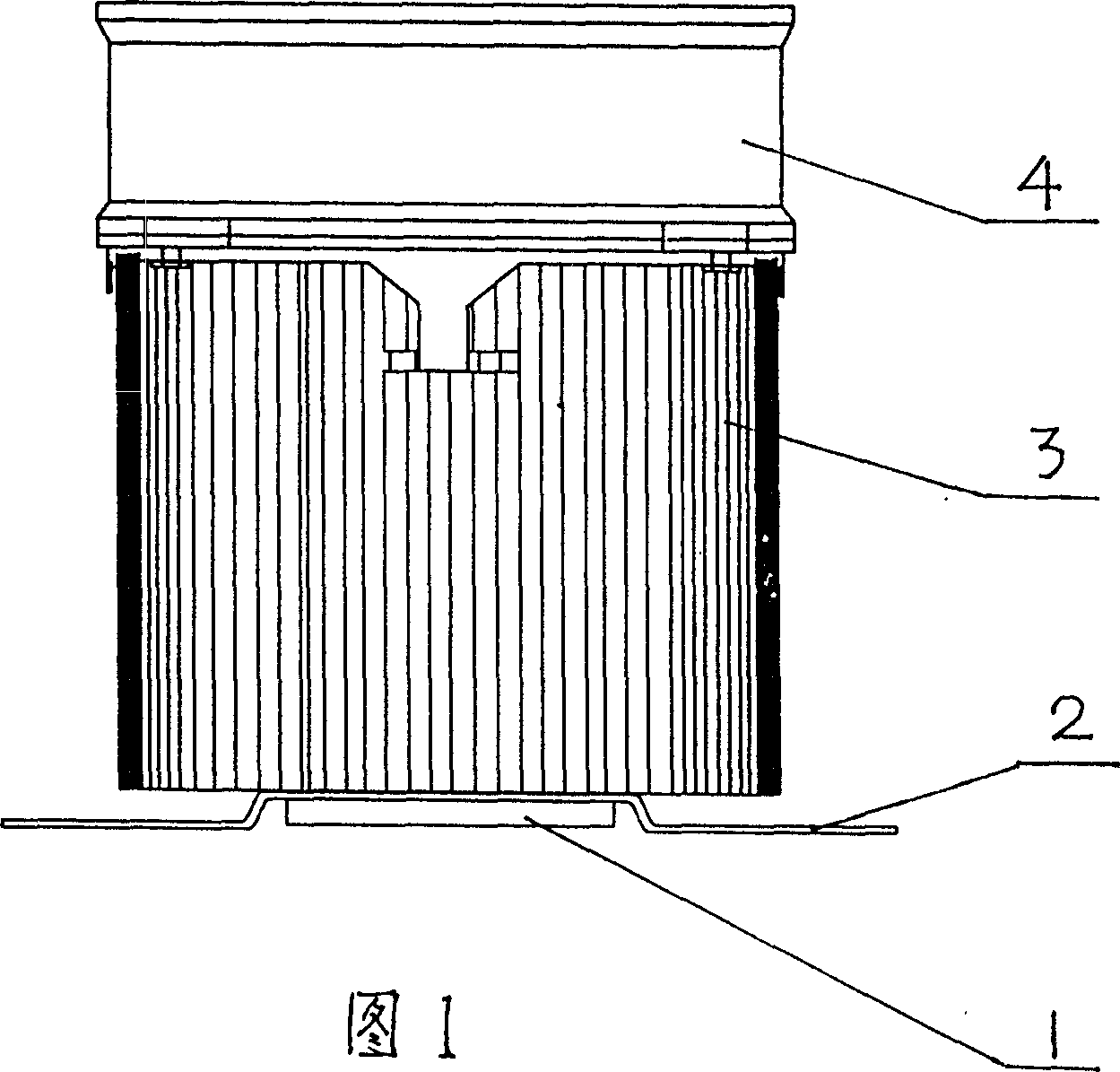

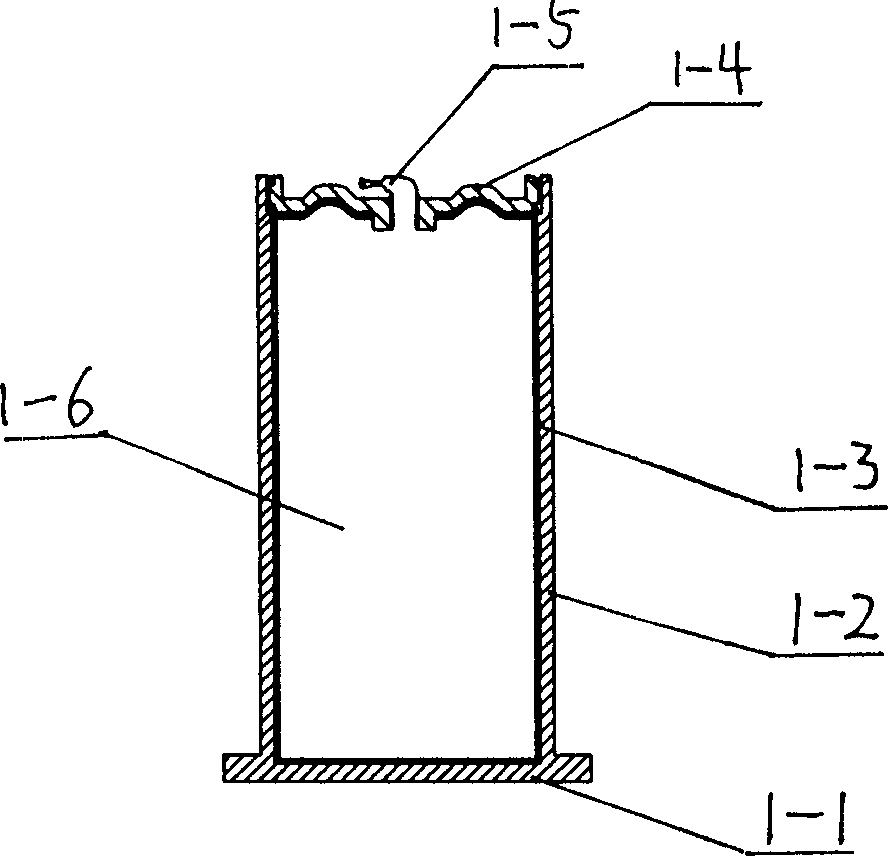

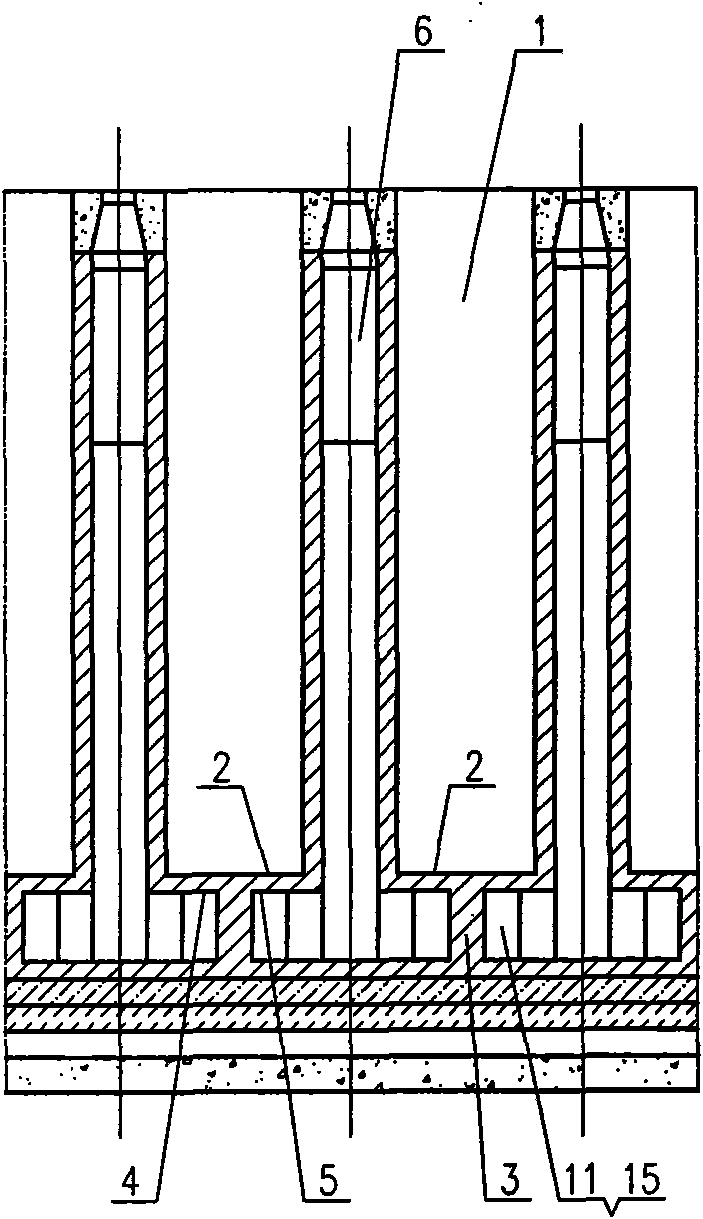

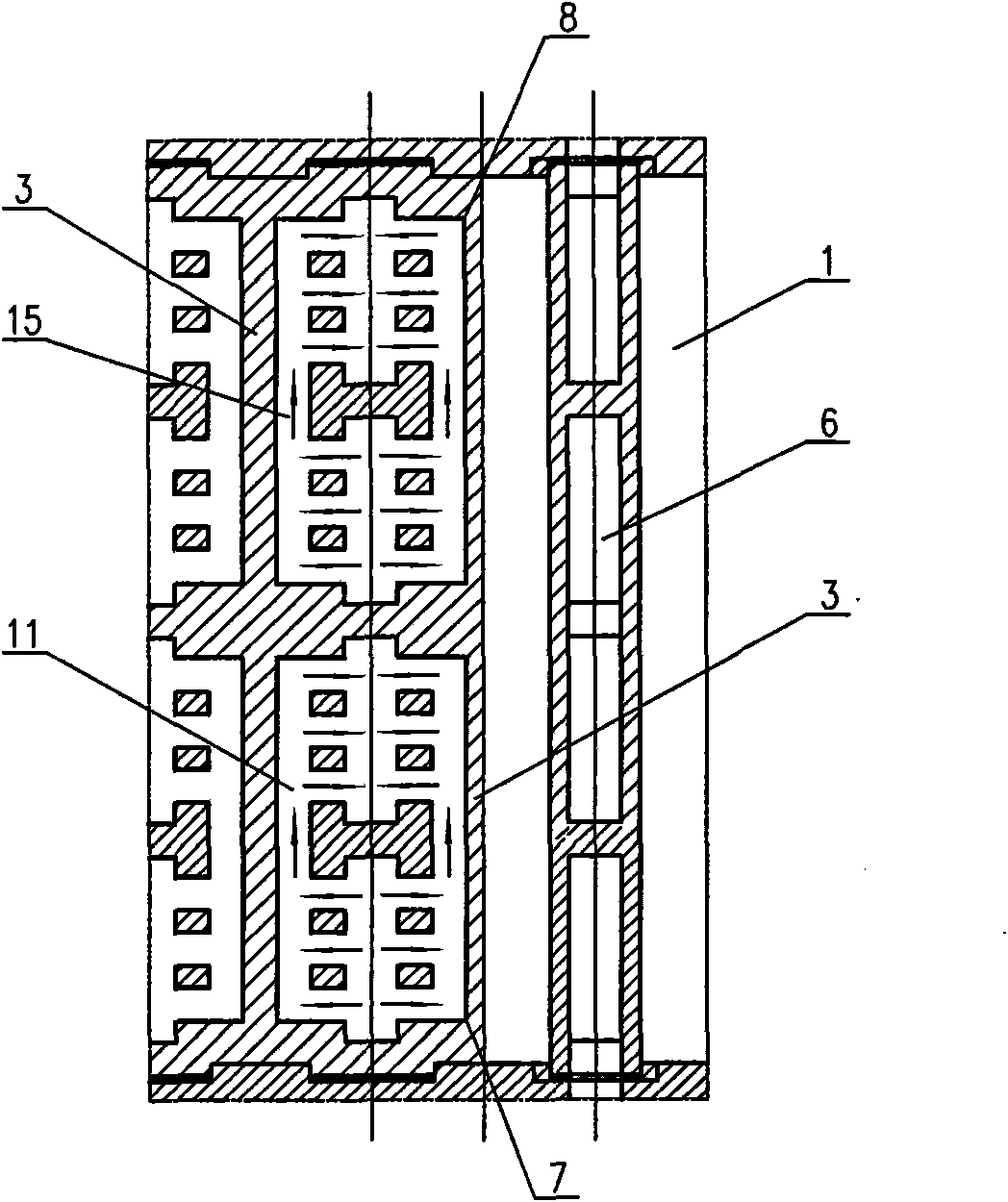

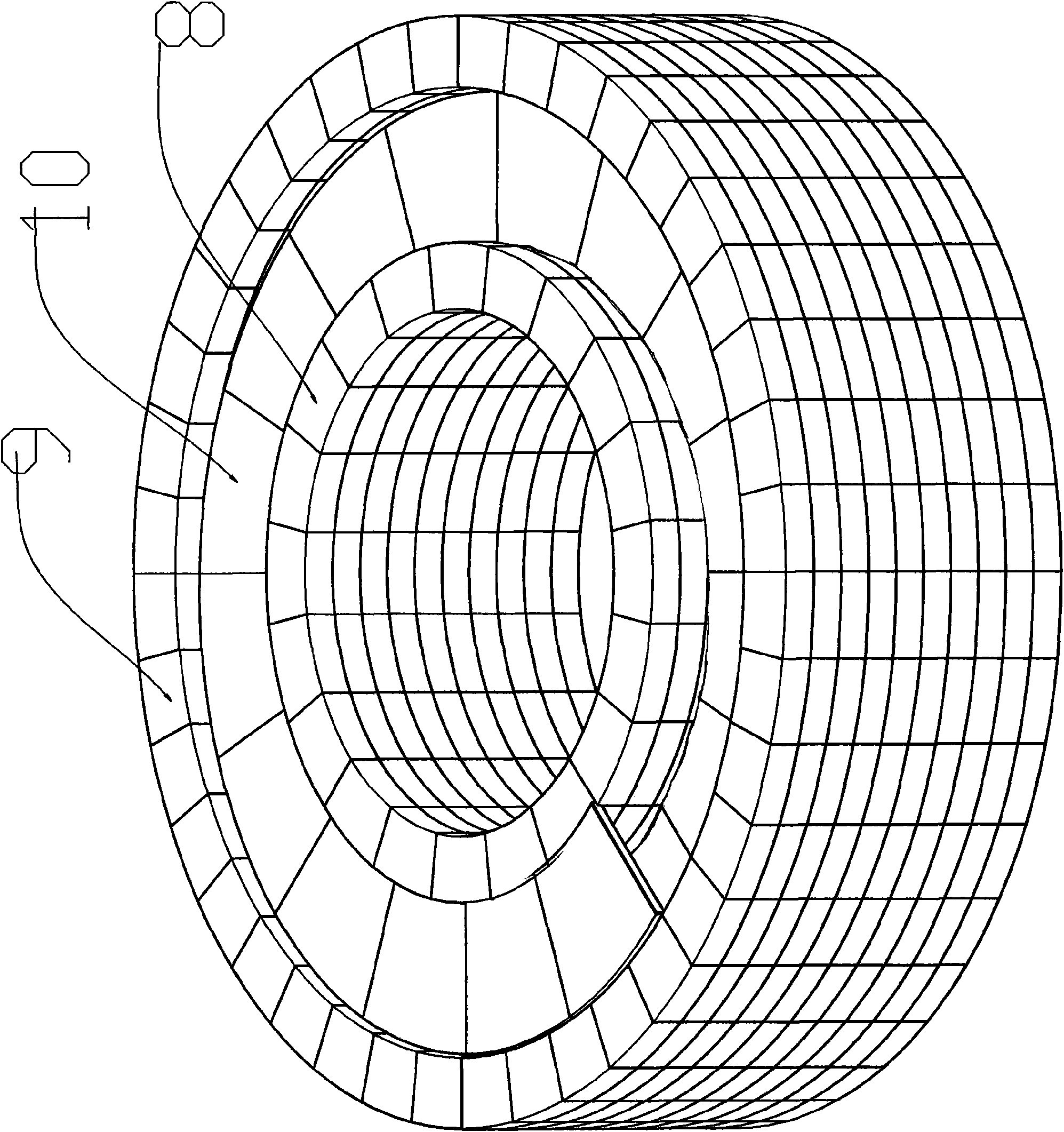

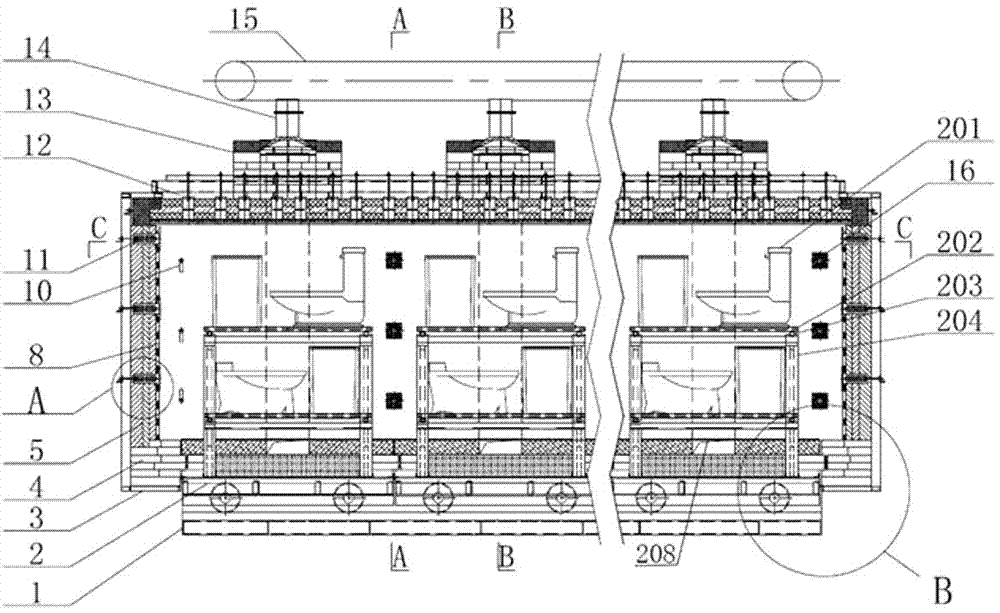

Glow-ion-nitriding inner-hot-wall type vacuum ion nitriding furnace and utilization method thereof

InactiveCN107385382AImprove temperature uniformityUniform hardnessSolid state diffusion coatingMachine partsMetallurgy

The invention discloses a glow-ion-nitriding inner-hot-wall type vacuum ion nitriding furnace and a utilization method thereof. The vacuum ion nitriding furnace comprises a furnace cylinder, a resistance heating elements and inner hot walls. The inner hot walls which are annular are positioned in the furnace cylinder, inner diameters of the inner hot walls are larger than outer diameters of cathode discs, three or more of the inner hot walls overlapped axially form an inner hot wall assembly in the furnace cylinder, the upper end of each inner hot wall assembly is positioned above the lateral upper end of the resistance heating elements while the lower end of each inner hot wall assembly is positioned below the lateral upper end of the resistance heating elements, the cathode discs are positioned in an annular area formed by the inner hot wall assemblies, and to-be-machined parts are positioned on the cathode discs and in the annular area formed by the inner hot wall assemblies. The resistance heating elements are positioned outside the inner hot wall assemblies. The glow-ion-nitriding inner-hot-wall type vacuum ion nitriding furnace has the advantage of reduction of temperature difference between inside and outside as well as between the upper portion and the lower portion.

Owner:武汉武热研热处理科技有限公司

Top-blown heat pipe radiator and its manufacturing method

InactiveCN1744806AReduce the temperature difference between upper and lowerImprove cooling efficiencyDigital data processing detailsSemiconductor/solid-state device detailsEvaporationEngineering

The radiator includes heat pipe, basal body of thermal fin, and fan. There are through holes inside basal body of thermal fin, and heat pipes are setup in through holes. Inner diameter of through hole is close fitted to external diameter of heat pipe. Multiple radial thermal fins are setup around. Being setup on top of basal body of thermal fin, fan is in use for forcing air to pass through radial thermal fins from upper to lower. Being in mode of evaporation condensed phase change, heat pipe conducts heat, providing features of quick conduction rate, large heat transfer power. Multiple radial thermal fins possess large area of dissipation. Forced air driven by fan passes through radial thermal fins in small wind resistance. Features of the invention are: large heat sinking capability, small thermal resistance, and lightweight.

Owner:嘉善华昇电子热传科技有限公司

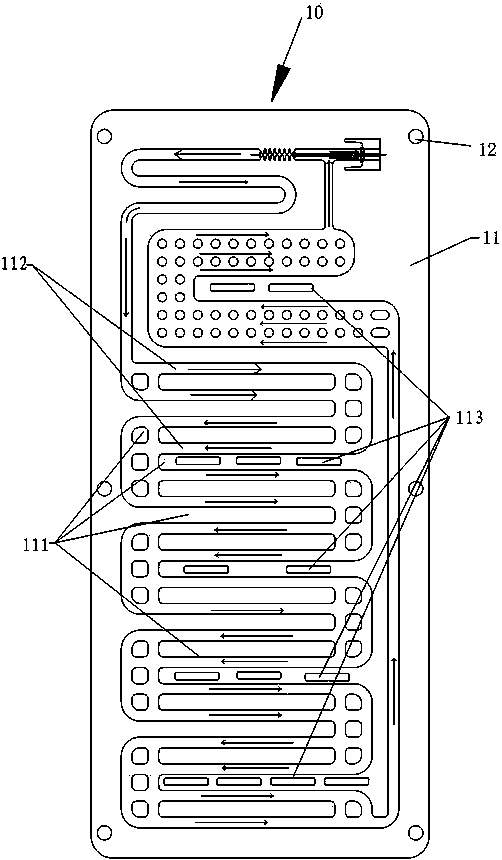

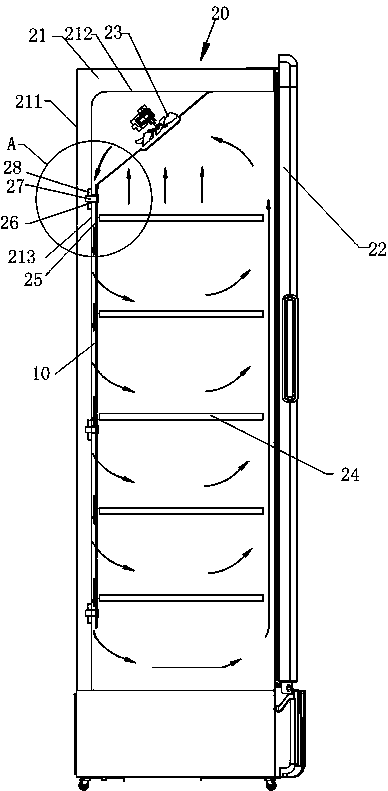

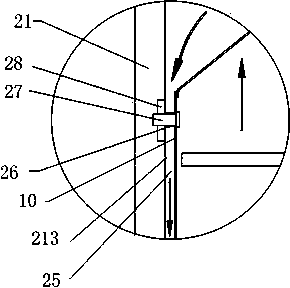

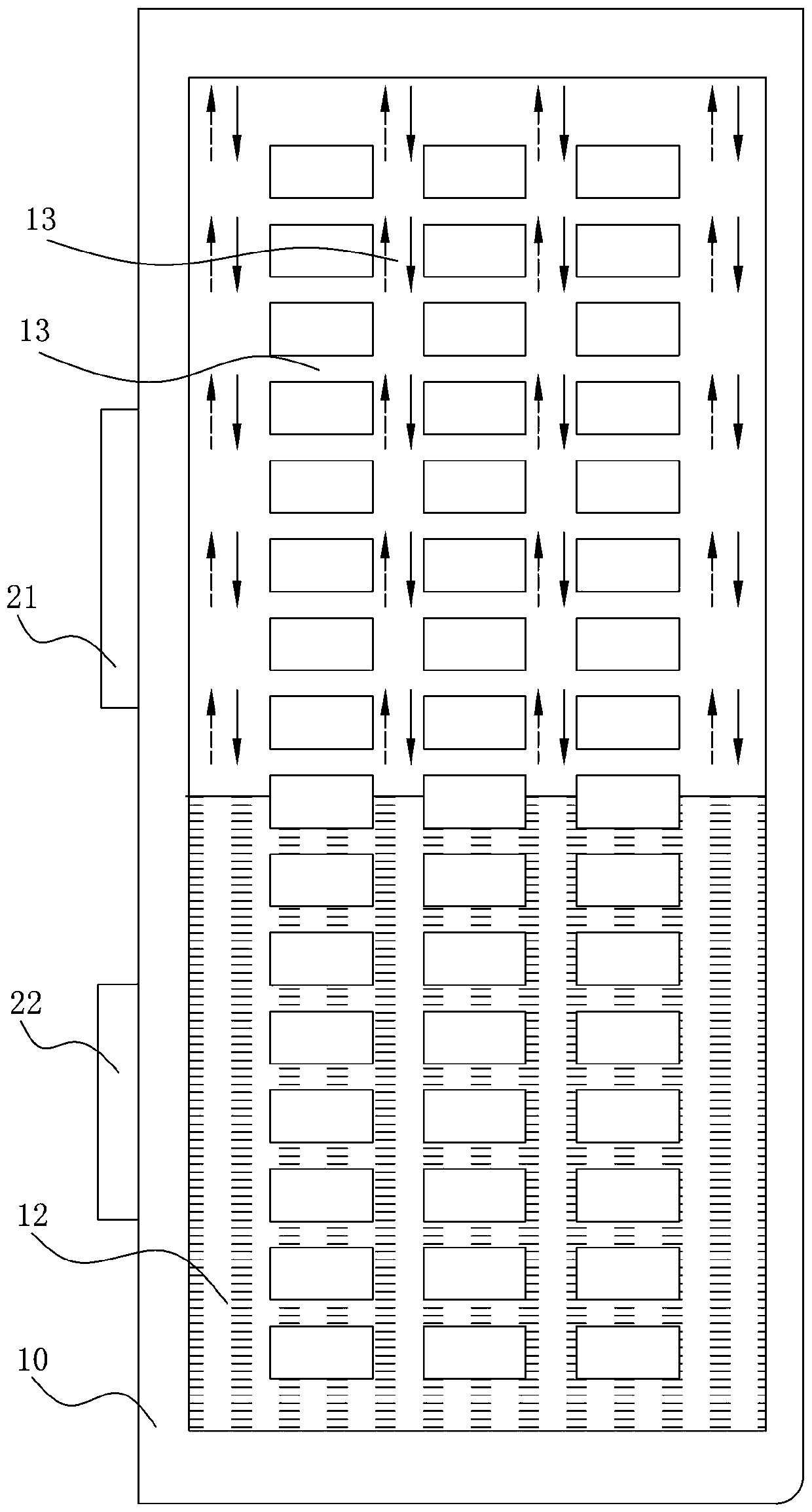

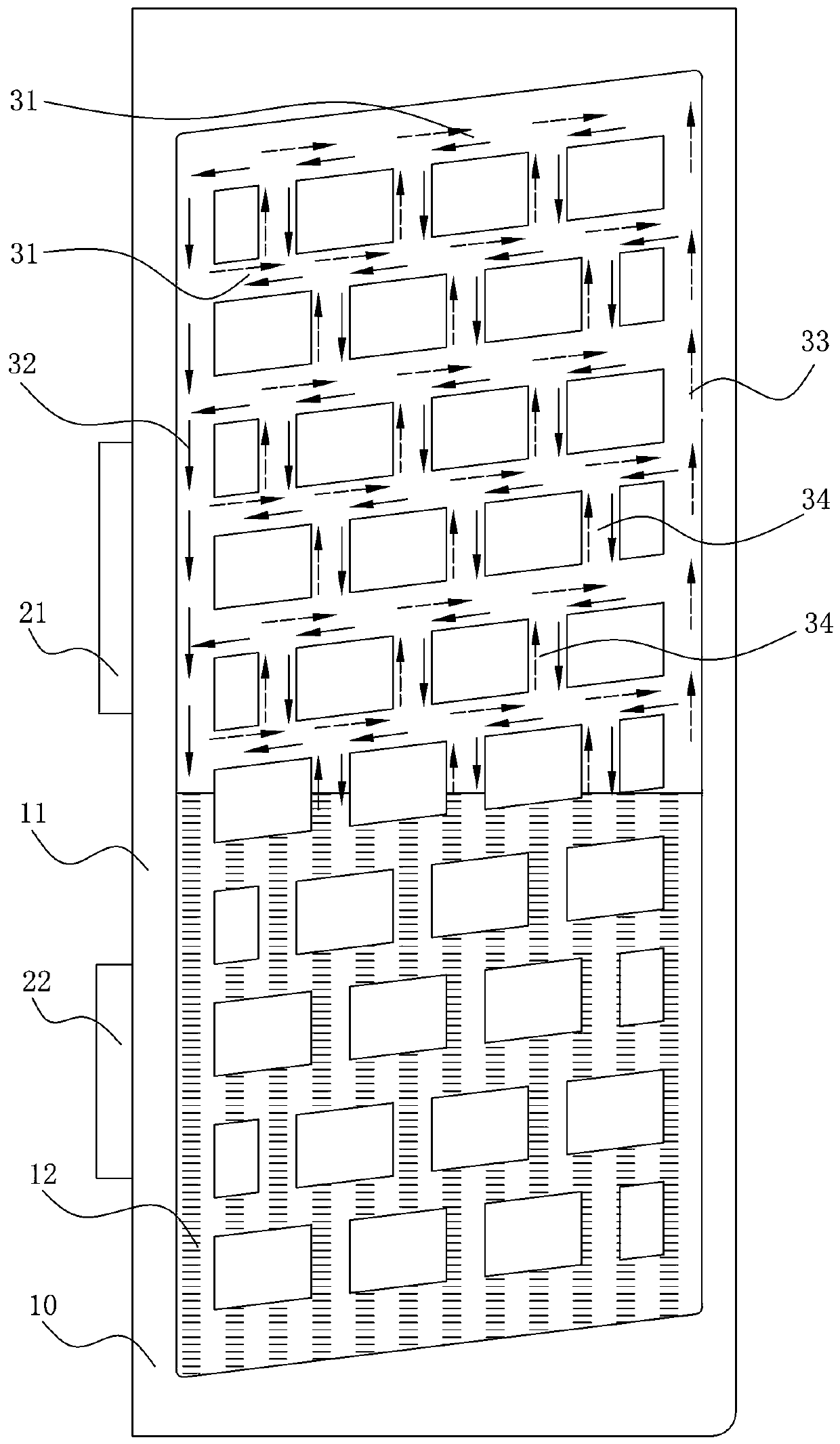

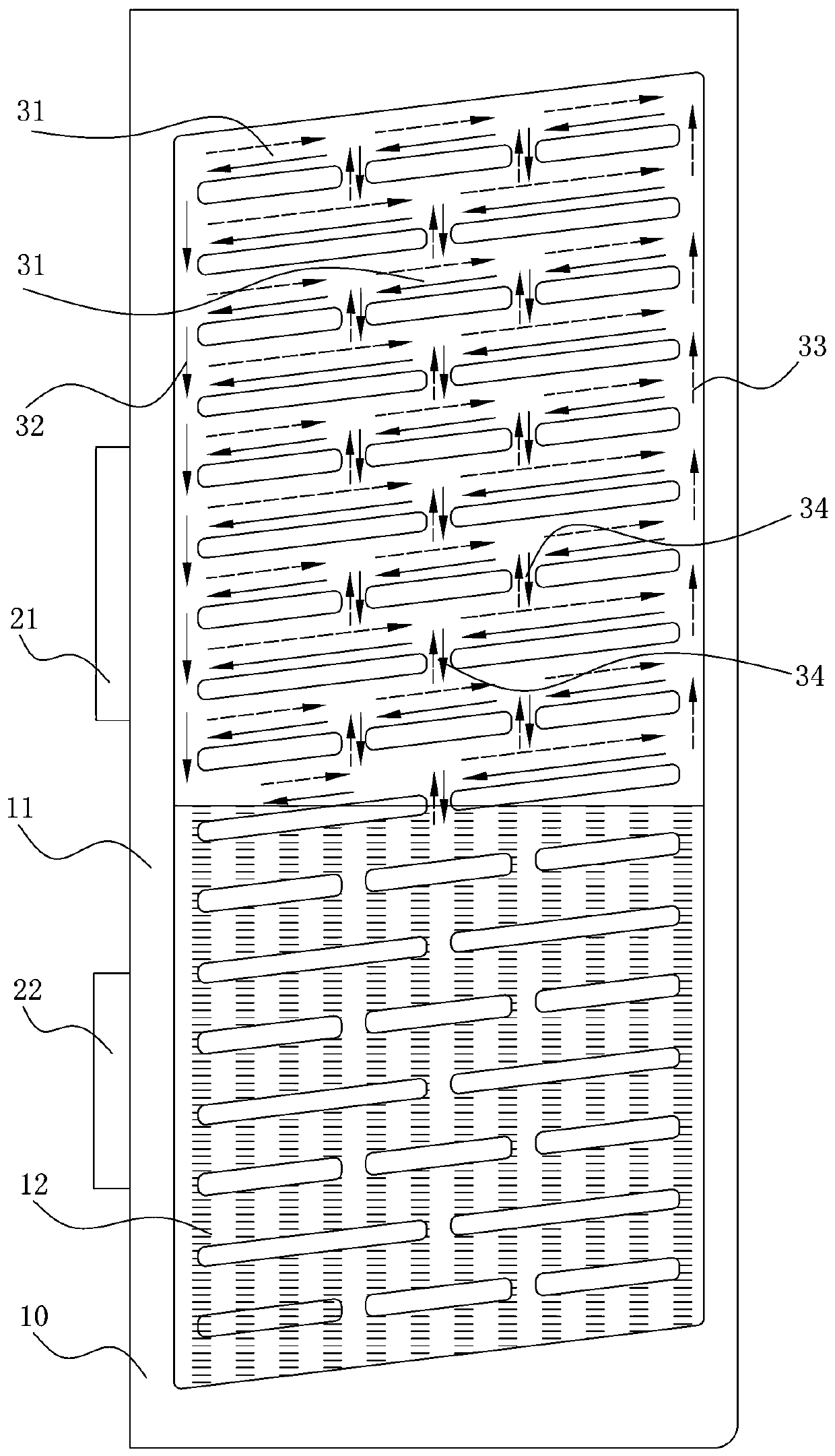

Composite board evaporator and refrigeration equipment

ActiveCN104279797ARetain cooling functionUniform air supplyEvaporators/condensersRefrigeration devicesCold airEngineering

The invention provides a composite board evaporator and refrigeration equipment. The composite board evaporator comprises two aluminum boards combined together in a pressing mode, wherein the peripheries of the two aluminum boards are combined in a pressing mode and provided with fixing holes, the centers of the two aluminum boards comprise pressing combination parts and passage parts, and the pressing combination parts at the centers of the two aluminum boards are provided with a plurality of vents. The invention further provides the refrigeration equipment with the composite board evaporator. An air passage is formed between the composite board evaporator and the rear wall of an inner container, the composite board evaporator serves as a heat exchanger and has the function of an air passage board, and a fan supplies cold air into a box through the air passage and the vents in the evaporator so that the temperature inside the box can be uniform. As the air passage board is omitted, the cost is reduced, and the heat exchange efficiency is high.

Owner:HAIER GRP CORP +1

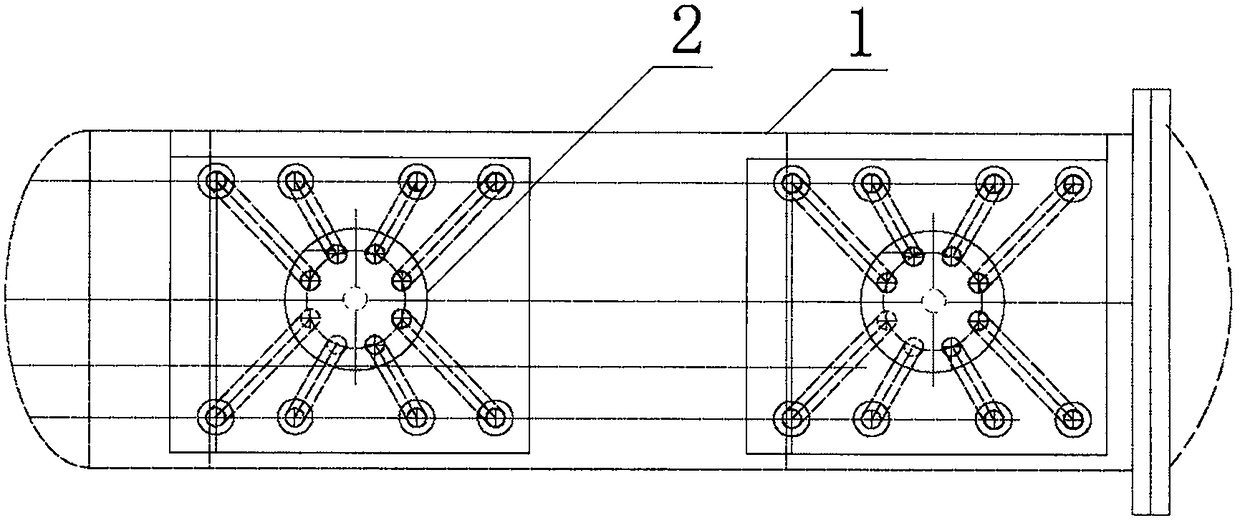

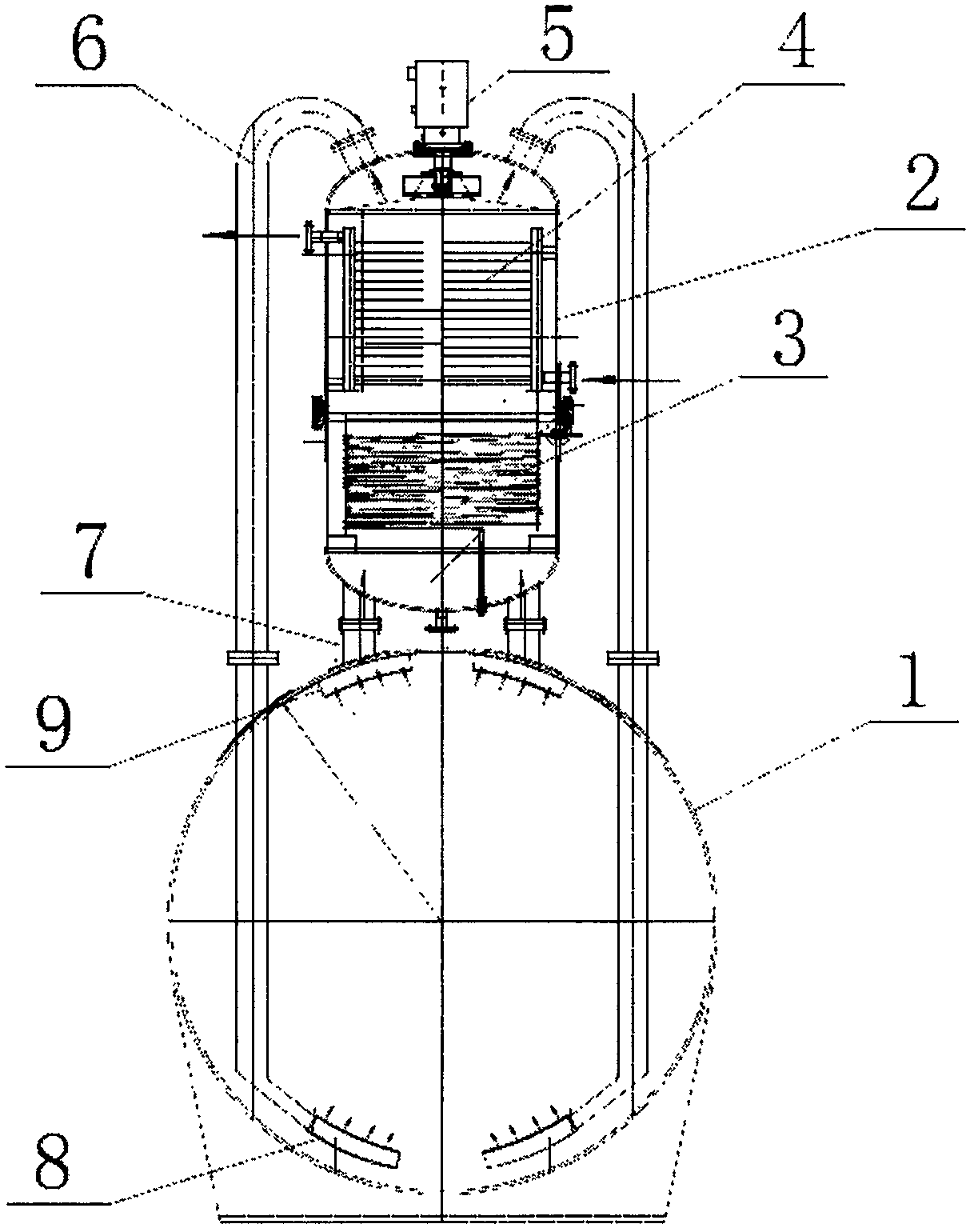

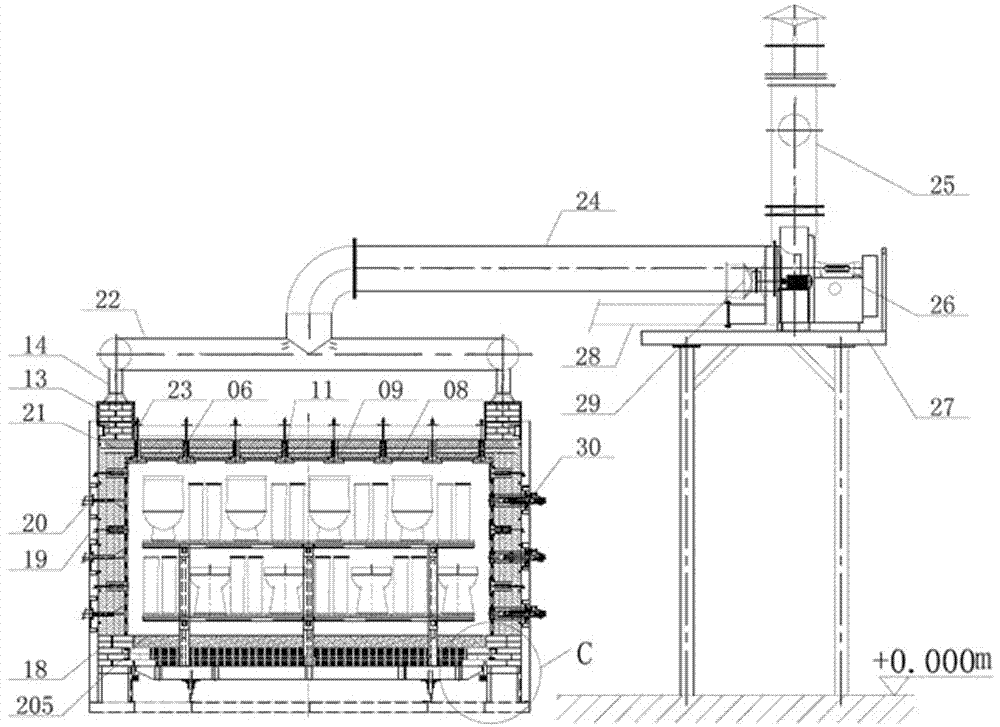

Longitudinal-circulation autoclave provided with external thermal-cold cycling device

PendingCN108297525AUniform temperature distributionEasy to replace and maintainLaminationLamination apparatusEngineeringTemperature difference

The invention relates to a longitudinal-circulation autoclave provided with an external thermal-cold cycling device. The longitudinal-circulation autoclave comprises a main tank body, air suction connection pipelines, air blowing connection pipelines and the thermal-cold cycling device, wherein the main tank body is connected with airflow distributors through the air suction connection pipelines and the air blowing connection pipelines respectively; the thermal-cold cycling device is located outside the main tank body. According to the autoclave with the structure, the complicated heating, cooling and circulating device is moved out of the main tank body, and loading rate is remarkably increased; the circulation path is shortened by means of a new longitudinal-circulation mode, and under cooperation with the airflow distributors, the temperature distribution in the tank is uniform, vertical temperature difference is reduced, and front and back temperature difference is almost zero; with adoption of an electromagnetic heating mode with higher efficiency, not only is energy saved, but also efficiency is remarkably improved; the external thermal-cold cycling device can be wholly replaced and dismounted for maintenance due to presence of spare parts, and the condition of production delay caused by equipment failure maintenance is avoided.

Owner:王新志

Heat management assembly for battery module, battery module and vehicle

ActiveCN111048864AHigh precision of temperature regulationEasy to switch between hot and coldSecondary cellsThermodynamicsHeat management

The invention relates to a heat management assembly for a battery module, a battery module comprising the heat management assembly, and a vehicle comprising the battery module. The heat management assembly comprises a heat conduction piece, a fixed bottom plate, radiating fins and a Peltier device, wherein the heat conduction piece is suitable for being arranged inside the battery module and directly contacted with a battery cell of the battery module; the fixed bottom plate is fixed on a shell which defines a battery cavity of the battery module, and is attached to the heat conduction piece;the radiating fins are fixed on the fixed bottom plate by means of at least one fixing component; and the Peltier device is arranged between the fixed bottom plate and the radiating fins and is used for cooling / heating the battery cell. The heat management assembly integrates cooling, heating and constant temperature functions required by the battery module, has no risk of cooling liquid leakage,can lighten the battery module, and solves the problem of large temperature difference between the upper part and the lower part during cooling / heating of the battery cell, so that the temperature ofthe battery module is controlled within the optimal range.

Owner:WEBASTO SHANGHAI

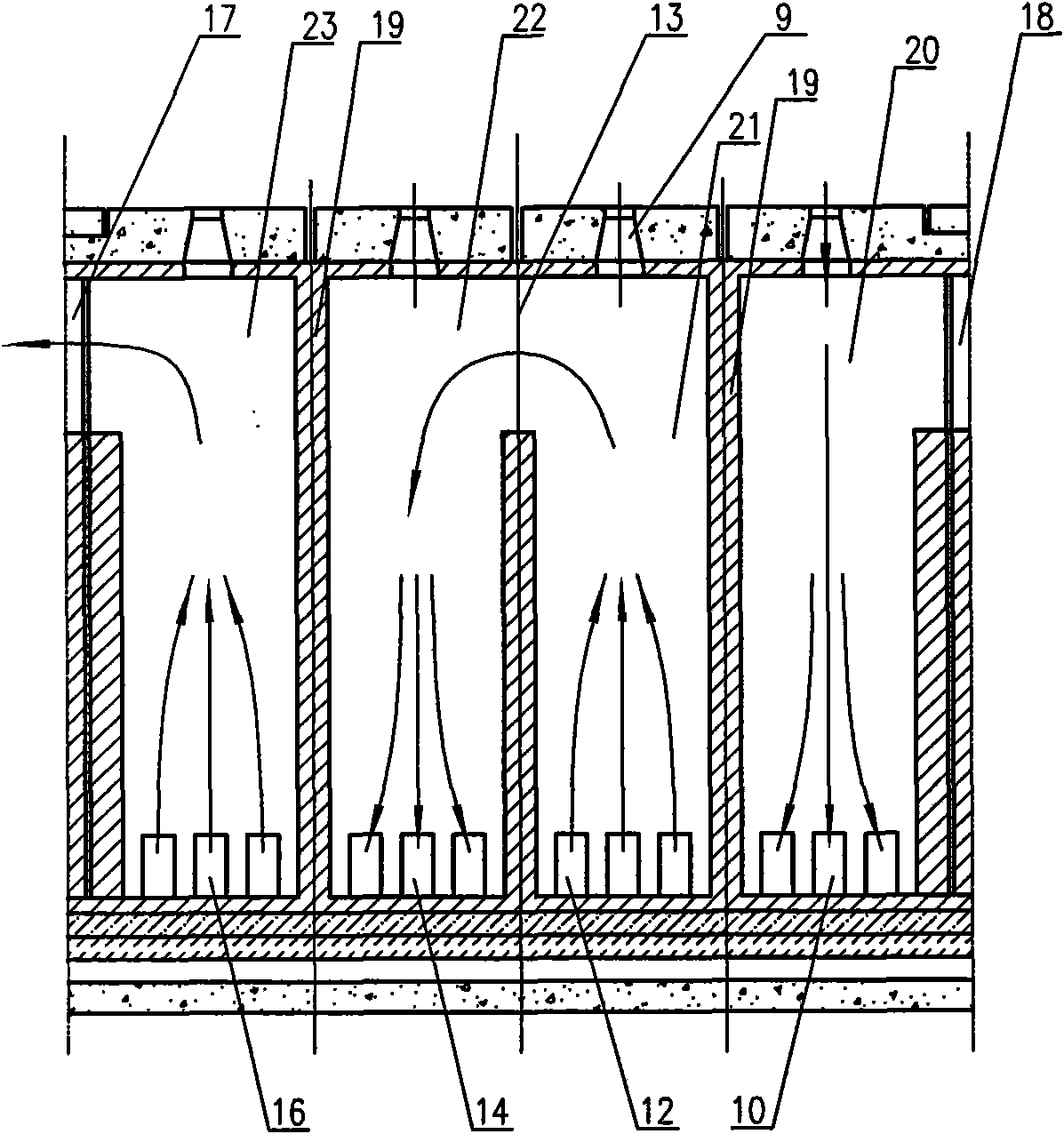

Heating structure at bottom of bin of aluminium anode baking furnace

InactiveCN101929796AImprove roast qualityReduce the temperature difference between upper and lowerMuffle furnacesRetort furnacesTemperature differenceFlue

The invention discloses an anode baking furnace in the aluminium anode production field and in particular relates to a heating structure at the bottom of a bin of the aluminium anode baking furnace. The heating structure comprises a bin and flues at the two sides of the bin and is characterized in that hot bin bottoms are arranged at the bottom of the bin; isolating stacks are arranged in the middle below the hot bin bottoms; left and right heating zones communicated with the flues at the two sides of the bin are arranged at the two sides of the isolating stacks; each left heating zone and each right heating zone are respectively provided with a front heating section and a rear heating section; and each flue is divided into a front flame zone and a rear flame zone. The heating structure solves the following problems: low temperature of the bottoms of the bins of the previous anode baking furnaces, high upper and lower temperature difference of the bins, high flue control temperature, high fuel consumption, reduced capacity of the furnaces, high burning loss of fillers, short change period of flue walls, zero benefit to energy conservation and emission reduction, etc.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

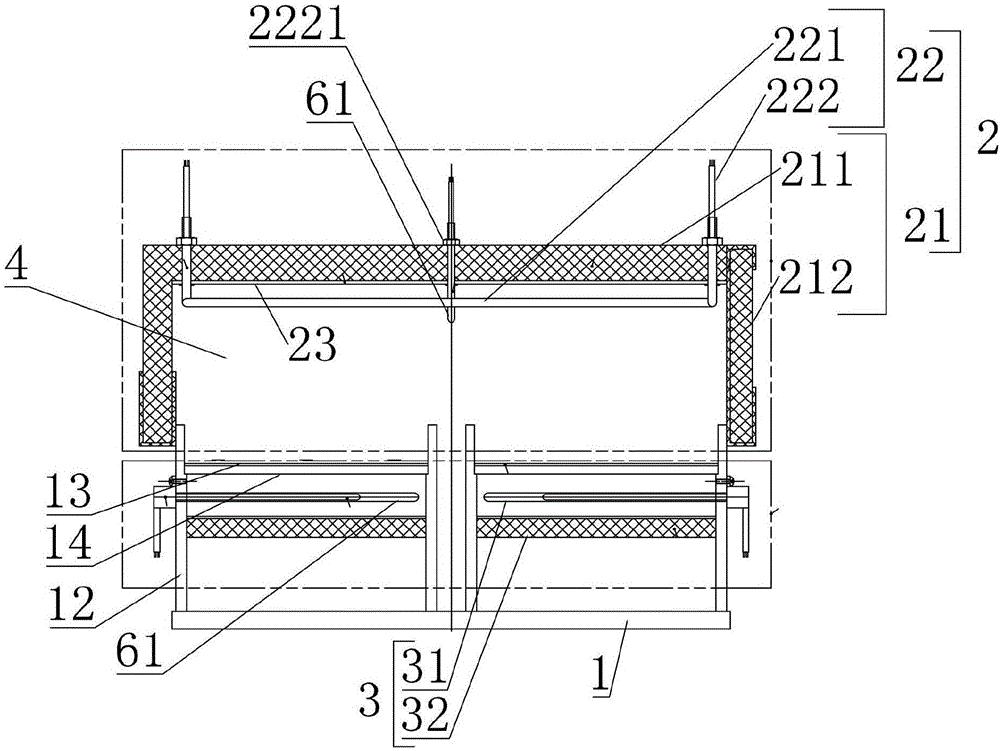

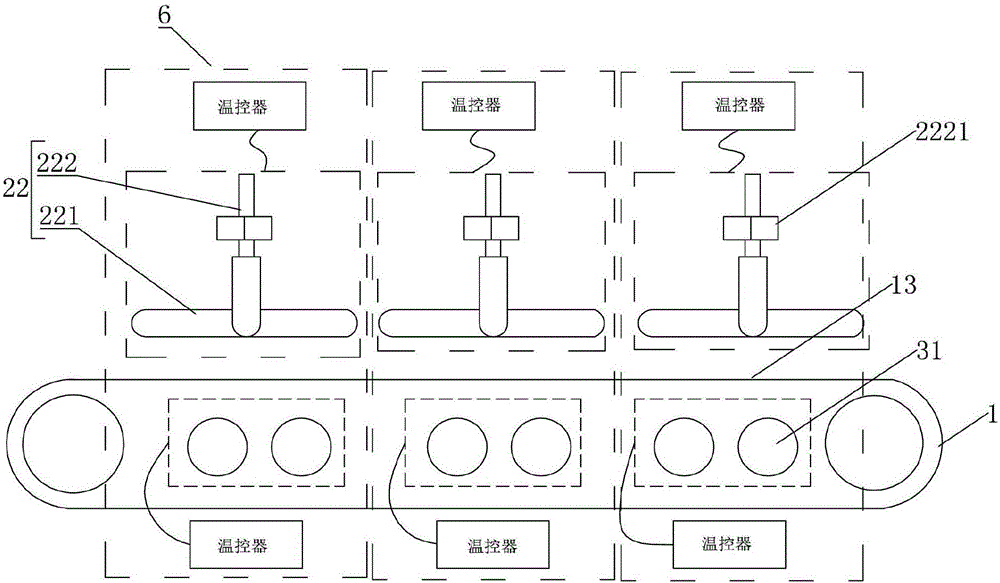

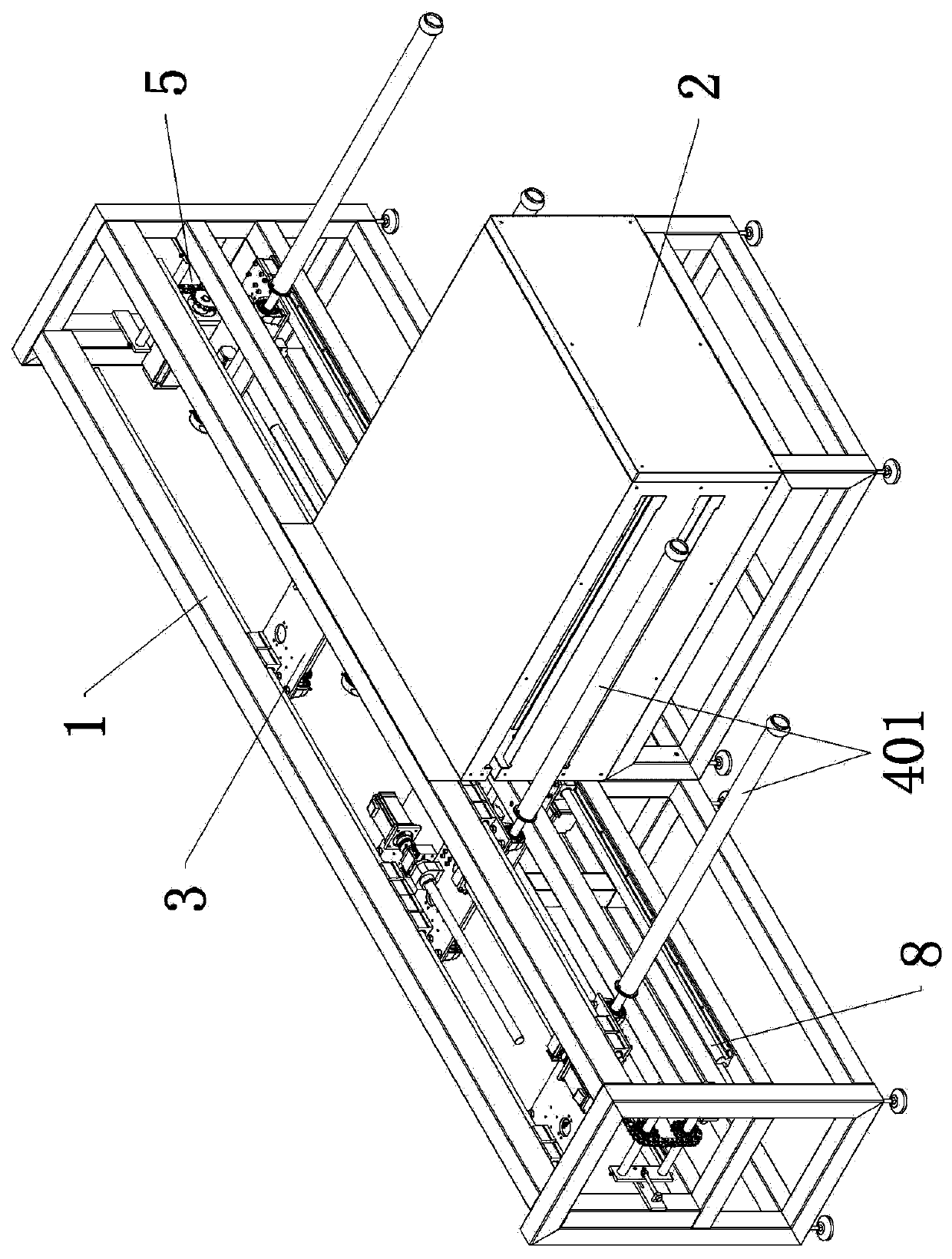

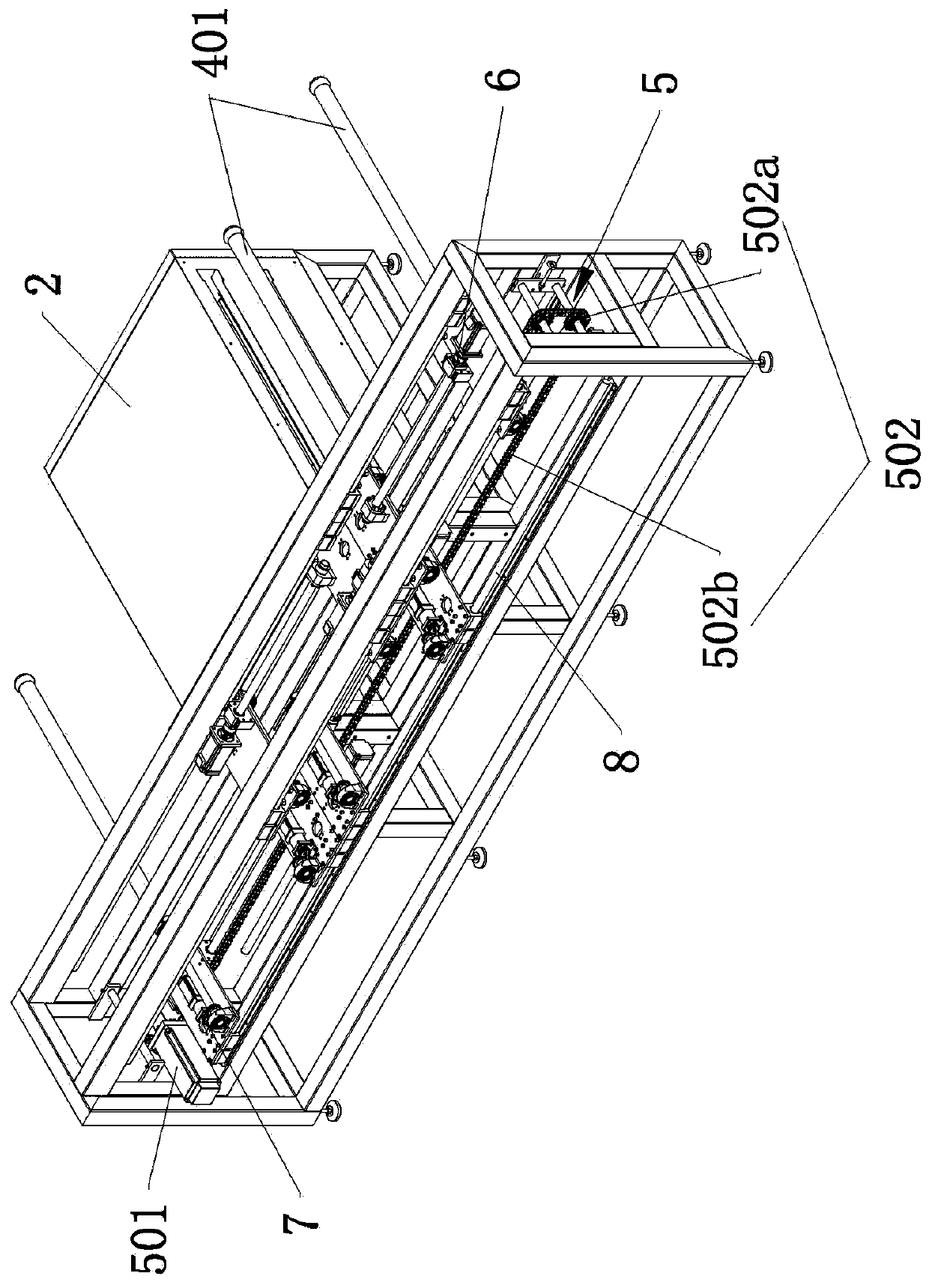

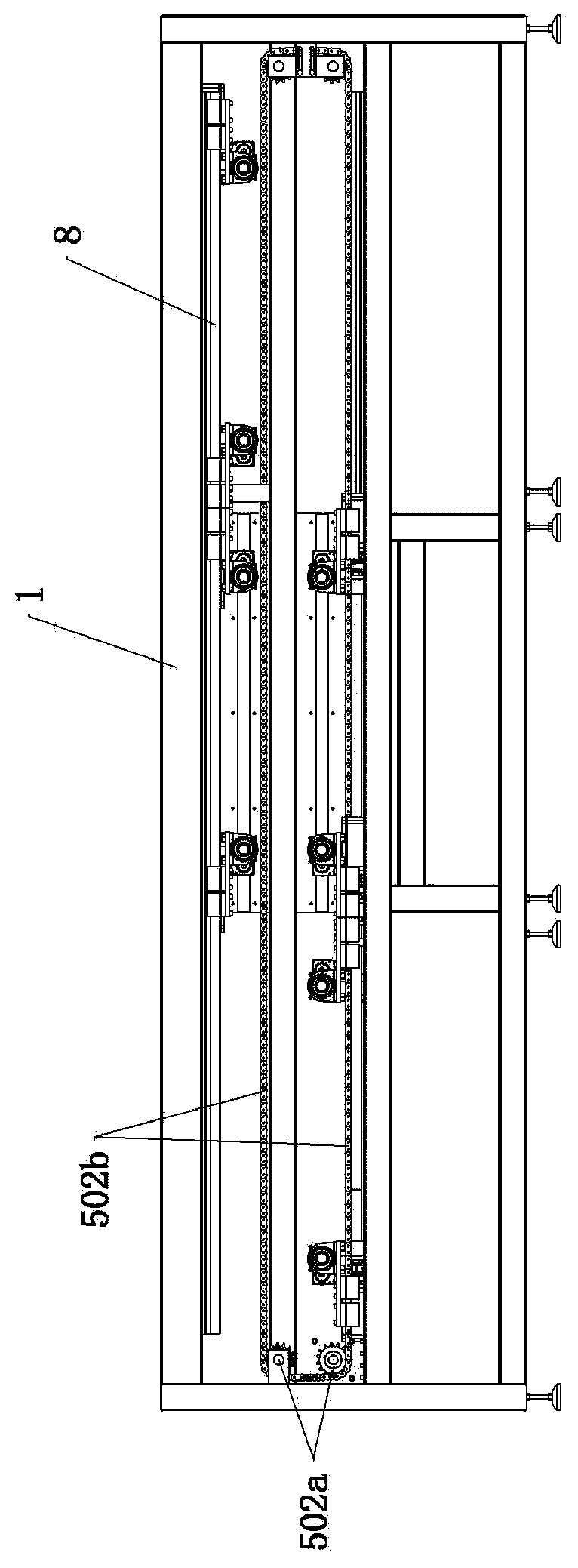

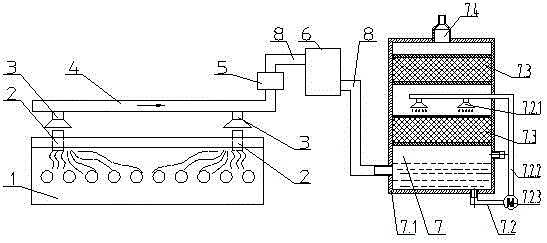

Insulated conveying system, insulated method thereof and application

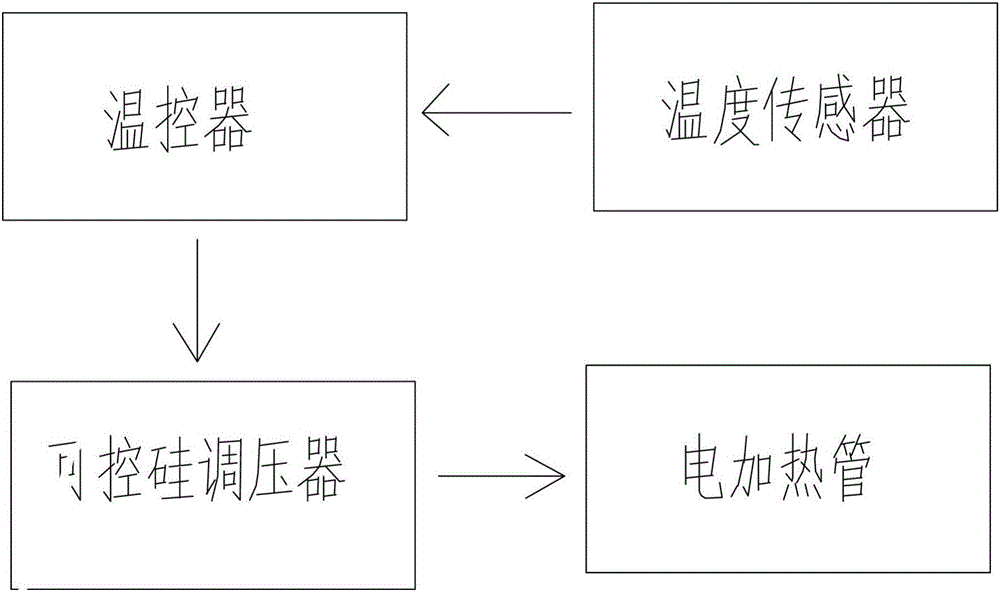

PendingCN106628836AAvoid interferenceGuaranteed control reliabilityConveyorsHeater elementsEngineeringHeating effect

The invention discloses an insulated conveying system. The insulated conveying system comprises a conveying component, an upper heating device and a lower heating device, wherein an insulated space is formed between the upper heating device and the lower heating device; and the conveying component penetrates through the insulated space. The insulated conveying system disclosed by the invention has the beneficial effects that by adoption of the technical scheme, active heating is carried out from top to bottom simultaneously, so that materials on the conveying component can be kept at a certain temperature; and due to simultaneous heating from top to bottom, the heating effect is better; and the production quality of products is guaranteed.

Owner:CHONGQING JIANGDONG MACHINERY

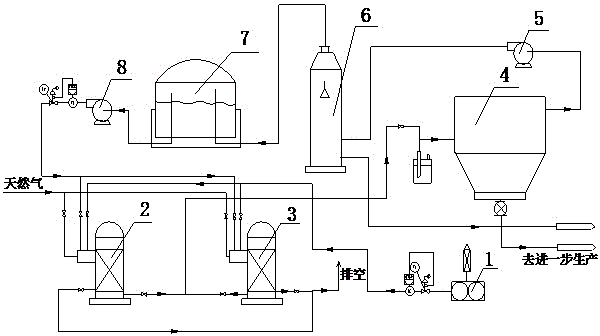

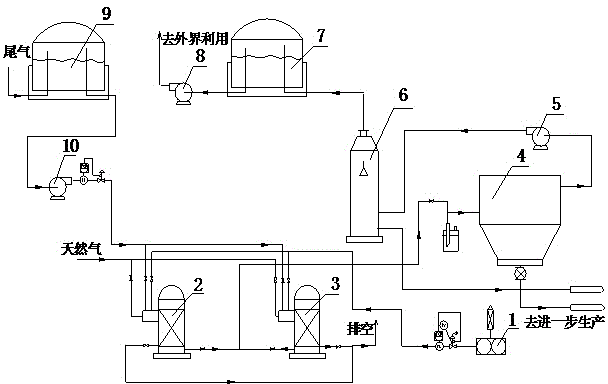

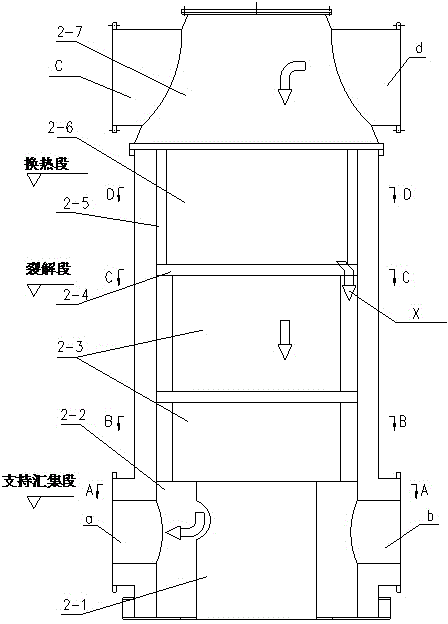

Apparatus for producing carbon black through thermal cracking method

InactiveCN103333529ANarrow temperature changeIncrease production capacityPigmenting treatmentChemical industryHydrogenProcess engineering

The invention discloses an apparatus for producing carbon black through a thermal cracking method. The apparatus comprises a main wind supply device respectively connected with a cracking furnace A and a cracking furnace B, wherein the cracking furnace A and the cracking furnace B are connected with a bag filter, the bag filter is sequentially connected with a hydrogen-rich induced fan, a washing tower and a hydrogen-rich gas cabinet, the cracking furnace A structure comprises a cavity, the lower end of the cavity is connected with the furnace body, the furnace body is sequentially divided into a pre-heating section and a cracking section from top to bottom, the lower end of the cracking section is connected with a support collection section, the upper end of the cavity is provided with a fuel gas spraying interface, the left end of the cavity is provided with an explosion prevention port, and the right end of the cavity is provided with a natural gas inlet. According to the present invention, tail gas produced during semi-reinforcing carbon black production can be adopted to heat, such that the tail gas produced during semi-reinforcing carbon black production can be completely recycled, energy sources are saved, and air pollution caused by the tail gas is reduced so as to provide characteristics of energy saving and environmental protection; operation maintenance is convenient; and the produced carbon black product has stable quality, and production capacity is substantially increased.

Owner:中昊黑元化工研究设计院有限公司 +1

Air duct assembly of refrigerator

PendingCN109237860ASolve problems prone to short circuitsReduce the power consumption of the whole machineLighting and heating apparatusCooling fluid circulationInlet channelTemperature difference

The invention discloses an air duct assembly of a refrigerator, and relates to the technical field of refrigerators. The air duct assembly comprises a support board, an air duct board, an air openingboard and an air duct sealing plate; the air duct board is clamped to the support board, the air opening board is clamped on the upper portion of the air duct board, the air duct sealing plate is attached to one surface of the air duct board, one surface of the support board is at least provided with an air outlet, one surface of the air duct board is provided with an air inlet channel and an airreturn channel, and the upper end of the air inlet channel extends to the upper portion of the air duct board in the length direction of the air duct board to form an air duct inlet; the lower end ofthe air return channel extends to the lower portion of the air duct board in the length direction of the air duct board to form an air duct air return opening. Accordingly, by means of reasonable design of the air inlet channel and air return channel of the air duct assembly, the problem that for air inlet and return of an existing refrigerator, a short circuit is likely to occur is solved, the up-down temperature difference of a refrigerating chamber of the refrigerator is reduced, and power consumption of the whole refrigerator is lowered.

Owner:CHANGHONG MEILING CO LTD

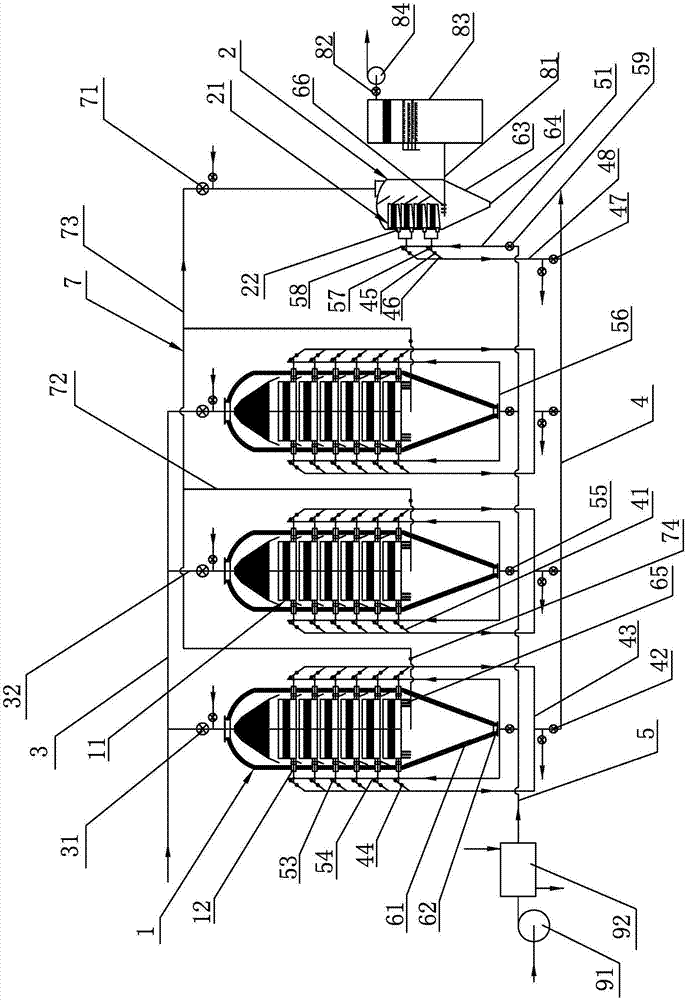

Method for comprehensively using outward-exhausting waste heat in refrigerating process of supermarket showcase

InactiveCN102519169AReduce the temperature difference between upper and lowerReduce local temperature differenceShow cabinetsHeating and refrigeration combinationsThermal energyEngineering

Provided is a method for comprehensively using outward-exhausting waste heat in a refrigerating process of a supermarket showcase. A heat exchanger is arranged at the top of the showcase, a controllable three-way valve capable of blocking refrigerant or reducing flow of the refrigerant flowing to the condenser is arranged in a connection pipeline capable of conveying externally-exhausting media carrying heat energy to an outdoor condenser after refrigerating of a compressor unit, the other port of the controllable three-way valve is directly connected with the heat exchanger arranged at the top of the showcase to form a waste heat system pipeline input passage, and the controllable three-way valve is further connected into a behind-valve pipeline which leads a three-way control valve to be communicated with the condenser of the compressor through the connection pipeline, so that a waste heat system pipeline back output passage is formed. Simultaneously, waste heat obtained by the heat exchanger can be communicated with the lower bottom of the showcase through a showcase back air passage to form a waste heat inner exhausting passage. Therefore, low temperature of the front ground of the showcase can be eliminated, temperature difference of partial areas of a supermarket can be reduced, purchasing environment of the supermarket can be improved, and simultaneously, the heat exchanger can serve as an indoor air conditioner to perform warming and heat preservation complement.

Owner:上海海立中野冷机有限公司

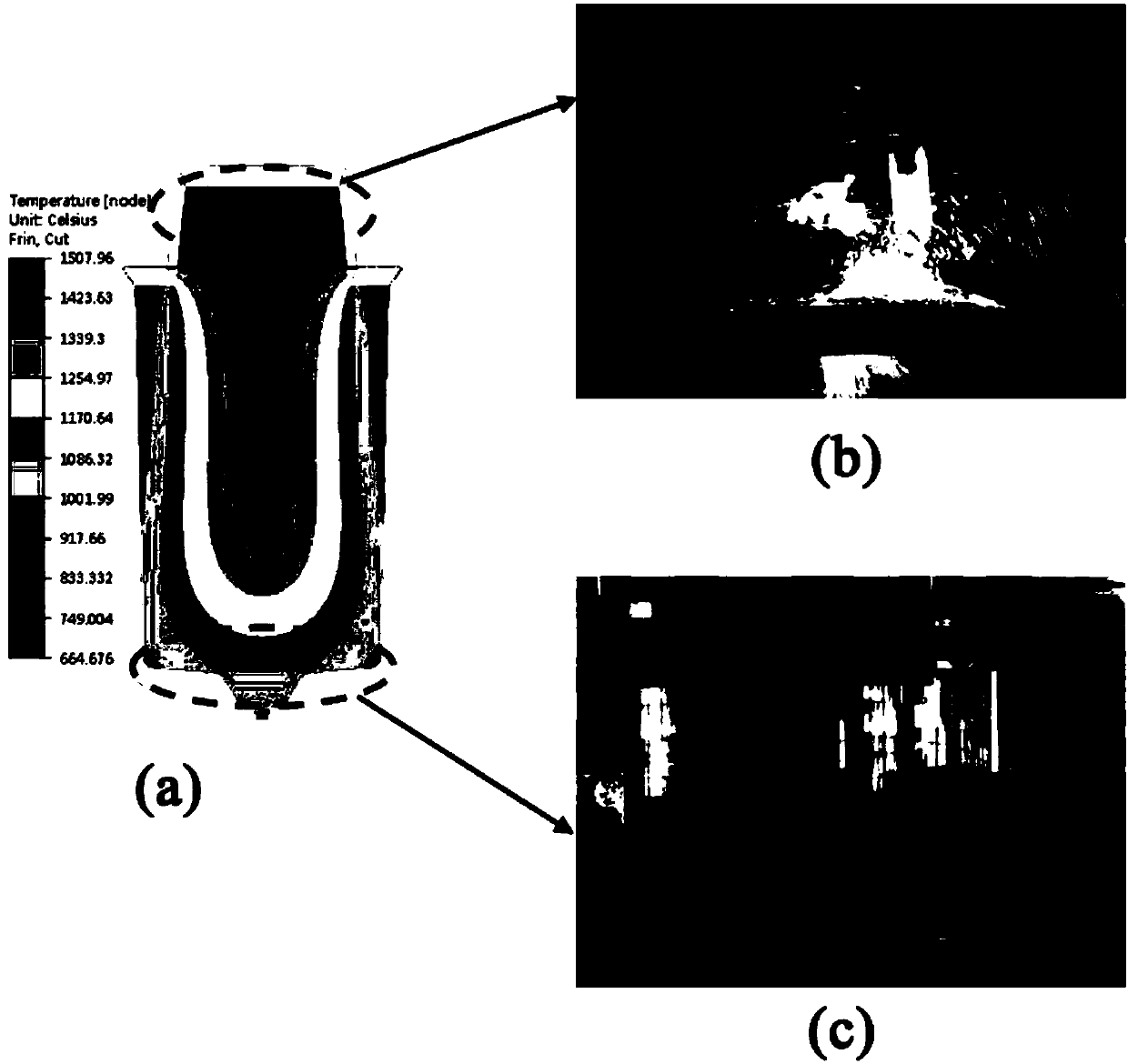

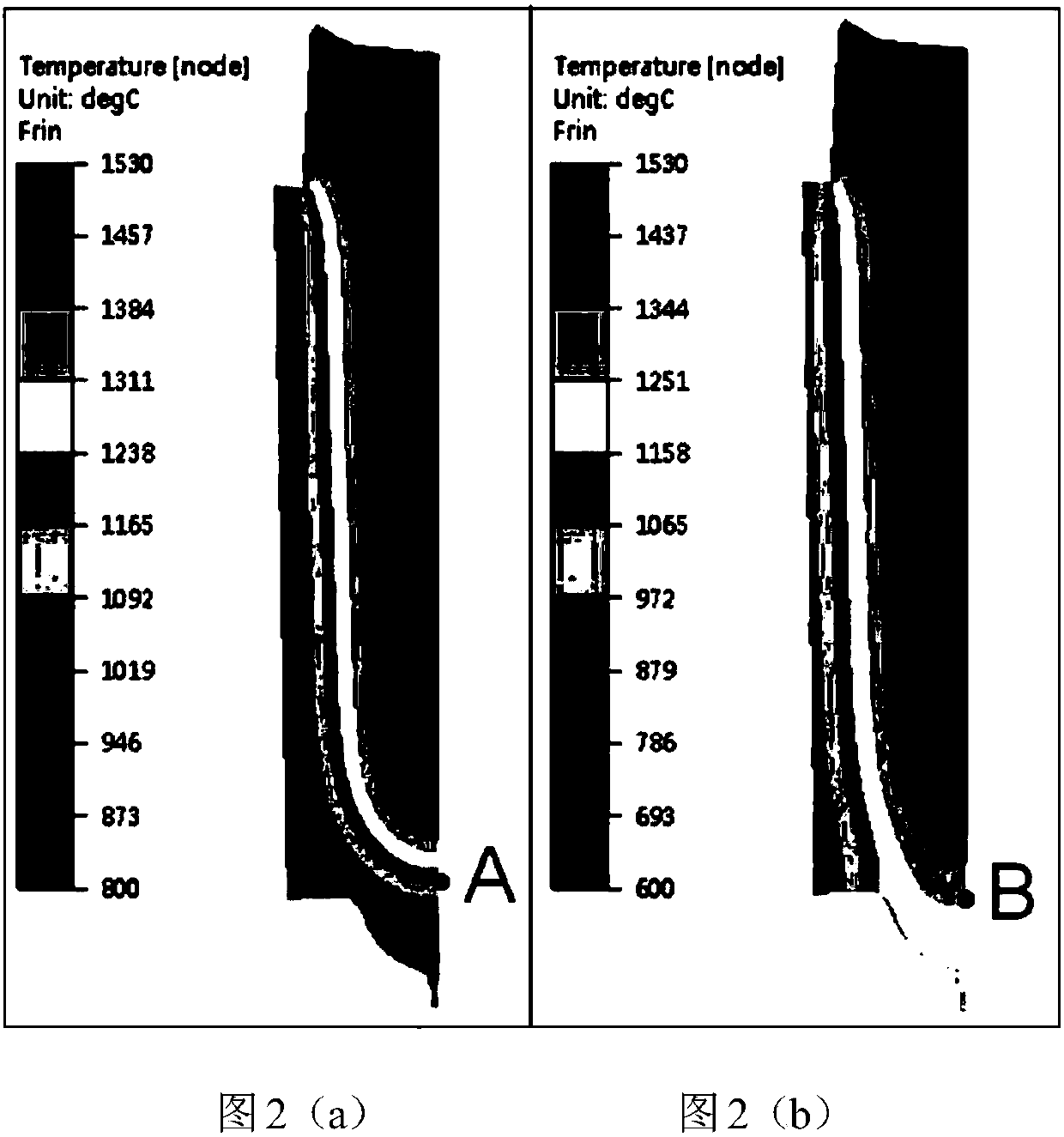

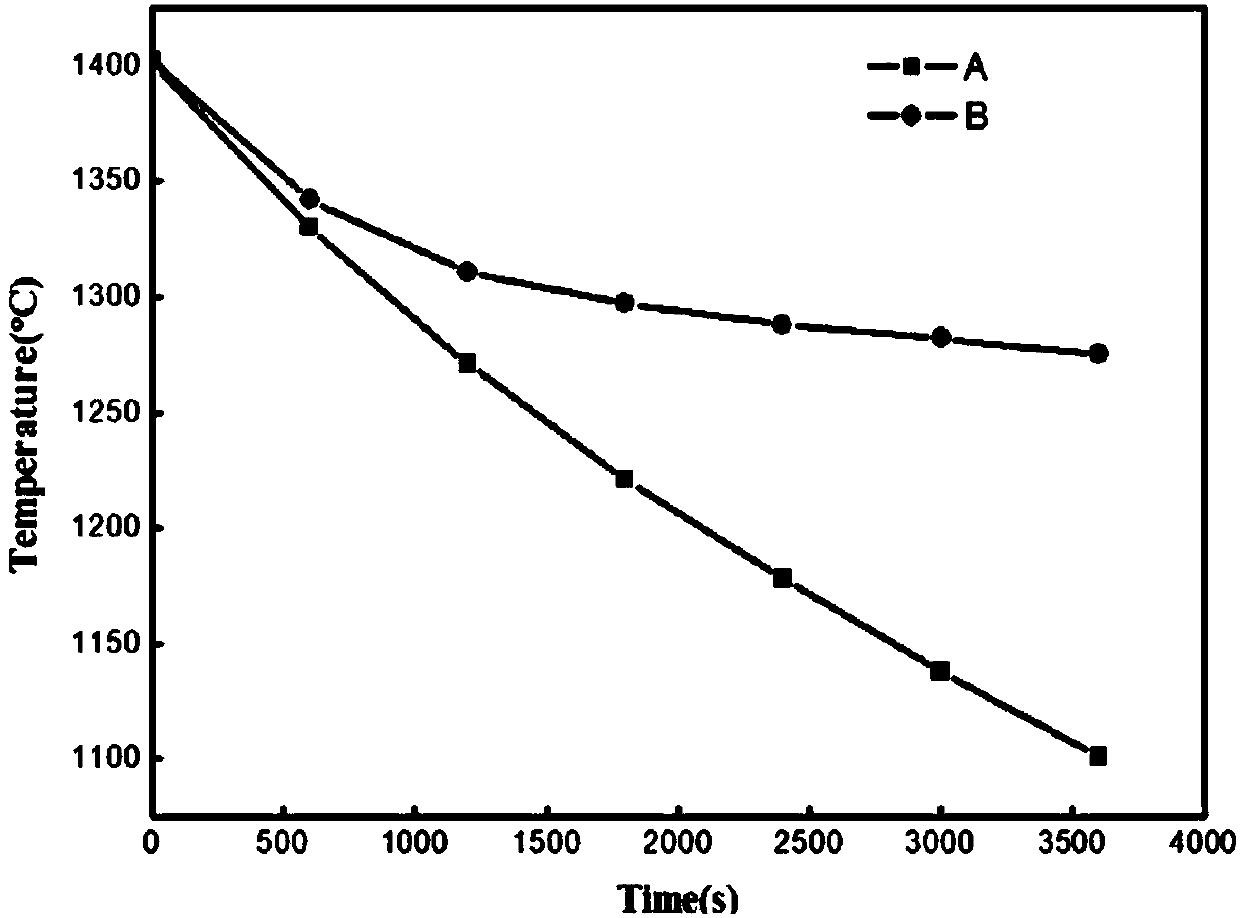

Processing method of conventional ingot-cast steel ingot for ultra-high temperature soft core forging

ActiveCN109513887AEnsure safetySolve the problem of molten steel splashing on the riserThermal insulationDiameter ratio

The invention belongs to the field of forging, and particularly relates to a processing method of a conventional ingot-cast steel ingot for ultra-high temperature soft core forging. A numerical simulation method is adopted and processing parameters of steel ingot forging for ultra-high temperature soft core forging are combined. The processing method comprises the following steps of (1) bottom thermal insulation designing, and (2) flash groove sealing designing, wherein according to the bottom thermal insulation designing, when the steel ingot surface has certain strength, the steel ingot witha die is lifted and placed on a thermal insulation chassis which thermal insulation cotton is laid on, and static temperature uniforming processing is conducted, and according to the flash groove sealing designing, during the steel ingot cooling process, forced cooling measures are adopted to a flash groove, and therefore molten steel at the top solidifies to form a solidified shell with certainthickness. A method of changing local temperature field distribution of the steel ingot is adopted to reduce the upper and lower temperature difference of the steel ingot, and therefore the prepared steel ingot for ultra-high temperature soft core forging can meet the forging requirements in the subsequent forging process. The processing method is suitable for the conventional ingot-cast steel ingot for ultra-high temperature soft core forging, and can solve the problem that a steel ingot with high height-diameter ratio for soft core forging is uneven in temperature after demolding.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

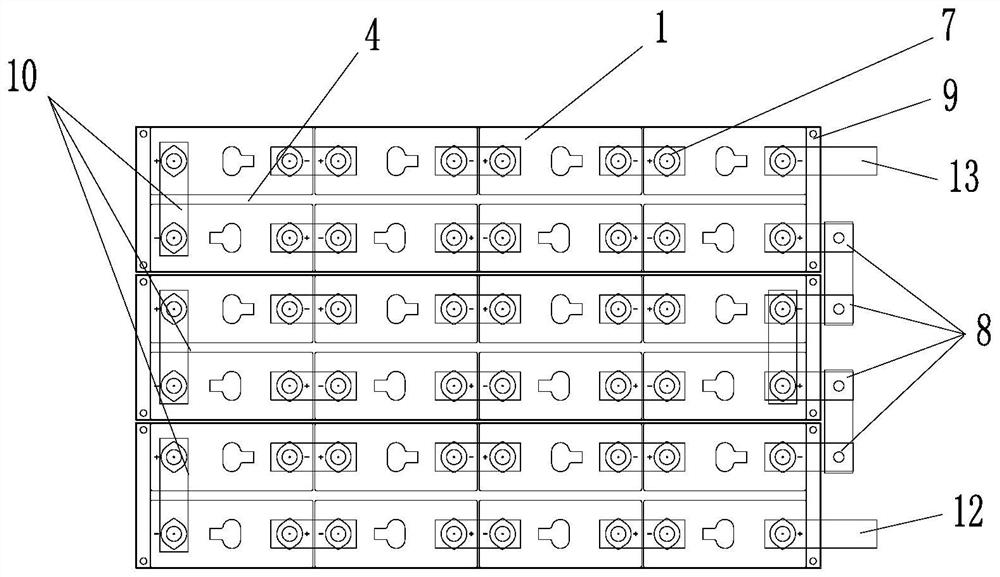

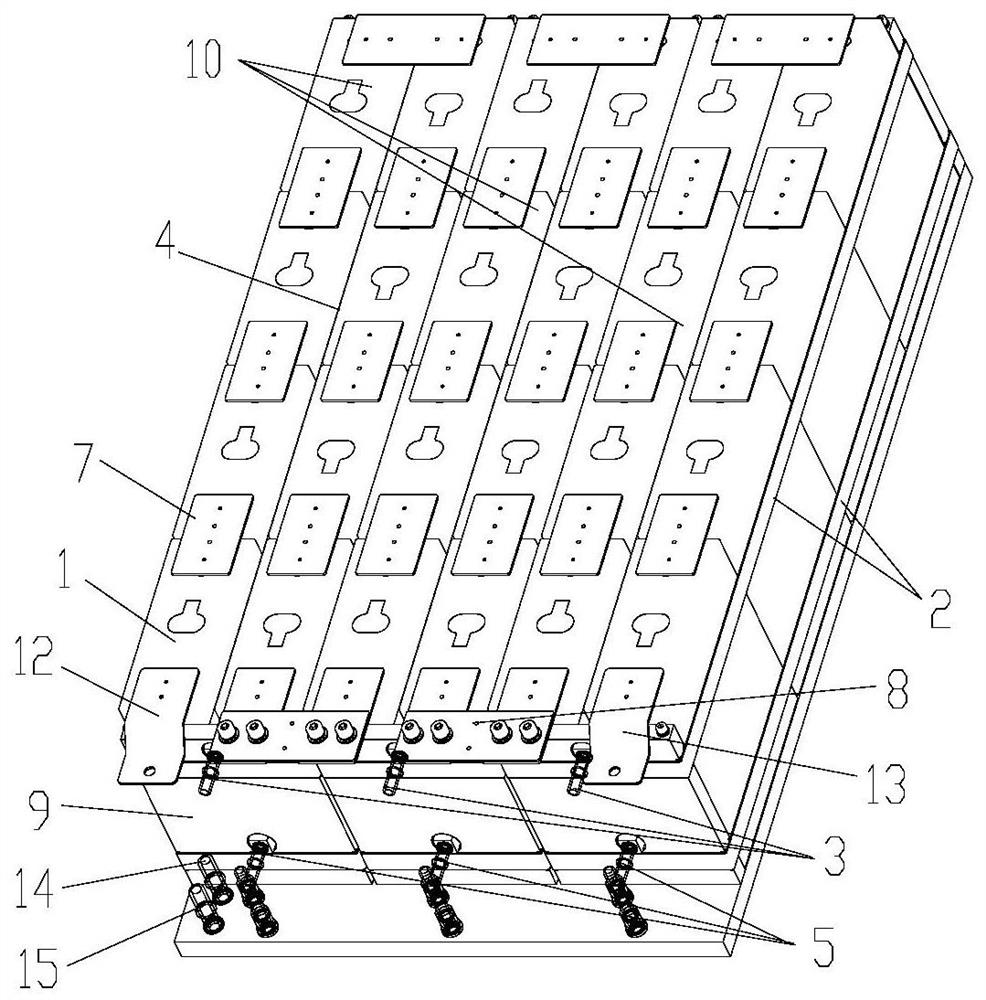

Numerical control setting machine

PendingCN111206359AIncrease the number ofIncrease productivityShaping/stretching tubular fabricsNumerical controlControl engineering

The present invention relates to a numerical control setting machine. The numerical control setting machine comprises a setting frame, an oven and setting mechanisms, and also comprises moving seats and a driving assembly, wherein the moving seats are mounted on the setting frame through a slideway; the setting mechanisms are mounted on the corresponding moving seats, and the setting mechanisms and the oven are located on a same side of the setting frame; the driving assembly drives the moving seats to move back and forth along the setting frame; and the oven is at least provided with an inletfor the setting mechanisms to enter or leave the oven. The driving assembly controls multiple groups of setting assemblies to enter or leave the oven, so that the number of fabrics subjected to setting by drying in machine operation is increased and the production efficiency is improved; and the front and rear groups of setting assemblies enter or leave the oven alternately to finish setting by drying and replacement of the fabrics alternately, so that the utilization rate of the oven is improved, the width and the volume of the oven are reduced, and the energy consumption of the oven is reduced. The numerical control setting machine is simple in structure, convenient to operate, small in overall volume, low in energy consumption and small in setting temperature difference, and meets thesetting requirement of high quality.

Owner:ZHEJIANG NEU MACHINERY EQUIP CO LTD

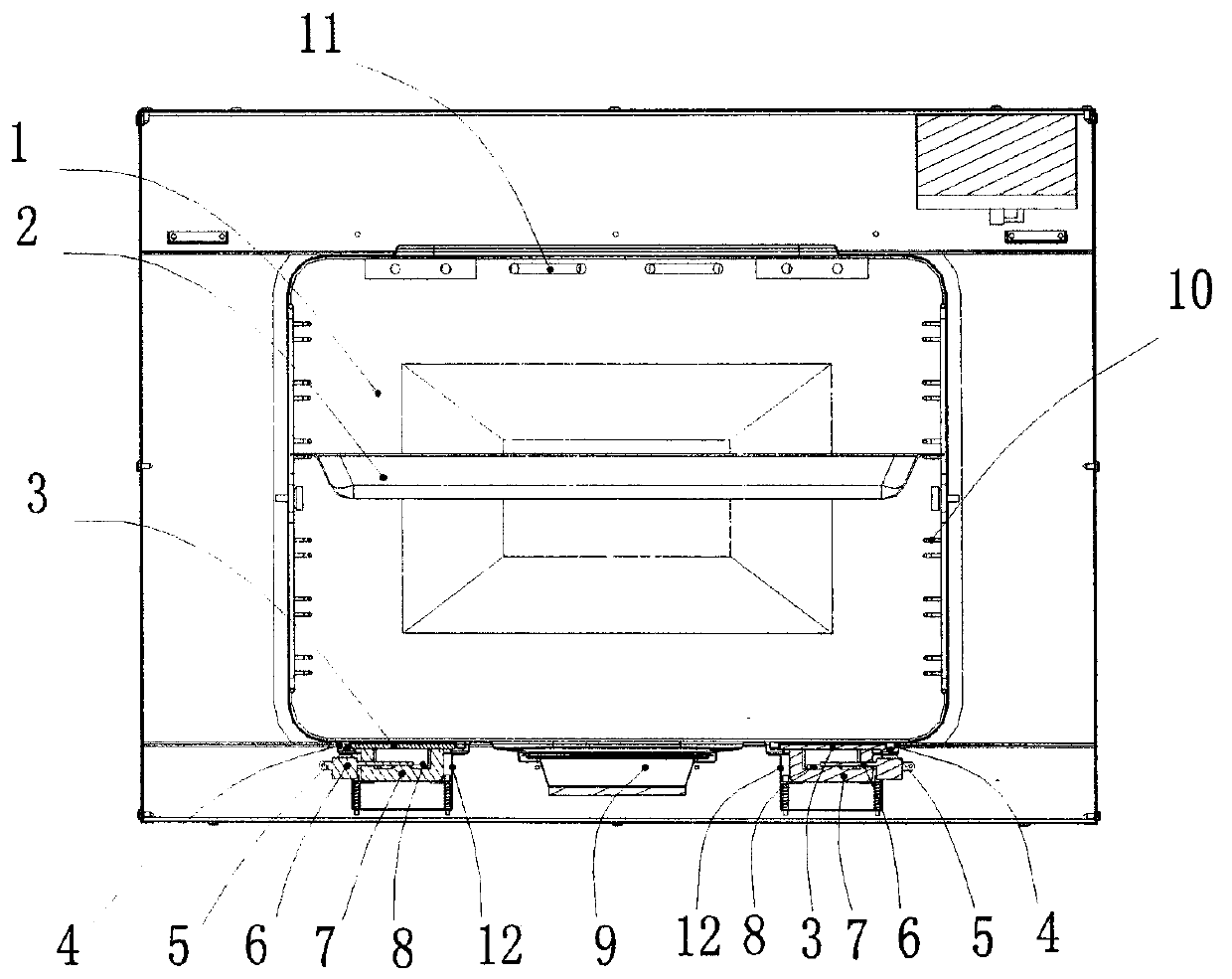

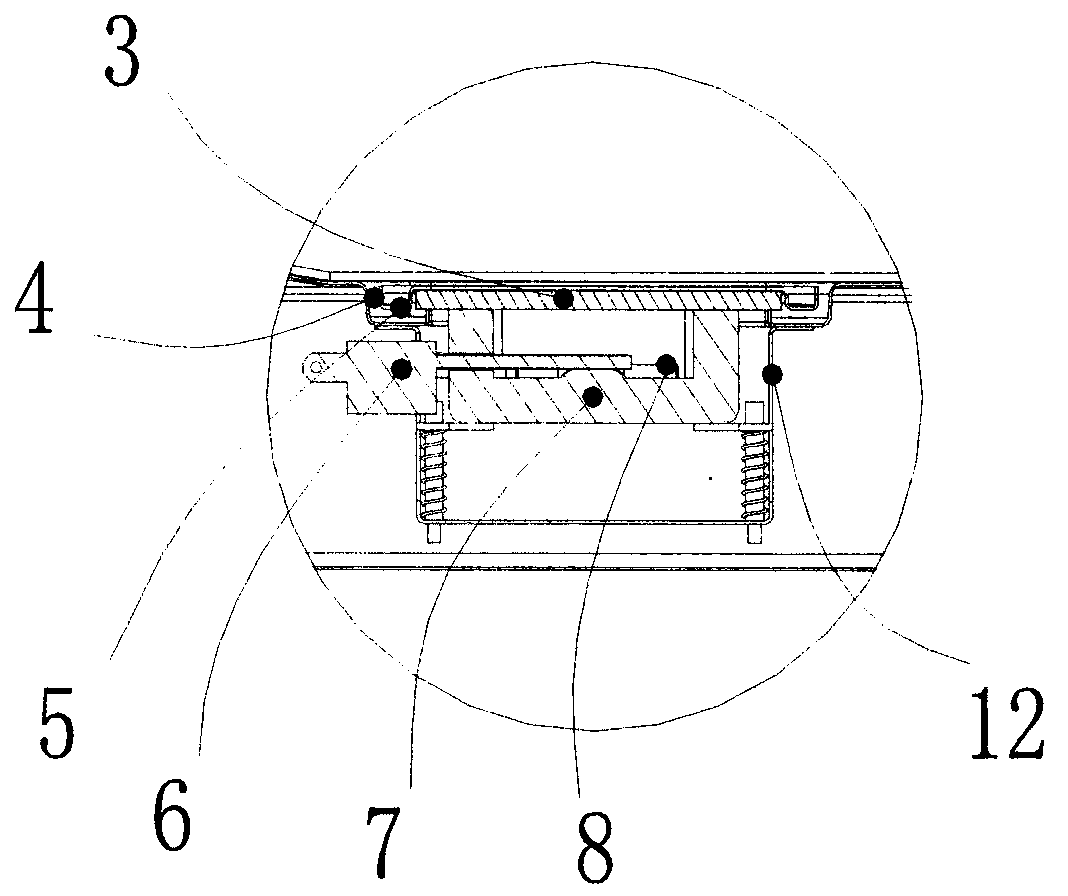

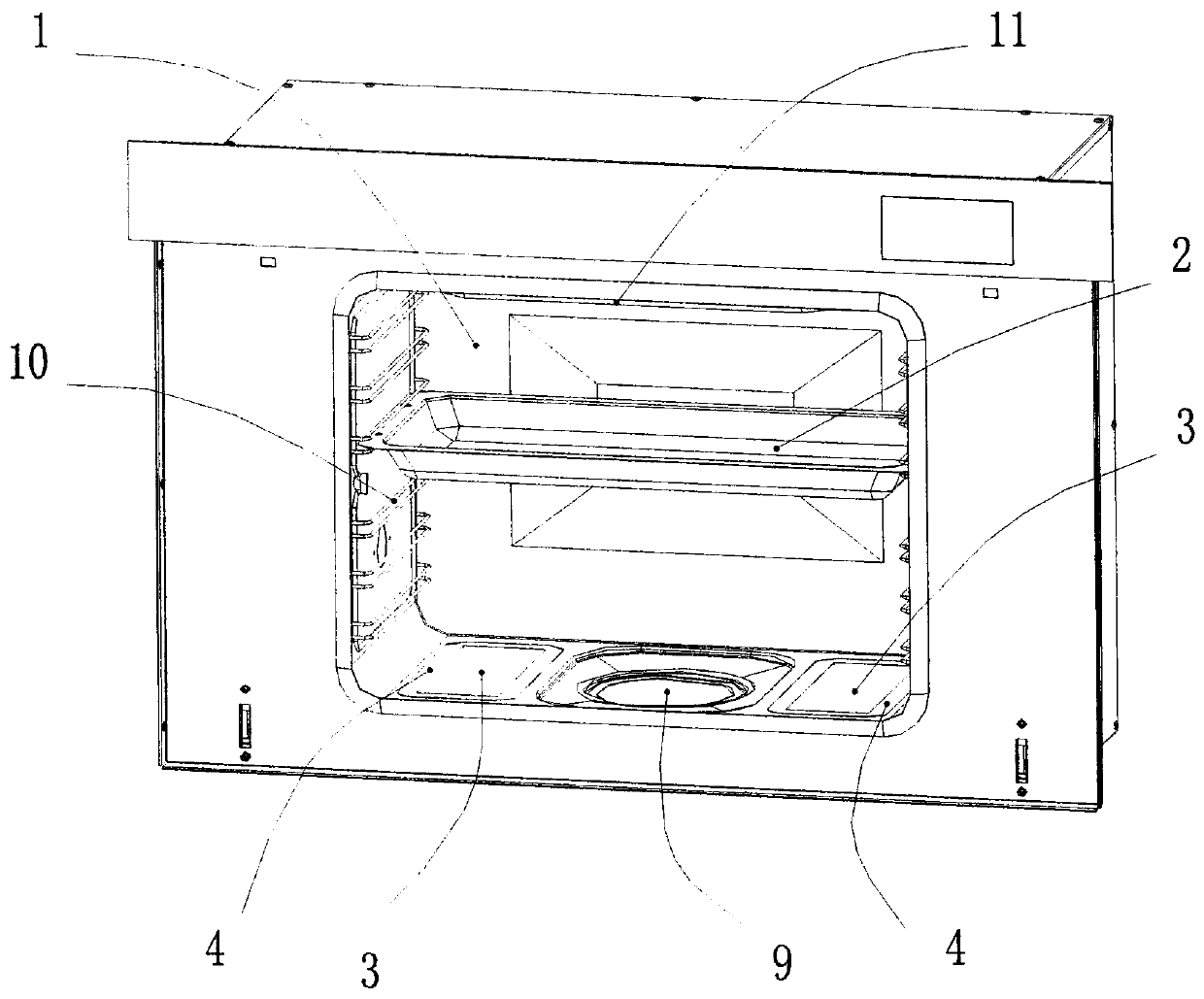

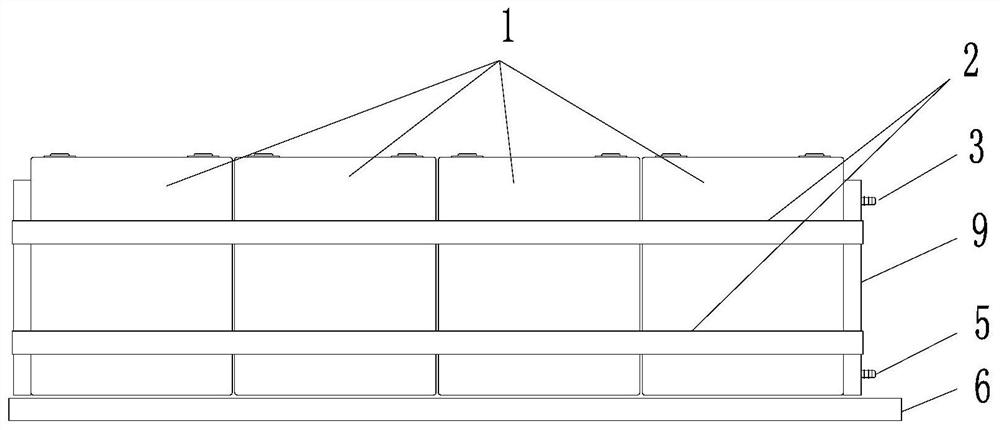

Steam oven

The invention relates to a steam oven which comprises a cavity, a hanging rack, a baking tray, a steam generator, an electric heating tube and a ceramic heating tray assembly, wherein a heating wire and a temperature sensor are fixed in the ceramic heating tray assembly; the ceramic heating tray assembly are fixed at the bottom of the cavity by a bracket; microcrystalline glass is arranged on theceramic heating tray assembly; the microcrystalline glass is connected with the bottom of the cavity by a stainless steel glass fixing frame sleeved with a sealing ring, so that the ceramic heating tray assembly is laminated to the microcrystalline glass; and the electric heating tube is mounted at an upper part of the cavity. Thus, when a consumer bakes food with a steaming and baking integratedmachine, a ceramic heating tray at the bottom of the cavity of the machine and the heating tube at the upper part may work simultaneously; and a lot of heat generated by an electric heating wire in the ceramic heating tray assembly is transferred to the cavity by utilizing excellent unidirectional heat conductivity of the microcrystalline glass, thereby reducing an upper and lower temperature difference of the cavity, reducing a heating time of the cavity body, and making food baking be more convenient and rapid and better meet needs of consumers.

Owner:宁波旺牌厨具科技有限公司

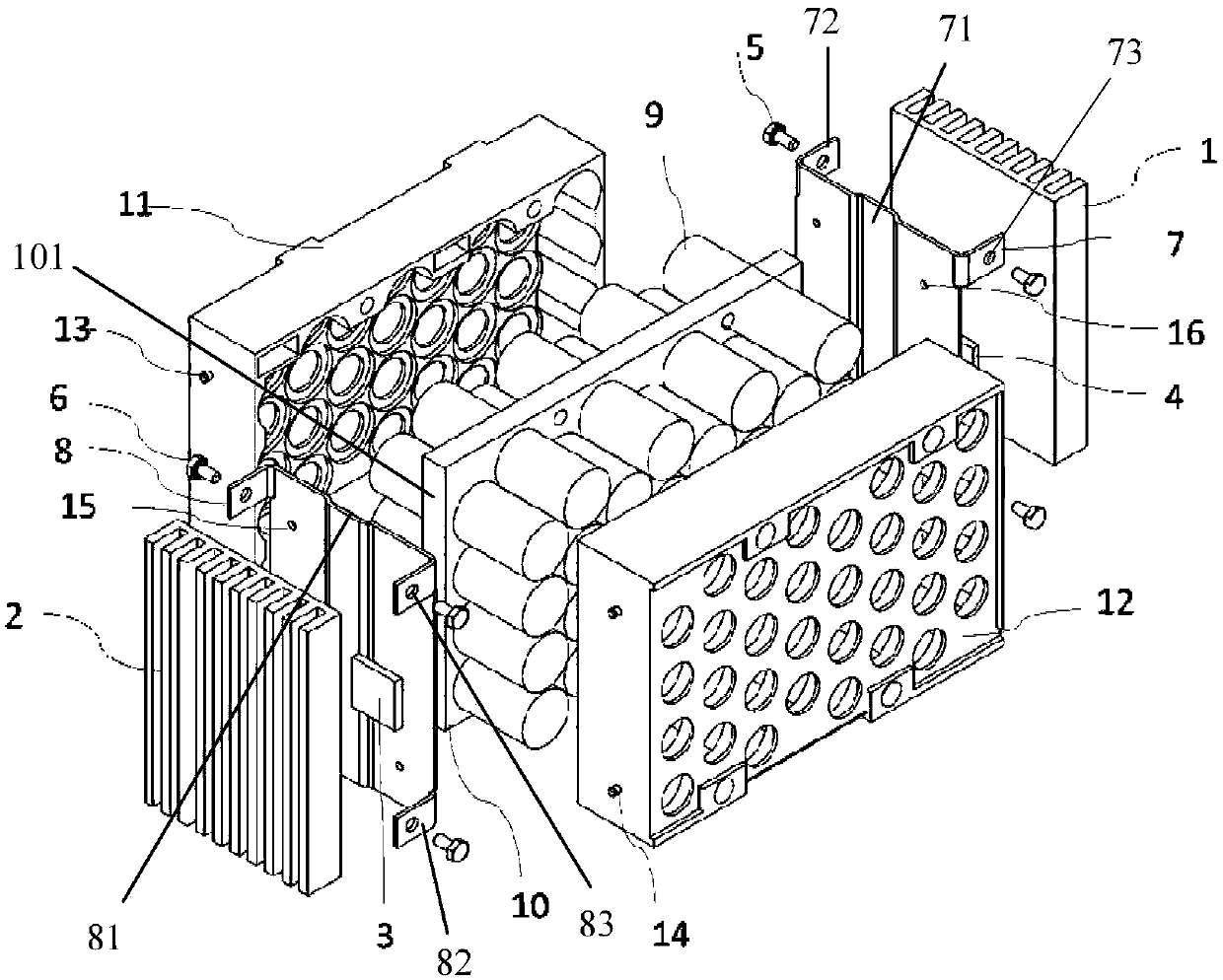

Energy storage liquid-cooled battery pack

PendingCN113571799AReduce the temperature difference between upper and lowerImprove temperature consistencySecondary cellsPower batteryMechanical engineering

The invention belongs to the technical field of power batteries, and particularly relates to an energy storage liquid-cooled battery pack. The battery pack comprises a bottom liquid cooling plate and a plurality of battery modules arranged on the bottom liquid cooling plate, and the plurality of battery modules are bound together through a fixing belt; a side liquid cooling plate is arranged in each battery module, and a plurality of side liquid cooling plates are connected in parallel. The battery module comprises a plurality of battery cells, and the plurality of battery cells are arranged on the two sides of the side liquid cooling plate respectively; and the plurality of battery cells are sequentially connected in series through the connecting bar. The bottom liquid cooling plate is used for main heat dissipation, the side liquid cooling plates play a role in temperature equalization, the temperature difference between the upper part and the lower part of the battery pack is obviously reduced, the temperature consistency of the battery pack is improved, and the energy density of the battery pack is improved, so that the purpose of high-rate operation is achieved.

Owner:广州智光储能科技有限公司

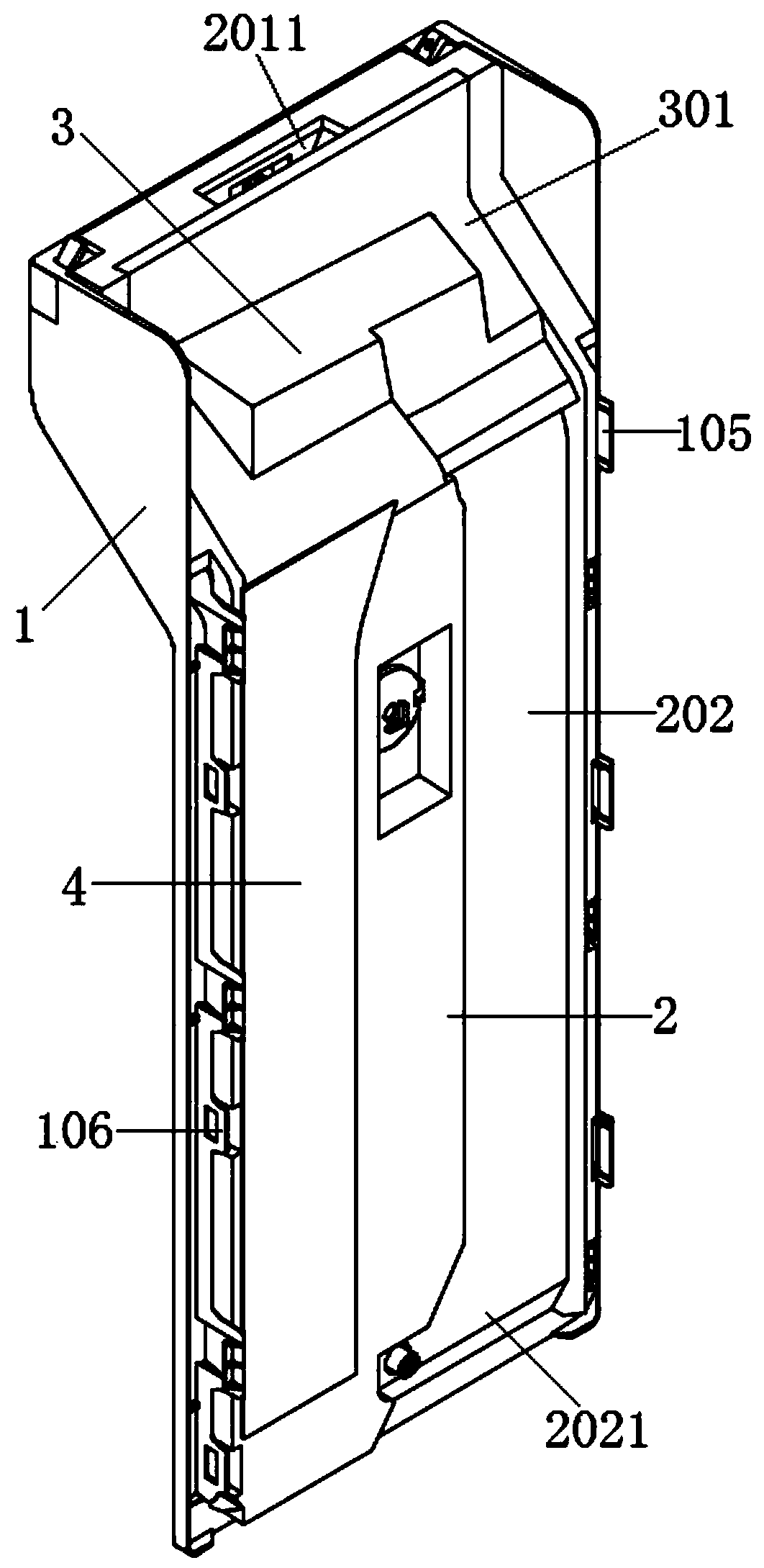

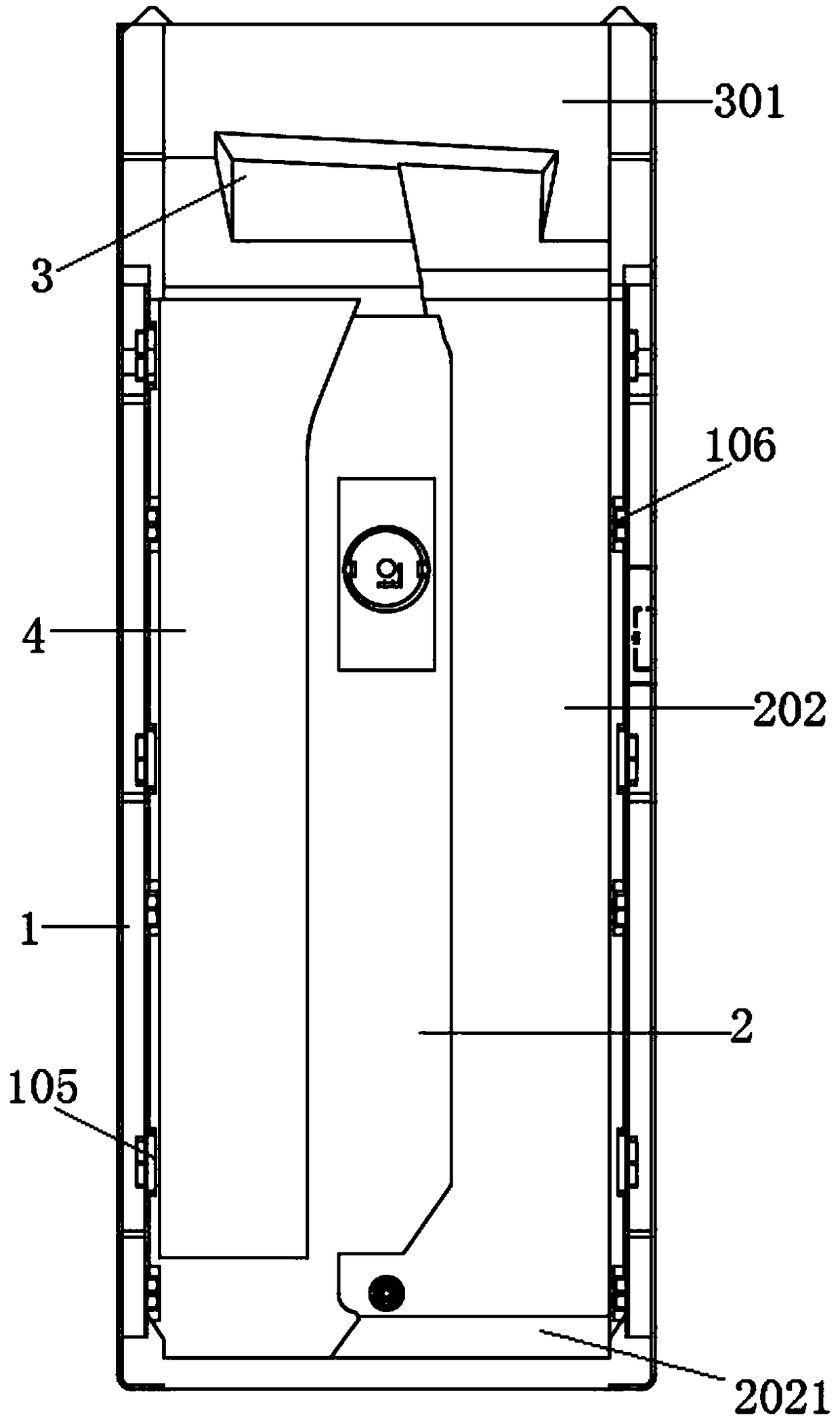

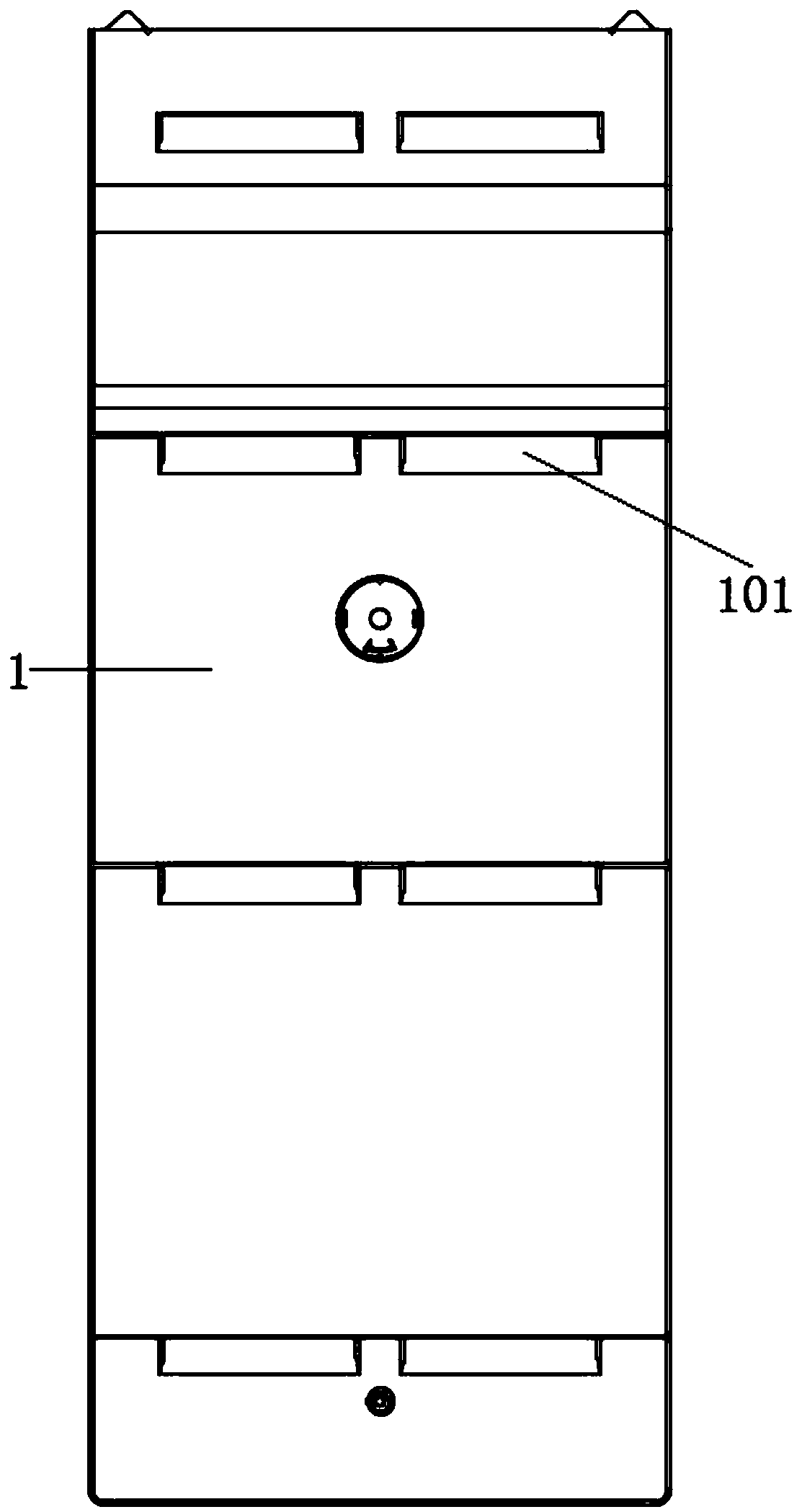

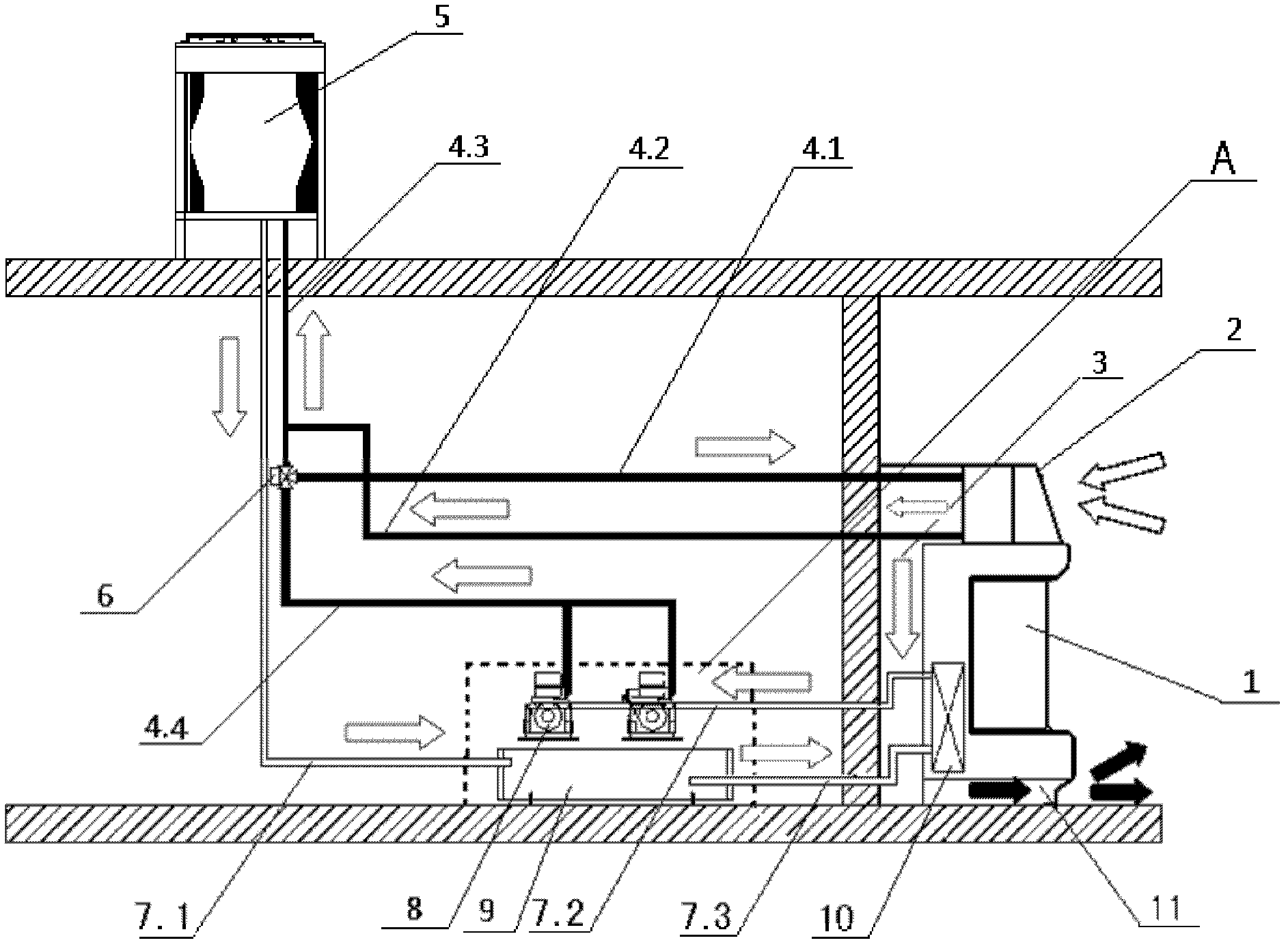

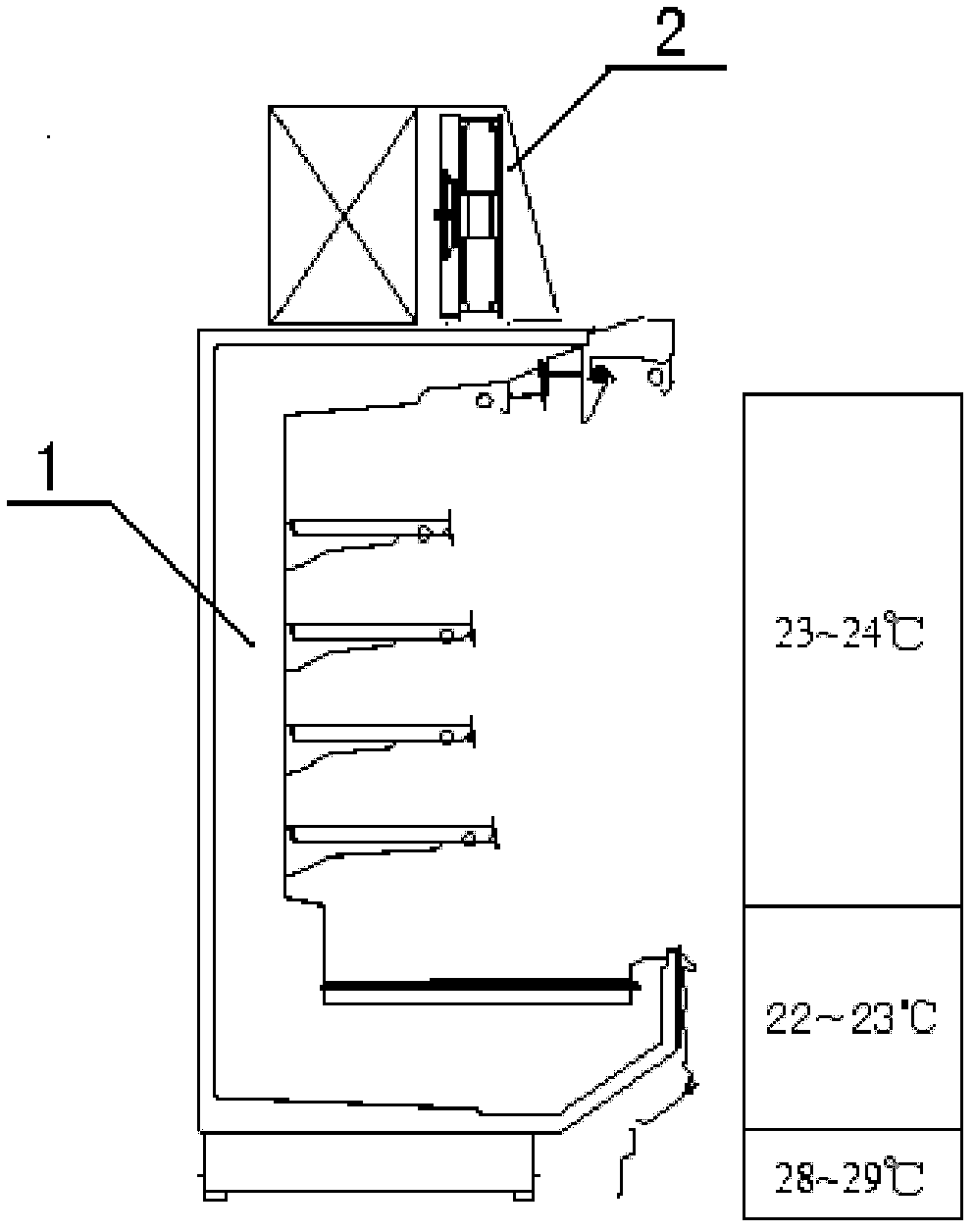

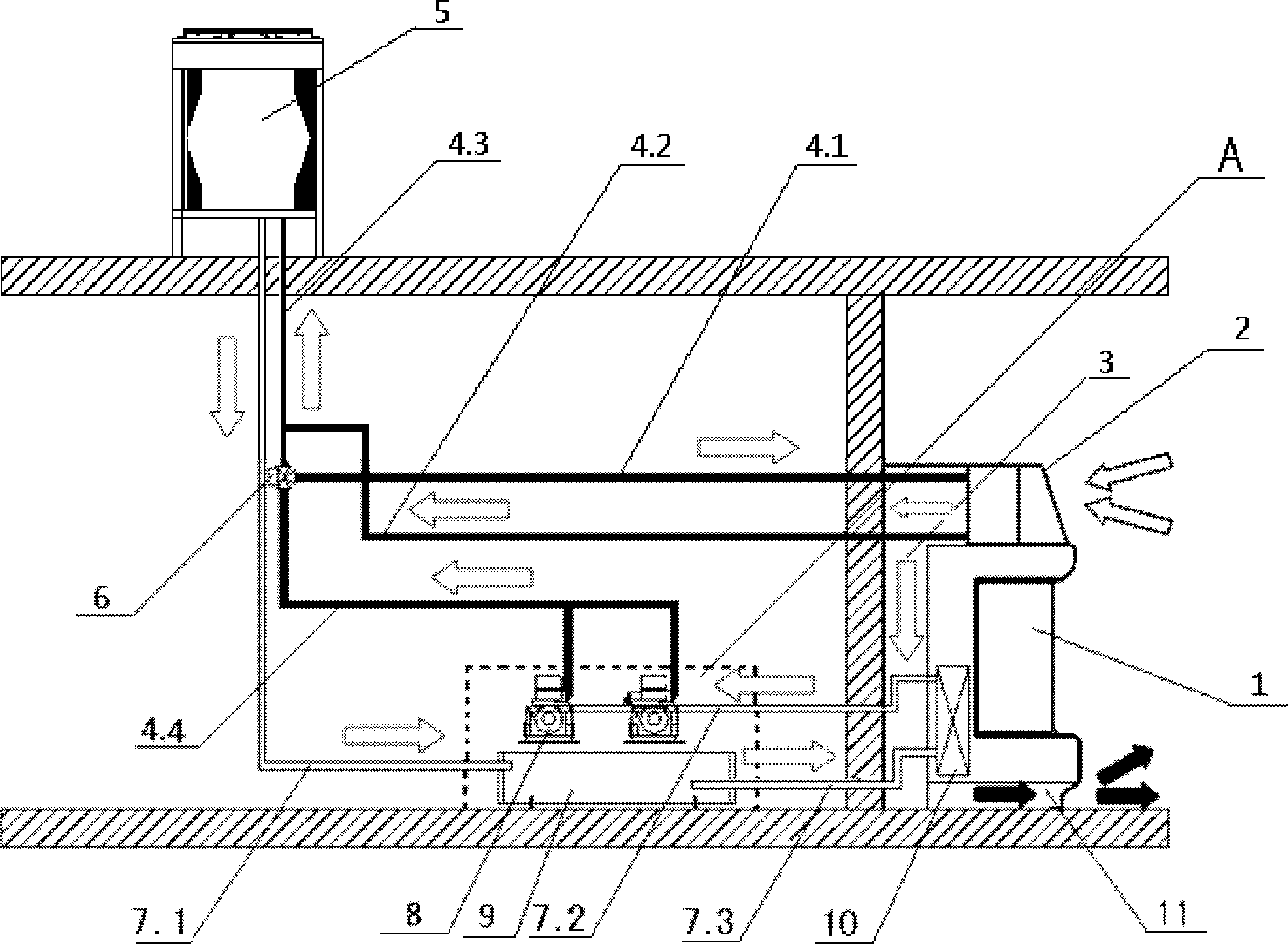

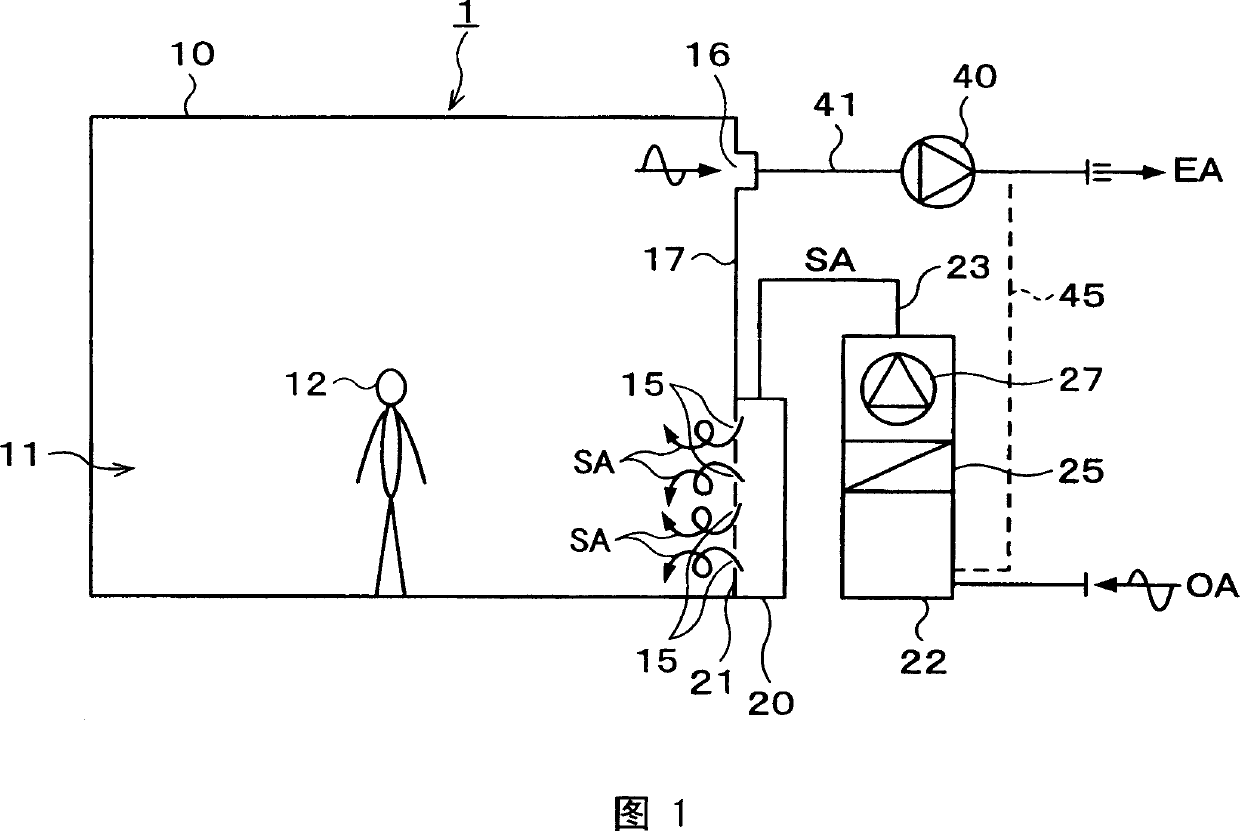

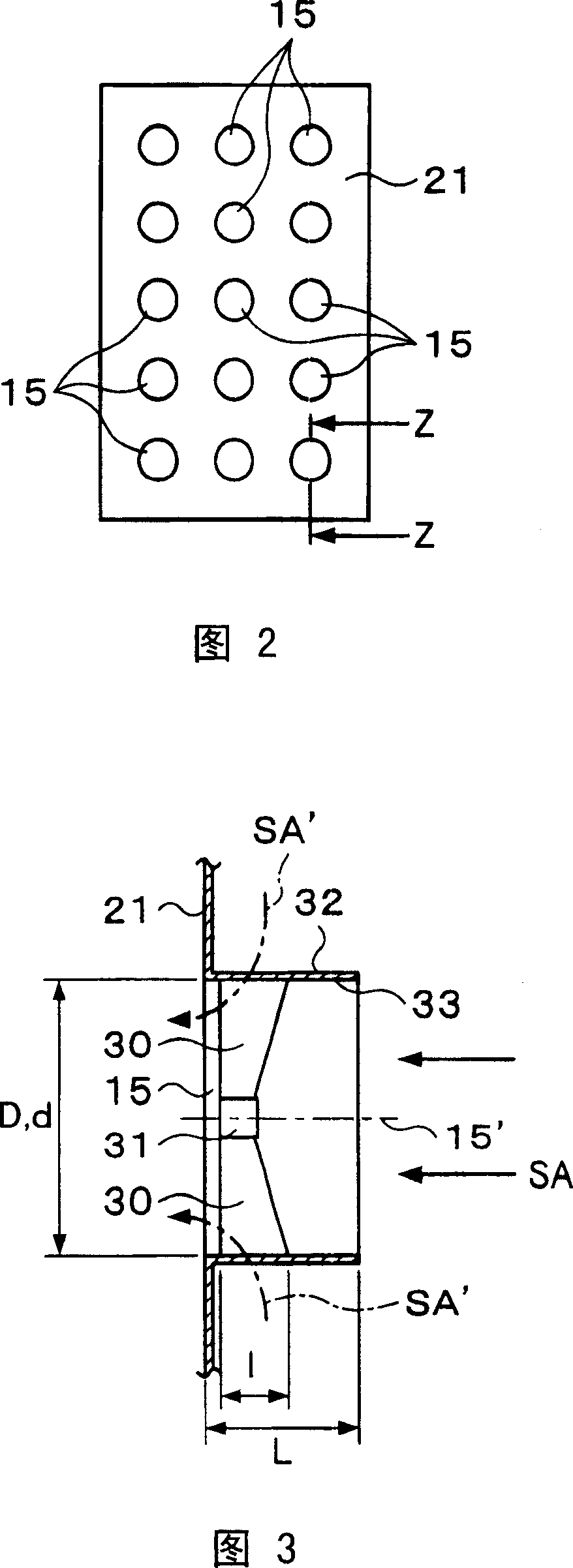

Ventilation system

ActiveCN1677006AReduce the temperature difference between upper and lowerSlow downDucting arrangementsLighting and heating apparatusEngineeringBlow out

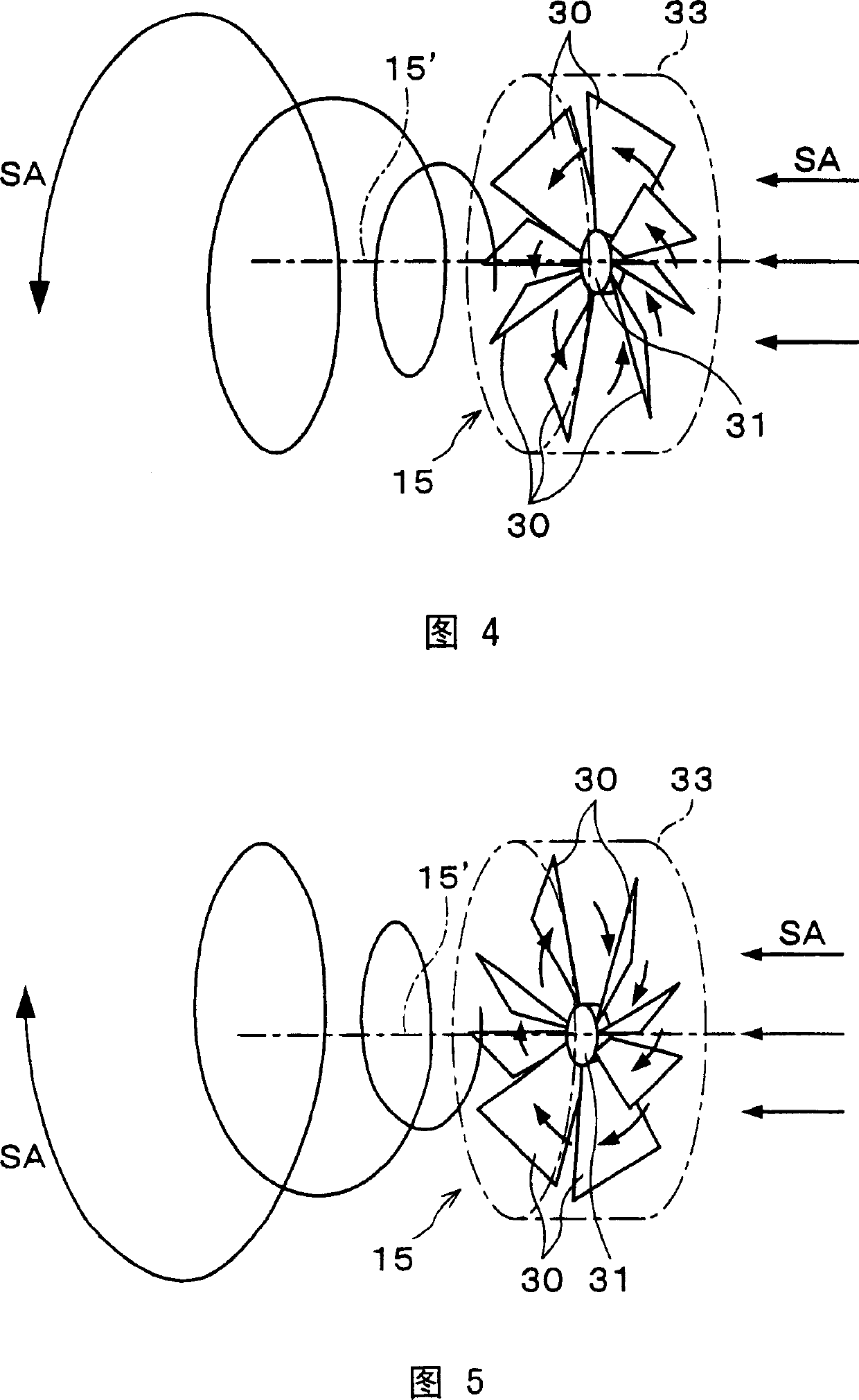

In this exchange ventilation system 1 where the low-temperature air SA is supplied into an air conditioning space, and the heated air raised by being heated in the air conditioning space is exhausted EA to perform the ventilation, a plurality of guide fins 30 are mounted on an air supply hole for the low temperature air SA to give the swirling component to the low temperature air SA blown out into the air conditioning space, the plurality of guide fins are radially mounted around a central axis of the air supply hole, and respectively inclined to a plane orthogonal to the central axis of the air supply hole at the same angle, and a cylindrical inner wall face applying the central axis of the air supply hole as its central axis, is formed around the plurality of guide fins.

Owner:TAKASAGO THERMAL ENG CO LTD

Siphon type dewatering wiper for hot plate blank

PendingCN111906155ASimple structureEasy to useDrying solid materials without heatWork cleaning devicesSiphonEngineering

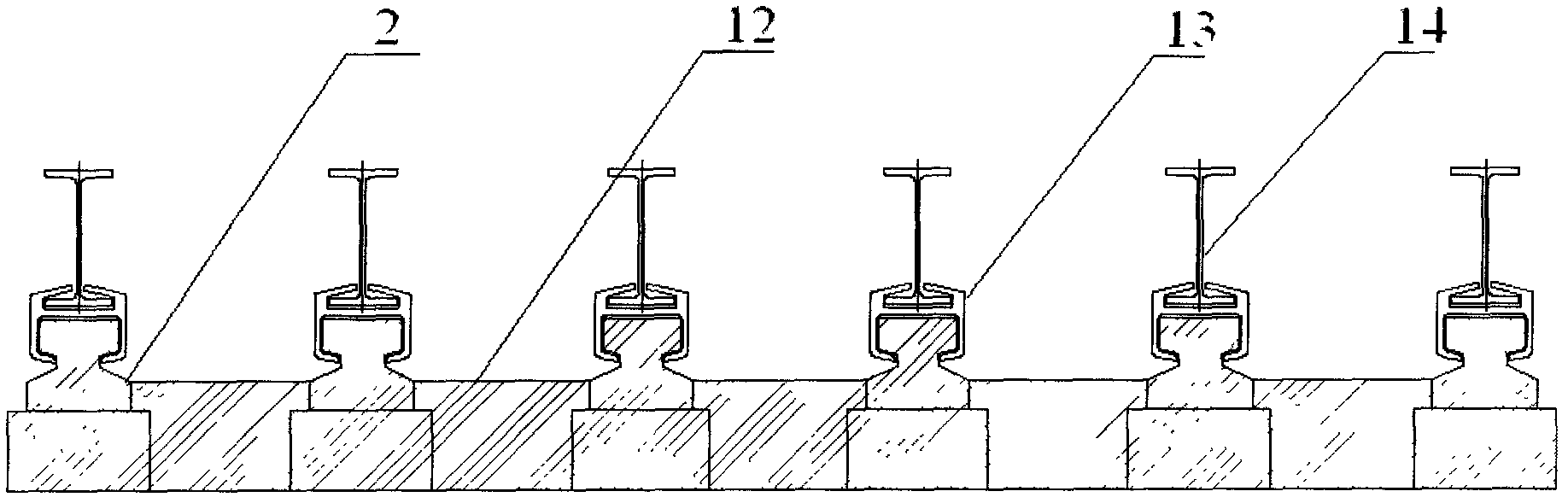

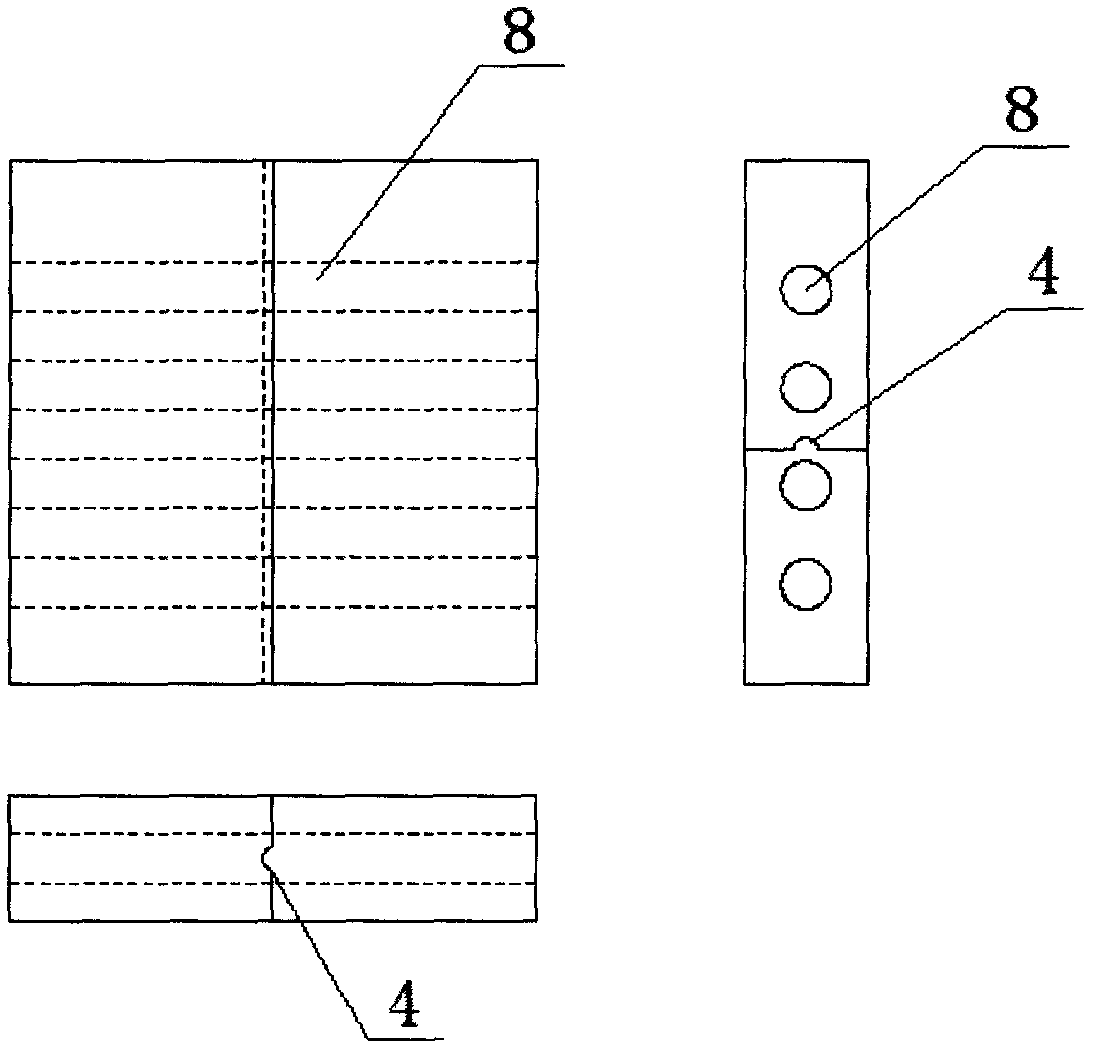

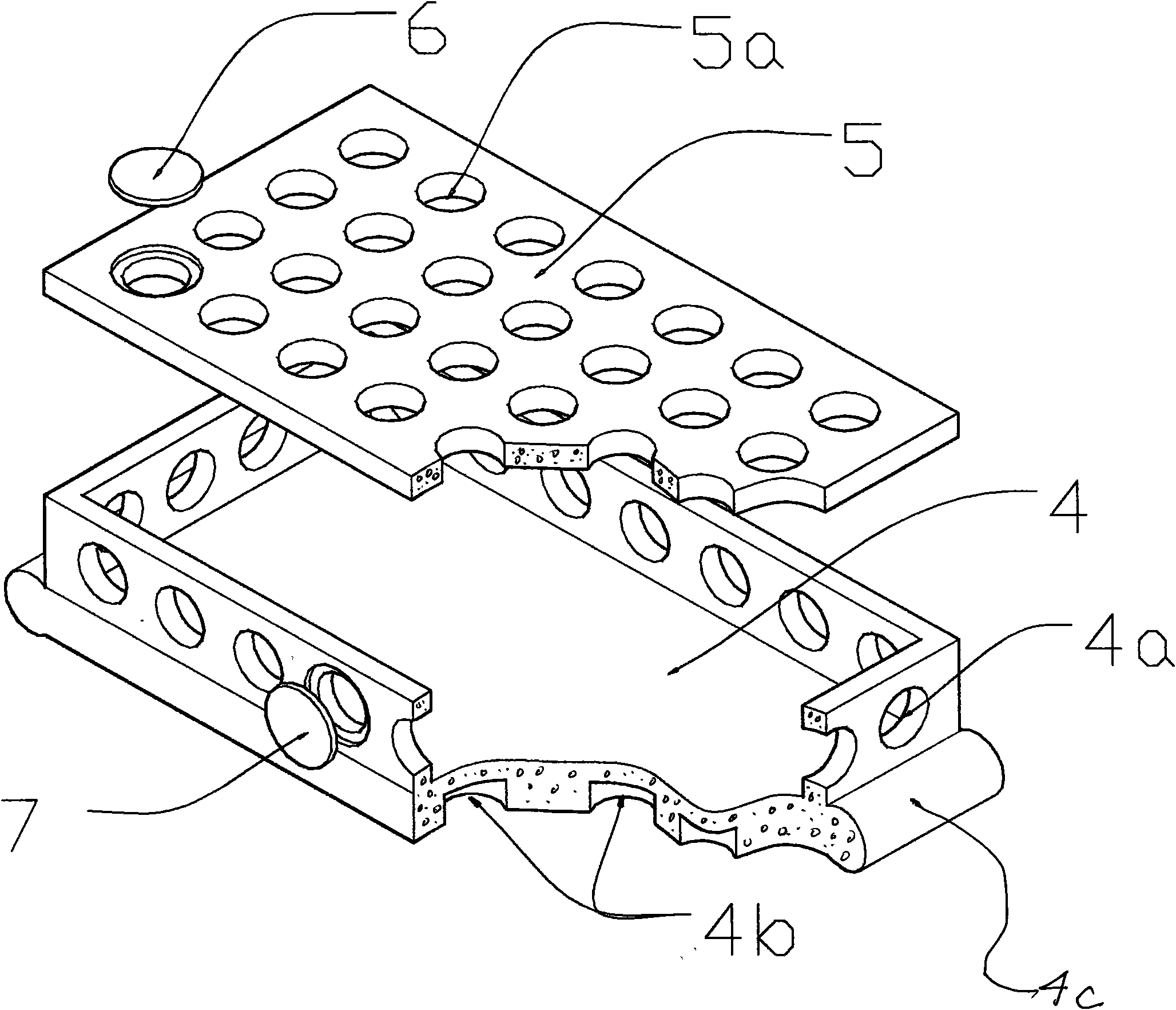

The invention relates to a siphon type dewatering wiper for a hot plate blank, and belongs to the technical field of hot rolling equipment in the metallurgical industry. According to the technical scheme, the siphon type dewatering wiper comprises a fixing support (1), hoisting connecting rods (3), siphon dewatering rollers (4), water collecting tanks (5) and a hot rolling conveying roller way (6), wherein the multiple siphon dewatering rollers (4) arranged side by side are arranged above the hot rolling conveying roller way (6) in the running direction of the hot plate blank, the two ends ofthe siphon dewatering rollers (4) are rotationally connected to the fixing support (1) through hoisting connecting rods (3), the water collecting tanks (5) are arranged below the two ends of the siphon dewatering rollers (4), the roller bodies of the siphon dewatering rollers (4) are concave roller with the thin middles and the two thick ends, a plurality of identical grooves (9) are engraved in the surface of the roller bodies in the axial direction, and each groove (9) is of a structure with the narrow middle and the two wide ends. The siphon type dewatering wiper has the beneficial effectsthat residual water on the surface of the hot plate blank passing through a dephosphorization machine or a rolling mill can be effectively and rapidly removed, the temperature difference between the upper portion and the lower portion of the hot plate blank is reduced, and head warping or buckling of the hot plate blank is prevented.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP +1

Novel blown aluminum uniform temperature plate

PendingCN110779364AReduce the temperature difference between left and rightReduce the temperatureSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsEngineering

The invention discloses a novel blown aluminum uniform temperature plate. The novel blown aluminum uniform temperature plate comprises a shell; one side of the shell is a heat source end; the internalof the shell is negative pressure and injected with working mediums; multiple drainage channels are formed in the shell; the drainage channels are aslant arranged, and the inclined directions are inclined to the heat source end from high to low; the condensed working mediums flow to the heat source end along the drainage channels; and the evaporated working mediums are far away from the heat source end along the drainage channels. In the novel blown aluminum uniform temperature plate, through arrangement of the drainage channels inclined to the heat source end from high to low, the condensedworking mediums are guided to the heat source end, and the evaporated working mediums are guided away from the heat source end, so that the left-right temperature difference of the shell is lowered, and the heat dissipation performance is improved; and meanwhile, the condensed working mediums are preferably fed to the upper part of the side, near the heat source end, in the shell, so that the heatof an upper heat source is taken away, the temperature of the upper heat source is effectively lowered, the up-down temperature difference of the shell is reduced, and the heat dissipation performance is improved.

Owner:DONGGUAN WANWEI THERMAL CONDUCTION TECH CO LTD

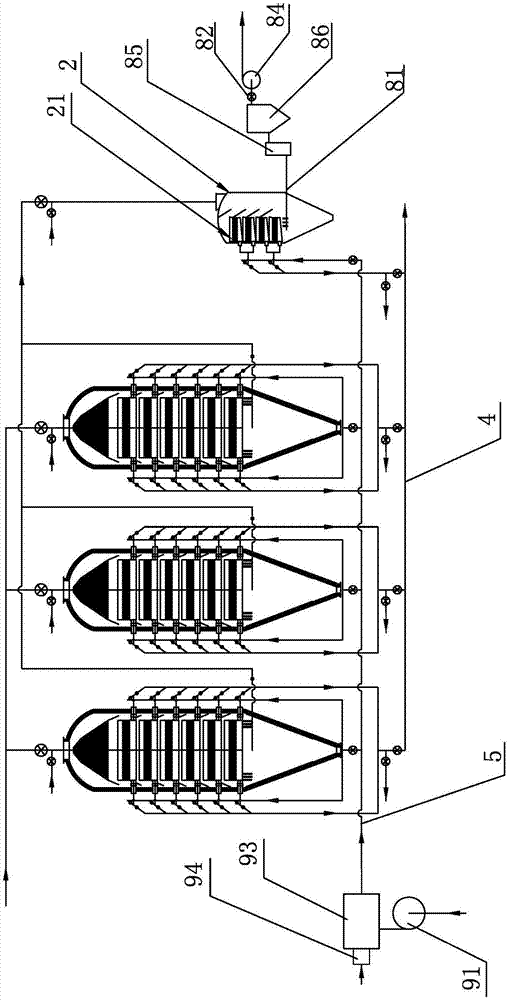

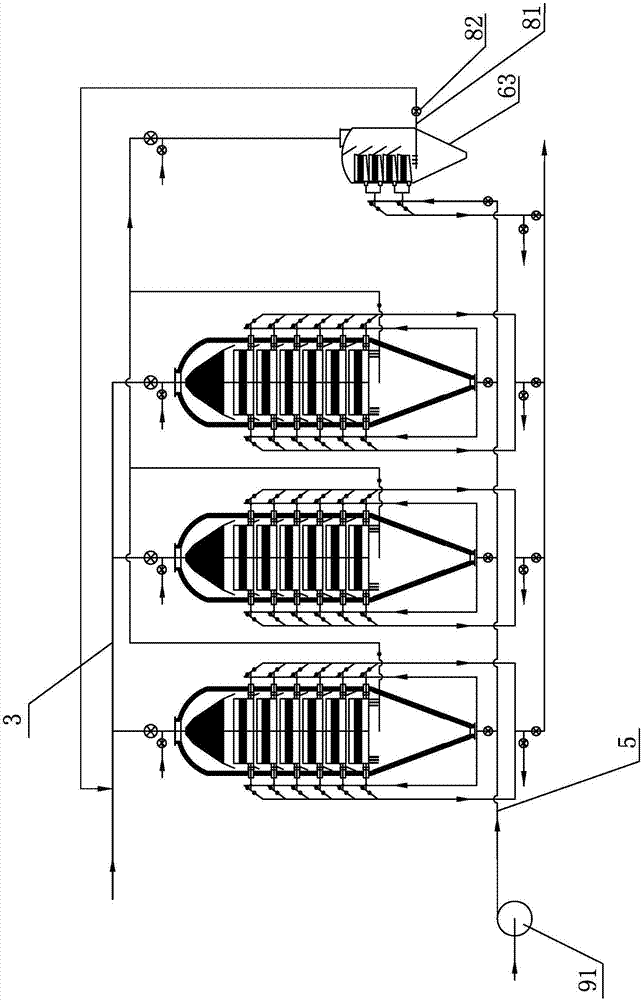

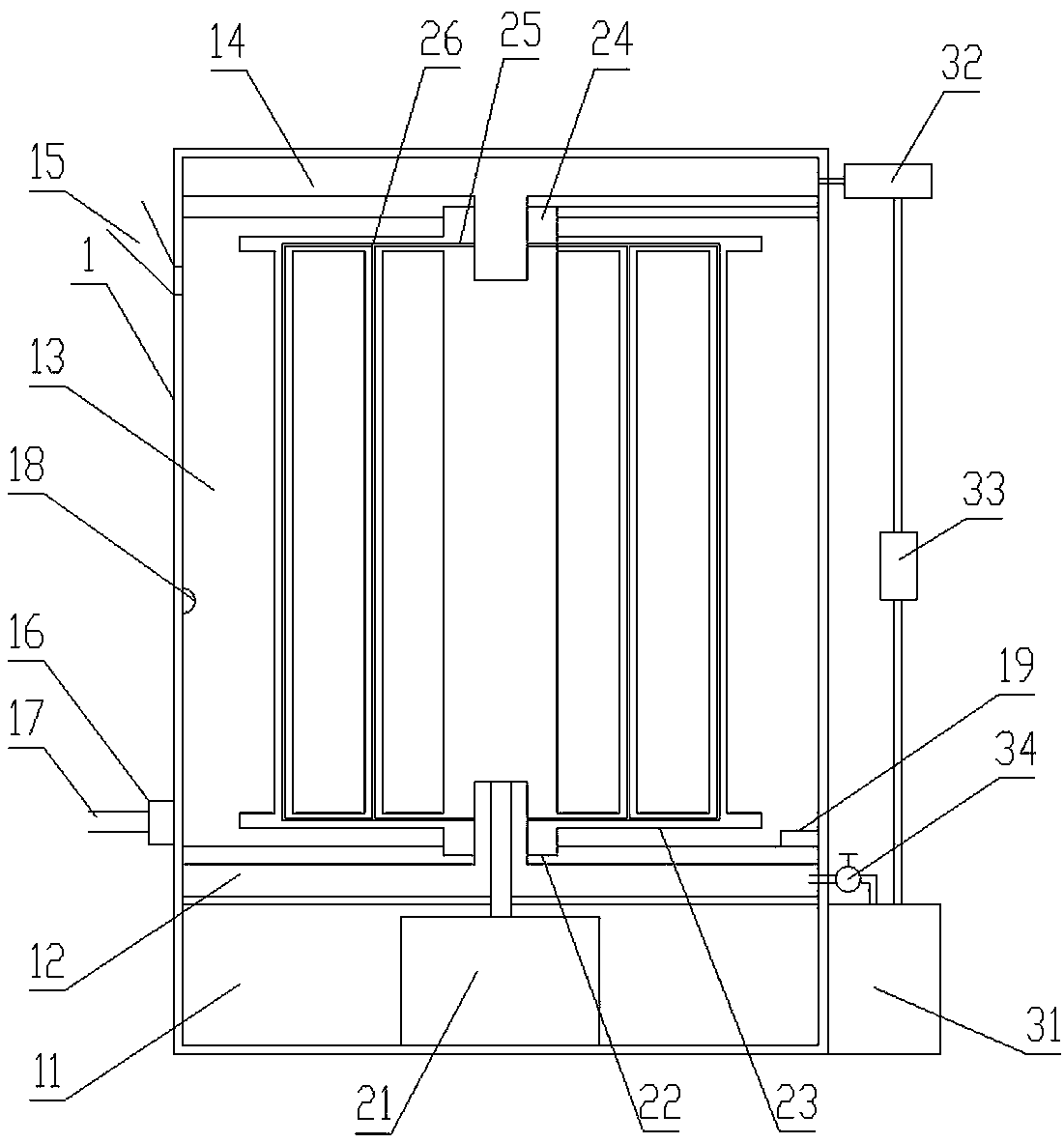

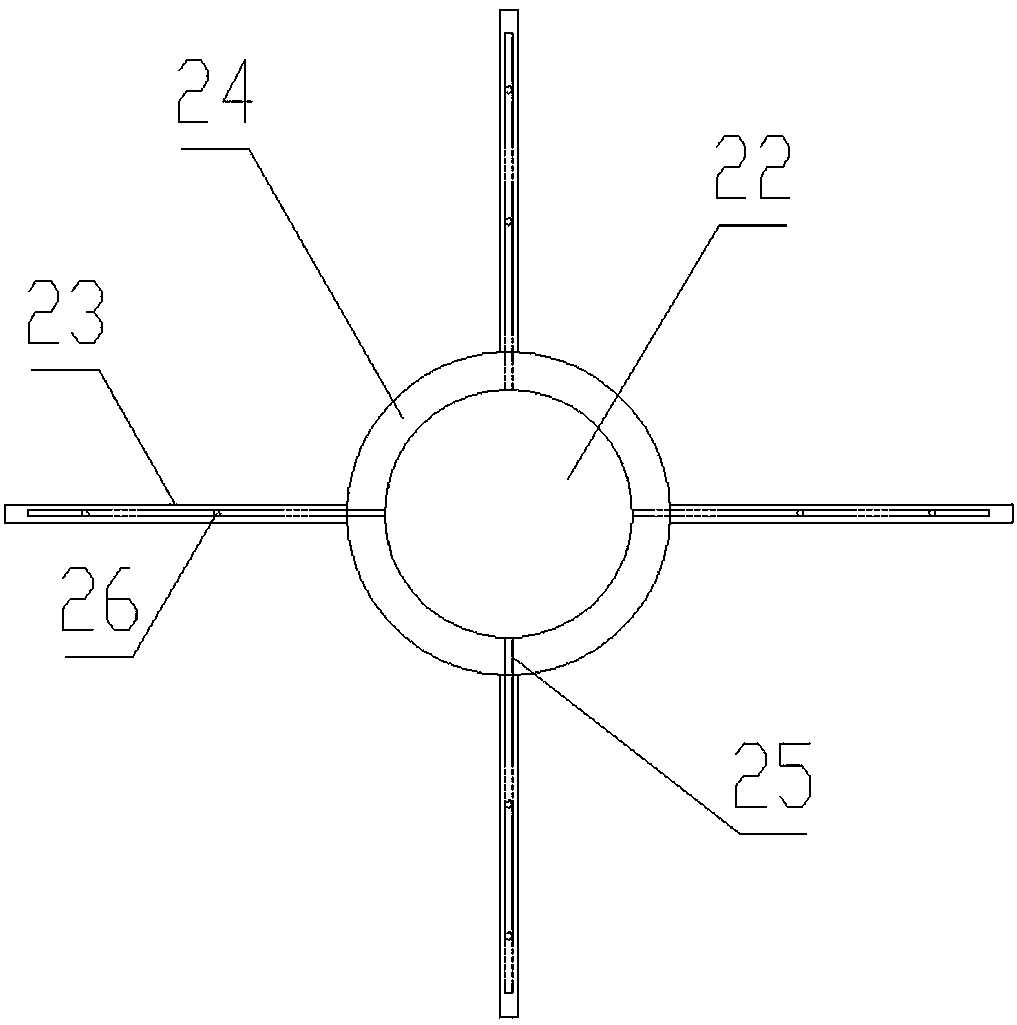

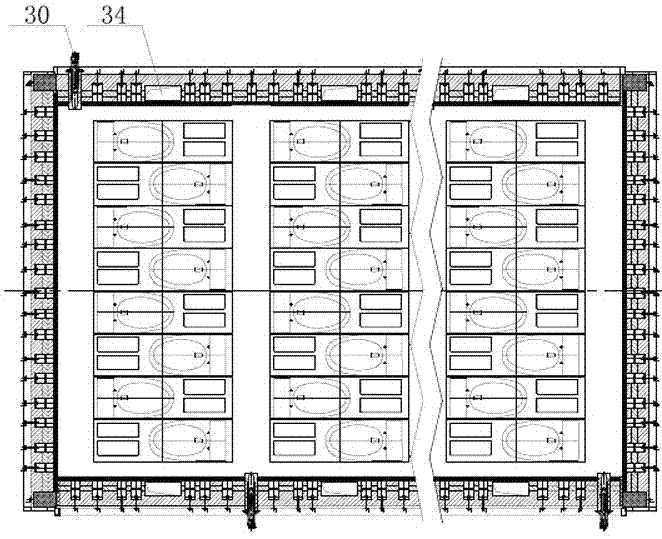

Granular bed filtering dust removal system

ActiveCN106975305ASmall fluctuations in air flowSmall stable job impactCombination devicesAir filterDust collector

The invention discloses a granular bed filtering dust removal system. The granular bed filtering dust removal system comprises at least one main granular bed filtering dust collector and a secondary granular bed filtering dust collector, a dust-containing air main pipe, a clean air main pipe and a blowback air main pipe, wherein the dust-containing air main pipe conveys dust-containing air into the main granular bed filtering dust collector, the clean air main pipe outputs clean air filtered by the main granular bed filtering dust collector, the bottom of the main granular bed filtering dust collector is provided with a main ash hopper, the blowback air main pipe conveys blowback air into the main granular bed filtering dust collector, the secondary granular bed filtering dust collector is provided with a dust-containing air introduction pipe used forcommunicating the secondary granular bed filtering dust collector with the upper portion of the main ash hopper, the dust-containing air introduction pipe conveys powder-containing air into the secondary granular bed filtering dust collector, the clean air main pipe outputs clean air filtered by the secondary granular bed filtering dust collector, the blowback air main pipe conveys blowback air into the secondary granular bed filtering dust collector, and the bottom of the secondary granular bed filtering dust collector is provided with a secondary ash hopper. The granular bed filtering dust removal system has the advantage that the fine dust that is difficult to settle can be efficiently and reliably removed.

Owner:NINGBO UNIV

Gelatin dissolving device with steam-type heating function

InactiveCN108032458AImprove melting effectNot easy to damageCapsule deliveryLiquid waterWater circulation

The invention provides a gelatin dissolving device with a steam-type heating function. The gelatin dissolving device comprises a heating stirring mechanism and a steam circulating mechanism, wherein the heating stirring mechanism comprises a stirring motor, a stirring shaft and stirring paddles; convex rings are correspondingly arranged at the upper and lower ends of the stirring shaft; a plurality of through holes distributed at equal intervals are formed in the upper-end and lower-end convex rings; the stirring paddles are fixed on the stirring shaft; steam channels are arranged in the stirring paddles in a penetrating manner; the lower ends of the steam channels communicate with the through holes of the lower-end convex rings; the upper ends of the steam channels communicate with the through holes of the upper-end convex rings; the steam circulating mechanism comprises a steam generator; steam enters the steam channels of the stirring paddles from the through holes of the lower-endconvex rings, and then enters a cooler from the through holes of the upper-end convex rings for being cooled; and after the steam is cooled into liquid water, the liquid water enters the steam generator in a circulating manner. Compared with a conventional gelatin dissolving device, the gelatin dissolving device provided by the invention has the advantages that the heating temperature is more uniform, the product service life is long, and the maintenance is convenient.

Owner:魏发宝

Ceiling-attached multi-function fan with sterilizing and purifying part for polluted air

InactiveCN106247443BSmooth circulation airflowEnhance cooling/heating efficiencyDispersed particle filtrationPump componentsCeiling fanFiltration

The present invention relates to a ceiling-mounted multifunctional fan comprising a polluted air sterilization and purification member. The fan is simply attached to the ceiling of the interior of a building so as to generate wind and circulate indoor air, and thus the fan circulates the stagnant indoor air and makes the interior pleasant in the spring and the autumn. Contrary to common fans, when the fan is used together with a cooler in the summer, the fan lowers the indoor temperature by enabling the cool air to diffuse by means of air circulation of normal rotation (blowing the wind downwards), thereby enhancing the cooling efficiency by enabling the set temperature of the cooler to be increased and excessive air conditioner operation time to be reduced. In the winter, when the fan is used together with a heater, the fan compensates for the difference between a higher indoor temperature and a lower indoor temperature by enabling the hot air at the ceiling to flow to the floor surface by means of reverse rotation (pulling the wind upwards), thereby enhancing the heating efficiency by enabling unnecessary heater operation time to be reduced. Accordingly, since the fan enables coolness or warmth to be felt throughout the entire interior by means of circulation of the indoor air, the fan maintains the original functions of an indoor air circulation ceiling fan which creates a pleasant indoor environment and enables energy saving and reduction of environmental pollution. Furthermore, the fan complexly performs filtration fan functions of filtering and collecting large and small fine dust, etc. floating in the contaminated air, and air purification functions of effectively sterilizing / disinfecting various bacteria and viruses in the contaminated air. Thus, by means of one apparatus, the fan can perform multiple functions of an air circulation ceiling fan, a contaminated air sterilizing and deodorizing apparatus, a drying apparatus, an insect extermination apparatus, an anion generation apparatus, and an aesthetically excellent interior ornament.

Owner:丘冀升

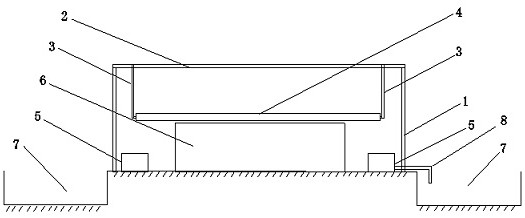

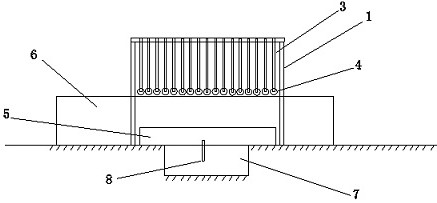

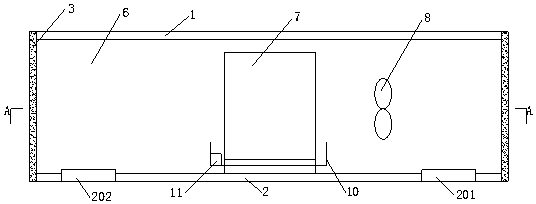

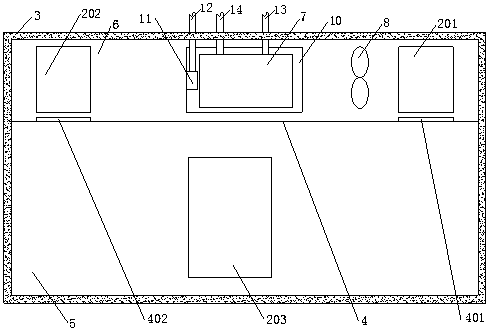

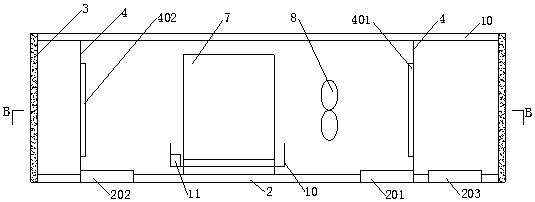

High-precision annealing furnace

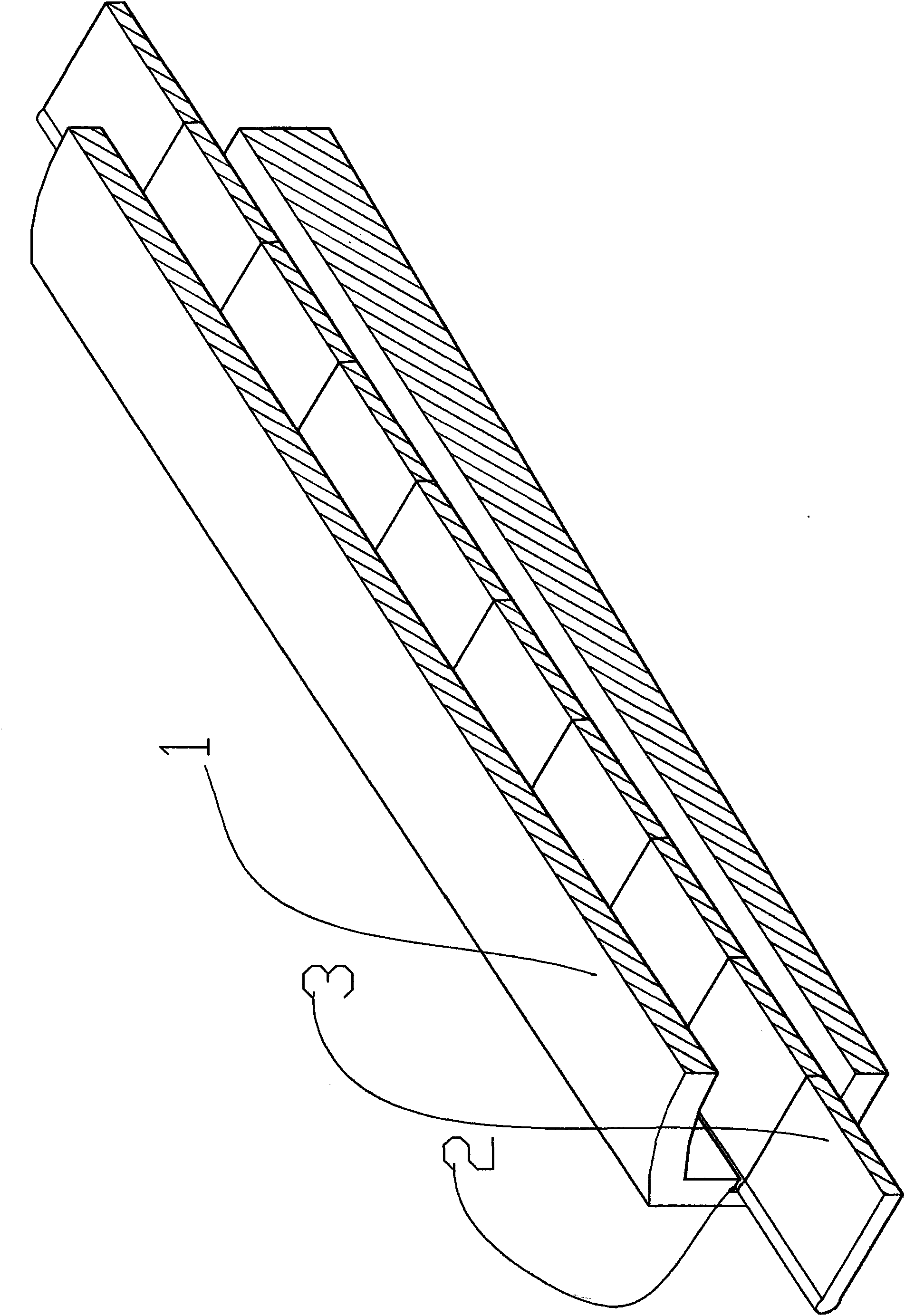

The invention relates to a high-precision annealing furnace, which consists of a counter celling structure (1), a side wall curved sealing structure (4) and a bottom refractory brick (6), wherein the counter celling structure (1) comprises a curved sealing structure (2); a heating device (8) is arranged at the bottom of the annealing furnace to raise the bottom temperature of the annealing furnace; a thermoelectric pair (11) is arranged on the top of the annealing furnace; a glass block (3) and the like are placed on a mesh belt bracket (9) in the middle of the annealing furnace; and the bottom of the annealing furnace is provided with a mesh belt towing launch (7). Due to the adoption of the high-precision annealing furnace, the height of a kiln is reduced, and the temperature difference between the upper and lower parts of a hearth is reduced; the radiating uniformity of a side wall is enhanced; temperature difference caused by air leakage at the bottom of the furnace is eliminated; and the temperature difference between the upper and lower parts of the hearth is + / -2 DEG C, the temperature difference between the left and right parts of the hearth is + / -1 DEG C, and a remarkable energy-saving effect is achieved.

Owner:浙江宇清热工科技股份有限公司

Novel kiln, construction method and application thereof

InactiveCN101556113AReduce the cross-sectional area of the kiln bodyReduce the temperature difference between upper and lowerFurnace typesThin walledEngineering

The invention relates to a novel kiln, in particular to a continuous kiln which is characterized in that the continuous kiln at least consists of a cylindrical kiln body and a slideway kiln car sliding mainly by gravity in the kiln body; materials are loaded on the slideway kiln car and slide with the slideway kiln car from the top end to the tail end of the kiln; the cylindrical kiln body can be a straight cylinder, a bent cylinder or an equal-diameter spiral cylinder. The slideway kiln car is plate-shaped or has the structure of a casket, a crucible or a tubular container. Through holes sealed by a thin wall refractory material and blind holes are distributed on the walls of the slideway kiln car with various shapes.

Owner:徐林波

A micro-convective radiation cooling and heating ceiling device

ActiveCN105115088BReduce the temperature difference between upper and lowerReduce working fluid flowDucting arrangementsCeilingsAir volumeThermal insulation

Owner:KRUEGER AIR CONDITIONING TECH BEIJING

Smoke discharge device of steel strip type reduction furnace

The invention discloses a smoke discharge device of a steel strip type reduction furnace, which is arranged at the top of a heating hearth of the steel strip type reduction furnace. The smoke discharge device comprises flues, a smoke acquirer, a smoke discharge pipe and a smoke discharge fan; the flues are arranged at two ends of a furnace head and a furnace tail of the heating hearth; the smoke acquirer is arranged above the flues; a horn port in the lower end of the smoke acquirer is corresponding to smoke outlets of the flues, and the upper end is connected and communicated with the smoke discharge pipe from the side surface; and one end of the smoke discharge pipe is closed, and the other end is connected with an intake port of the smoke discharge fan. The smoke discharge device of the steel strip type reduction furnace is additionally provided with a tail gas purifying box; a spraying system, a purifying system and an exhaust way are arranged in the tail gas purifying box; a dust remover is arranged in a connecting pipeline between an exhaust port of the smoke discharge fan and the tail gas purifying box; and smoke discharged by the smoke discharge fan is filtered by the dust remover to enter the tail gas purifying box, is exhausted from the exhaust way after being purified by the spraying system and the purifying system. The smoke discharge device of the steel strip type reduction furnace prominently improves the energy utilization rate, reduces the hearth temperature difference, prominently reduces the discharge, and purifies the ecological environment.

Owner:孙颖

Energy saving kiln for preventing ash contamination and with low heat storage

ActiveCN107131760AAvoid direct flushingWill not polluteFurnace typesCeramic materials productionFiberProcess engineering

The invention discloses an energy saving kiln for preventing ash contamination and with low heat storage. The kiln comprises a kiln door, a kiln crown and side walls, and is characterized in that light insulation cottons are arranged on the kiln door, the kiln crown and the side walls; heavy refractory insulation plates are arranged on a fire seeing surface in the kiln; the refractory insulation plates adopt hollow structures, and are formed by splicing insulation plates; heavy refractory guide rails are arranged between upper and lower adjacent insulation plates; the insulation plates are inserted in chucks on the upper and lower sides of the refractory guide rails; and refractory fixed pieces connected with a kiln body are arranged at the middle parts of the refractory guide rails. The kiln crown, the kiln walls and the kiln door adopt all-cotton structures; the heavy refractory insulation plates are added on the internal fire seeing surface and the tabletop of a kiln car insulated by light materials at the bottom for preventing direct scouring of the wall fiber cottons by flame. Thus, even if fibers are pulverized and loosened to fall, due to stop by the refractory plates, products cannot be polluted. The kiln saves the energy, and solves the ash contamination problem.

Owner:DLT TECH CO LTD

Air conditioner for vehicle

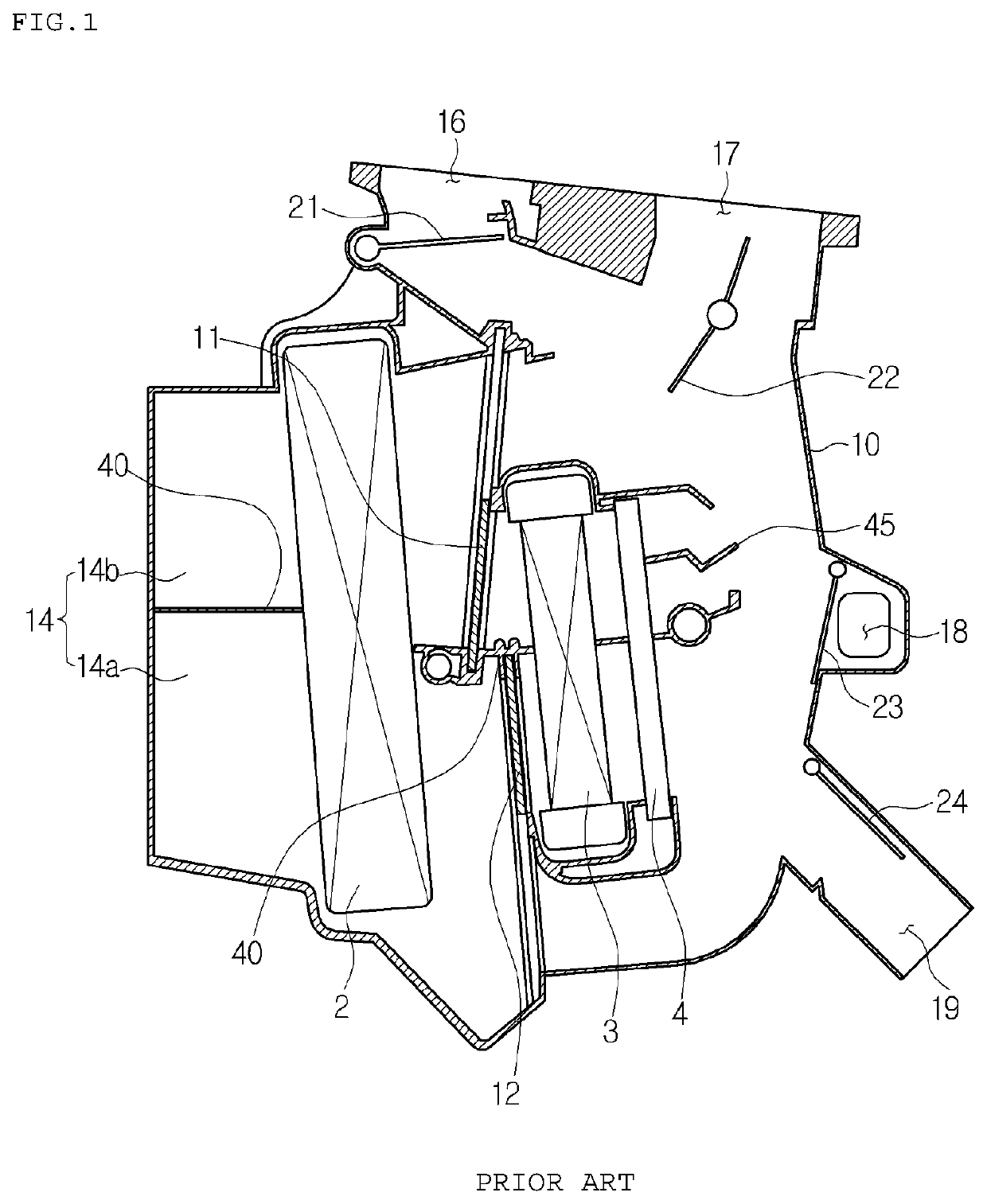

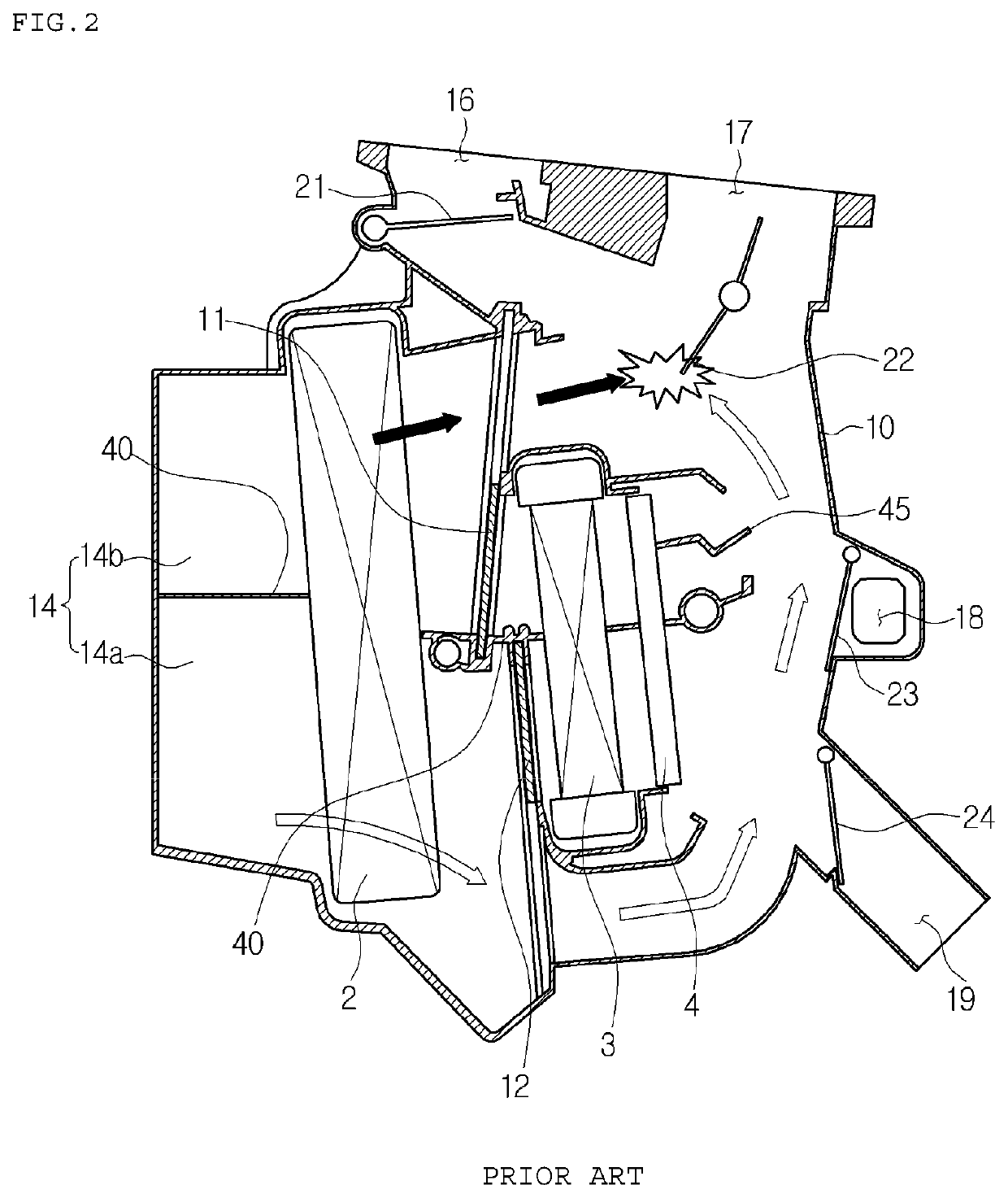

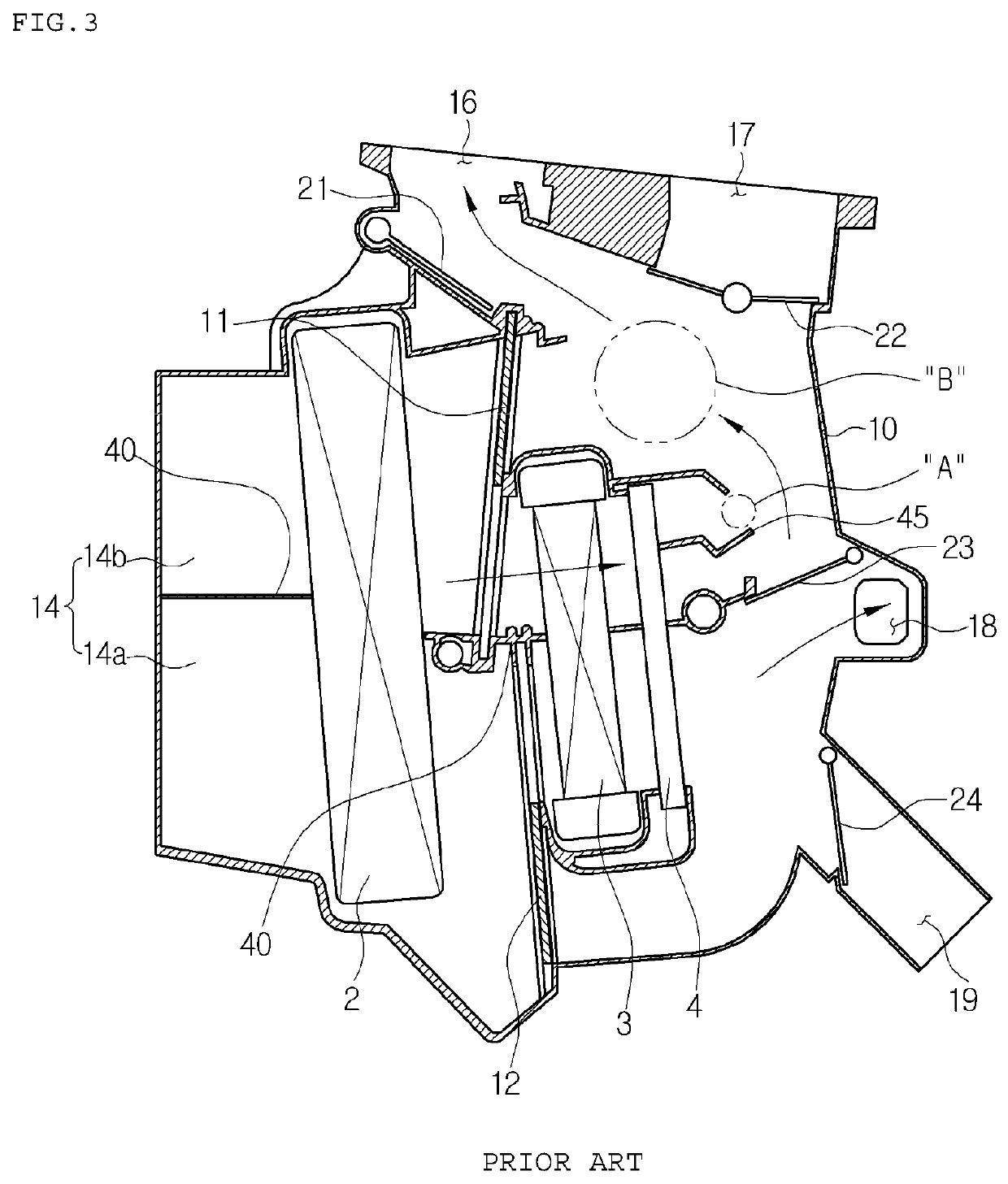

PendingUS20220212520A1Increase air volumeImprove manufacturabilityAir-treating devicesVehicle heating/cooling devicesAir volumeEngineering

Disclosed is an air conditioner for a vehicle, the air conditioner having an improved guide structure capable of increasing an air volume by preventing a collision between air flowing through an upper passage and air flowing through a lower passage. The air conditioner for a vehicle comprises: an air conditioning case having an air passage formed therein and an air outlet which includes a defrost vent and a face vent; and a heat exchanger for cooling and a heat exchanger for heating, which are provided in the air passage of the air conditioning case. The air conditioner for the vehicle further comprises: a temperature door arranged between the heat exchanger for cooling and the heat exchanger for heating in order to adjust the degree to which cold air, which has passed through the heat exchanger for cooling, is heated by the heat exchanger for heating; a cold air passage through which cold air that has passed through the heat exchanger for cooling bypasses the heat exchanger for heating; a warm air passage through which cold air that has passed through the heat exchanger for cooling passes through the heat exchanger for heating; a cold air guide unit for guiding the cold air downstream of the heat exchanger for cooling; and a warm air guide unit for guiding the warm air downstream of the heat exchanger for heating.

Owner:HANON SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com