High-precision annealing furnace

An annealing furnace and high-precision technology, which is applied in the field of high-precision annealing furnaces, can solve the problems of incomplete annealing, low added value of products, and low product qualification rate, and achieve the effects of reducing heat dissipation, significant energy saving effects, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

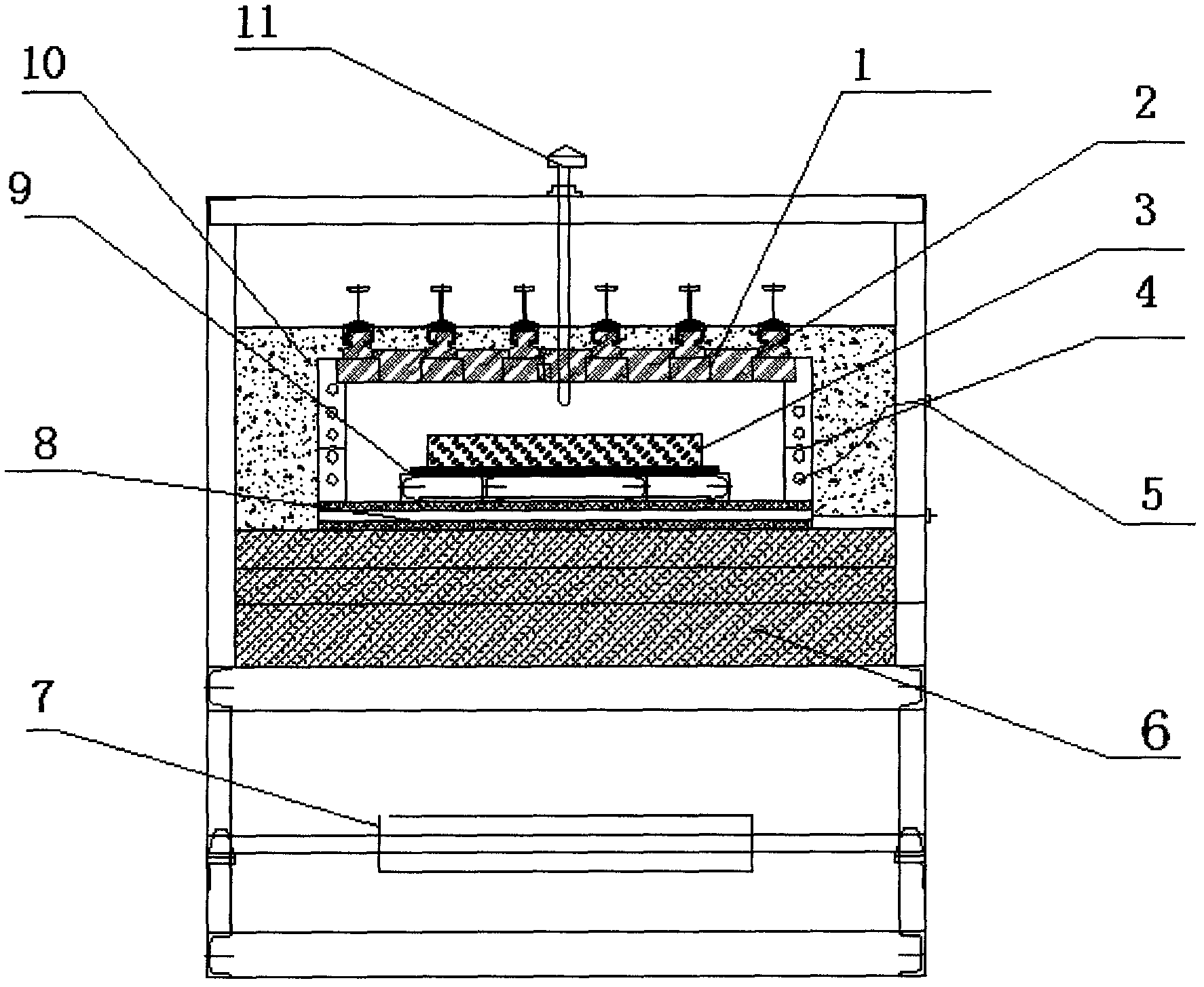

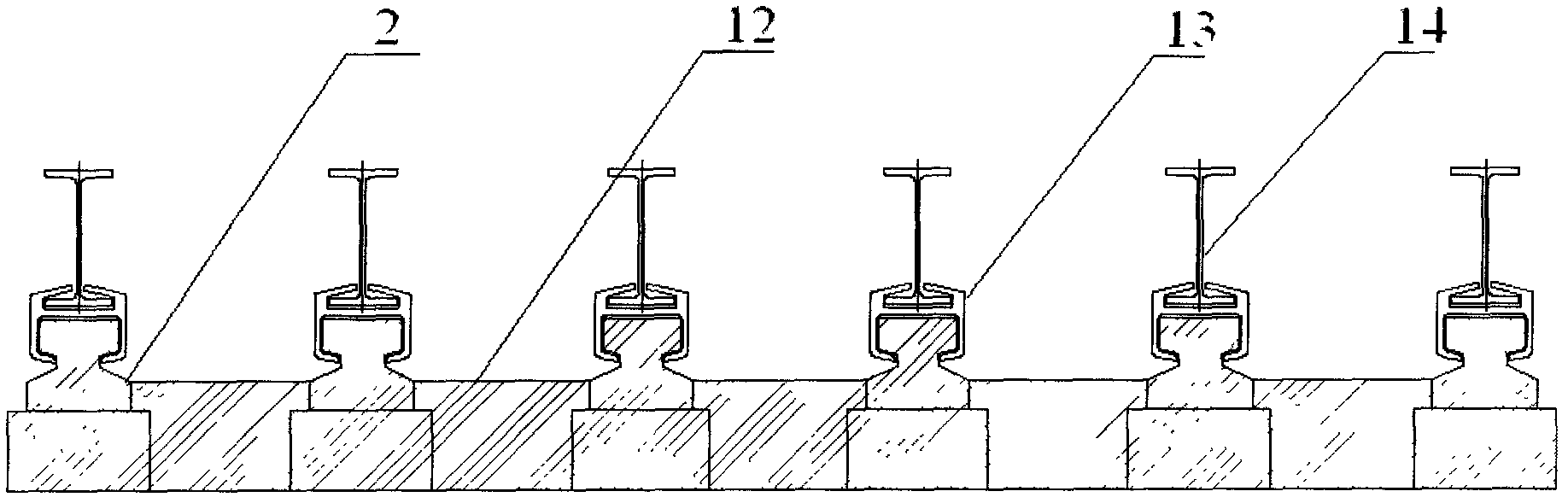

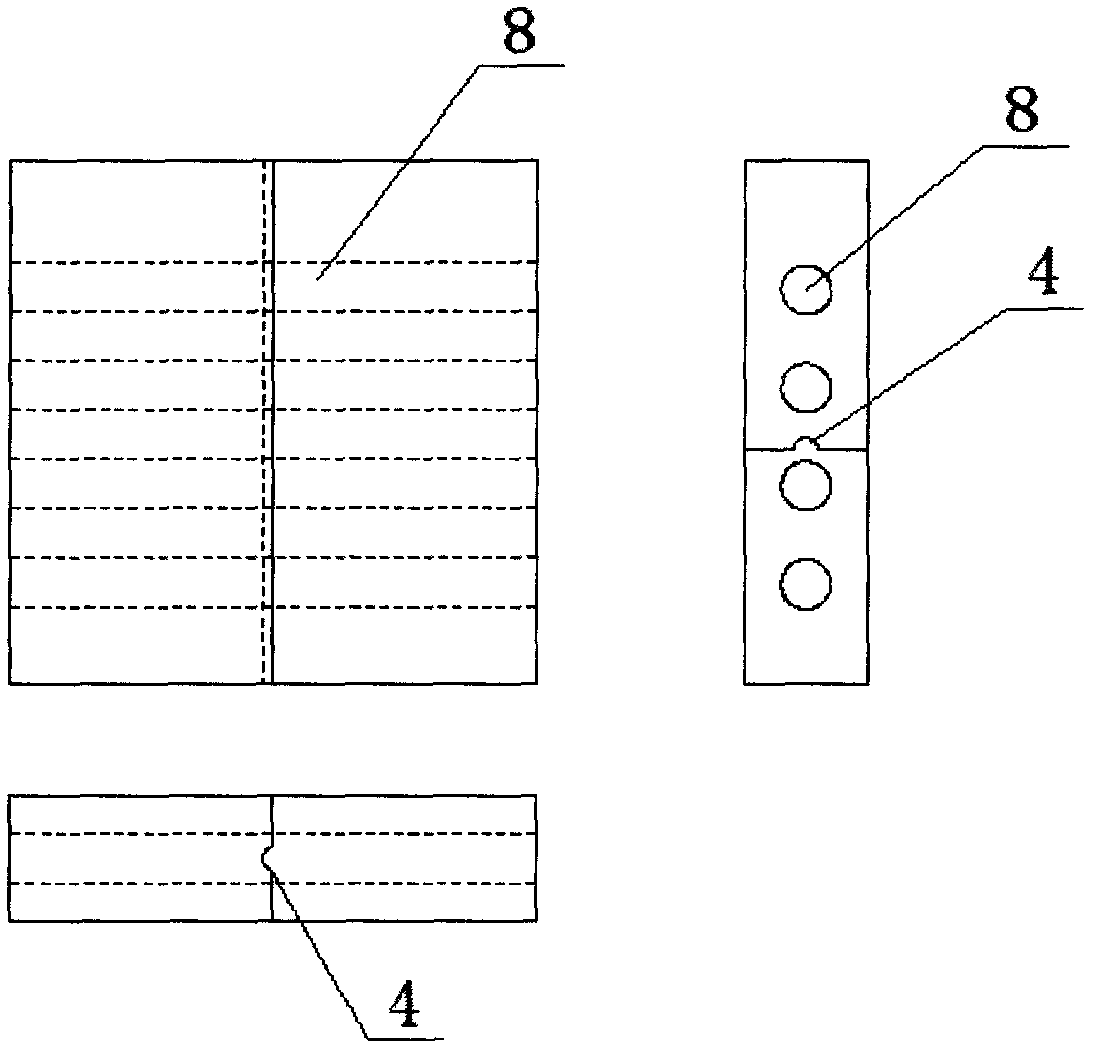

[0023] Such as Figure 1-Figure 3 As shown, a high-precision annealing furnace is composed of a suspended flat roof structure (1), a side wall curved sealing structure (4) and a bottom refractory brick (6). The suspended flat roof structure (1) contains a curved sealing structure (2), in order to improve the bottom temperature, a heating device (8) is set at the bottom, a thermocouple (11) is set at the top, and glass blocks (3) etc. are placed on the mesh belt bracket (9) in the middle of the annealing furnace. There is a mesh belt tug (7) at the bottom of the annealing furnace.

[0024] The invention can be mainly used for the annealing of optical glass and laser glass.

[0025] The high-precision annealing furnace produced by a research institute in Shanghai using this invention is applied to the annealing of laser glass. It passed the high temperature assessment at 560°C, and it ran at 460°C for one week and carried out temperature measurement. The deviation between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com