Processing method of conventional ingot-cast steel ingot for ultra-high temperature soft core forging

A processing method and ultra-high temperature technology, applied in the field of forging, can solve the problems of uneven temperature distribution of steel ingots, inability to efficiently deform, and sputtering molten steel from risers, so as to improve efficiency and implementability, reduce maintenance costs, and reduce upper and lower The effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In the present embodiment, the height-to-diameter ratio of the selected ingot is 2.28, the taper is 3.2%, and the split type steel ingot mold with insulation riser, steel ingot mold and chassis separation, the material is 42CrMo, and the steel ingot weighs 11t. According to the simulation analysis results, the following process scheme is formulated: ( 1) After the steel ingot is poured, it is naturally cooled for 1 hour. (2) After 1 hour, lift the steel ingot belt mold, and place the steel ingot on the chassis covered with thermal insulation cotton. Figure 4 shown. (3) Continue to stand still for 1 hour, remove the covering agent on the riser, and spray water on the riser for about 15 minutes. Figure 5 shown. (4) After water spraying, the steel ingot is transported to the forging workshop for demoulding, and then forging.

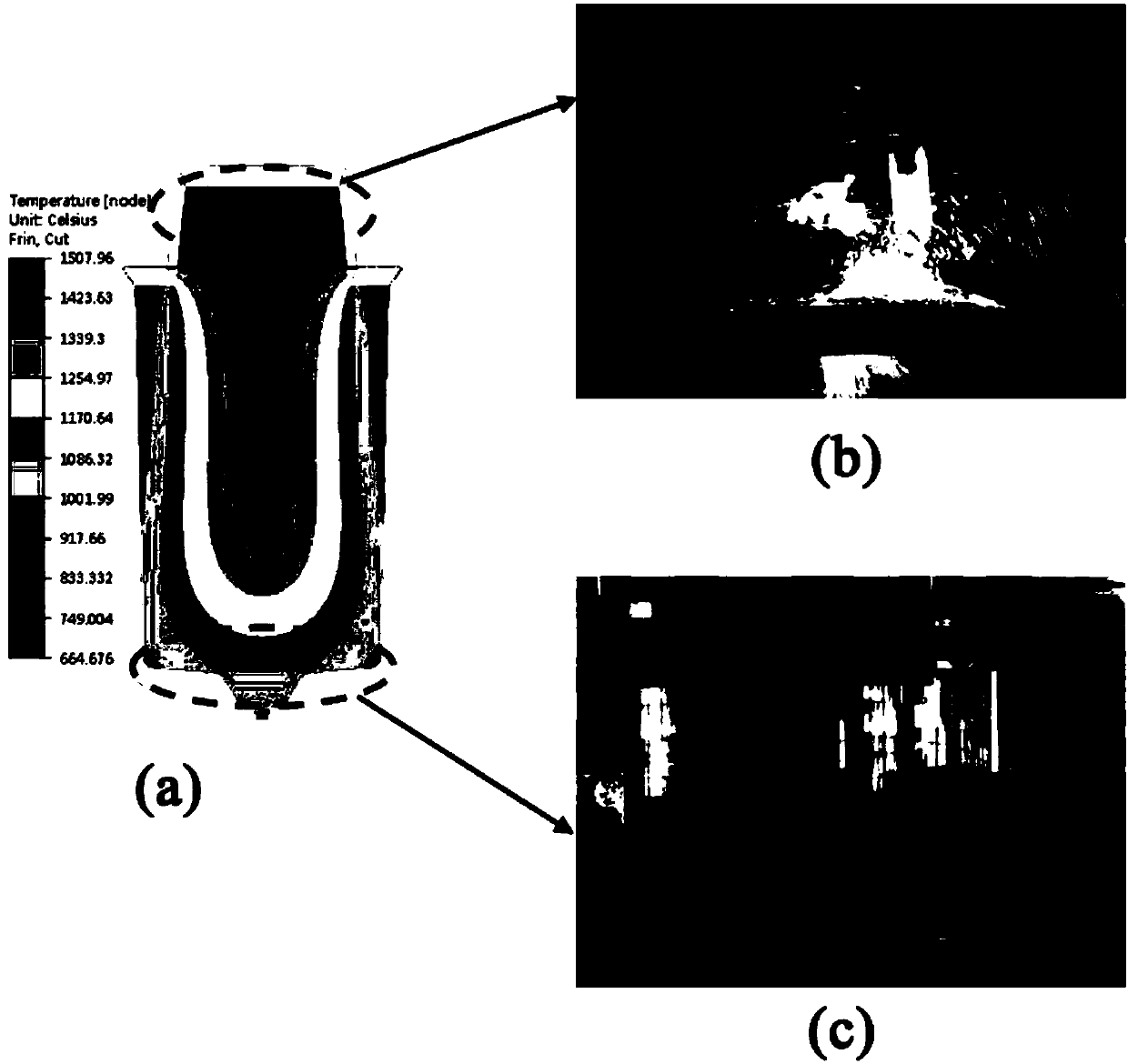

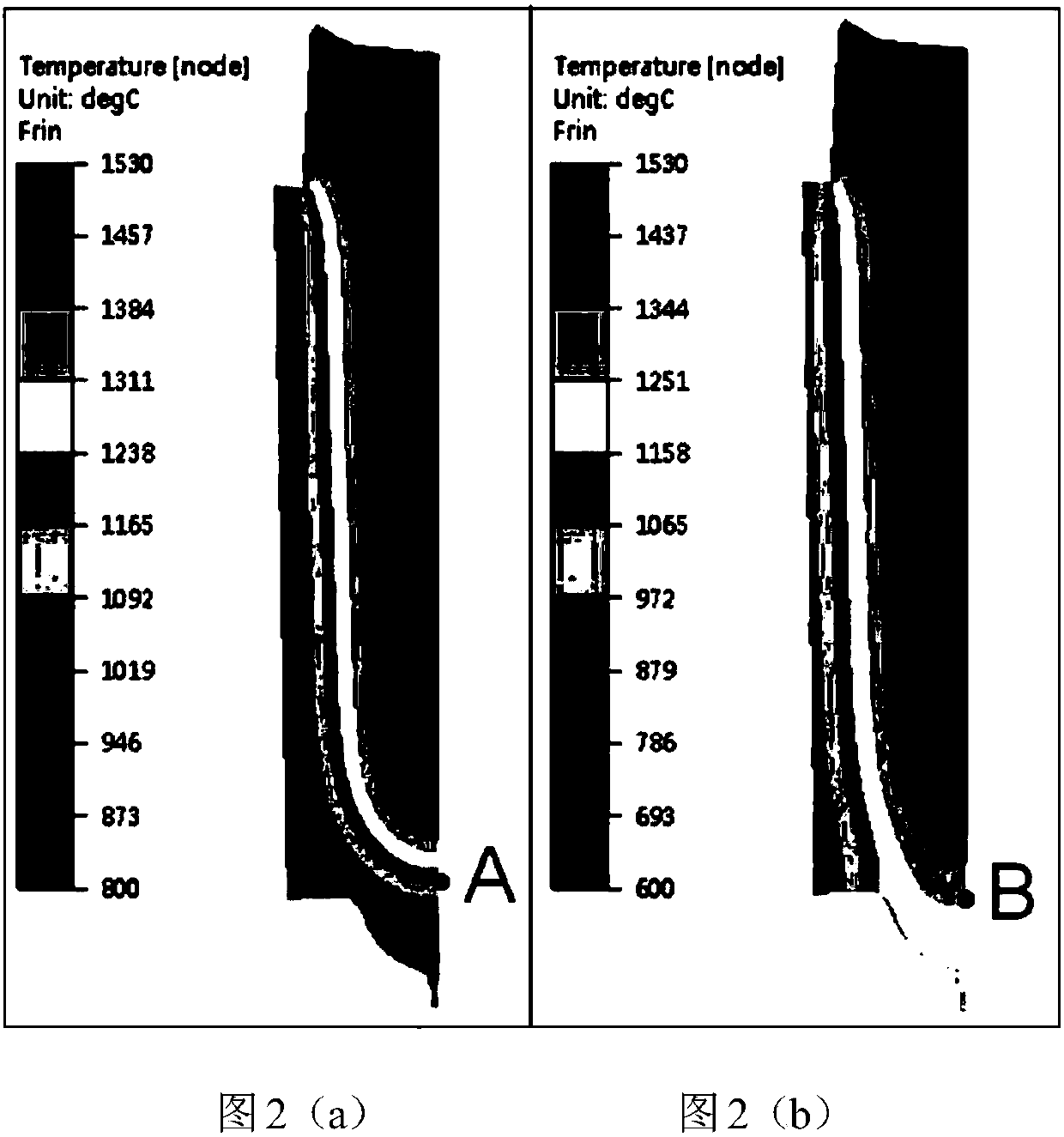

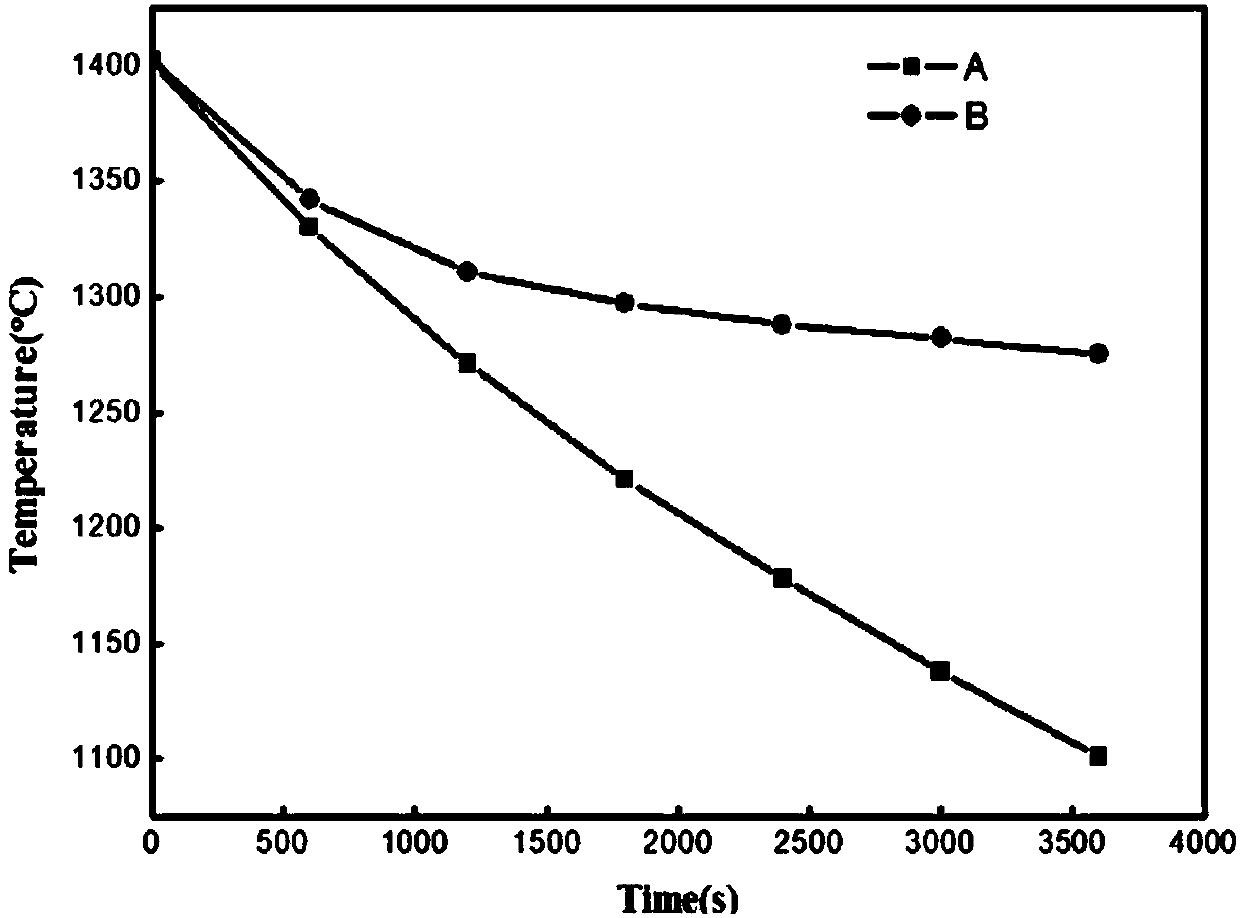

[0038] Such as Figure 6 As shown, the conventional ingot-shaped steel ingot tail (a) and the riser end (b) of the ingot body during ultra-hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com