Composite board evaporator and refrigeration equipment

A technology of refrigeration equipment and evaporator, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., which can solve the problems of high cost of air duct plate and high temperature of stored items, and achieve uniform temperature in the box, ensure quality and temperature uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

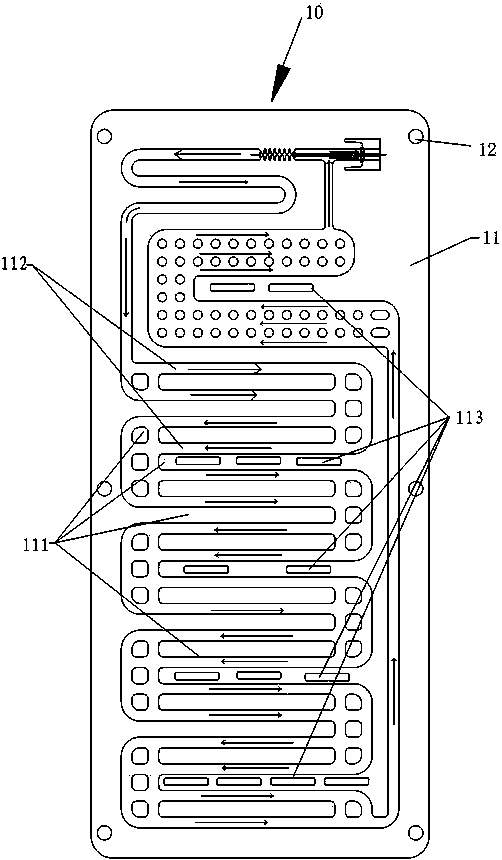

[0029] refer to figure 1 As shown, a composite plate evaporator 10 includes two aluminum plates 11 that are pressed together. The periphery of the two aluminum plates 11 is all pressed and has fixing holes 12 to facilitate fixing the evaporator on the inner tank. The center of the two aluminum plates 11 It includes a pressing part 111 and a channel part 112, that is, the central part of each aluminum plate 11 includes a pressing part 111 and a channel part 112, and several ventilation holes 113 are opened on the pressing part 111 in the center of the two aluminum plates 11.

[0030] Ventilation holes 113 are strip-shaped, and the ventilation holes 113 are distributed in the whole body of the evaporator 10 from top to bottom, including 5 rows, and the number of ventilation holes 113 on each row is 2, 3, and 2 from top to bottom. , 3, 4.

[0031] Such as figure 1 As shown, the channel part 112 between the two aluminum plates 11 is a strip-shaped cavity formed by continuous ben...

Embodiment 2

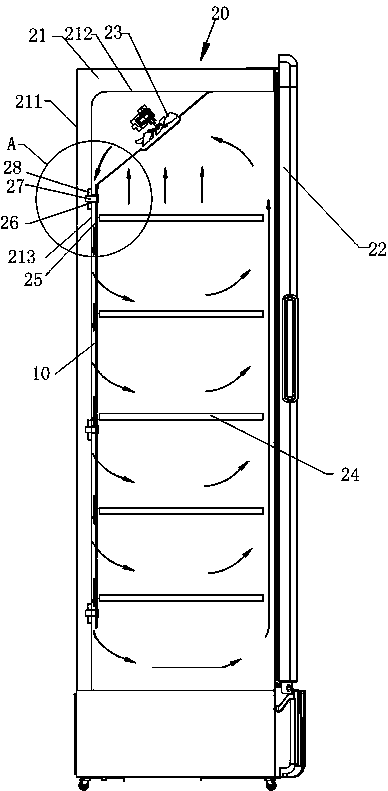

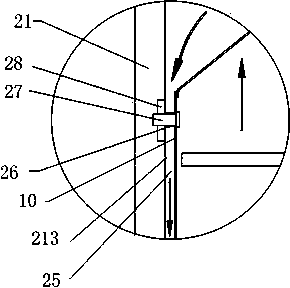

[0034] Such as figure 2 As shown, a refrigerator 20 includes a box body 21 and a glass door 22. The box body 21 includes a box shell 211 and an inner container 212. The inner container 212 is provided with a composite plate evaporator 10, a fan 23, and a shelf 24. The composite plate evaporator 10 is fixedly connected to the inner container rear wall 213. The structure of the composite plate evaporator 10 is the same as that described in Embodiment 1, and will not be repeated here. Wherein, the composite plate evaporator 10 and the inner container rear wall 213 The air duct 25 is formed in between, that is, the inner tank rear wall 213 and the composite plate evaporator 10 enclose the air duct 25, the composite plate evaporator 10 serves as the function of the air channel plate, and the composite plate evaporator 10 serves as a heat exchanger while simultaneously The function of the air channel plate is dual-purpose, which saves costs. The fan 23 sends cold air to the box thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com