Novel wind chamber enabling wind to enter in a tapered way

An air chamber and air intake technology, which is applied in the direction of combustion air/fuel supply, combustion method, combustion equipment, etc., can solve problems such as uneven air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

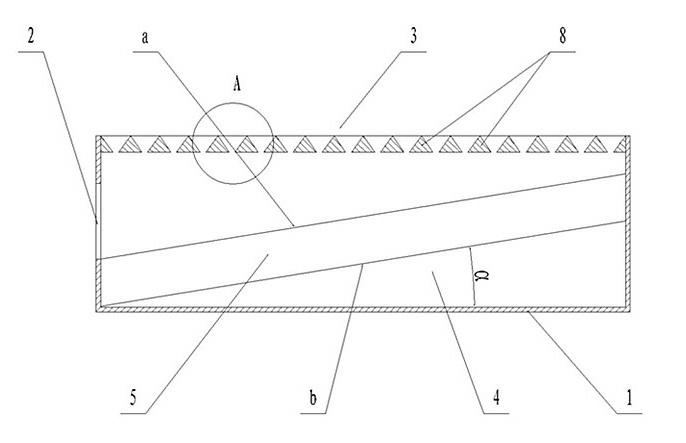

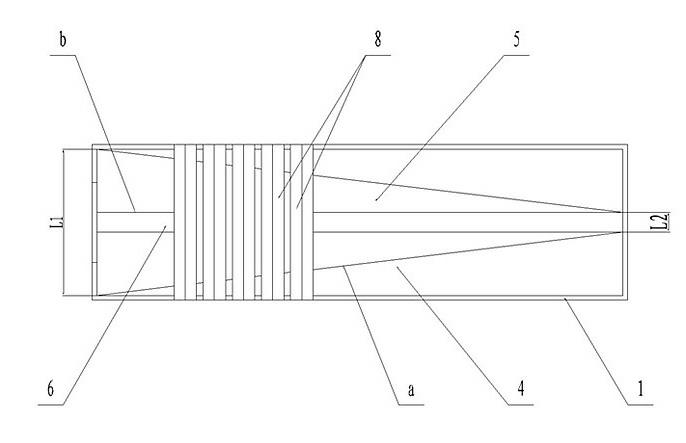

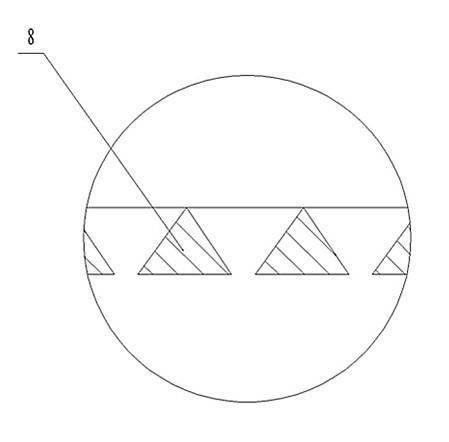

[0011] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like figure 1 , figure 2 Shown: a new type of tapered air inlet air chamber, including the air chamber body 1, the air chamber body 1 is a cavity structure with an air inlet 2 at one end, and its upper end is an air outlet 3, inside the air chamber body 1 , along the axial direction (air inlet direction), there is an air deflector 4 obliquely upward. This air deflector 4 is composed of two sub-air deflectors 5 arranged symmetrically along the axial direction of the air chamber body 1. The two wind deflectors The lower edges of the plates 5 are parallel to each other, and a gap 6 is left between each other; the upper edges a of the two sub-air deflectors 5 are on the side close to the air inlet 2, and the distance between them is L1, and the distance between them is L1 away from each other. On one side of the air inlet 2, the distance betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com