Novel kiln, construction method and application thereof

A construction method and kiln technology, which can be applied to furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of material pollution by fuel, expensive construction and operation costs, difficult maintenance, etc. body cross-sectional area, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

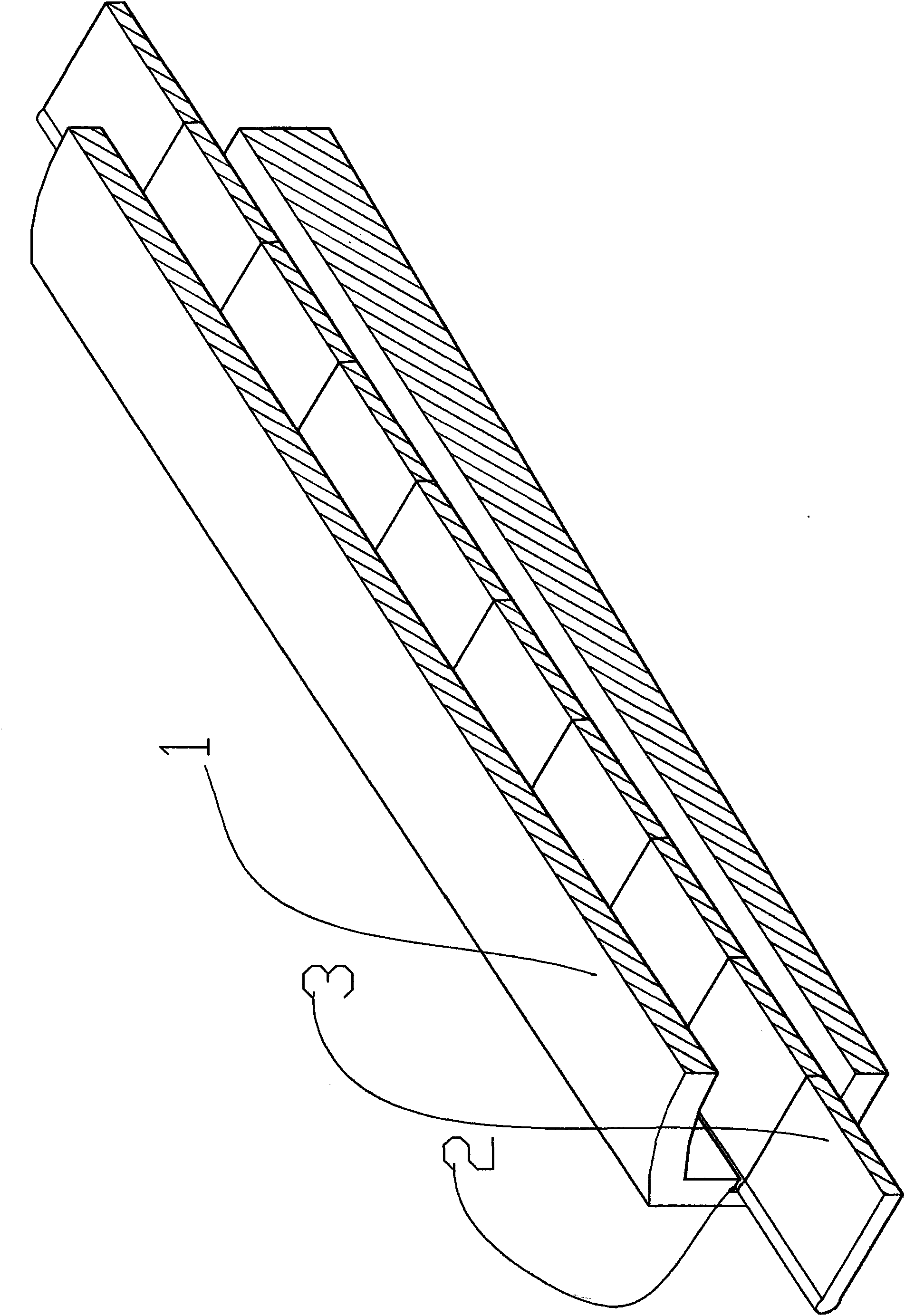

[0024] figure 1 What is described is a three-dimensional structure diagram of a "linear slide kiln". In the figure, a row of closely connected flat kiln cars (3) slides from the beginning to the end of the kiln under the action of gravity in the kiln wall slide rail (2) with a certain slope.

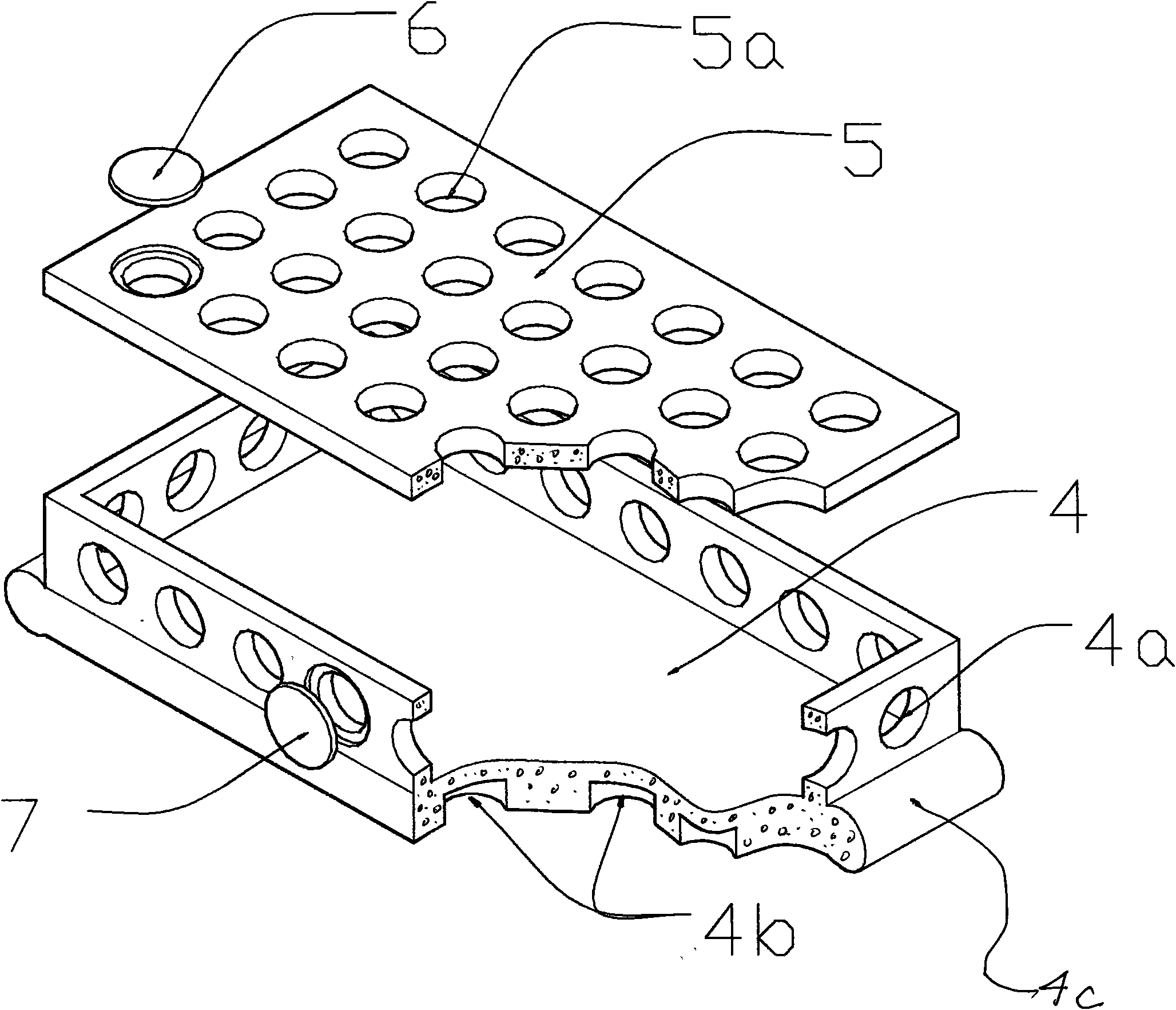

[0025] figure 1 Described is a three-dimensional structural schematic diagram of a box-shaped slide kiln car; the through-holes (5a) and (4a) are blocked with thin-walled refractory materials (6), so that the heat mainly passes through the through-holes and blind holes. The thin-walled refractory material on the top is passed into the box. This not only improves the heat transfer efficiency, but also reduces the weight of the slide kiln car.

[0026] Various refractory tubular components can also be used as slide kiln cars. After loading the materials into the tubes and closing their sections, they are placed one by one on the chute or slide rail in the kiln to slide down; Jointed tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com