Energy saving kiln for preventing ash contamination and with low heat storage

A kiln and heat storage technology, applied in furnaces, furnace types, waste heat treatment, etc., can solve the problems of over-burning color difference of upper products, raw burning of bottom products, unreasonable smoke exhaust structure, etc., to achieve less heat storage, kiln body well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

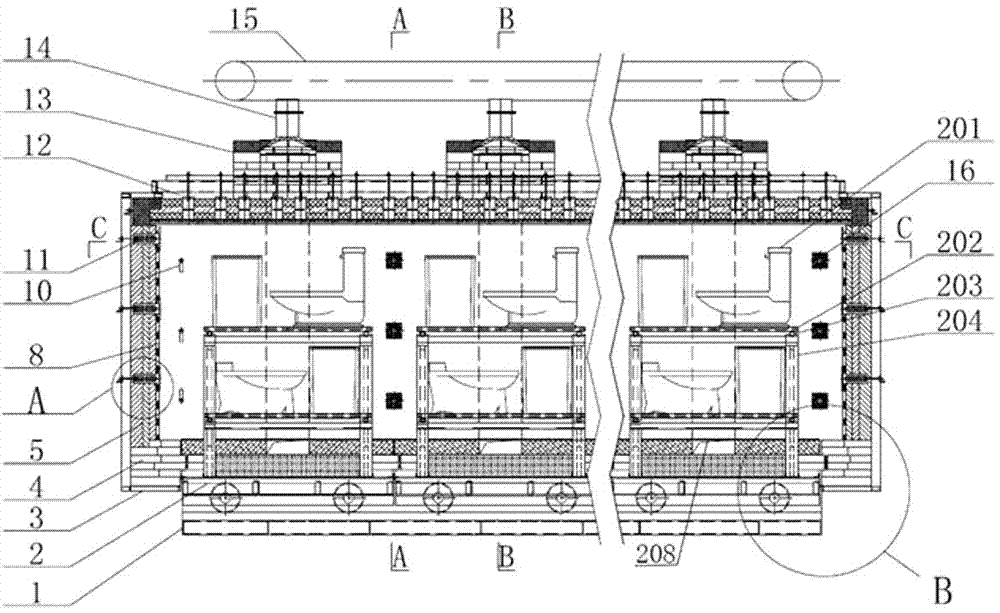

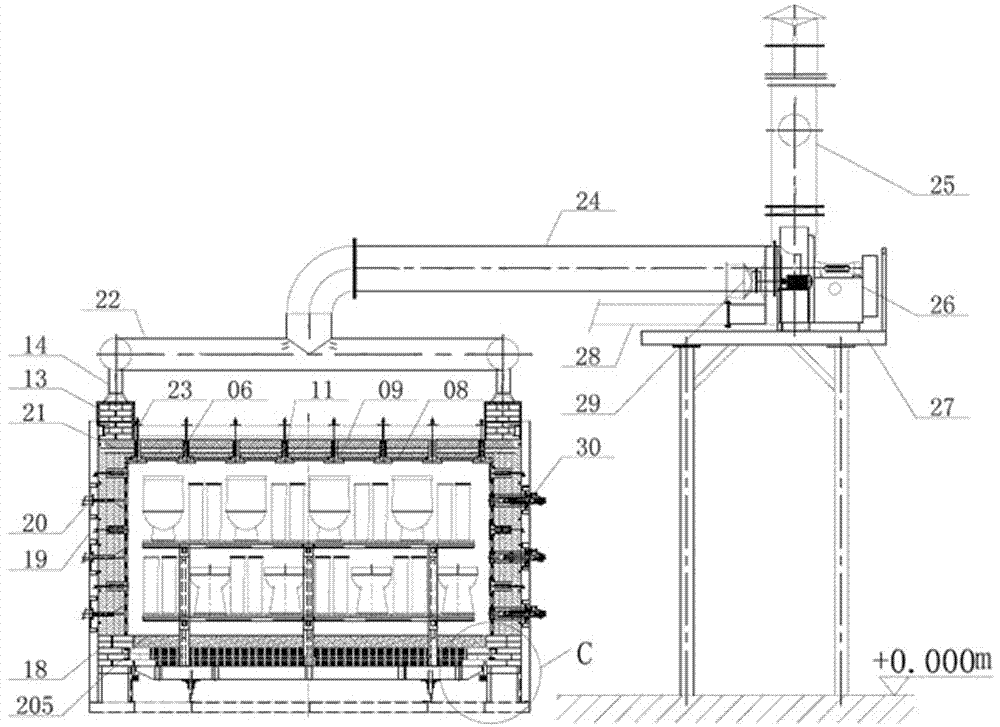

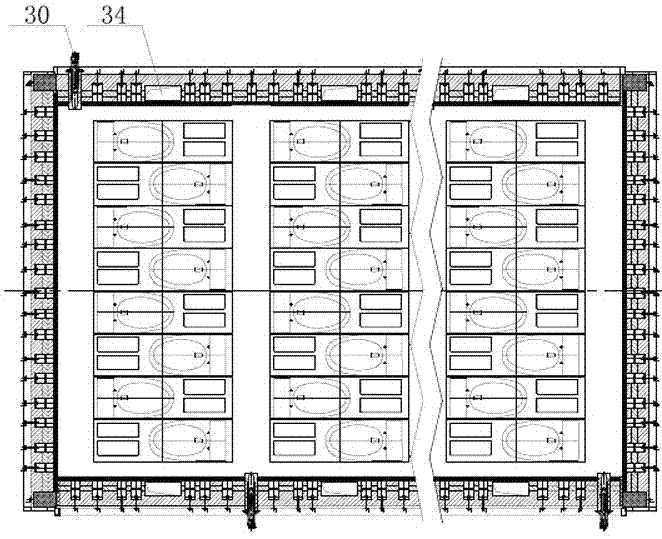

[0032] Such as figure 1 , figure 2 As shown, the embodiment of the present invention provides an energy-saving kiln with anti-staining and less heat storage, including:

[0033] Kiln door 3, kiln roof 12, side wall 19 and multiple kiln cars 2 at the bottom form a shuttle kiln, forming a sealed kiln body structure with fire-resistant and heat-preserving functions, and all of them are installed on the base 1.

[0034] The kiln door 3 and the side wall 19 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com