Method for manufacturing lining plastic pipe by using welded connection

A welding connection and steel pipe technology, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems that steel-plastic pipes cannot be directly welded and connected, electrochemical corrosion, etc., to achieve expanded processing and manufacturing technology, good rigidity , Expand the effect of the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

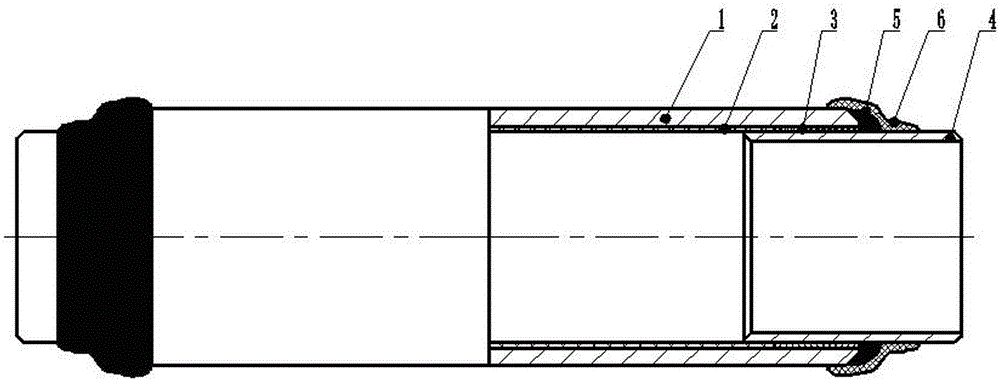

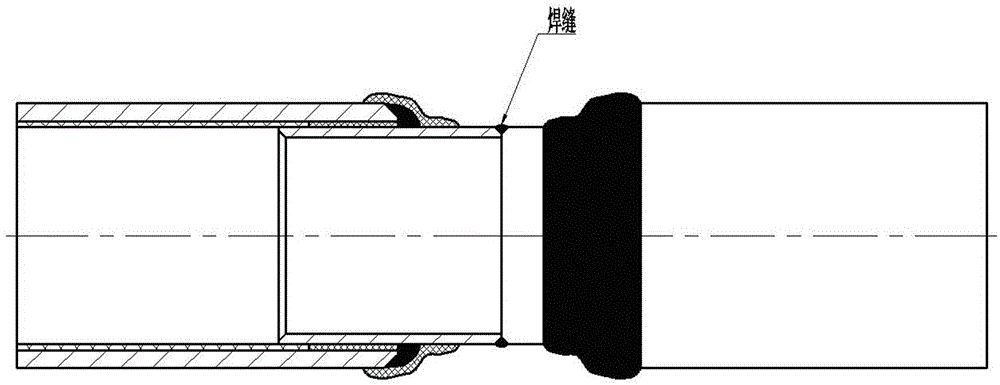

[0032] A method for preparing plastic-lined steel pipes connected by welding, comprising the steps of:

[0033] (1) The inner wall between the connecting ends of the outer steel pipe is lined with a plastic anti-corrosion layer, and the inner wall of the connecting end is not lined with a plastic anti-corrosion layer; the connecting end is used to connect stainless steel pipes, and the length of the connecting end is generally (240-300mm) . The plastic-lined steel pipe that has been lined with plastic is about to be completed (that is, the inner wall of the outer steel pipe is completely lined with plastic anti-corrosion), and a section of the plastic anti-corrosion layer at both ends of the plastic-lined steel pipe is peeled off (this section is the connecting end of the outer steel pipe) , so that there is no plastic anti-corrosion layer on the inner wall of the connection end.

[0034] (2) hot-melt adhesive is bonded and lined on the inner wall of the connecting end that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com