Anti-corrosion device and method for main cable of suspension bridge

A technology for anti-corrosion and suspension bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of shortened bridge life, failure to realize automatic control, bridge safety threats, etc., achieve the effect of increasing costs and solving electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

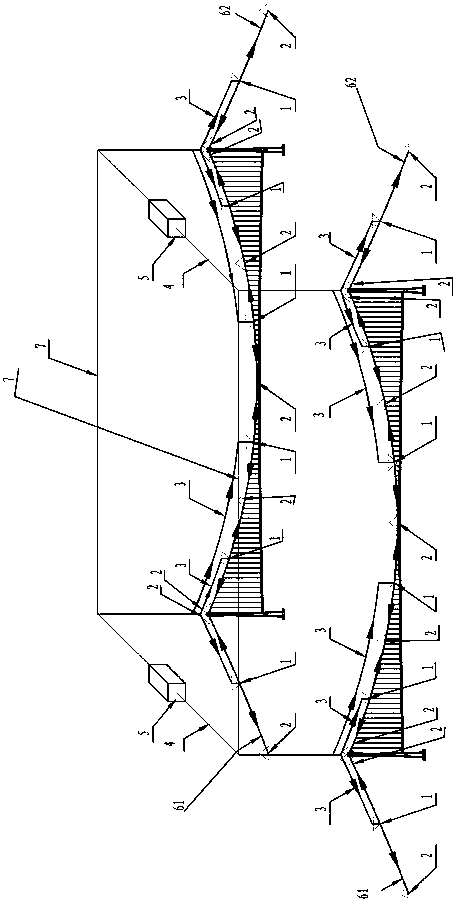

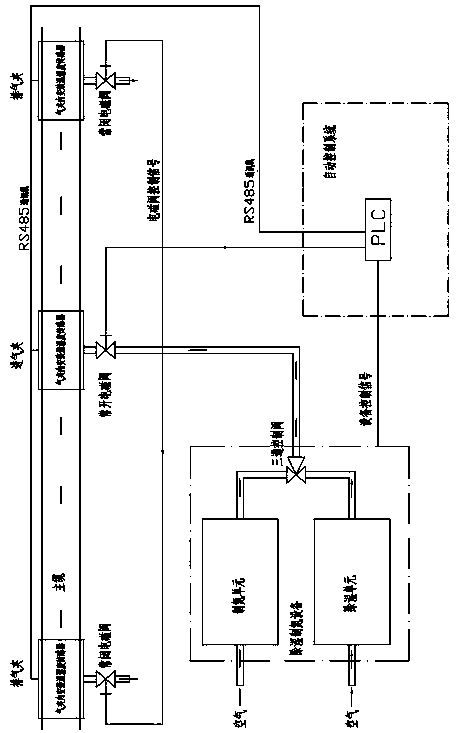

[0033] Such as figure 1 As shown, the outside of the main cable of the suspension bridge is sealed with sealant, and a closed space is formed inside; the first and second spans 61 and 62 on both sides are 360m and 480m respectively, and the cable diameter is 852mm; the middle span 7 is 1200m, and the cable diameter is 852mm .

[0034] During implementation, two sets of anti-corrosion devices of the present invention need to be installed on the main cable of the suspension bridge: a dehumidification and nitrogen-making anti-corrosion device 5 is respectively installed at 4 places of the two upper beams; Air intake clip 1 and two exhaust clips 2 located on both sides; four air intake clips 1 and five exhaust clips 2 are set on each cable of mid-span 7, and the air intake clip 1 and exhaust clip 2 are arranged alternately.

[0035] According to the characteristics of the main cable of the suspension bridge, the air supply distances of the first and second spans 61 and 62 on bot...

Embodiment 2

[0038] General layout and figure 1 similar. The outside of the main cable of the suspension bridge is sealed by wrapping tape, and a closed space is formed inside, and two sets of anti-corrosion devices of the present invention need to be installed. Among them, the first and second spans 61 and 62 on both sides are 460m and 491m respectively, and the cable diameters are 886mm and 901mm respectively. Each cable on both sides spans is respectively provided with an air intake clip 1 and two rows located on both sides of the air intake clip 1. Air clamp 2. The mid-span is 1480m, and its cable diameter is 886mm. Each cable of the mid-span is provided with four intake clamps 1 and five exhaust clamps 2, and the intake clamps 1 and exhaust clamps 2 are arranged alternately. A dehumidification and nitrogen production anti-corrosion equipment 5 is respectively installed at the two upper beams 4 .

[0039] According to the characteristics of the main cable of the suspension bridge, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com