Durability testing platform of automobile air brake manual controlling valve

A durability test and air brake technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as lengthening the development cycle, increasing development costs, and affecting the authenticity of test results. Achieve the effect of improving service life, reducing impact and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

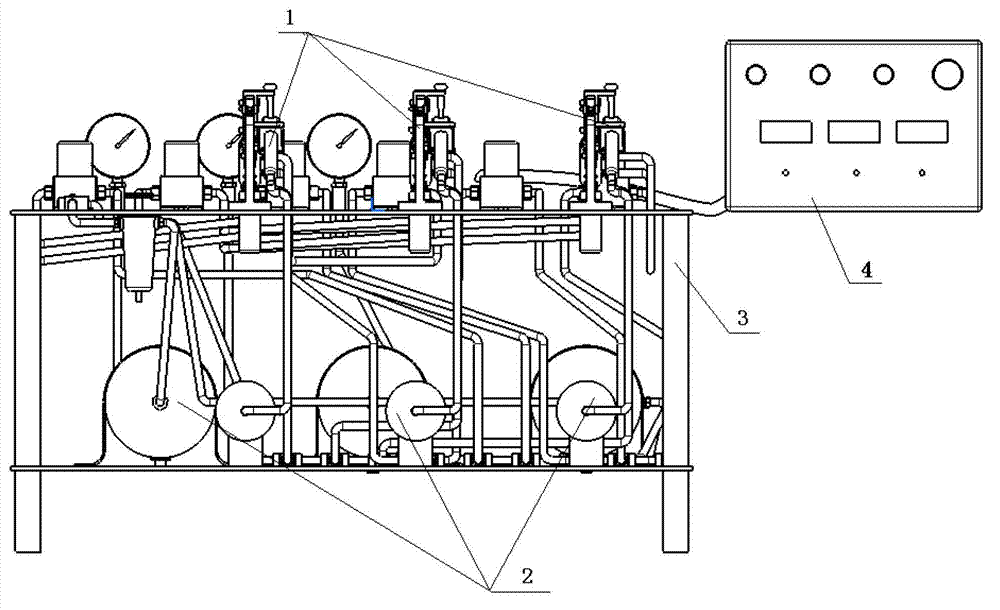

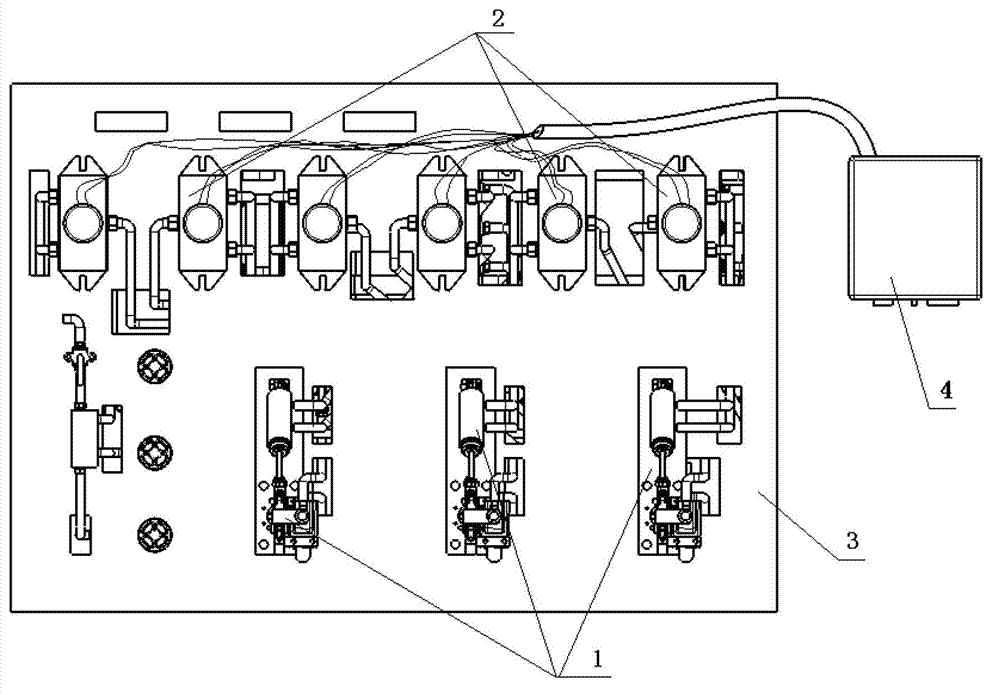

[0029] Such as figure 1 , figure 2 : This test bench is mainly installed on the platform body 3 by the simulated action mechanical loading part 1 and the pneumatic part 2 driven by it, and works under the control of the electric control 4.

[0030] Platform: Steel platform for mounting and fixing pneumatic loading, mechanical loading and electrical control components. It can be made into an open structure or a closed structure with a door as required.

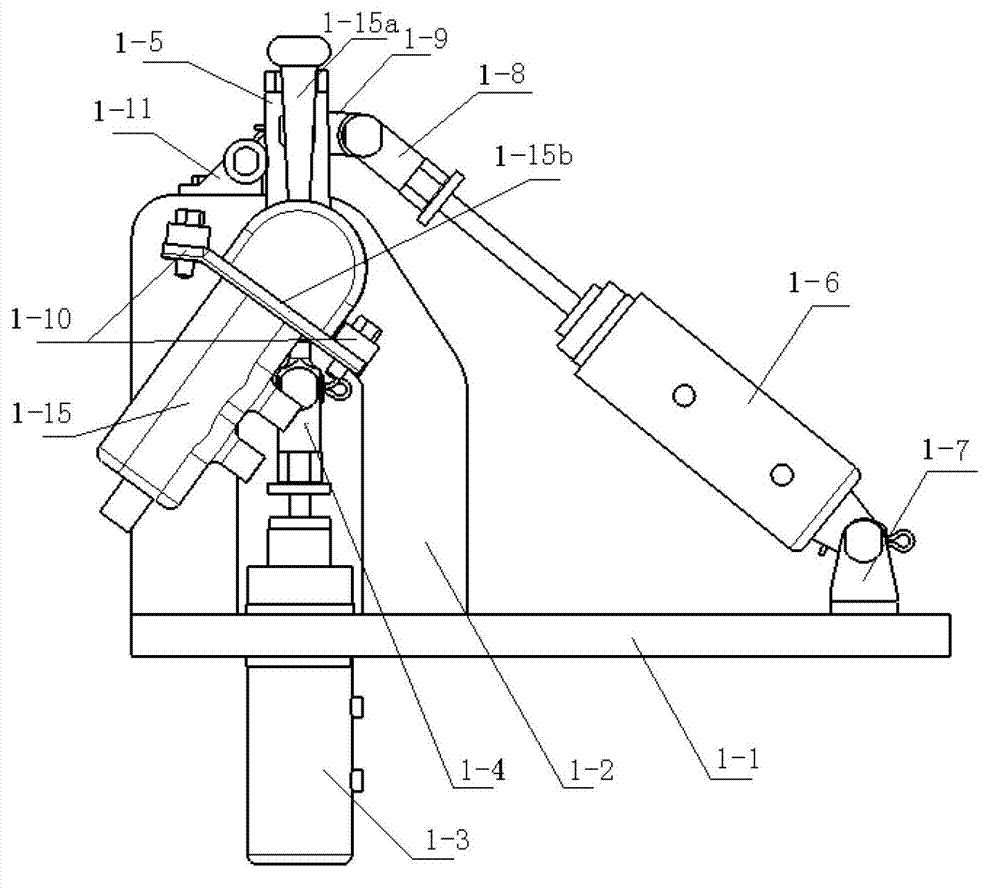

[0031] Such as Figure 3 ~ Figure 7 The mechanical loading part 1 includes a support part, a sample fixing part, a handle swing arm and a swing arm driving part, and is characterized in that the support part includes a bottom plate 1-1, and a vertical plate 1-1 vertical to the bottom plate on one side of the bottom plate 1-1. 2. There is a vertical opening 1-2a in the middle of the vertical plate 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com