High temperature flue gas moisture instrument anti-abrasive anti-plugging method and device

A high-temperature flue gas and moisture meter technology, which is applied in the field of anti-wear and anti-blocking, and can solve the problems of blockage, gas and dust wear, and products without high-temperature flue gas moisture measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

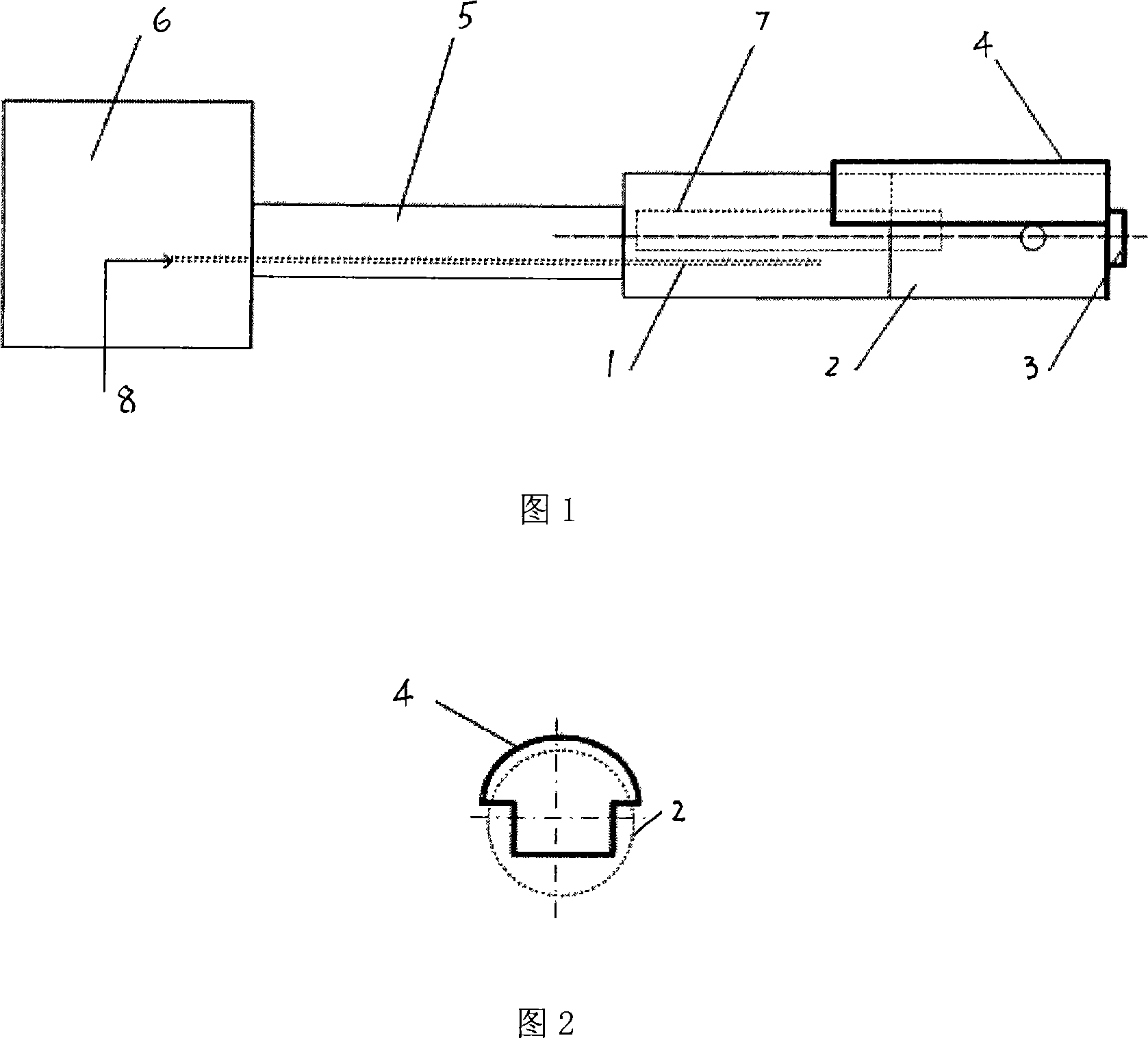

[0030] The end-sampling of the high-temperature flue gas moisture measuring instrument is equipped with 1) a wear-resistant arc-shaped baffle sampling device that can be adjusted at any angle:

[0031] It includes: a wear-resistant sampling sleeve that can be self-excited and cleaned, and a wear-resistant arc-shaped baffle that can be adjusted at any angle. The two can be adjusted and combined into a wear-resistant and anti-blocking device according to the flow direction of the flue gas and the position of the measurement sampling point. flue gas moisture meter sampling device.

[0032] According to the direction of the flue gas flow, the relative position of the wear-resistant sampling arc baffle and the sampling device can be adjusted at any angle to prevent the flue gas from directly washing the sampling hole of the sampling sleeve. The baffle is sprayed with polymer wear-resistant and anti-corrosion paint to solve the problem. Flue gas dust wear and blockage problems in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com