Biomass double square coil pipe heat conduction oil furnace

A heat-conducting oil furnace and biomass technology, applied in the boiler field, can solve the problems of small heating area, high heating efficiency, and low heat transfer system, and achieve the effects of improving heat transfer efficiency, reducing heating temperature, and increasing heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

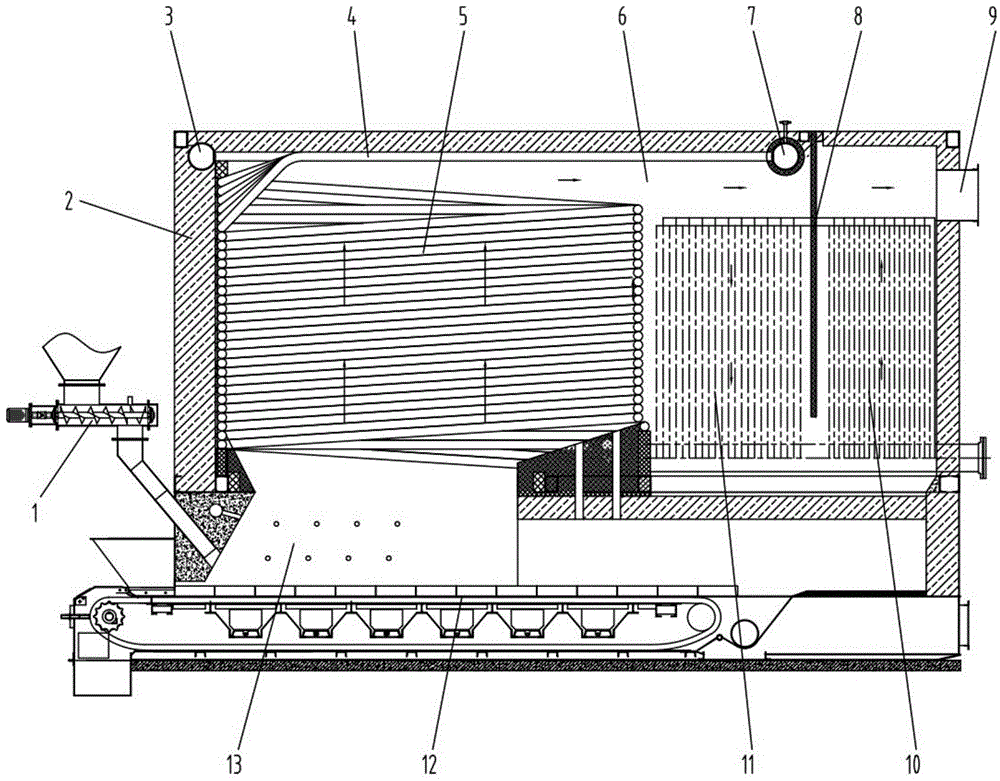

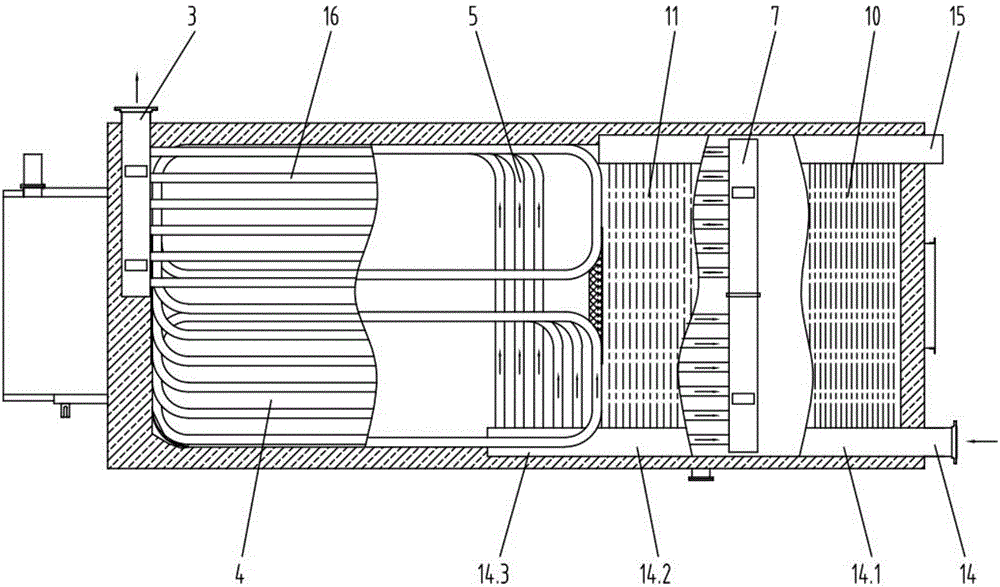

[0017] A biomass double-shaped coil heat-conducting oil furnace mainly includes a furnace body 2 , a chain-type grate 12 and a feeder 1 . Body of furnace 2 is arranged horizontally as a whole. The bottom of the furnace body 2 is provided with a chain type fire grate 12 . The smoke chamber 6 in the furnace body 2 is divided into a radiation zone and a convection zone, and the furnace 13 and its upper part are the radiation zone.

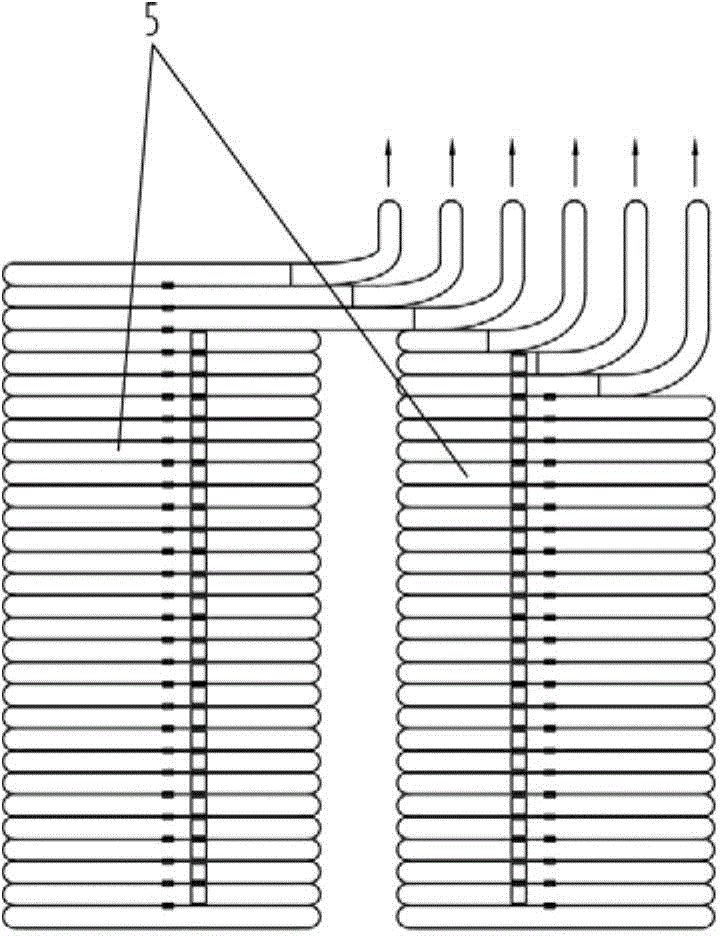

[0018] The convection zone is arranged with meandering serpentine tube bundles 10 and 11 as convection heating surfaces, and the serpentine tube bundles are used for two-way convective heat release. A partition 8 is hoisted on the top wall of the furnace body in the convection zone, and the partition 8 separates the convection zone into two parts, and the first return serpentine tube bundle 11 and the second return serpentine tube bundle 12 are arranged respectively.

[0019] The serpentine tube bundles 10 and 11 are connected between the oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com