Device for preventing high-temperature corrosion of heating surface of waste incineration boiler

A technology of waste incineration and high-temperature corrosion, applied in incinerators, combustion types, combustion methods, etc., can solve problems such as high engineering cost, increased production cost, and reduced incineration frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

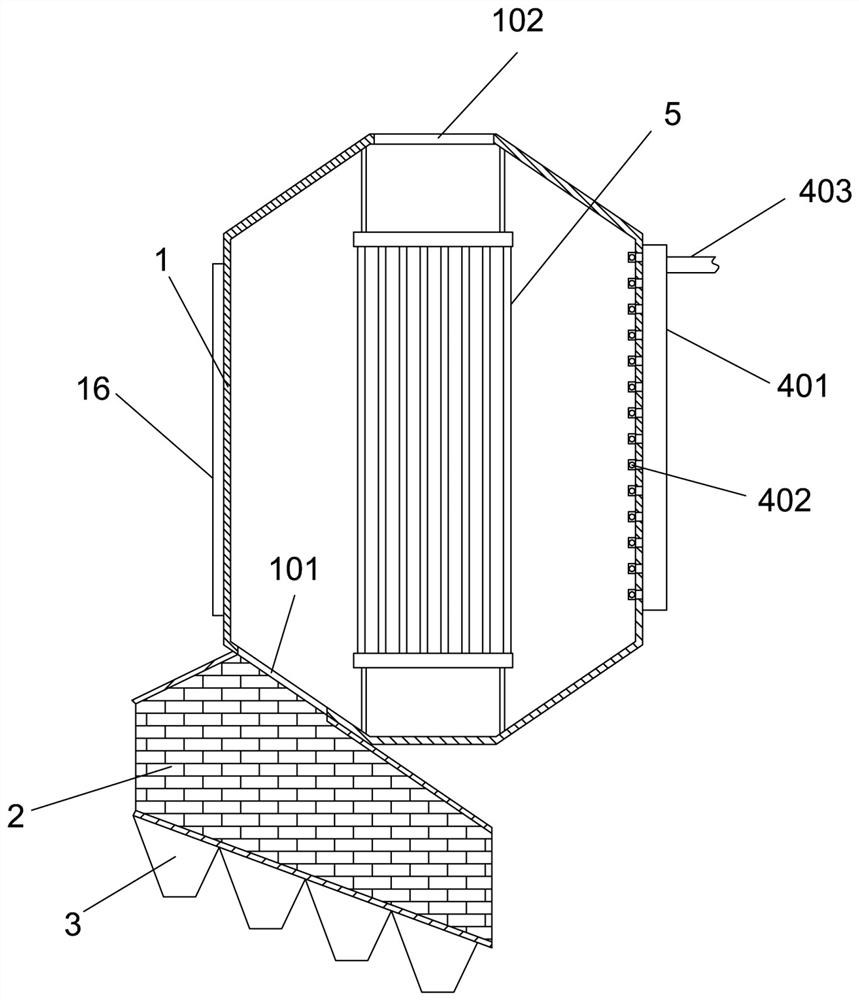

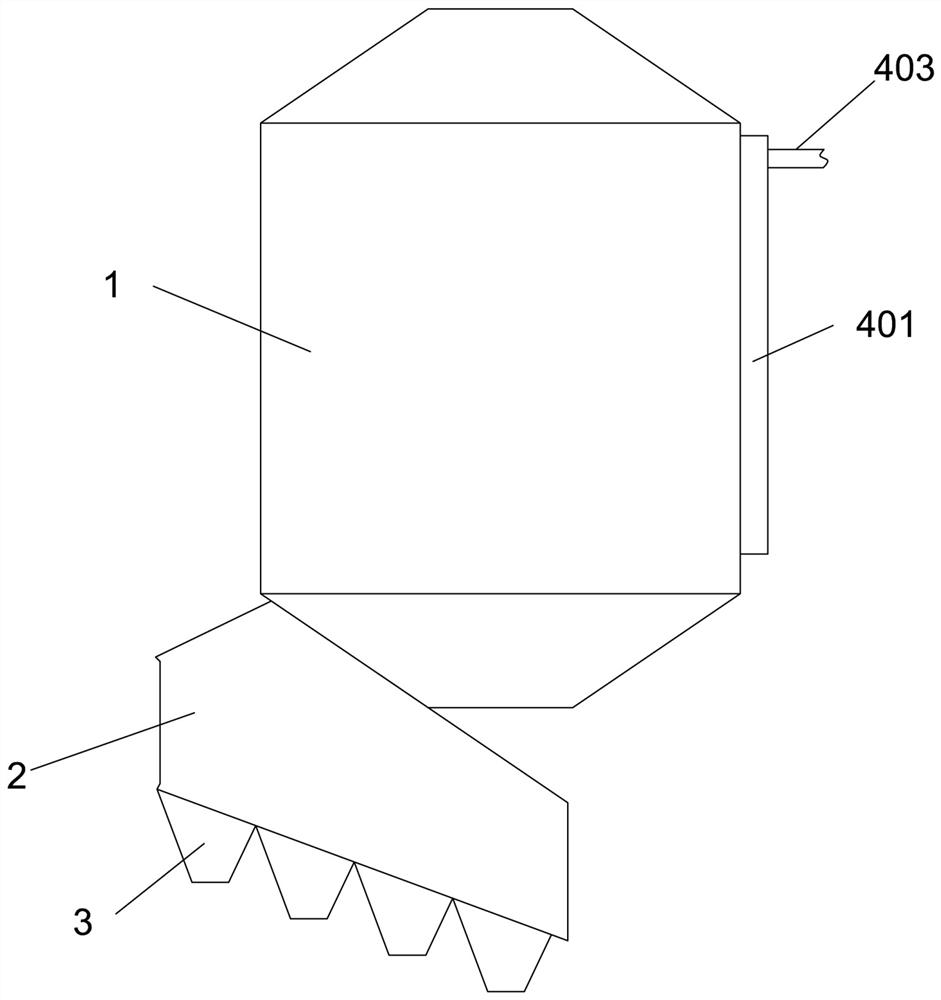

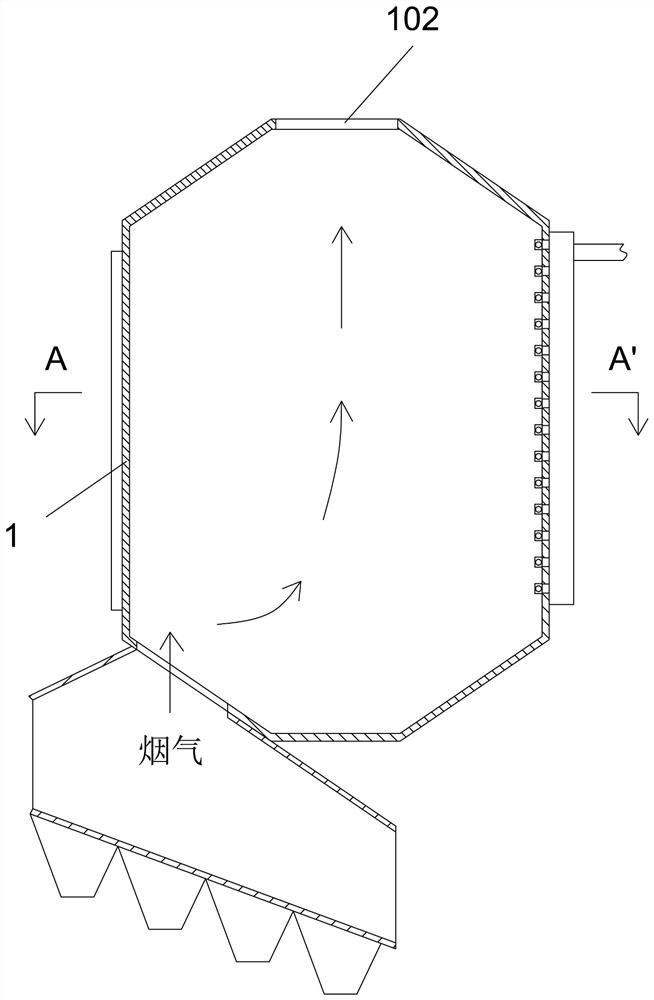

[0031] Example 1. At present, in the process of incinerating garbage in waste incineration boilers, high-temperature corrosion will occur on the heating surface of the boiler. The important reason for the high-temperature corrosion of the heating surface of waste incineration boilers is that various chlorides in the flue gas affect the metal pipe wall. The corrosion of chlorine, the chloride formed by a large amount of chlorine corrosive elements in the flue gas, causes high-temperature corrosion damage to the heating surface of the boiler, thereby increasing the maintenance frequency of the boiler, increasing the production cost, reducing the frequency of incineration, and the existence of The adhesion and deposition of fixed dust particles on the heating surface will also accelerate the corrosion and damage of the heating surface. During the process of waste incineration, the serious high-temperature chlorine corrosion and heavy metal deposition on the heating surface have bec...

Embodiment 2

[0034] Embodiment 2, a device for preventing high-temperature corrosion of the heating surface of a waste incineration boiler in this implementation will be described centering on the differences from Embodiment 1.

[0035] During the implementation of Example 1, when the high-temperature flue gas temperature is too high and overheating occurs in the incinerator, the heat exchange effect between the swirling high-pressure cold air flow and the heating surface may be reduced, reducing the heat transfer effect on the heating surface. The heat exchange effect of the surface may also lead to a decrease in the heat exchange effect of the water cooling frame, resulting in high temperature corrosion of the heating surface by the high temperature flue gas, and the cold air flow will delay the falling speed of the heavy metal dust during the heat exchange process between the swirling flow and the heating surface , increase the falling stroke of the heavy metal dust, the heavy metal dust...

Embodiment 3

[0037] Embodiment 3, a device for preventing high-temperature corrosion of the heating surface of a waste incineration boiler in this implementation will be described centering on the differences from Embodiment 1.

[0038] During the implementation of Embodiment 2, when the high-pressure cold airflow swirls through the arc-shaped lifting deflector, it will flow along the outer wall of the lifting deflector, and the high-pressure cold airflow will flow through the arc-shaped lifting deflector When the cold air flow is accelerated, the acceleration of the cold air flow will not affect the inner wall of the incinerator, but the heavy metal dust in the flue gas will also be accelerated when it is swirled through the arc-shaped deflector, resulting in a change in the speed of the heavy metal dust. Fast, it may cause impact wear on the inner wall of the incinerator and affect the inner wall of the incinerator. In view of the above problems, this embodiment provides a device for prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com