Method for producing rose hydrosol

A technology of rose hydrosol and rose dew, which is applied in the functions of food ingredients, ultra-high pressure food processing, food ingredients containing natural extracts, etc. , The effect of reducing the heating temperature and reducing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for generating rose water is provided, comprising the steps of:

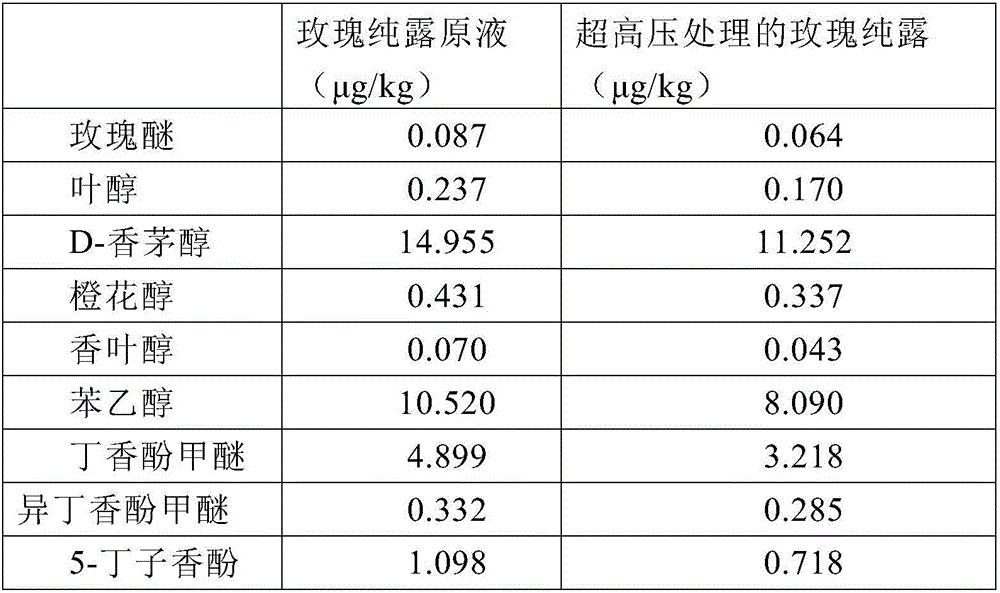

[0029] (1) Low-temperature dry extraction: use a low-temperature vacuum circulation extraction device to distill and extract from fresh roses under the condition of 30Ⅲ to obtain the rose stock solution;

[0030] (2) Fill the rose dew stock solution in step (1) into a sterilized plastic bottle, so that the rose dew stock solution fills the entire plastic bottle, discharges the air in the plastic bottle, and fills a single plastic bottle. The residual air in the bottle is 0.5%, and the percentage is the volume percentage of the residual air in the package;

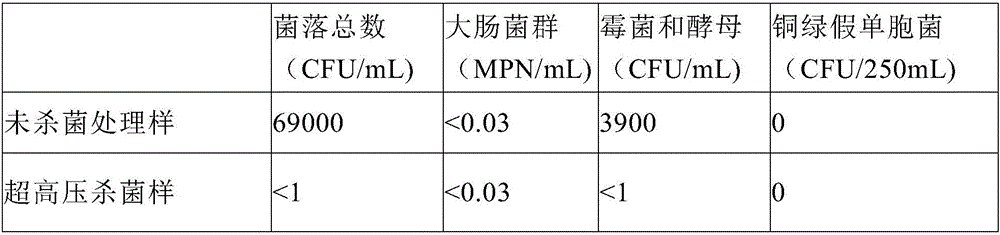

[0031] (3) Carry out high-pressure sterilization treatment with the filled rose dew stock solution, the temperature of sterilization is 25Ⅲ, the pressure of sterilization is 400MPa, and the holding time is 10min;

[0032] (4) After the high-pressure sterilization of the system is completed, the pressure will be 0MPa. After all the water in th...

Embodiment 2

[0039] A method for producing rose water is provided, comprising the steps of:

[0040] (1) Low-temperature dry extraction: using a low-temperature vacuum circulation extraction device, distilled and extracted from fresh roses under 40Ⅲ conditions to obtain the rose stock solution;

[0041] (2) Fill the rose dew stock solution in step (1) into a sterilized plastic bottle, so that the rose dew stock solution fills the entire plastic bottle, discharge the air in the plastic bottle, and fill a single plastic bottle The residual air content is 1%, and the percentage is the volume percentage of the residual air in the package;

[0042] (3) Carry out high-pressure sterilization treatment with the filled rose dew stock solution, the sterilization temperature is 25Ⅲ, the sterilization pressure is 350MPa, and the pressure holding time is 15min;

[0043] (4) After the high-pressure sterilization of the system is completed, the pressure will be 0MPa. After all the water in the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com