Patents

Literature

53results about How to "Less heat storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-insulating material

ActiveUS20140112861A1Reduce in quantityLess energy supplyMangesium aluminatesCeramicwareMetallurgyPore diameter

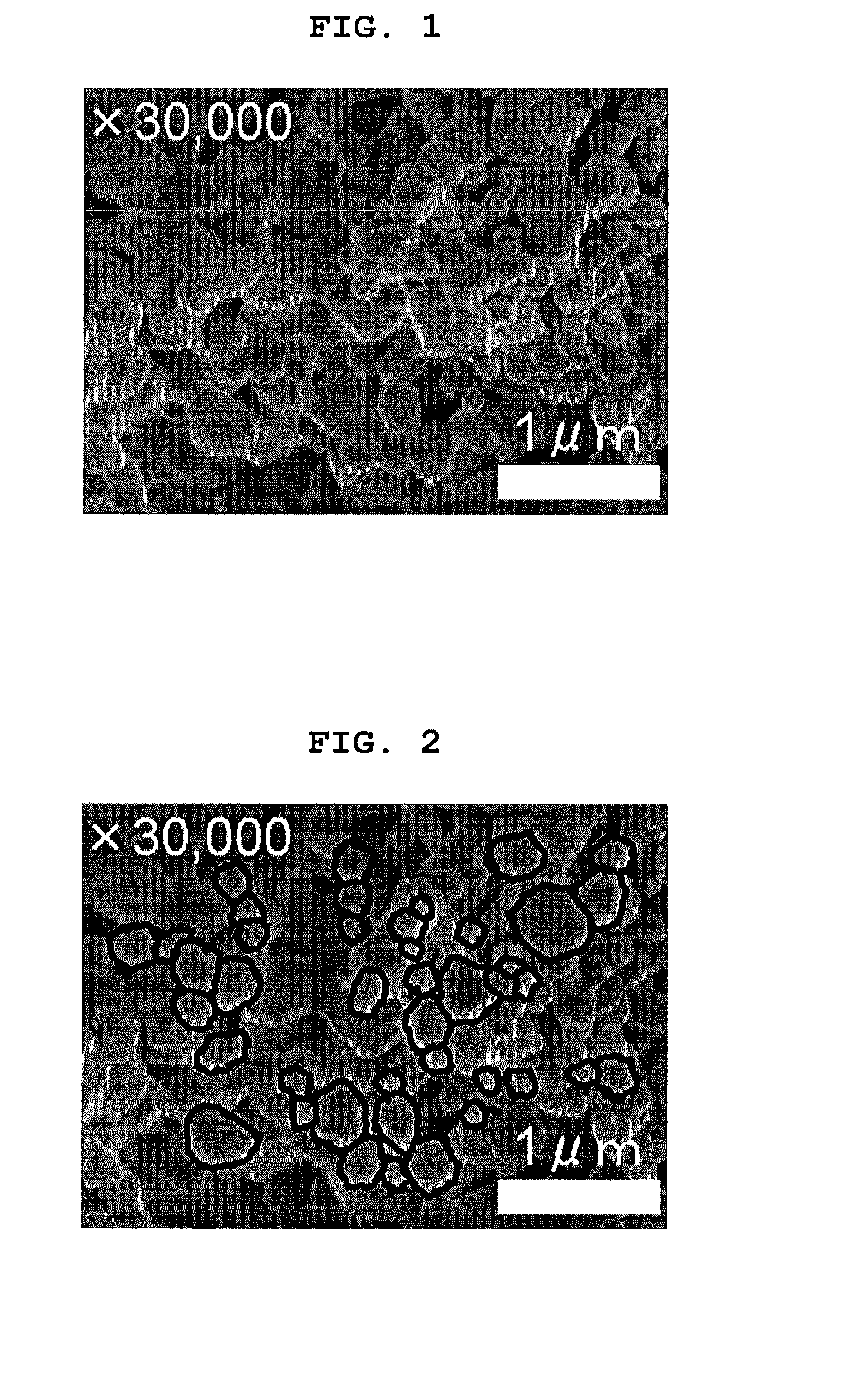

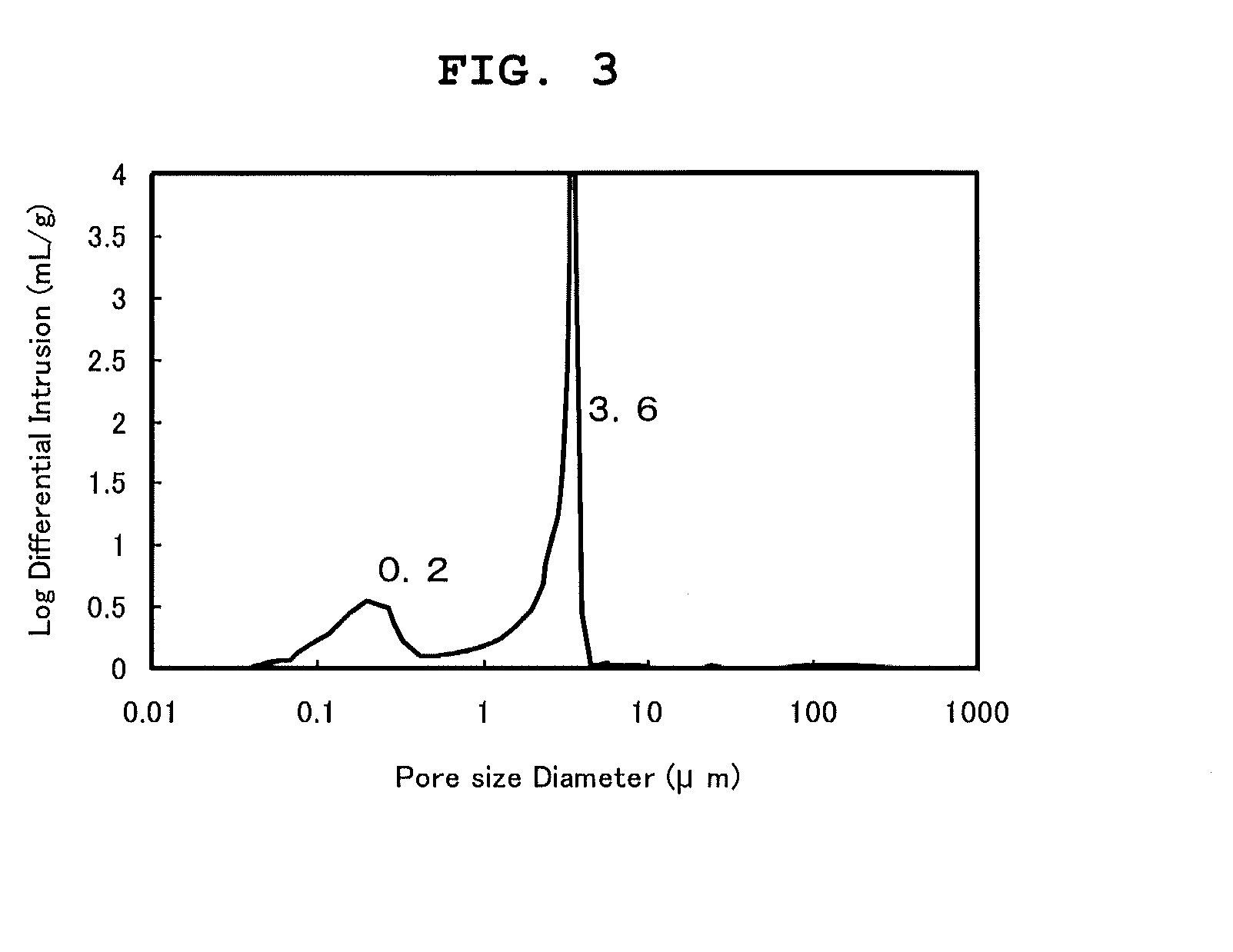

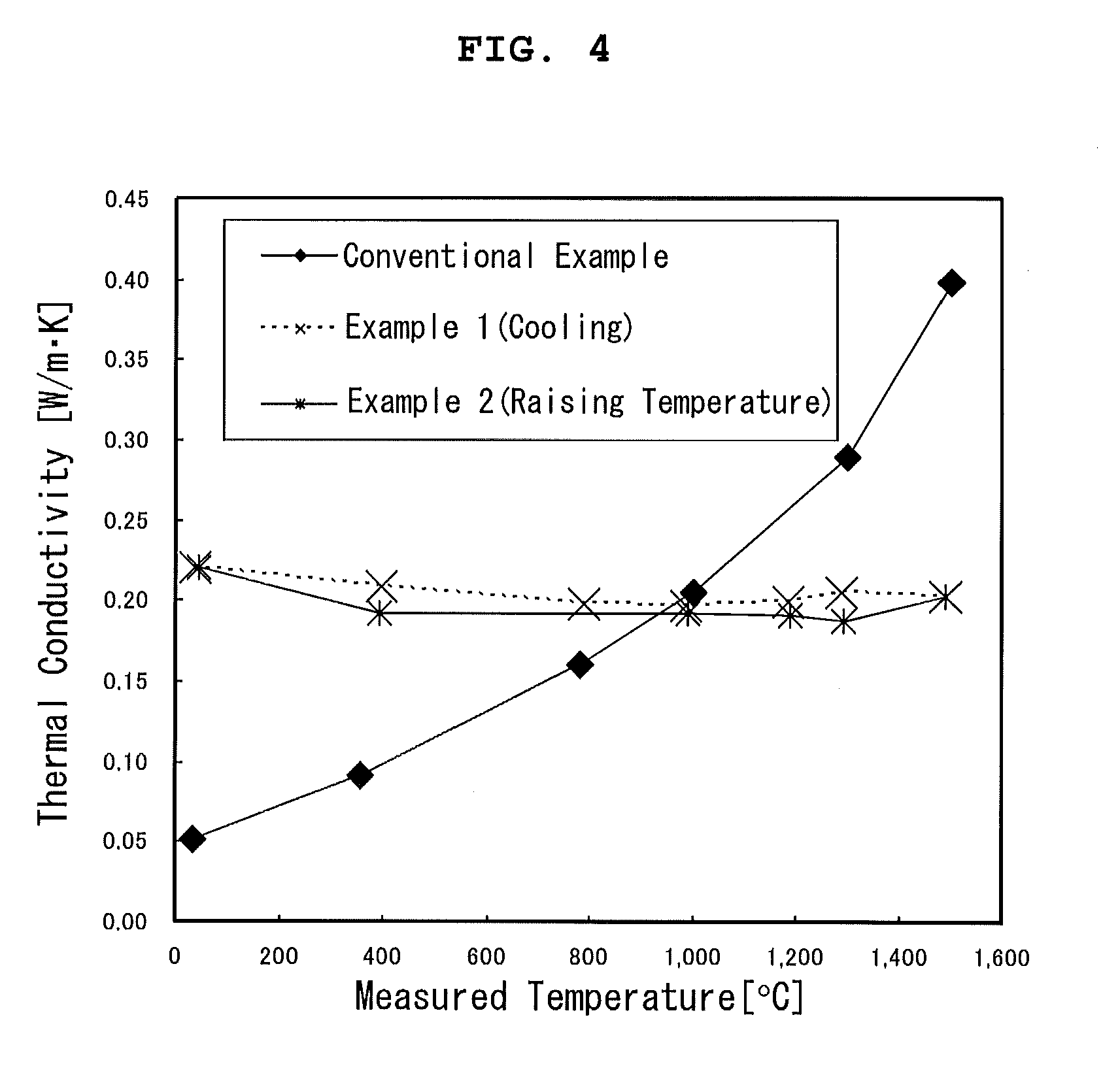

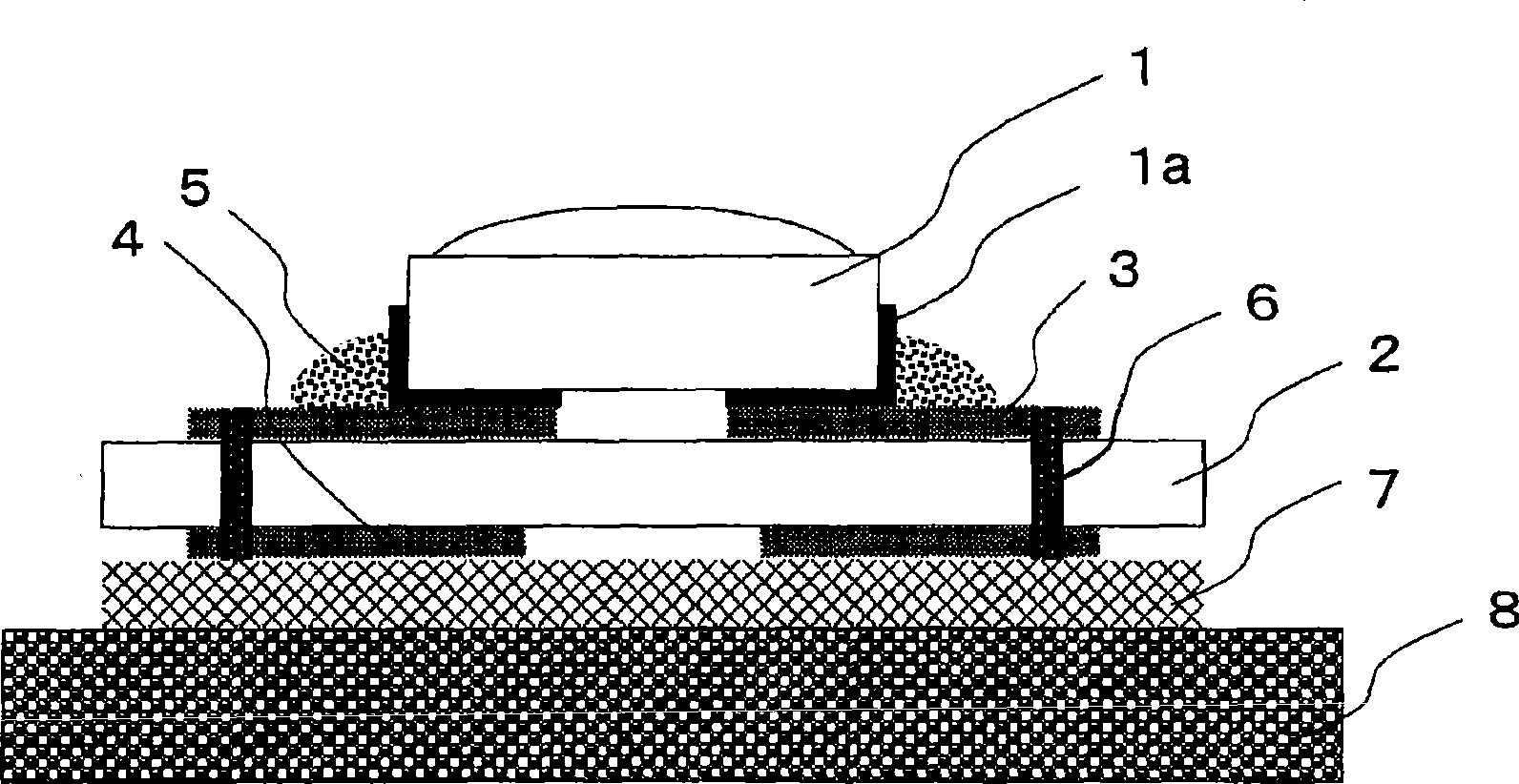

A heat-insulating material is provided in which thermal conductivity is controlled not to increase and good insulation properties are held even in a high temperature range. The heat-insulating material is formed of a spinel porous sintered body having a porosity of 65 to 90 vol. % and represented by a chemical formula XAl2O4 (X═Zn, Fe, Mg, Ni, or Mn) which is arranged such that large pores having a diameter of greater than 1000 μm occupy 25 vol. % or less of the total pore volume, fine pores having a diameter of 0.45 μm or less occupy 5 to 40 vol. % of the volume of the pores having a diameter of 1000 μm or less, at least one pore-diameter distribution peak is within a range of 0.14 to 10 μm, and is formed of sintered particles having a calculated average particle diameter of 0.04 to 1 μm.

Owner:COORSTEK INC

Method for preparing lightweight alumina hollow sphere heat insulation product

The invention relates to a method for preparing a lightweight alumina hollow sphere heat insulation product. The method comprises the following steps: by taking an alumina hollow sphere as aggregate and alumina micro powder as a matrix, adding water and a foaming agent into the alumina micro powder, mixing and foaming, introducing pores into the hollow sphere brick matrix, thereby obtaining a porous matrix; carrying out a polymerization reaction between an organic monomer and a crosslinking agent in a foaming slurry under the actions of an initiator and a catalyst, curing the foaming slurry, standing and demolding, thereby obtaining a blank consisting of the porous matrix and the hollow sphere aggregate; and drying and sintering the blank, thereby obtaining the lightweight alumina hollow sphere heat insulation brick. The hollow sphere heat insulation product prepared by the invention has low density of 600-1000kg / mg<3> and low heat conductivity of 0.36-0.83W.m<-1>.K<-1> and is good in heat insulation effect, low in heat storage and obvious in energy-saving effect.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Energy-efficient mullite zirconia multiphase refractory material, and preparation method thereof

The invention relates to an energy-efficient mullite zirconia multiphase refractory material, and a preparation method thereof. According to the preparation method, zircon mine tailing and alumina aremixed at a Al2O3:SiO2 mass ratio of (2.55-2.85) :1 so as to obtain a mixture; titanium oxide accounts for 3 to 5wt% of the mixture, lanthana accounts for 0.6 to 0.8wt% of the mixture, polyvinyl alcohol accounts for 4 to 6wt% of the mixture, and water accounts for 30 to 40wt% of the mixture are added, and ball milling is carried out for 5 to 7h so as to obtain a ball milling product; the ball milling product is subjected to extrusion moulding and drying, and thermal insulation treatment at 1550 to 1650 DEG C for 4 to 8h, and natural cooling is carried out so as to obtain the energy-efficient mullite zirconia multiphase refractory material. The preparation method is low in production cost, low in environment pollution, and convenient for industrialized production. The prepared energy-efficient mullite zirconia multiphase refractory material is relatively low in thermal expansion coefficient, excellent in energy saving effect, and wide in application range.

Owner:无锡市宜刚耐火材料有限公司

Preparation method of compound refractory kiln furniture

The invention discloses a preparation method of compound refractory kiln furniture. In the preparation method, firstly, a kiln furniture main body is selected; surface pretreatment is carried out on the surface of the kiln furniture main body to cause the surface to have certain adsorption activity; a negative-pressure dipping method is adopted to evenly adsorb stable zirconia slurry prepared in advance to the surface of the kiln furniture main body and fill into the air holes or microcracks of the kiln furniture main body; and the obtained product is dried and sintered at high temperature to obtain the compound refractory kiln furniture of the invention. The compound kiln produced by the invention has the advantages of low cost, even coating, good integrity, small possibility of deforming, low volatility and the like. The manufacturing method is also scientific and reasonable, is easy to popularize and apply, etc.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

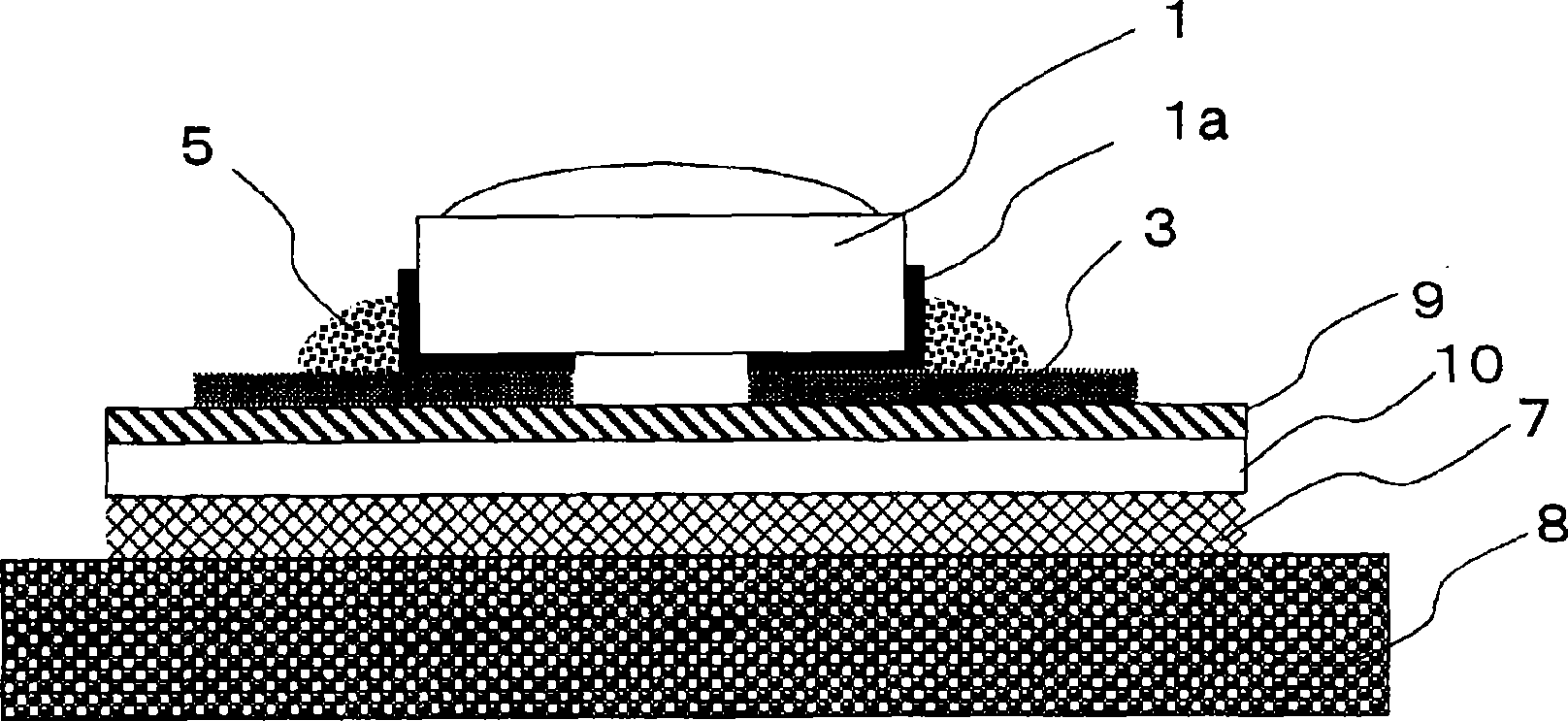

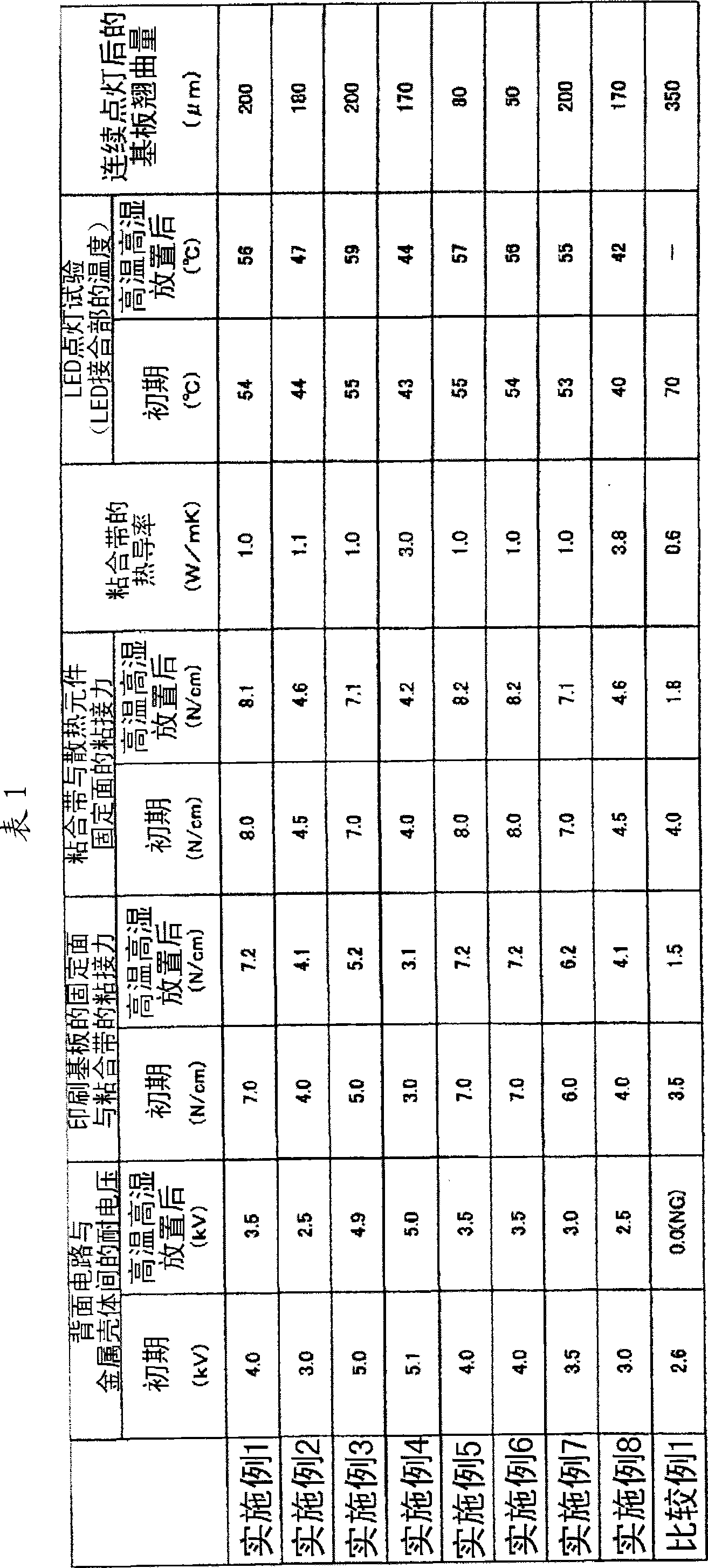

Led light source unit

ActiveCN101454909AReduce temperature riseReduced luminous efficiencyPoint-like light sourceLighting heating/cooling arrangementsEngineeringLight-emitting diode

Owner:DENKA CO LTD

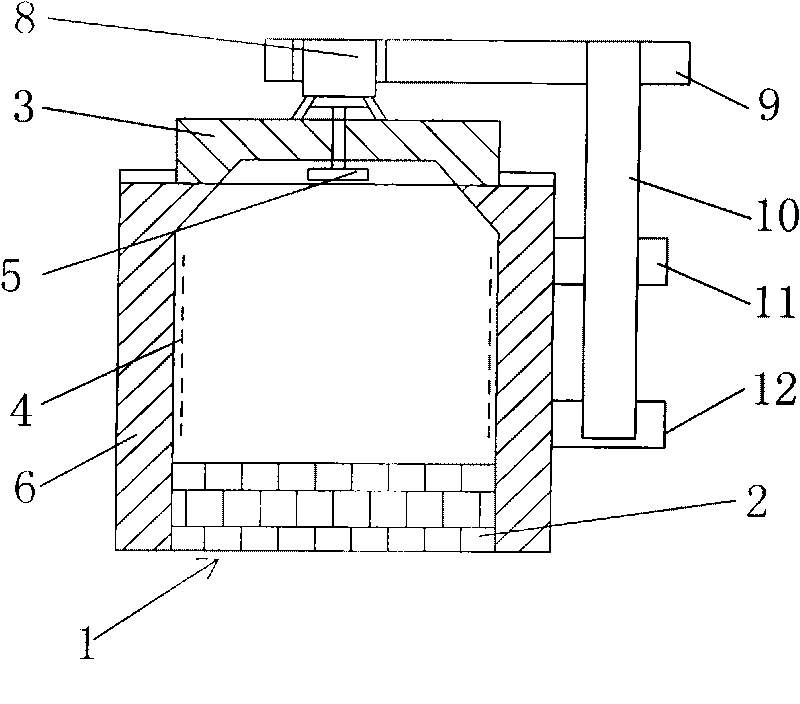

Energy-saving heat treatment well type heating furnace

The invention provides an energy-saving heat treatment well type heating furnace which comprises a furnace body, a furnace cover, a belt-shaped electric heater, an electric fan and a furnace cover moving mechanism. The furnace body is composed of a furnace wall and a furnace bottom, the furnace bottom is built by refractory bricks, the belt-shaped electric heater is fixed on the inner wall of the furnace wall, and both the furnace wall and the furnace cover are made from alumina silicate fibers. The furnace body is fixedly arranged in a furnace outer shell body made of metal, and a furnace cover outer shell body is fixed on the outer wall of the furnace cover. The using average temperature of the furnace wall and the furnace cover made from the alumina silicate fibers is 980 DEG C, the average degree of fire resistance is 1,100 DEG C, the volume density is within 2.52 to 2.53g / cm3, a heating wire is shrunk lower than 110 DEG C and is within 1.96 to 2.02% in 24 hours, the breaking strength is 0.03MPa, and the heat conduction coefficient is 0.094w / m.k. The energy-saving heat treatment well type heating furnace has the advantages of low heat conduction coefficient, less heat accumulation, quick temperature rising, good integrity, no seams, good heat-preservation effect, less radiating losses, energy saving and the like (more than 30% energy consumption can be saved). Moreover, the heating furnace not only can effectively prevent the internal temperature of the furnace from spreading to the outside of an electric furnace, but also can reduce heat losses and prolong the service life of the furnace body.

Owner:瓦房店金海轴承制造有限公司

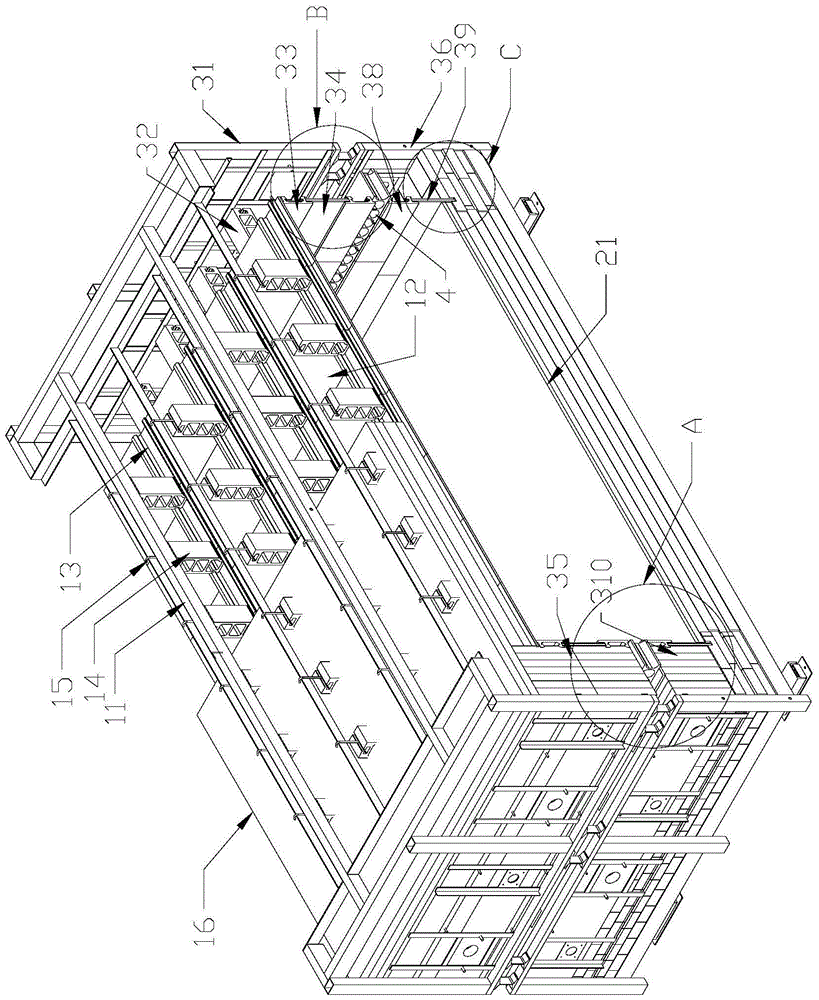

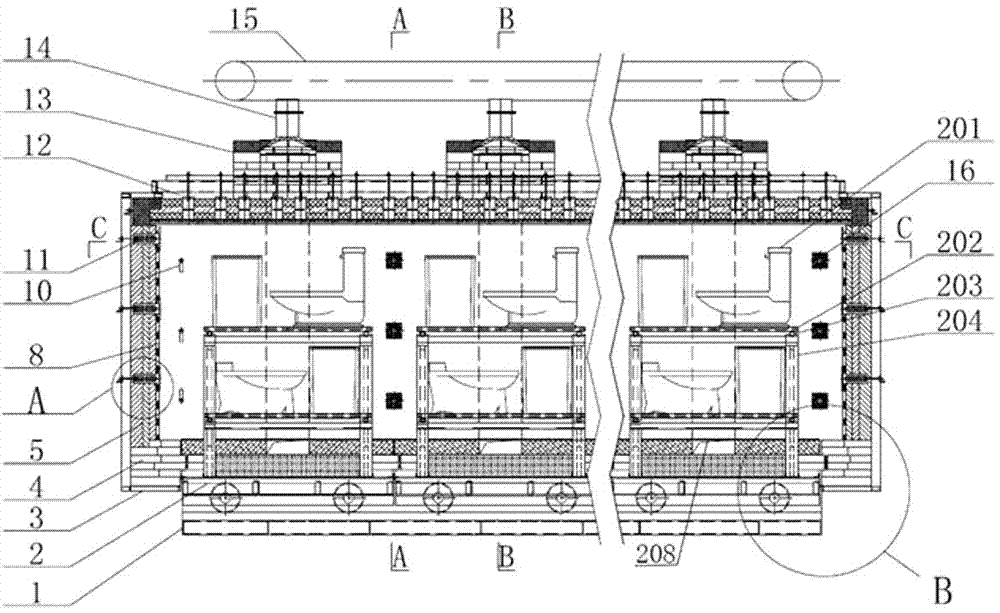

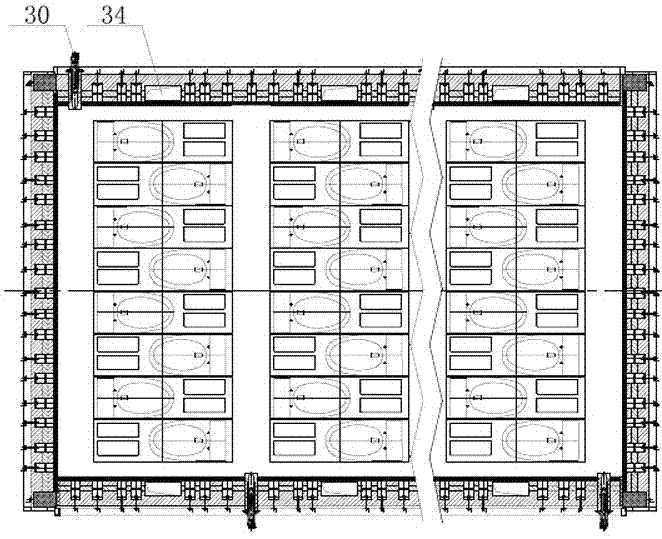

Electrical kiln with double backward push plates

The invention discloses an electrical kiln with double backward push plates, comprising a furnace body, a hearth longitudinally penetrated in the furnace body and heating elements distributed in both side walls of the hearth, wherein both ends of the hearth are respectively provided with an advancing mechanism, and two advancing mechanisms mutually have backward synchronous advancements and respectively have an individual advancement line; the hearth consists of two sintering channels longitudinally penetrating the furnace body, and the two sintering channels are communicated at intervals; feed inlets and discharge outlets of the two sintering channels are oppositely arranged; and the advancing mechanisms are arranged at the feed inlets of the two sintering channels. Products in the channels are backwards synchronously moved so as to ensure that partial afterheat of products ignited of the outlet channel is absorbed and utilized by preheated products of the other inlet channel near the outlet channel. The temperature decreasing curve of the electrical kiln is smooth, and the temperature of the products at the outlet of the furnace is low so as to achieve the purposes of recycling energy consumption, reducing the firing cost of the products and improving the firing efficiency of the products.

Owner:周建华

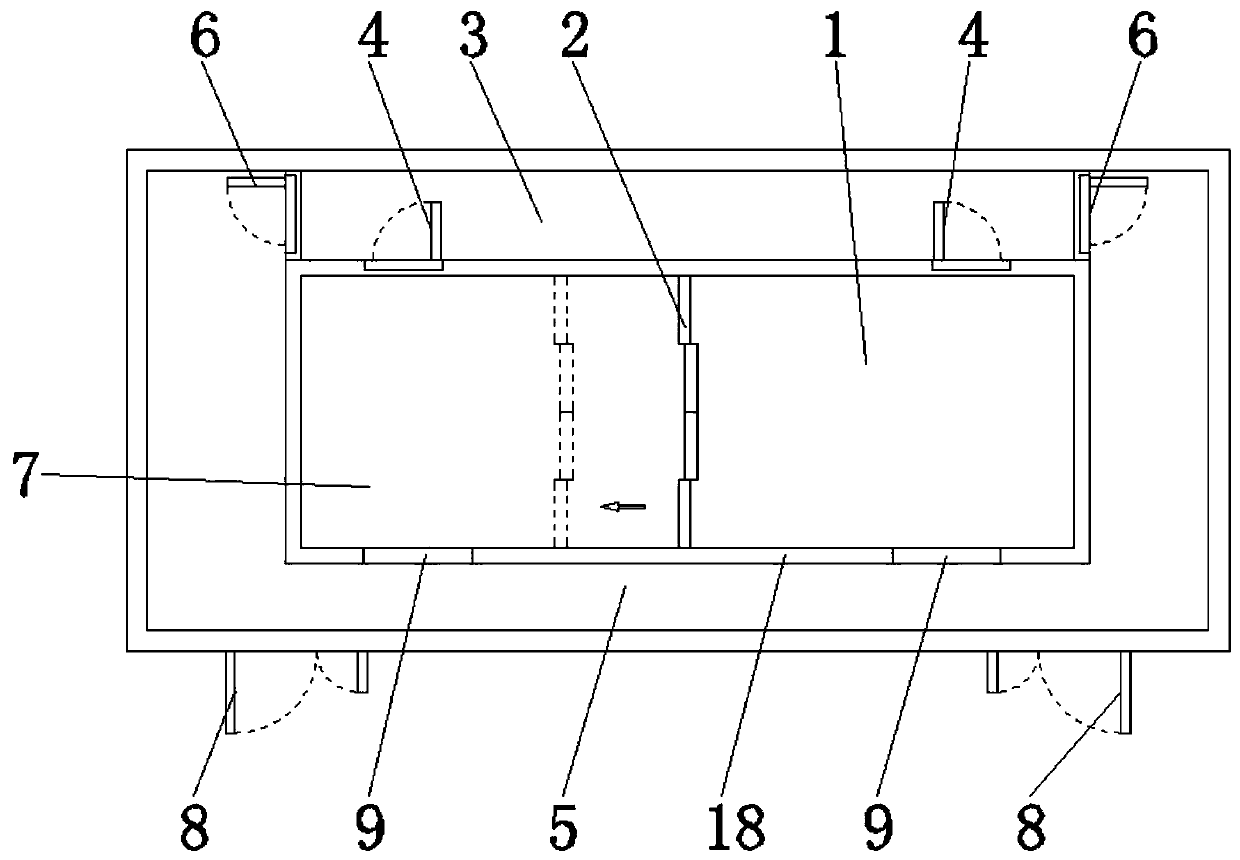

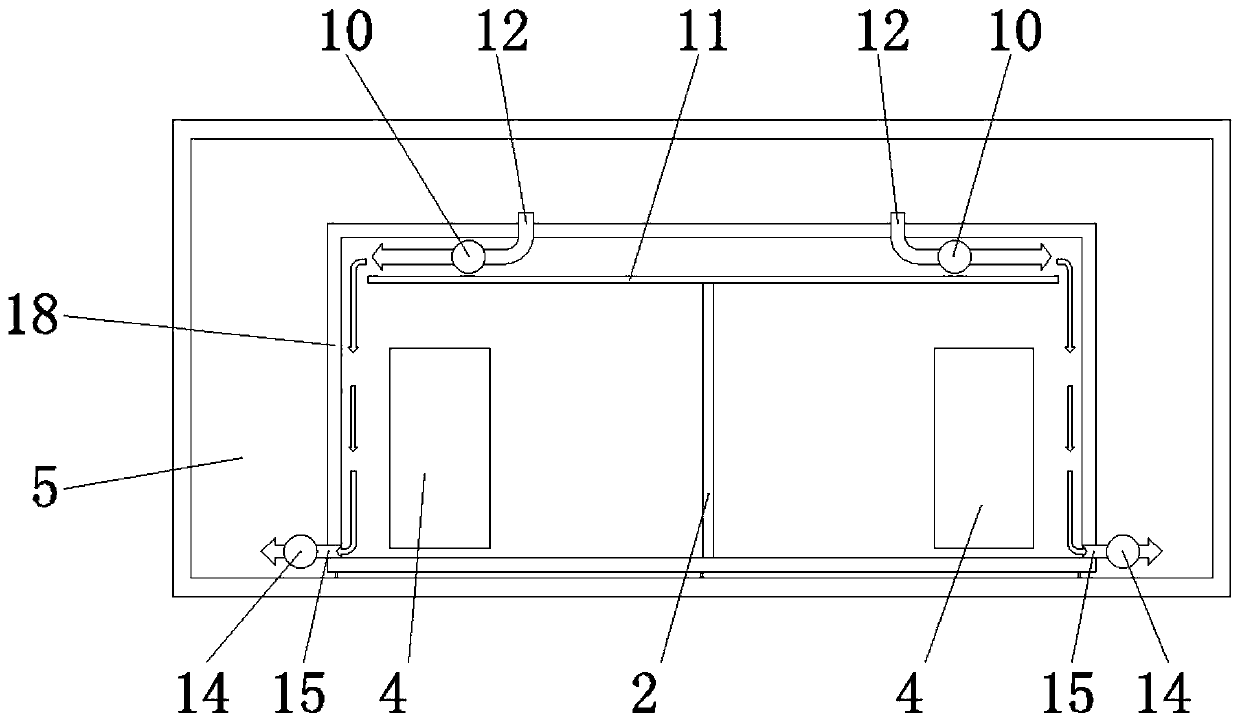

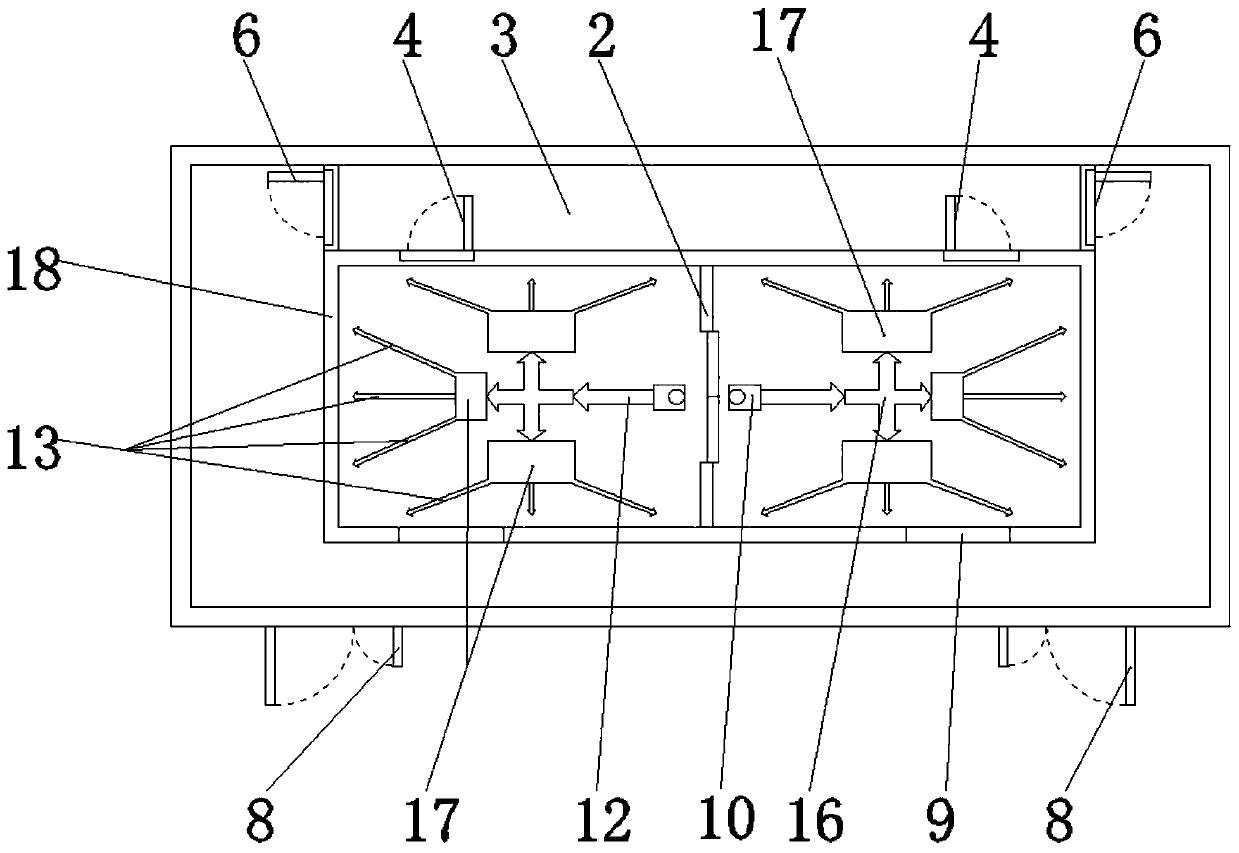

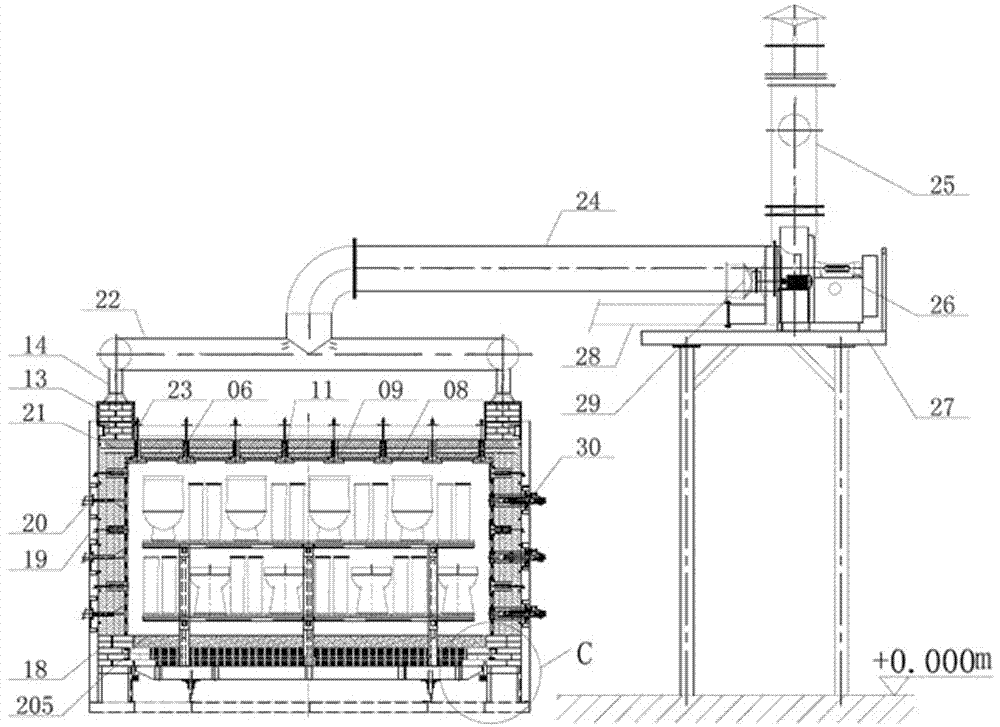

Air conditioner comfort environment laboratory capable of controlling heat load

PendingCN111121194AAvoid the problem of too little loadIncrease profitMechanical apparatusLighting and heating apparatusThermal insulationEngineering

The invention belongs to the technical field of heat load regulation, and particularly relates to an air conditioner comfort environment laboratory capable of controlling heat load. The air conditioner comfort environment laboratory comprises an inner chamber, an outer chamber and an air circulation system, each of the inner chamber and the outer chamber is provided with an enclosed space corresponding, the inner chamber is arranged in the outer chamber, and the inner chamber is enclosed by thermal insulation materials; and the air circulation system comprises an airflow inlet channel and an airflow exhaust channel which communicate with the inner chamber and the outer chamber. According to the air conditioner comfort environment laboratory, the heat load in the inner chamber is controlledby changing the input amount of cold and hot air in the outer chamber by means of the air circulation system, the problems that the load of the common brick wall thermal environment laboratory is difficult to adjust and load capacity cannot be accurately calculated are solved, the problem that in the past, the load of the laboratory based on the thermal insulation library plate is too small is solved, and the air conditioner comfort environment laboratory has more advantages compared with the problem of the condensation of the wall surface of the inner chamber caused by using a water coil pipe to input the load, the environment stabilization time is reduced, and the laboratory utilization rate is fully improved.

Owner:CHINA NAT INST OF STANDARDIZATION

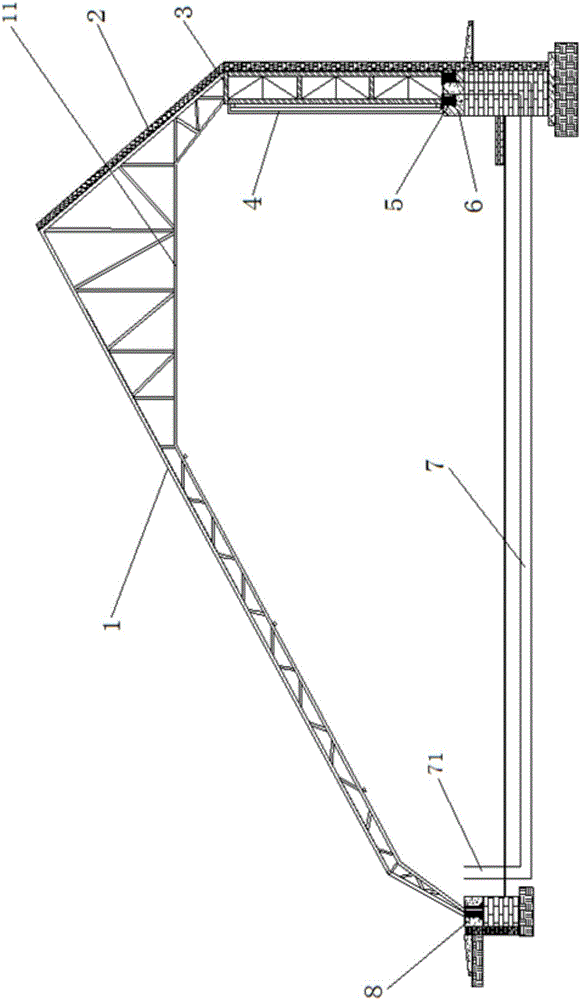

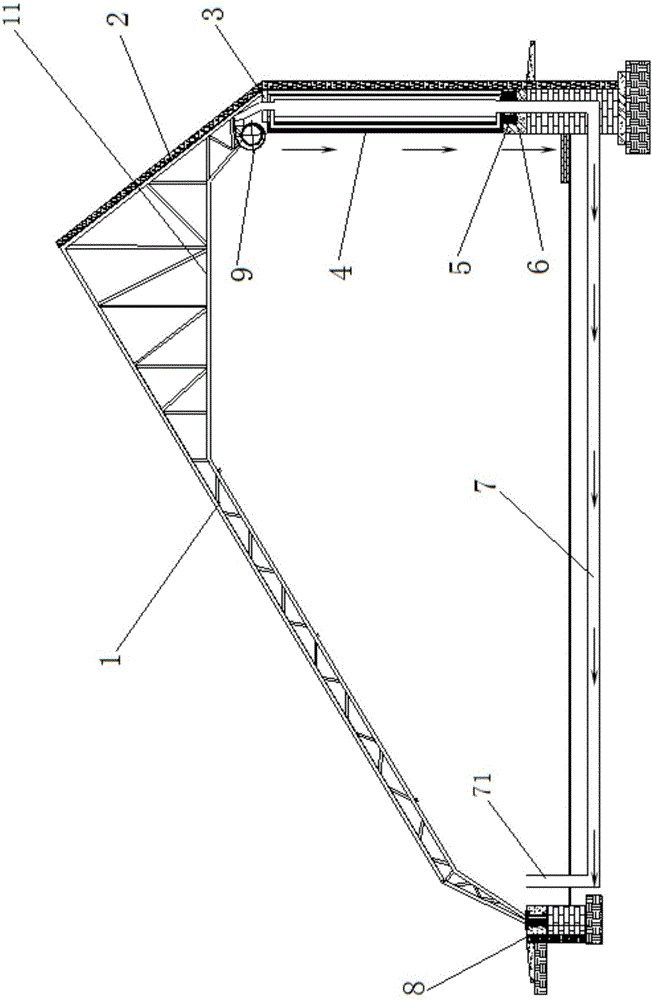

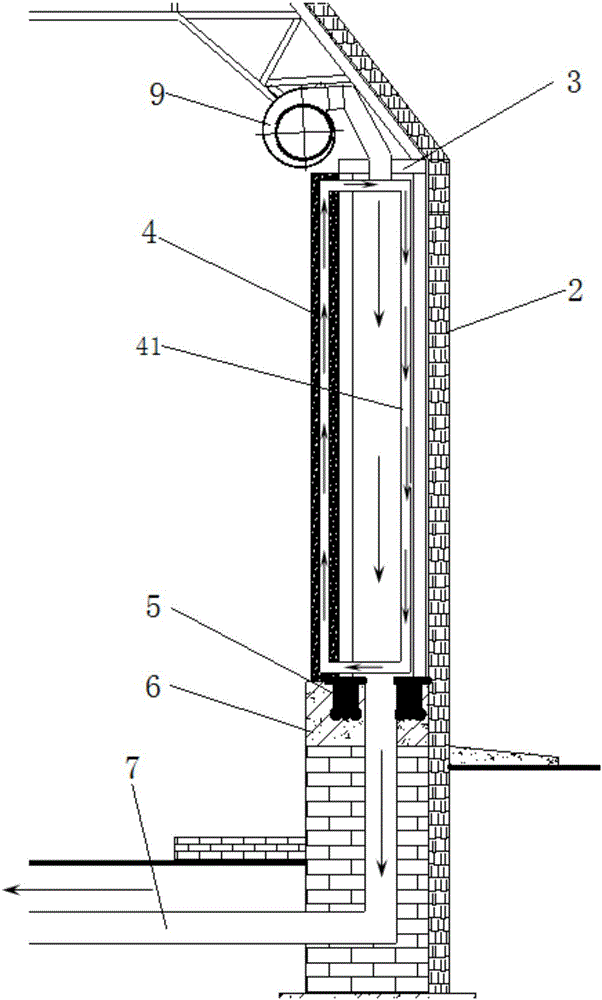

Ceramic solar modular phase change heat storage sunlight greenhouse and phase change solution thereof

InactiveCN106386255AReduce construction difficultyImprove structural stabilityClimate change adaptationRenewable energy machinesGreenhouseDaylight

The invention discloses a ceramic solar modular phase change heat storage sunlight greenhouse and a phase change solution thereof. A rear greenhouse wall comprises a heat preservation thermal insulating component, a rear greenhouse wall steel structure component and a solar ceramic phase change component, wherein the solar ceramic phase change component comprises a ceramic solar panel and a ceramic solar panel water returning pipeline; the heat preservation thermal insulating component, the rear greenhouse wall steel structure component and the ceramic solar panel form a rear greenhouse wall body structure; the ceramic solar panel water returning pipeline communicates with the inner cavity of the ceramic solar panel and is arranged inside the rear greenhouse wall steel structure component; the ceramic solar panel water returning pipeline is filled with the phase change solution. The ceramic solar modular phase change heat storage sunlight greenhouse can be rapidly manufactured and assembled in a modular manner, meanwhile heat can be stored and released actively by using a fan assembled on the rear greenhouse wall, and furthermore heat can be directly acquired from sunshine by using a liquid phase change material inside the rear greenhouse wall.

Owner:NORTHWEST A & F UNIV

Mullite-chromium light weight castable

The invention provides a mullite-chromium light weight castable. The mullite-chromium light weight castable is prepared from the following raw materials in parts by weight: 50 to 65 percent by weight of mullite microporous spheres, 20 to 45 percent by weight of low-iron three-grade high-aluminum clinker powder, 1 to 5 percent by weight of chrome oxide green, 3 to 8 percent by weight of silica micropowder, 4 to 7 percent by weight of pure calcium aluminate cement, and 0.01 to 0.5 percent by weight of a dispersing agent; the mullite microporous spheres are spherical mullite granules formed by secondary granulation sintering of raw ores; the content of Fe2O3 in the low-iron three-grade high-aluminum clinker powder is not greater than 1.5 percent by weight. The mullite-chromium light weight castable has the advantages of higher strength at normal temperature and high temperature, good volume stability and lower heat conduction coefficient; direct reduction of nodules on the surface of an iron furnace lining can be reduced, and the aims of reducing the usage of a furnace lining material, saving energy and prolonging the service life of the furnace lining are achieved.

Owner:JIAOZUO JINXIN HENGTUO REFRACTORIES

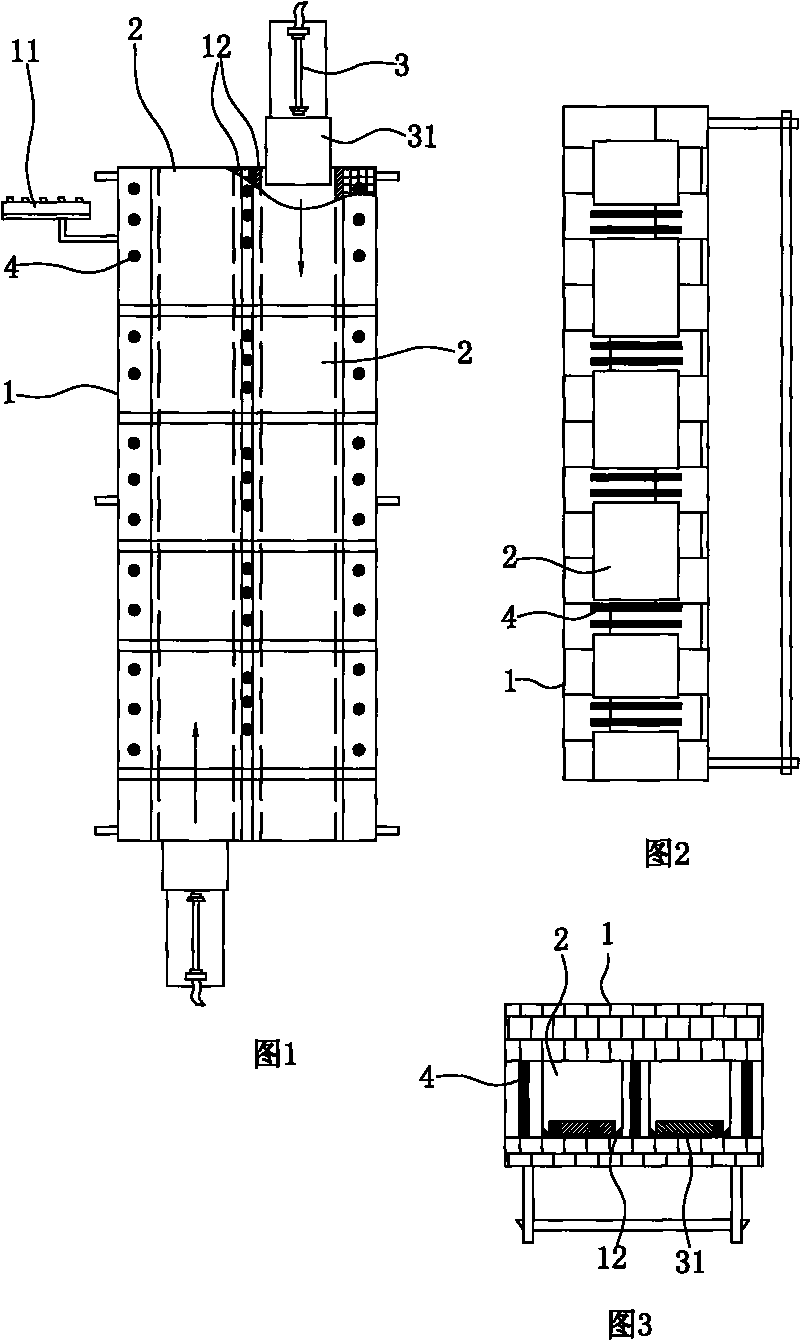

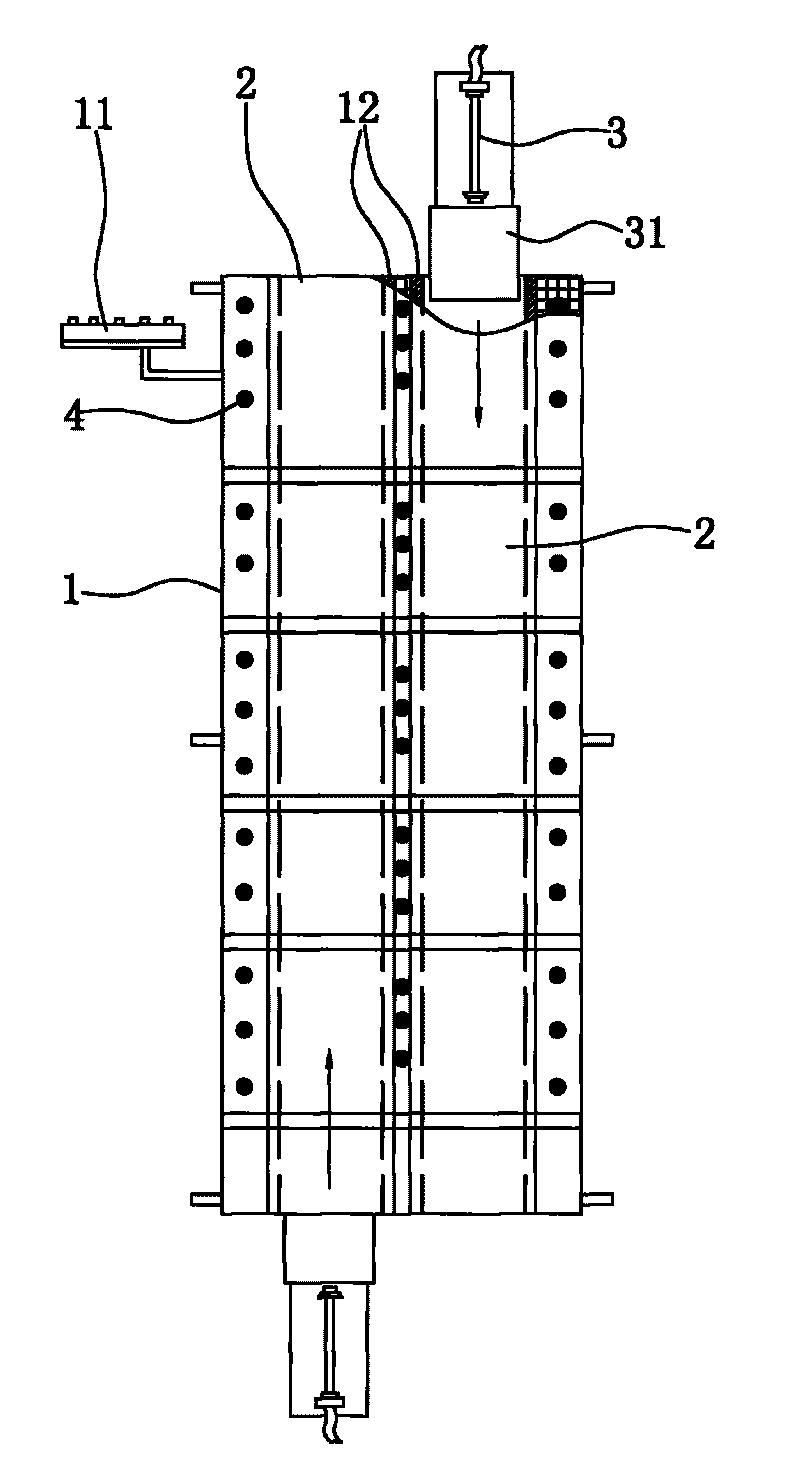

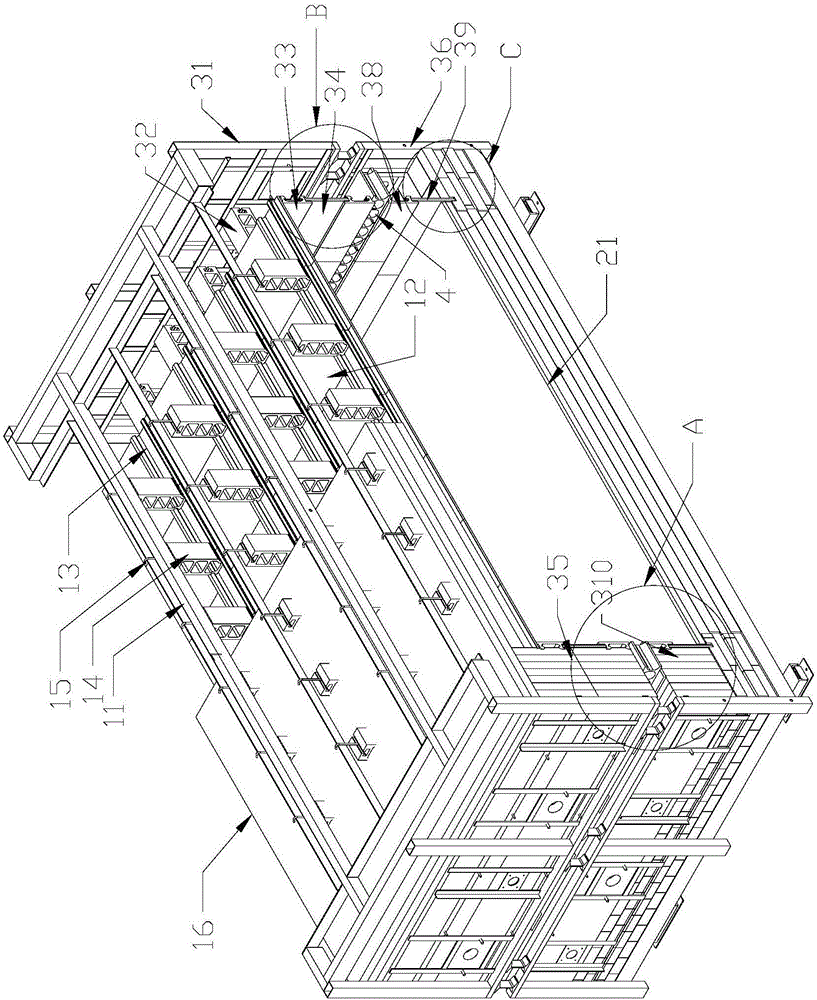

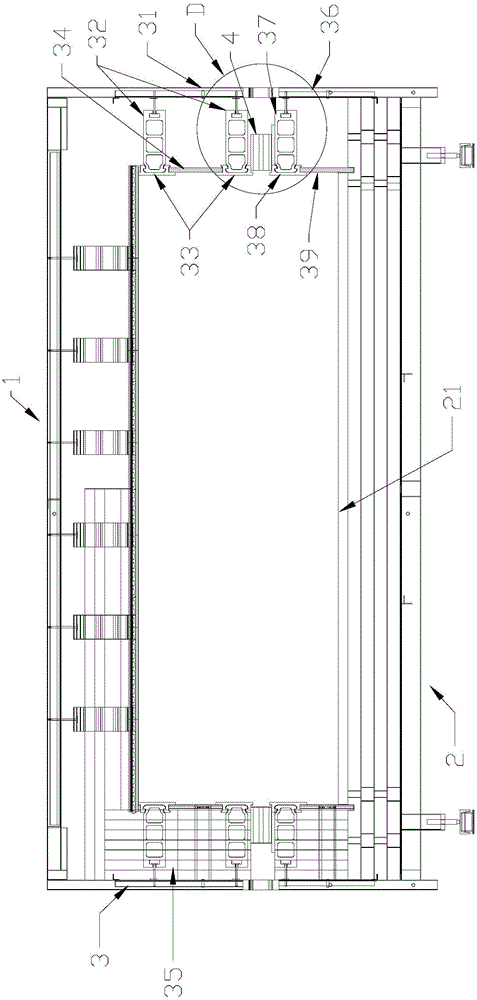

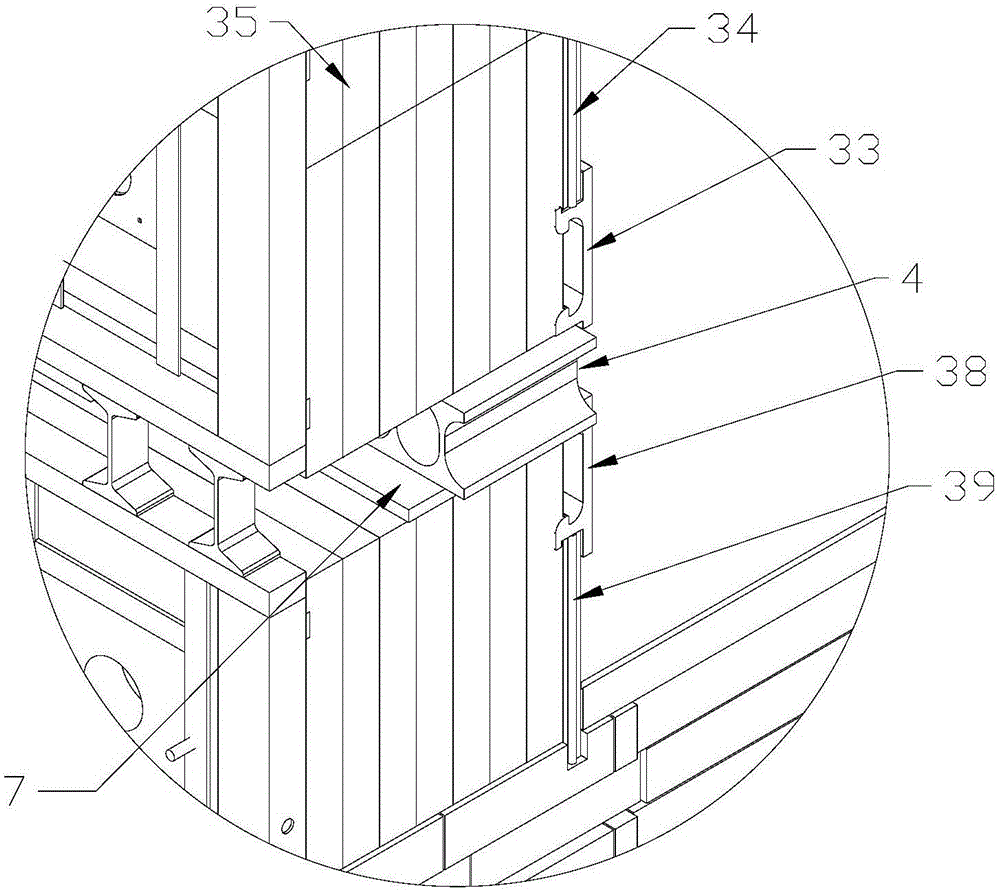

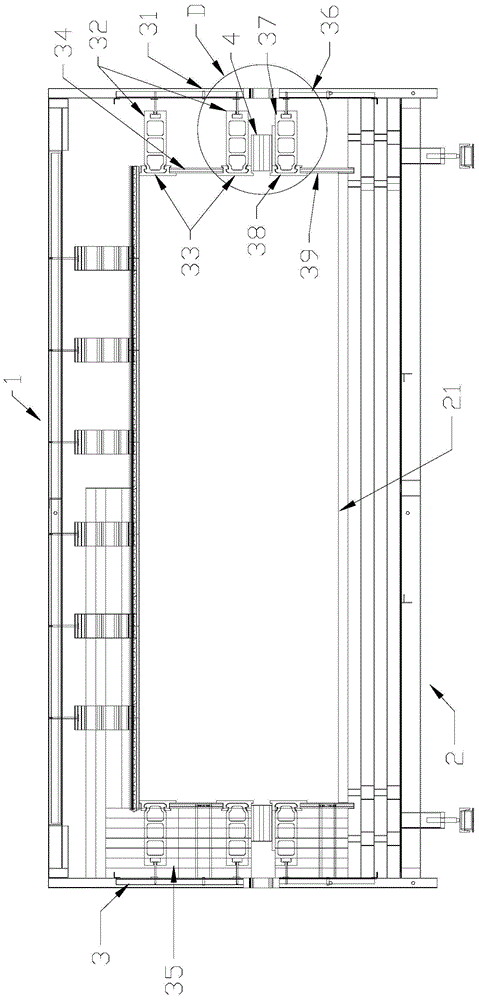

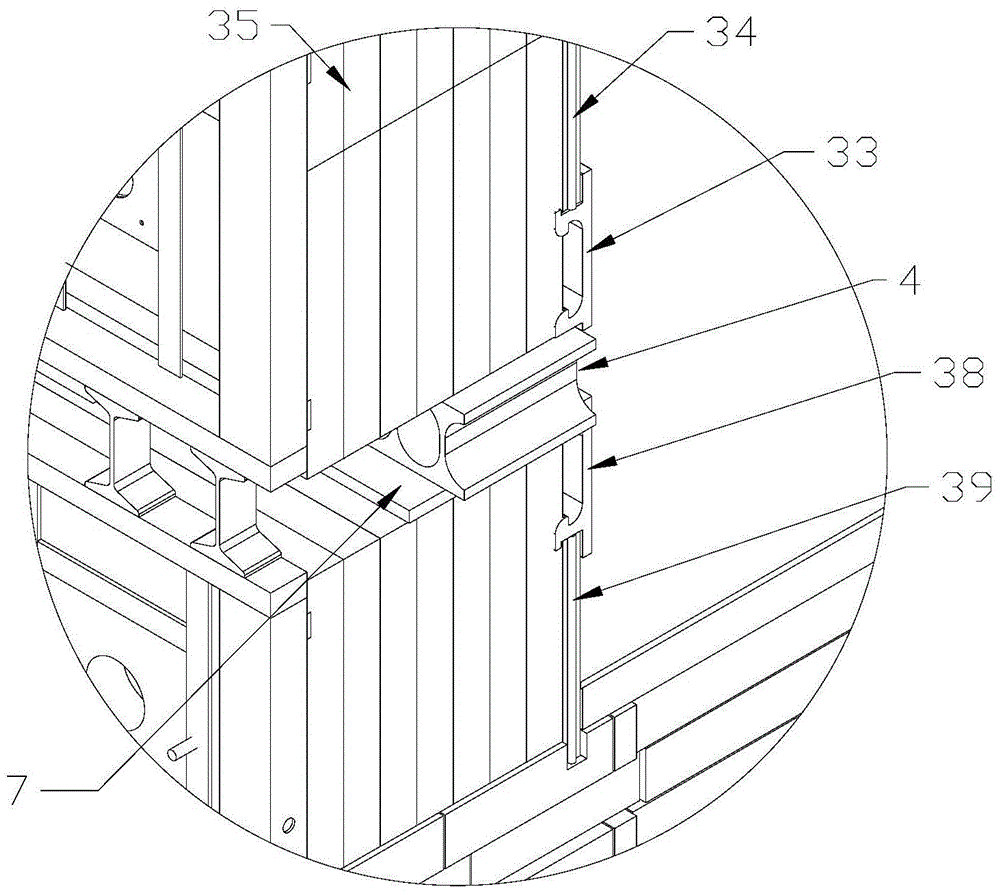

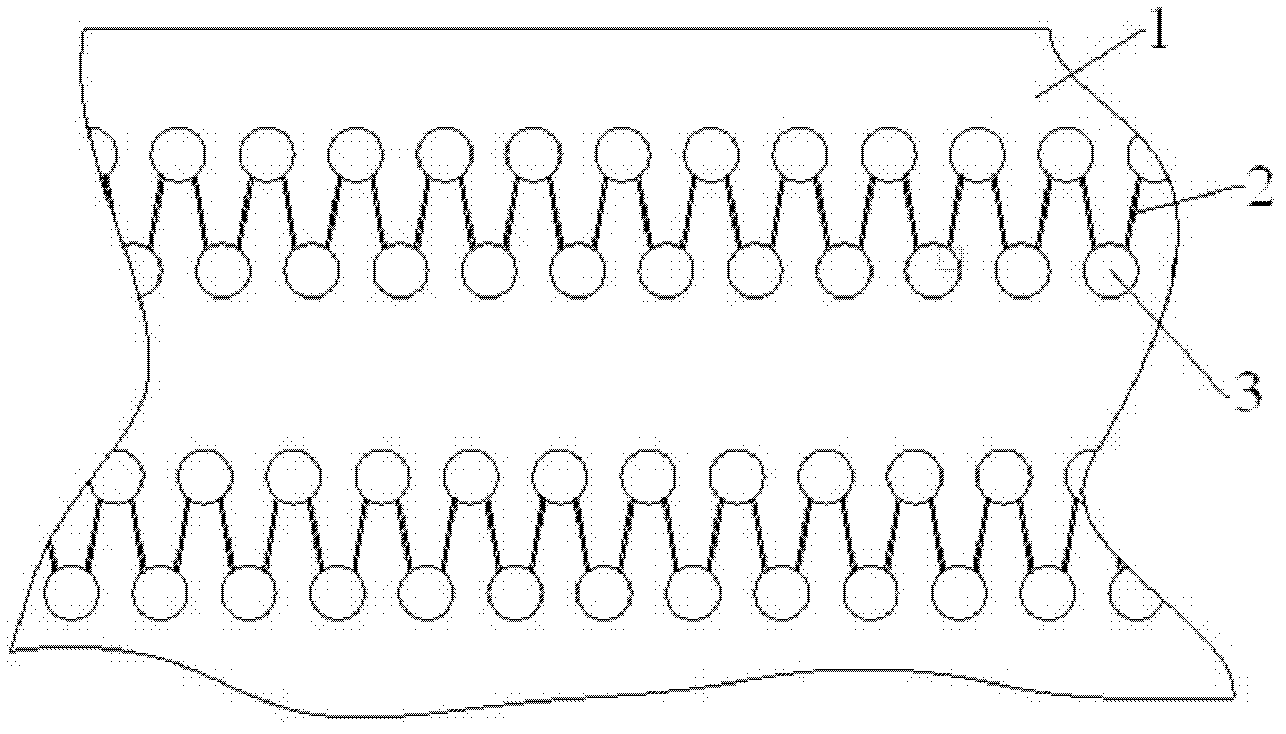

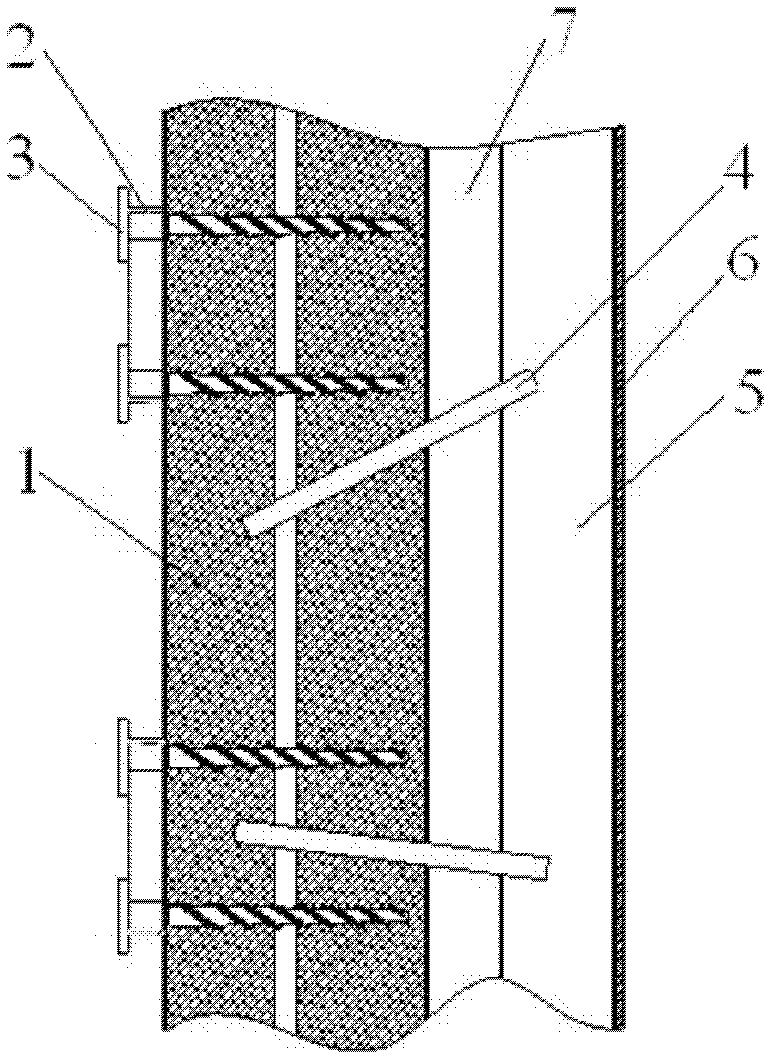

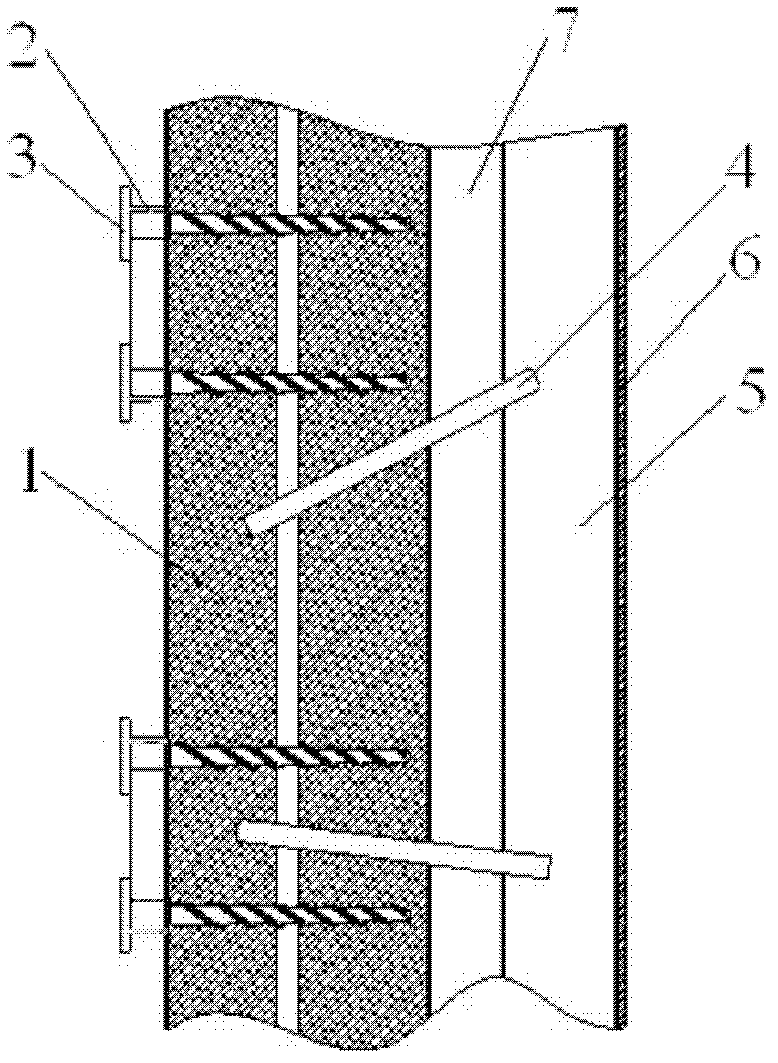

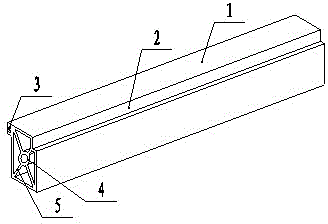

Energy-saving roller kiln low in thermal storage

ActiveCN105004185AReduce energy consumptionThe effect of blocking dirtFurnace componentsFurnace typesBrickThermal energy storage

The invention relates to a kiln, in particular to an energy-saving roller kiln low in thermal storage. Roller hole bricks of the roller kiln are made of light aluminum silicate cellucotton. Kiln walls above the roller hole bricks comprise an upper kiln wall framework; a plurality of rows of lateral hanging brackets are arranged inside the upper kiln wall frameworks in the kiln length direction; each row of lateral hanging bracket is provided with a lateral hanging rail; high-temperature-resisting dense material boards are arranged between the lateral hanging rails. The lateral hanging brackets, the lateral hanging rails and the high-temperature-resisting dense material boards tension and fix multiple layers of refractory thermal-insulation light materials onto the upper kiln wall framework for sealing and thermal insulation. The kiln walls below the roller hole bricks comprise a lower kiln wall framework; one or more rows of lateral hanging brackets are arranged inside the lower kiln wall framework in the kiln length direction; each row of lateral hanging bracket is provided with a lateral hanging rail; high-temperature-resisting dense material boards are arranged between the lateral hanging brackets and / or between the lateral hanging brackets and the kiln bottom. The whole fire face in the energy-saving roller kiln low in thermal storage adopts thin and heavy refractory slabs to ensure the firm structure and the periphery is mainly light aluminum silicate cellucotton; thermal storage is low, the thermal insulation performance is good, and energy consumption is low.

Owner:MODENA TECH LTD

Energy-saving heating furnace

An energy-saving heating furnace includes a furnace body, a furnace cover, a strip-like electric heater, an electric fan, and a furnace cover moving mechanism. The furnace body is composed of a furnace wall and a furnace bottom. The furnace bottom is built from fire-refractory bricks. The strip-like electric heater is fixed on an inner wall of the furnace wall. The furnace wall and the furnace cover are both produced from aluminum silicate fibers. The energy-saving heating furnace is low in heat conductive coefficient, is less in heat accumulation, is high in temperature increasing speed, is good in integrality, is free of seam joints, is good in heat preservation effects, is less in heat dissipation loss, can save resources (reducing more than 30% of energy consumption), can effectively prevent heat dissipation of heat from interior to exterior of the furnace, can reduce heat loss and can prolong service life of the furnace body.

Owner:高俊杰

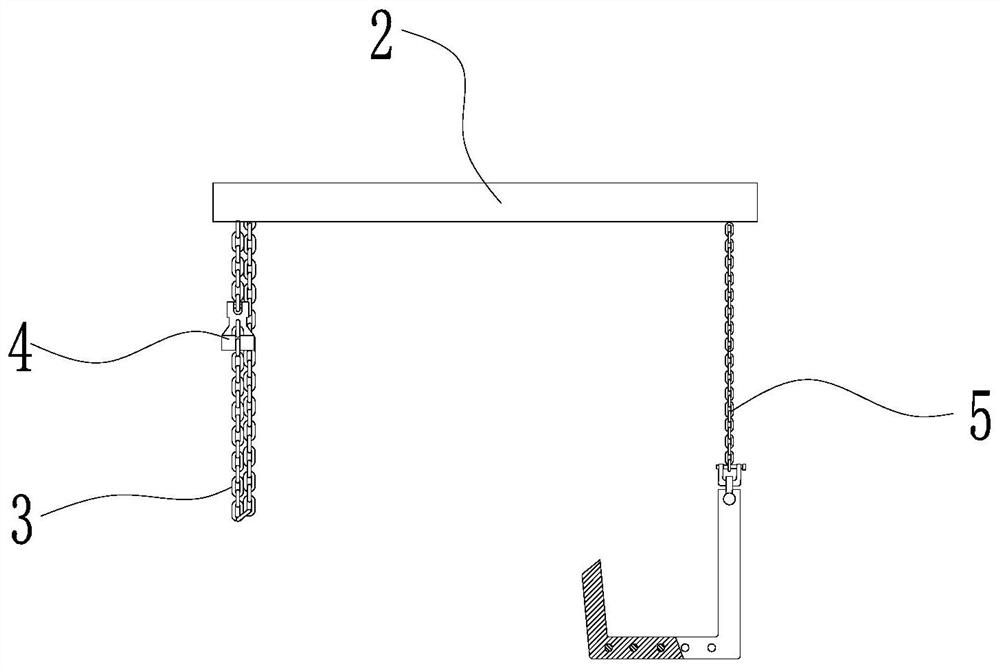

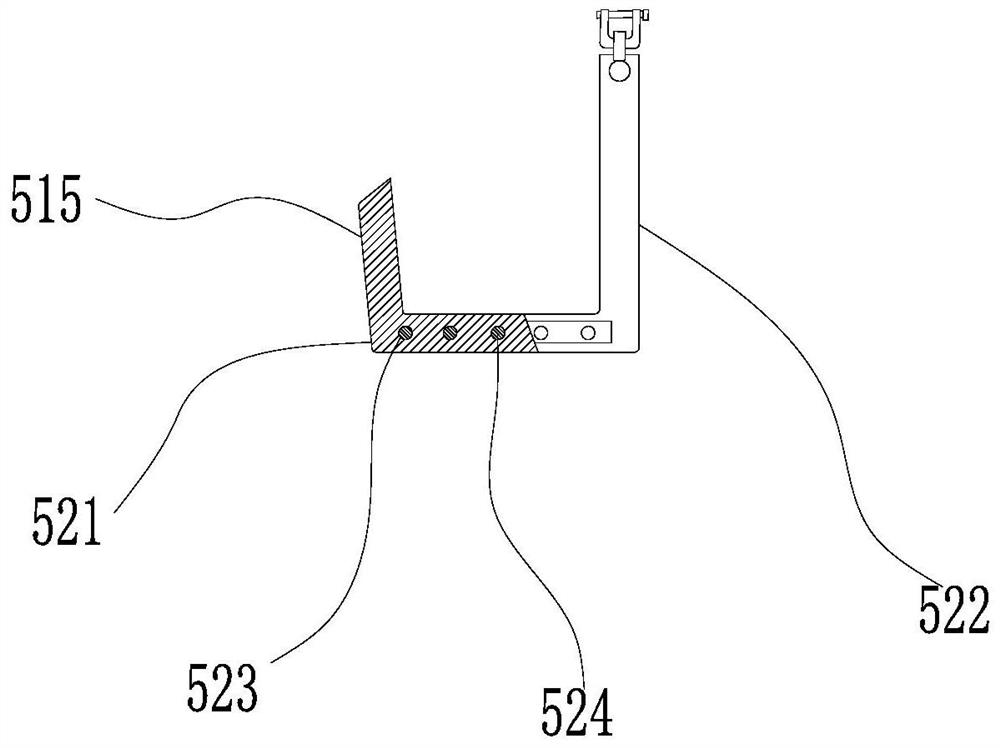

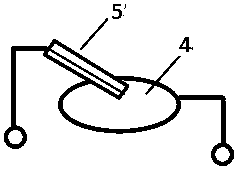

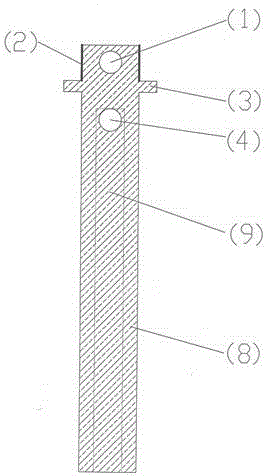

Quenching hoisting tool for special-shaped flange forge piece

ActiveCN113371589AEnsure safetyLess heat storageLoad-engaging elementsQuenching devicesEngineeringForge

The invention provides a quenching hoisting tool for a special-shaped flange forge piece, the influence on the quenching effect of the special-shaped flange forge piece can be reduced on the premise of ensuring the hoisting safety, and the invention relates to the technical field of hoisting tools. The quenching hoisting tool for the special-shaped flange forge piece comprises a hoisting beam, a first hoisting rope is arranged at one end of the hoisting beam, a flange hoisting tool is arranged at the other end of the hoisting beam, and the two ends of the first hoisting rope are connected with the hoisting beam after the first hoisting rope is bent to form a rod hoisting tool; and the flange hoisting tool comprises a first U-shaped hoisting hook, a second U-shaped hoisting hook, a second hoisting rope, a third hoisting rope and a tension piece. The quenching effect can be greatly improved by adopting the tool to hoist the special-shaped flange forge piece for quenching.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

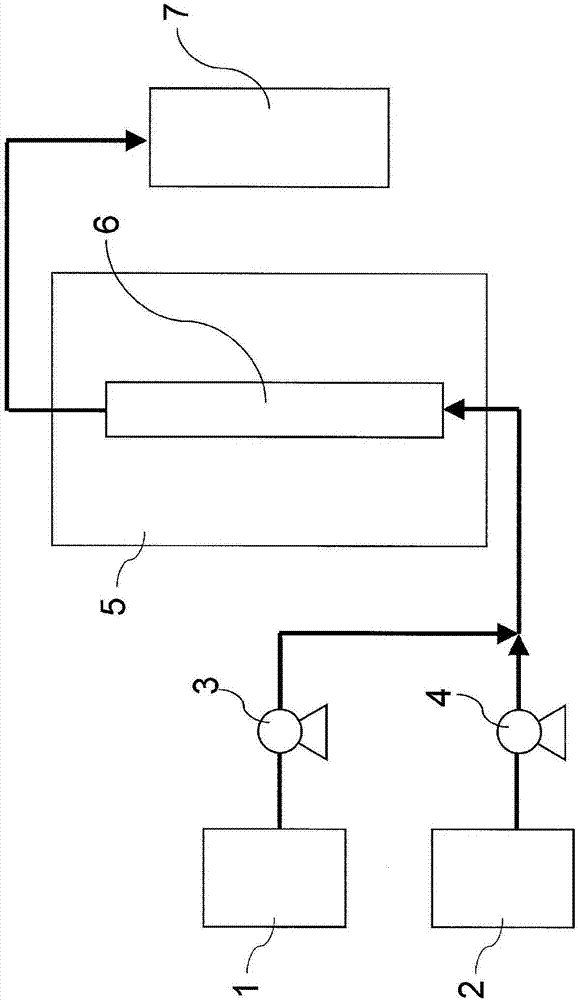

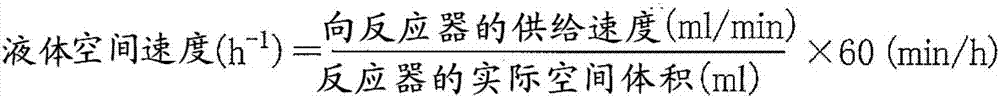

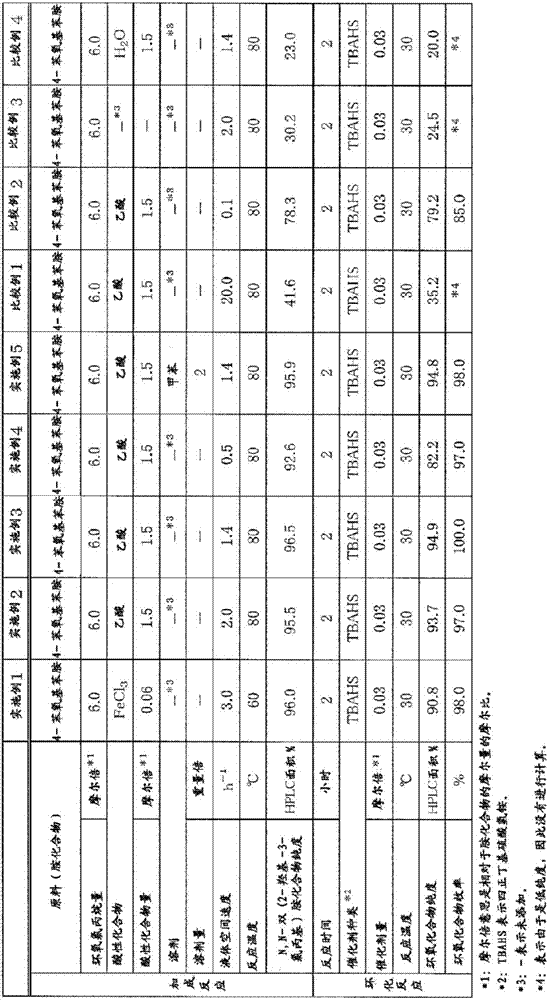

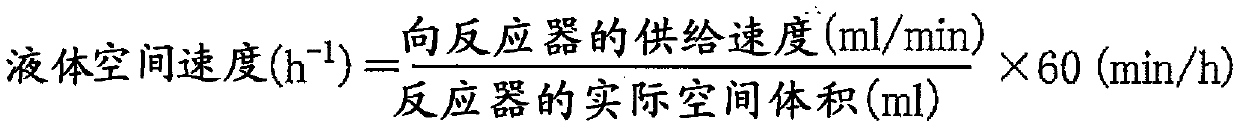

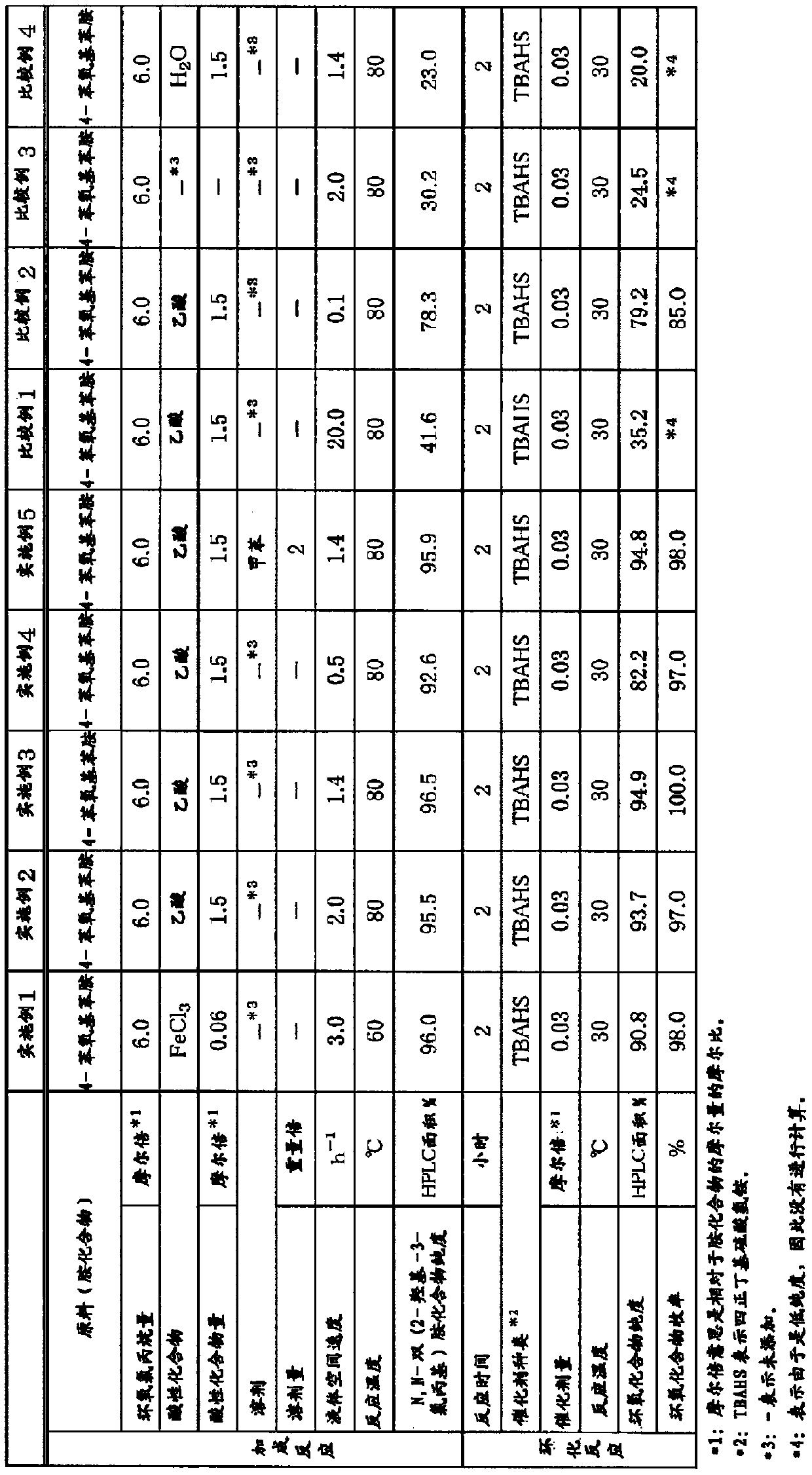

Method for producing compound having N,N-bis(2-hydroxy-3-chloropropyl)amino group

ActiveCN107207408AIncrease production capacityFacilitated DiffusionOrganic compound preparationOrganic chemistry methodsEpoxyReaction temperature

Provided is a method for efficiently and safely producing a compound having an N,N-bis(2-hydroxy-3-chloropropyl)amino group on an industrial scale. A compound having an N,N-bis(2-hydroxy-3-chloropropyl)amino group is produced by continuously supplying, to a flow type reactor, (1) an amine compound or a solution thereof, (2) epichlorohydrin or a solution thereof, and (3) an acidic compound or a solution thereof, and reacting the same at a reaction temperature of 40-130 degree centigrade and at a liquid space velocity of 0.2-10 h-1. The thus obtained compound having an N,N-bis(2-hydroxy-3-chloropropyl)amino group is reacted with an alkali followed by dehydrochlorination to thereby give a polyfunctional glycidylamine type epoxy compound.

Owner:TORAY FINE CHEMICALS CO LTD

An energy-saving roller kiln with low heat storage

ActiveCN105004185BReduce energy consumptionThe effect of blocking dirtFurnace componentsFurnace typesBrickThermal insulation

The invention relates to a kiln, in particular to an energy-saving roller kiln low in thermal storage. Roller hole bricks of the roller kiln are made of light aluminum silicate cellucotton. Kiln walls above the roller hole bricks comprise an upper kiln wall framework; a plurality of rows of lateral hanging brackets are arranged inside the upper kiln wall frameworks in the kiln length direction; each row of lateral hanging bracket is provided with a lateral hanging rail; high-temperature-resisting dense material boards are arranged between the lateral hanging rails. The lateral hanging brackets, the lateral hanging rails and the high-temperature-resisting dense material boards tension and fix multiple layers of refractory thermal-insulation light materials onto the upper kiln wall framework for sealing and thermal insulation. The kiln walls below the roller hole bricks comprise a lower kiln wall framework; one or more rows of lateral hanging brackets are arranged inside the lower kiln wall framework in the kiln length direction; each row of lateral hanging bracket is provided with a lateral hanging rail; high-temperature-resisting dense material boards are arranged between the lateral hanging brackets and / or between the lateral hanging brackets and the kiln bottom. The whole fire face in the energy-saving roller kiln low in thermal storage adopts thin and heavy refractory slabs to ensure the firm structure and the periphery is mainly light aluminum silicate cellucotton; thermal storage is low, the thermal insulation performance is good, and energy consumption is low.

Owner:MODENA TECH LTD

Silicon-based polymer filling material for coal mines, and preparation method thereof

InactiveCN110054748AAvoid destructionImprove flame retardant performancePlasticizerFilling materials

The invention discloses a silicon-based polymer filling material for coal mines, and relates to the technical field of filling materials for the coal mines. The silicon-based polymer filling materialis prepared from a component A and a component B through mixing, wherein the mass ratio of the component A to the component B is (1.2-1.6):1, the component A is prepared from water glass, a compositecatalyst, a foam stabilizer and a surfactant through mixing, and the component B is prepared from isocyanate, a flame retardant and a plasticizer through mixing. The invention also discloses a preparation method of the silicon-based polymer filling material for the coal mines. The silicon-based polymer filling material has the advantages of environment protection, adjustability in expansion times,low heat storage and self-extinguishing, solving the problems of poor environmental protection property, low tight-filling rate, high heat release and no flame retardance of current filling materialsfor the coal mines.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation method of large-size machinable fire-resistant heat-insulating plate

PendingCN112710153AHigh strengthImprove thermal shock resistanceMonolithic liningsThermal insulationXonotlite

The invention relates to a preparation method of a large-size machinable fire-resistant heat-insulating plate. According to the preparation method of the large-size machinable fire-resistant heat-insulating plate, the fire-resistant plate is prepared by taking silicon oxide as a main material, adding xonotlite whiskers or wollastonite mineral fibers with good compatibility with a main base material, and adding chopped ceramic fibers in an auxiliary mode for reinforcement and toughening. The plate not only has high strength and good thermal shock resistance of a quartz plate, but also has thermal insulation and machinability of a ceramic fiber product; the board has wood-like texture, and the machining precision is far superior to that of the fiber product; in addition, the plate is formed through wet filter pressing, and the large-size plate with the length being 2 m and the width being about 1 m can be obtained; and due to the fact that the size of the plate is large, when the plate serves as the counter-fire face of thermal equipment, attractiveness is achieved, chippings do not fall off, use and installation are more convenient and efficient, professionals are not needed, and rapid replacement can be achieved.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Kiln

InactiveCN106895706AReduce lossHigh utilization rate of waste heat recoveryCharge manipulationIncreasing energy efficiencyHeat lossesEnergy conservation

The invention provides a kiln which comprises a kiln body and a kiln furniture, wherein the kiln furniture can move in the kiln body and is used for placing objects to be fired; the kiln body comprises a furnace top and a side wall, which form a firing channel; the firing channel comprises a preheating zone, a firing zone and a cooling zone, which are communicated in order; a chimney is arranged on the side wall on the entry side of the preheating zone, and a waste heat channel extending along the direction of the firing channel is formed in the side wall; one end of the waste heat channel is communicated with the cooling zone, and the other end of the waste heat channel is communicated with the chimney; the chimney has extracting force for extracting the waste heat of the cooling zone back to the preheating zone through the waste heat channel for recycling. The kiln has the advantages of high recycling rate of waste heat and small heat loss, reduces noises, reduces electric energy loss, and saves energy.

Owner:STATE GRID FUJIAN DEHUA POWER SUPPLY

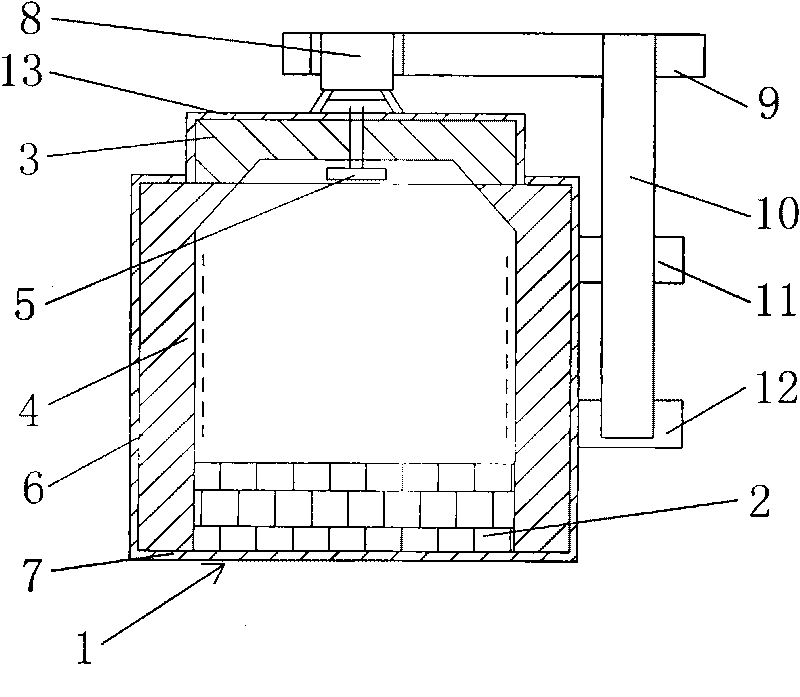

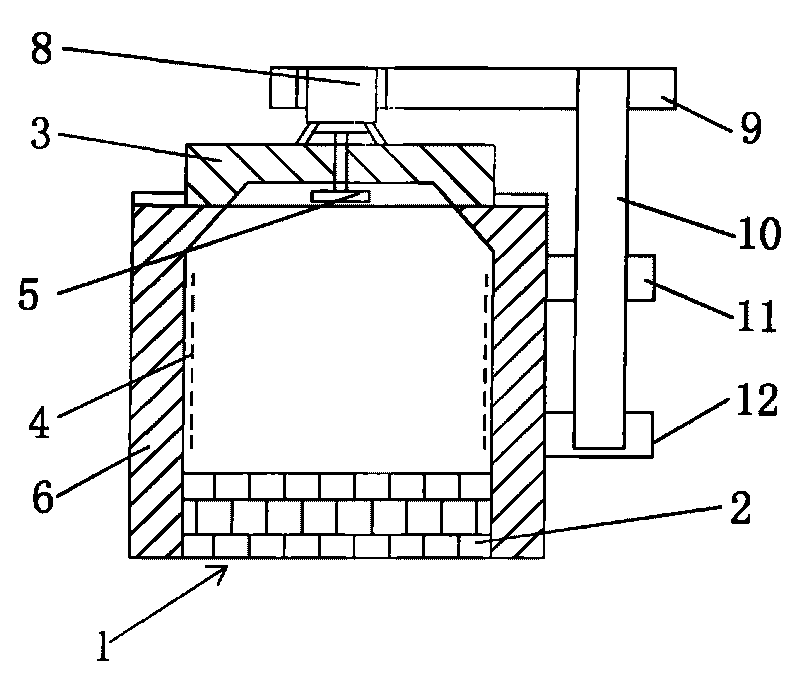

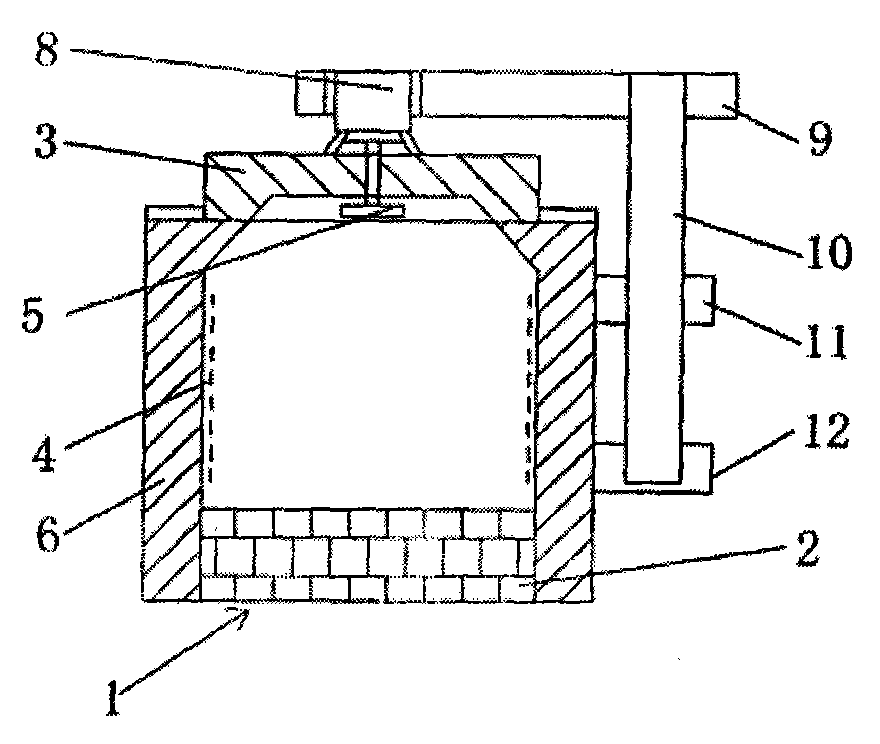

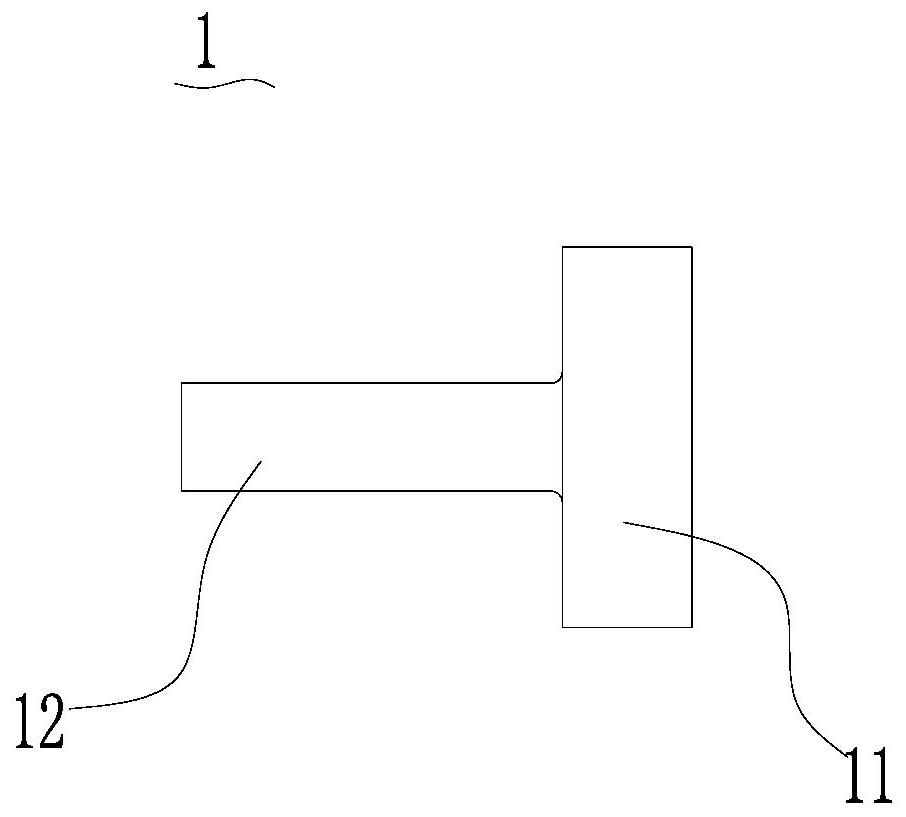

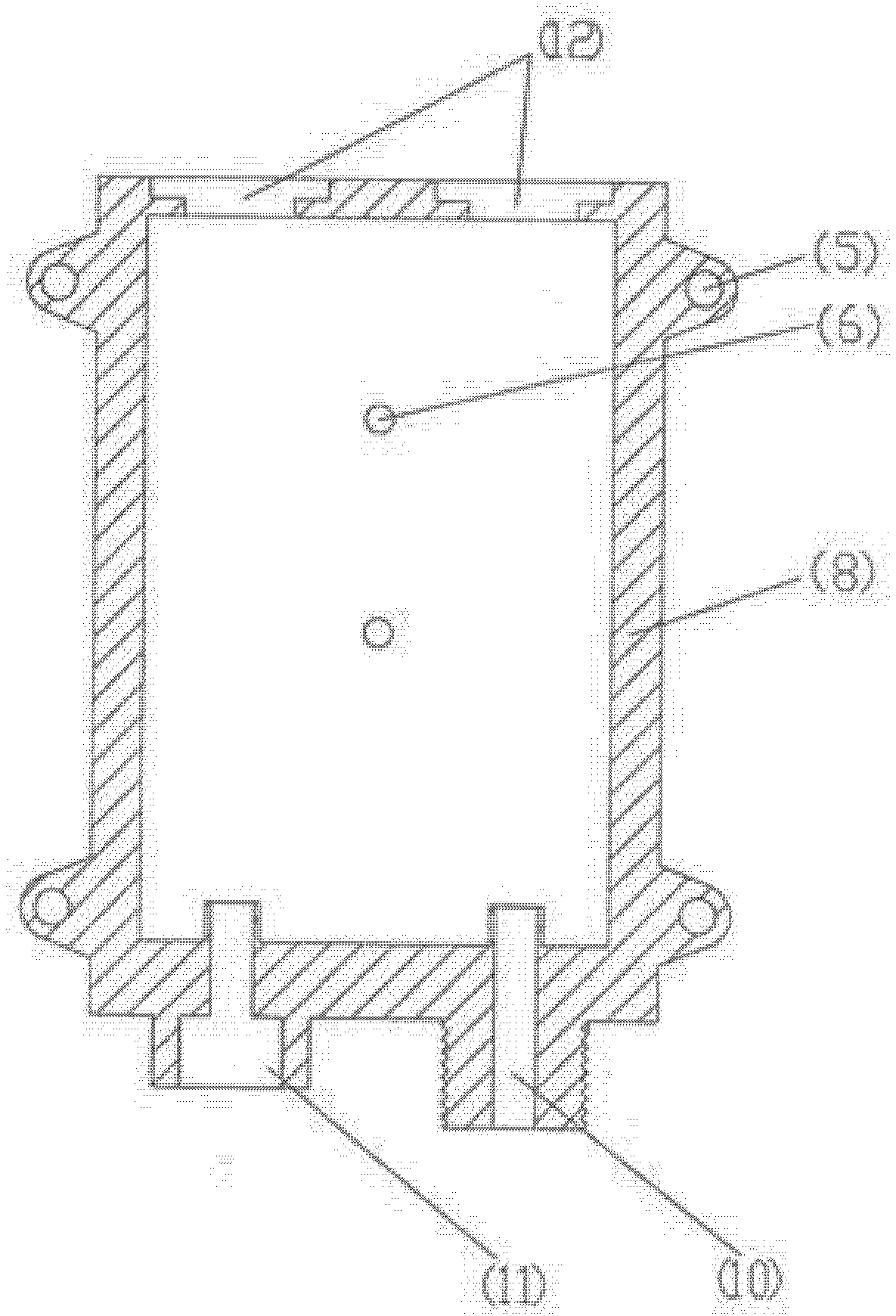

Box type heat treatment device

ActiveCN102560012AShorten heating timeSave heatFurnace typesElectric heating for furnacesThermal insulationElectric heating

The invention discloses a box type heat treatment device, which comprises a furnace body (5), a furnace body panel (6) and an electric heating wire belt (2). The inner side surface of the furnace body (5) is provided with a furnace lining (1), wherein the gap is arranged between the furnace lining (1) and the furnace body (5), and the material of the furnace lining (1) is high temperature resistant fiber cotton. The electric heating wire belt (2) is fixed on the furnace lining (1). With the technical scheme of the present invention, the furnace wall heat storage is reduced, such that the heating time of the blank furnace is shortened, the heat energy is saved, and the thermal insulation effect of the heat treatment furnace is improved; the phenomena similar to refractory brick structure oxidizing, re-qualitation, and the like are overcome, the performance of the device is stabilized, the service life of the device is prolonged, and the production cost is saved.

Owner:ANHUI NINGGUO XINNING IND

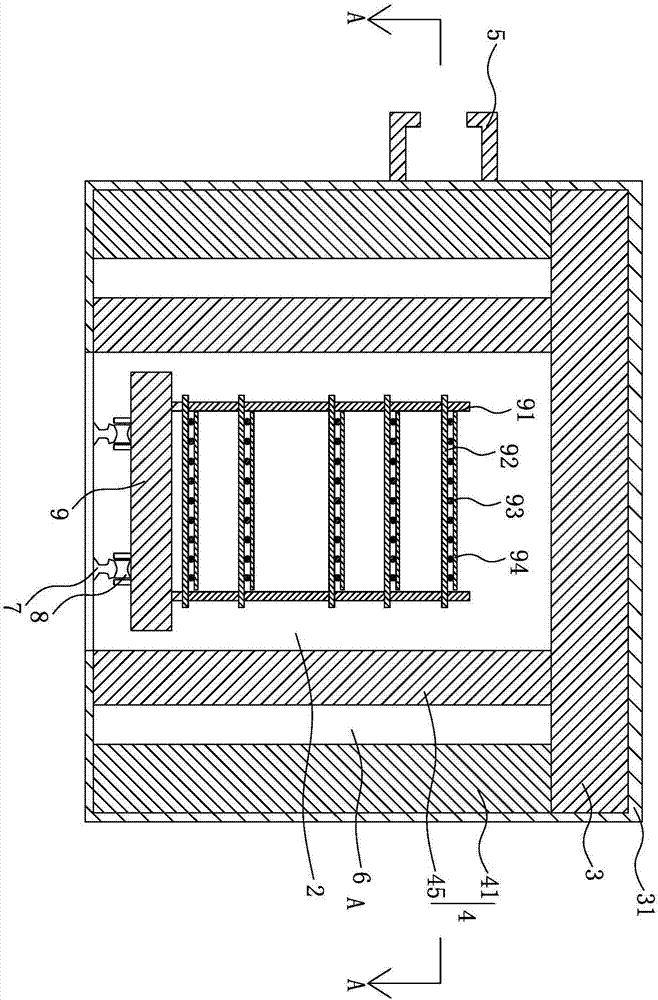

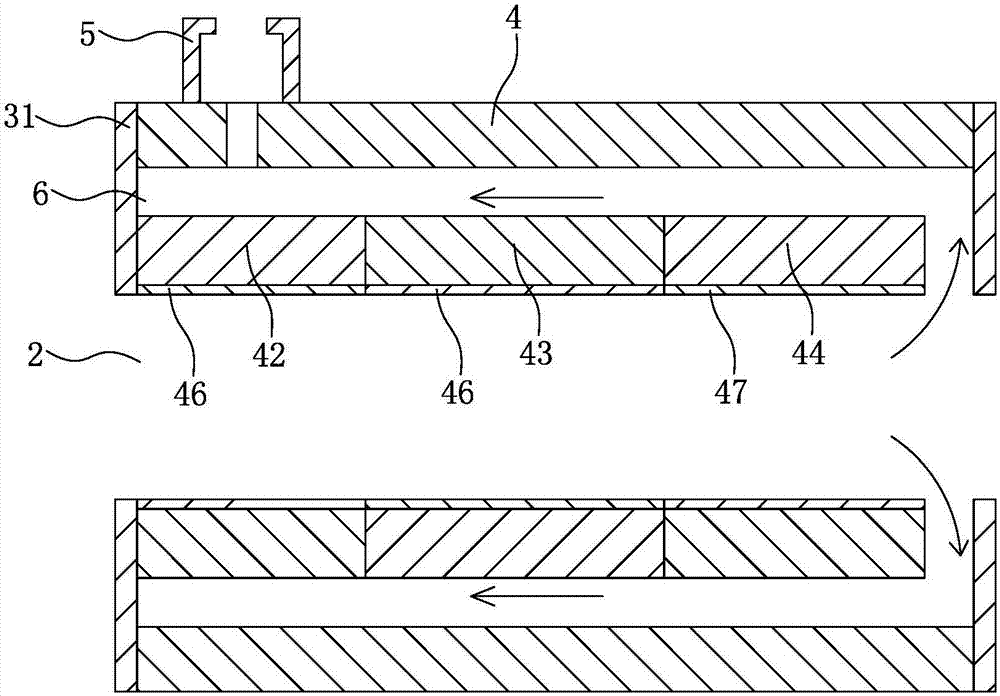

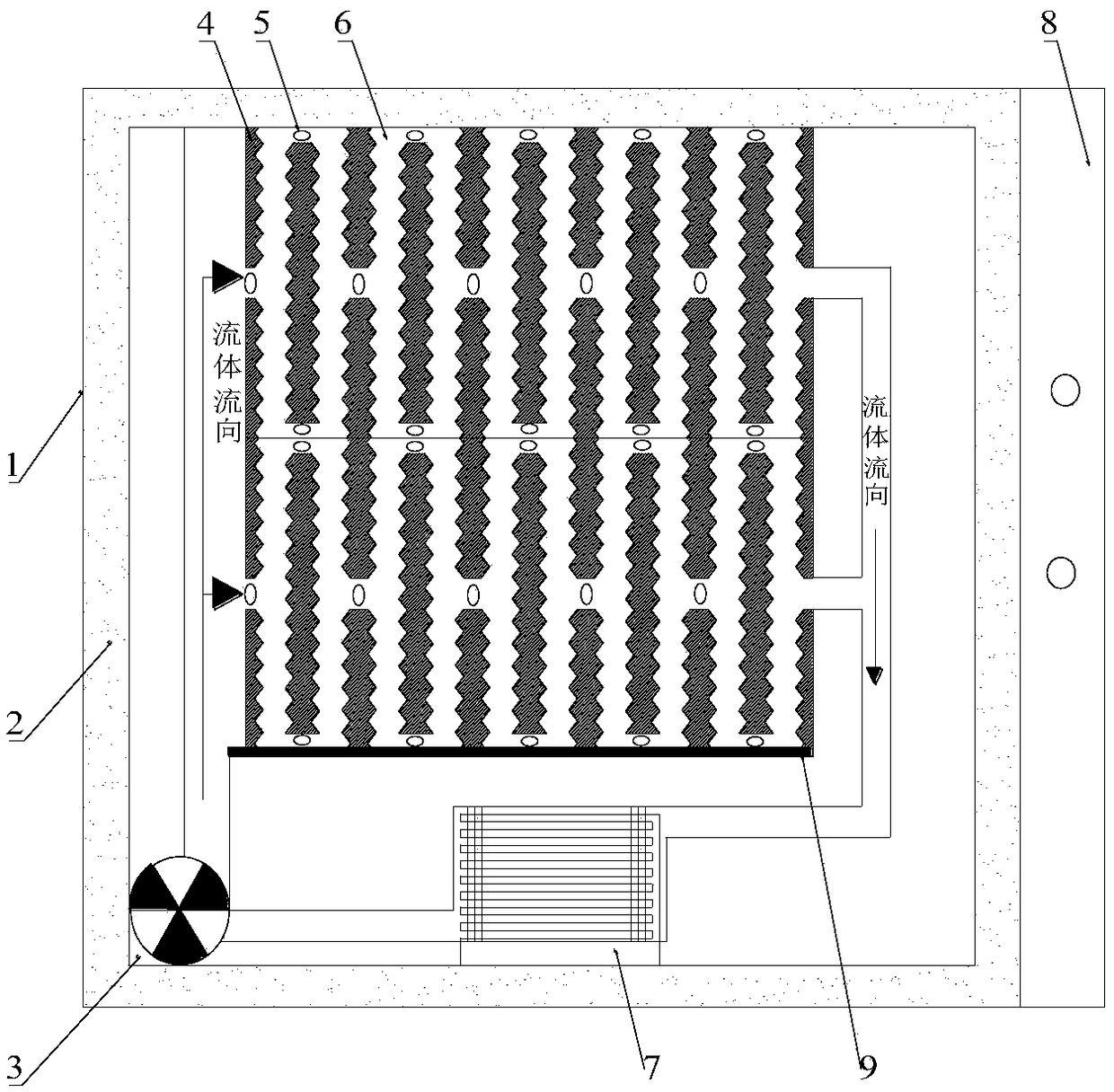

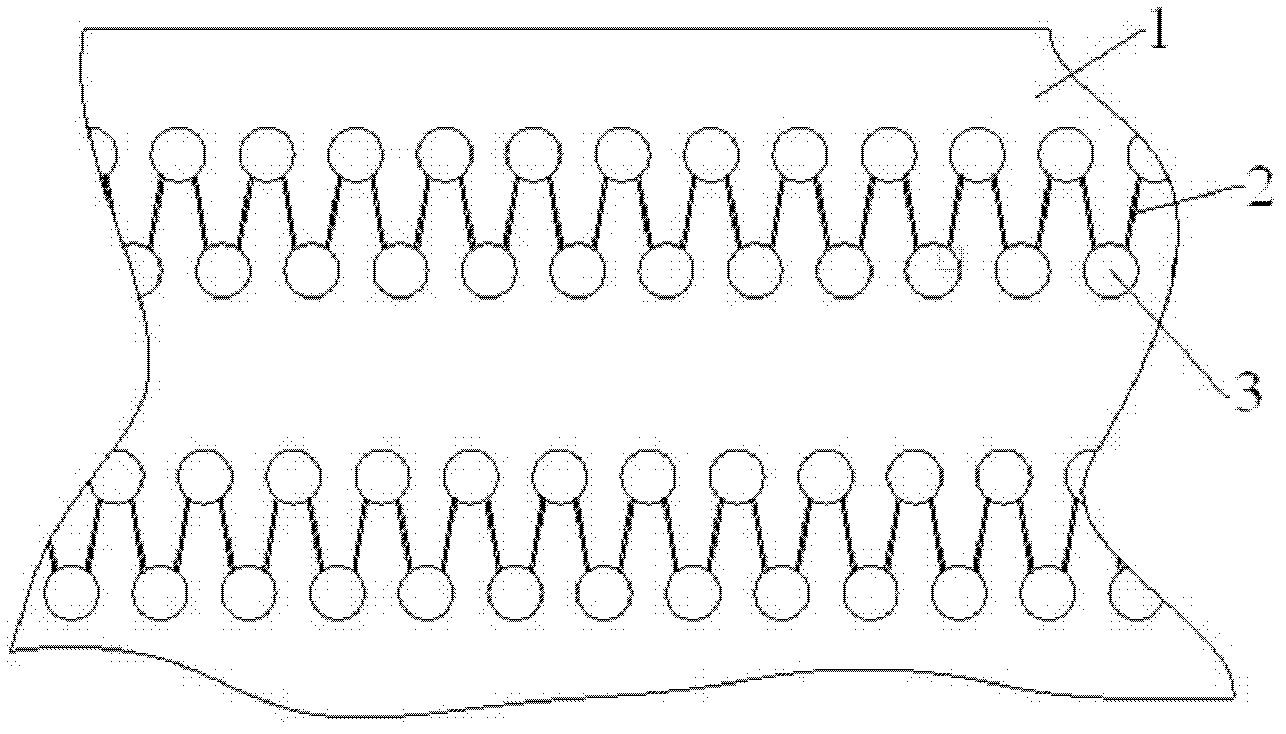

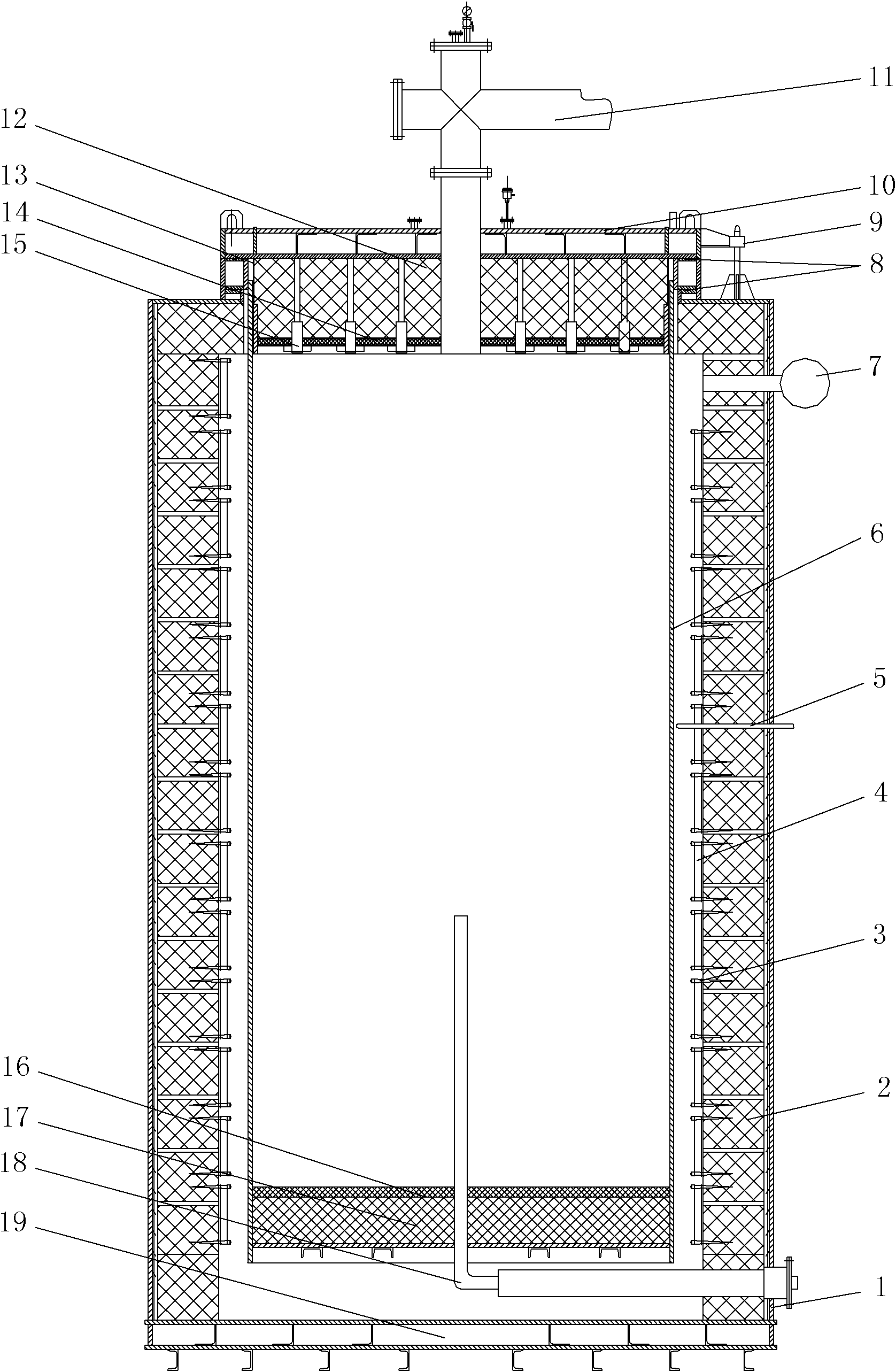

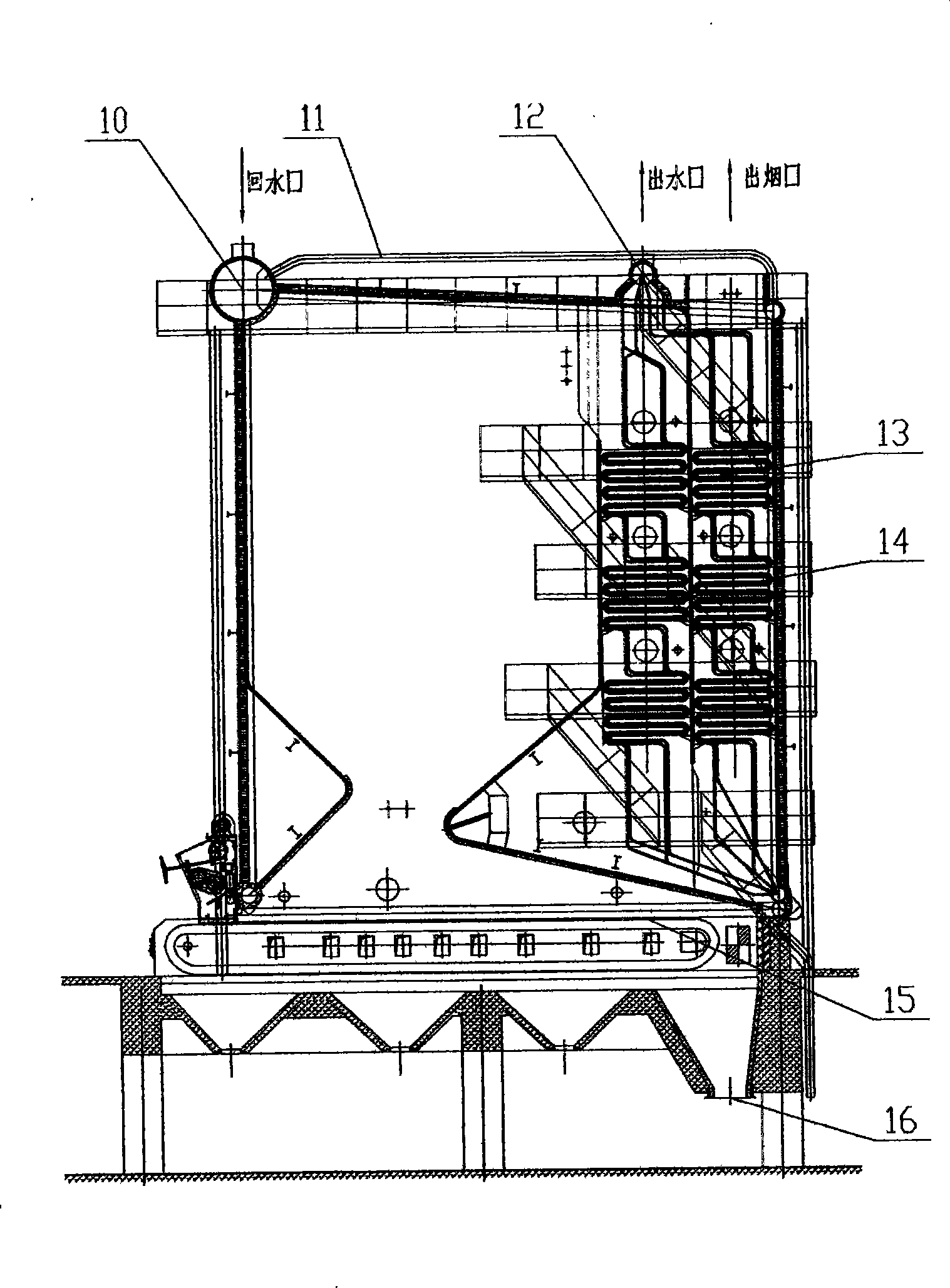

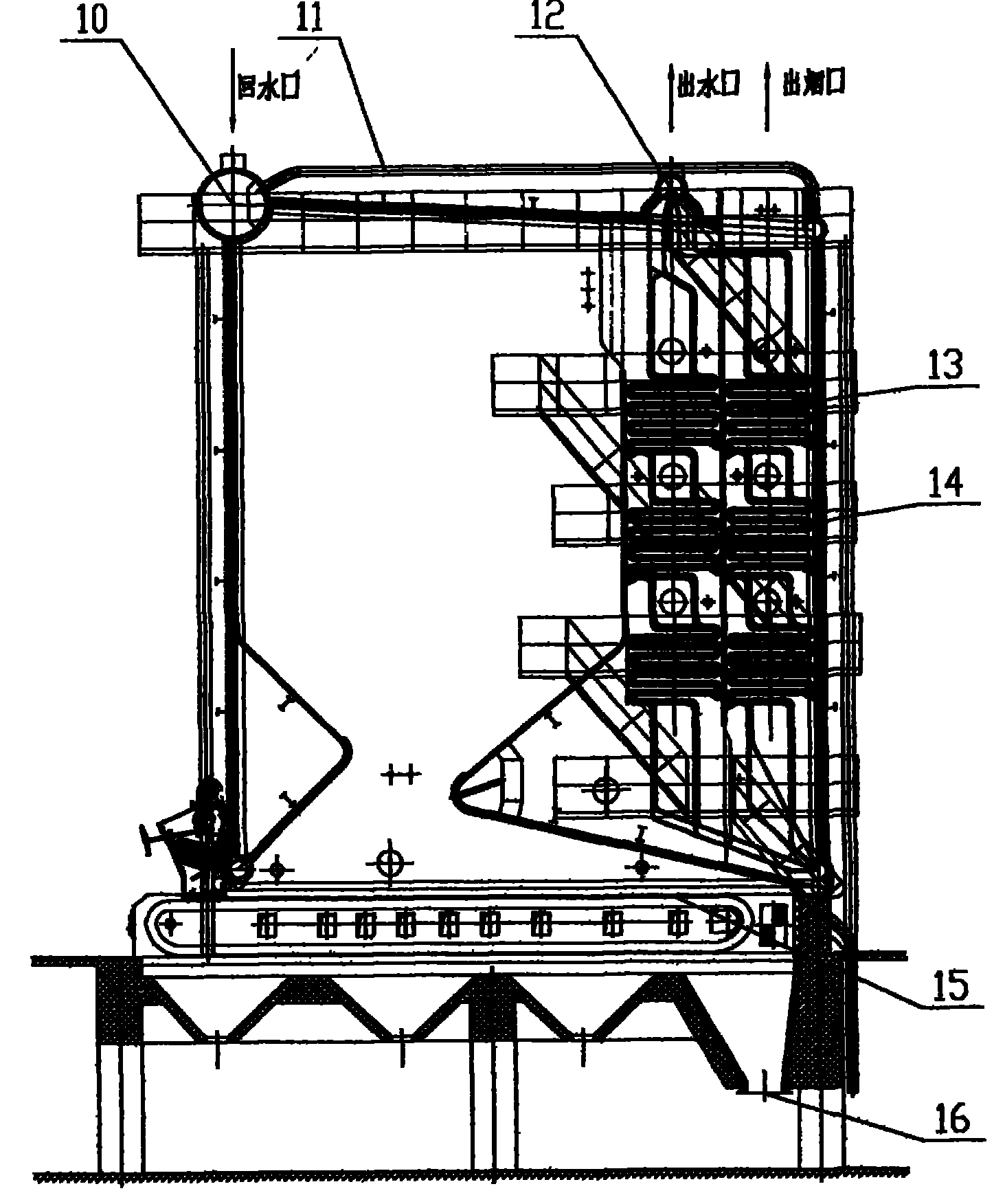

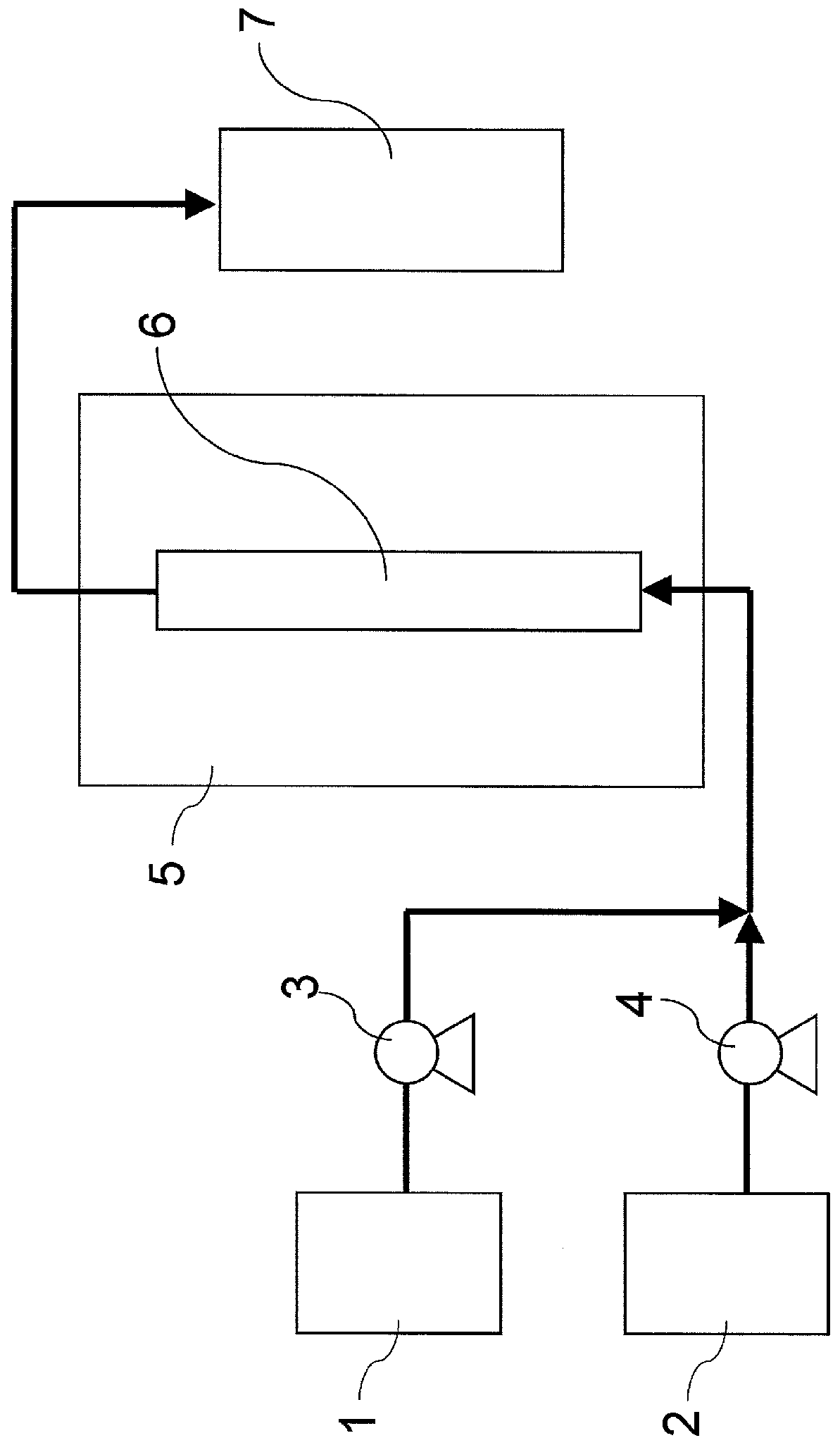

Reinforced heat transfer high-temperature phase-change heat storage type electric boiler

PendingCN109282494AImprove heating efficiencyReduce loadStorage heatersAutomatic controlElectric heating

The invention discloses a reinforced heat transfer high-temperature phase-change heat storage type electric boiler, and relates to the field of heating equipment. The reinforced heat transfer high-temperature phase-change heat storage type electric boiler structurally comprises a heat preservation shell, a circulating fan, a heat storage module, an electric heating element, an air-water heat exchanger, an automatic control system and a shell main body. The high-temperature phase-change heat storage type electric boiler can store heat at night at the electricity utilization valley and release the heat in the daytime at the electricity utilization peak, so that the load caused on a public power transmission line in the daytime is reduced, and the potential safety hazard is reduced under thecondition that the heating efficiency is improved. In the aspect of control, the high-temperature phase-change heat storage type electric boiler can also realize the switching use among three controlmodes of automatic control, manual operation control and remote control, and the intelligent control can be achieved on the fan heating output, a return water supply system and the heat storage module. According to the reinforced heat transfer high-temperature phase-change heat storage type electric boiler, besides an alarm function is achieved when an abnormal fault occurs to a system, an automatic abnormity processing function is also achieved so that the equipment safety can be guaranteed.

Owner:BEIJING UNIV OF TECH

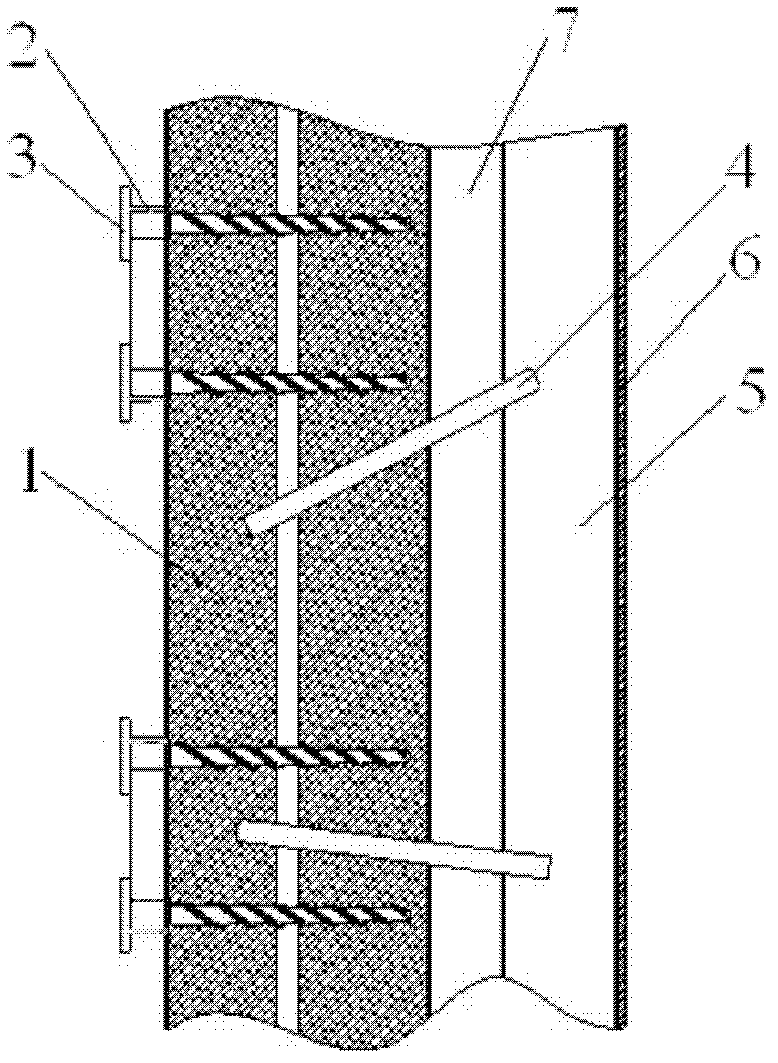

Energy saving kiln for preventing ash contamination and with low heat storage

ActiveCN107131760AAvoid direct flushingWill not polluteFurnace typesCeramic materials productionFiberProcess engineering

The invention discloses an energy saving kiln for preventing ash contamination and with low heat storage. The kiln comprises a kiln door, a kiln crown and side walls, and is characterized in that light insulation cottons are arranged on the kiln door, the kiln crown and the side walls; heavy refractory insulation plates are arranged on a fire seeing surface in the kiln; the refractory insulation plates adopt hollow structures, and are formed by splicing insulation plates; heavy refractory guide rails are arranged between upper and lower adjacent insulation plates; the insulation plates are inserted in chucks on the upper and lower sides of the refractory guide rails; and refractory fixed pieces connected with a kiln body are arranged at the middle parts of the refractory guide rails. The kiln crown, the kiln walls and the kiln door adopt all-cotton structures; the heavy refractory insulation plates are added on the internal fire seeing surface and the tabletop of a kiln car insulated by light materials at the bottom for preventing direct scouring of the wall fiber cottons by flame. Thus, even if fibers are pulverized and loosened to fall, due to stop by the refractory plates, products cannot be polluted. The kiln saves the energy, and solves the ash contamination problem.

Owner:DLT TECH CO LTD

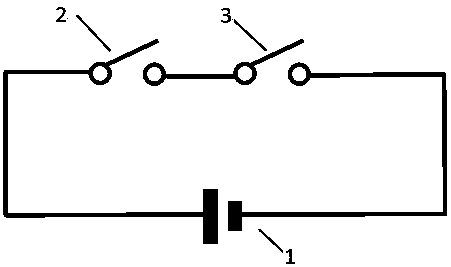

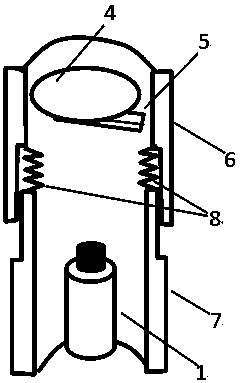

Temperature-controlled erasing device for friction-erase pens

The invention discloses a temperature control erasing device used for a friction easy-to-erase pen, and relates to the field of de-coloration of thermosensitive ink, in particular to erasing of scripts written by the friction easy-to-erase pen for students. Aiming to prevent paper from being broken, according to the technical scheme, the temperature control erasing device for the friction easy-to-erase pen is characterized in that a power supply is in series connection with two switches, namely, a normally-closed temperature control switch and a normally-open power switch in a power-off state at normal times; the temperature control switch consists of a heating resistor disc and a dual-metal sheet; the heating resistor disc generates heat when being electrified; when the dual-metal sheet is up to a designed temperature, a circuit is disconnected; the designed temperature is 55 to 70 DEG C. The temperature control erasing device has the beneficial effects that the surface of the paper does not need to be abraded, so that the paper is protected from being broken; the use of an eraser is reduced, so that social resources are saved; the device can be used separately, can be attached to the friction easy-to-erase pen to use, and can be detached, so that the device is economical and practical; the device is low in cost, is easy to make, and is convenient and easy to use.

Owner:SICHUAN UNIV

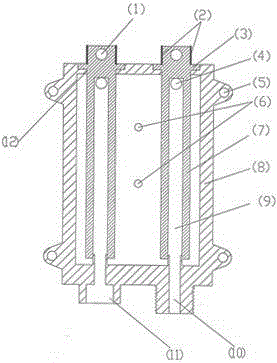

Box type heat treatment device

ActiveCN102560012BLess heat storageShorten heating timeFurnace typesElectric heating for furnacesFiberHeating time

The invention discloses a box type heat treatment device, which comprises a furnace body (5), a furnace body panel (6) and an electric heating wire belt (2). The inner side surface of the furnace body (5) is provided with a furnace lining (1), wherein the gap is arranged between the furnace lining (1) and the furnace body (5), and the material of the furnace lining (1) is high temperature resistant fiber cotton. The electric heating wire belt (2) is fixed on the furnace lining (1). With the technical scheme of the present invention, the furnace wall heat storage is reduced, such that the heating time of the blank furnace is shortened, the heat energy is saved, and the thermal insulation effect of the heat treatment furnace is improved; the phenomena similar to refractory brick structure oxidizing, re-qualitation, and the like are overcome, the performance of the device is stabilized, the service life of the device is prolonged, and the production cost is saved.

Owner:ANHUI NINGGUO XINNING IND

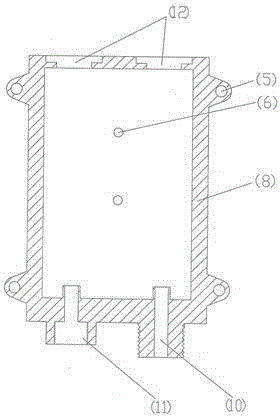

Large resistive double-vacuum gas-phase carbon deposition device

ActiveCN102020482BSolve the deformationExtended service lifeChemical vapor deposition coatingFiberGas phase

Owner:XIAN CHAOMA SCI TECH

Ceramic electric heating liner

Owner:PUTIAN QINGHUAYUAN ELECTRICAL APPLIANCE DEV

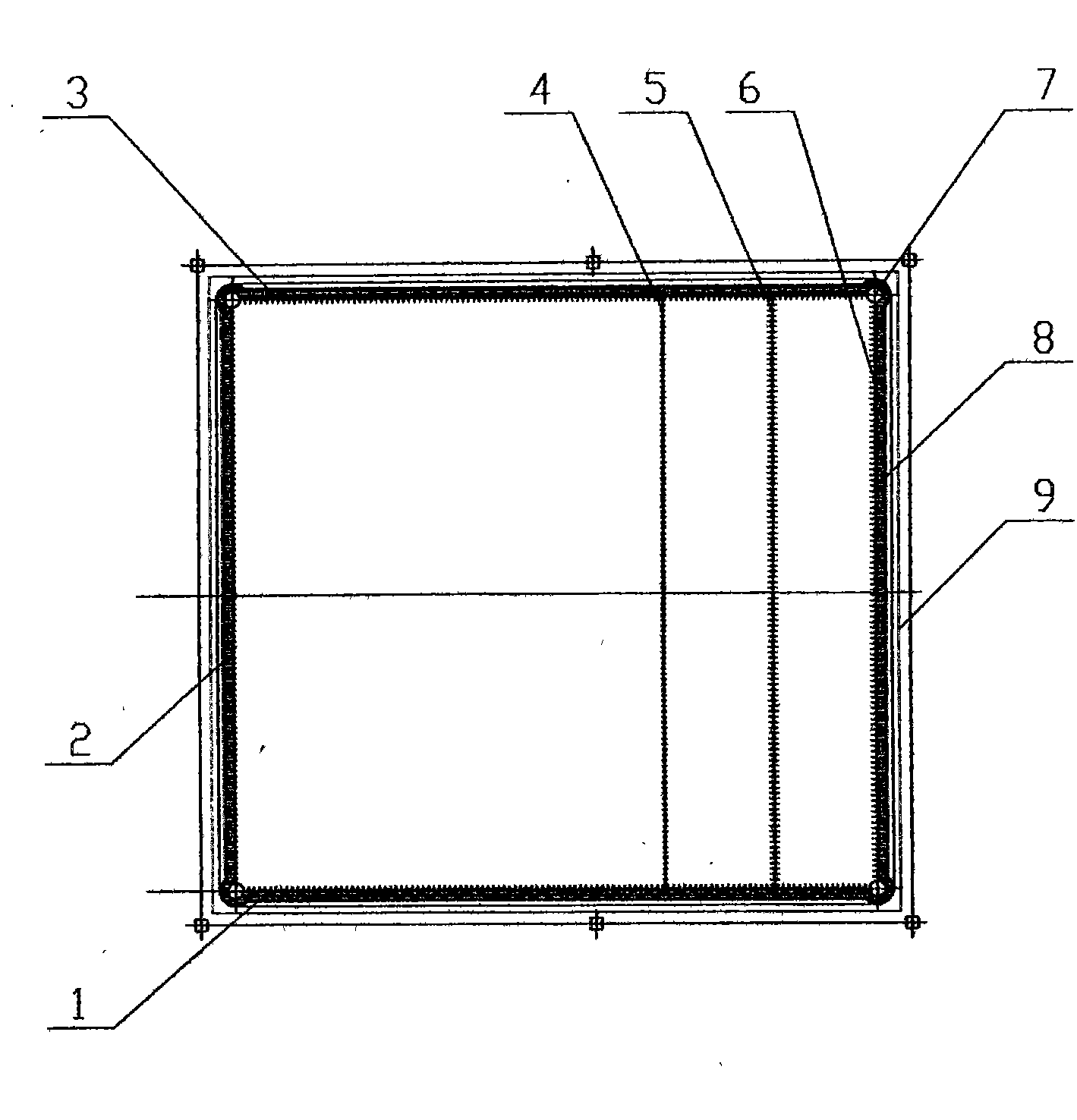

Full film type wall angle pipe hot water boiler

Owner:鞍山锅炉厂有限公司

Production method of compound having n,n-bis(2-hydroxy-3-chloropropyl)amino group

ActiveCN107207408BIncrease production capacityFacilitated DiffusionOrganic compound preparationOrganic chemistry methodsEpoxyReaction temperature

The present invention provides a method for efficiently and safely producing a compound having an N,N-bis(2-hydroxy-3-chloropropyl)amino group on an industrial scale. (1) amine compound or its solution, (2) epichlorohydrin or its solution, and (3) acidic compound or its solution are continuously supplied to the flow reactor, at a reaction temperature of 40 to 130°C and a liquid space velocity of 0.2 ~10h ‑1 It was reacted under to produce a compound having N,N-bis(2-hydroxy-3-chloropropyl)amino group. In addition, the obtained compound having an N,N-bis(2-hydroxy-3-chloropropyl) amino group is reacted with a base to dehydrochlorinate it, thereby producing a polyfunctional glycidylamine-type epoxy compound.

Owner:TORAY FINE CHEMICALS CO LTD

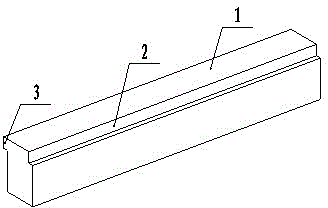

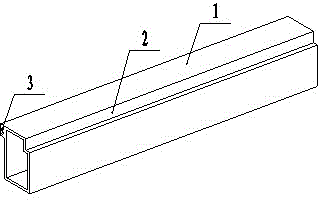

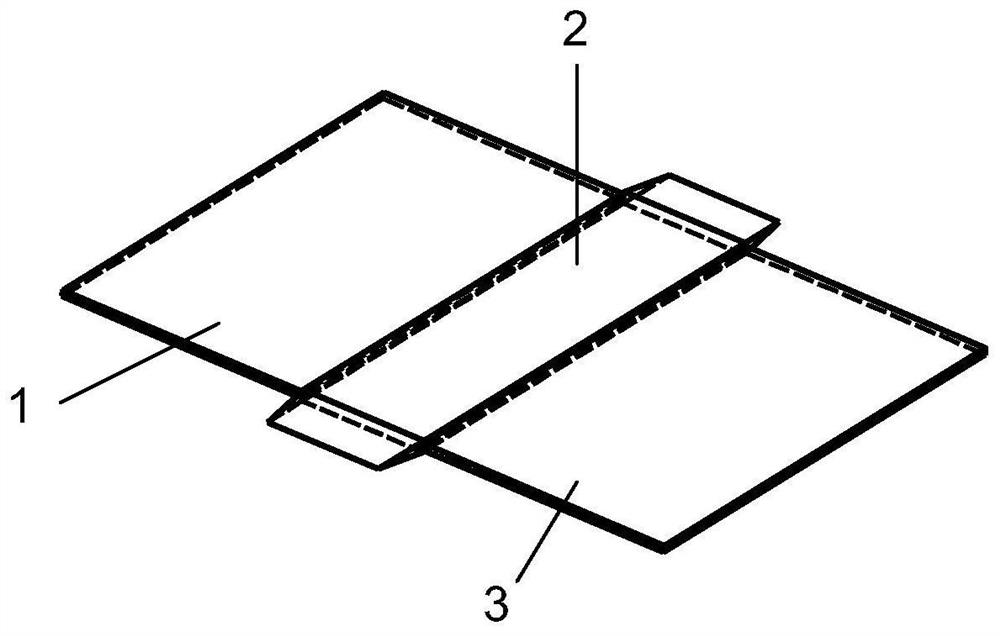

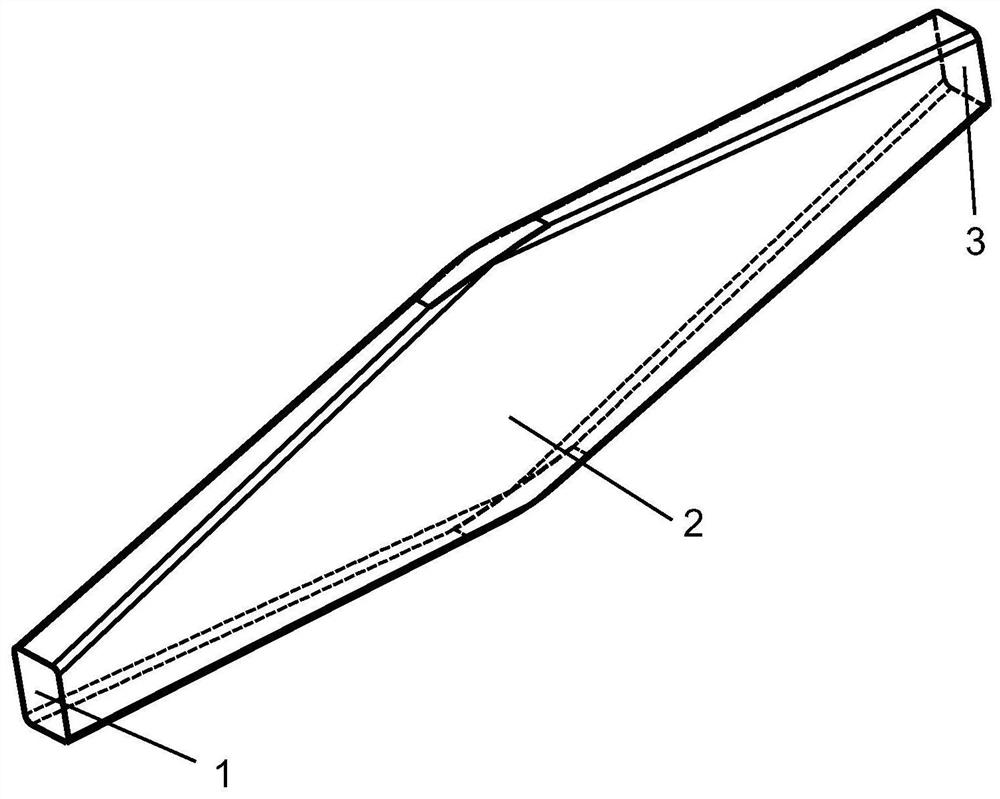

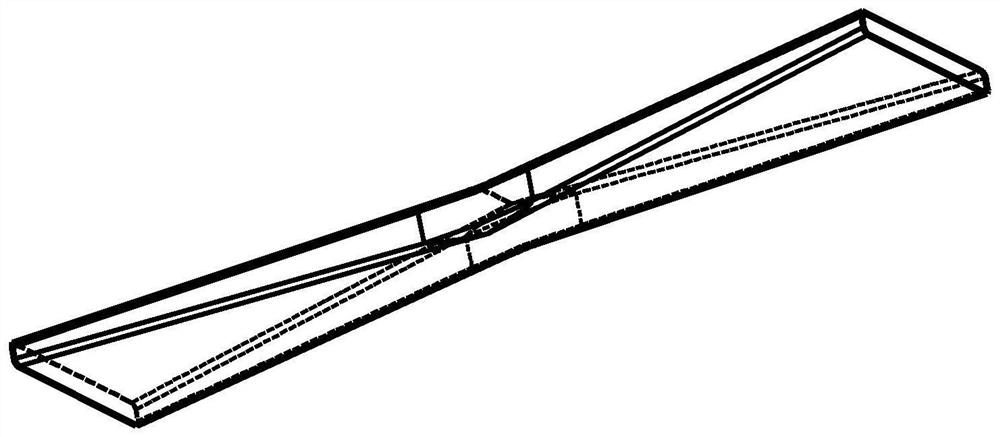

Kiln crown component of kiln

The invention provides a kiln crown component of a kiln, and belongs to the technical field of kiln crown bricks of kilns. The kiln crown component of the kiln is light in weight, convenient to install, and has long service life. The technical scheme is that a groove is arranged at one side of the top of a main body beam, and a bump in match with the groove in size and shape is arranged at the other side of the top of the main body beam; the main body beam is hollow, or solid; the bump is hollow, or solid; the main body beam is a quadrate beam; a circular tube is arranged in an internal cavity of the hollow main body beam; the circular tube is connected with the internal wall of the hollow main body beam through at least one reinforcing rib plate; the main body beam is a plate-shaped beam; at least one upright separating plate is distributed in the internal cavity of the hollow main body beam; a reinforcing rib is arranged in a cavity which is formed between the internal wall of the hollow main body beam and the upright separating plate; and the top or the bottom of the main body beam is flat or arched. The kiln crown component is especially suitable for building the kiln crowns of industrial kilns.

Owner:韩城腾龙陶瓷有限公司

Ceramic electric heating liner

The invention discloses a ceramic electric heating liner, and relates to the field of electric heating technology. The ceramic electric heating liner mainly comprises a cast aluminum main body and ceramic heating pipes, wherein the cast aluminum main body comprises a temperature controller installing seat, a main body fixing hole, a heating pipe installing seat, a water inlet and a water outlet, wherein each ceramic heating pipe comprises a water channel, a flow guide hole, a flange, a power wiring column, and an ultra-temperature probing hole, when the ceramic heating pipe is electrified to run, the heated water flows from the water inlet through the water channel and the flow guide hole of the ceramic heating pipe to a chamber body of the cast aluminum main body, and then flows to the water outlet through the flow guide hole and the water channel of another ceramic heating pipe; the water is heated at a high speed, so that hot water can be supplied, and the purposes of heating at a high speed, isolating water and electricity and resisting corrosion are achieved.

Owner:PUTIAN QINGHUAYUAN ELECTRICAL APPLIANCE DEV

A Gradient Tab with Nearly Equal Cross-sectional Area

ActiveCN108123091BIncrease the effective heat conduction cross-sectional areaSpeed up exportCell component detailsMechanical engineeringContact plane

The invention discloses a near-equal-sectional-area gradual-change tab, which includes a tab body, the tab body includes a sealing area in the middle, and lead-in ends and lead-out ends respectively arranged on both sides of the seal area, the lead-in end There is a gradual change to the middle of the sealing area, and the gradual change from the lead-out end to the middle of the sealing area is also a gradual change of nearly equal cross-sectional area, and the range of gradual change of the near-equal cross-sectional area is controlled within 30%. Through the present invention, the effective cross-sectional area of the tab heat conduction can be increased to improve the thermal conductivity of the tab; the effective conductive cross-sectional area of the tab can be increased to reduce the internal resistance of the tab; the shape of the tab can be changed to reduce the packaging under the condition of nearly equal cross-section Difficulty; the thickness and shape of the outer lead-out end of the tab can be increased, and the mechanical strength and contact area can be enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com