Large resistive double-vacuum gas-phase carbon deposition device

A vacuum device and resistive technology, applied in the direction of gaseous chemical plating, coating, metal material coating process, etc., can solve the problems of low manufacturing cost and low energy consumption, and achieve long service life, less heat storage, The effect of shortening the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

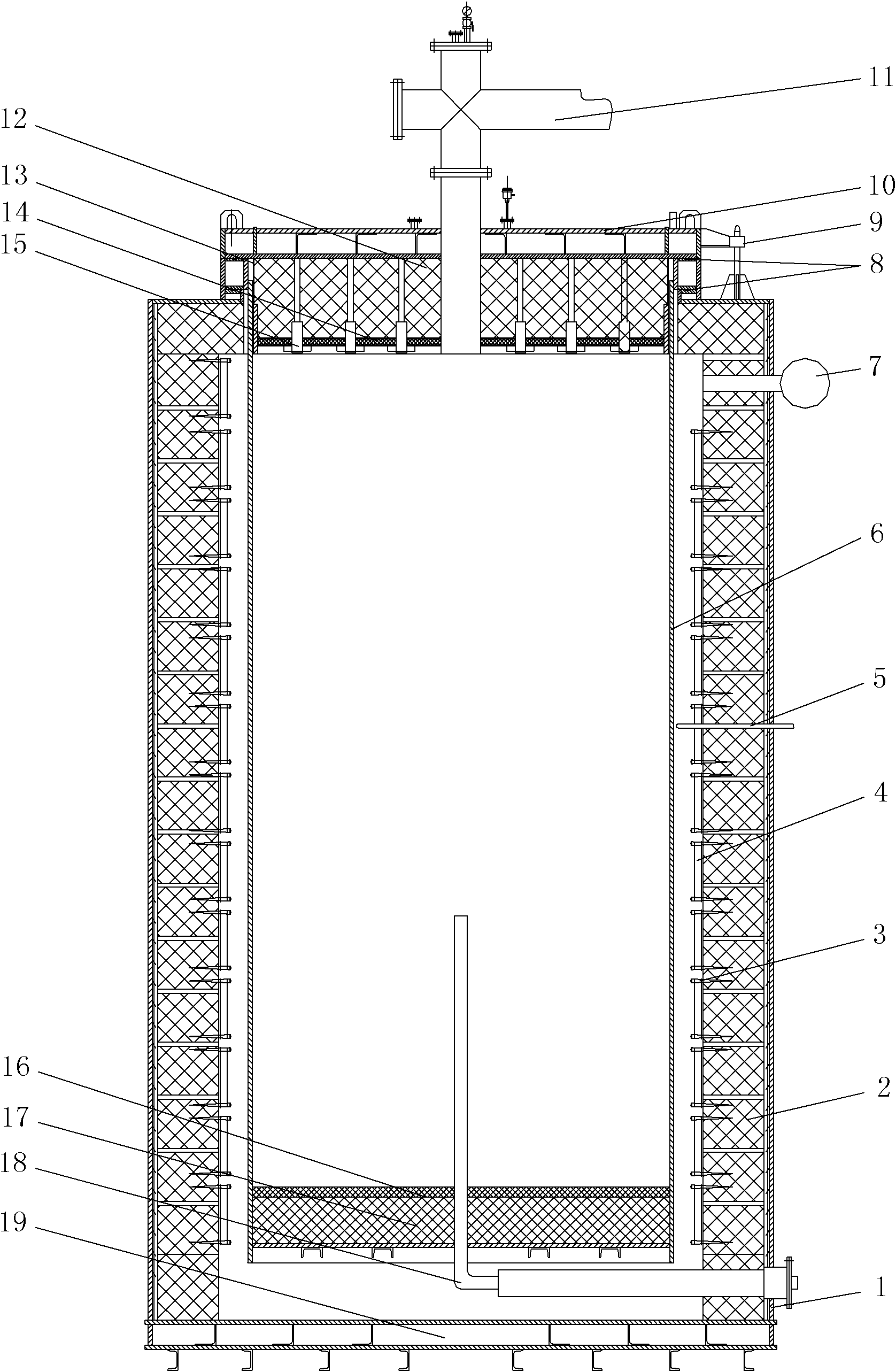

[0035] Such as figure 1 As shown, the present invention comprises a furnace outer tank 1, a ceramic fiber lining 2 arranged on the inner wall of the furnace outer tank 1, a plurality of nickel-chromium heating belts 4 suspended and fixed on the inside of the ceramic fiber furnace lining 2 by a suspension device, and the outer furnace tank 1 Internally communicated vacuum pipeline-7, a temperature detection unit arranged inside the outer furnace tank 1 and for real-time detection of the internal temperature of the furnace outer tank 1, a control cabinet electrically connected to the temperature detection unit, coaxial from top to bottom The furnace inner tank 6 that is set in the furnace outer tank 1 and the lower part is suspended, the air inlet pipe 18 inserted into the furnace inner tank 6 from bottom to top, the vacuum pipeline 2 11 communicating with the furnace inner tank 6 and the furnace inner tank 6 The sealed furnace cover on the top, the outer ends of the vacuum pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com