Ceramic electric heating liner

A ceramic heating and ceramic technology, applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve problems such as leakage accidents, inconvenient maintenance, complex structure, etc., and achieve the effect of less heat storage, simple structure, and continuous supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

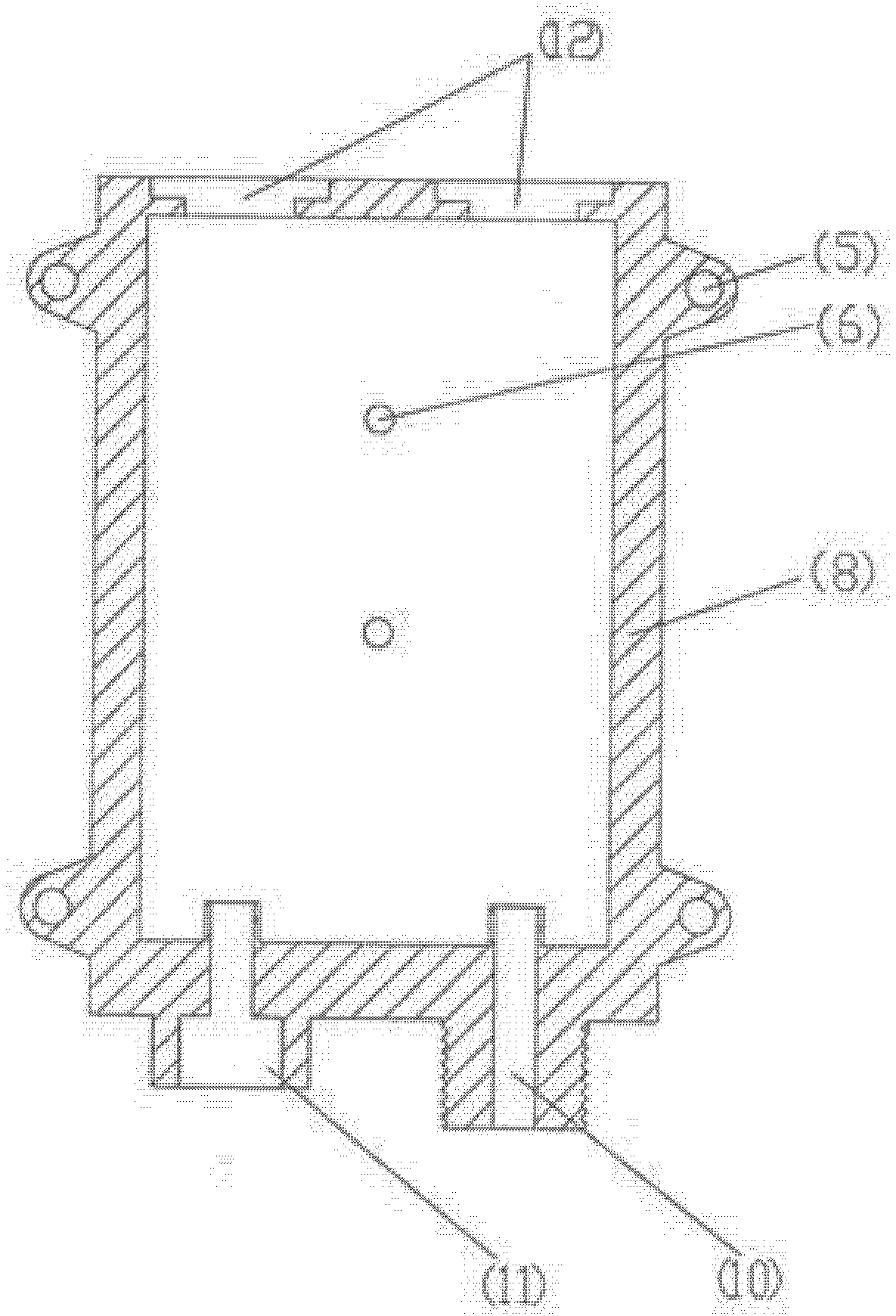

[0015] see figure 1 , figure 2 , image 3 , Figure 4 , the cast ceramic electric heater of the present invention includes a cast aluminum body ⑻, a ceramic heating tube ⑺, the cast aluminum body ⑻ includes a thermostat mounting seat ⑹, a body fixing hole ⑸, a heating pipe mounting seat ⑿, a water inlet ⑽, an outlet Nozzle ⑾, the ceramic heating tube ⑺ includes water channel ⑼, diversion hole ⑷, flange ⑶, power supply terminal ⑵, over-temperature detection hole ⑴, when the ceramic heating tube ⑺ is connected to the power supply, water flows through the water inlet ⑽ Ceramic heating tube⑺water passage⑼, diversion hole⑷ to the cavity of the cast aluminum body⑻, and then through another ceramic heating pipe⑺ diversion hole⑷, water channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com