Hydrogen gas sensor with concentration function and hydrogen gas sensor probe used in same

A sensor probe, sensor technology, used in instruments, scientific instruments, analyzing gas mixtures, etc., can solve problems such as loss of hydrogen selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

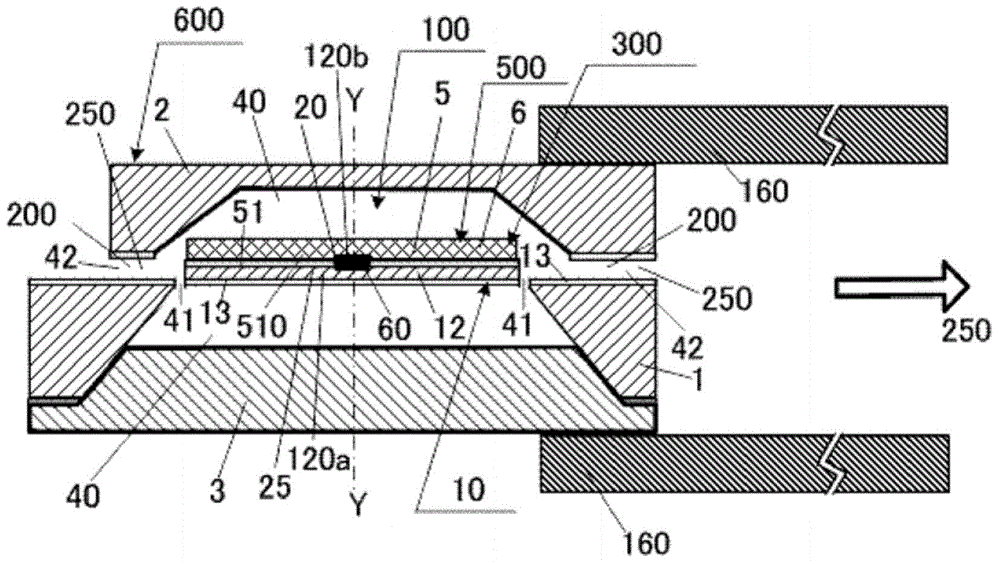

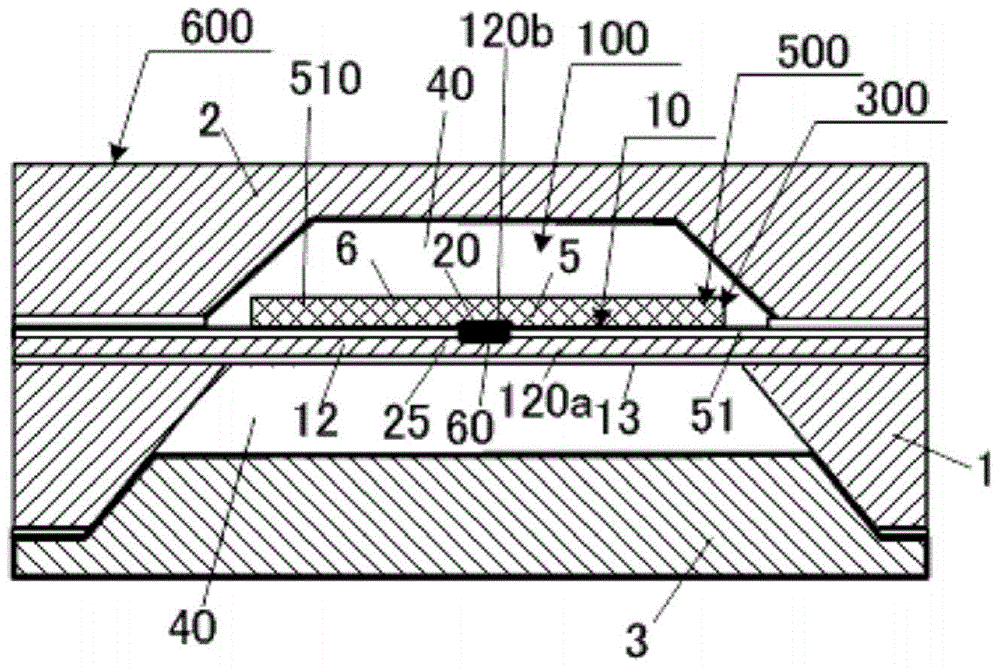

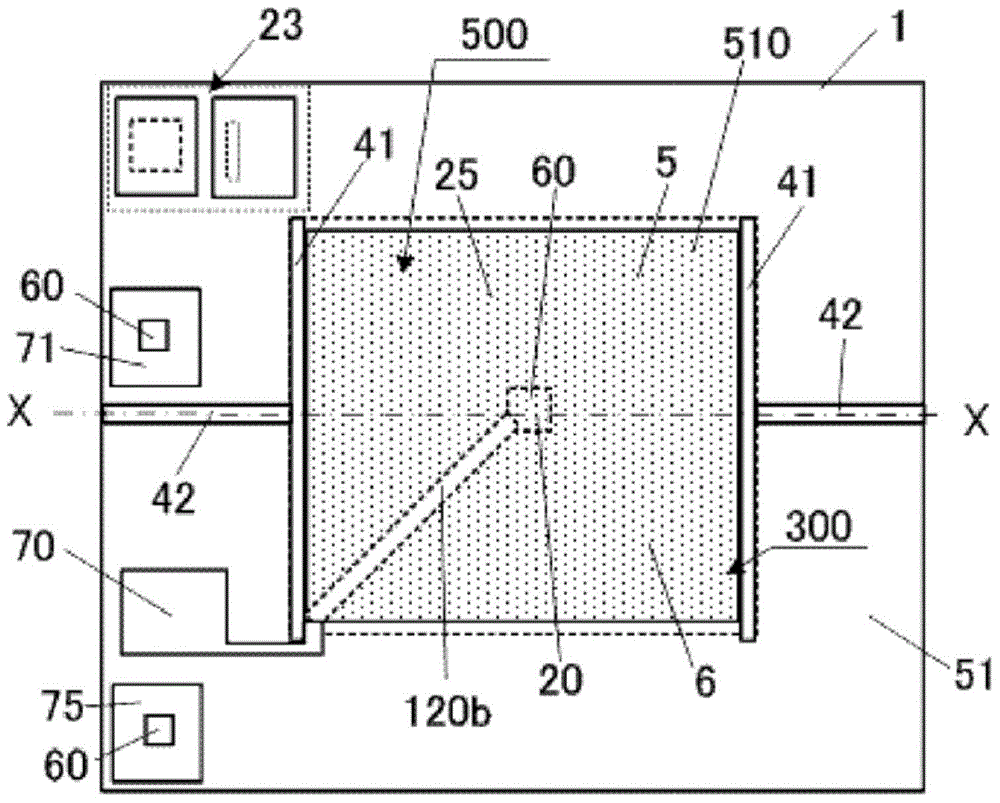

[0064] figure 1 is a schematic cross-sectional view of an embodiment of a hydrogen sensor probe 600 with a thin tube 160 as a feature of the hydrogen sensor of the present invention, figure 2 is a schematic cross-sectional view along its Y-Y line. in addition, image 3 express figure 1 as well as figure 2 A schematic top view of an embodiment of the substrate 1 in the hydrogen sensor probe 600 shown. Here, it is implemented using an SOI substrate as the substrate 1 and has a structure floating in the air due to thermal separation from the substrate 1 . On the thin film 10, there is a concentrating part 300. This concentrating part 300 includes a heater 25, a temperature sensor 20, and a hydrogen absorbing material 5. Here, the following situation is shown: further forming the The temperature difference sensor 20 , that is, a thermocouple, passes an electric current through the heater 25 to perform energization and heat dissipation. In addition, the concentration unit 3...

Embodiment 2

[0073] Figure 4 A schematic cross-sectional view showing another embodiment of a hydrogen sensor probe 600 with a capillary tube 160 as a feature of the hydrogen sensor of the present invention, Figure 5 expressed in Figure 4 The hydrogen sensor probe 600 shown is a schematic top view of an embodiment of the housing 2 with the hydrogen sensor element 500 . The case where the SOI layer 12 is formed of a silicon single crystal substrate regarding the cover 2 will be described. with Example 1 Figure 1 to Figure 3 The big difference of the shown hydrogen sensor probe 600 is that the enrichment part 300 having the heater 25, the temperature sensor 20 and the hydrogen absorbing material 5 formed on the thin film 10 of the bridging structure in Example 1 is also used as the hydrogen gas sensor element 500, but here, as the hydrogen gas sensor element 500, the hydrogen gas detection part 510 having the heater 26, the temperature sensor 21, and the hydrogen sensing layer 6 is fo...

Embodiment 3

[0078] Figure 6 A schematic cross-sectional view showing another embodiment of the hydrogen gas sensor probe 600 with the capillary tube 160 which is a feature of the hydrogen gas sensor of the present invention. In this embodiment, when the hydrogen sensor element 500 in the above-mentioned embodiment 2 is used as a FET-type hydrogen sensor, an SOI substrate is used in the case 2 in the same manner as in the case of embodiment 2, and the SOI layer 12 is used to form a MOSFET to make the hydrogen detection part 510. As the hydrogen sensing layer 6, a platinum (Pt) film whose work function (WF) changes when hydrogen gas is absorbed is used, and the other structures are completely the same as in the second embodiment. The principle of operation of the FET type hydrogen sensor is to form a platinum (Pt) film in which the work function (WF) changes equivalently when hydrogen is absorbed on the gate oxide film of the MOSFET in advance as the hydrogen sensing layer 6, According t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com