Electrical kiln with double backward push plates

A dual-channel push plate electric kiln and push plate technology, applied in the field of electric kiln, can solve the problems that the production efficiency of electric kiln cannot be further improved, the heat utilization rate of the firing process is reduced, and it is not well utilized, so as to reduce the burning Reduce manufacturing cost, achieve energy recovery and utilization, and smooth cooling curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

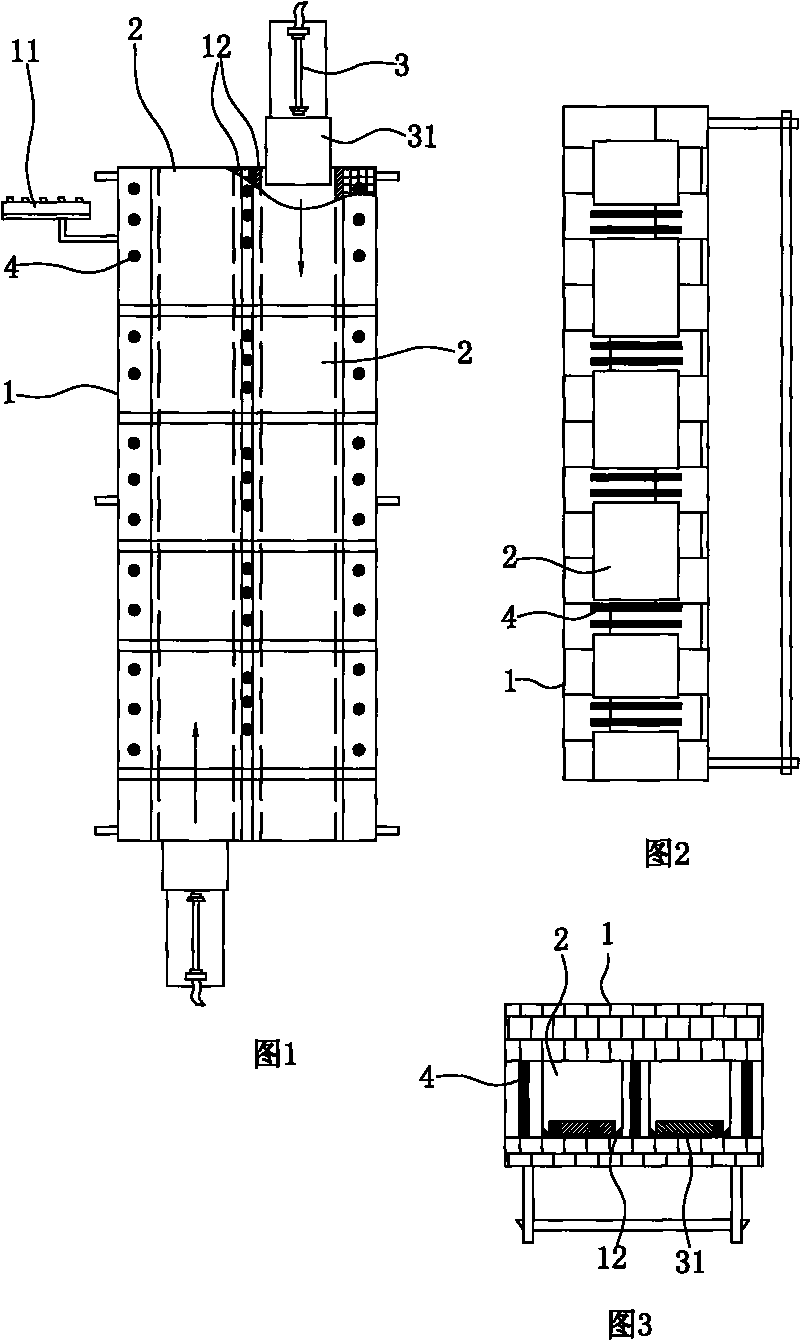

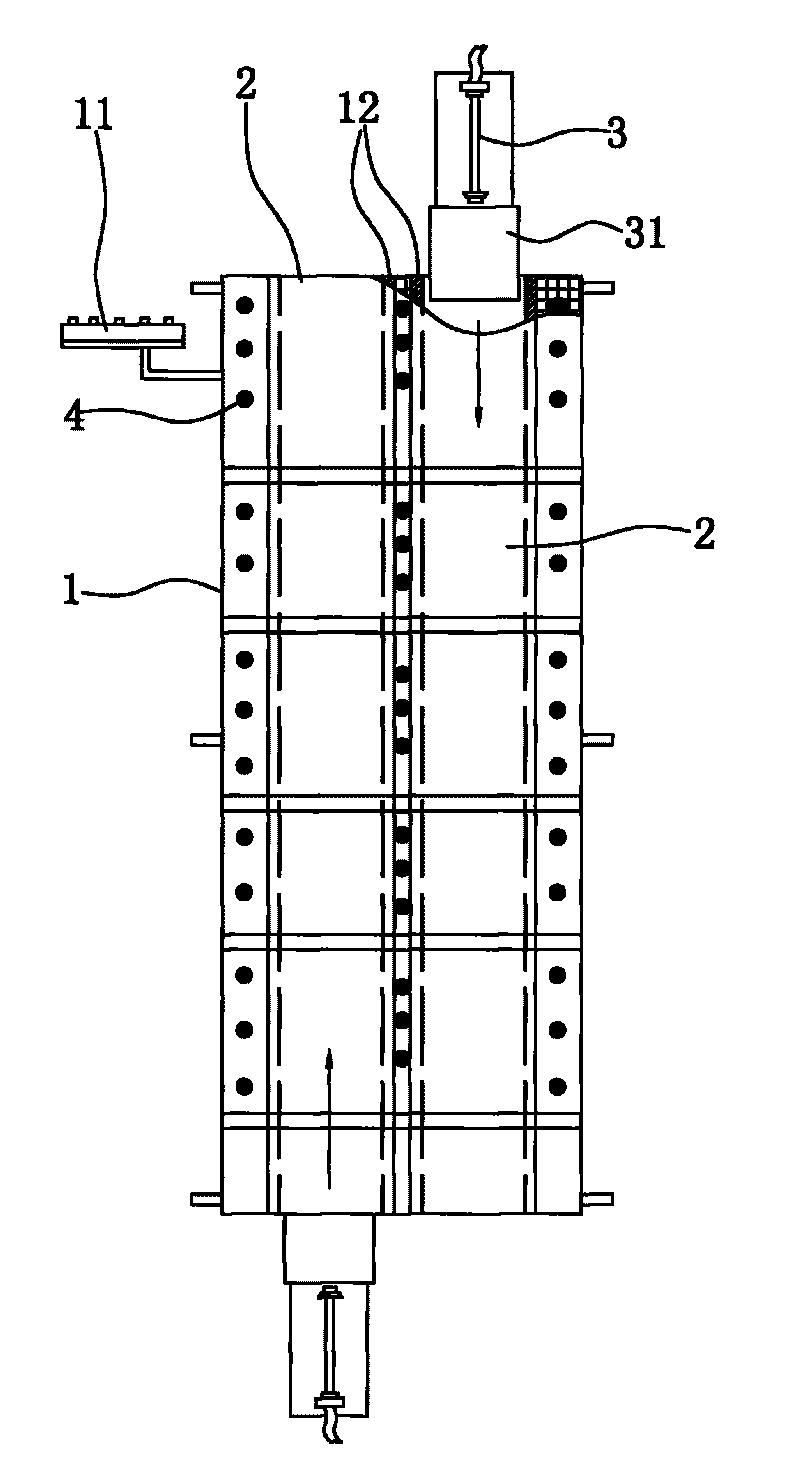

[0015] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a reverse double-channel push plate electric kiln, which includes a furnace body 1, a furnace chamber longitudinally penetrating through the furnace body 1, and heating elements 4 distributed in the two side walls of the furnace chamber. Mechanism, the two propulsion mechanisms are carried out in reverse and synchronously with each other and have their own separate propulsion routes. The furnace can be arranged as two longitudinally running through the firing channels 2, and the two firing channels 2 are connected to each other. into the inlet of channel 2. The propulsion mechanism includes a push plate 31 for placing products. The push plate 31 is installed on the track 12 set in the firing channel 2. A propeller is set at the feeding port of the firing channel 2 to act on the push plate 31 in the track 12. To slide, propeller 3 can adopt hydraulic propeller or mechanical propeller. There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com