Patents

Literature

76results about How to "Reduce firing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

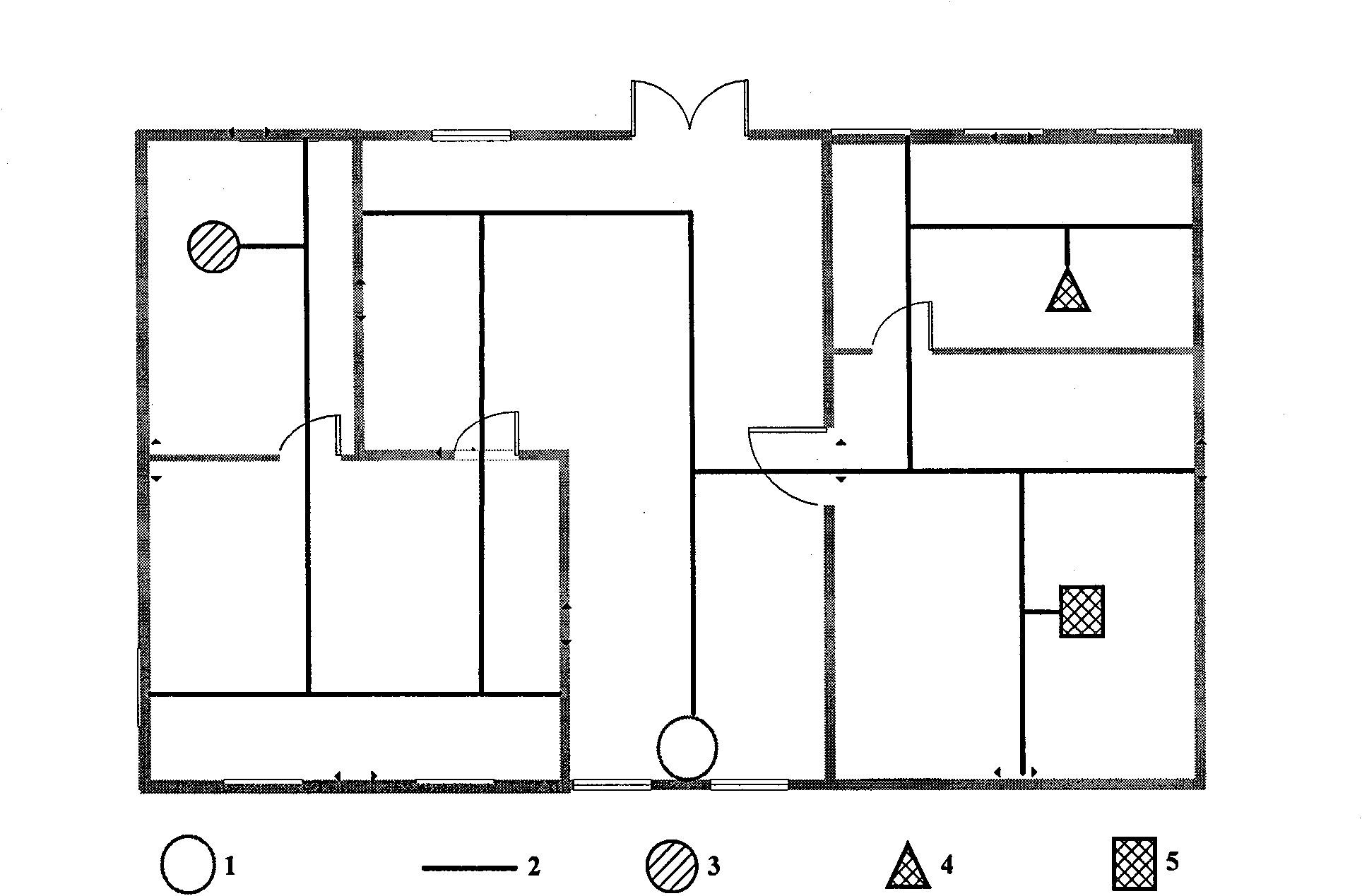

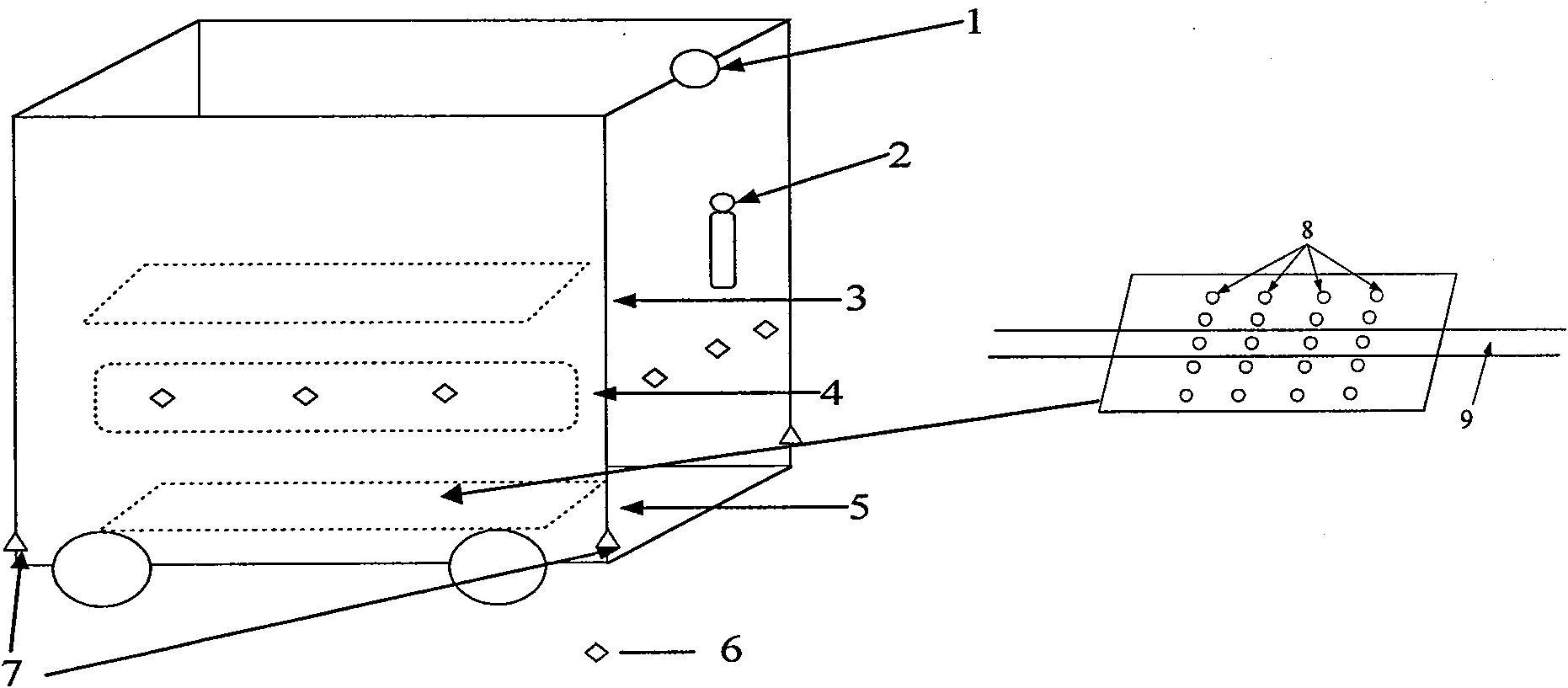

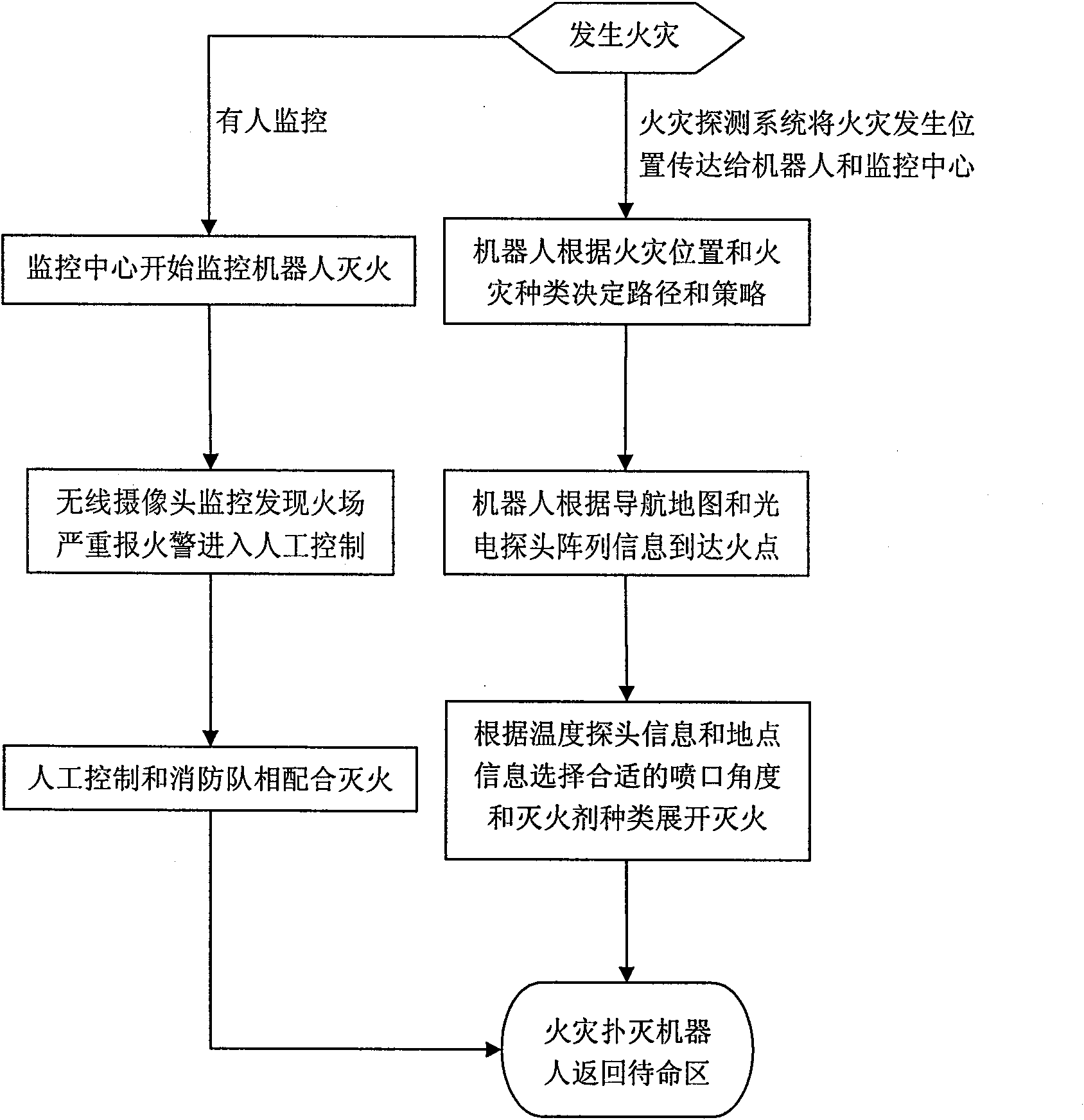

Firefighting robot system

InactiveCN101884830ALower requirementReduces the chance of misroutingInstruments for road network navigationFire rescueRobotic systemsFirefighting

The invention discloses a robot system, which changes the application way of a firefighting robot. The robot system is characterized in that: on the basis of making maximum use of the conventional mature robot technology, the utilization of the robot with the maximum efficiency is realized by reforming the working environment of the robot reasonably. Leading lines and position identifiers are added into the working environment to realize the simplification of a two-dimensional working map, and a robot working navigation map is established to realize high-efficiency movement and positioning of the robot; and the association of the robot and a fire warning system with an image monitoring system is established to realize automatic firefighting and manual remote control and improve the application flexibility of the robot. In the system, the novel robot working modes expand the application range of the functional firefighting robot, reduce the application cost of the robot, and realize the systematic robot application. If the robot working navigation map mode and the manual linkage mode are recognized nationally, a future firefighting mode is expected to be changed by the large-scale application of the robot.

Owner:UNIV OF SCI & TECH OF CHINA

Glaze material of high temperature fast firing crystal glaze archaized brick and preparation process thereof

The invention discloses a glaze material of a high temperature fast firing crystal glaze archaized brick and preparation process thereof. Raw material types of crystal glaze are few and wide in sources. A preparation method of the crystal glaze archaized brick is simple, traditional crystal glaze complex process and specific firing rules are broken through, the crystal glaze archaized brick can be obtained through once firing, operability is good, energy is saved, environment is protected, and firing cost is reduced. By adjusting proportion of glaze material components and colorants and the process method, crystal glaze with different colors and crystal flowers in different sizes are obtained through firing, glaze is light, a few needle holes exist occasionally, and firing yield reaches more than 92%.

Owner:FOSHAN DOWSTONG TECH

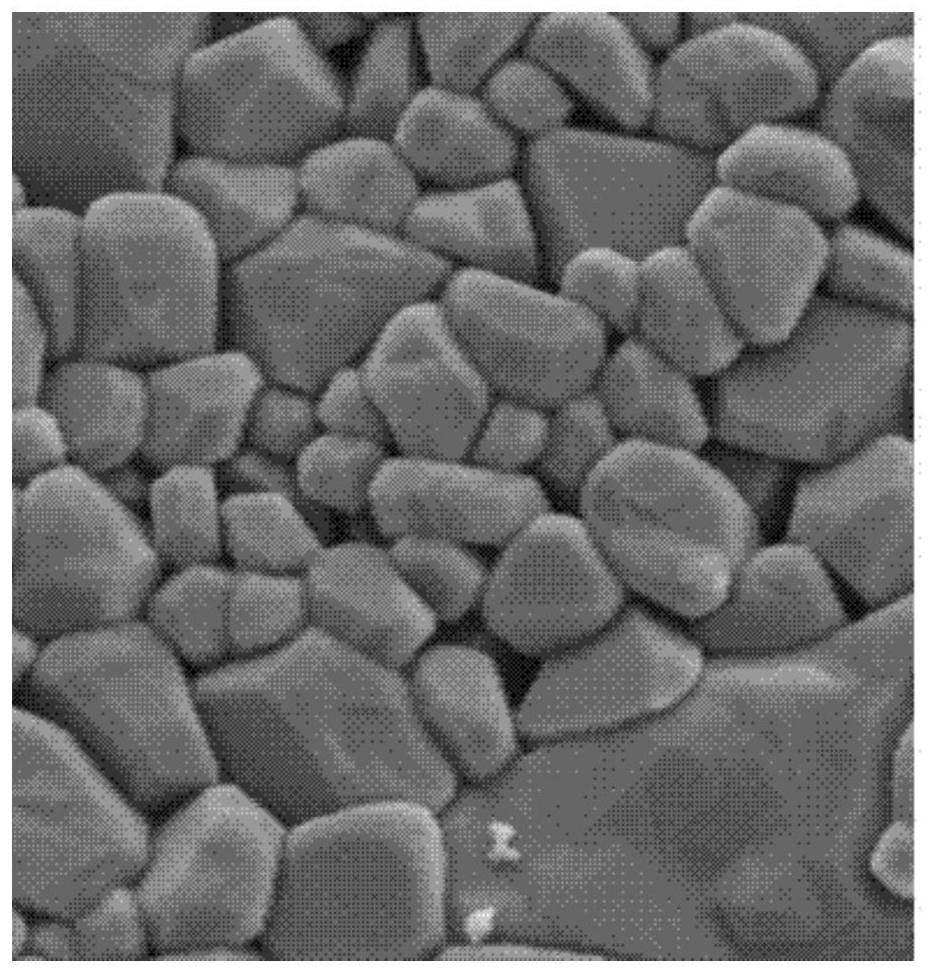

Ceramic product prepared from waste ceramic and preparation method thereof

The invention relates to a ceramic product prepared from waste ceramic and a preparation method thereof. The blank formula of the ceramic product comprises the following components in part by weight: 32-36 parts of waste ceramic powder, 25-28 parts of kaolin, 15-22 parts of plastic clay and 17-25 parts of feldspar. The basic glaze formula of the ceramic product comprises the following components in part by weight: 30-35 parts of miniumite, 8-12 parts of limestone, 20-30 parts of feldspar, 8-14 parts of clay and 20-25 parts of quartz. A right amount of coloring metal compounds and / or coloring materials are added into the basic glaze. Compared with the prior art, a large amount of waste ceramic powder is used for replacing the traditional ceramic raw material for the basic glaze formula, and the technological difficulties of waste ceramic powder compounding, grain composition, sintering, decoration and the like are overcome. Not only is the waste changed into the valuable and a large amount of waste ceramic products are fully utilized, but also the sintering temperature of the ceramic product can be lowered, the energy consumption is reduced, the production cost of ceramic manufacturers is lowered, and the market competitiveness of the product is increased.

Owner:FUJIAN DEHUA NINGCHANG CERAMIC

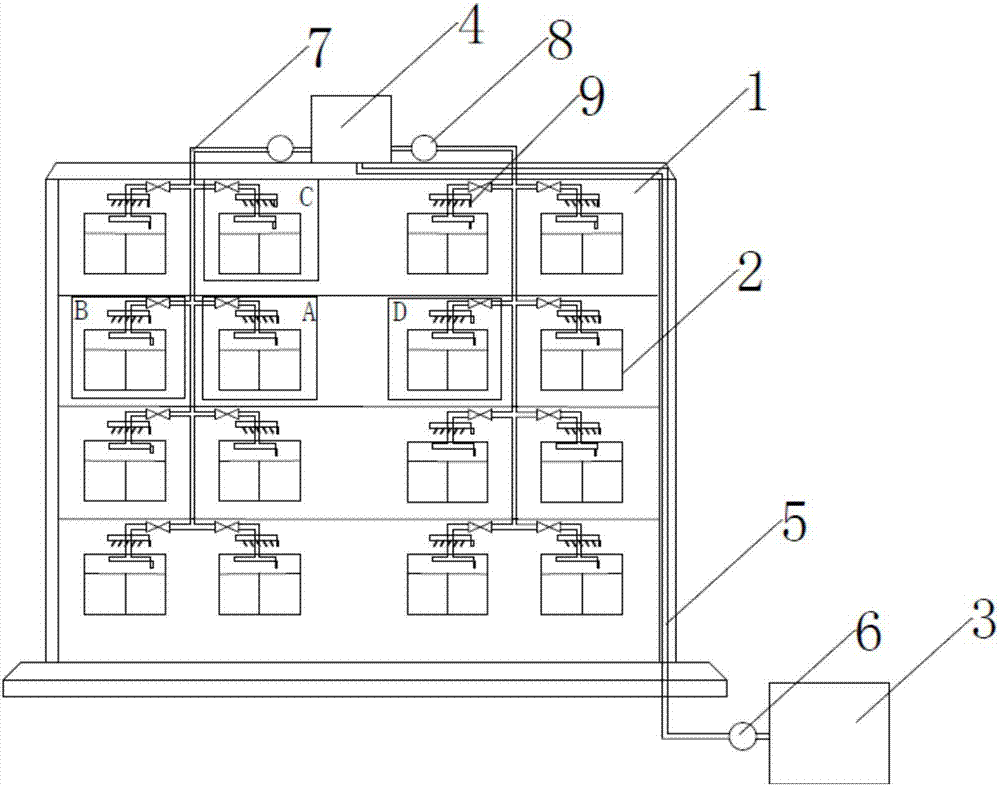

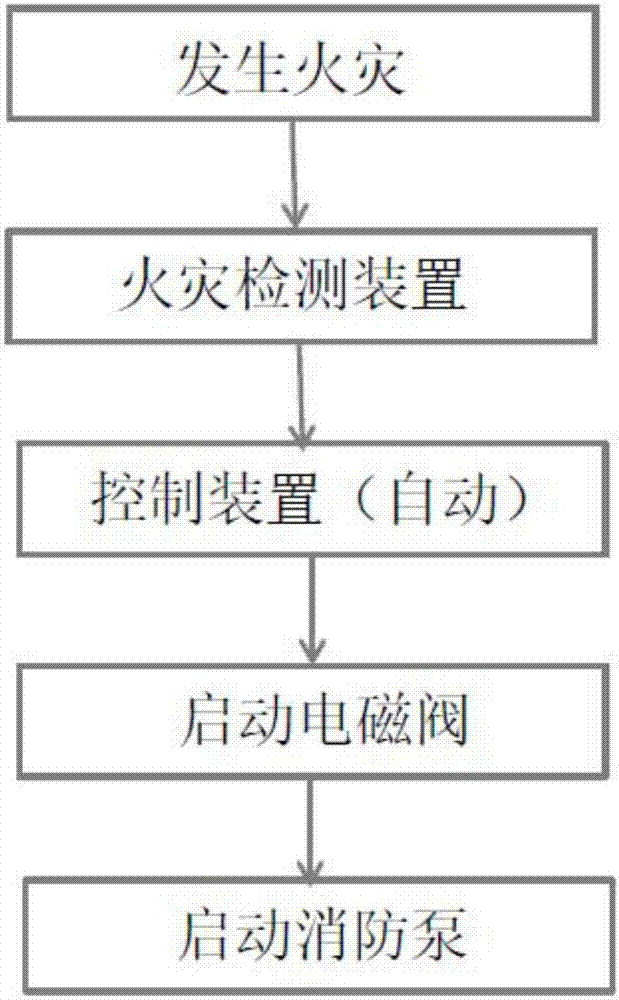

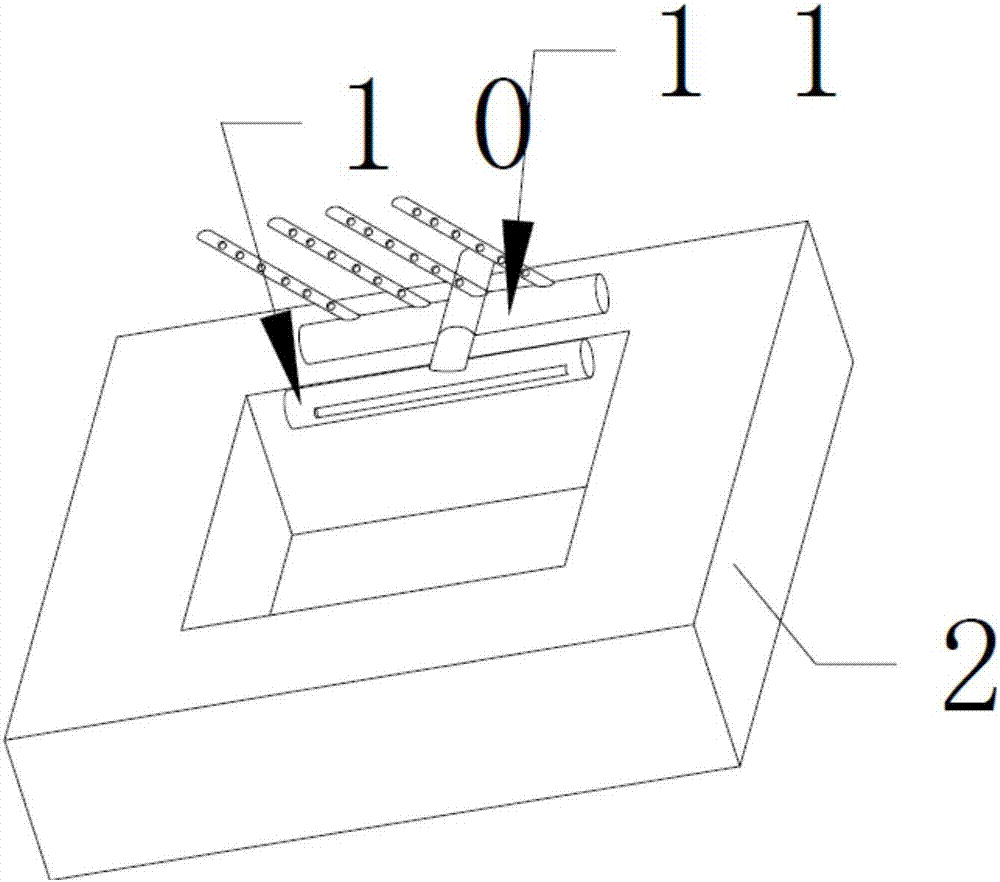

Intermittent high-rise building external wall automatic monitoring and fire extinguishing system

InactiveCN106943690AOutstanding advantagesOutstanding effectFire rescueAutomatic controlAutomatic fire suppression

The invention provides an intermittent high-rise building external wall automatic fire extinguishing system. The intermittent high-rise building external wall automatic fire extinguishing system comprises a plurality of fire detection devices, a control device, a plurality of fire extinguishing devices and a water supply device. The fire detection devices are distributed on the external wall of a building to form a fire detection network for detecting a fire situation at the outer wall of the intermittent high-rise building and transmitting the obtained information to the control device; the control device is used for acquiring a fire locus position of the intermittent high-rise building external wall according to the fire information of the fire detection devices and automatically controlling the water storage operation of the water supply device and the fire extinguishing operation of the fire extinguishing devices according to the preset procedure; the fire extinguishing devices located on the external wall of the building; each fire extinguishing device comprises a water curtain firefighting spray nozzle and a rain firefighting spray nozzle connected with a firefighting pipe in a controlling mode; the water supply device is connected with each fire extinguishing device through the fire pipe in a controlling mode to supply the water to the fire extinguishing device; the opening and closing of the firefighting pipe are controlled through the control device. According to the intermittent high-rise building external wall automatic fire extinguishing system, the role of effective fire retardance, cooling, isolation and fire fighting is achieved under the situation that the external wall of the building is on fire caused by the fire of some areas of the high-rise building or the external wall of the building is directly on fire, the spread of fire is avoided and the losses are reduced.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

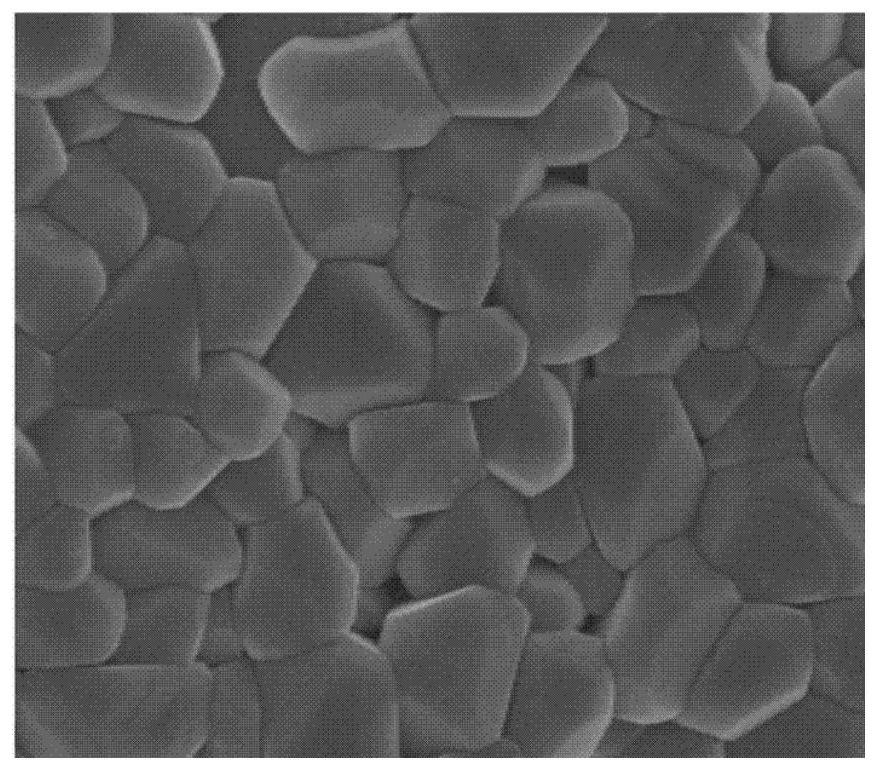

High-flux ceramic flat sheet membrane and preparation method thereof

The invention relates to a high-flux ceramic flat sheet membrane and a preparation method thereof. The high-flux ceramic flat sheet membrane comprises a ceramic flat sheet membrane supporting body and a separation membrane layer wrapping the outer surface of the ceramic flat sheet membrane supporting body. The ceramic flat sheet membrane support body is prepared from the following raw materials in parts by mass: 40-57 parts of diatomite, 30-40 parts of alpha-alumina powder, 4-12 parts of a pore forming agent, 20-40 parts of a support body binding agent, 8-12 parts of a lubricant, 9-13 parts of a plasticizer and 12-18 parts of chopped fibers. The separation membrane layer is prepared from the following raw materials in parts by mass: 40-43 parts of ceramic powder particles, 4-6 parts of ethanol, 19-40 parts of a separation membrane layer binding agent and 9-12 parts of polyethylene glycol. The high-flux ceramic flat sheet membrane product is low in sintering temperature, low in production cost, high in product porosity, small in filtering resistance and high in water flux.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Glaze composition

The invention provides a glaze composition and belongs to the technical field of ceramic products. The glaze composition is prepared from the following raw materials in parts by weight: 7 to 10 parts of Longyan kaolin, 38 to 42 parts of potassium feldspar, 25 to 30 parts of quartz, 18 to 22 parts of wollastonite, 0.5 to 2 parts of bone ash and 1.02 to 2.1 parts of pigment. The glaze provided by the invention has high viscosity and low flowability in a firing process and the defects that the thickness of a glaze surface is not uniform and the color is not uniform, caused by glaze flowing and glaze stacking, are avoided; a firing method of the glaze provided by the invention has a high reduction temperature point and a relatively wide high-temperature firing temperature range; the yield of a product is easy to guarantee; furthermore, a ceramic product fired by the invention has high glaze surface glossiness, pure color, beautiful appearance and long implication.

Owner:JINGDEZHEN CERAMIC INSTITUTE

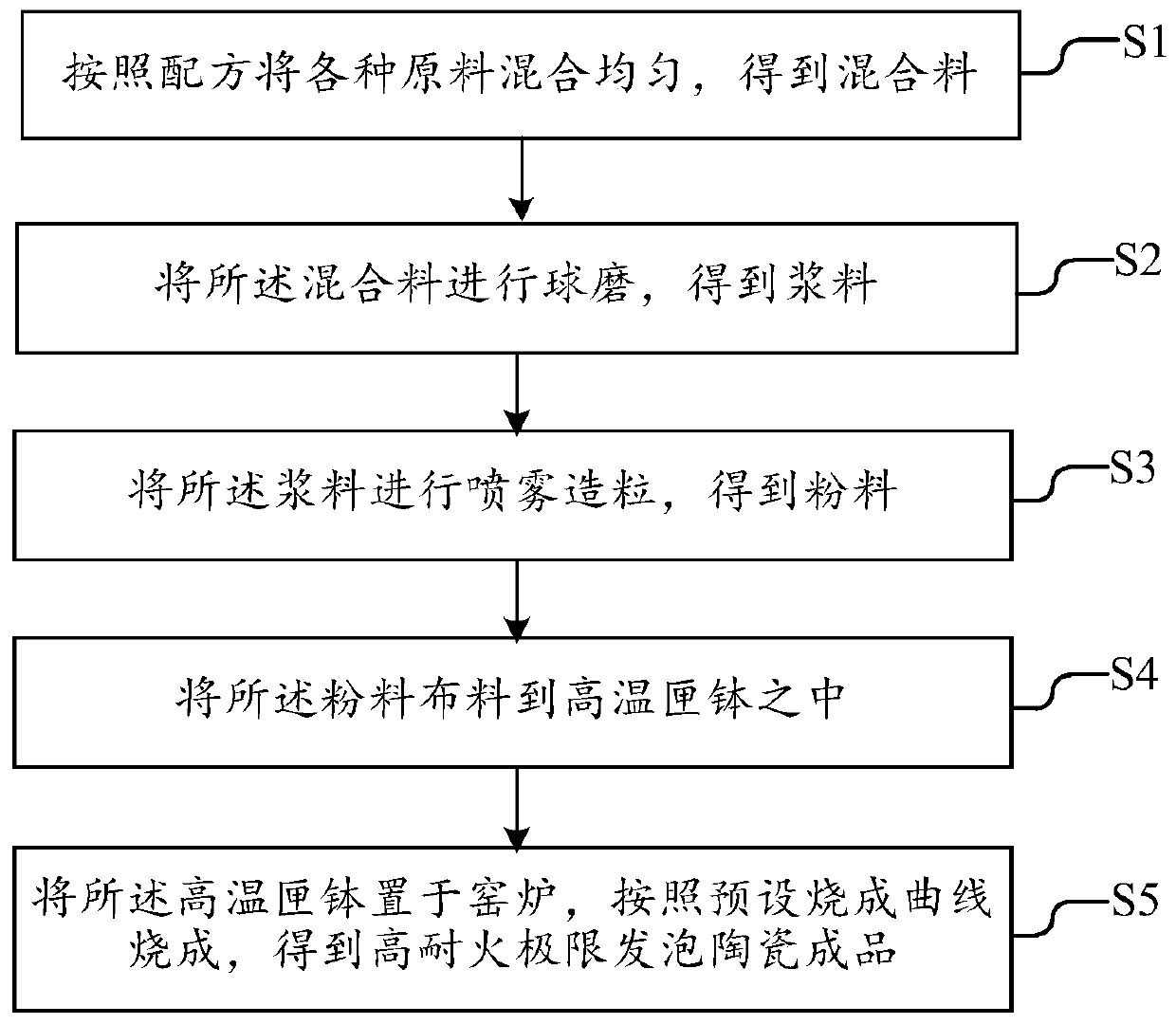

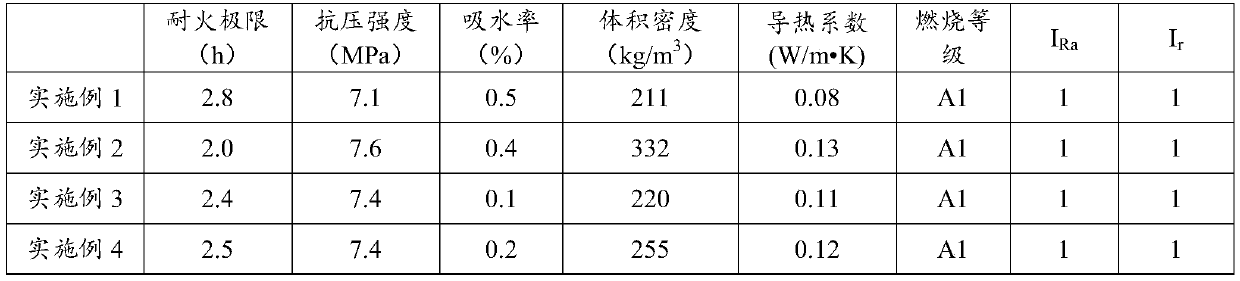

High fire resistance limit foamed ceramic and preparation method thereof

InactiveCN110526681AReduce crystallization tendencySmall coefficient of thermal expansionCeramic materials productionCeramicwareThermal expansionLithium compound

The invention discloses a high fire resistance limit foamed ceramic. The foamed ceramic is mainly prepared by the following raw materials in parts by weight: 90-95 parts of Luoyuan red tailings, 1-5 parts of a lithium compound, 1-3 parts of clay, 0.5-1 part of a foaming agent, and 0.2-1 part of a stabilizer, and the sum of parts by weight of each raw material component is 100 parts, wherein the lithium compound is one or more selected from spodumene, lithium porcelain stone, lithia mica, amblygonite, petalite, lithia mica, and zinnwaldite. The lithium-containing compound is added into the formula, the Li particle has a small radius and large electric field strength, so that the Li particle has the effect of strengthening a network, and thereby a thermal expansion coefficient of the foamedceramic can be reduced, crystallization tendency is reduced, fire resistance of the foamed ceramic can be improved, and application fields of the foamed ceramic is broadened.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Method for producing potassium chloride and co-producing calcium, magnesium, phosphorus and silicon composite fertilizer by potassium feldspar

ActiveCN103183364ASignificant progressLower firing temperatureAlkali metal chloridesFertilizer mixturesPhosphateDolomite

The invention relates to a method for producing potassium chloride and co-producing a calcium, magnesium, phosphorus and silicon composite fertilizer by potassium feldspar. The method comprises the following steps of: preparing materials, crushing and mixing the materials to form raw materials, homogenizing and calcining, and finally preparing potassium chloride and calcium, magnesium, phosphorus and silicon composite fertilizer, wherein the raw materials comprise the components in percentage by weight as follows: 40-46% of potassium feldspar, 30-38% of phosphate ore, 12-16% of dolomite and 9-11% of industrial salt; calcining at 850-950 DEG C, and if a rotary kiln is selected, calcining at 850-900 DEG C; water-quenching red hot clinkers obtained, separating liquid from dregs and concentrating the liquid to obtain potassium chloride; drying, dehydrating and crushing residual solid dregs to 150-200 meshes, and packaging to obtain the calcium, magnesium, phosphorus and silicon composite fertilizer. Compared with the prior art, not only is the sintering temperature reduced by 40 DEG G, but also the calcining cost is reduced by 50% and the yield is improved by 5-6 times.

Owner:江苏纳鼎材料科技有限公司

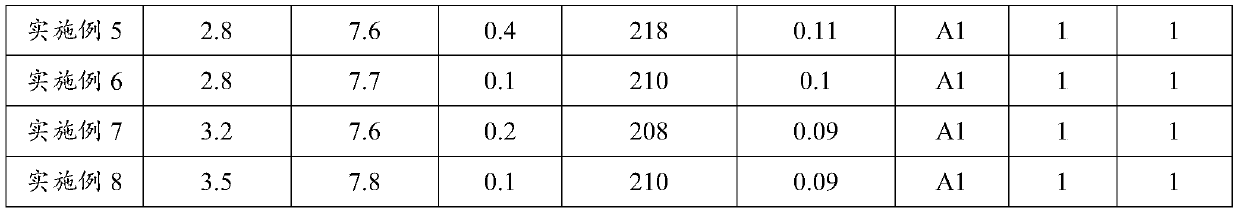

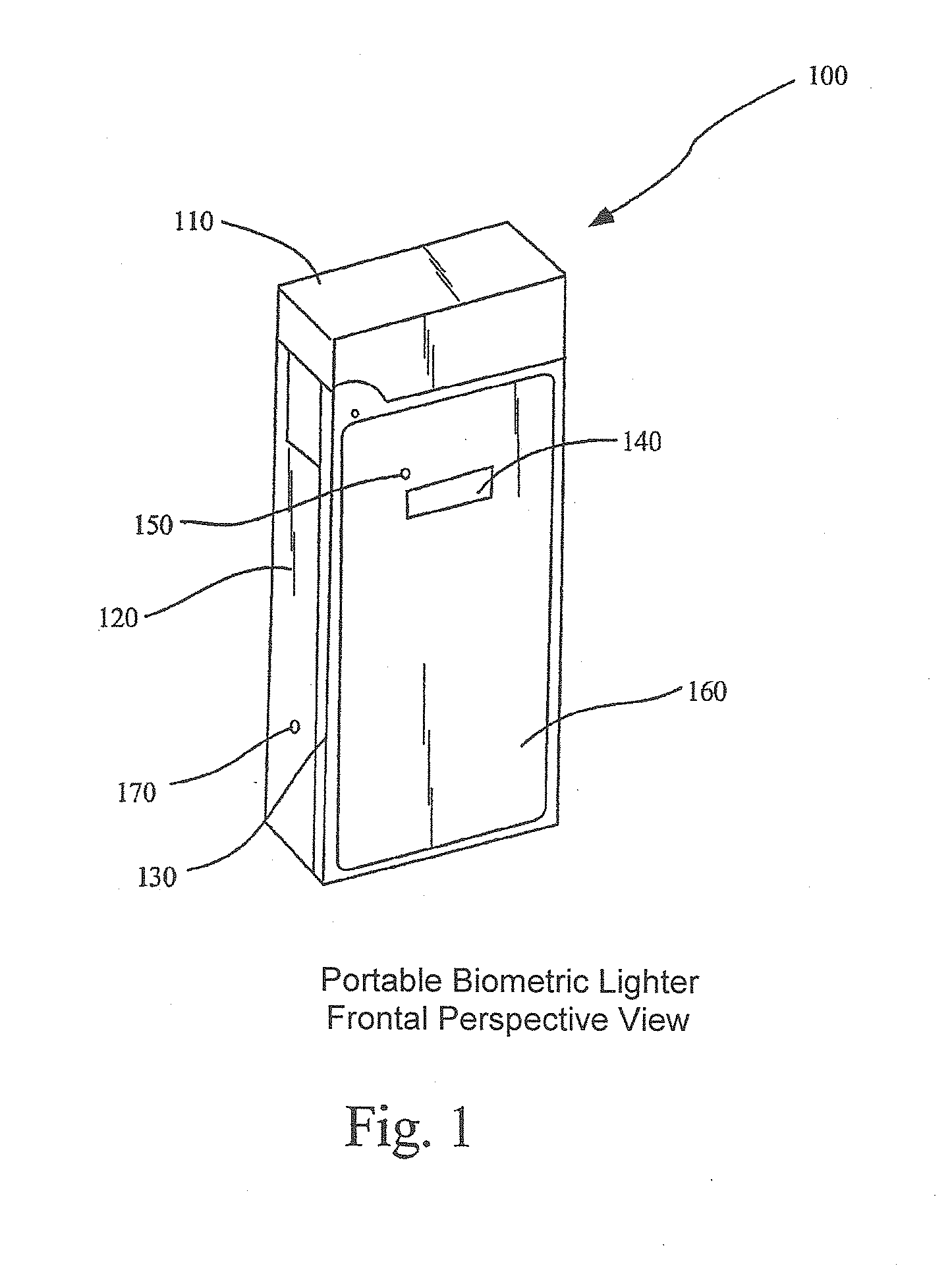

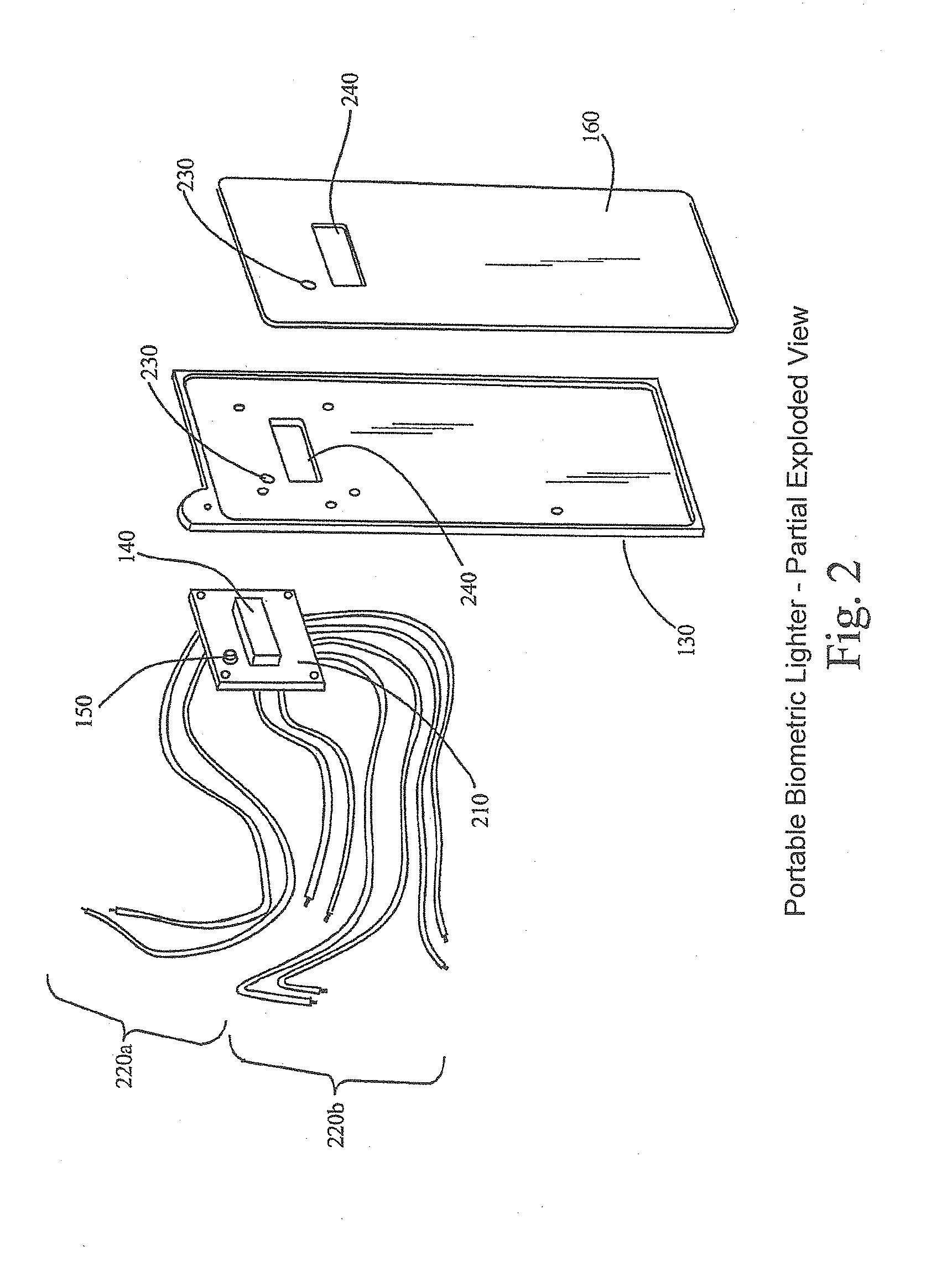

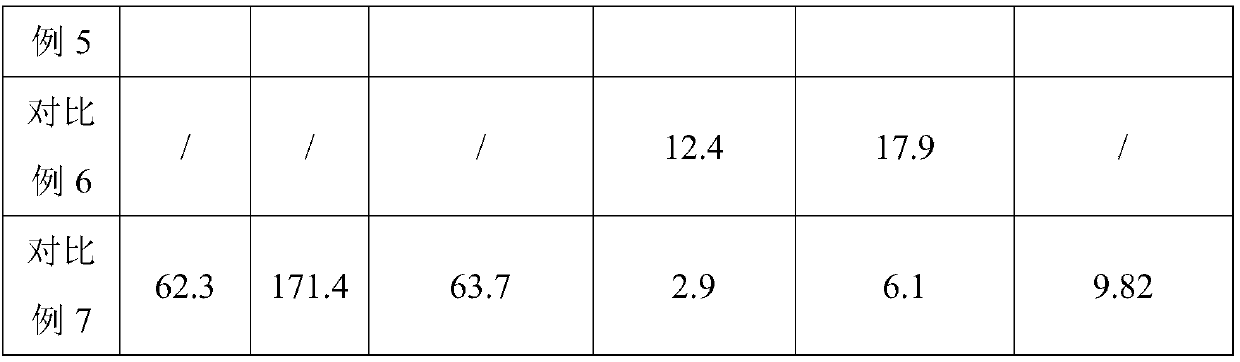

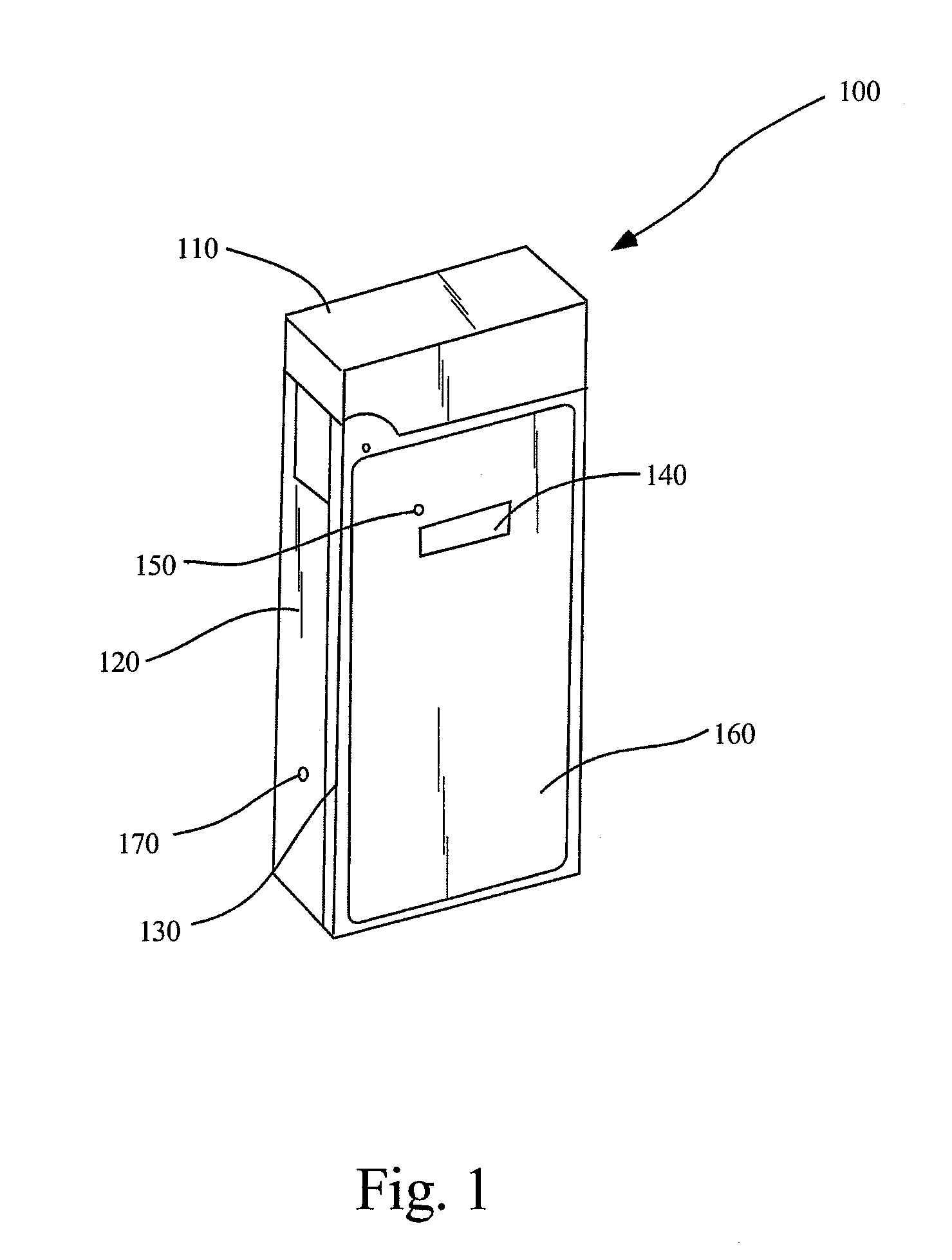

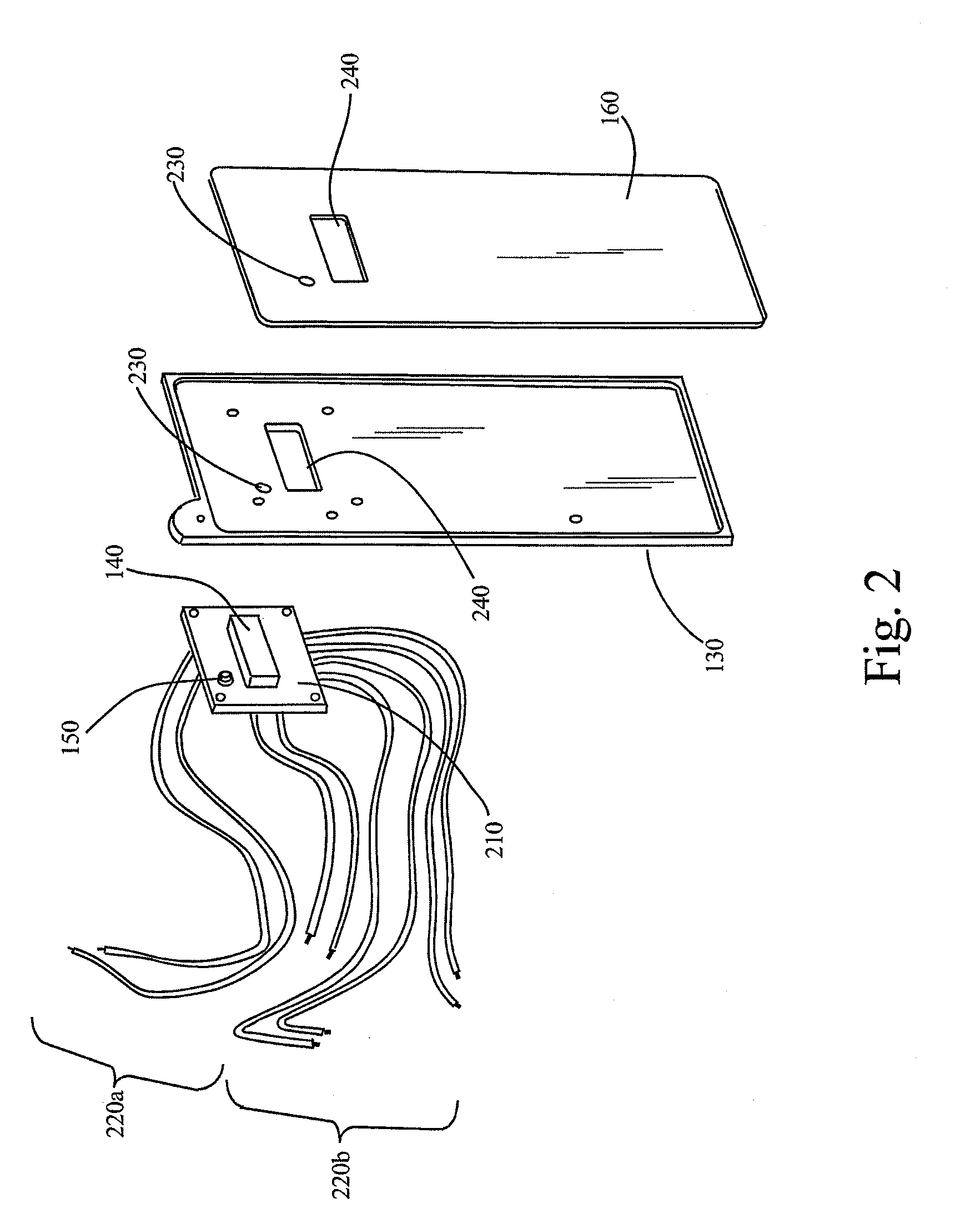

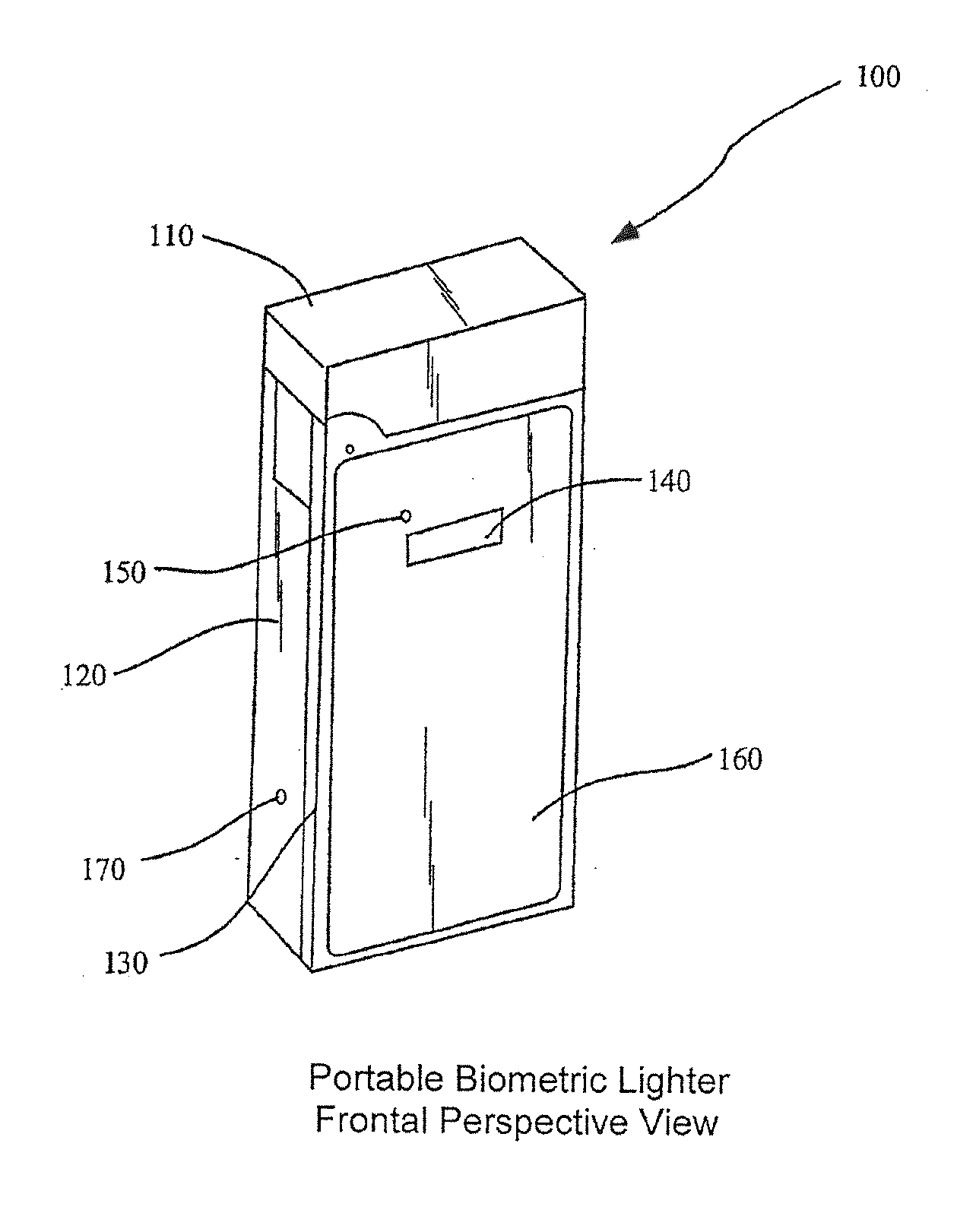

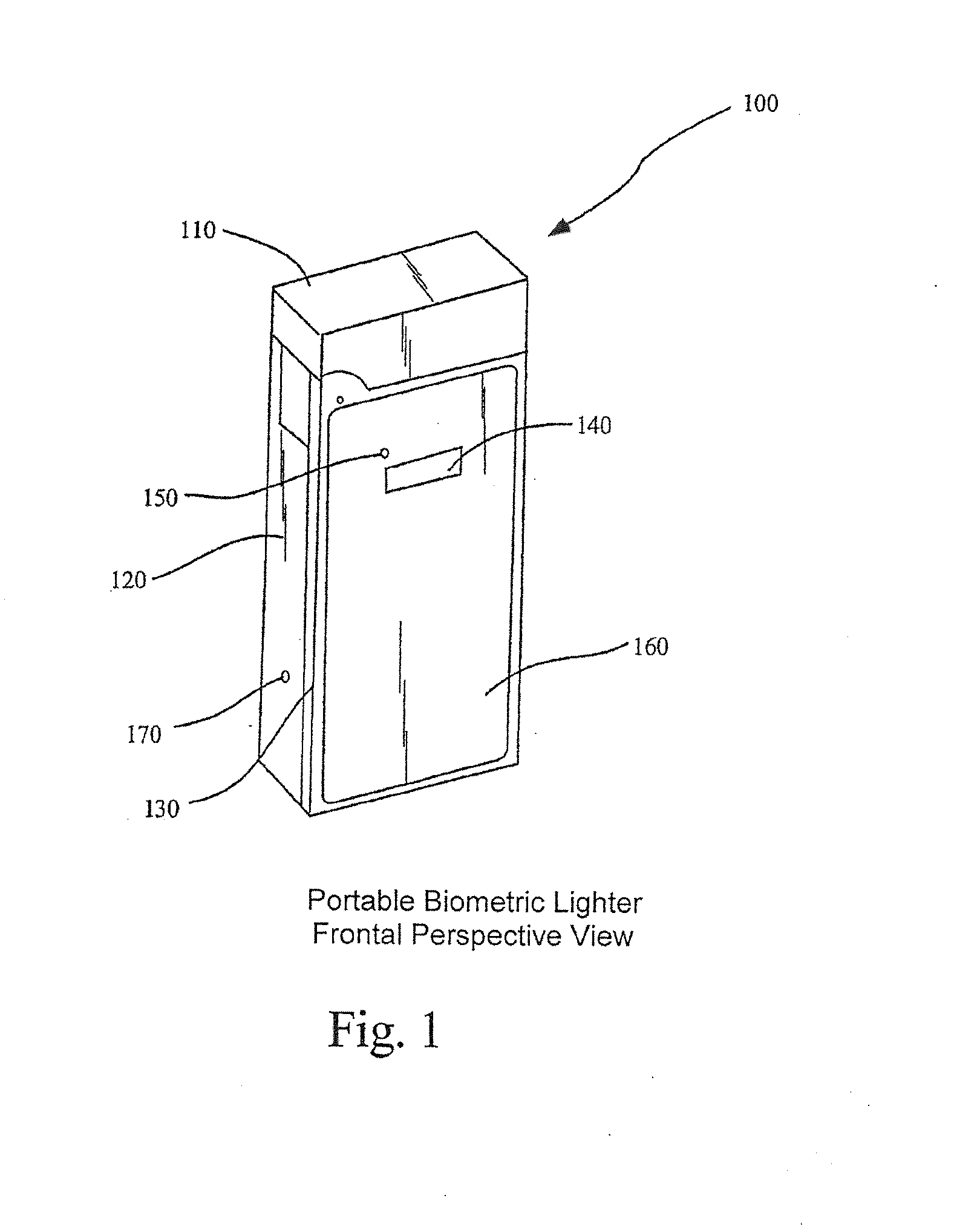

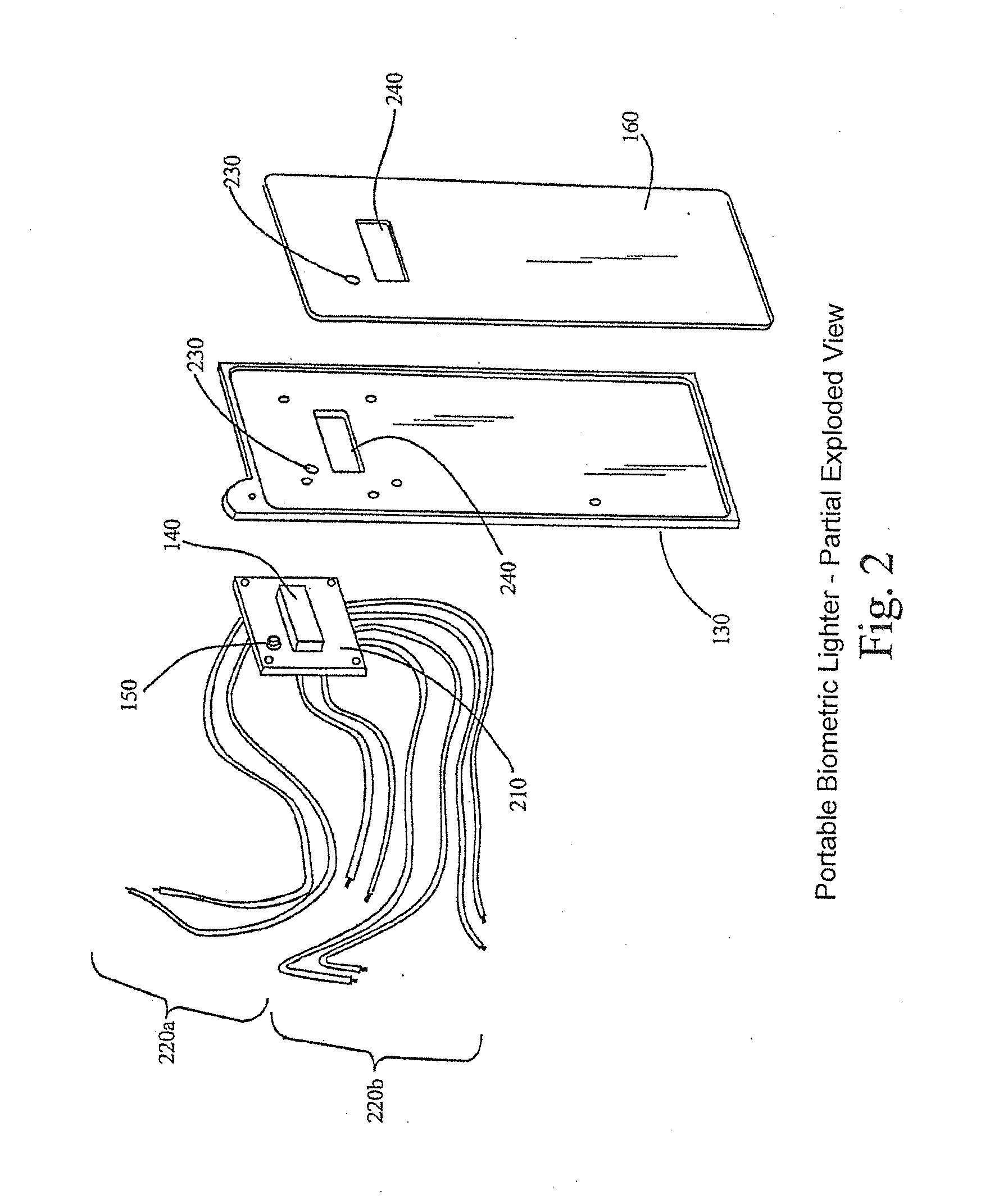

Portable biometric lighter

ActiveUS8653942B2Improve securityReduce probabilityElectric signal transmission systemsImage analysisComputer hardwareBiometric data

A portable biometric lighter device (100) generally involving a control unit (210), a biometric sensor, such as a fingerprint sensor (140), wherein the biometric sensor is configured to scan a biometric data of a user and is operably coupled to the control unit (210), and an ignition element, wherein the ignition element is activated by the control unit (210) upon a match of the scanned biometric data of the user and a biometric data of an authorized user that is stored in a memory device.

Owner:GIBSON JOHN

Heterogeneous ceramic material containing silicon phase quatermary system zicronium oxide

The present invention discloses a four-component system zirconium oxide complex phase ceramic material containing silicon phase, its formula is characterized by that on the four-component system formula containing stable 2-3 mol% of yttrium oxide, 0.5-5 mol% of magnesium oxide, 4-15 vol% of aluminium oxide and zirconium oxide the 0.4-1.0 wt% of silicon oxide component in the form of mullite (3Al2O3.2SiO2) can be compounded, and then they are undergone the processes of ball-grinding, granularing, forming and firing so as to obtain the invented complex phase ceramic material with uniform structure and good mechanical property. It can be used for preparing lining of pump. valve and grinding machine and its related component.

Owner:TIANJIN UNIV

Crystalline glaze for sanitary ceramic sanitary ware and preparation process thereof

The invention discloses crystalline glaze for sanitary ceramic sanitary ware and a preparation process thereof. Proceeded from a process formula, the invention provides novel crystal glaze which meets the requirements of modern ceramic sanitary ware. The crystal glaze is few in type of raw materials required and wide in source and is beneficial for effectively controlling the production cost. The crystalline glaze for sanitary ceramic sanitary ware disclosed by the invention is simple in preparation process. The sintering temperature of the crystalline glaze is controlled at 1170-1230 DEG C, the sintering period is 13-15 hours, the complex process and unique sintering system of crystalline glaze are broken through, and the crystalline glaze for sanitary ceramic sanitary ware is sintered at one time. The crystalline glaze for sanitary ceramic sanitary war is strong in operability and beneficial for energy conservation and environmental protection, and the sintering cost is lowered.

Owner:GUANGDONG DOWSTONE TECH

Glaze material of high temperature fast firing crystal glaze archaized brick and preparation process thereof

Owner:FOSHAN DOWSTONG TECH

Lithium manganate production method

InactiveCN103618078AIncrease reaction rateIncrease production capacityCell electrodesManganates/permanganatesElectrolysisThermal insulation

The present invention provides a lithium manganate production method, which comprises: taking electrolytic manganese dioxide, trimanganese tetraoxide and lithium carbonate as raw materials, carrying out matching and material mixing according to a molar ratio of Mn to Mn to Li of 5:3:5, and carrying out dry mixing to obtain the completely-mixed raw material; heating the mixed raw material to achieve a temperature of 500-550 DEG C, and carrying out thermal insulation for 1-2 h; briquetting the pre-burnt material, stacking, and firing, wherein a firing temperature is 800-900 DEGC; and carrying out thermal insulation for 3-5 h, and naturally cooling to complete the sintering process so as to obtain the product. According to the present invention, the lithium manganate firing time is shortened, volatilization of the lithium element during the sintering process is reduced, the resources and the material cost are saved, and production capacity is increased.

Owner:WUXI JEWEL POWER & MATERIALS

Ladle bottom argon blowing air brick for smelting high-purity high manganese steel

The invention discloses ladle bottom argon blowing air brick for smelting high-purity high manganese steel. The air brick is prepared from the following materials: forsterite sand, fused magnesia, corundum, sodium silicate, sodium permanganate, an explosion-proof admixture, a polycarboxylate dispersion water reducing agent and water. Uniformly-distributed tiny pores can be formed in the air brickdisclosed by the invention, and the permeation volume is 1.5 times or more than 1.5 times of the permeation volumes of slit and diffuse air bricks; argon is permeated in molten steel through the plurality of pores, so that the purification rate of the molten steel is obviously increased, and the contents of oxygen and hydrogen in the molten steel are reduced; the problems that a small number of straight thick holes are caused by slag-clearing iron oxygen burning, the argon intensively passes through the molten steel and quickly escapes from the liquid level and the like are solved; the purification rate of the molten steel is obviously increased.

Owner:广西长城机械股份有限公司

Low-temperature semiwhite porcelain and manufacturing method thereof

The invention discloses a low-temperature semiwhite porcelain and a manufacturing method thereof, belonging to the technical field of ceramics. The blank of the low-temperature semiwhite porcelain comprises the following raw materials in parts by mass: 30-40 parts of Longyan clay, 25-35 parts of Gangxi kaolin raw ore, 20-28 parts of flint, 7-12 parts of feldspar, 2-9 parts of talcum and 5-10 parts of dolomite. The low-temperature semiwhite porcelain can be quickly fired at the low temperature of 1000 DEG C, and can be discharged out of the kiln only by 7-8 hours from firing to cooling. The linear shrinkage is low and can be kept at 12% or below. The low-temperature semiwhite porcelain has high hardness and excellent whiteness (85% or above), and has comparable whiteness with light-weight porcelain. The low-temperature semiwhite porcelain has low water absorptivity (which can be kept at 3% or below and can reach the porcelain industry standard), has the advantages of high strength excellent high temperature resistance and excellent microwave resistance, can be subjected to 180-DEG C drying oven testing more than twice, and can pass the microwave oven and dishwasher performance test. The low-temperature semiwhite porcelain has wide applicability, and can be widely used for producing medium / high-grade domestic ceramics.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

Portable biometric lighter

ActiveUS20100045430A1Improve securityReduce probabilityProgramme controlElectric signal transmission systemsData matchingComputer hardware

A portable biometric lighter device (100) generally involving a control unit (210), a biometric sensor, such as a fingerprint sensor (140), wherein the biometric sensor is configured to scan a biometric data of a user and is operably coupled to the control unit (210), and an ignition element, wherein the ignition element is activated by the control unit (210) upon a match of the scanned biometric data of the user and a biometric data of an authorized user that is stored in a memory device.

Owner:GIBSON JOHN

Portable biometric lighter

ActiveUS20140193049A1Improve securityReduce probabilityFuel lightersCharacter and pattern recognitionData matchingComputer hardware

Owner:JOHN GIBSON ENTERPRISES

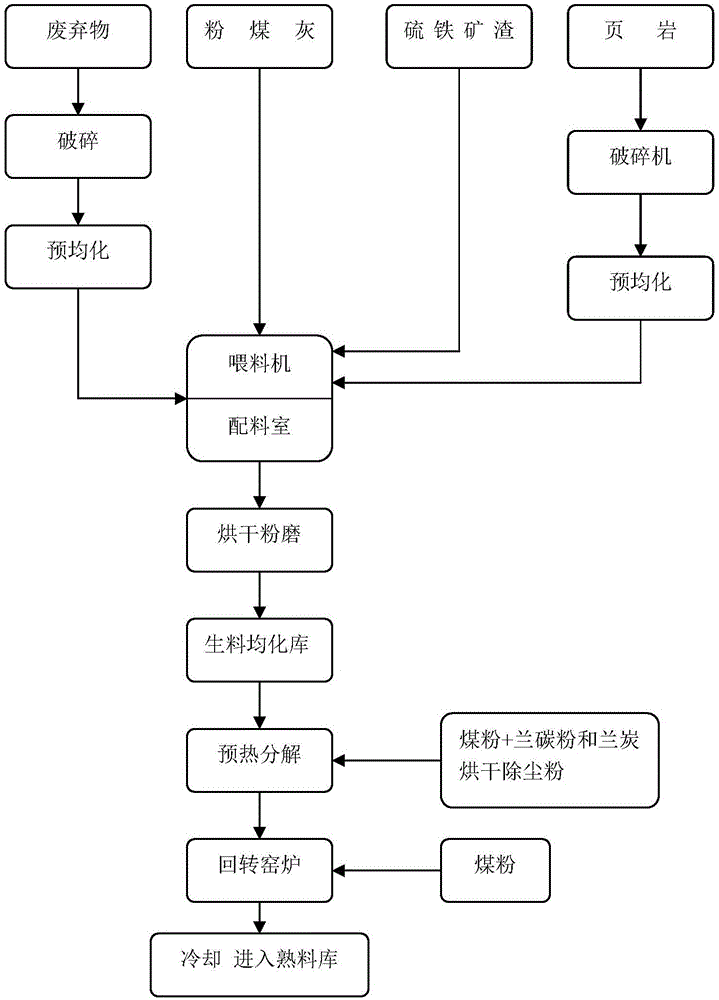

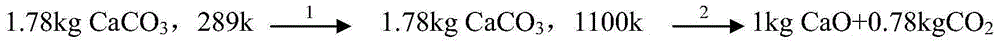

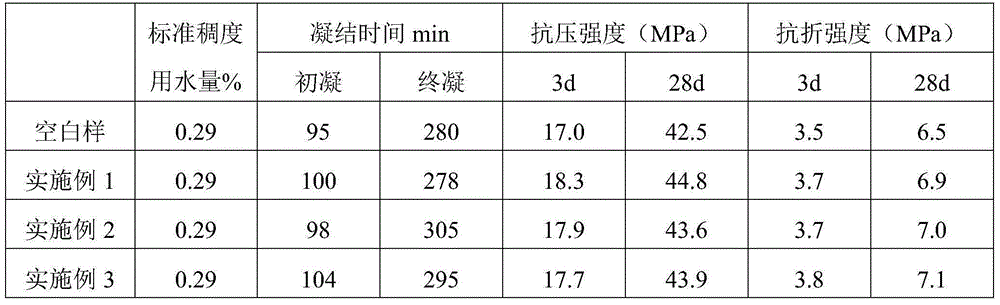

Production method for cement clinker by utilizing waste materials from calcium carbide production

The invention relates to a production method for cement clinker by utilizing waste materials from calcium carbide production. The method comprises the following steps: 1) weighing materials: weighing the following raw materials by mass: 30% to 40% of quicklime powder, 30% to 40% of limekiln dust removing powder, 8.5% to 12.5% of shale, 2% to 3.5% of pyrite slag and 11.5% to 15.5% of fly ash; 2) dewatering the quicklime powder and the limekiln dust removing powder; 3) taking the raw materials and carrying out extruding and grinding, and mixing and homogenizing the obtained materials; and 4) carrying out conveying into a kiln, and carrying out calcining according to a novel dry process so as to prepare the cement clinker. The production method provided by the invention uses the quicklime powder and the limekiln dust removing powder in the calcium carbide production process as the raw materials, and employs a novel cement-production dry process which has the advantages of large production capacity, high degree of automation and high thermal efficiency, so secondary utilization of industrial waste materials is realized.

Owner:溧阳天山水泥有限公司

Electrical kiln with double backward push plates

The invention discloses an electrical kiln with double backward push plates, comprising a furnace body, a hearth longitudinally penetrated in the furnace body and heating elements distributed in both side walls of the hearth, wherein both ends of the hearth are respectively provided with an advancing mechanism, and two advancing mechanisms mutually have backward synchronous advancements and respectively have an individual advancement line; the hearth consists of two sintering channels longitudinally penetrating the furnace body, and the two sintering channels are communicated at intervals; feed inlets and discharge outlets of the two sintering channels are oppositely arranged; and the advancing mechanisms are arranged at the feed inlets of the two sintering channels. Products in the channels are backwards synchronously moved so as to ensure that partial afterheat of products ignited of the outlet channel is absorbed and utilized by preheated products of the other inlet channel near the outlet channel. The temperature decreasing curve of the electrical kiln is smooth, and the temperature of the products at the outlet of the furnace is low so as to achieve the purposes of recycling energy consumption, reducing the firing cost of the products and improving the firing efficiency of the products.

Owner:周建华

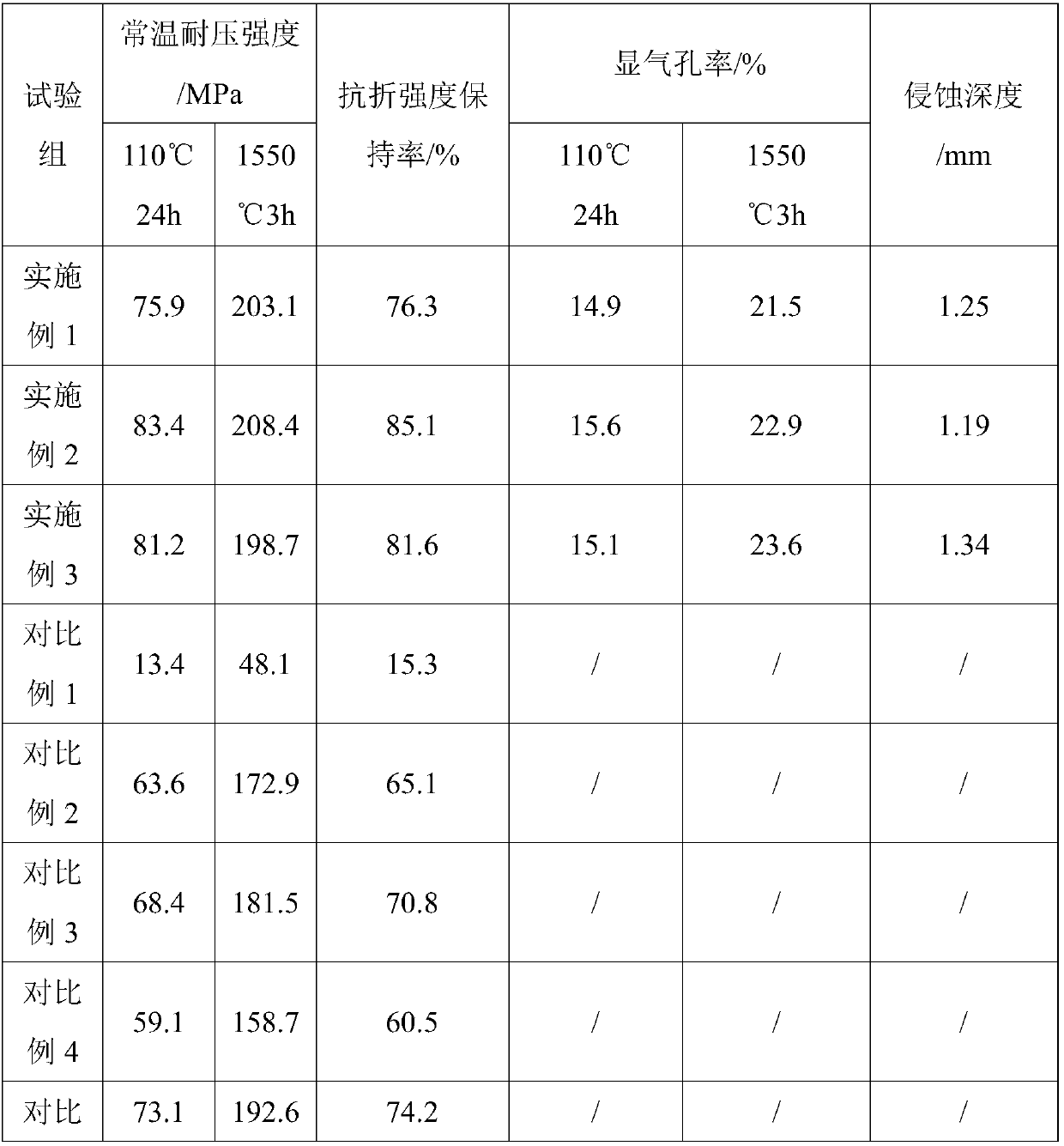

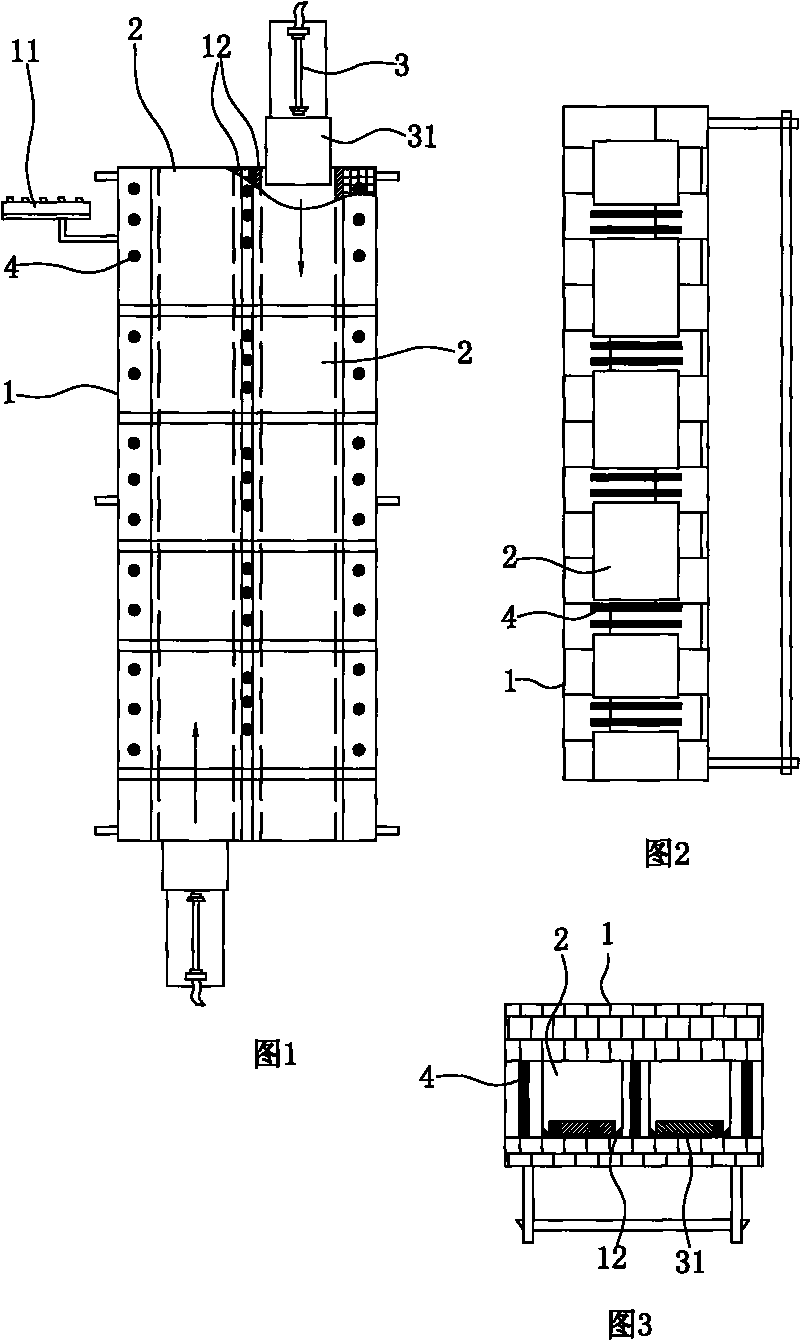

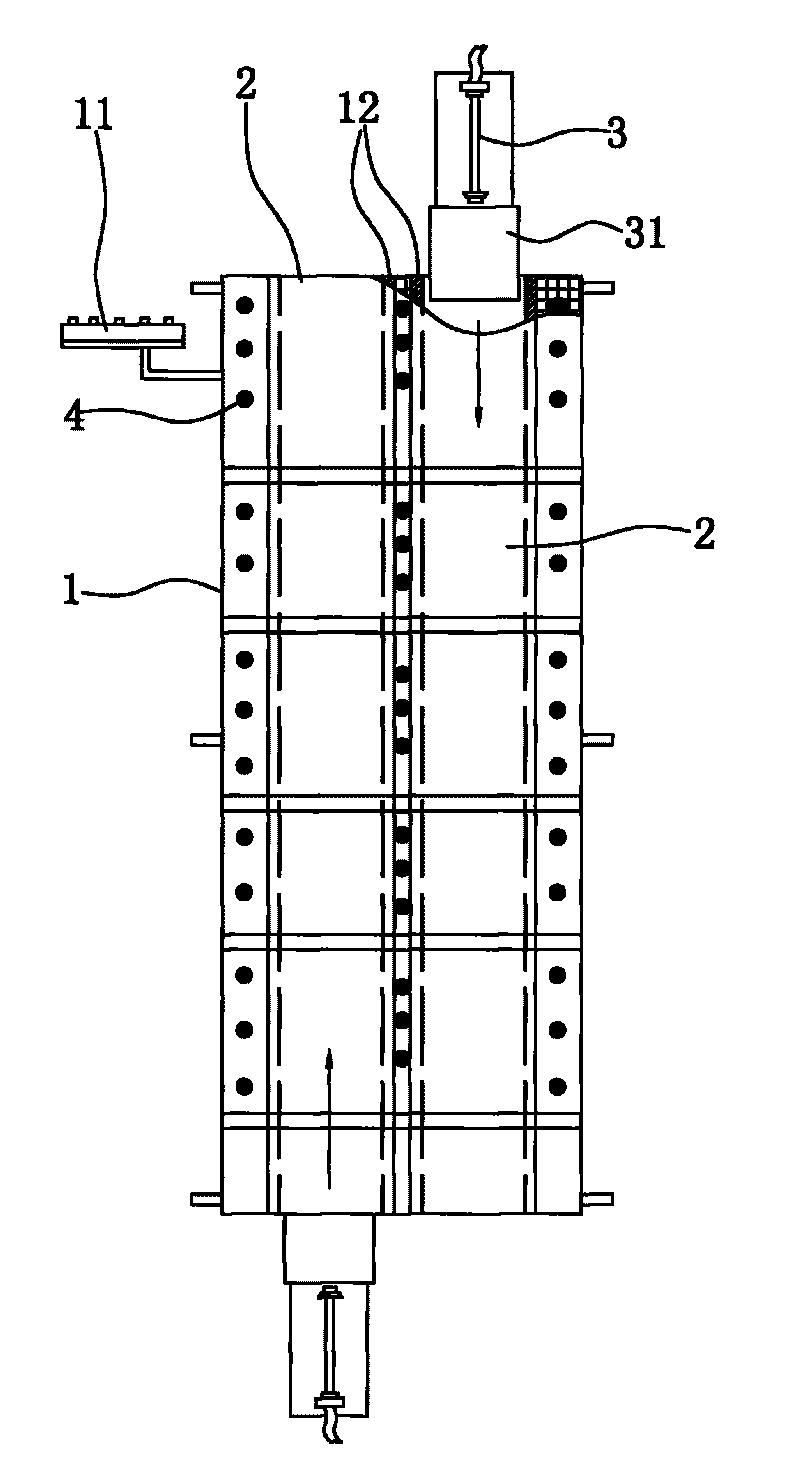

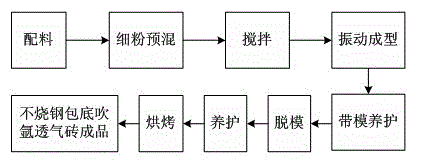

Non-burning permeable brick for steel ladle bottom argon bubbling and preparation process thereof

The invention discloses a non-burning permeable brick for steel ladle bottom argon bubbling and a preparation process of the non-burning permeable brick. The non-burning permeable brick for steel ladle bottom argon bubbling comprises the following components by weight: 65-85 of tabular corundum, 6-14 of spinel, 5-10 of a-Al2O3, 4-8 of CMA cement, 0.3-0.8 of pore-forming agent and 0.3-0.8 of dispersing agent. According to the non-burning permeable brick, the problems that the strength at low temperature and moderate temperature is low, and the strength inflection point exists in the moderate temperature, the volume of each temperature section is not stable, and cracks can be generated easily in the use process can be solved; a novel composite binding agent is selected, so that the linear change rate of the permeable brick is reduced, the stable volume of each temperature section is realized, and the strength of the permeable brick at moderate temperature and the low temperature is improved; uniform micro pores are formed by adopting a pore forming technology, so that the heat-resistance and vibration-resistance stable performance and the anti-corrosion performance of the permeable brick are improved; and the non-burning permeable brick has the advantages that the using performances are equivalent to those of a sintered product, the sintering cost is lowered, the production cycle is shortened by more than four days, and the like.

Owner:成都府天新材料科技有限公司

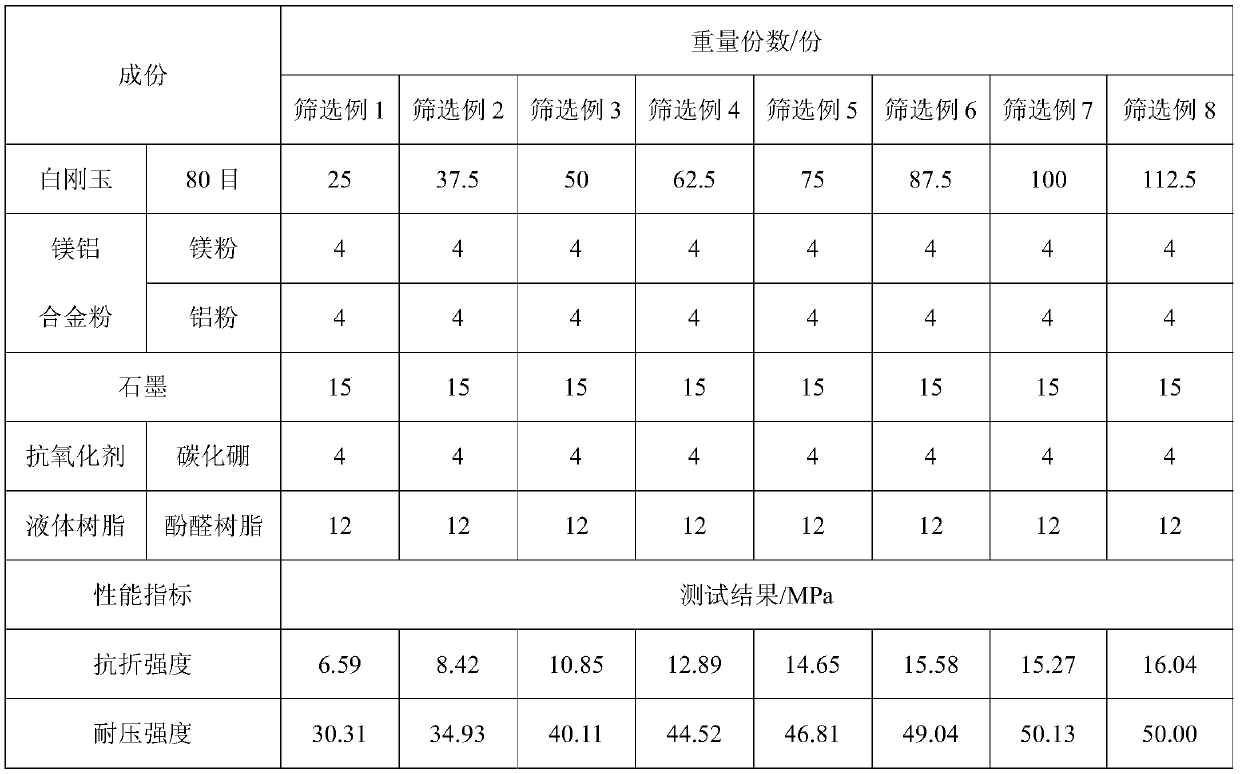

High-strength long-life stopper rod and preparation method thereof

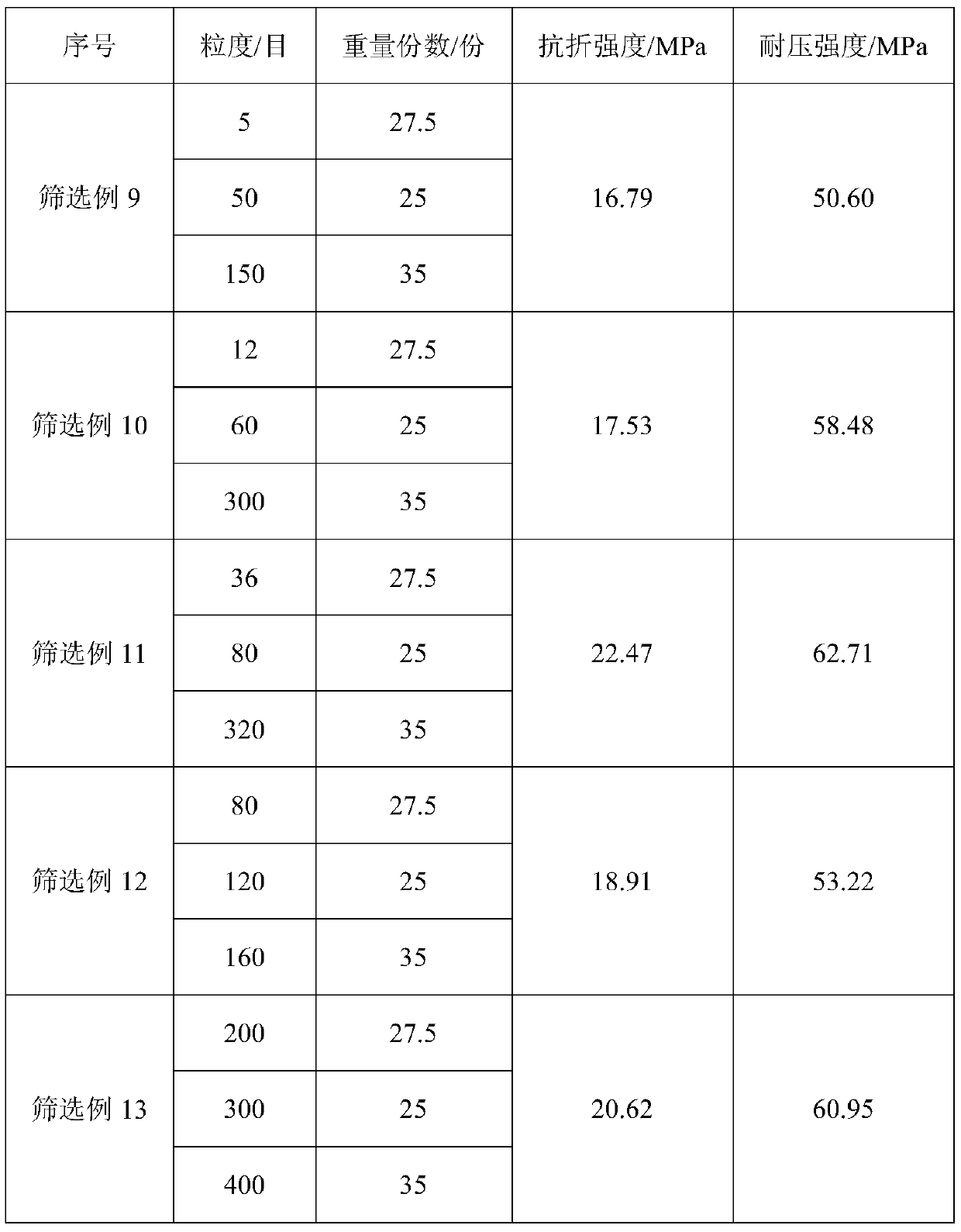

The invention relates to the technical field of refractory material products, in particular to a high-strength long-life stopper rod and a preparation method thereof. The raw materials of the stopperrod include white corundum, magnesium-aluminum alloy powder, graphite, an antioxidant and liquid resin, and the preparation method includes the following steps: (1) weighing the raw materials, and performing stirring so as to obtain mud; (2) drying the mud, and putting the dried mud in a closed container for curing; (3) putting the cured mud into a rubber mold; (4) performing pressure forming so as to obtain a semi-finished product; (5) putting the semi-finished product obtained after forming into a drying kiln, and performing drying and solidification; (6) processing the dried semi-finished product into a regular shape by using a lathe, and then coating an anti-oxidation coating layer on the processed semi-finished product; and (7) putting the product into a firing kiln after complete drying of the coating, and performing heat preservation so as to obtain the finished product stopper rod. The stopper rod has bending strength of 15-23 MPa and compressive strength of 60 MPa or above, and the service life can be prolonged by 3-5 hours.

Owner:山东铭特陶瓷材料有限公司

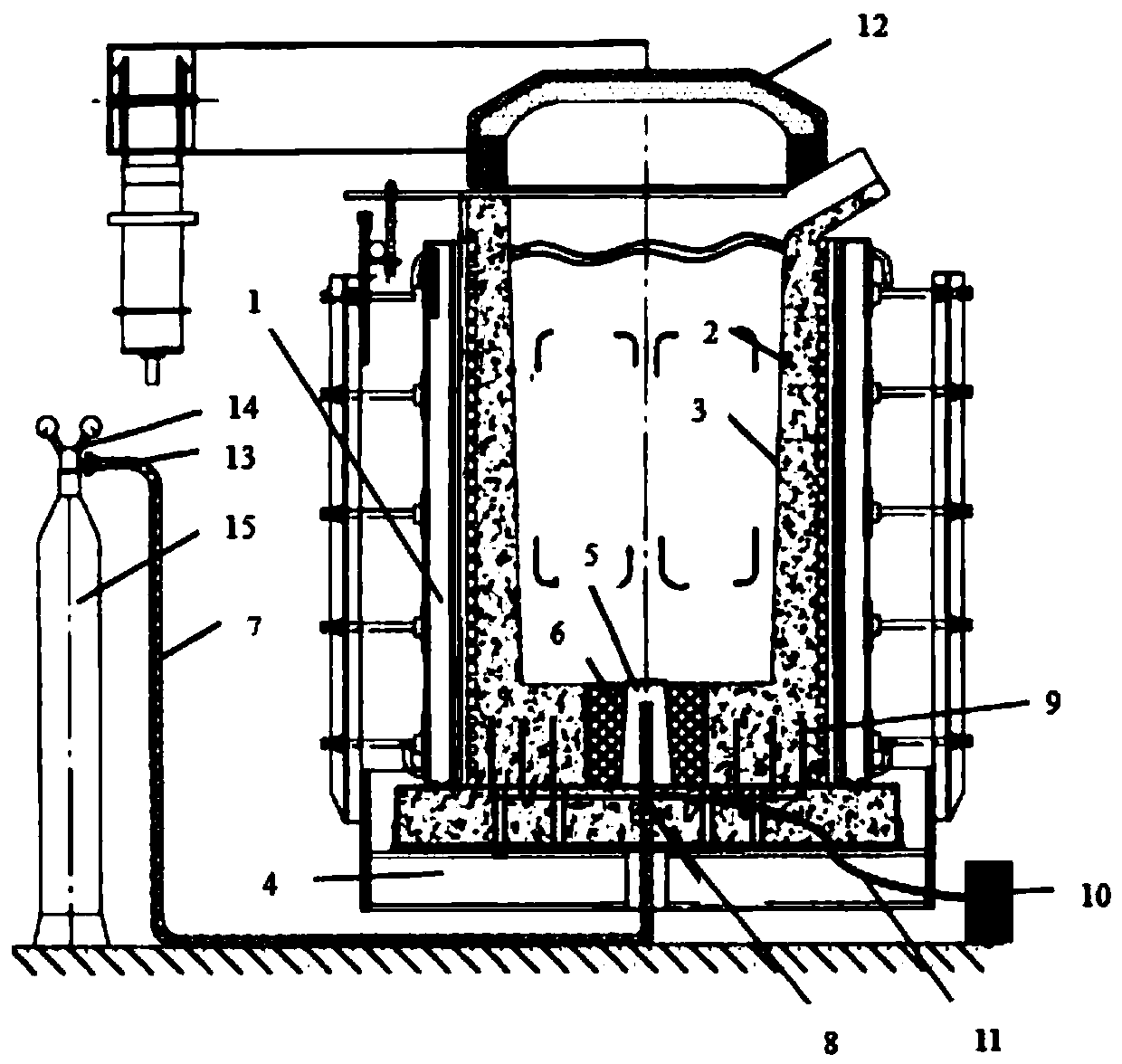

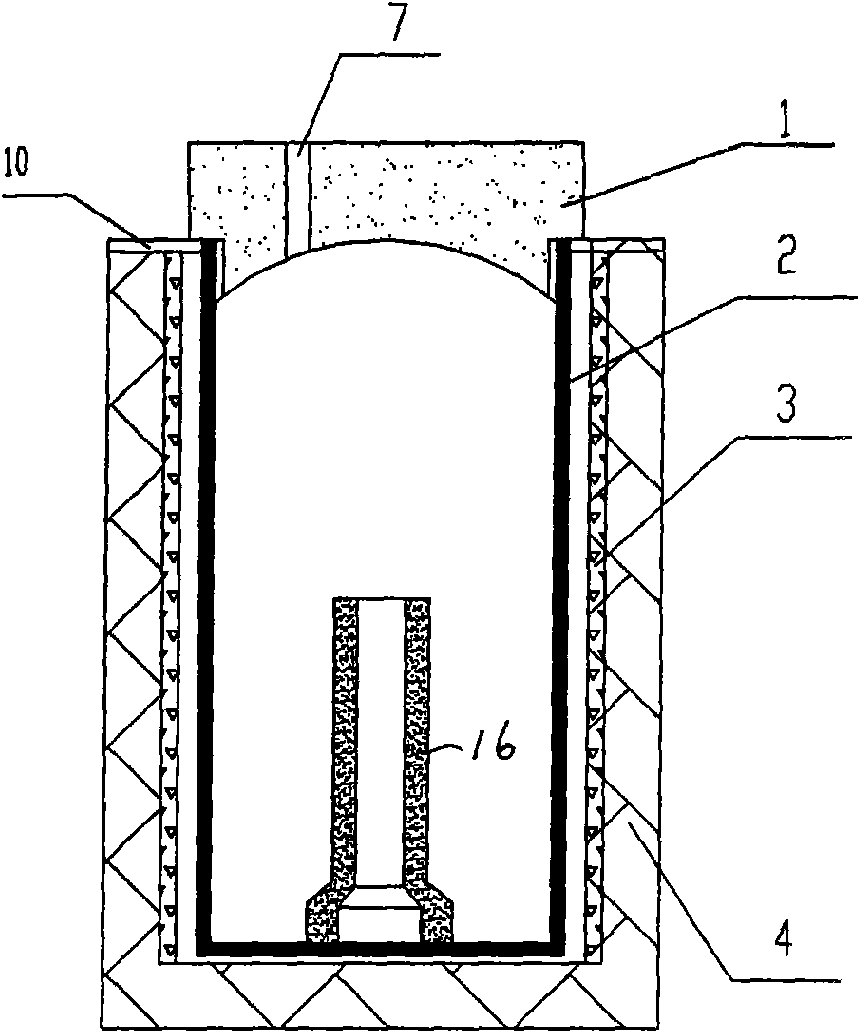

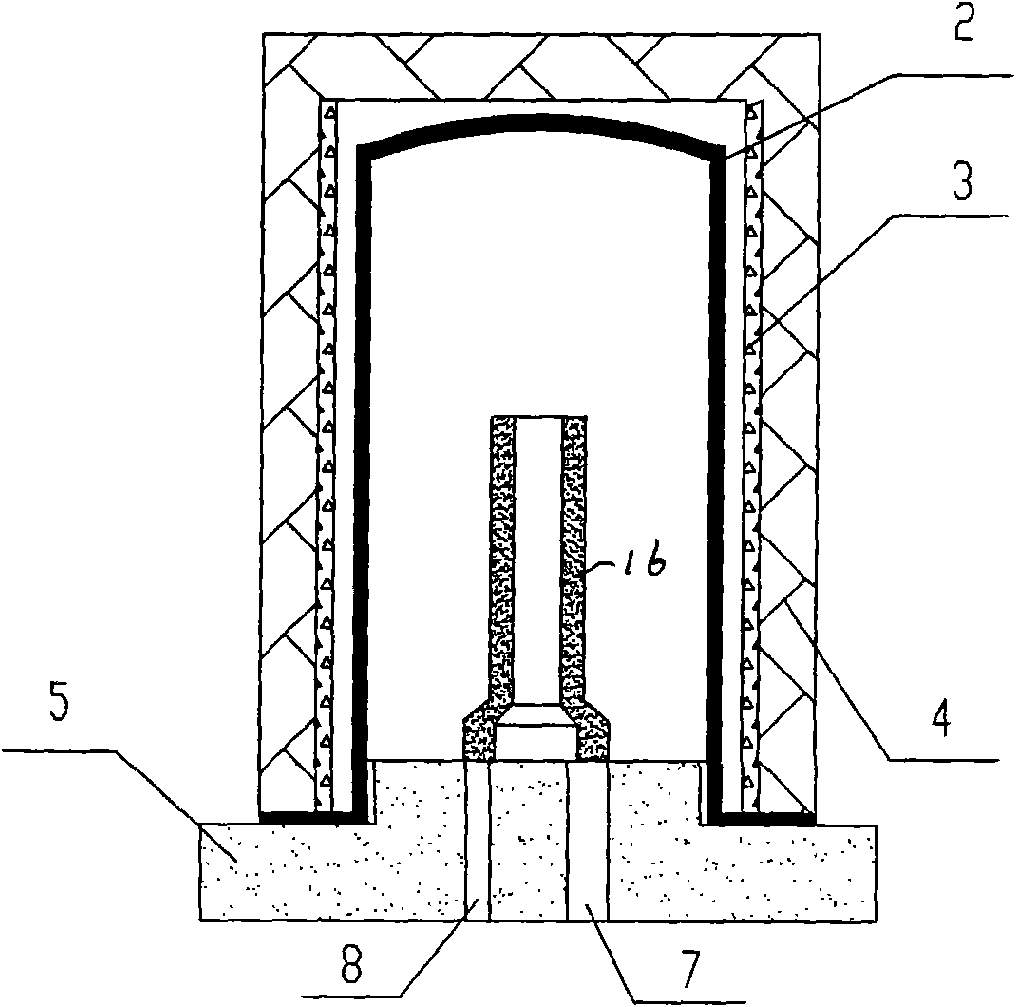

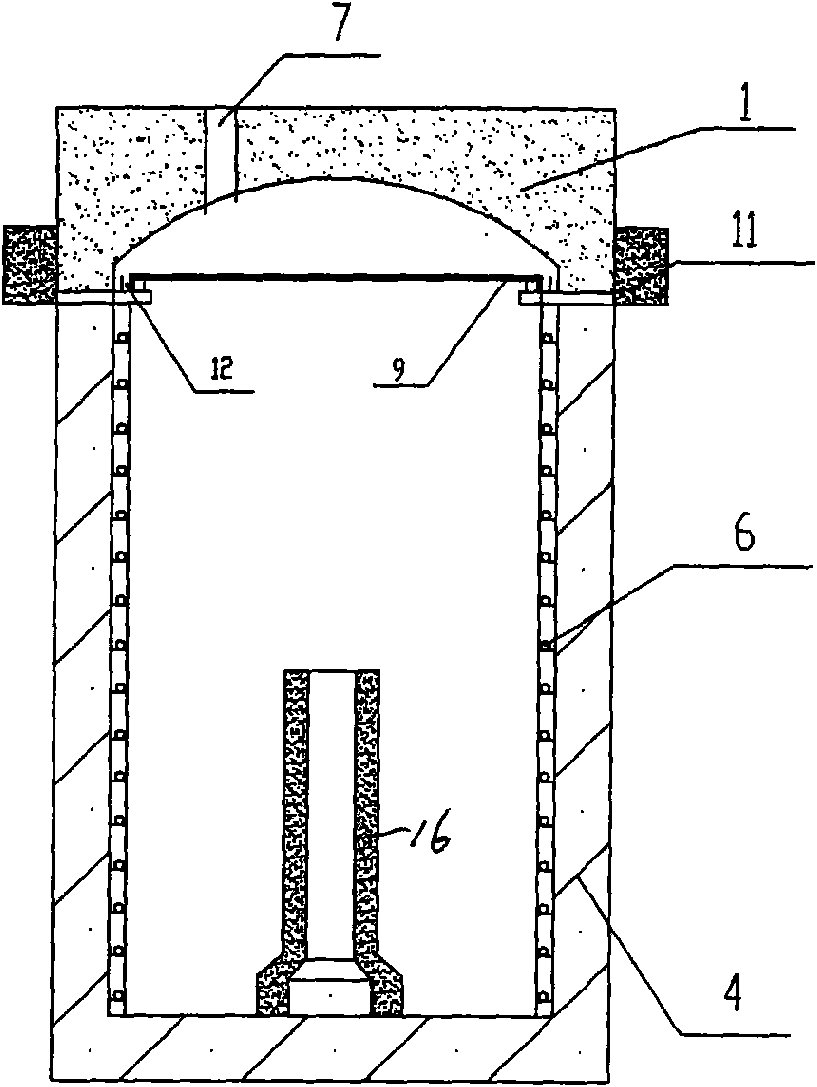

Improvement on non-oxidation firing electric furnace for carbon-containing materials

ActiveCN101556110AAvoid pollutionSolve problemsMuffle furnacesRetort furnacesElectricityHeating power

The invention relates to the improvement on a non-oxidation firing electric furnace for carbon-containing materials, which is characterized in that the inner cover of a sealed cavity, which serves the function of one-way discharging, is arranged on the opening of a furnace body; a furnace cover provided with a discharging passage is located above the inner cover; and electric heating elements are particularly split-type surface-insulated electric heating tubes. Compared with the prior art, the invention can overcome the shortcomings of inner containers and greatly save the heating power, particularly, the invention can save the energy by about 30% to 50%; the carbon-containing materials can also be fired rapidly and directly without the inner containers, and meanwhile, the shortcomings caused by the original exposed electric heating wires can be avoided; the invention can greatly accelerate the cooling process in a sealed manner at the high temperature and greatly improve the service factor and the utilization factor of equipment; an external discharge cooling device allows the heavily polluted substances in the discharge to be cooled and returned from the original discharge pipe and further collected between the inner and the outer furnace covers, thereby reducing the environmental pollution.

Owner:江苏奥能耐火材料有限公司

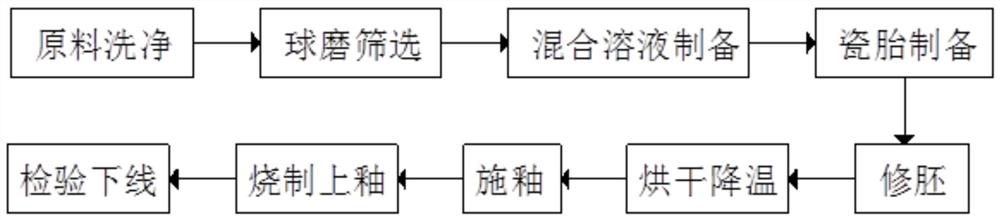

Preparation method of multi-layer glaze daily-use porcelain

The invention provides a preparation method of multi-glaze daily-use porcelain. The multi-glaze daily-use porcelain is prepared from the following raw materials of: aluminum oxide, silicon dioxide, ferric oxide, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, titanium dioxide, chromium carbonate, diboron trioxide, barium oxide, pigment and deionized water. Through reasonable matching of the raw materials, the selection of the ceramic materials is changed, the chemical reaction sufficiency of the ceramic materials is improved, the reaction among the chemical components of the ceramic materials is more stable. The preparation method comprises the following steps of: raw material washing, ball-milling and screening, mixed solution preparation, porcelain body preparation, blanktrimming, drying and cooling, glazing, firing and glazing, and inspecting and discharging. Clean and standard raw materials are used, meanwhile, the manufacturing precision of each link is guaranteed;the thermal stability of a ceramic product is improved; the ceramic product is not prone to cracking in a high-temperature or low-temperature environment; the ceramic is sintered at the medium temperature, the sintering cost of the ceramic is greatly reduced, and the energy-saving and consumption-reducing functions are achieved.

Owner:GUANGDONG SITONG GROUP

A kind of crystalline glaze for sanitary ceramic sanitary ware and its preparation process

Owner:GUANGDONG DOWSTONE TECH

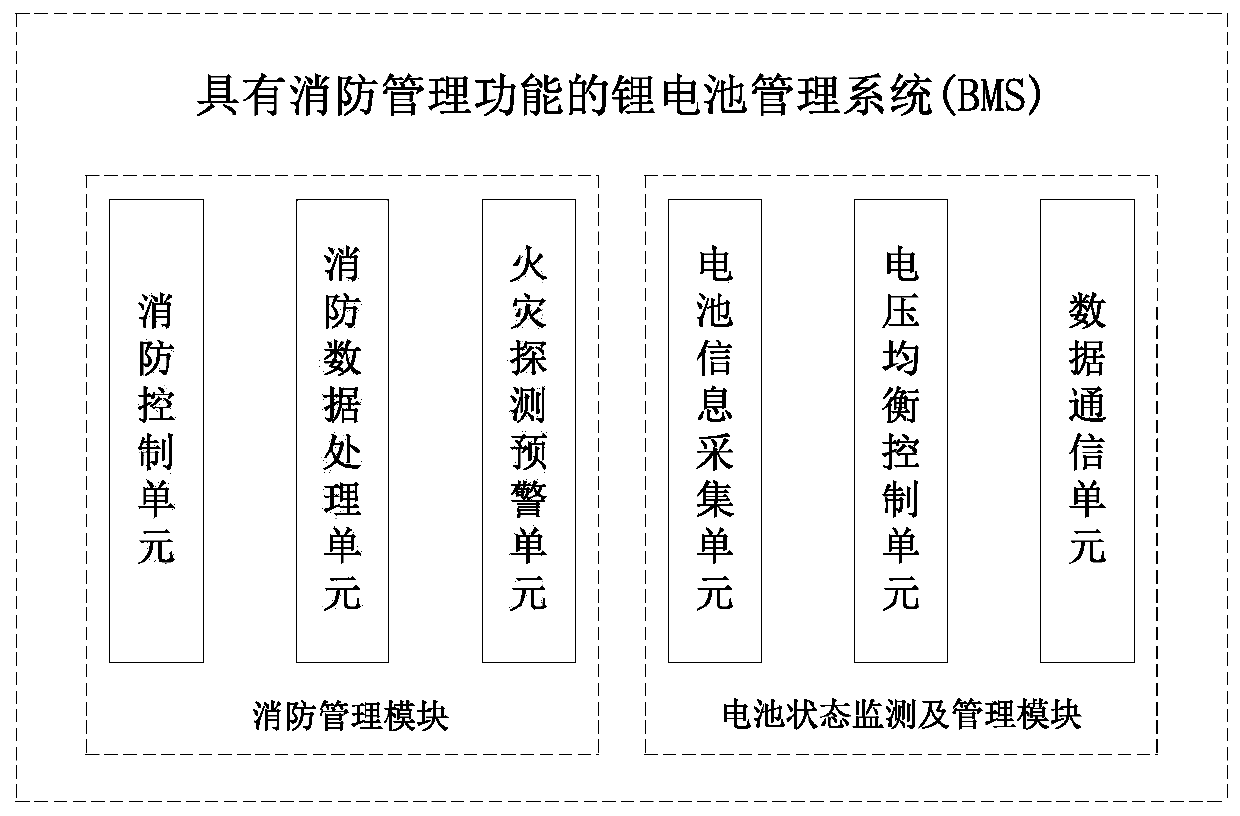

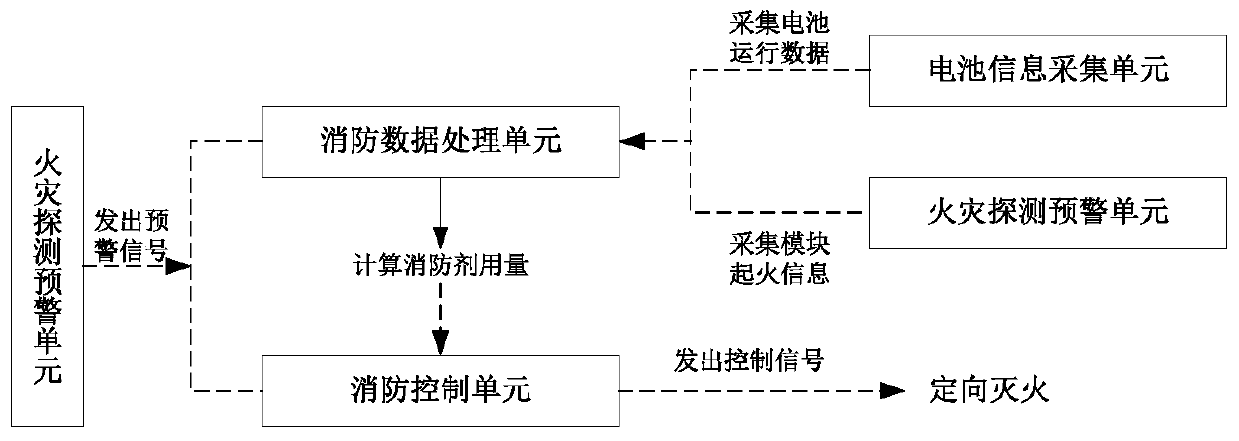

Lithium battery management system with fire management function

InactiveCN110401235AAvoid fire or even explosionImprove securityBatteries circuit arrangementsElectric powerCondition monitoringFire detection

The invention discloses a lithium battery management system with a fire management function, which comprises a battery condition monitoring and management module and a fire management module, whereinthe fire management module comprises a fire detection early warning unit, a fire data processing unit and a fire control unit; the fire detection early warning unit is used for detecting the fire state of the battery module, collecting the fire information and sending an early warning signal; the fire data processing unit is configured to calculate the fire extinguishing agent amount required forthe fire extinguishing of the battery module after receiving the early warning signal; and the fire control unit is used for sending a control signal according to the early warning signal, spraying the fire extinguishing agent to the fire battery module corresponding to the early warning signal for directional fire extinguishing and accurately controlling the fire extinguishing agent use amount according to the fire extinguishing agent use amount parameter. Through linkage control of the battery management and the fire management, directional and accurate fire extinguishing for each module inthe lithium battery energy storage system can be realized, the safety of the lithium battery energy storage system is improved, the fire extinguishing agent use amount can also be accurately controlled, and the fire cost is reduced.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +2

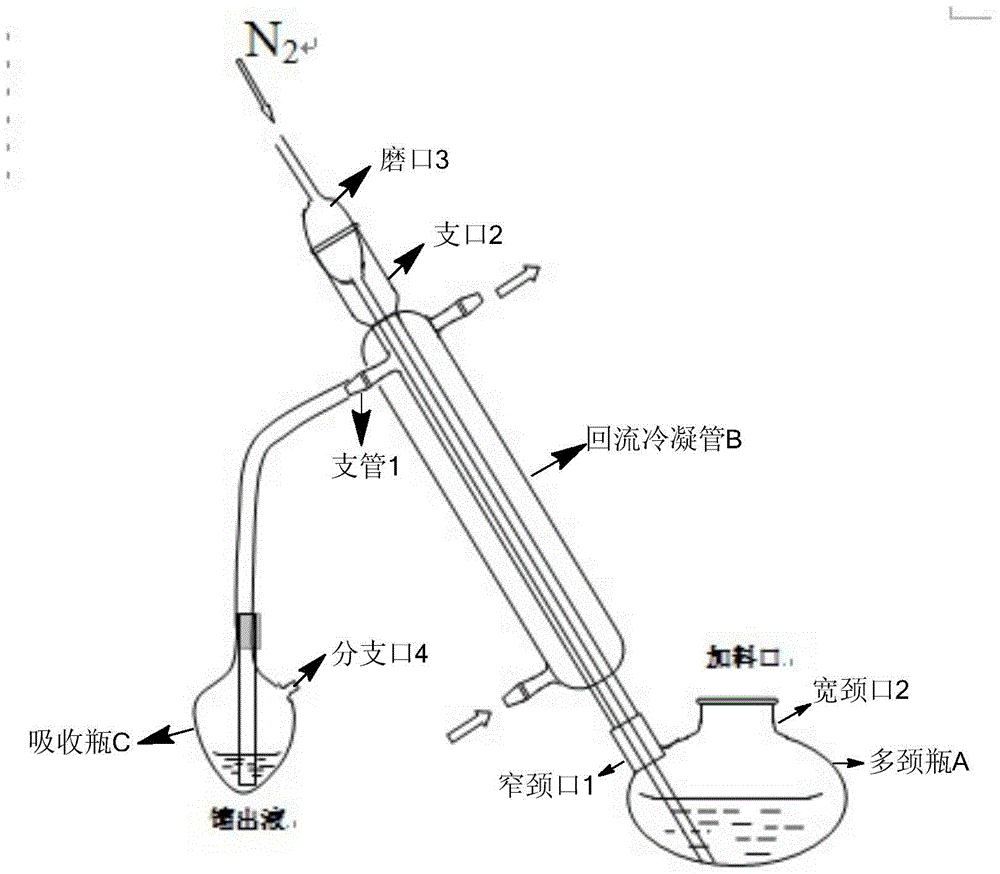

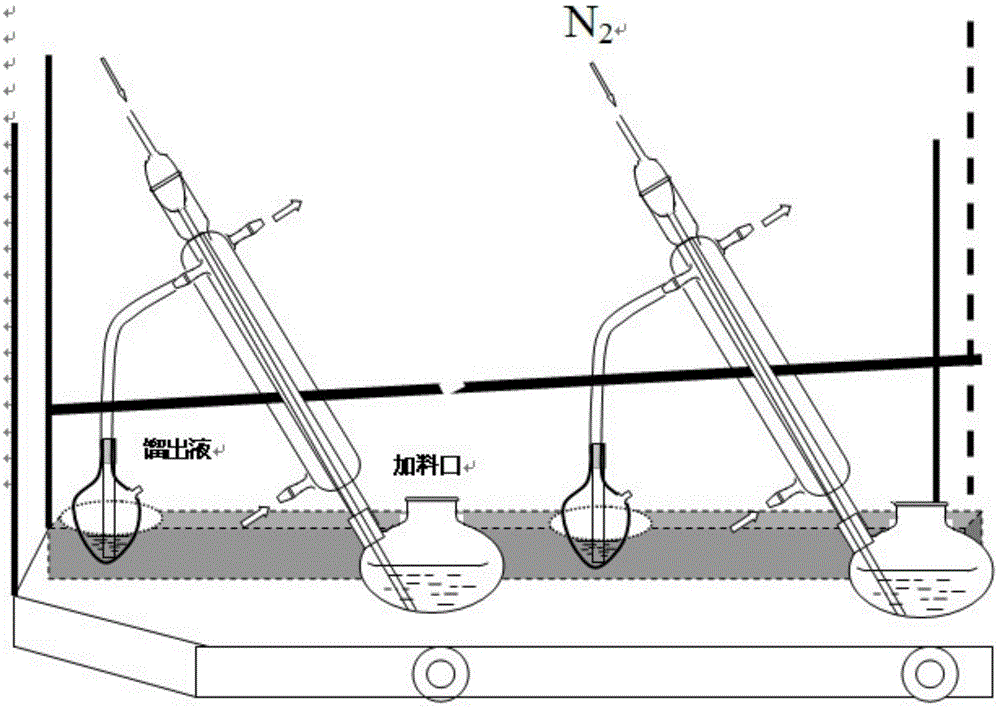

Inflating and deflating device

The invention discloses an inflating and deflating device. The inflating and deflating device comprises a multi-neck flask (A), a reflux condensing tube (B) and an absorption bottle (C) and is characterized in that a narrow neck (1) of the multi-neck flask (A) is connected with the reflux condensing tube (B), a branch tube (1) of the reflux condensing tube (B) is connected with the absorption bottle (C), a branch mouth (2) of the reflux condensing tube (B) is connected with a ground mouth (3) with branch tubes at the two ends, and one end of the ground mouth (3) is connected with an inflating device (D). The inflating and deflating device is simple and low in firing cost, and operation is convenient when carbon dioxide in food is detected.

Owner:COMPREHENSIVE TECH SERVICE CENT OF QUANZHOU ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF P R C

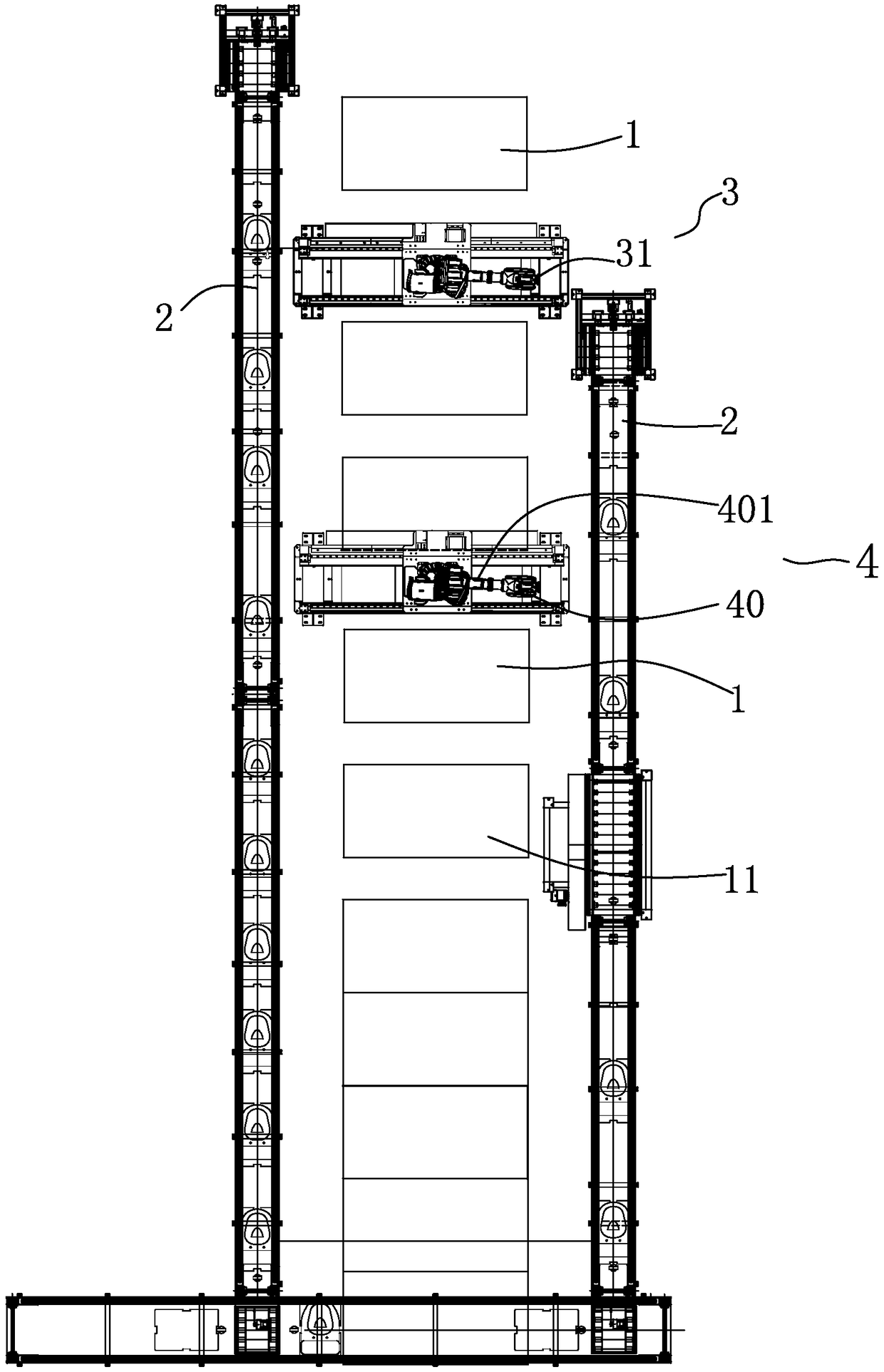

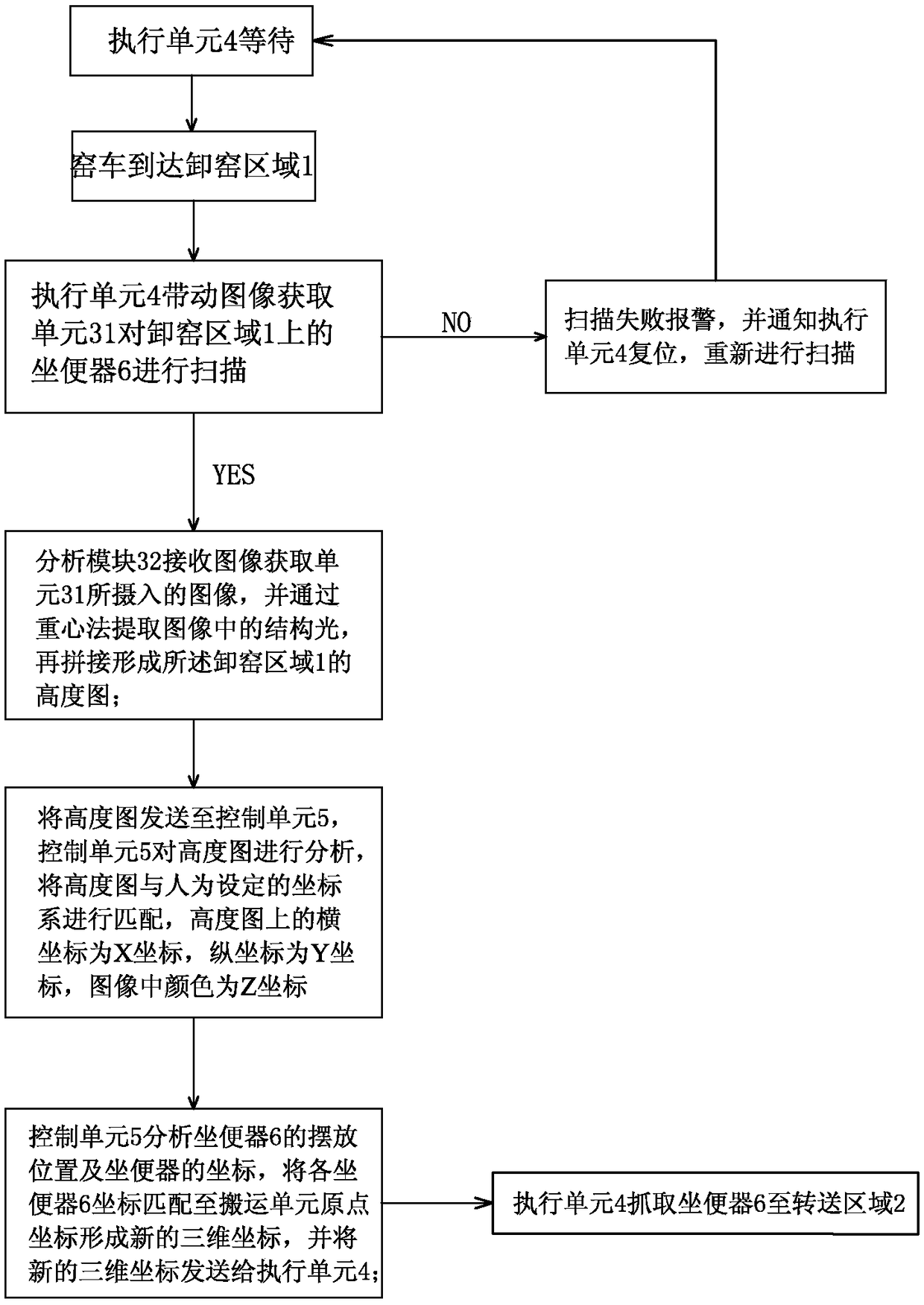

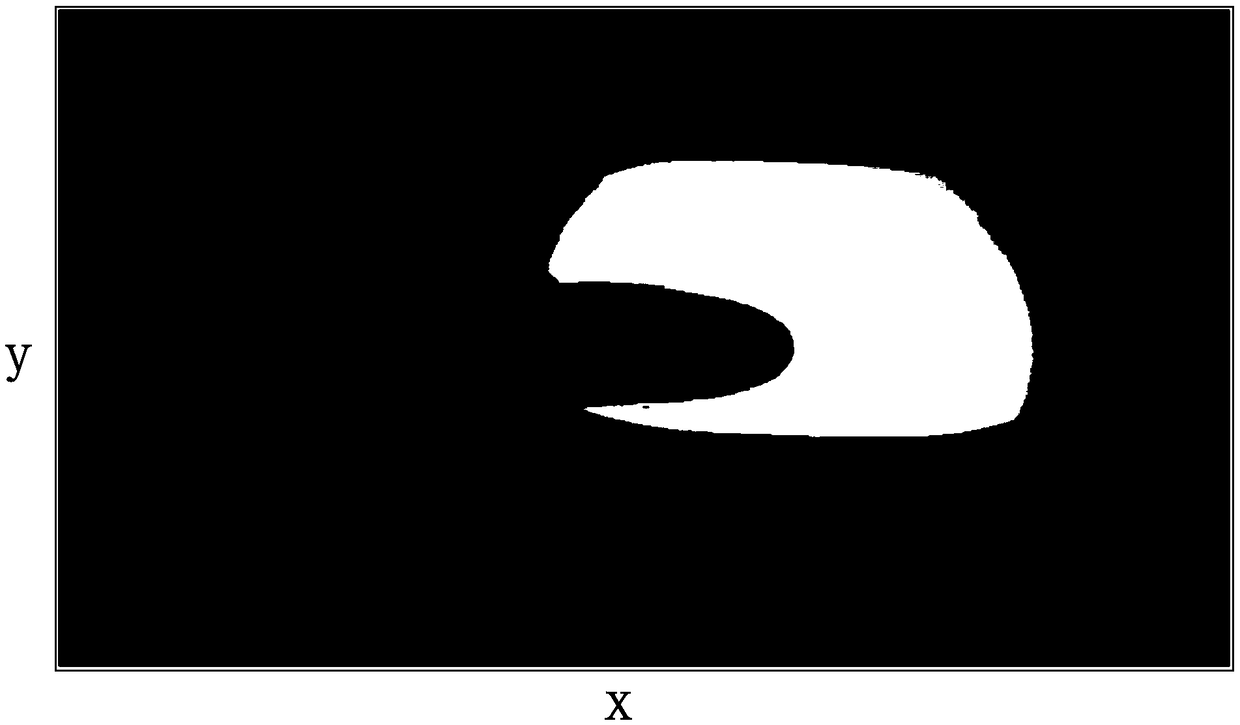

Sanitary ceramic toilet automatic kiln unloading method and automatic kiln unloading device

PendingCN108805925ASimple structureReasonable designImage analysisCharge manipulationComputer scienceCeramic

The invention discloses a sanitary ceramic toilet automatic kiln unloading method and an automatic kiln unloading device. The method comprises the following steps that a toilet in a kiln unloading area is scanned and photographed so that the image of the toilet in the kiln unloading area is acquired; the photographed image is analyzed, the image is extracted through a centroid method and the height image of a whole kiln unloading area is formed; the height image and a coordinate system which is manually set are matched; a control unit analyzes the placement position of the toilet and the coordinate of the toilet, and matches the coordinate of each toilet to the original point coordinate of a carrying unit to form a three-dimensional coordinate used for grabbing the toilet; the carrying unit carries out displacement according to the coordinate used for grabbing the toilet; and the carrying unit grabs the toilet and then transports to a transfer area, and the carrying unit returns to anoriginal point to carry the next toilet. By using the automatic kiln unloading method and the automatic kiln unloading device, the automatic kiln unloading of the toilet is realized, traditional manual kiln unloading, carrying and the like are not needed, the labor intensity of a worker is greatly reduced and a batch production demand is satisfied.

Owner:JOMOO KITCHEN & BATHROOM

Method for producing potassium sulphate and co-producing calcium, magnesium, phosphorus and silicon composite fertilizer by potassium feldspar

InactiveCN103183365BImprove solubilityLower firing temperatureSulfate/bisulfate preparationFertilizer mixturesApatiteDolomite

The invention relates to a method for producing potassium sulphate and co-producing a calcium, magnesium, phosphorus and silicon composite fertilizer by potassium feldspar. The method comprises the following steps of: preparing materials, crushing and mixing the materials to form raw materials, homogenizing and calcining, and finally preparing potassium sulphate and calcium, magnesium, phosphorus and silicon composite fertilizer. According to the method provided by the invention, compared with the prior art, not only is the sintering temperature reduced by 200 DEG G, but also the calcining cost is reduced by about 40% and the yield is improved by 4-5 times. The method is suitable for middle and medium enterprises in potassium feldspar, gypsum, apatite, cadmia or dolomite mineral resource areas to produce potash fertilizers and calcium, magnesium, phosphorus and silicon composite fertilizers.

Owner:兴安盟隆华农业科技有限公司

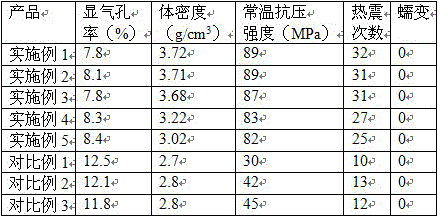

A pillar brick used for wear-resistant ceramics and a preparing method thereof

A pillar brick used for wear-resistant ceramics and a preparing method thereof are disclosed and belong to the technical field of refractory materials. The pillar brick and the method are characterized in that that pillar brick is prepared from, by weight, 27-29 parts of alumina powder, 0.7-2.1 parts of silica fume, 5-6 parts of plate-shaped emery powder, 33-37 parts of white fused alumina particles having a size of 60 meshes, 5-6 parts of fused mullite having a size of 14-150 meshes, 2.5-3.5 parts of a binder, and 3.4-4.7 parts of a suspending agent. The preparing method includes mixing the white fused alumina, the fused mullite, the binder and water by stirring, adding the alumina powder, the silica fume, the plate-shaped emery powder and the suspending agent, mixing by stirring, sealing the mixed materials, fermenting for 20-30 h, performing compression moulding, drying and firing at a low temperature. Mainly through component matching and particle size matching, the pillar brick after being fired forms a special surface crystal phase, and a low apparent porosity and high compressive strength can be maintained in long-term repeated heating and cooling.

Owner:山东铭特陶瓷材料有限公司

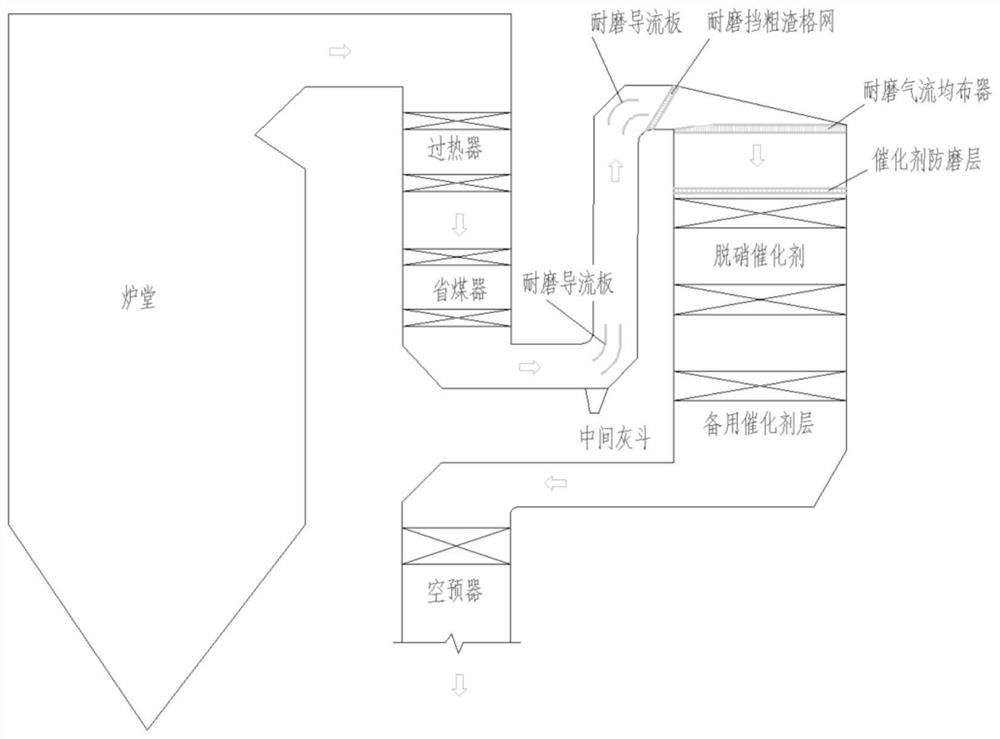

Preparation method of honeycomb-shaped wear-resistant ceramic block

The invention discloses a preparation method of a honeycomb-shaped wear-resistant ceramic block, which comprises the following steps: adding an adhesive and a forming aid into the raw materials of thehoneycomb-shaped wear-resistant ceramic block, kneading, pugging, forming, drying and sintering; the raw materials comprise 40-55wt% of cordierite powder, 10-25wt% of mullite powder, 16-22wt% of kaolin, 4-8wt% of talc, 3-6wt% of potassium feldspar, 1-3wt% of quartz and 1-2wt% of calcium carbonate; wherein the forming aid comprises a solution of xanthan gum, sodium alginate and sodium polyacrylate. The method provided by the invention is environment-friendly and low in cost, the prepared honeycomb wear-resistant ceramic block is long in service life, and the wear amount of the flue gas denitration catalyst can be reduced by more than 80%.

Owner:湖南安普诺环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com