A pillar brick used for wear-resistant ceramics and a preparing method thereof

A wear-resistant ceramic and pillar technology, which is applied in the field of refractory materials, can solve the problems of uneven density of upper and lower structures, difficulty in ensuring uniformity of products, and high product rejection rate, and achieve lower firing costs, uniform upper and lower structures, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

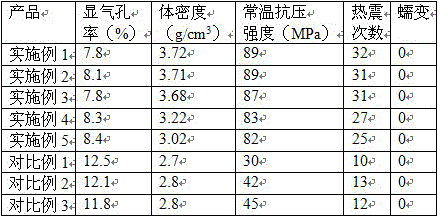

Examples

Embodiment 1

[0031] 1) Mix 35 parts of 60-mesh white corundum particles and 5.5 parts of 14-150 mesh fused mullite in proportion, and mix them evenly in a mixer;

[0032] 2) After mixing 3.1 parts of dextrin with water, add it into the mixer and mix it thoroughly for 8 minutes;

[0033] 3) Then add 28 parts of alumina powder, 1.2 parts of silica fume, 5.5 parts of platy corundum powder and 4.2 parts of polyvinyl alcohol into the mixer and mix for 8 minutes;

[0034] 4) Seal and ferment the mixed materials for 20 hours;

[0035] 5) Put the fermented material in the mold and press it into shape with a friction press;

[0036] 6) Dry the semi-finished product at 65°C after demoulding;

[0037] 7) Firing after drying, the maximum temperature of the firing curve is controlled at 1385°C and kept for 7 hours.

Embodiment 2

[0039] 1) Mix 34 parts of 60-mesh white corundum particles and 5.7 parts of 14-150 mesh fused mullite in proportion, and mix them evenly in a mixer;

[0040] 2) After mixing 3.3 parts of dextrin with water, add it into the mixer and mix it thoroughly for 10 minutes;

[0041] 3) Then add 28.5 parts of alumina powder, 0.9 parts of silica fume, 5.7 parts of platy corundum powder, and 3.8 parts of polyvinyl alcohol into the mixer and mix for 10 minutes;

[0042] 4) Seal and ferment the mixed materials for 21 hours;

[0043] 5) Put the fermented material in the mold and press it into shape with a friction press;

[0044] 6) Dry the semi-finished product at 60°C after demoulding;

[0045] 7) Firing after drying, the highest temperature of the firing curve is controlled at 1387°C for 8 hours.

Embodiment 3

[0047] 1) Mix 36 parts of 60-mesh white corundum particles and 5.3 parts of 14-150 mesh fused mullite in proportion, and mix them evenly in a mixer;

[0048] 2) After mixing 2.7 parts of dextrin with water, add it into the mixer and mix it thoroughly for 13 minutes;

[0049] 3) Then add 27.5 parts of alumina powder, 1.6 parts of silica fume, 5.2 parts of platy corundum powder and 4.5 parts of polyvinyl alcohol into the mixer and mix for 13 minutes;

[0050] 4) Seal and ferment the mixed materials for 24 hours;

[0051] 5) Put the fermented material in the mold and press it into shape with a friction press;

[0052] 6) Dry the semi-finished product at 75°C after demoulding;

[0053] 7) Firing after drying, the highest temperature of the firing curve is controlled at 1390°C for 9 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com