Production method for cement clinker by utilizing waste materials from calcium carbide production

A technology of cement clinker and waste, which is applied in the field of building materials, can solve the problems of fewer reports on process methods, and achieve the effects of reducing firing costs, reducing emissions, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

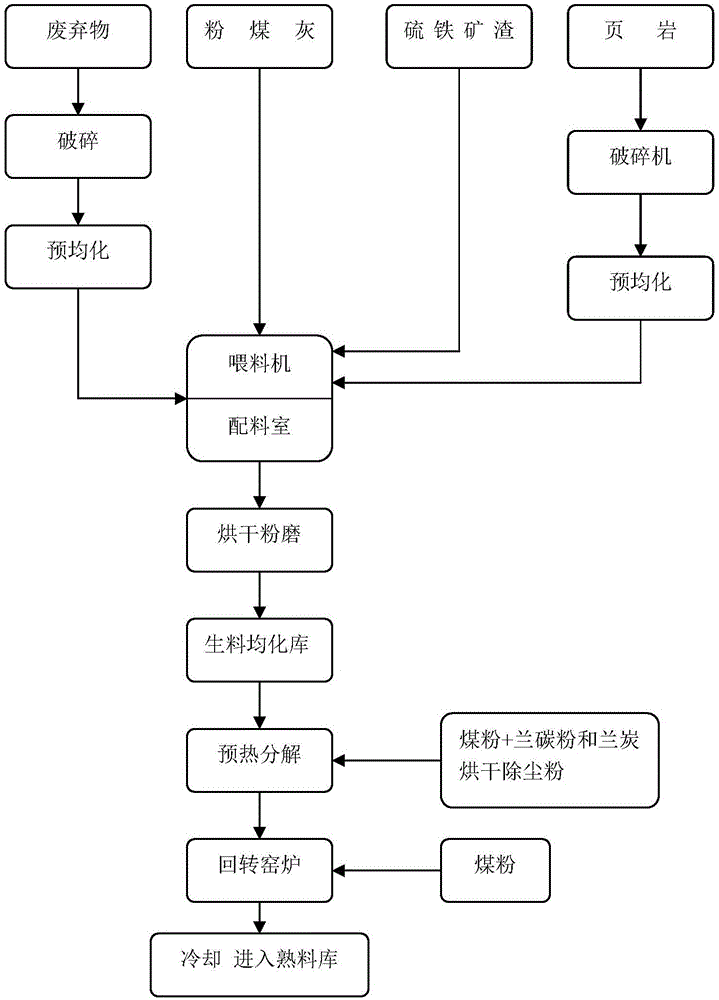

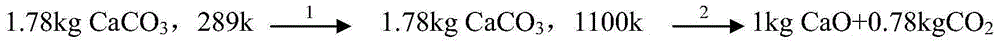

Method used

Image

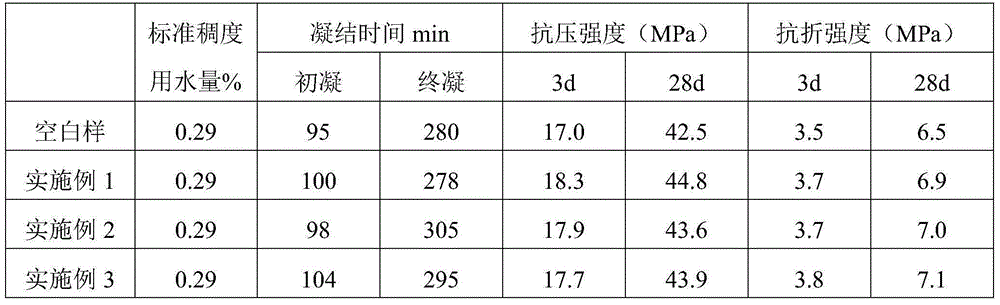

Examples

Embodiment 1

[0035] The preparation steps of the embodiment of the present invention are as follows:

[0036] 1. Calculate the ratio of raw materials by calculating the silicon rate (SM), aluminum rate (IM) and clinker saturation coefficient (KH) of cement clinker; the main chemical composition of each raw material (%)

[0037] name

Fe 2 o 3

SiO 2

CaO

al 2 o 3

63.46

12.07

3.35

1.9

4.46

53.52

4.79

26.2

shale

6.87

52.24

4.27

8.39

quicklime powder

0.4

0

83.5

0.9

0.19

2.42

53.13

0.31

[0038] In this example, 3% of pyrite slag, 14% of fly ash, 12% of shale, 40% of quicklime powder, and 31% of lime kiln dust removal powder

[0039] Among them: Fe 2 o 3 %=63.46×0.03+4.46×0.14+6.87×0.12+0.4×0.4+0.19×0.31=3.57

[0040] SiO 2 %=12.07×0.03+53.52×0.14+52.24×0.12+0×0.4+2.42×0.31=14.9

[0041] ...

Embodiment 2

[0052] The preparation steps of the embodiment of the present invention are as follows:

[0053] 1. Calculate the ratio of raw materials by calculating the silicon rate (SM), aluminum rate (IM) and clinker saturation coefficient (KH) of cement clinker; the main chemical composition of each raw material (%)

[0054] name

Fe 2 o 3

SiO 2

CaO

Al 2 o 3

pyrite slag

63.46

12.07

3.35

1.9

fly ash

4.46

53.52

4.79

26.2

shale

6.87

52.24

4.27

8.39

quicklime powder

0.4

0

83.5

0.9

Lime kiln dust removal powder

0.19

2.42

53.13

0.31

[0055] In this example, 3% of pyrite slag, 14% of fly ash, 10% of shale, 35% of quicklime powder, and 38% of lime kiln dust removal powder

[0056] Among them: Fe 2 o 3 %=63.46×0.03+4.46×0.14+6.87×0.10+0.4×0.35+0.19×0.38=3.4

[0057] SiO 2 %=12.07×0.03+53.52×0.14+52.24×0.10+0×0.35+2.42×0.38=14.0

[0058]...

Embodiment 3

[0069] The preparation steps of the embodiment of the present invention are as follows:

[0070] 1. Calculate the ratio of raw materials by calculating the silicon rate (SM), aluminum rate (IM) and clinker saturation coefficient (KH) of cement clinker; the main chemical composition of each raw material (%)

[0071] name

Fe 2 o 3

SiO 2

CaO

Al 2 o 3

pyrite slag

63.46

12.07

3.35

1.9

fly ash

4.46

53.52

4.79

26.2

shale

6.87

52.24

4.27

8.39

quicklime powder

0.4

0

83.5

0.9

Lime kiln dust removal powder

0.19

2.42

53.13

0.31

[0072] In this example, 3% of pyrite slag, 14% of fly ash, 11% of shale, 32% of quicklime powder, and 40% of lime kiln dust removal powder

[0073] Among them: Fe 2 o 3 %=63.46×0.03+4.46×0.14+6.87×0.11+0.4×0.32+0.19×0.4=3.48

[0074] SiO 2 %=12.07×0.03+53.52×0.14+52.24×0.11+0×0.32+2.42×0.4=14.6

[0075] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com