Method for carrying out secondary equipment whole life cycle management by electronic label

A technology with a full life cycle and secondary equipment, applied in data processing applications, collaborative devices, instruments, etc., can solve the problems of inconsistent accounts, large workload, and error-prone, avoid idle waste, and improve the level of standardization , Improve the effect of lean level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method for managing the life cycle of secondary equipment using electronic tags provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

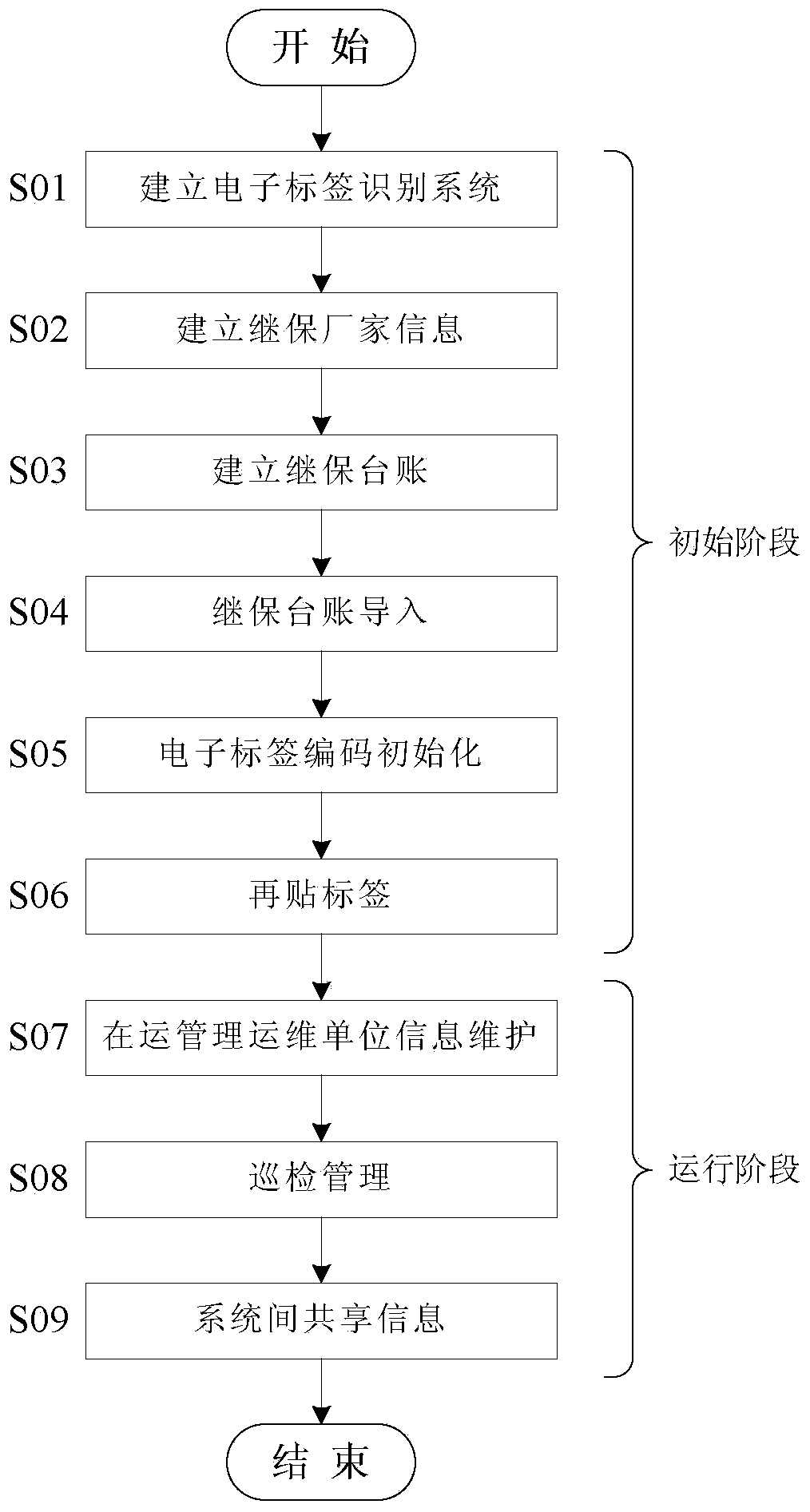

[0025] Such as figure 1 As shown, the method for applying electronic tags to manage the life cycle of secondary equipment provided by the present invention includes the following steps performed in order:

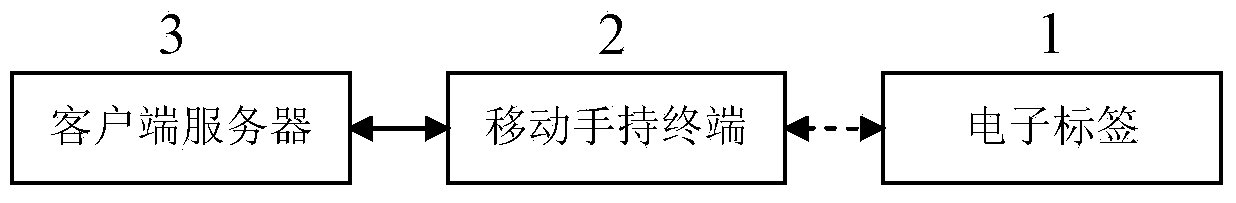

[0026] Step 1) set up the S01 stage of the electronic tag identification system: set up as figure 2 The shown electronic tag identification system based on RFID technology includes: an electronic tag 1, a mobile handheld terminal 2 and a client server 3; wherein: the mobile handheld terminal 2 communicates with the electronic tag 1 through electromagnetic induction; the mobile handheld The terminal 2 is a handheld computer with the function of reading and writing the electronic tag 1, which is used to realize the initialization of the electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com