Patents

Literature

170results about How to "Conform to energy saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-density composite foaming cement and preparation method thereof

The invention discloses low-density composite foaming cement and a preparation method thereof, relating to a light building material. The foaming cement is prepared by adopting a normal-temperature foaming technology, and comprises the following components in parts by weight: 100 parts of cement, 10-50 parts of active admixture, 1-5 parts of redispersible emulsion powder, 1-4 parts of water repellent, 0.5-1.5 parts of cellulose ether, 0.3-0.7 parts of reinforced fiber, 0.2-0.5 parts of foam stabilizer, 3-8 parts of foaming agent and 50-80 parts of water. The method comprises the following preparation steps of: proportionally mixing and stirring the cement, active admixture, redispersible emulsion powder, water repellent, cellulose ether, reinforced fiber, foam stabilizer, and water into cement slurry; adding the foaming agent; and stirring, molding by casting and naturally curing. The foaming cement disclosed by the invention has the advantages of low volume weight, small heat conducting coefficient, small shrinkage ratio, high intensity, integration of heat preservation, sound insulation, fire prevention and low carbon, simple and convenient production preparation process and easiness in controlling.

Owner:JIANGSU JINMAO TECH DEV

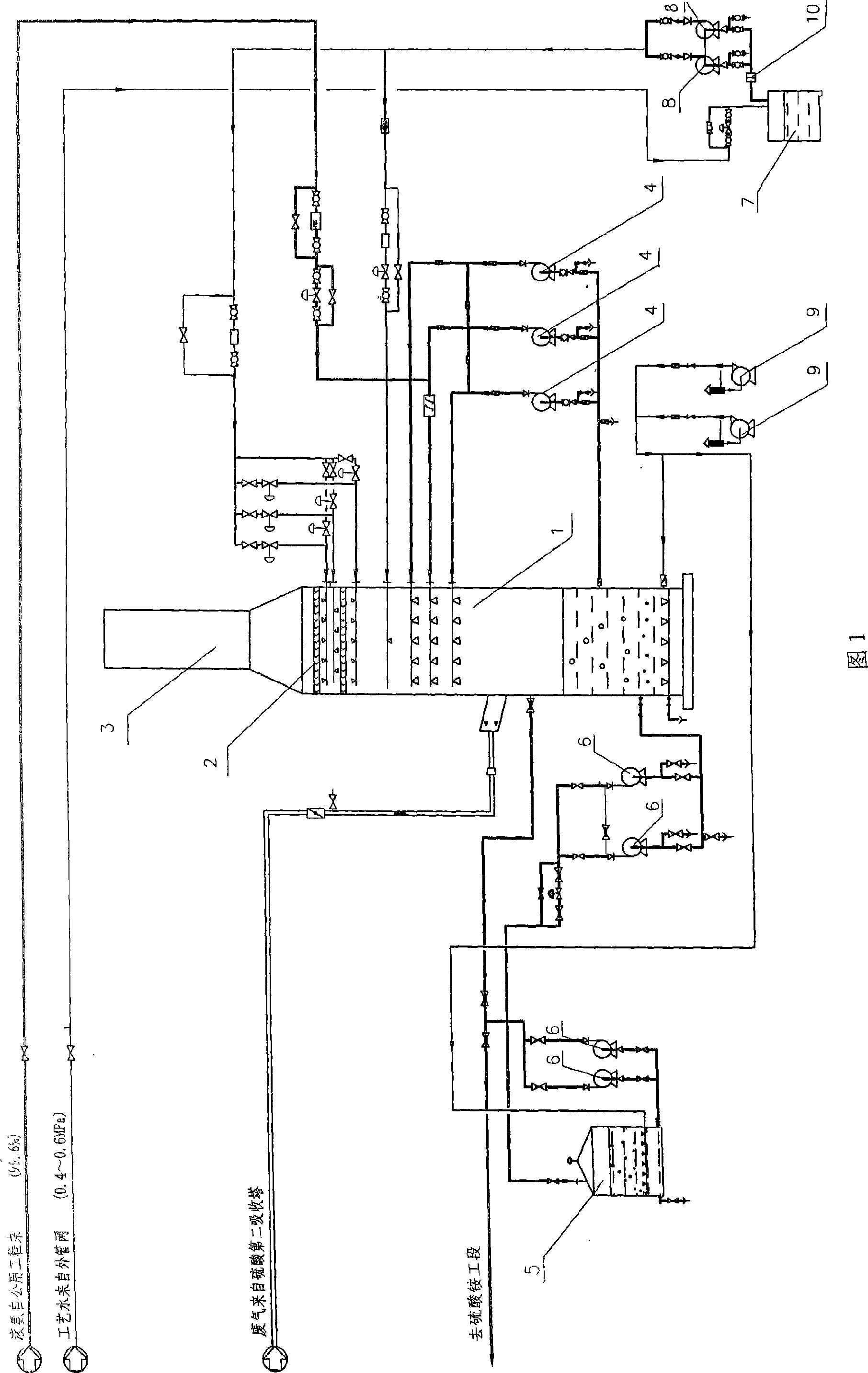

Sulphuric acid tail-gas deep desulfurization method

InactiveCN101422693AEmission reductionBig investmentDispersed particle separationEnergy conservationChemistry

The invention discloses a deep desulfurization method of sulfate acid tail gas. The method additionally arranges a desulfurization tower behind a second adsorption tower of a sulphuric acid device; after the waste gas discharged from the second adsorption tower enters the desulfurization tower, an ammoniation absorbent is used for adsorbing SO2 in the waste gas to generate ammonium sulfite; the tail gas after the desulfurization passes through a demisting layer in the tower to eliminate acid fog; the purified tail gas is discharged through a chimney at high altitude; the ammonium sulfite in the absorbent is aerated and oxidized to be ammonium sulfate solution at the bottom of the tower; and after the concentration of circulation liquid ammonium sulfate meets the requirement, the circulation liquid ammonium sulfate is sent to a follow-up process to be processed and used. The deep desulfurization method of sulfate acid tail gas can cause the concentration of the SO2 in the tail gas to be lower than 100mg / m<3> in a standard state, greatly reduces the emission of the SO2 in the tail gas, is beneficial to the improvement of the atmospheric environment quality, meets the construction principles of energy conservation, emission reduction and sustainable development and has good social benefits; in addition, the deep desulfurization method can increase the recovery amount of the ammonium sulfate, and has certain economic benefits.

Owner:GUIZHOU KAILIN GRP CO LTD

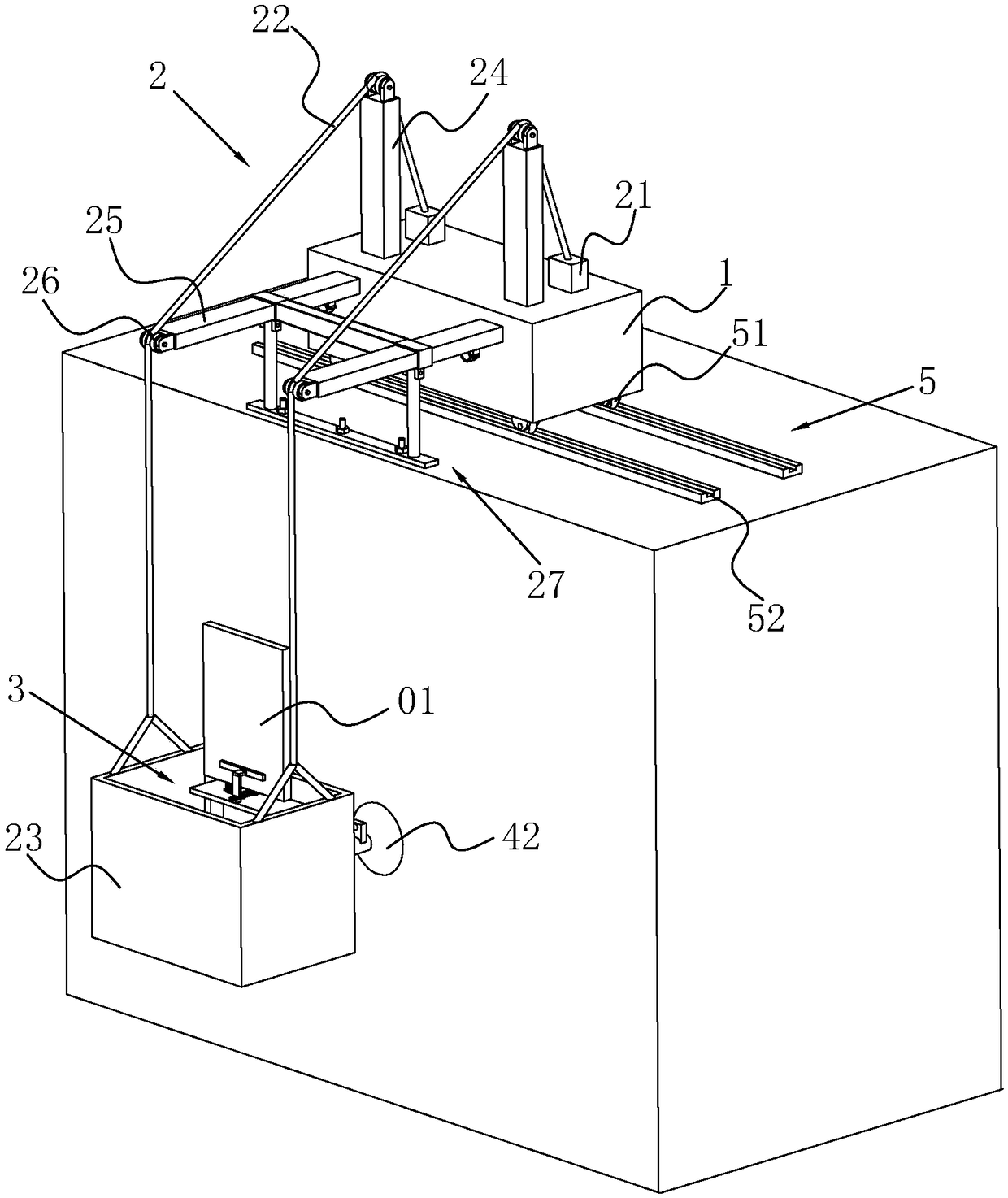

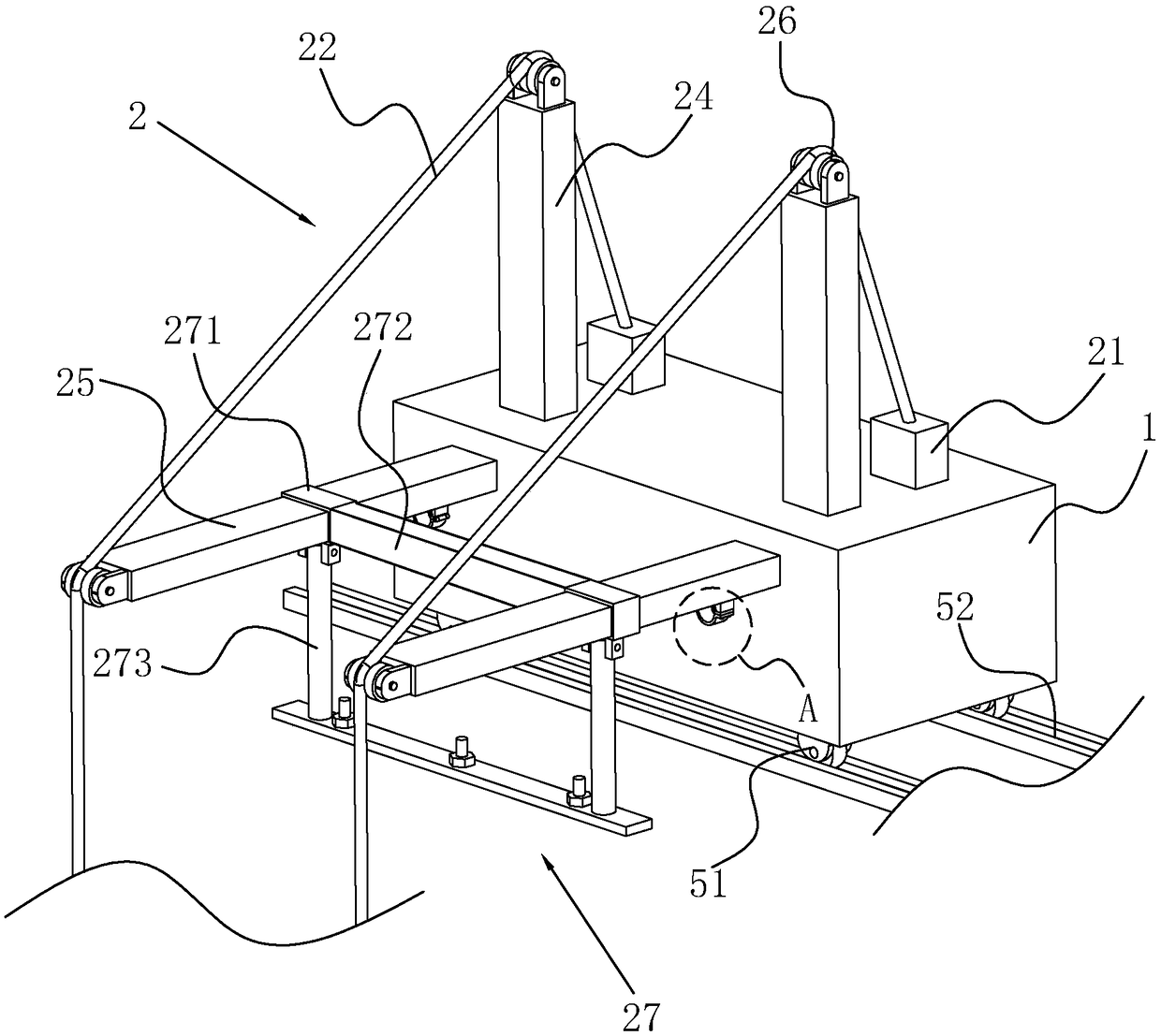

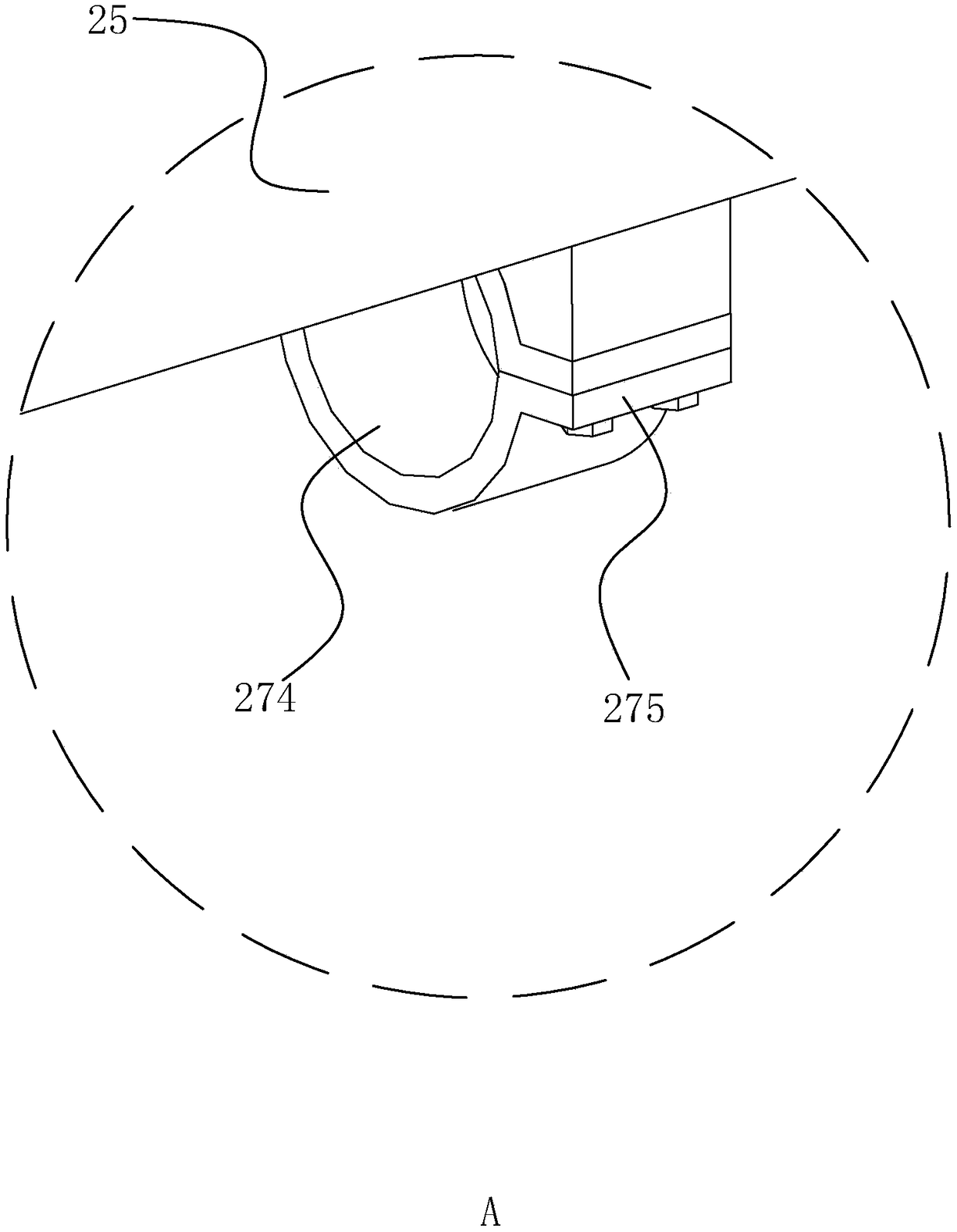

Fabricated architectural decoration stone artificial board curtain wall mounting frame

InactiveCN108952184AImprove conveniencePlay a supporting roleWallsBuilding material handlingEngineeringHanging basket

The invention discloses a fabricated architectural decoration stone artificial board curtain wall mounting frame and relates to the technical field of curtain wall mounting. The problems that in the prior art, the overall weight of a mounting frame is difficult to support by a guide rail attached to a wall, a large quantity of areas around the roof surface are occupied, consequently the strength is low, stability is poor, and curtain wall mounting is inconvenient are solved. The fabricated architectural decoration stone artificial board curtain wall mounting frame is characterized in that thefabricated architectural decoration stone artificial board curtain wall mounting frame comprises a base, a hoisting support facing the outer side of a roof is arranged on the base, and a winch is mounted on one side of the hoisting support; the winch is connected with a hanging basket through a steel rope which is arranged along the hoisting support in a penetrating mode, and the hoisting supportcomprises two spaced supporting rods which are longitudinally arranged on the base, and two spaced cantilevers which are transversely arranged on the base; the distance between the supporting rods isequal to the distance between the cantilevers and equal to the length of the hanging basket, and fixed pulleys are arranged at the ends, away from the base, of the supporting rods as well as the ends,away from the supporting rods, of the cantilevers correspondingly; and the ends, close to the fixed pulleys, of the cantilevers are provided with roof surface steel trusses. The fabricated architectural decoration stone artificial board curtain wall mounting frame has the advantages that the strength is high, the stability is good, and curtain wall mounting is convenient.

Owner:江苏华欣装饰集团有限公司

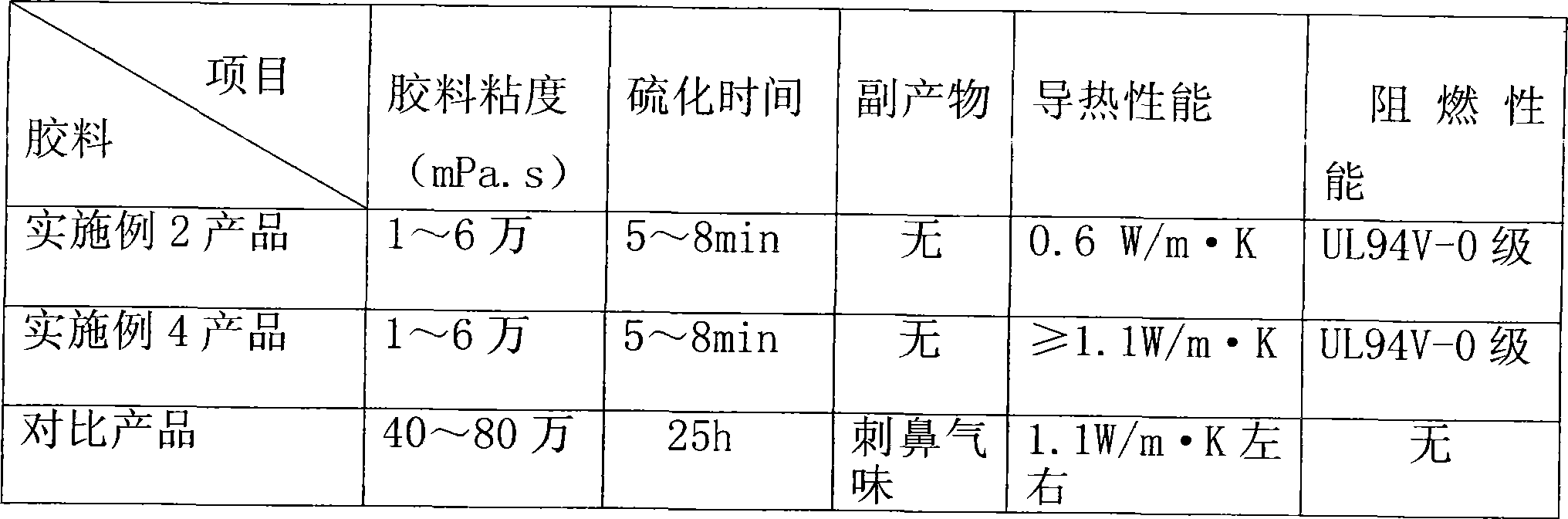

Heat-conducting anti-flaming liquid silicon rubber and preparation method thereof

InactiveCN101168620AReduce consumptionIncrease demandHeat-exchange elementsVulcanizationHeat conducting

The invention discloses heat conduction flame retardant liquid silica gel, which comprises components with the following parts by weight: 10 to 40 parts of vinyl end organopolysiloxane with 500 to 5000 mPa.s polymeric viscosity in 25 DEG C, 10 to 40 parts of vinyl end organopolysiloxane with 10000 to 50000 mPa.s in 25 DEG C, and 1 to 5 parts of hydrogen-containing polymethylsiloxane, 2 to 8 parts of alkyl disilazane, 20 to 50 parts of surface hydrophobicity Al2O3 powder with average particle diameter of 5 to 20 microns, 10 to 50 parts of Al(OH)3 powder with average particle diameter of 5 to 20 microns, 0.3 to 2 parts of addition solidification catalyst, 0.01 to 0.06 part of alkynol depressant and 0.5 to 2 parts of distilled water, wherein, R is methyl, ethyl, propyl or butyl. The invention is prepared by the way of addition type heat vulcanization, toxic substance or irritant gas is not produced in the production process, the vulcanization rate is quick, and the energy saving, the consumption decreasing and the environmental protection requirements are conformed. The storage stability of the product is good, the viscosity is moderate, the operability is good, the product integrates the heat conduction, insulation and flame retardant performances into a whole, and the performance-price ratio is high.

Owner:兆舜科技(广东)有限公司

Fermented organic fertilizer

InactiveCN104744087AReduce usageImprove filtration efficiencyBio-organic fraction processingOrganic fertiliser preparationMicrobial agentCorn meal

The invention discloses a fermented organic fertilizer. The fermented organic fertilizer comprises the following components in parts by mass: 1000-1500 parts of stalk, 1000-1300 parts of chicken manure, 1000-1500 parts of cattle manure, 800-1200 parts of pig manure, 1200-1800 parts of soybean meal, 35-50 parts of a microbial agent, 10-20 parts of peat humic acid, 50-80 parts of corn meal, 60-90 parts of composite enzyme preparation and 30-60 parts of complex bacteria. The invention also discloses a fermentation method of the fermented organic fertilizer. As the method adopts the microbial bacteria and the composite enzyme preparation, the fermentation efficiency is improved, the fermentation time is effectively reduced, the consumption amount of water, electricity and steam is reduced, the production cost is lowered, and the method is suitable for industrial large-scale production; the fermented organic fertilizer disclosed by the invention has no malodor when used in fields, is cost-saving due to the reduction in the consumption, does not result in soil impoverishment, hardening and salinization, and meets the trend of energy-saving, environment-friendly and sustainable development.

Owner:福建亚森农业综合开发股份公司

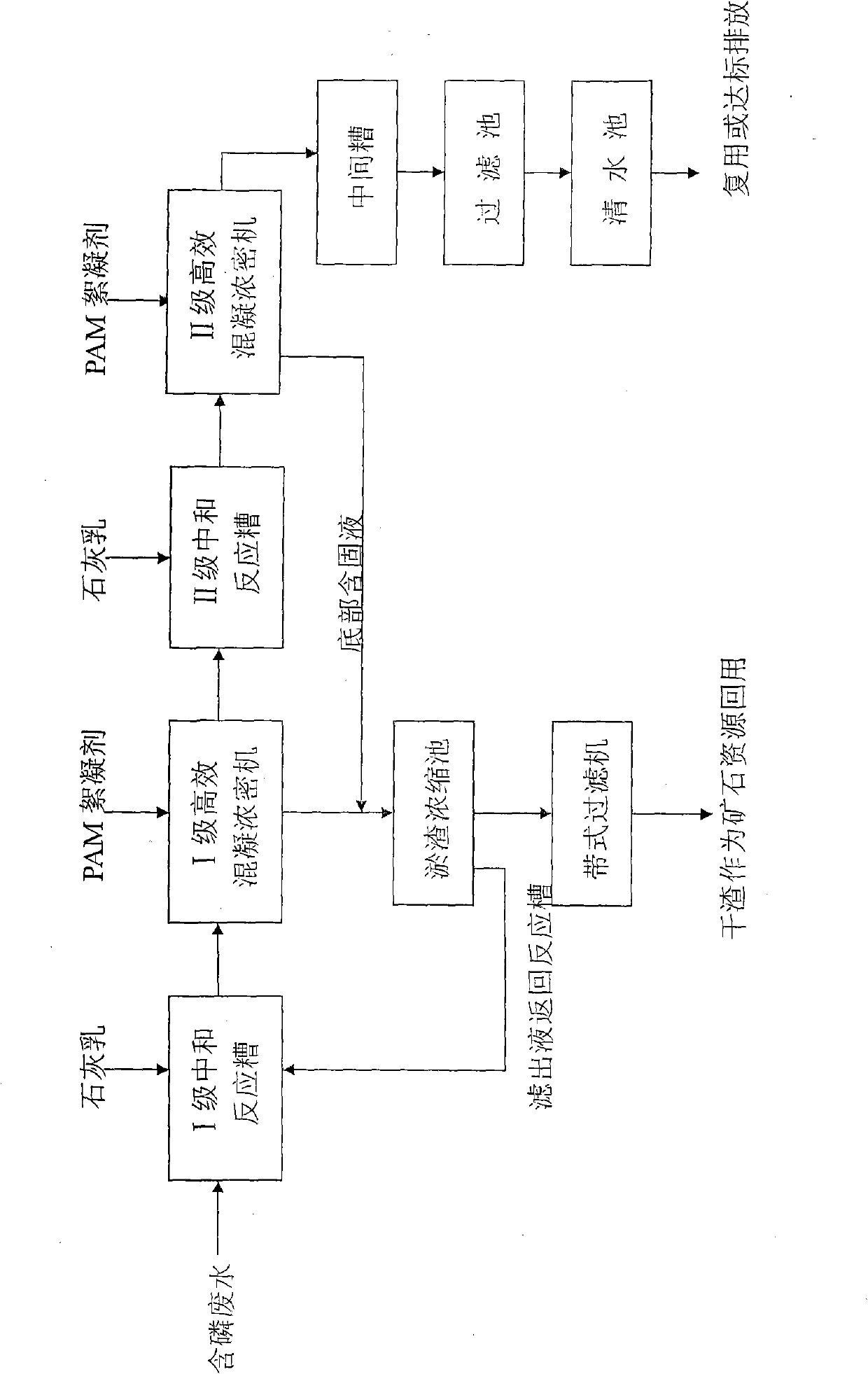

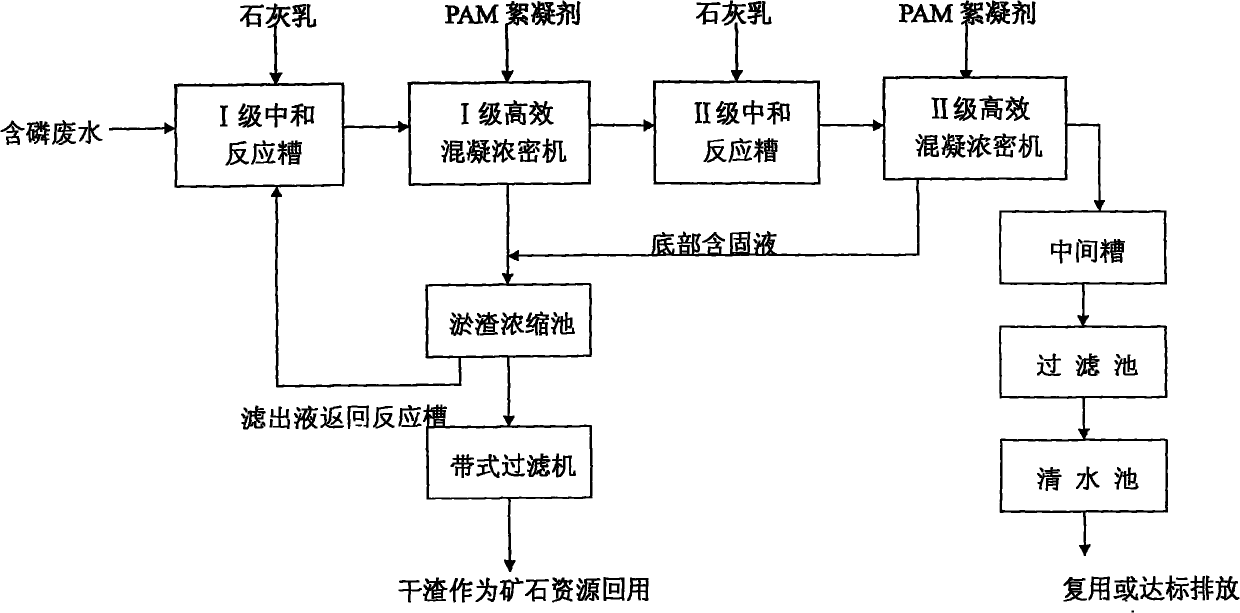

Treating method for phosphoric waste water and sludge generated in production process of phosphatic compound fertilizer

InactiveCN101905933AConform to energy savingEconomicalMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludgeFiltration

The invention discloses a treating method for phosphoric waste water and sludge generated in the production process of a phosphatic compound fertilizer, which comprises the following steps: adding lime milk into the phosphoric waste water to be treated firstly, and controlling a pH value to be 5-6; carrying out neutralization reaction for the first time; adding a PAM flocculating agent for flocculation reaction and then carrying out separation of mud and water; adding the lime milk in the aqueous phase again, and controlling the pH value to be 10-11 for the neutralization reaction for the second time; and adding the PAM flocculating agent again for the flocculation reaction and then carrying out the separation of mud and water, wherein the aqueous phase reaches a effluent standard after filtration. The invention realizes the multiplexing or the standard-reaching discharge of the waste water, the zero release of the sludge, accords to the developing direction of the energy saving and emission reduction and circular economy. The clear liquid treated by the process of the invention contains 0.4-0.5mg / L of phosphate (calculated by being based on P2O5), 8-9mg / L of F and 60-80mg / L of COD, meets the primary standard emission requirement of GB8978-1996, the ultimate clear liquid can be returned to a phosphoric acid device for multiplexing, and also be directly discharged after reaching standards; and the sludge produced by the filtration comprises the following main components: calcium phosphate, calcium fluoride, calcium carbonate and calcium sulfate, which can be totally reused as phosphorite resources.

Owner:中化重庆涪陵化工有限公司

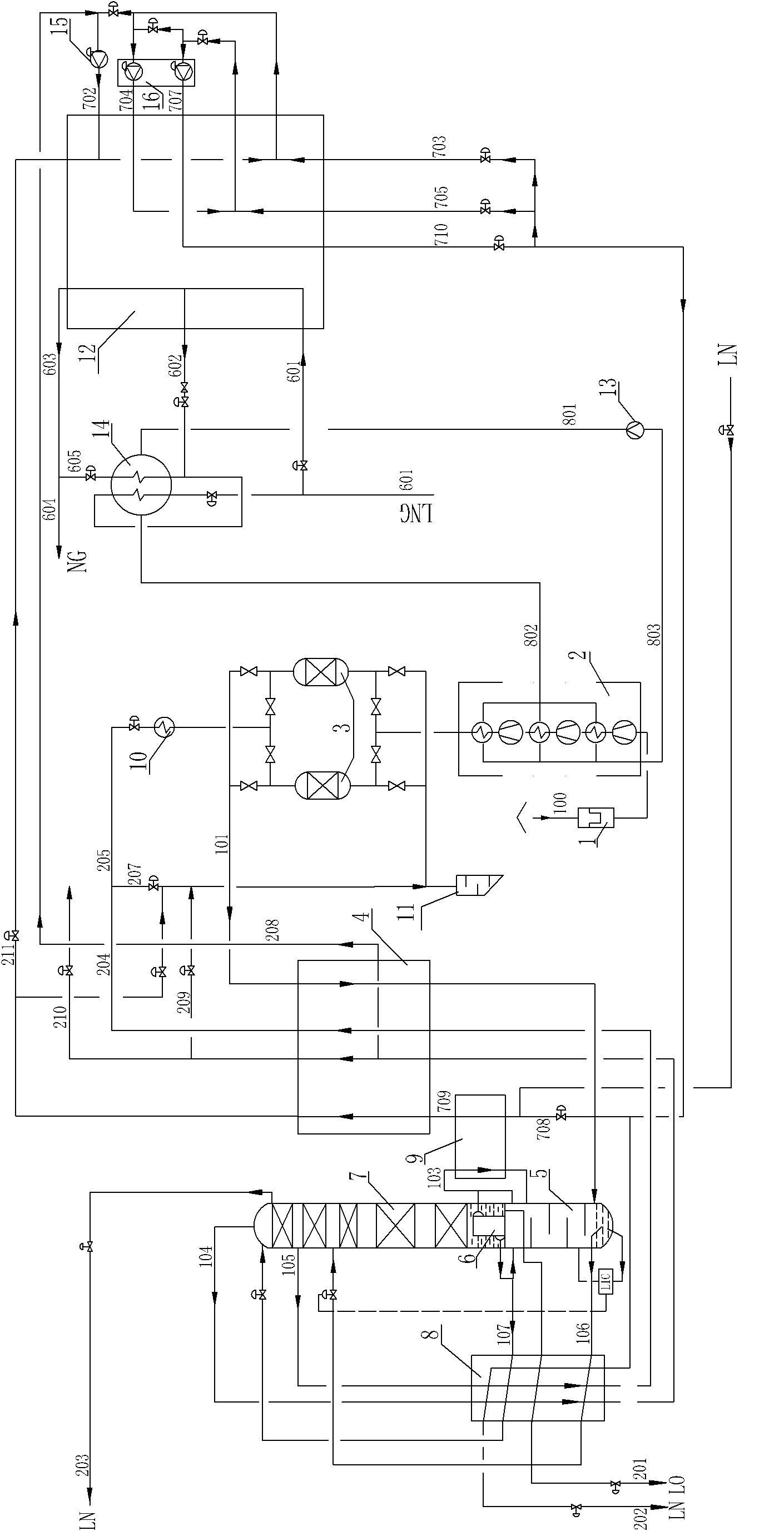

Air separation method utilizing liquefied natural gas cold energy

ActiveCN101571340AReduce unit power consumptionConform to energy savingSolidificationLiquefactionLiquefied natural gasSocial benefits

The invention discloses an air separation method utilizing liquefied natural gas cold energy, comprising an air separation unit, an LNG cold energy utilization unit providing refrigeration energy for the LNG cold energy utilization unit and a glycol water solution circulation unit utilizing NG high temperature cold energy. In the invention, low temperature cold energy of the LNG is applied to the air separation system, thus unit power consumption of a liquid air separation product can be reduced to about 0.30kwh / m, which is one third of the unit power consumption of a liquid air separation product in conventional process production; and unit power consumption of the internal compressed gas product also can be greatly reduced, and meanwhile a large number of cooling water can be saved, thus being in accordance with the trend of energy saving, consumption reduction and circular economy developing and having obvious social benefit and economic benefit.

Owner:CHINA NAT OFFSHORE OIL CORP +3

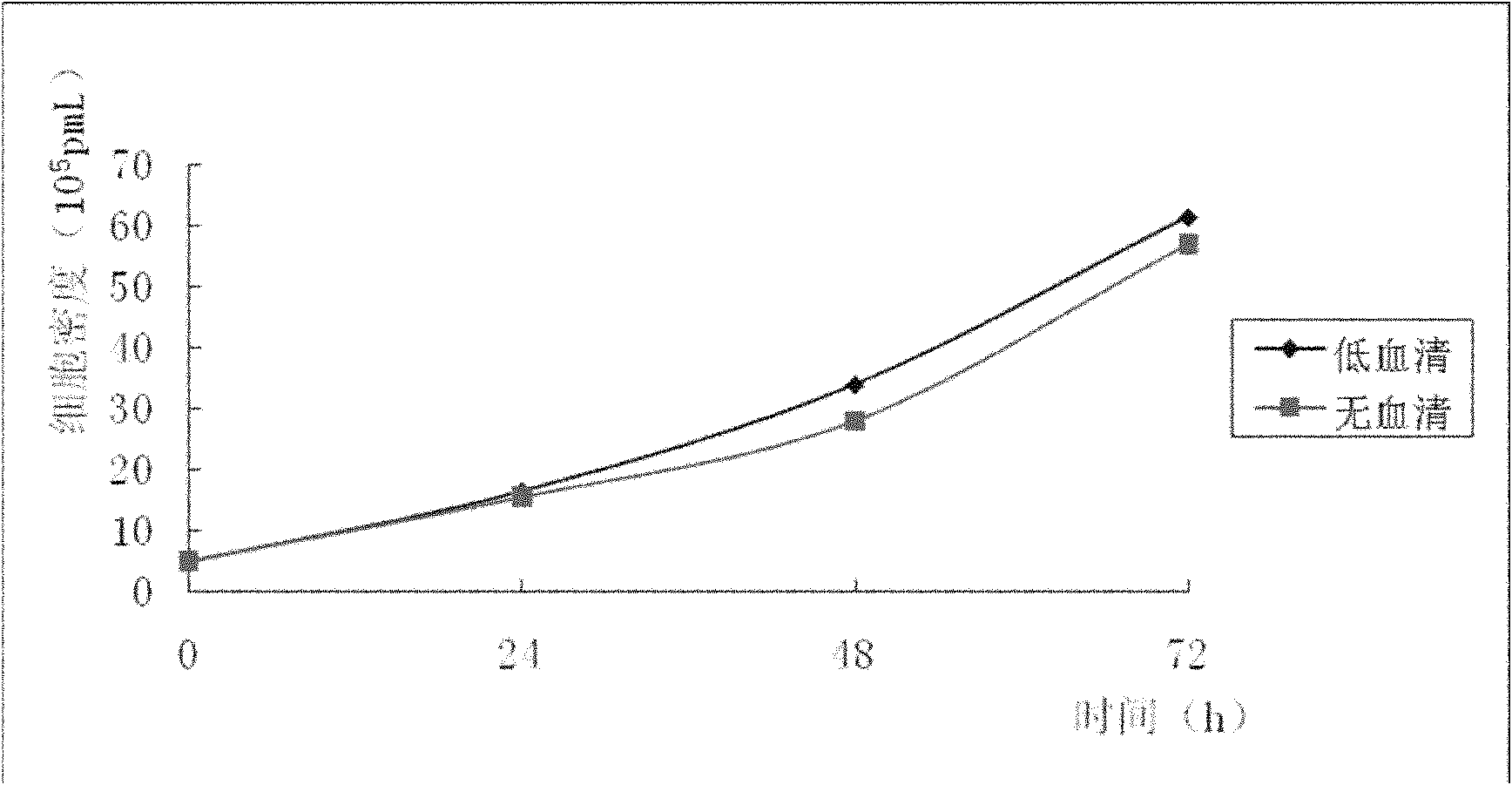

Baby hamster kidney (BHK)-21 cells obtained by high-density suspension culture in low-serum and serum-free culture medium and preparation method thereof

ActiveCN102154197AReduce investmentConform to energy savingArtificial cell constructsVertebrate cellsCulture fluidHamster

The invention provides BHK-21 cells obtained by high-density suspension culture in a low-serum and serum-free culture medium and a culture method thereof. The culture method comprises the following steps: 1) resuscitating frozen BHK-21 cells and performing adherent culture to obtain adherently cultured BHK-21 cells; 2) subculturing the adherently cultured BHK-21 cells in culture solution to obtain suspension-cultured BHK-21 cells and freezing the BHK-21 cells; 3) performing resuscitation culture of the suspension-cultured BHK-21 cells and performing biological property identification; and 4) performing bioreactor adaptive culture of the suspension-cultured BHK-21 cells identified to be qualified. The invention has the advantages that: a cell domesticating method provided by the invention and the obtained BHK-21 cells which can be cultured in a suspended manner save culture solution and bovine serum, are in accordance of current energy-saving, environment-protection and low-carbon concepts for the application of suspended-cultured cells into actual production saves floor area and labor investment greatly, and create considerable economic benefit and social benefit.

Owner:马忠仁

Sintered light-weight environment-friendly brick produced from electroplating sludge and manufacture method thereof

The invention relates to a sintered light-weight environment-friendly brick produced from electroplating sludge and a manufacture method thereof. The sintered light-weight environment-friendly brick is characterized by being prepared by adopting electroplating sludge, base waste sludge, furnace slag, refuse ash, calcium oxide, calcium sulfate, sodium carbonate, boric acid, ferrous sulfate, magnesium sulfate, Li macromolecular heavy metal trapping agent and water are adopted as raw materials; and the manufacture method comprises the following steps of: mixing and stirring the raw materials in a biaxial mixer to be in a moisture state; extruding into rectangular bars by a vacuum sludge extruder; cutting and forming by a blank cutter; manufacturing light-weight environment-friendly brick blanks of electroplating sludge under the pressure of 20-30 MPa; and conveying the formed and naturally dried light-weight environment-friendly brick blanks into a tunnel kiln to roast and manufacture light-weight environment-friendly brick products. Air laying bricks and pavement bricks in different specifications can also be manufactured by the raw materials of the invention, and the product has the advantages and the effects of light weight, great strength, zero pollution, low cost and good benefits.

Owner:清远绿由环保科技有限公司

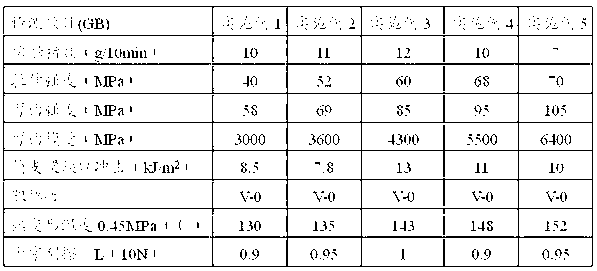

Kitchen flame-retardant and scrapping-resistant polypropylene materials and preparation method of the same

The invention discloses kitchen flame-retardant and scrapping-resistant polypropylene materials, and further discloses a preparation method of the kitchen flame-retardant and scrapping-resistant polypropylene materials. The kitchen flame-retardant and scrapping-resistant polypropylene materials are prepared from the following components: by weight, 29-55.5 parts of polypropylene, 5-20 parts of continuous glass fiber, 5-10 parts of compatilizer, 19-27 parts of compound flame retardant and 1.5-3 parts of scrapping-resistant agent. The kitchen flame-retardant and scrapping-resistant polypropylene materials have the advantages of being flame-retardant, scrapping-resistant, environment-friendly, non-poisonous, free of sucking water, mould-proof, anticorrosion, acid-alkali resistant, anti-aging, heat-resisting, recoverable, capable of conducting injection molding, convenient to process, capable of having different color custom-made according to requirements and being made into different styles and patterns in an injection molding mode according to requirements and the like, simple in production flow, continuous in production process, high in production efficiency and stable in production quality, and satisfies requirements for energy conservation, emission reduction, environmental-friendly residence, comfort and beauty, and are ideal kitchen materials.

Owner:HEFEI GENIUS NEW MATERIALS

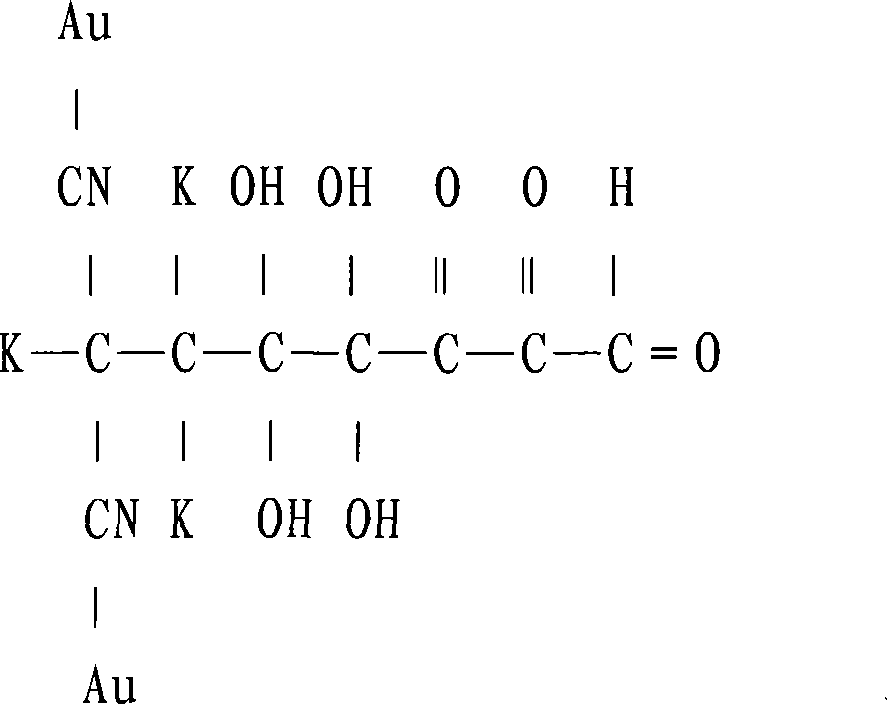

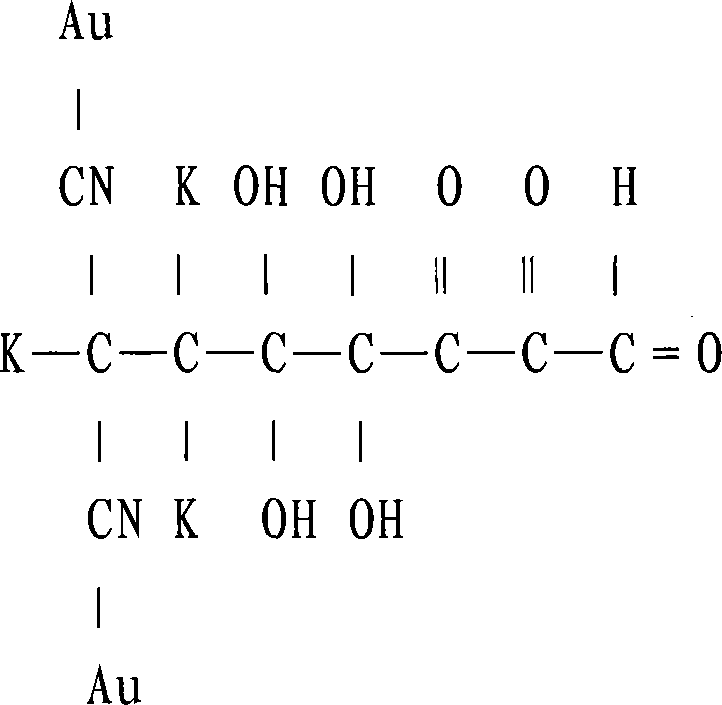

Gold potassium lemon acid for gold plating and method for producing the same

ActiveCN101172946AReduce processing costsReduce pollutionCarboxylic acid salt preparationGold contentPotassium

The invention discloses citric acid gold potassium used for gold plating and the preparation method thereof. The molecular formular of the citric acid gold potassium is K3Au2C9H5O7N2. The method comprises the steps as follows: gold trichloride is dissolved in water of certain temperature, is concentrated and diluted under the temperature for multiple times, and is reacted with potassium citrate, ethylene diamine tetraacetic acid and malononitrile in a reactor under the certain temperature and the certain time to produce the organic gold salt which has low toxicity and contains no free cyanogen. When the product has the same gold content with the potassium gold cyanide, the total CN- is 5 to 6 percent, being 50 percent lower than that of the CN- in the potassium gold cyanide. The waste liquid after gold plating contains free the CN- in small amount. The invention reduces the cost of waste water treatment for the electroplating plants.

Owner:HENGSHENG TECH R&D CO LTD

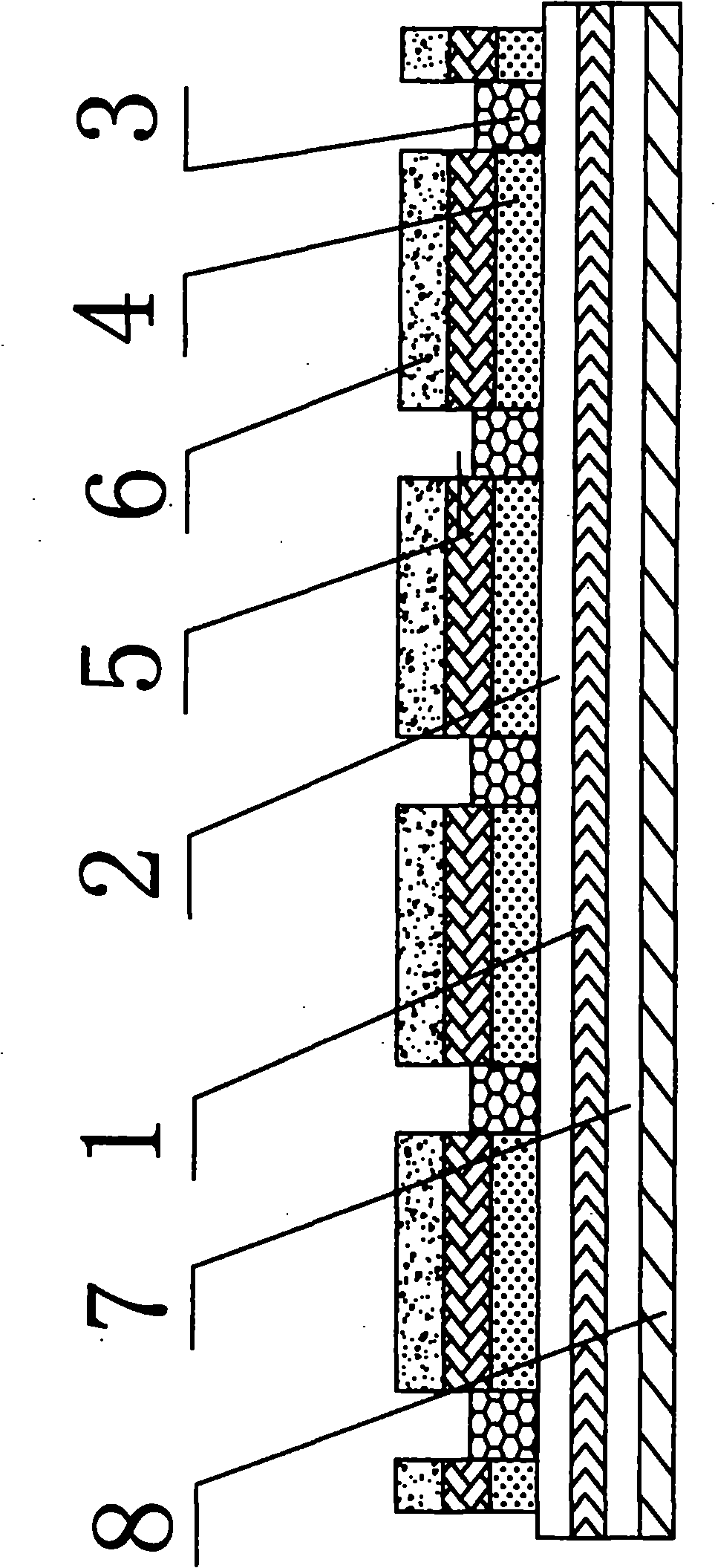

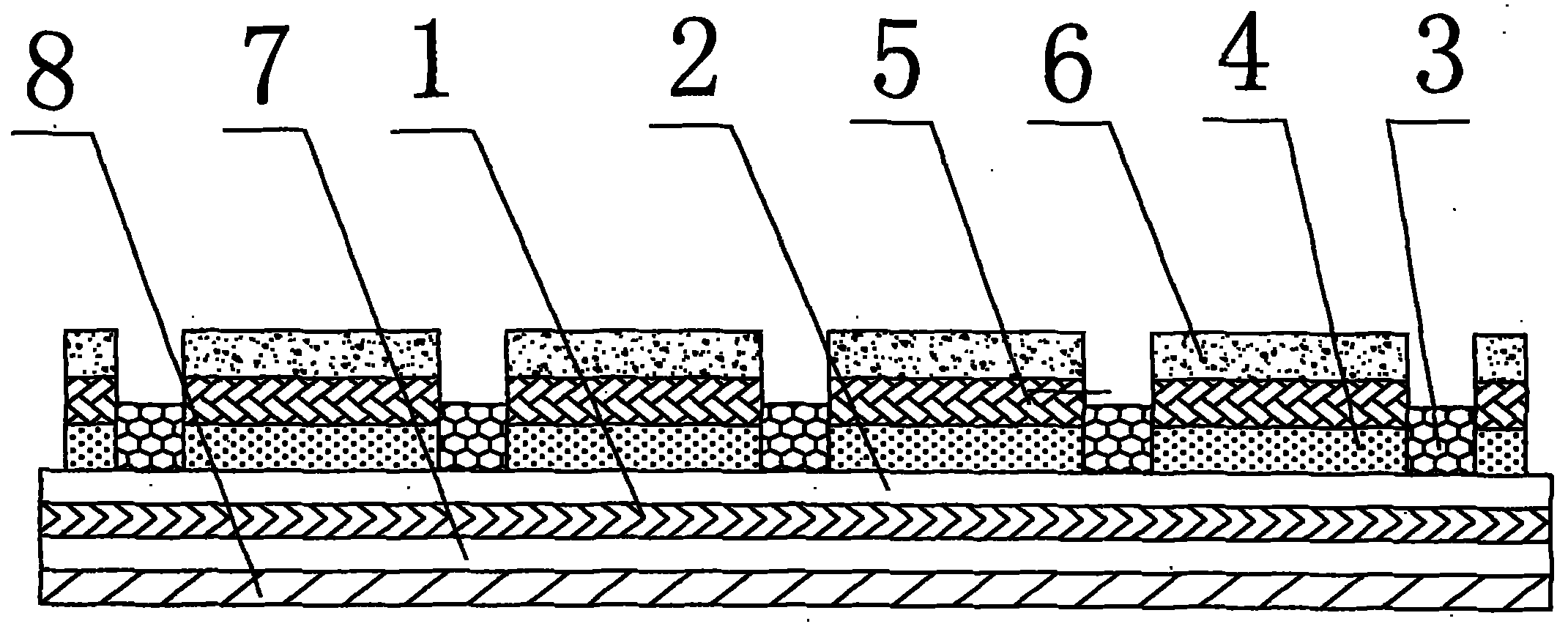

New, luminous, reflective and photochromic security warning poster

InactiveCN101894505AIncrease brightnessNo power consumptionIlluminated signsChange colorCarbon product

The invention relates to a new, luminous, reflective and photochromic security warning poster. The poster comprises a substrate, wherein the front of the PVC plastic substrate is provided with a white semi-mat paint layer, a photochromic layer and a corresponding overprinted colorless reflective layer, luminous layer and transparent protection layer which are arranged at intervals are separately arranged on the white semi-mat paint layer; the back of the substrate is provided with a self-adhesive layer and a release paper layer. If iron, aluminum and another metal material is used to prepare the substrate, the back of the substrate is provided with an anti-rusting paint layer and a plurality of installing holes are arranged on the periphery. The security warning poster can be luminous at night (under no light), reflect light under the irradiation of the light and change colors with the air humidity and the ambient temperature; and the indicating arrow is combined with the poster. The invention belongs to an environmentally friendly and energy-saving and emission-reducing low carbon product; and by using the poster of the invention, the security warning education can be normalized and the aims of enhancing safety consciousness, performing prevention and taking preventive measures can be achieved.

Owner:龚昌政

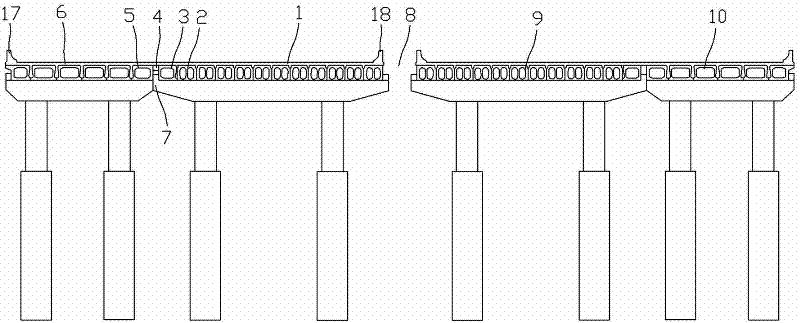

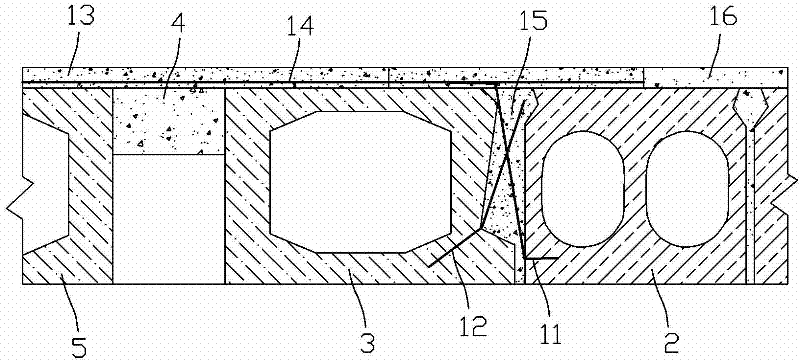

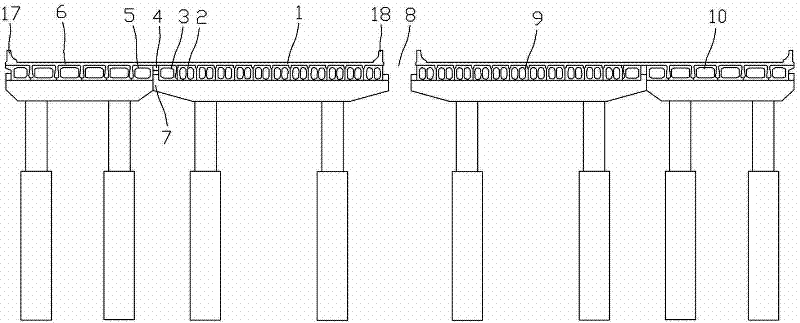

Bridge widening splicing structure and its construction method

InactiveCN102286921AEnsure connection integrityExtended service lifeBridge erection/assemblyBuilding energyResource saving

The invention relates to a bridge widening splicing structure and a construction method thereof. The present invention adopts the design principle of "connecting at the top and not connecting at the bottom", that is, the wet joint of cast-in-situ concrete is realized between the upper hollow slabs of the new and old bridges, the bridge deck is continuous, and the lower piers and foundations are no longer connected, and they are relatively independently stressed. To adapt to the differential settlement between the new and old bridges; the outer side plate of the old bridge is replaced, and the pier cover beam is not removed, only the anti-collision guardrail of the old bridge is removed. After the old bridge plate is replaced, the plate is replaced next to the old bridge The edge of the rear beam slab is connected with the beam slab of the new bridge by planting bars, so that the old and new bridges form a solid whole. The inventive method combines many advantages such as simple construction, short construction period, low construction cost, new and old bridges are formed into a whole to bear the force together, etc. The hollow slabs can be replaced by centralized prefabrication and factory construction, and are suitable for highway bridges of all grades. Wide construction, in line with the requirements of building energy saving, building a resource-saving, environment-friendly society, after promotion, it has good economic benefits and social value.

Owner:河南省九建工程有限公司 +1

Air separation method utilizing cold energy of liquefied natural gas

ActiveCN101943512AHigh extraction rateReduce unit power consumptionSolidificationLiquefactionEngineeringEnergy conservation

The invention discloses an air separation method utilizing cold energy of liquefied natural gas (LNG), which comprises three parts of an air separation unit, an LNG cold energy utilization unit for providing the cold energy for the air separation unit and a circulating coolant circulation unit utilizing NG high-temperature cold energy. The air separation method can greatly reduce the unit power consumption of a liquid air separation product or an internal compressed gas product after utilizing low-temperature cold energy of the LNG for the air separation unit, obtain a large number of liquid nitrogen products, lead the extraction rate of argon to be high, simultaneously save a large amount of cooling water, be in line with the big trend of energy conservation, consumption reduction and development of cyclic economy and have obvious social benefits and economic benefits.

Owner:CNOOC ENERGY TECH & SERVICES +1

Double-membrane wastewater biological treatment system

InactiveCN103359885ASimple processEasy to operateMultistage water/sewage treatmentHigh concentrationUv disinfection

The invention discloses a double-membrane wastewater biological treatment system. The double-membrane wastewater biological treatment system comprises a pool (case) body, a pretreatment zone, a biomembrane reaction zone and a membrane separation reaction zone; and all the above zones are separated through a wall or a separator to form respectively independent work systems, relevant zones are communicated through water flowing ports, a high pressure fan, a membrane water outlet pump and an ultraviolet ray disinfection instrument are arranged outside the pool (case) body, and water discharged from a membrane assembly is pumped into the ultraviolet ray disinfection instrument through the membrane water outlet pump, is disinfected and is discharged outside. The wastewater biological treatment system has the advantages of simple technological structure, good treatment effect, stable running and wide application range, is suitable for the low-concentration organic sewage treatment in hospitals, health centers, rural, the country and towns, and is also suitable for the high-concentration organic wastewater treatment in the industries of bave wastewater, slaughtering wastewater, food processing and the like, so treated water reaches recycled water reuse standards, accords with Chinese energy saving, emission reduction and circular economy policies, and the system can well play an important role in the public campaigns of Wild China, Urban and Rural Cleaning at present, and has large social and economic benefits.

Owner:邹振生

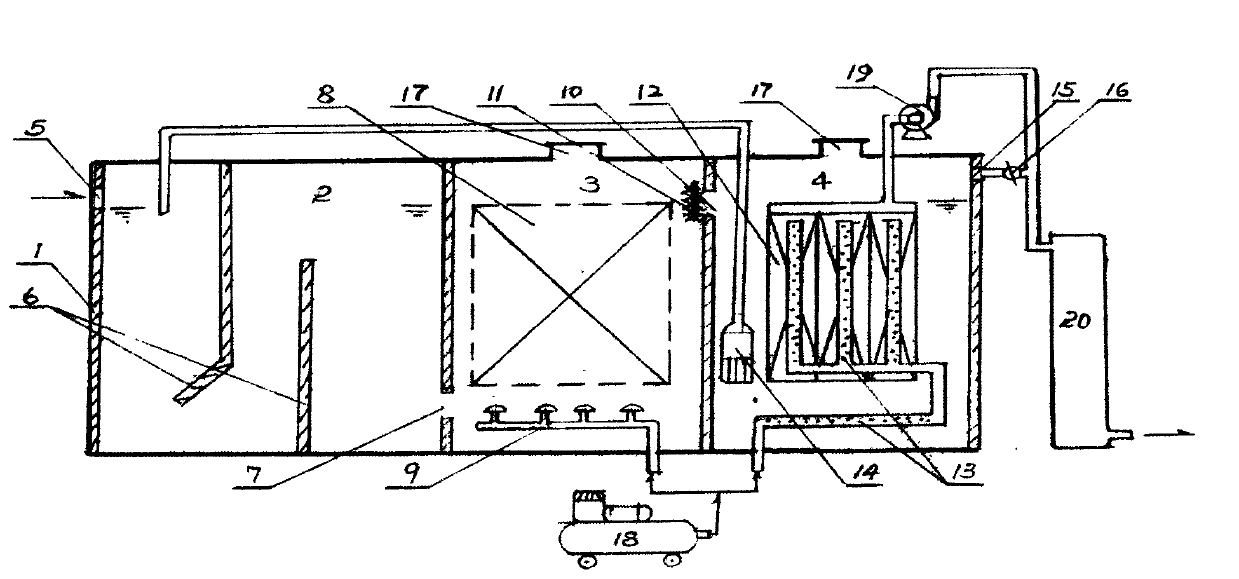

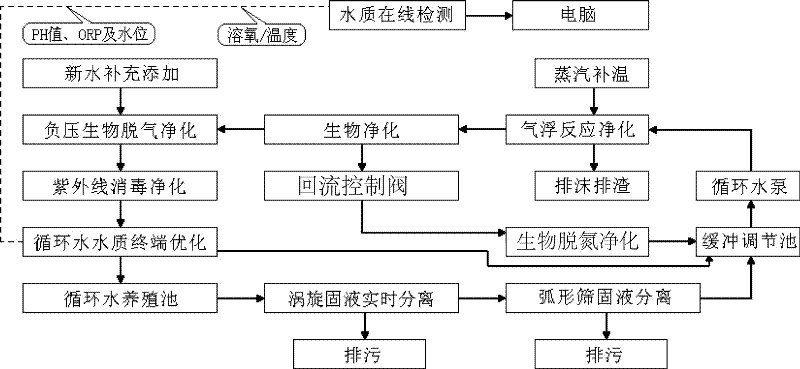

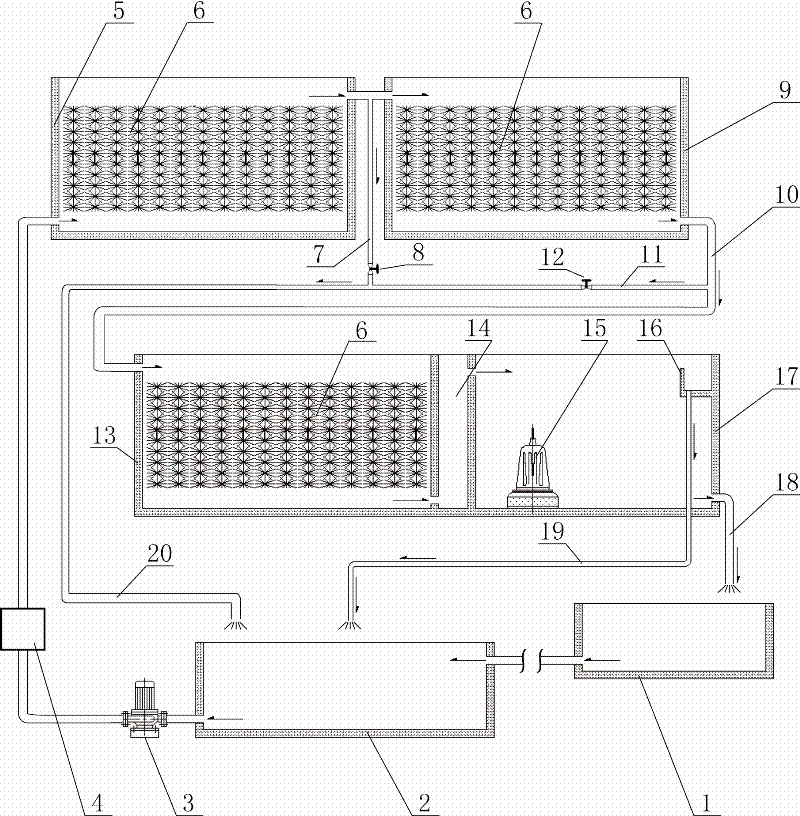

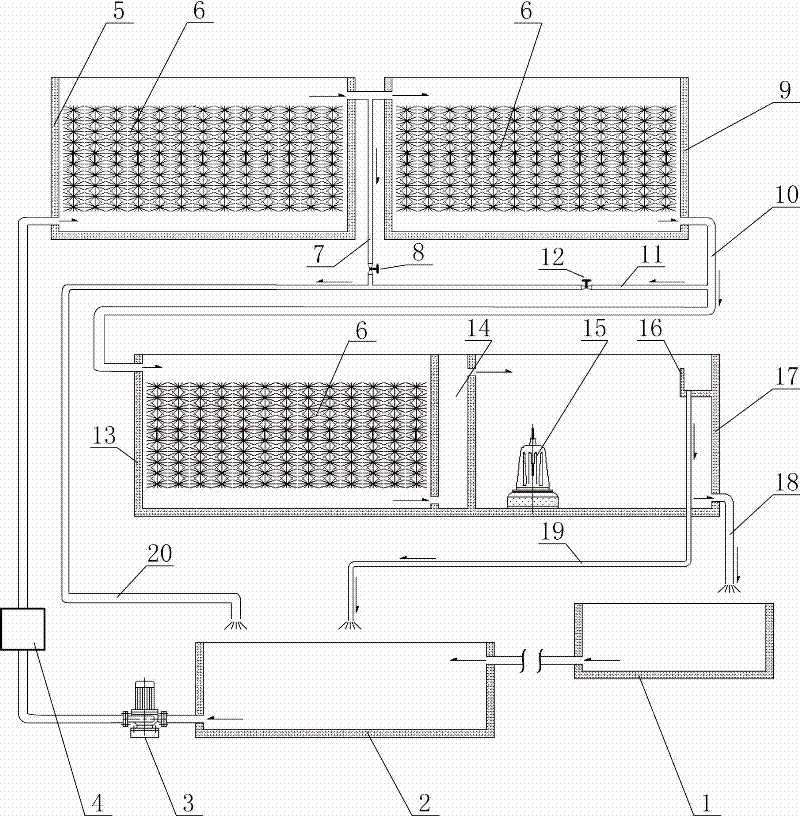

Energy-saving factorized fully-sealed seawater circulation culture process method and special device thereof

ActiveCN102499131AReduce in quantityTo achieve the purpose of converting to nitrateClimate change adaptationPisciculture and aquariaBio filtrationBiological filter

The invention relates to an energy-saving factorized fully-sealed seawater circulation culture process method and a special device of the process method. Water in a culture pool is subjected to eddy current separation and solid-liquid separation and then enters a buffer regulation pool, the water enters two stages of biological purification pools: the front biological purification pool and the back biological purification pool after air floatation reaction purification, a biological filter pool self maintenance inoculation avoidance is carried out, and backflow water is respectively led out from water outlet ends of the two stages of biological purification pools and enters a circuit system. Rest water flown out from the back stage biological purification pool is subjected to the third-stage biological filtering, is then subjected to disinfection treatment, enters a water quality terminal optimization pool and finally flows to the culture pool to form a fully sealed circulation water culture system. The heat loss is avoided to a great degree through the adopted circulation water culture, so the water change (circulation) quantity can be increased, and the water freshness is improved. Compared with the traditional water flowing culture process, the process method has the advantages that the water and the energy are saved, and the discharge quantity of waste water and waste gas is reduced.

Owner:莱州明波水产有限公司

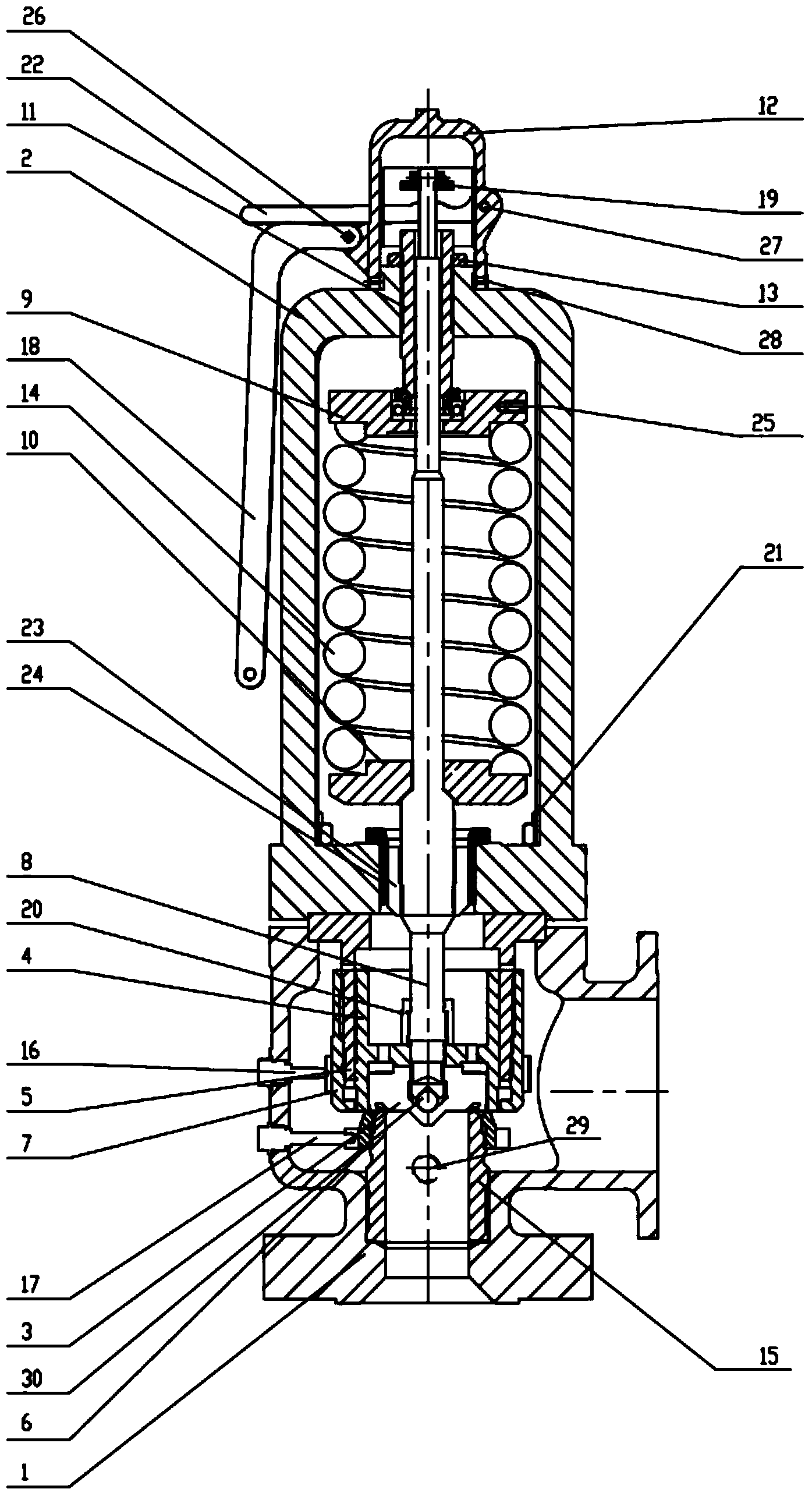

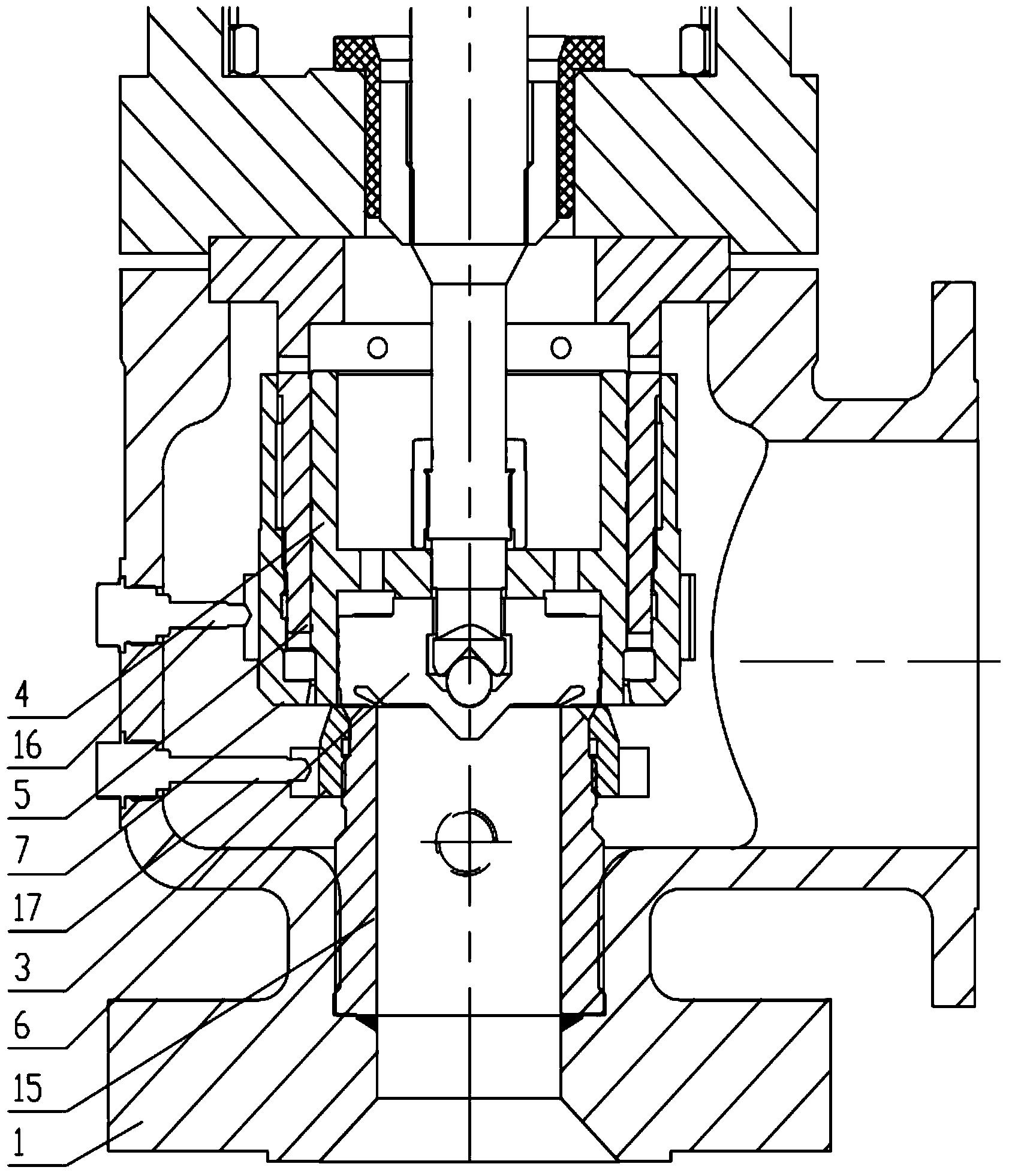

Valve rod sealing type closed backpressure adjusting type steam security valve

ActiveCN103511693AGood seat tightnessEasy to adjustSpindle sealingsEqualizing valvesPressure systemEngineering

The invention provides a valve rod sealing type closed backpressure adjusting type steam security valve which comprises a valve seat, a valve body and a valve cover. An inlet in the lower portion of the valve body is connected with a protected pressure system through a flange, the valve cover is arranged on the upper portion of the valve body, a valve bonnet is arranged above the valve cover, a spring is arranged inside the valve cover, the valve rod and a clamping ring penetrate through a pressing ring, the pressing ring and the clamping ring form a sealing structure, and a lower adjusting ring and an upper adjusting ring are arranged inside the valve body. The valve rod sealing type closed backpressure adjusting type steam security valve has good valve seat sealing performance, motion performance and adjusting performance on the working condition of high temperature and high pressure steam, and does not pollute the external environment. The design of the valve rod sealing type structure, the closed valve body and the closed backpressure adjusting mechanism meets the requirement of minimal overpressure performance parameters, avoids medium leakage, and meets the actual demands of energy conservation, emission reduction and environmental protection.

Owner:BEIJING AEROSPACE PROPULSION INST

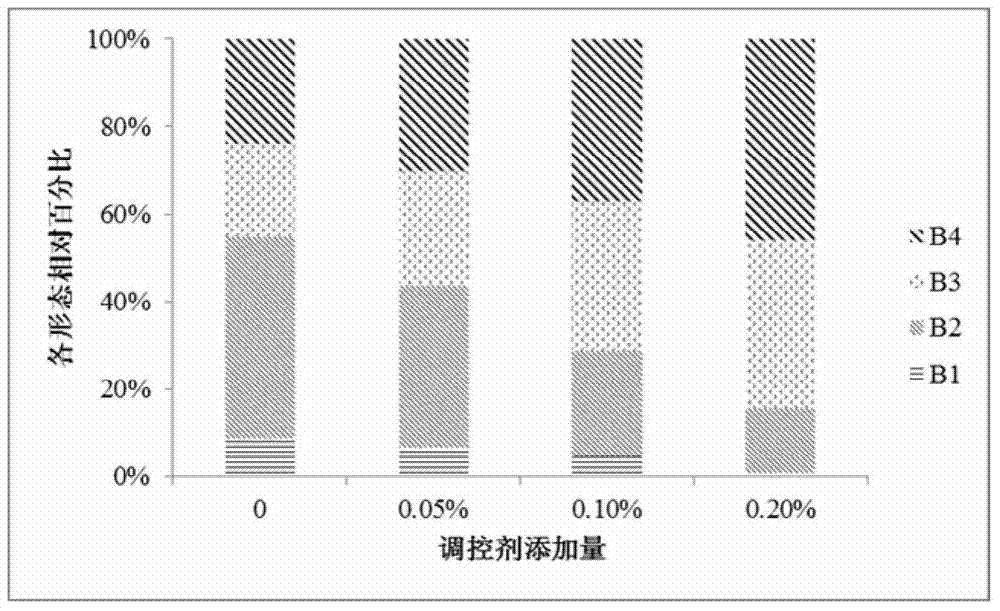

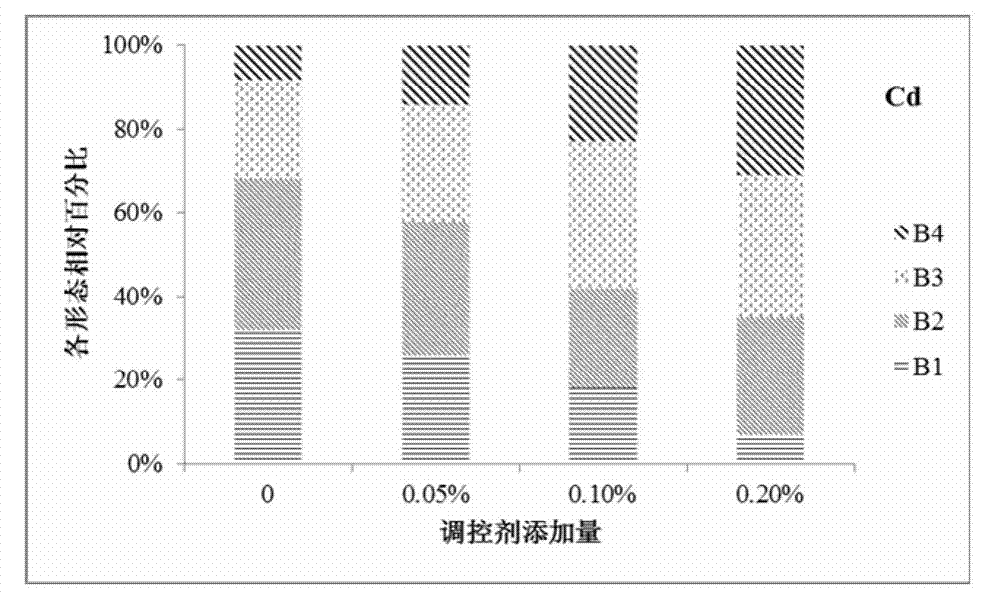

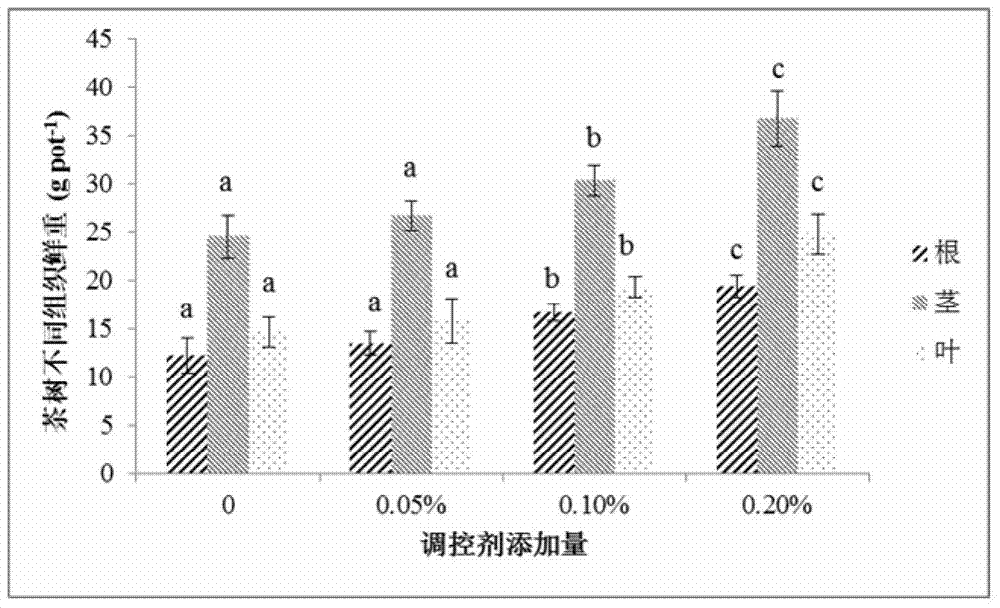

Natural regulating agent for treating heavy metal polluted farmland soil and preparation method thereof

ActiveCN103589435AReduce absorptionReduce heavy metal contentAgriculture tools and machinesOrganic fertilisersMaterial removalPotassium

The invention relates to a natural regulating agent for treating heavy metal polluted farmland soil and a preparation method thereof. The natural regulating agent comprises tea waste and potassium humate. The preparation method comprises the following steps of firstly, drying tea waste in the sun and reserving for standby application; secondly, removing impurities of the material rich in humic acid, air drying and grinding, sieving by a 5-mesh sieve and reserving for standby application; then adding KOH (potassium hydroxide) into the material rich in humic acid, oscillating intermittently, filtering by filter cloth, and obtaining potassium humate; finally, uniformly mixing the tea waste and potassium humate, grinding, sieving by a 5-mesh sieve, thereby obtaining the natural regulating agent for heavy metal polluted farmland soil. The natural regulating agent comprises tea waste and potassium humate which are rich in functional groups for adsorbing and fixing heavy metals, such as phenolic hydroxyl group and carboxyl, thus being capable of effectively adsorbing various active heavy metals in the farmland soil.

Owner:ZHEJIANG UNIV

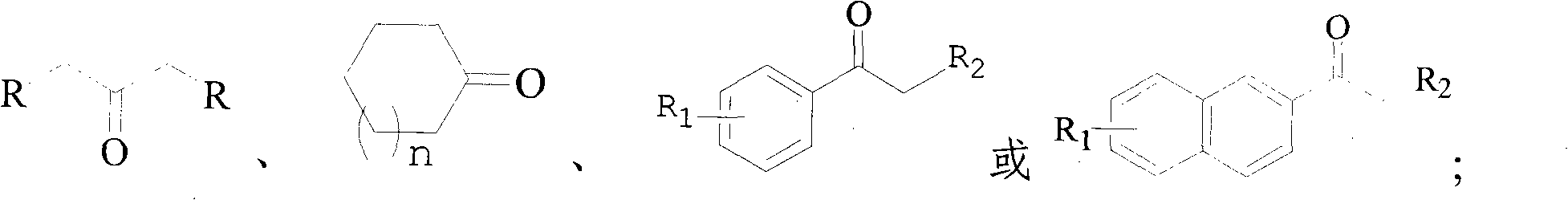

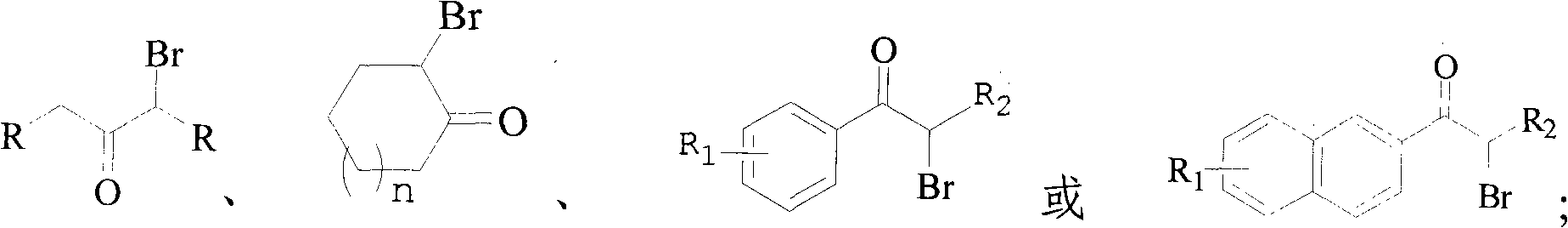

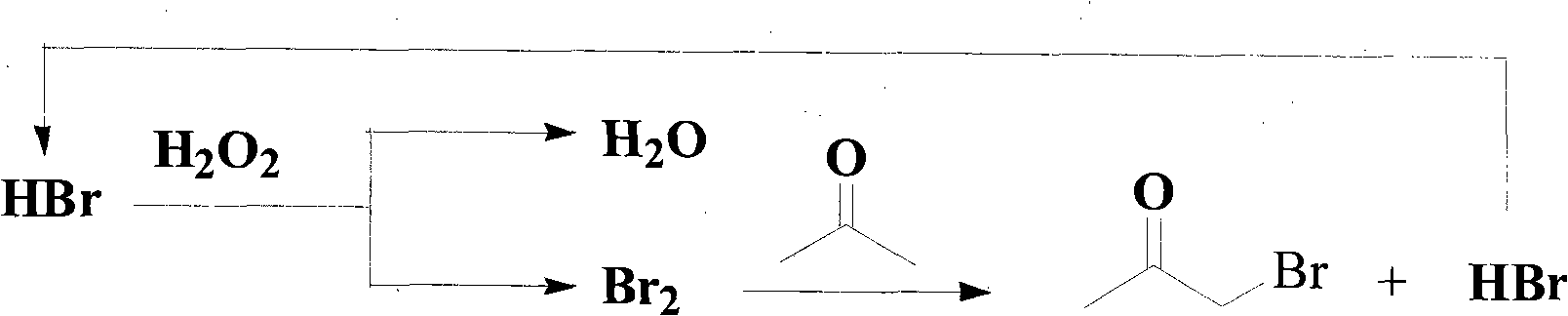

Method of synthesizing alpha-brominated ketone compound by hydrogen peroxide oxidizing and brominating method

InactiveCN101928208AAvoid pollutionAvoid harmOrganic compound preparationCarbonyl compound preparationKetoneSolvent

The invention discloses a new process for synthesizing alpha-brominated ketone compound by a hydrogen peroxide oxidizing and brominating method and the process comprises a hydrogen bromide-hydrogen peroxide oxidizing and brominating method and a bromine-hydrogen peroxide oxidizing and brominating method. The process comprises the following specific steps of: when hydrogen bromide (solution of hydrobromic acid) is used as a bromination agent, mixing the ketone compound and the hydrobromic acid and directly dripping hydrogen peroxide into the mixture to oxidize the hydrogen bromide into bromine, and then performing a bromination reaction to generate alpha-brominated ketone; when the bromine is used as the bromination agent, brominating the ketone compound by using bromine liquid to generatethe alpha-brominated ketone compound and the hydrogen bromide; and after the bromine is completely reacted, oxidizing the hydrogen bromide generated in the reaction into the bromine by using the hydrogen peroxide, continuing to perform the bromination reaction on the bromine and the ketone until the ketone compound is completely reacted to generate the alpha-brominated ketone. In the invention, water is used as a solvent, the utilization rate of the bromine is nearly 100 percent, the final products of the reaction are only the alpha-brominated ketone and water; especially, when the hydrobromic acid is used as the bromination agent, the hydrobromic acid is nontoxic, tasteless and free of high corrosion of the bromine liquid without generating any harmful substance; and the process has the advantages of more convenient operation, high efficiency, energy conservation and environmental protection.

Owner:HEBEI UNIVERSITY

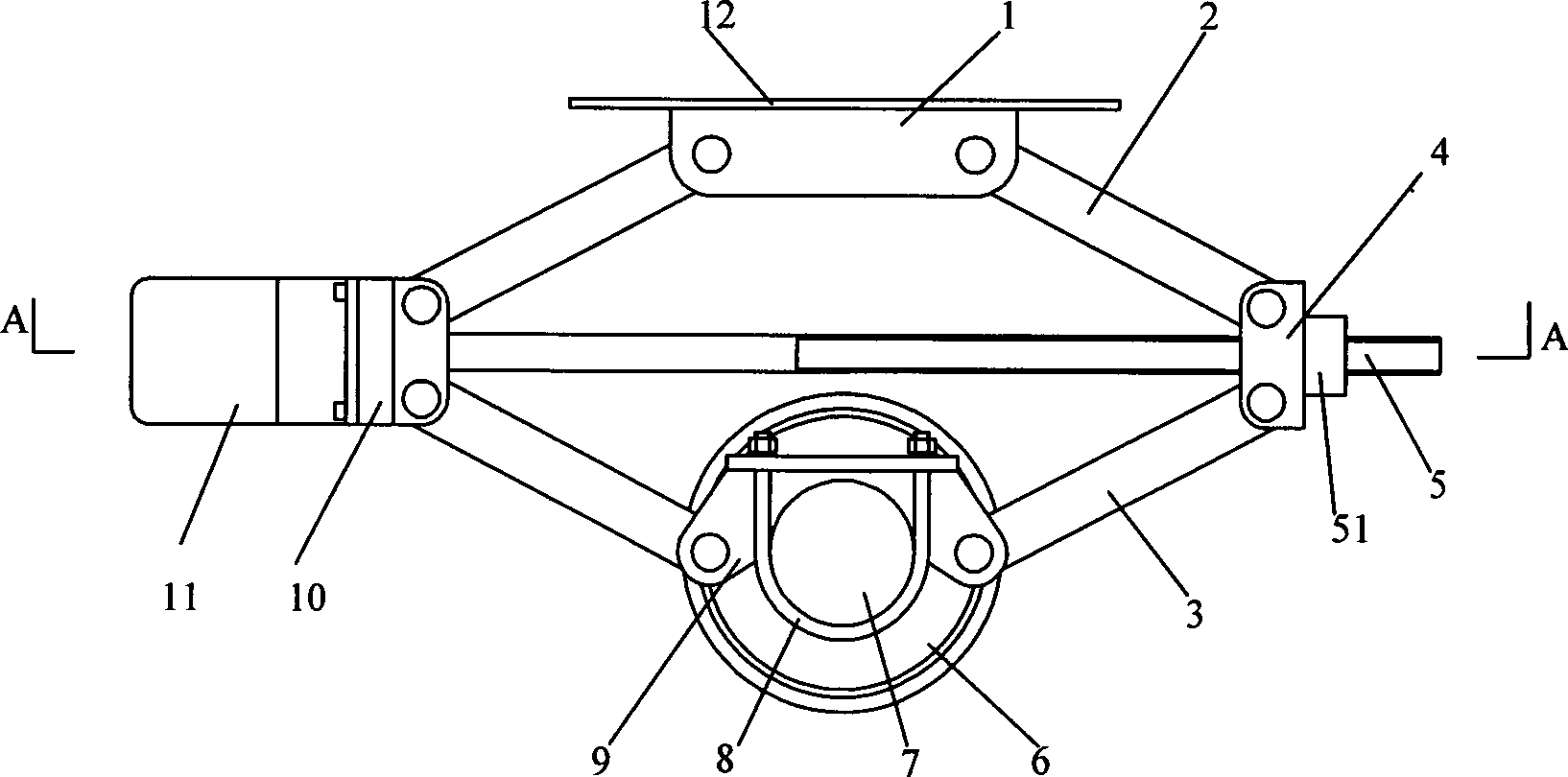

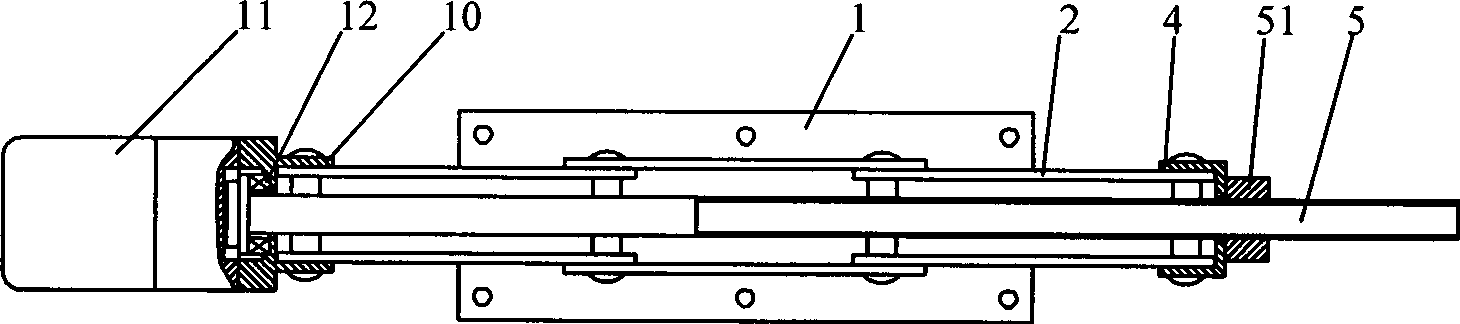

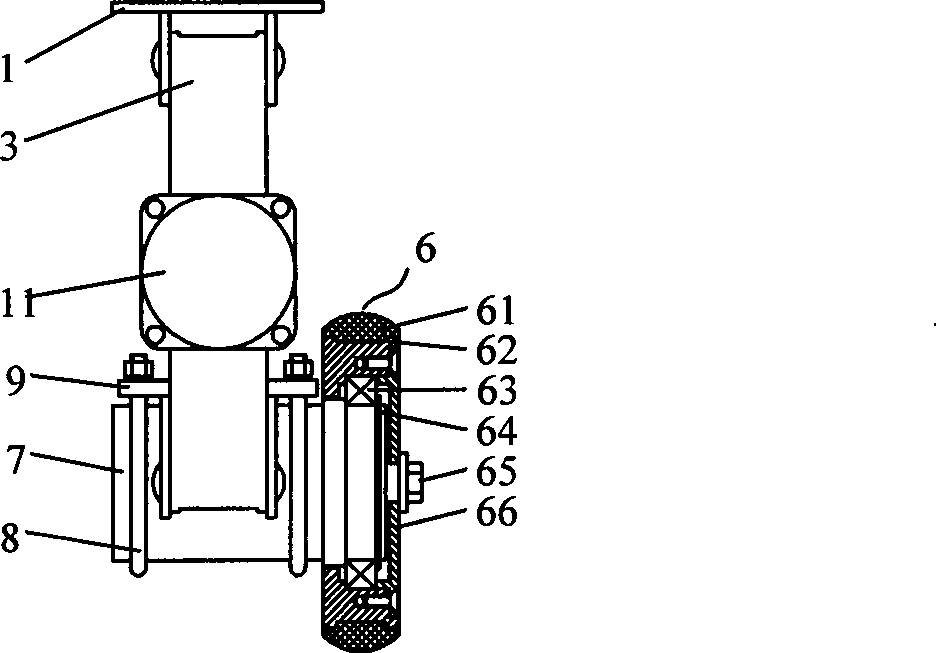

Vehicle transverse swinging parking device

The invention discloses a vehicle transverse swinging stopping device, which comprises a lifting mechanism and a transverse swinging mechanism, wherein the lifting mechanism comprises a lifting power unit, screw mandrels, nuts screwed on the screw mandrel, two upper stay bars and two lower stay bars; the two upper stay bars and the two lower stay bars respectively take the screw mandrels and the nuts as movable pairs to form an upper plane four-bar mechanism and a lower plane four-bar mechanism; and the transverse swinging mechanism comprises a transverse swinging power unit and a transverse driving wheel. The vehicle transverse swinging stopping device adopts a movable pair type plane four-bar mechanism which is combined with a transverse driving wheel structure to complete lift and sideslip of the tail of a vehicle, is convenient to put straight the tail of the vehicle under the condition of parking, does not require arrangement of complex pipelines and lines, is simple and convenient to arrange, has low manufacturing cost and light weight, accords with the development trends of light weight, energy saving and emission reduction of the modern vehicle, and is suitable for parking of middle-size and small-size vehicles such as sedans, etc. in a narrow place.

Owner:CHONGQING UNIV

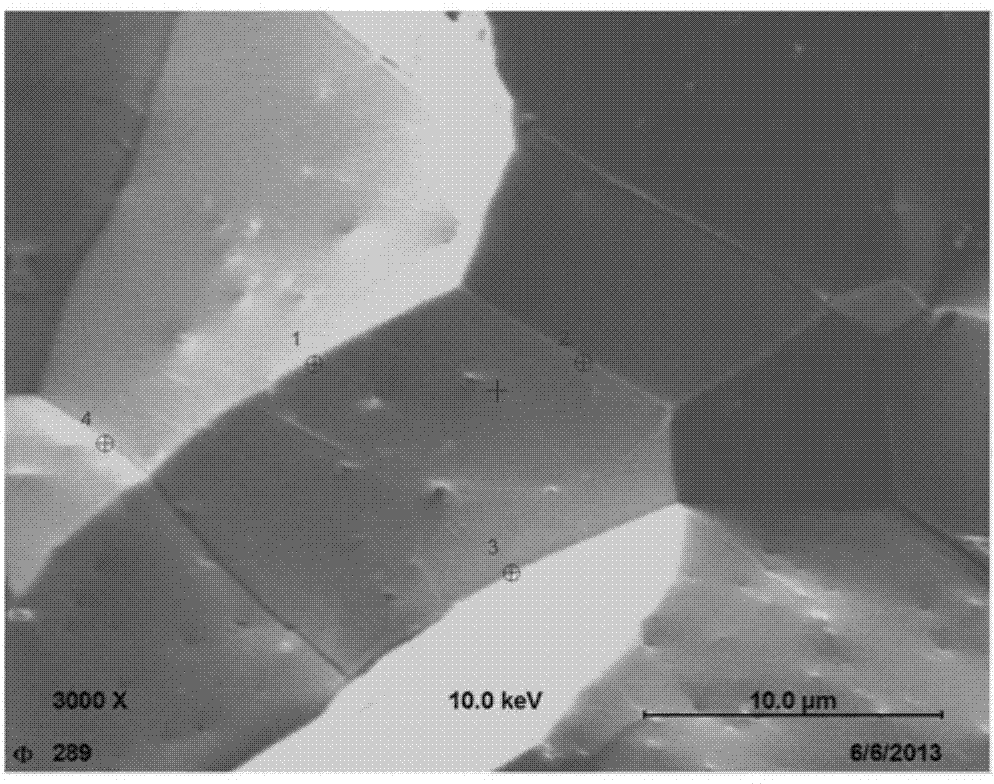

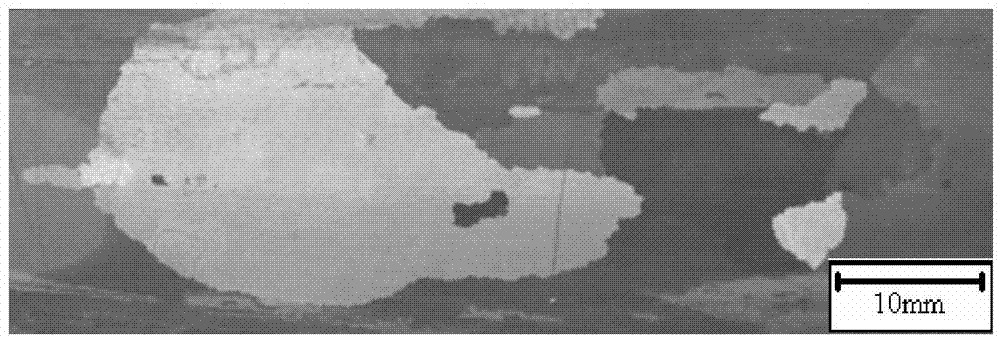

High-magnetic-induction oriented silicon steel prepared through thin slab continuous casting and rolling and preparation method thereof

ActiveCN103774042ALow heating temperatureAvoiding Insufficient Inhibition ProblemsChemical compositionThin slab

The invention provides high-magnetic-induction oriented silicon steel prepared through thin slab continuous casting and rolling and a preparation method thereof. The oriented silicon steel comprises the following chemical components by mass percent: 0.035-0.055% of C, 2.9-3.3% of Si, 0.09-0.15% of Mn, 0.1-0.2% of Cu, not more than 0.005% of S, 0.02-0.04% of AlS, 0.009-0.013% of N and 0.1-0.2% of Sn. The oriented silicon steel is prepared by the following steps: thin slab continuous casting, heating in a soaking pit, hot continuous rolling, normalizing, primary cold rolling, decarburizing annealing and high temperature annealing, wherein the heating temperature of the soaking pit is 1150-1180 DEG C and the soaking time is 30-60 minutes. The oriented silicon steel uses AlN as a main inhibitor and Cu2S as an auxiliary inhibitor, and meanwhile, the trace element Sn is added to the chemical components to avoid the problem of inadequate inhibiting capacities of the inhibitors caused by low temperature heating and serves as an auxiliary inhibitor thanks to the segregation capacity of Sn on the grain boundary. Therefore, the high-magnetic-induction oriented silicon steel can be produced by adopting the thin slab low temperature short-time soaking process, so that the casting blank heating temperature is effectively reduced and the soaking time is reduced. The preparation method has the advantages of short flow, low cost, low energy consumption, high production efficiency and the like.

Owner:CENT IRON & STEEL RES INST +1

Beam blank continuous casting machine tundish working lining, construction tire film of working lining and preparation method of working lining

ActiveCN102699316AImprove corrosion resistanceImprove anti-scourabilityMelt-holding vesselsFireproofingImpact area

The invention belongs to the technical field of steel metallurgy continuous casting tundish technique, in particular to a beam blank continuous casting machine tundish working lining, a construction tire film of the working lining and a preparation method of the working lining. The working lining, the construction tire film and the preparation method are characterized in that a working lining in an impact area is forming by carbonic fireproofing tiles (2), a layer of painting materials (3) are painted on the outer surfaces of the carbonic fireproofing tiles (2), corners (5) of the working lining in the impact area are all arc corners, wall wrapping working linings (8) and bottom wrapping working linings (10) except for a tundish impact area all adopt dry-type materials. Therefore, service life of the working lining of the tundish impact area and working linings at other portions are synchronous, monopack continuous casting time achieves more than 36 hours which shortens 12 hours than the time at the same condition, and continuous casting tundish material cost reduces more than 30% than the cost at the same condition.

Owner:LAIWU IRON & STEEL GRP

Composite molten steel slag washing agent based on LF (ladle furnace) refining waste slag and preparation method thereof

The invention discloses a composite molten steel slag washing agent based on LF (ladle furnace) refining waste slag and a preparation method thereof. The composite molten steel slag washing agent consists of 65 to 95% of LF refining slag, 10 to 30% of active lime and 5 to 15% of industrial soda. The LF refining slag is composed of 50 to 60% of CaO, 25 to 35% of Al2O3, 4 to 8% of SiO2, 4 to 7% of MgO, 0.5 to 1.0% of MnO and FeO, 0.005 to 0.02% of P2O5, and 0.01 to 0.3% of S; the active lime includes 90 to 94% of CaO, and HCl with activity of 350 to 380 ml / 4N and granularity of 0.5 to 3.0 mm; and the industrial soda includes 99.2% of Na2CO3 with granularity of 0.5 to 1.0 mm. The preparation method comprises the following steps of: processing the LF refining slag and the active lime into the powder with the granularity of 0.5 to 3.00 mm; uniformly mixing and stirring the materials according to the percentage, dry-pressing and moulding the materials with granularity of 25 to 35 mm and applying the waterproof packaging to the materials. On the condition that the adding quantity is 4 to 6 kg / t, the desulfurization rate of the invention achieves more than 30%, the reduction rate of the total oxygen content is more than 25% and the qualified rate of the thermal top forge is improved from 80% to 95%, so that the invention realizes the resource recycling of the LF refining waste slag and is beneficial to the energy-saving and emission reduction of the iron and steel enterprises.

Owner:NANJING IRON & STEEL CO LTD +1

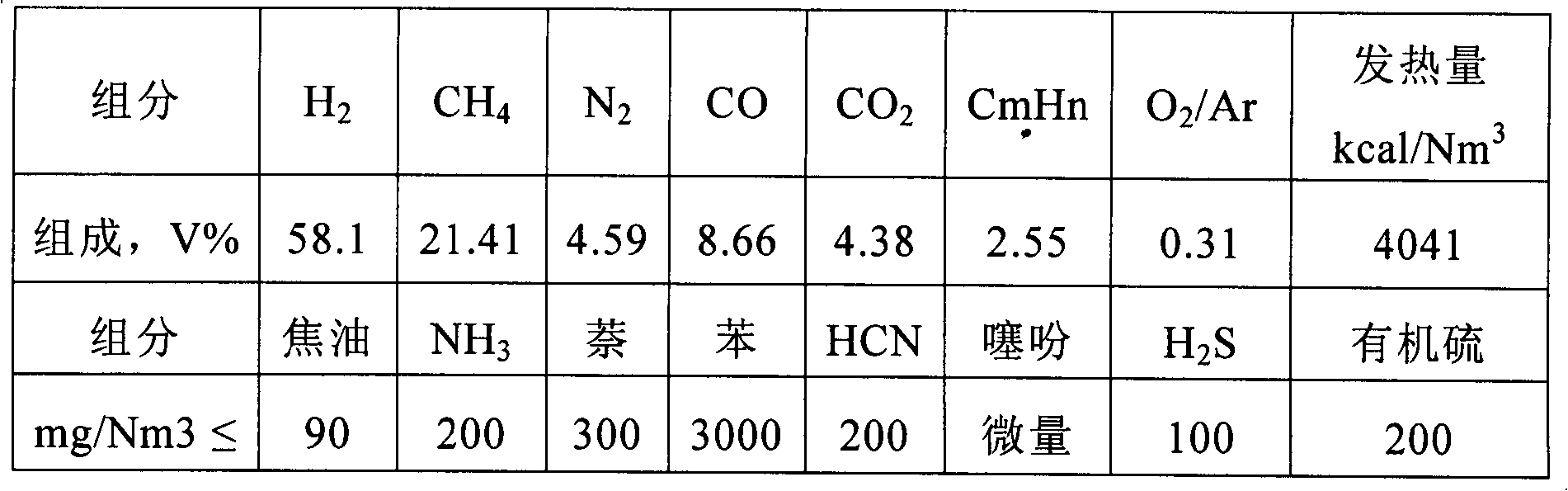

Combined process for preparing Fischer-Tropsch synthetic oil raw material gas by utilizing coke-oven gas

ActiveCN102642810AIncrease added valueConform to energy savingHydrogen separationLiquid hydrocarbon mixture productionResource utilizationFuel oil

The invention relates to a combined process for preparing a Fischer-Tropsch synthetic oil raw material gas by utilizing a coke-oven gas. The combined process comprises the following steps of: with coarse coke-oven gas as a raw material, removing naphthalene, tar, hydrogen sulfide, hydrocyanic acid, ammonia, organic sulfur and other heavy-hydrocarbon impurities out of coarse coke-oven gas in a pretreatment unit;; then pressurizing the coarse coke-oven gas in a gas compression unit; then converting into CH4 through oxidation of non-catalysis part of the coke-oven gas; and finally carrying out precision desulfurization and deep desulfurization, thereby obtaining the high-quality Fischer-Tropsch synthetic oil raw material gas. According to the invention, through a step-by-step purification combined process, impurities and the sulfurous gas in the coke-oven gas are removed efficiently, so that coke-oven gas becomes the synthetic gas with high additional value and high economic benefit; the coking industrial chain is prolonged; the coke-oven gas is converted into fuel oil, greenhouse gas and toxic gas which are brought about by gas combustion are reduced; the combined process meets national requirements of energy conservation, emission reduction and industry policy and has the advantages of low sulfur, high degree of purification, obvious environment effect, high resource utilization ratio, relative low construction investment in devices, low operating cost and the like.

Owner:SHANGHAI HUANQIU ENG

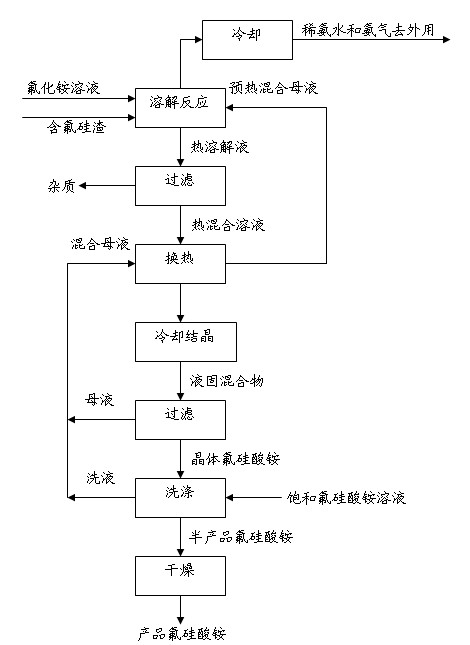

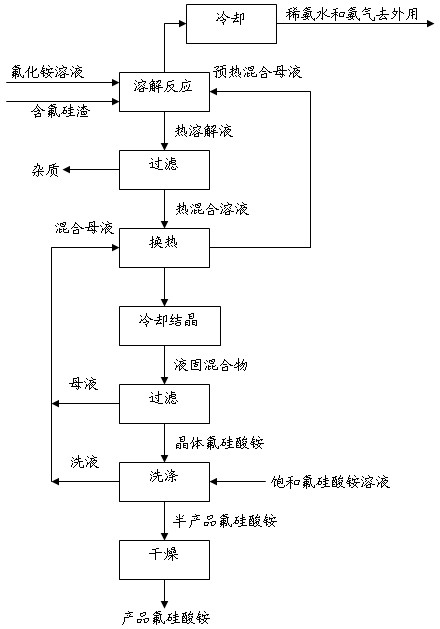

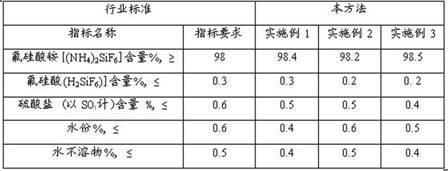

Method for preparing ammonium fluorosilicate by utilizing fluorine-containing white slime in anhydrous hydrogen fluoride production

ActiveCN102674367AReduce pollutionReduce utilizationSilicon halogen compoundsSolid waste disposalHydrogen fluoridePhysical chemistry

The invention discloses a method for preparing ammonium fluorosilicate by utilizing fluorine-containing white slime in anhydrous hydrogen fluoride production. The method comprises the following steps of: under the condition that the mol ratio of ammonium fluoride calculated based on SiO2 to the fluorine-containing white slime is 9-15, adding the fluorine-containing white slime, a mixed mother liquid and a supplementary ammonium fluoride solution under the conditions that the temperature is 90-108 DEG C and the pressure is minus 15 to 0Kpa, performing a dissolution reaction until the white slime is completely dissolved, so as to obtain a dissolved solution; while the dissolved solution is hot, filtering the dissolved solution to remove undissolved SiO2 and mechanical impurities, so as to obtain a mixed solution; performing heat exchange on the mixed solution until the temperature is 60-70 DEG C; cooling to 12-30 DEG C, separating out ammonium fluorosilicate crystal and performing liquid solid separation, so as to obtain a crystallization mother liquid and crystal ammonium fluorosilicate; washing and filtering to obtain the crystal ammonium fluorosilicate; and drying the crystal ammonium fluorosilicate, so as to obtain the product ammonium fluorosilicate. The method disclosed by the invention has the advantages of simple technical process, less equipment, simplicity and convenience in operation and low production cost.

Owner:WENGFU (GRP) CO LTD +1

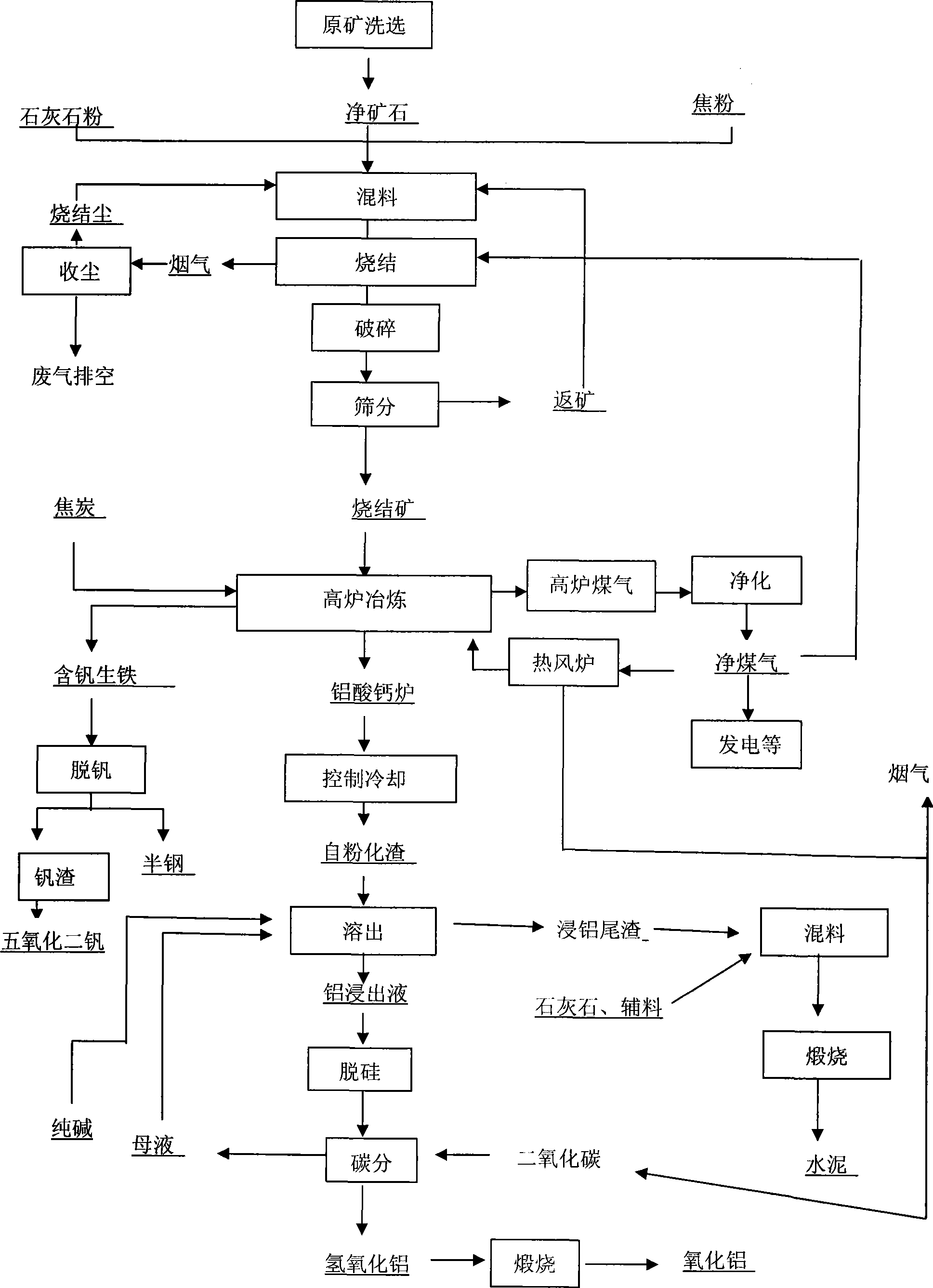

Iron and aluminum complex ore comprehensive utilization method

The invention relates to a method for comprehensively utilizing iron-aluminum composite mineral resources, which is to mix ferro-aluminum composite ores, limestone powder and coke powder according to proportion for ore proportioning, to sinter the mixture under the suction negative pressure between 3 and 10 kPa and with the sintering time between 20 and 30 minutes, to perform blast furnace process on high-basicity sintered ores obtained after sintering, coke and limestone according to the fact that the slag basicity CaO / SiO2 is equal to 2.5-6.0 by weight ratio to obtain pig-iron products and calcium aluminate slag, to use a sodium carbonate solution to leach out the calcium aluminate slag after pulverization, to obtain a sodium aluminate solution and immersed aluminum tailings by performing solid-liquid separation, washing and desiliconization on leached slurry, to prepare aluminum hydroxide by performing carbonating decomposition on the sodium aluminate solution, and to obtain alumina products by roasting the aluminum hydroxide, wherein the immersed aluminum tailings can be used as cement industrial materials. The method can simultaneously recover valuable elements such as iron, aluminum, vanadium and gallium in the iron-aluminum composite ores. Moreover, the immersed aluminum tailings, blast furnace gas and hot-blast furnace gas are effectively utilized.

Owner:GUANGXI INVESTMENT GROUP

Method for preparing adsorbent from oily sludge and method for treating industrial wastewater containing organisms by using absorbent

InactiveCN104307460AWide variety of sourcesReduce manufacturing costOther chemical processesWater contaminantsAfter treatmentSorbent

The invention discloses a method for preparing an adsorbent from oily sludge and a method for treating industrial wastewater containing organisms by using the adsorbent. The preparation method comprises the following steps: using oily sludge as a raw material, drying in the sun, washing and drying; activating dry oil sludge by using an activating agent, centrifuging the oily sludge solution after treatment, washing and drying the centrifuged oily sludge solid; placing the dry oily sludge in a muffle furnace, and pyrolyzing; and cooling and grinding, screening, washing and drying to obtain the efficient adsorbent. The method for treating the industrial wastewater containing the organisms comprises the following steps: adding the adsorbent in the industrial wastewater, oscillating for 3 hours at 25 DEG C, and filtering the solution. The method disclosed by the invention has the beneficial effect that raw material is wide in source, and low in production cost; the sludge activation is performed by using a solution dipping method, and the activating agent can be reused; and the adsorbent is economic, environment-friendly and has a good industrial application prospect.

Owner:LIAONING PETROCCHEM VOCATIONAL & TECH COLLEGE

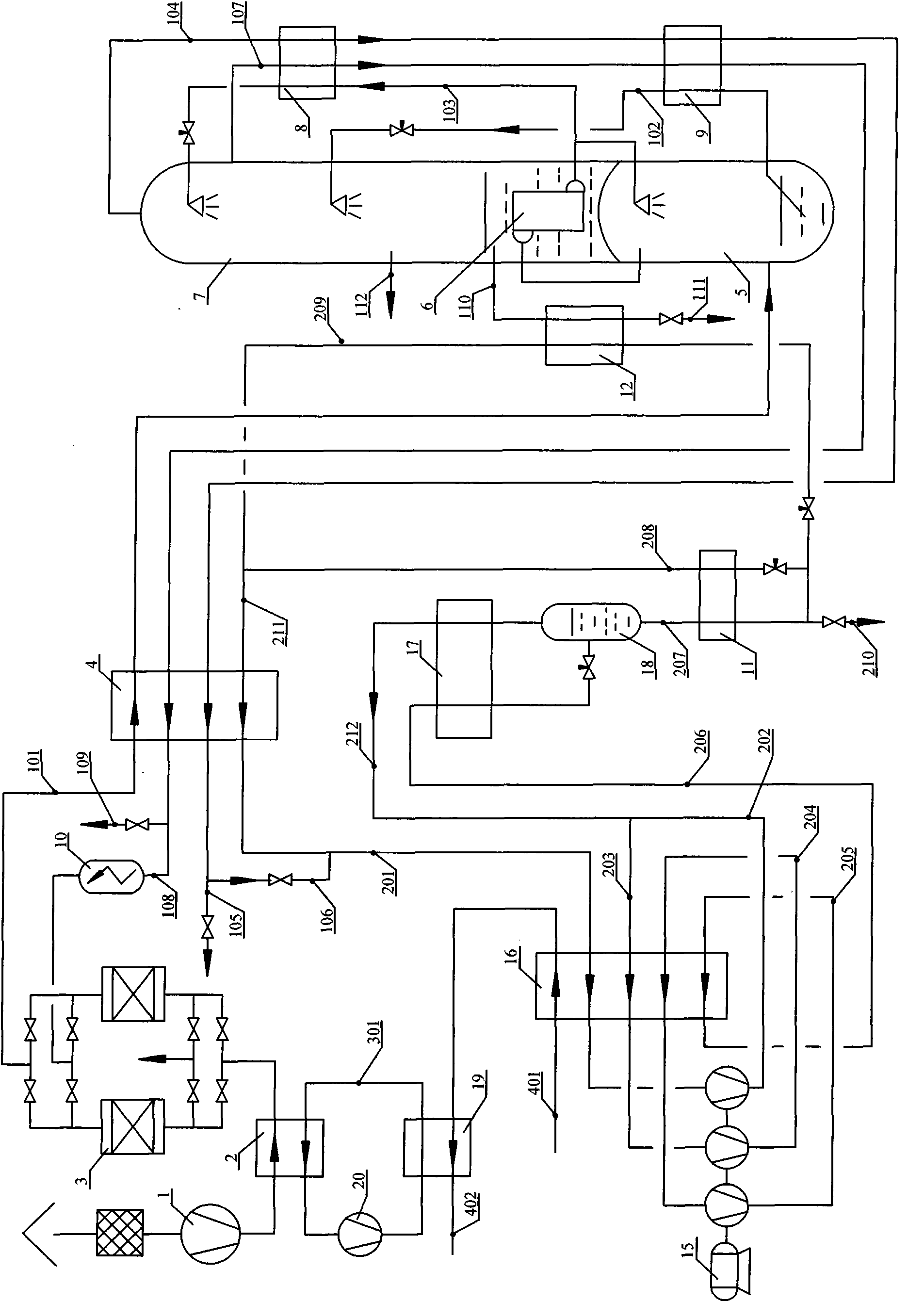

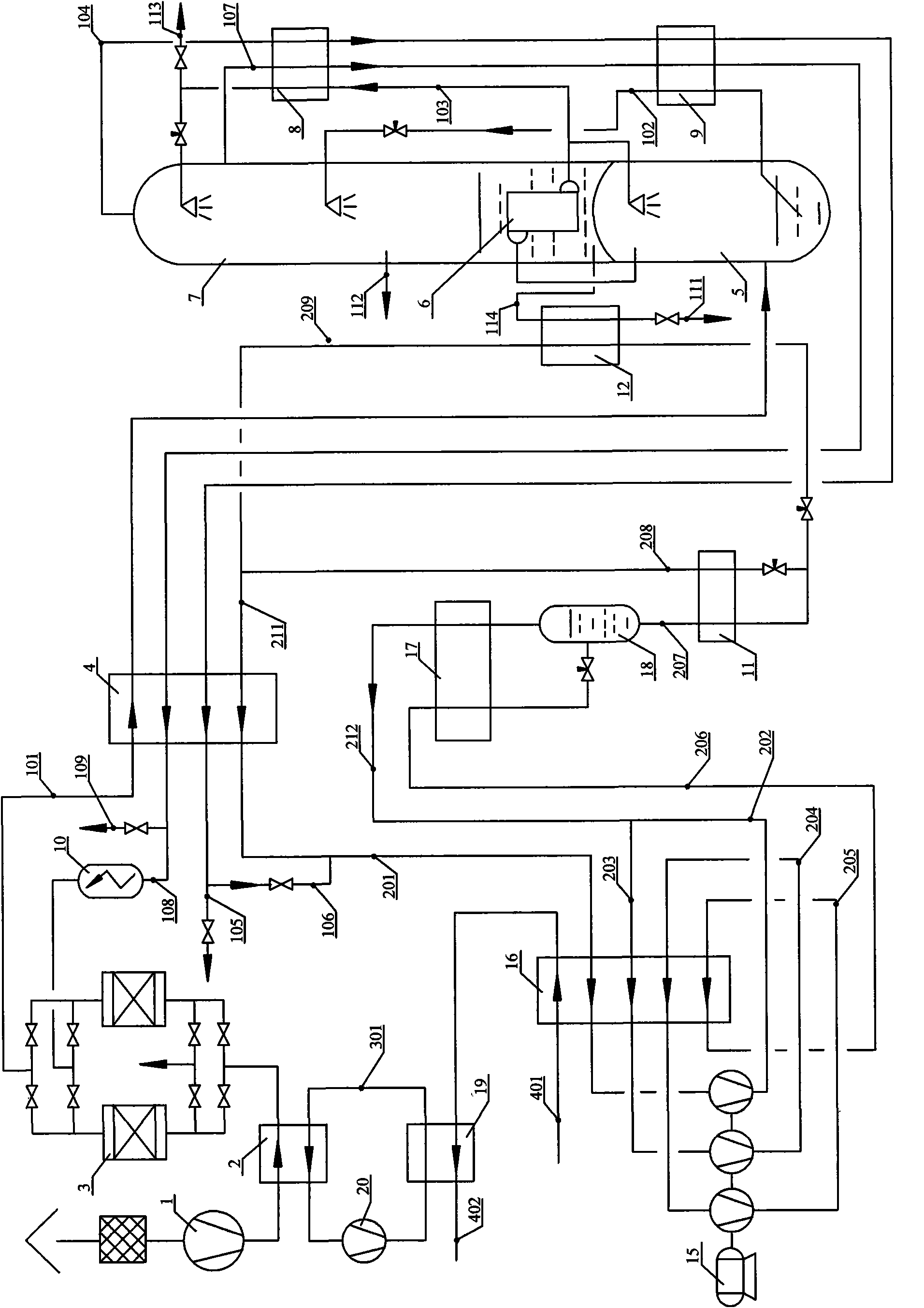

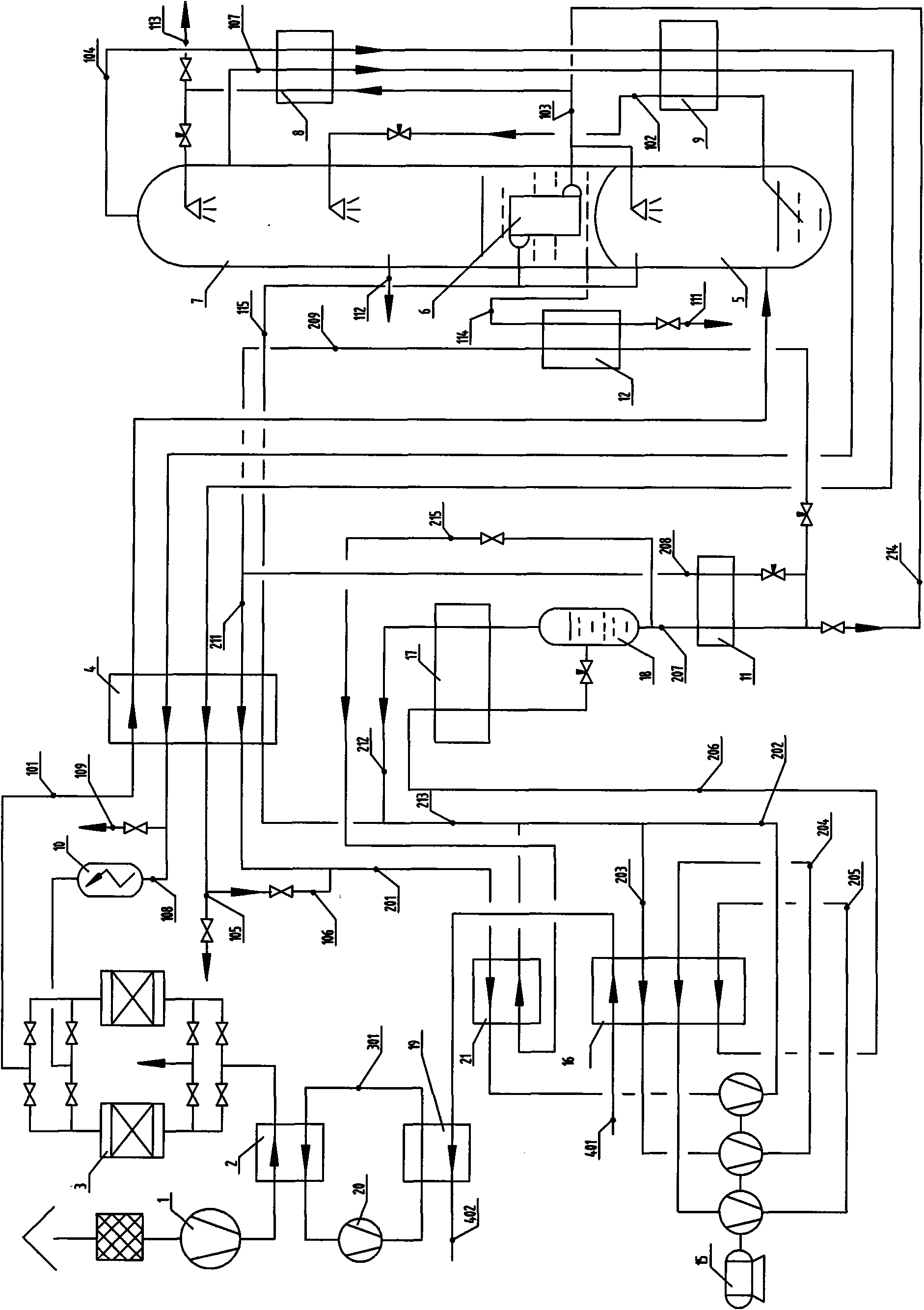

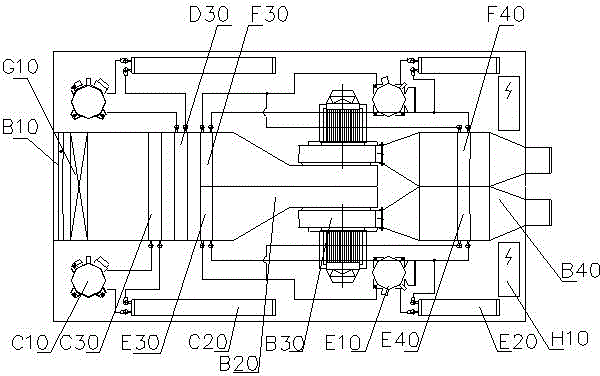

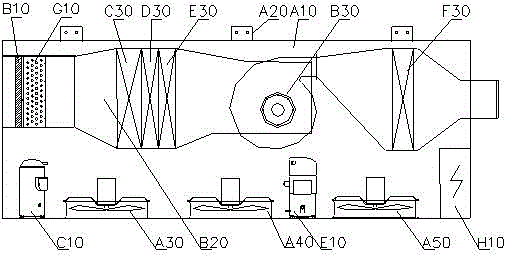

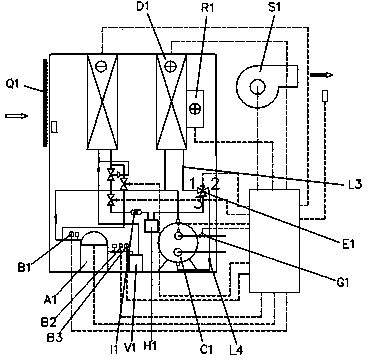

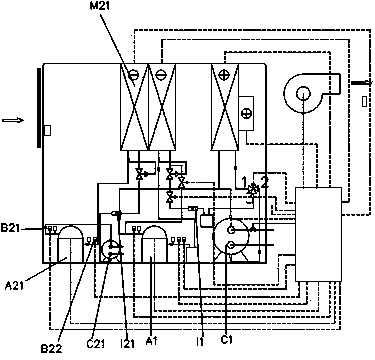

Variable frequency high-precision aircraft ground air conditioning unit and control method thereof

ActiveCN103332298AReasonable designHigh adjustment accuracyMechanical apparatusSpace heating and ventilation safety systemsAutomatic controlControl system

The invention discloses a variable frequency high-precision aircraft ground air conditioning unit and a control method of the aircraft ground air conditioning unit. The aircraft ground air conditioning unit comprises a frame structure, an air conditioning air supply system, a first refrigerating system, a second refrigerating system, a third variable frequency refrigerating system, a fourth variable frequency refrigerating system, a heating system and an automatic control system, wherein the frame structure comprises an air conditioning box, and a first axial flow fan, a second axial flow fan and a third axial flow fan which are arranged on the air conditioning box; all the systems are arranged in the frame structure; and the first axial flow fan, the second axial flow fan, the third axial flow fan, the air conditioning air supply system, all the refrigerating systems and the heating system are respectively connected with the automatic control system. The variable frequency high-precision aircraft ground air conditioning unit is reasonable in design, high in efficiency, energy-saving, high in adjustment accuracy, high in intelligence degree, compact in structure, small in volume, light in weight, high in safety performance and stable and reliable in running, saves the energy, reduces the environmental pollution, and is high in outlet air temperature adjustment accuracy.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

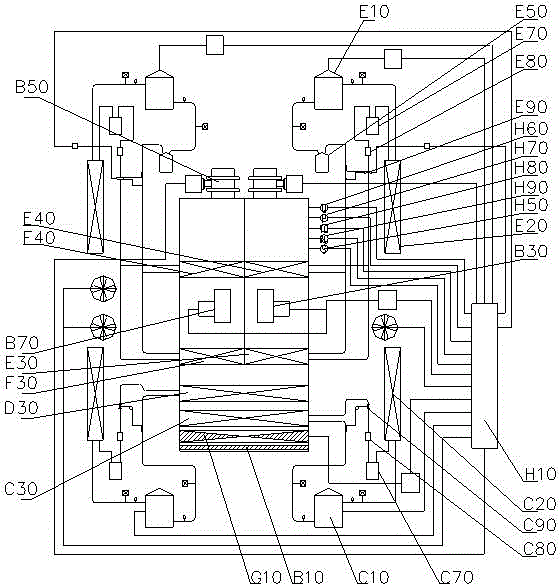

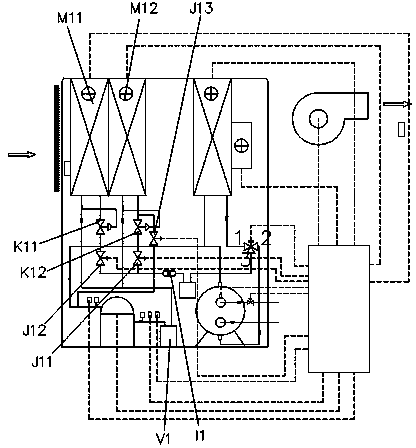

Energy-saving variable working condition air-conditioning system with precisely adjustable whole range and control method thereof

ActiveCN103822303AReasonable designHigh adjustment accuracySpace heating and ventilation safety systemsLighting and heating apparatusWater savingEngineering

The invention discloses an energy-saving variable working condition air-conditioning system with the precisely adjustable whole range and a control method thereof. The operation process of the air-conditioning system comprises the following steps that low-temperature and low-pressure refrigerant gas from an evaporator is absorbed by a compressor and is compressed into high-temperature and high-pressure gas through the compressor, then the gas enters a water cooling condenser and an air cooling condenser respectively to give off heat to air / water so as to be condensed into high-temperature and high-pressure liquid, the liquid is throttled through a throttling device to be a gas-liquid two-phase body which is then evaporated into low-temperature and low-pressure gas through the fact that the evaporator absorbs air heat, the low-temperature and low-pressure gas is then absorbed by the compressor, and the circulating is conducted repeatedly. The energy-saving variable working condition air-conditioning system with the precisely adjustable whole range is reasonable in design, efficient, saving in energy, suitable of variable working conditions, capable of achieving water saving operation, high in environmental adaptability, high in adjusting precision, high in intelligent degree, high in safety performance, and stable and reliable in operation, saves energy, meets the energy saving and environmental protection policy advocated in China, can achieve the purposes that the air outlet working condition is free of blind areas and is precisely adjustable, and provides a stable and reliable operation environment for various application occasions.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Coal ash lightweight board

InactiveCN101186470AImprove toughnessImprove mechanical propertiesSolid waste managementCeramicwarePulverized fuel ashCoal

The invention discloses a light-quality partition of pulverized fuel ash. The raw materials of the light-quality partition comprise pulverized fuel ash, cement, perlite, polypropylene fiber, water reducing agent, acrylic emulsion, foaming agent and water, and each component of the raw materials is calculated in ratio by weight: 40-60 portions of the pulverized fuel ash, 15-25 portions of the cement, 5-10 portions of the perlite, 0.1-0.5 portions of the polypropylene fiber, 0.5-1.0 portions of the water reducing agent, 1.0-5.0 portions of the acrylic emulsion, 0.1-0.5 portions of the foaming agent and 20-30 portions of the water. The invention takes the pulverized fuel ash as the main raw material; besides, various components are added into the pulverized fuel ash so as to be mixed organically. The invention not only conforms to the energy saving, waste utilizing, environmental protection policy advocated by the State, but also improves the intensity and toughness of the plates and leads the plates to be uneasy to be broken.

Owner:SHANDONG HONGTAI CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com