Energy-saving factorized fully-sealed seawater circulation culture process method and special device thereof

A technology of recirculating aquaculture and process method is applied in the field of marine fish industrialized aquaculture facilities and circulating water treatment fields, which can solve the problems of high boiler heating cost, pollution of aquaculture wastewater, increase in aquaculture costs, etc., so as to avoid heat loss and increase breeding density. The effect of high and saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

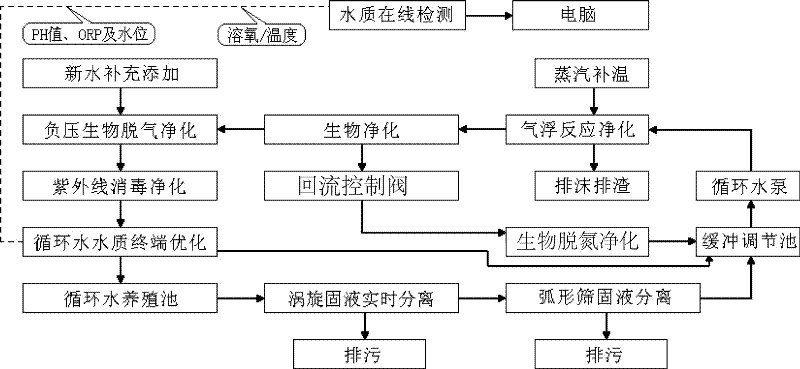

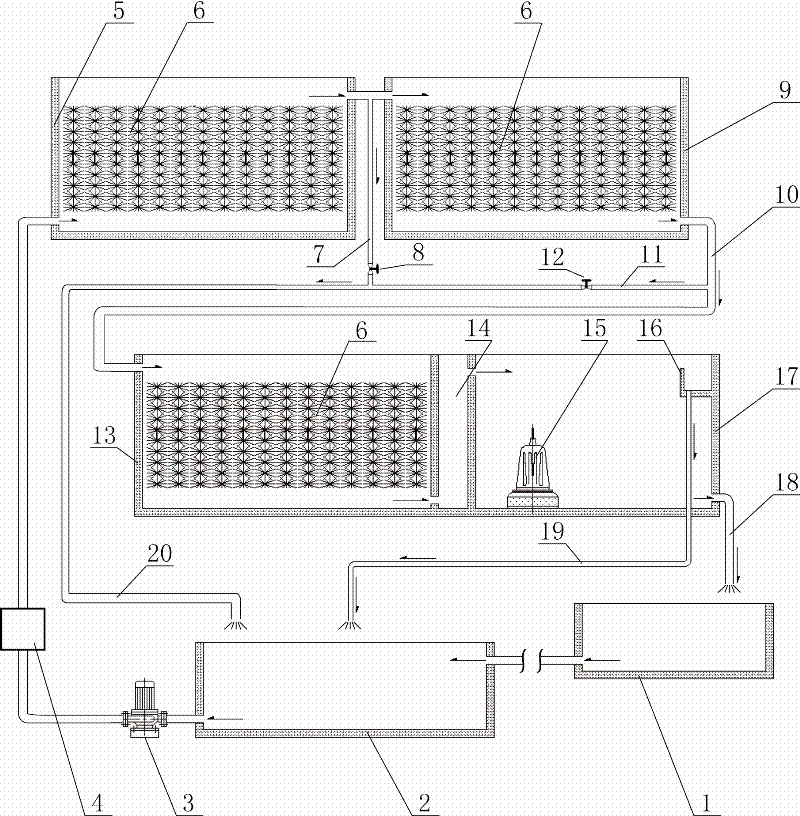

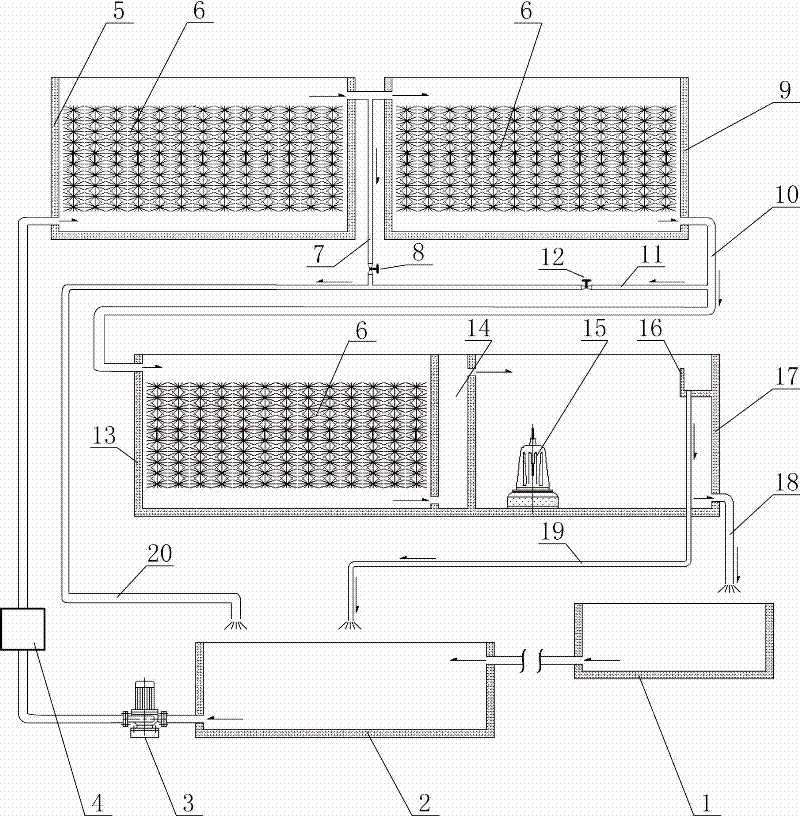

[0024] Process flow of the present invention such as figure 1 As shown, the water discharged from the circulating aquaculture tank first flows into the vortex separation tank by itself for vortex separation, and the vortex separates the heavier residual ear feces and impurities and discharges them.

[0025] Then, the solid-liquid separation is carried out from the effluent water to the curved sieve solid-liquid separation device, and the larger residual ear feces, impurities, etc. are separated and discharged.

[0026] The effluent flows into the buffer adjustment tank. The circulating water pump lifts water from the buffer adjustment tank to the air flotation tank for air flotation reaction purification, and separates lighter substances by air flotation, and separates fine impurities such as suspended solids and colloidal proteins that cannot be separated by the solid-liquid separator and discharges foam. Slagging.

[0027] The water flowing out of the air flotation tank f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com