Vehicle transverse swinging parking device

A parking device and yaw technology, which is applied in the field of simple parking devices for vehicles, can solve the problems of high manufacturing cost, high cost, and heavy weight, and achieve the effects of simple and convenient installation and arrangement, low manufacturing cost, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

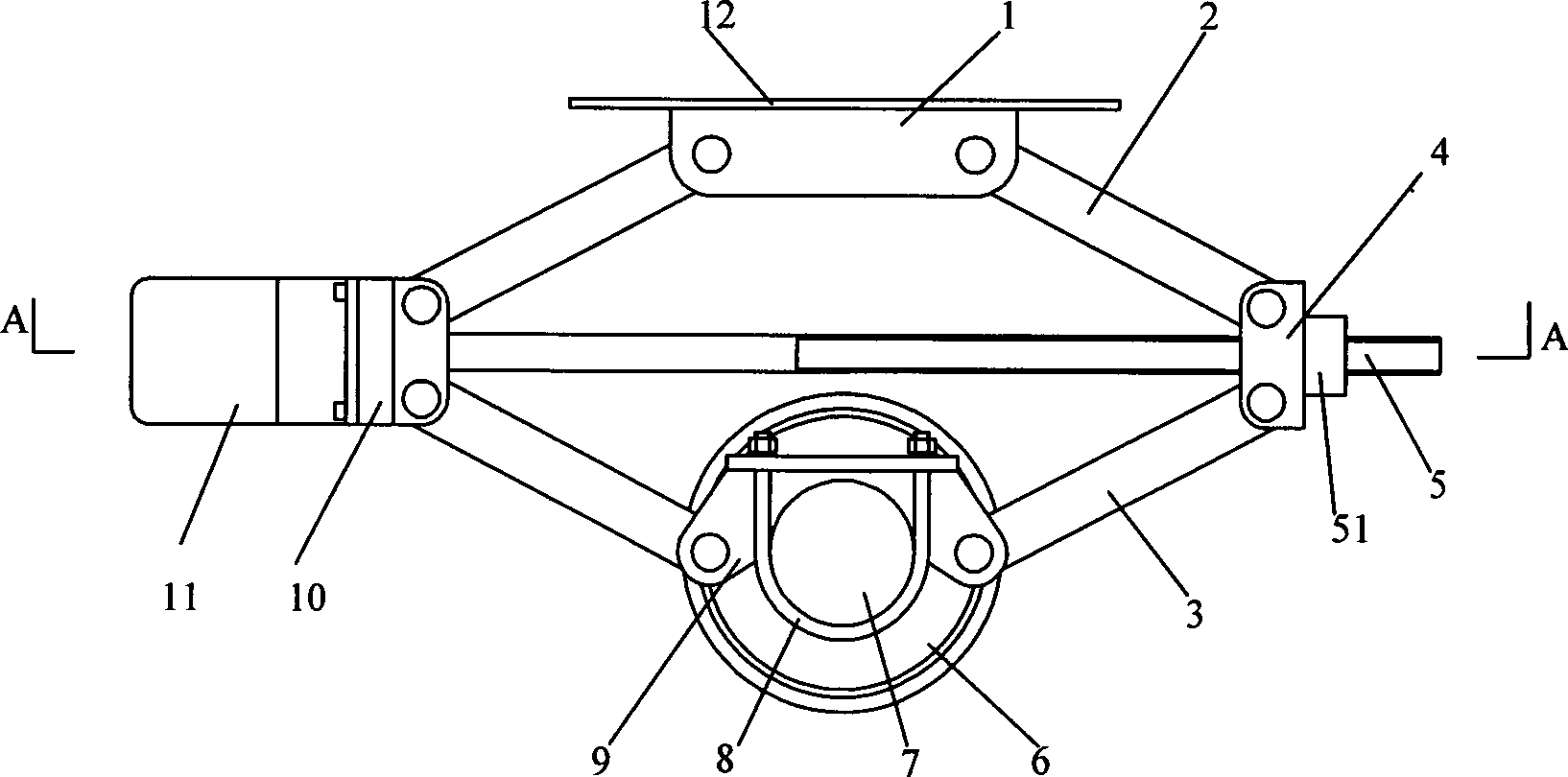

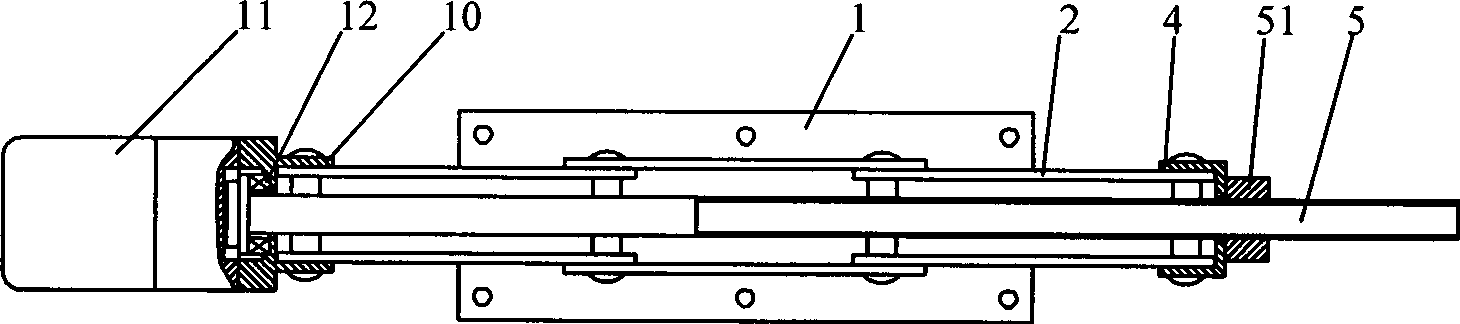

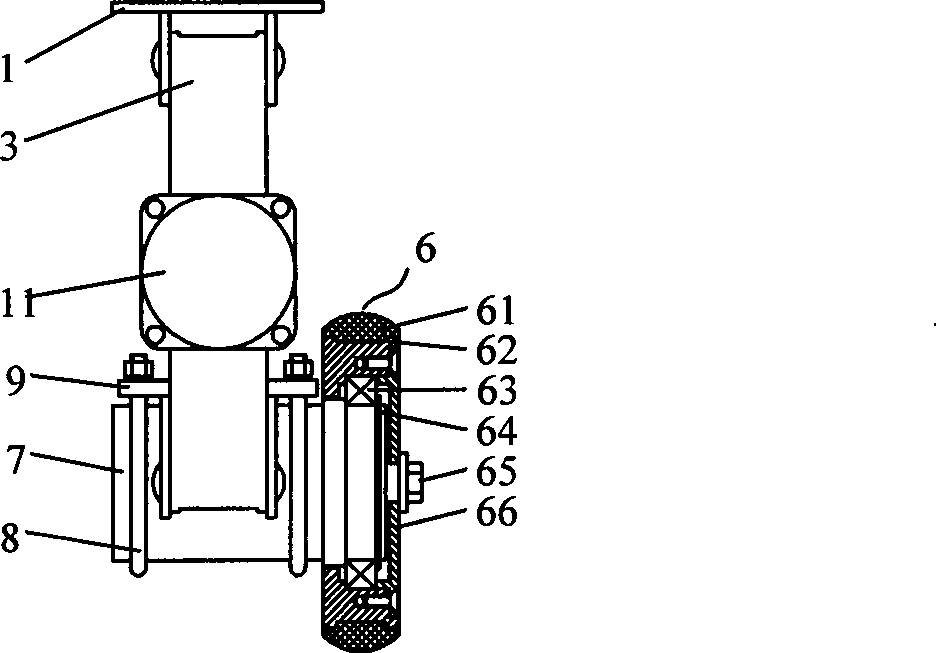

[0023] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, figure 2 for figure 1 Sectional view along A-A direction, image 3 It is a schematic diagram of the lateral drive wheel assembly of the present invention, as shown in the figure: the vehicle sway parking device of the present embodiment includes a lifting mechanism and a swaying mechanism, and the lifting mechanism includes a lifting power device 11, a screw mandrel 5, and a screw mandrel 5 screwed on Nut 51, two upper struts 2 and two lower struts 3, the lifting power device 11 can drive the screw mandrel 5 to rotate; two upper struts 2 and two lower struts 3 move with the screw mandrel 5 and the nut 51 respectively The pair consists of an upper plane four-bar mechanism and a lower plane four-bar mechanism;

[0024] The yaw mechanism includes a yaw power device 7 and a lateral drive wheel 6, the yaw power device 7 can drive the lateral drive wheel 6 to rotate, and the lower end ...

Embodiment 2

[0028] Figure 4 It is a structural schematic diagram of Embodiment 2 of the present invention, as shown in the figure: the difference between this embodiment and Embodiment 1 is: a second lateral drive wheel 13 is arranged in parallel with the lateral drive wheel 6 on the lower support 9, and the second lateral drive wheel 13 The wheel 13 is arranged on the lower support 9 through the rotational cooperation of the rotating shaft 14 and the second radial rolling bearing 15 . Because the second transverse driving wheel 13 and the transverse driving wheel 6 are arranged side by side laterally, the left and right balance can be kept after the rear of the vehicle is raised, and no tilting to the left or right can take place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com