Beam blank continuous casting machine tundish working lining, construction tire film of working lining and preparation method of working lining

A special-shaped billet continuous casting and working lining technology, which is used in casting equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the qualified rate of special-shaped billets, increasing the tundish casting surplus, erosion, etc., and improving single-ladle continuous casting. Time, good economic and social benefits, the effect of reducing the cost of refractory materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

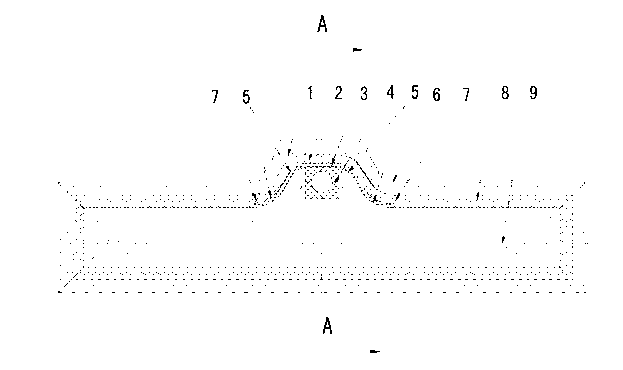

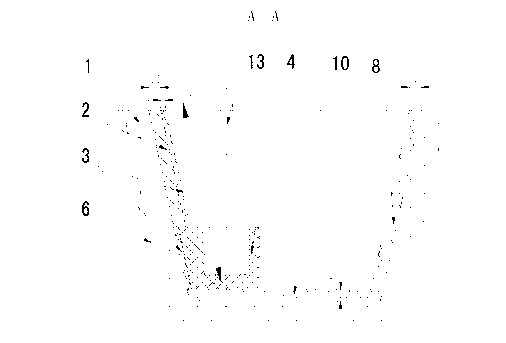

[0034] figure 1 , figure 2 As shown, a tundish working lining of a profiled billet continuous casting machine is characterized in that the working lining in the impact zone is built with carbon-containing refractory bricks 2, and a layer of smear 3 is applied on the outer surface of the carbon-containing refractory bricks (2), And the corners 5 of the working lining in the impact zone are all arc angles, and the wall working lining 8 and the bottom working lining 10 outside the impact zone are all made of dry materials. The corner 5 of the working lining in the impact zone is changed from a traditionally designed right angle to a circular arc angle, which reduces the resistance when the molten steel in the tundish flows through the corner of the working lining, thereby reducing the erosion of the corner by the molten steel and making the corner partially The technical problem of heavy erosion is solved.

[0035] The thickness a of the working lining carbon-containing refrac...

Embodiment 2

[0053] Others are the same as embodiment 1, the difference is:

[0054] The thickness a of the working lining 2 in the impact zone is 50 mm, and the thickness b of the smear material 3 is 30 mm.

[0055] The thickness x of the wall lining 8 outside the impact zone is 60 mm, and the thickness y of the bottom lining 10 is 50 mm.

[0056] The carbon-containing refractory brick is an aluminum-magnesia-carbon brick whose brand name is LMT-72, and its MgO+Al 2 o 3 The content is 72%, the MgO content is 10%, the C content is 7%, the apparent porosity is 10%, and the bulk density is 2.80g / cm 3 , The compressive strength at room temperature is 40MPa, and the softening temperature under 0.2MPa load is 1600℃.

[0057] The smear 3 refers to the magnesium smear produced in the prior art and used for the working lining of the tundish of the continuous casting machine.

[0058] The baffle 11 is made of heat-resistant cast steel, and the thickness of the baffle 11 is 30mm.

[0059] A met...

Embodiment 3

[0069] Others are the same as embodiment 1, the difference is:

[0070] The thickness a of the working lining 2 in the impact zone is 60 mm, and the thickness b of the smear material 3 is 20 mm.

[0071] The thickness x of the wall lining 8 outside the impact zone is 70 mm, and the thickness y of the bottom lining 10 is 60 mm.

[0072] The carbon-containing refractory bricks are MT-18C magnesia-carbon bricks with a MgO content of 69%, a C content of 18%, an apparent porosity of 4.0%, and a bulk density of 2.87g / cm 3 , The room temperature compressive strength is 30MPa.

[0073] The baffle 11 is made of heat-resistant cast steel, and the thickness of the baffle 11 is 25 mm.

[0074] A method for preparing a tundish working lining of a profiled billet continuous casting machine, comprising the following steps:

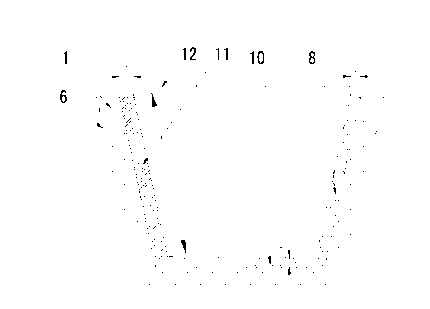

[0075] 1) Preparation of tire mold 12 for construction of dry lining material: before construction, clean the surface of tire mold 12 for construction of dry lining m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com