Patents

Literature

47results about How to "Lifetime Synchronization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ladle working liner and preparation method thereof

InactiveCN102728828ASolve surface oxidationSolve the iron seepage problemMelt-holding vesselsBrickRefractory

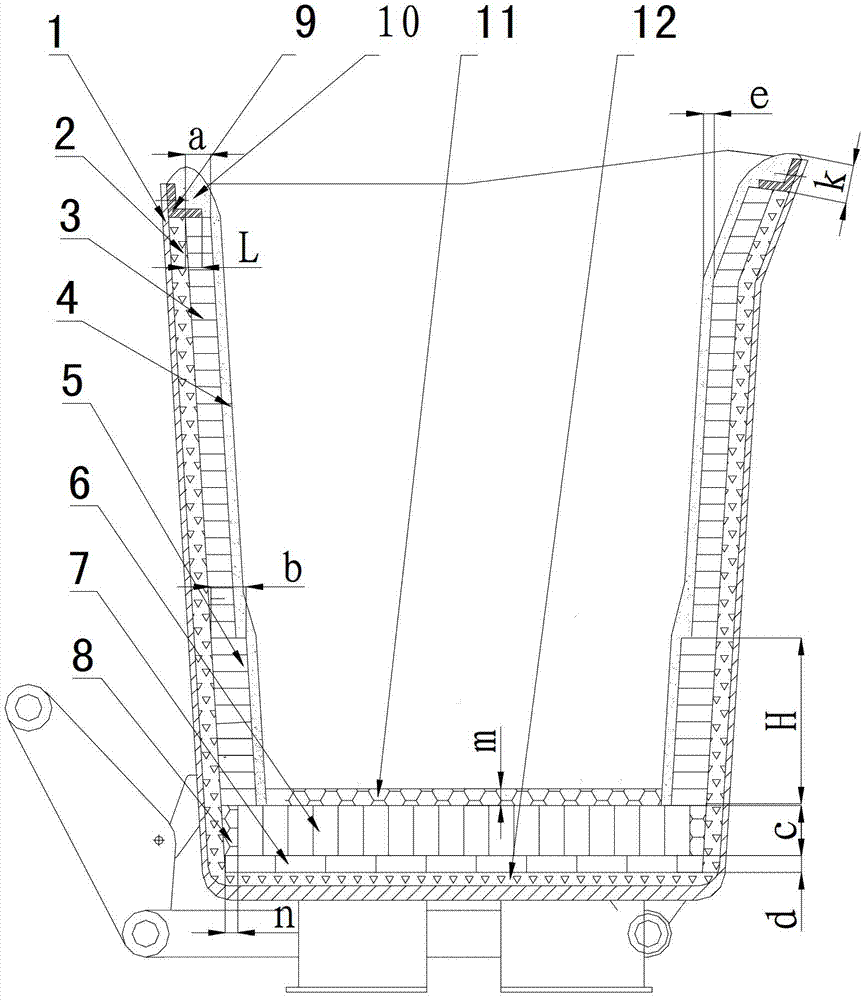

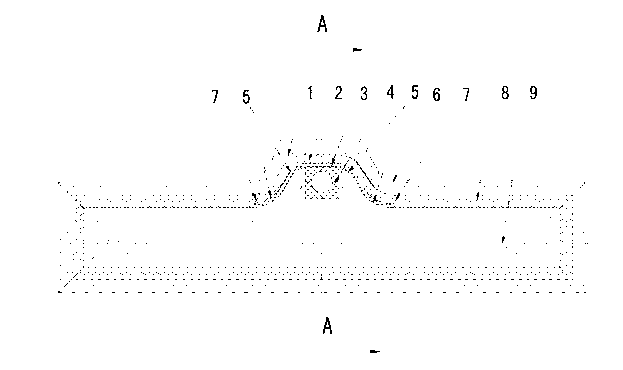

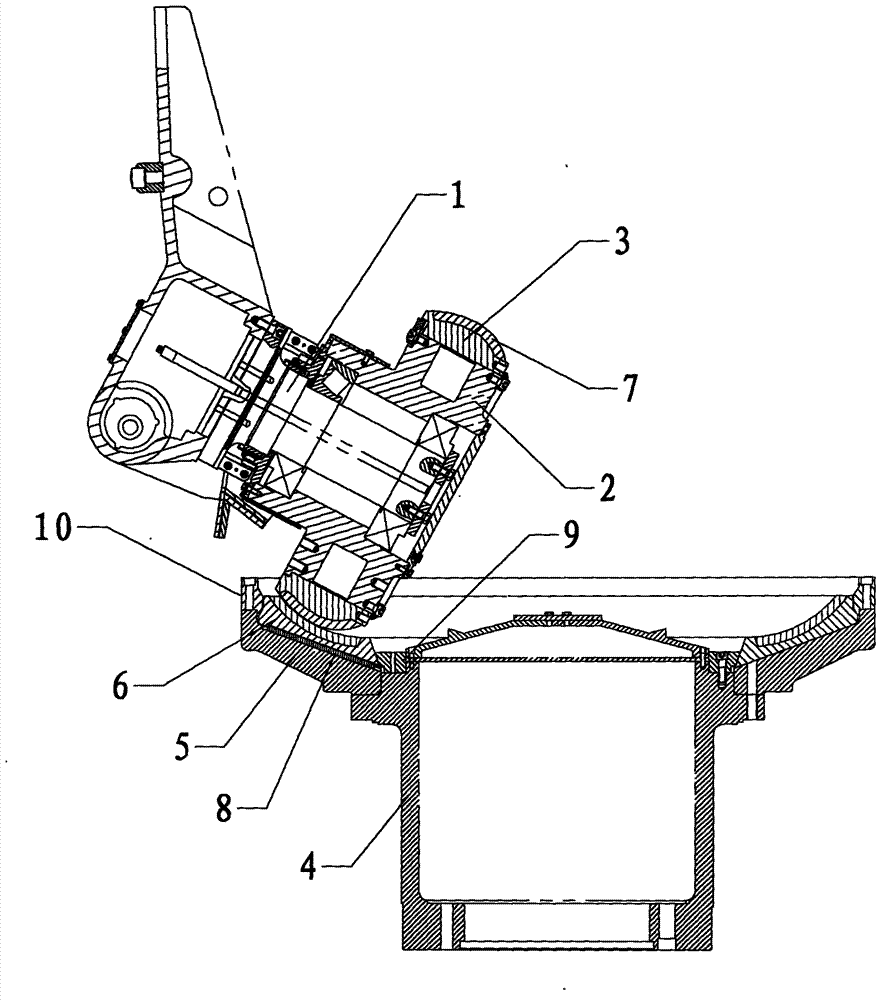

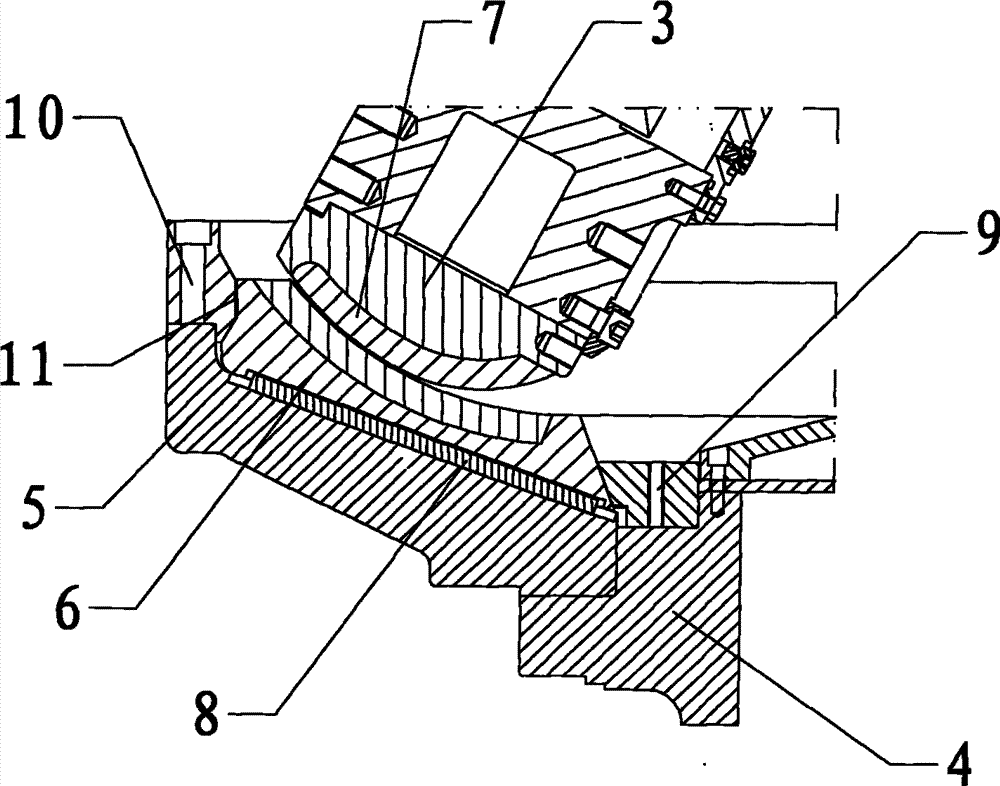

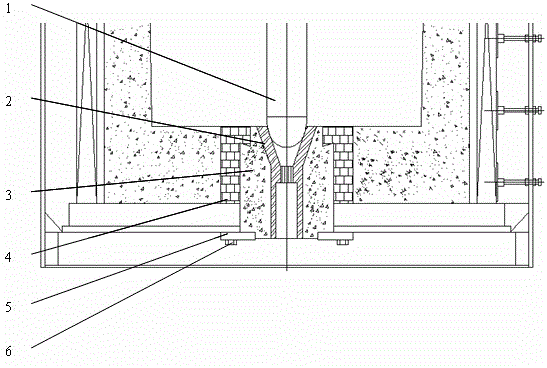

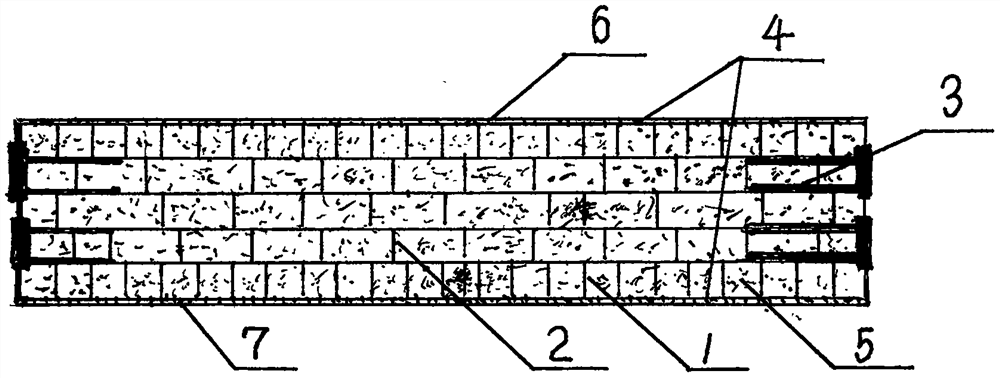

The invention relates to a ladle working liner and a preparation method thereof, and belongs to the technical field of a ferrous metallurgy ladle process. The ladle working liner is characterized in that a ladle bottom working liner consists of three layers of structures which are ladle bottom working liner flat laid refractory bricks (7), ladle bottom working liner vertical laid refractory bricks (6) and ladle bottom working liner castable (11) from bottom to top in sequence, wherein the iron flow impact region working liner refractory bricks (5) on the lower part of a ladle wall is 20-30 mm thicker than the working liner refractory bricks (3) on the upper part of the ladle wall; a ladle wall coating layer (4) is coated on the outer surfaces of the working liner refractory bricks (3) on the upper part of the ladle wall and the iron flow impact region working liner refractory bricks (5) on the lower part of the ladle wall; and a ladle edge coating layer (10) is coated on the upper part of a ladle edge pressing plate (9). By using the ladle working liner, the service life of the ladle working liner is prolonged by 300-400 heats and the ladle refractory material cost is reduced by over 30 percent on year-on-year basis.

Owner:LAIWU IRON & STEEL GRP

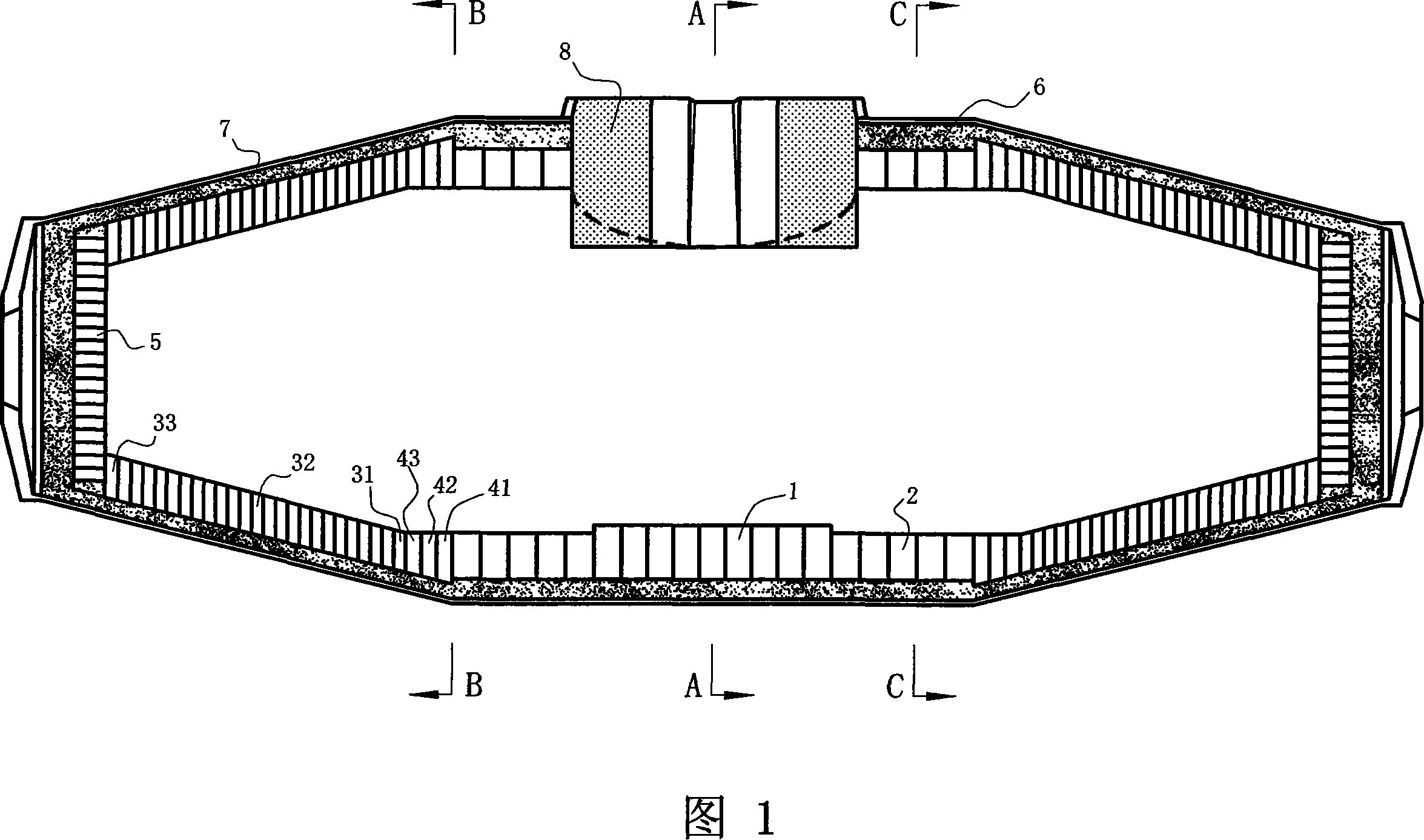

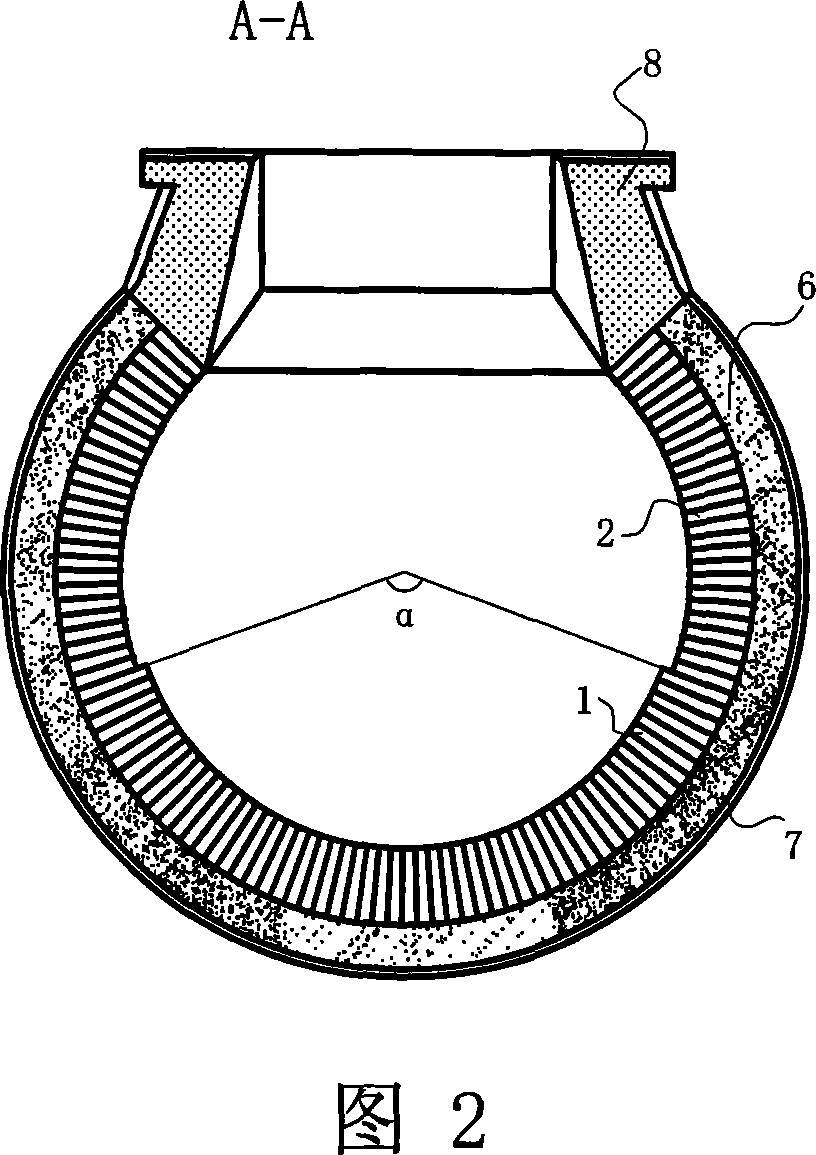

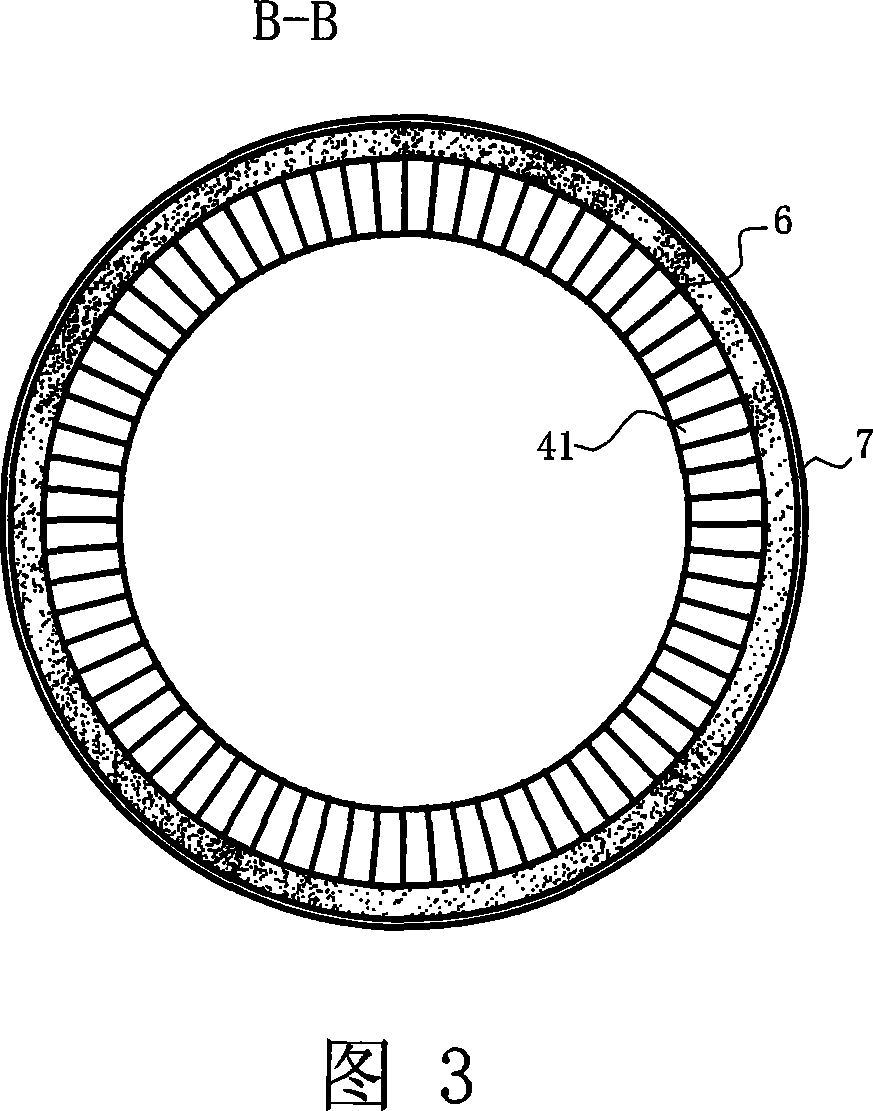

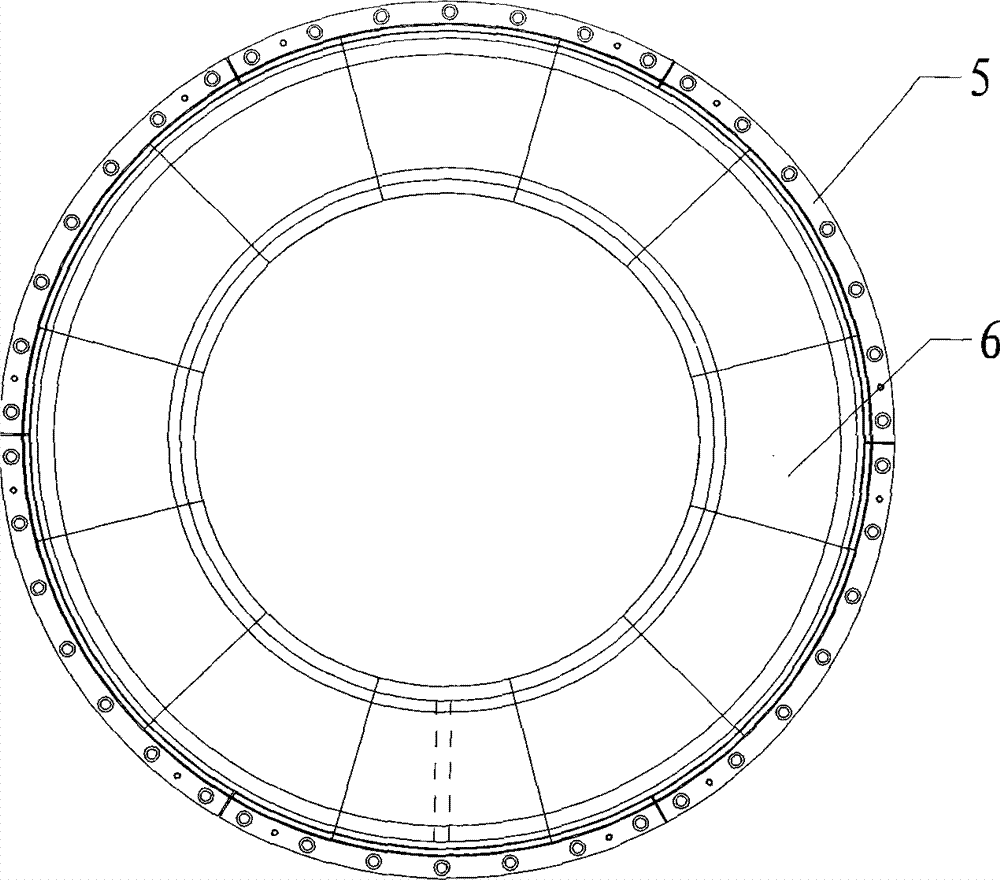

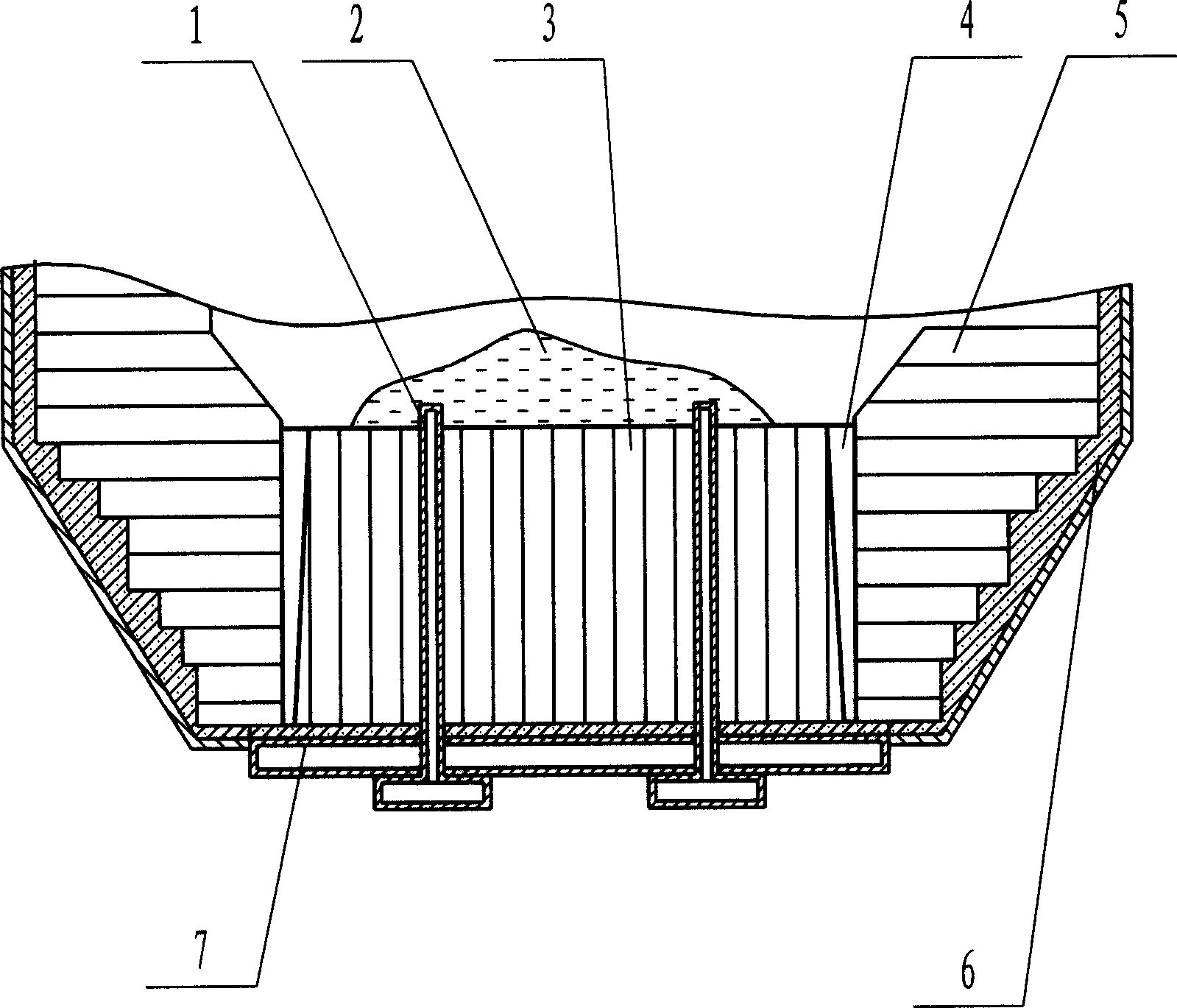

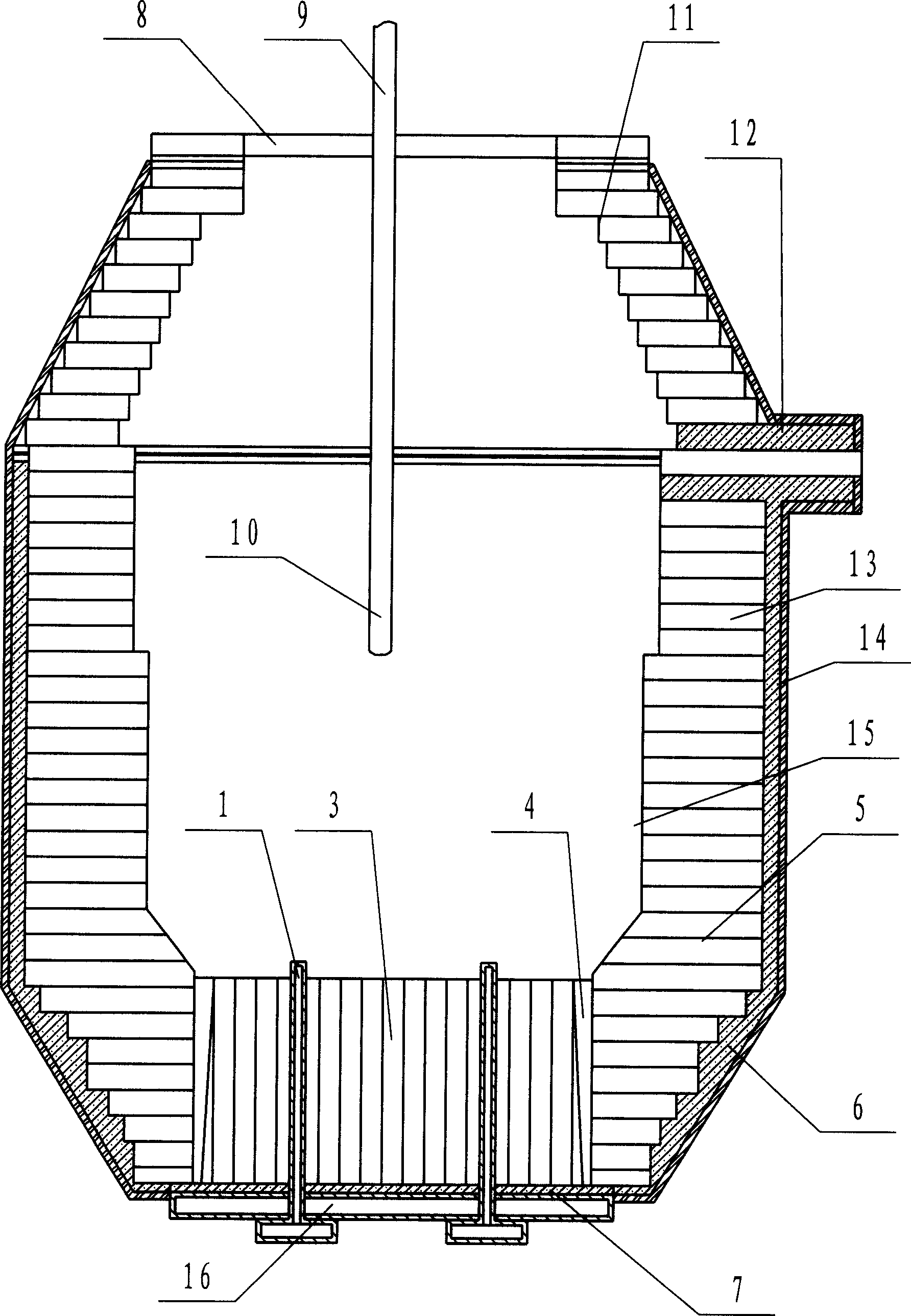

Inner lining structure for torpedo pot and aluminium carbonize silicon carbide brick and high aluminium brick used for torpedo pot

InactiveCN101058116ALifetime SynchronizationChange the phenomenon of less frequent useMelt-holding vesselsBrickCoesite

The invention relates to a torpedo pot liner structure and torpedo pot used aluminum carbonized silicon carbon brick, high aluminum brick. Bottom of the torpedo pot impact part uses nonburning aluminum carbonized silicon carbon brick, most of the rest using burnt stripping resistant high aluminum brick. Material for the aluminum carbonized silicon carbon brick comprises the alumina, electro-melting corundum, carbofrax, carbite, sintered corundum, aluminum, silicon, astringent, and so on, and the high aluminum brick comprises alumina, electro-melting corundum, carbofrax, silicon, silicon powder, bindeton and paper waste liquid. It is reasonable in formulation, mature in production process, with forming no need of high temperature baking with lower production cost. Using these two kinds of bricks, using durability of the overall torpedo can basically reach synchronic feature, application over 1700 times, with good effect and significant economical benefit.

Owner:GONGYI WINNA SCI & TECH DEV

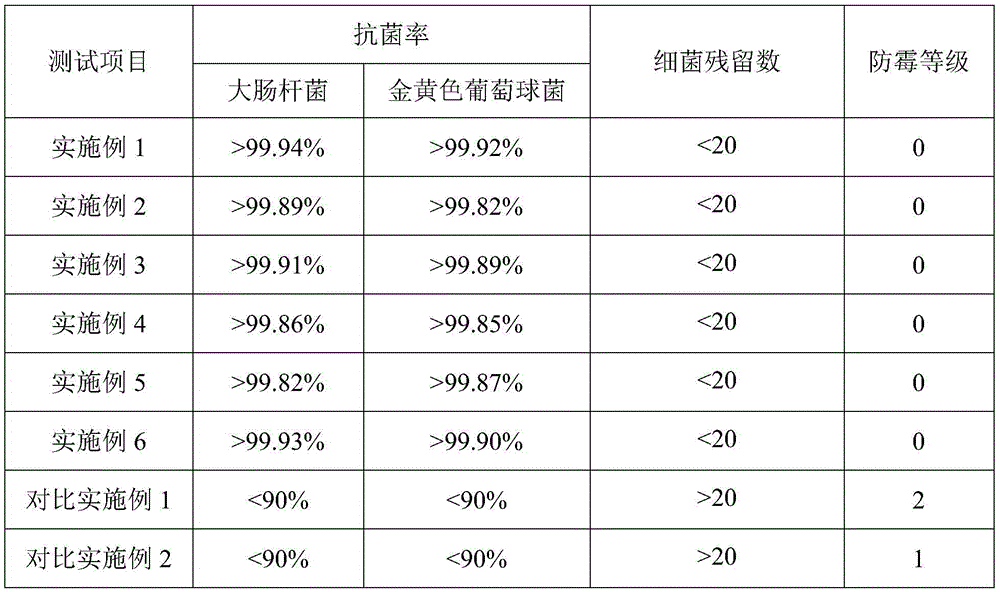

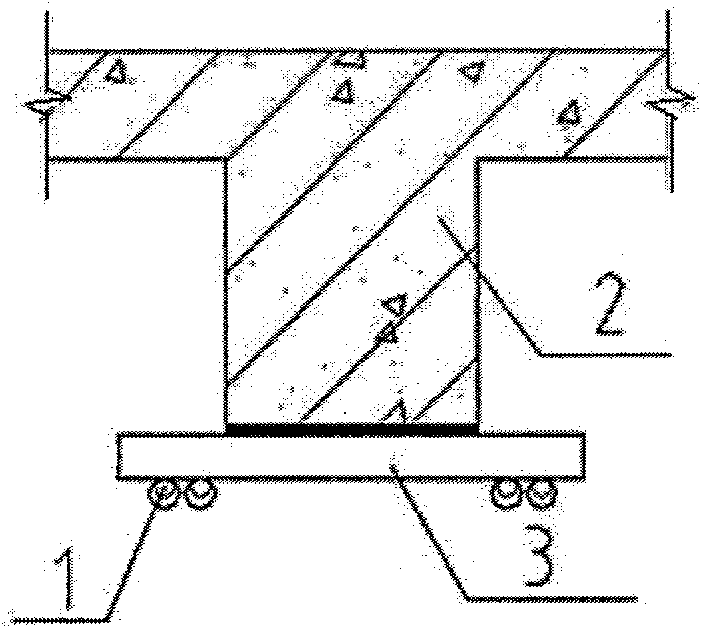

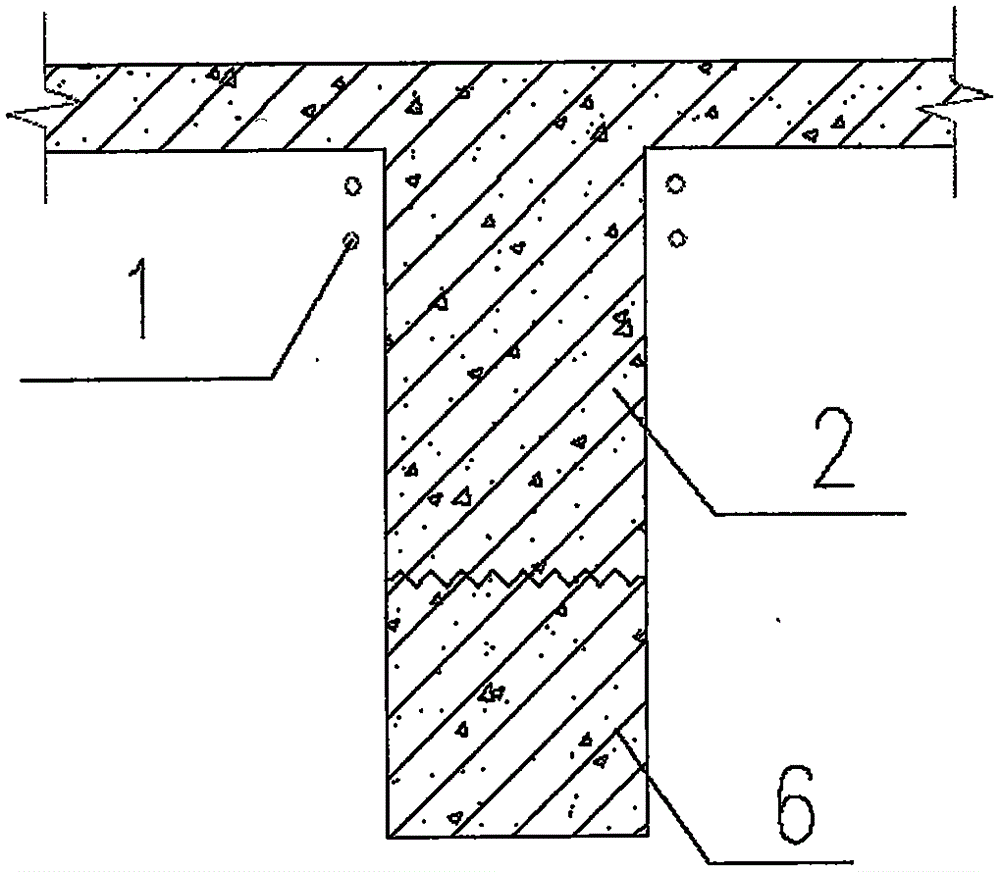

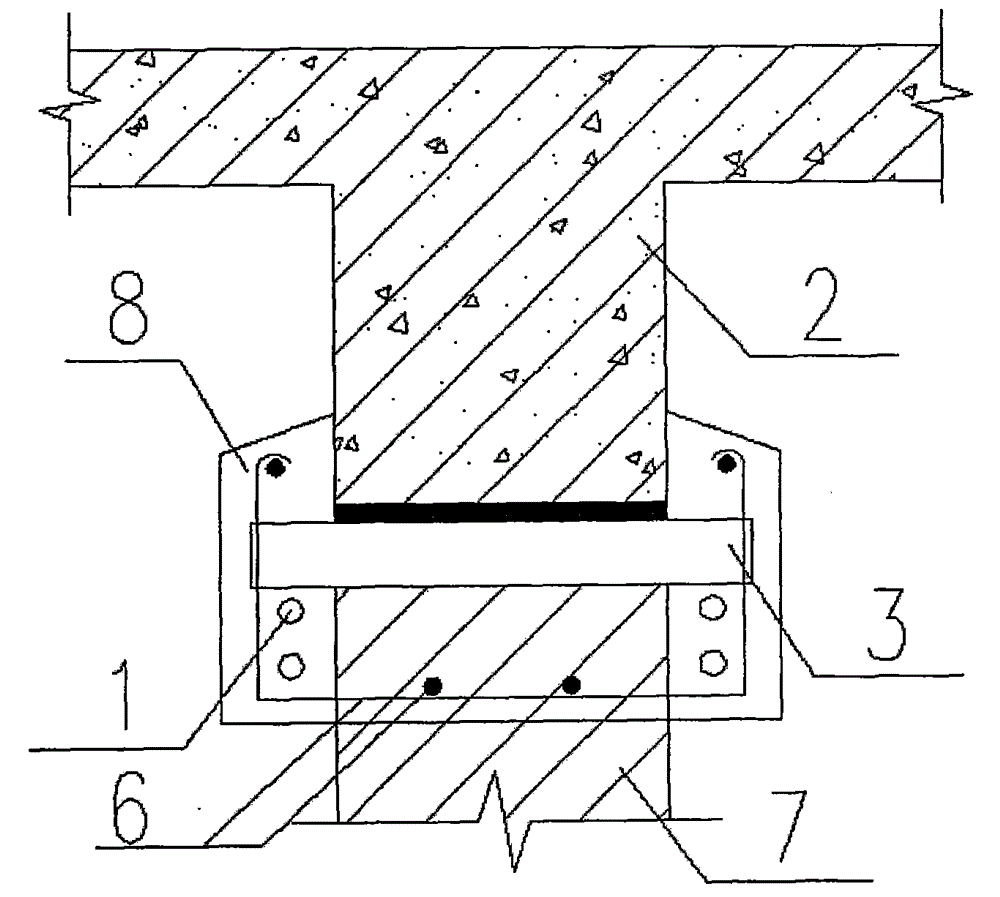

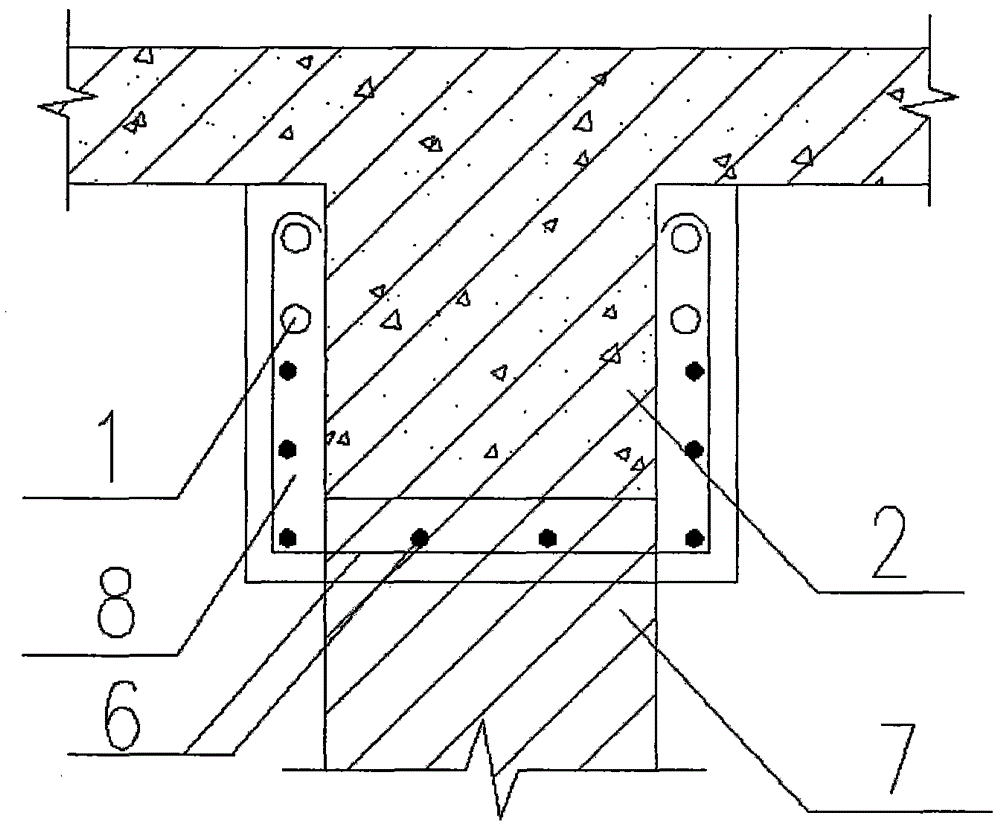

Beam blank continuous casting machine tundish working lining, construction tire film of working lining and preparation method of working lining

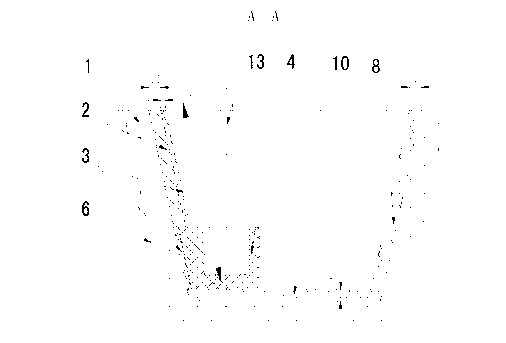

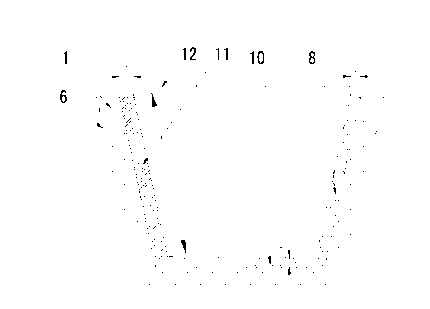

ActiveCN102699316AImprove corrosion resistanceImprove anti-scourabilityMelt-holding vesselsFireproofingImpact area

The invention belongs to the technical field of steel metallurgy continuous casting tundish technique, in particular to a beam blank continuous casting machine tundish working lining, a construction tire film of the working lining and a preparation method of the working lining. The working lining, the construction tire film and the preparation method are characterized in that a working lining in an impact area is forming by carbonic fireproofing tiles (2), a layer of painting materials (3) are painted on the outer surfaces of the carbonic fireproofing tiles (2), corners (5) of the working lining in the impact area are all arc corners, wall wrapping working linings (8) and bottom wrapping working linings (10) except for a tundish impact area all adopt dry-type materials. Therefore, service life of the working lining of the tundish impact area and working linings at other portions are synchronous, monopack continuous casting time achieves more than 36 hours which shortens 12 hours than the time at the same condition, and continuous casting tundish material cost reduces more than 30% than the cost at the same condition.

Owner:LAIWU IRON & STEEL GRP

Method for manufacturing agricultural film coated by high performance polyolefin

ActiveCN102744943AHigh transparencyImprove insulation effectSynthetic resin layered productsCoatingsMasterbatchPolyolefin

The invention relates to an agricultural greenhouse and a greenhouse cover material, and concretely relates to a preparation method of high performance polyolefin by using a coating technology and a nano modification technology. The high performance polyolefin coating agricultural film takes high performance polyolefin as a matrix, a functional master batch is added to prepare a base material film, and the agricultural film can be prepared by preciously coating through a coating liquid; the high performance polyolefin coating agricultural film is prepared by processes of preparing the functional master batch, preparing a base material thin film, performing corona treatment, winding the base material film, coating one surface by the coating liquid, drying the coating liquid, cooling and winding, on-line roll change, coating on the other surface by the coating liquid. The flow-dripping period and the service life can reach more than three years, and the agricultural film has the advantages of good heat insulating ability, pesticide resistance property and dirt resistance property.

Owner:白山市喜丰塑业有限公司

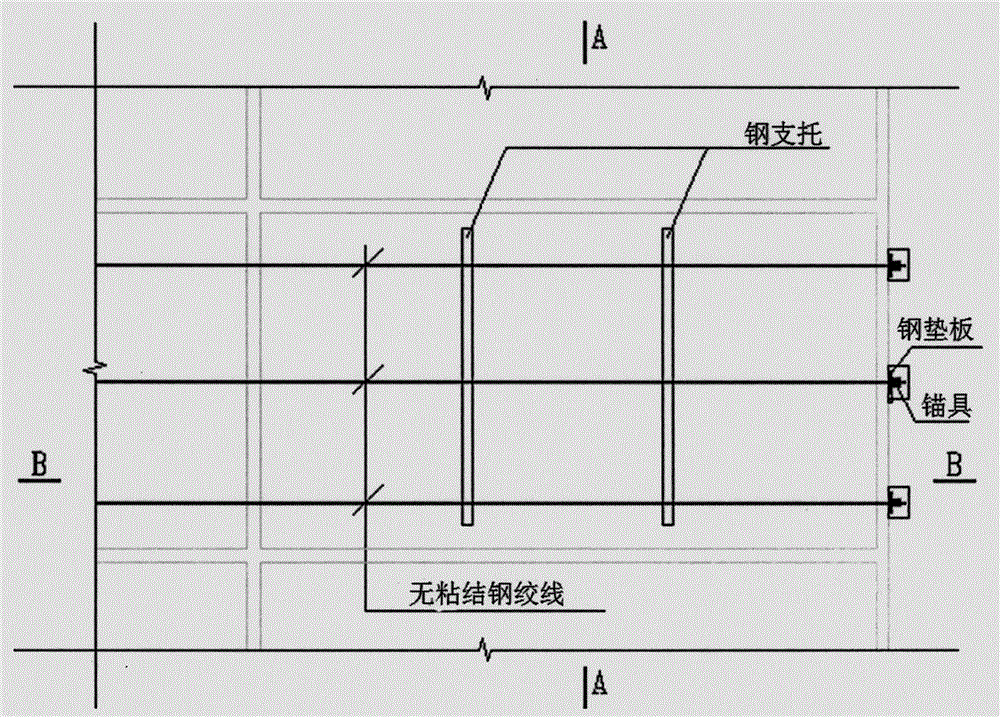

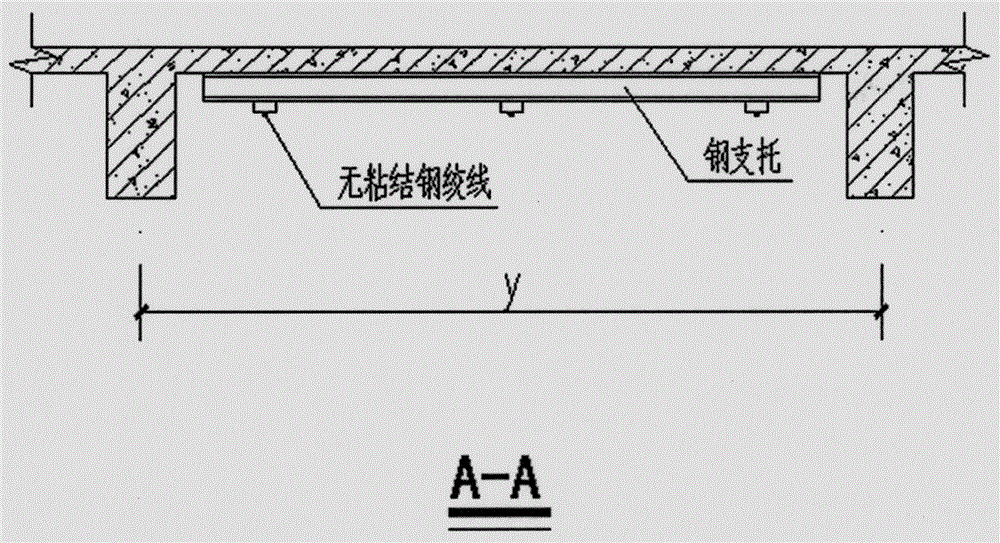

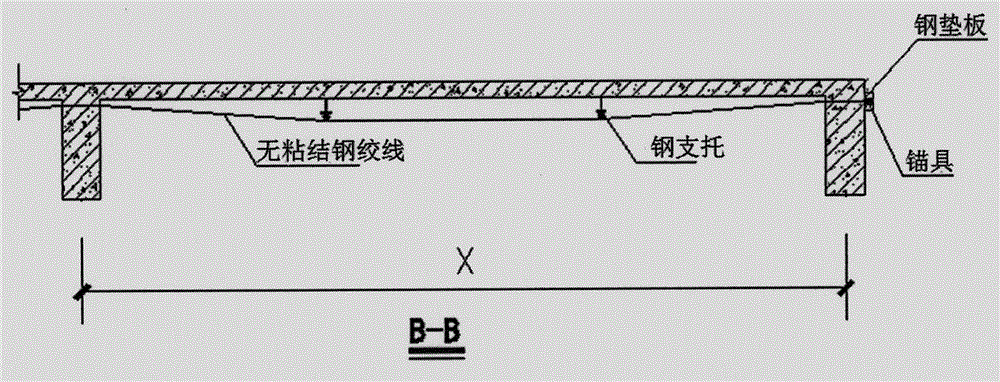

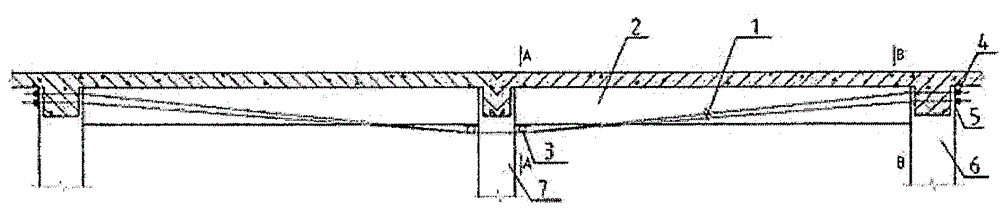

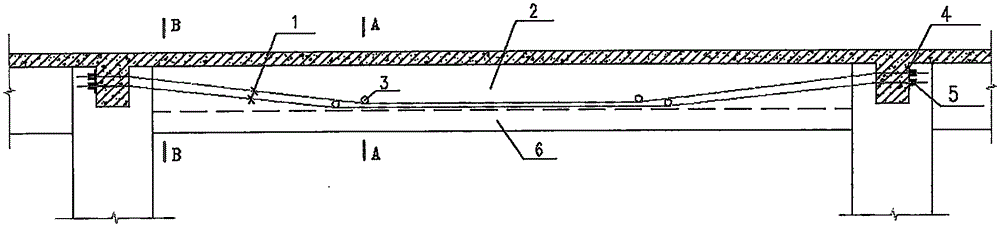

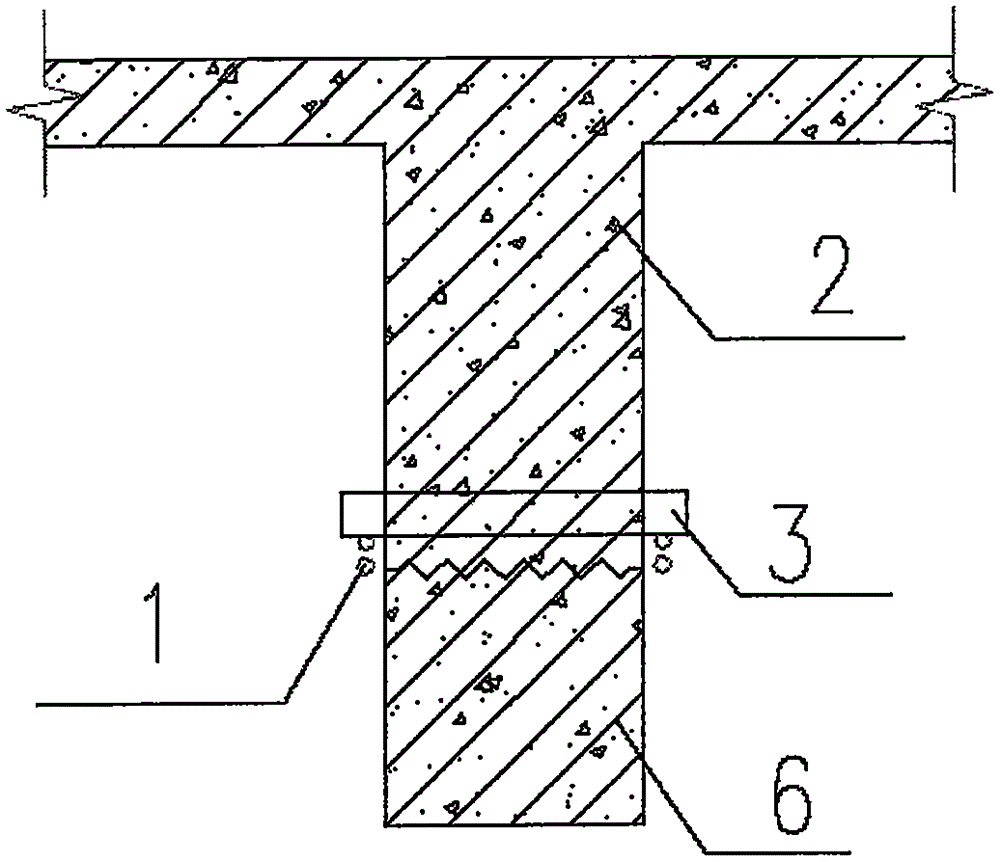

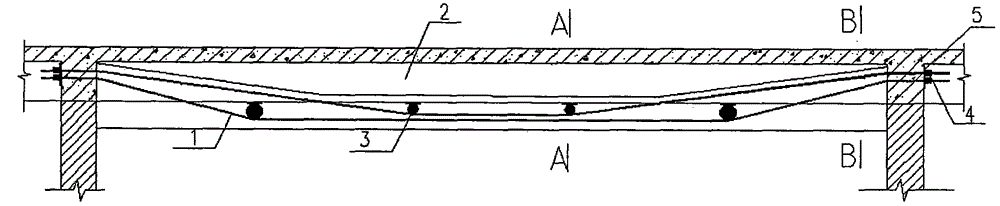

Steel-support non-cohesive steel strand lower support type prestress floor reinforcing method

The invention discloses a steel-support non-cohesive steel strand lower support type prestress floor reinforcing method. The method includes: two or one steel support is disposed at the one-third-span position or half-span position of the bottom of a floor to change the single-span floor into a three-span floor or a two-span floor; certain-distance three-folding-line-shaped or two-folding-line-shaped non-cohesive steel strands are disposed at the bottom of each steel support to serve as the support points of the steel support; two ends of the non-cohesive steel strands are fixed on floor beams or ring beams through steel base plates and anchoring tools; after the non-cohesive steel strands apply prestress, upward counterforce is generated at each steel support to balance off part of floor load so as to achieve the reinforcing effect. The method has the advantages that the steel supports can be made of small I-shaped steel, and brackets at two ends of the steel supports are not needed; the method is an active reinforcing method, the stress of the reinforcing steel bars in the floor becomes small with the application of the prestress, the original cracks of the floor can be reduced and effective controlled, and floor deflection is reduced.

Owner:项剑锋

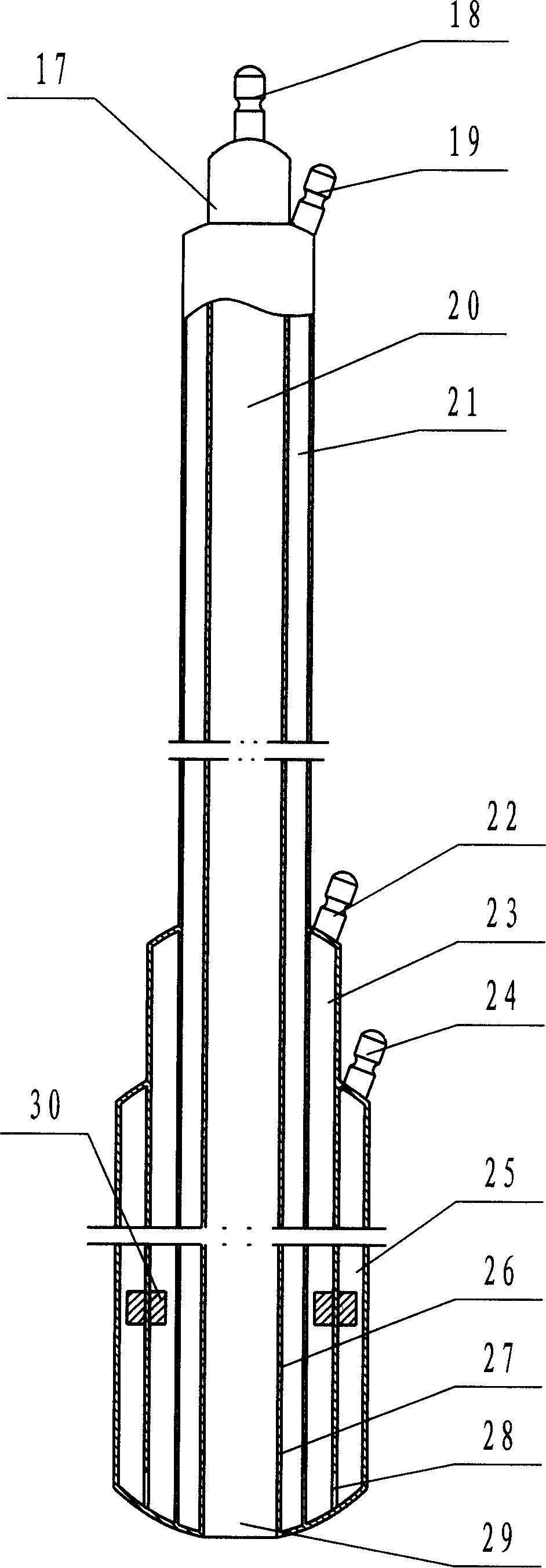

Gradient grinding type HP (High Power) type coal mill

The invention relates to a gradient grinding type HP (High Power) type coal mill. Abrasion-resistant alloy is surfaced on the outer surface of a roll sleeve of a grinding roll to form a roll tire type grinding roll with a cross section which is of a semi-arc structure, the abrasion-resistant alloy is surfaced on the surface of the inner side of a lining plate to form an arc structure which is inwards concave and adapts to the roll tire type grinding roll in shape, the surface of the outer side of the lining plate is connected with a grinding bowl through a flat key, the small end of the lining plate is compacted with a grinding bowl hub through a grinding bowl clamping ring, a grinding bowl extending baffle ring is fixed on the grinding bowl hub and positioned at the large end of the lining plate, and a gap is arranged between the inner wall of the grinding bowl extending baffle ring and the large end of the lining plate. According to the scheme, hard coal can be prevented from being discharged as coal gangue, the discharging mount of the coal gangue is reduced, and the working efficiency of ground coal is increased.

Owner:BEIJING XINYUAN BAOTONG POWER EQUIP

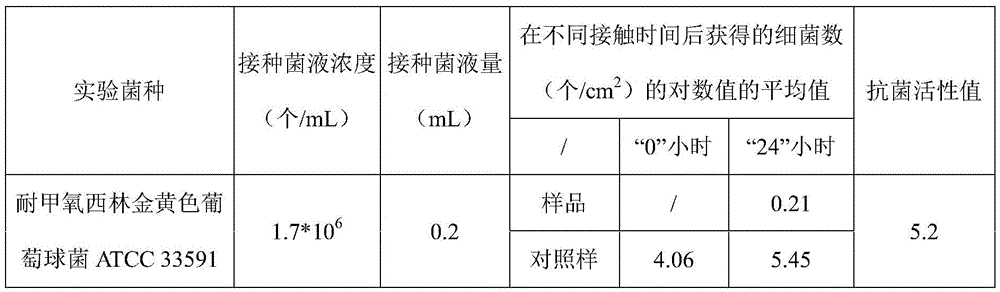

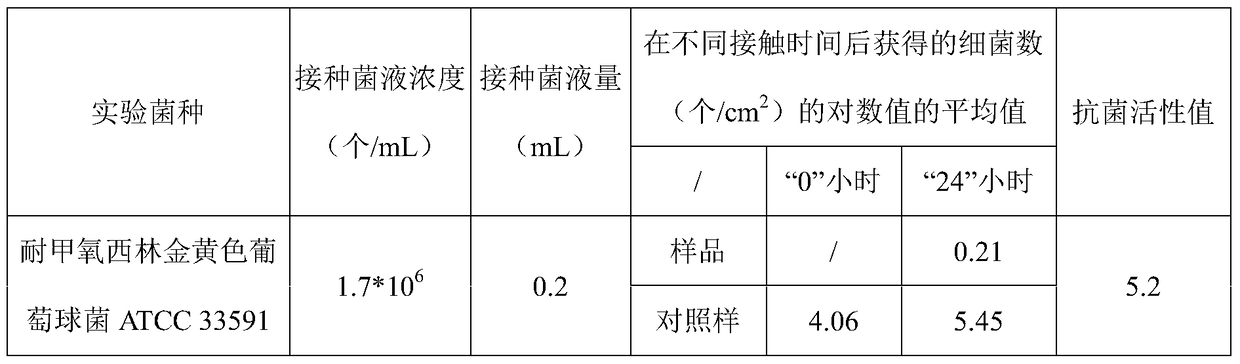

Ceramic or enamel sterilization glaze material and preparation method and application thereof

The invention provides a ceramic or enamel sterilization glaze material and a preparation method and application thereof. The ceramic or enamel sterilization glaze material is prepared from, by weight, 80-90% of ceramic or enamel glaze materials, 5-15% of silver powder and 5-15% of copper oxide powder or zinc oxide powder. By the adoption of the technical scheme, the surface of a ceramic or enamel product has the excellent sterilization and mould-proof ability, and the sterilization effect is kept synchronous with the service life of the ceramic or enamel product; the material components are environmentally friendly, and using safety of the ceramic or enamel product is ensured.

Owner:曹文

Production method of ceramsite concrete enhanced aerated block

The invention discloses a production method of a ceramsite concrete enhanced aerated block. The product belongs to the field of construction materials. According to the invention, common-performance biological sludge ceramsite, fly ash, cement, vegetable oil foaming agent, and water are adopted as raw materials; and processes such as doping and blending, stirring, shaping, and standing are carried out, such that the aerated block is prepared. The production method has the advantages of simple process, easy operation, and low production cost. The product has the advantages of high strength, low shrinkage, good impermeability, and convenient facing construction. The aerated block also has low self weight. The density of the aerated block is only 1 / 3 of that of clay brick. Therefore, building self weight can be greatly reduced. The service life of the aerated block is same with that of the building, such that secondary temperature-maintaining and maintenance are avoided.

Owner:XINYI JINDA WALL MATERIAL CO LTD

Method for pulling pillar through prestress using non-binding steel strands

InactiveCN105155868AEasy constructionShort construction periodBuilding repairsReinforced concretePre stress

The invention discloses a method for pulling a pillar through prestress using non-binding steel strands. The method comprises a method of pulling the pillar through external prestress and a method of pulling the pillar through internal prestress, wherein the method of pulling the pillar through external prestress comprises the following steps: the bottom parts of the non-binding steel strands which are separately of a two-fold line shape or a three-fold line shape are inserted into the pillar, or the bottom parts of the non-binding steel strands support a bearing plate at the bottom of a girder on the two sides of the pillar; after the prestress is applied, an opposite force is generated at the pillar to balance the axial force of the pillar; and then the bearing pillar is pulled out. The method of pulling the pillar through internal prestress comprises the following steps: a non-binding steel strand internal prestress girder is arranged on the outer side of the original reinforced concrete girder on the two sides of the pillar, and the two sides and the bottom surface of the original reinforced concrete girder are wrapped inside; non-binding steel strands which are separately of a three-fold line shape or a parabola shape are arranged in the girder, and linear non-prestressed rebars are arranged; after the prestress is applied, an opposite bending moment is generated by the girder, so that a bending moment generated by load is balanced; and then the pillar is pulled out. The method disclosed by the invention fills the gap in pillar pulling rebuilding technology in China, and has the advantages that the construction is simple; unloading is not needed; temporary support does not need to be additionally arranged; the construction period is short; the cost is low; a structure above is not affected; the service life is consistent with that of an original structure; and the like.

Owner:项剑锋

New steel pipeline anti-corrosion process adopting modified asphalt and polyethylene

InactiveCN104119686AStrong adhesionSolve the problem of winding pipeline anticorrosion process productsCorrosion preventionPipe protection against corrosion/incrustationMedium frequencySteel pipeline

The invention relates to a new steel pipeline anti-corrosion process adopting modified asphalt and polyethylene. The process comprises the following steps: firstly, removing rust of a steel pipe, conveying and connecting the pipe, heating at medium frequency, spraying powder, putting modified asphalt powder in a high-speed mixer to form uniform modified asphalt powder through high-speed mixing, extruding the powder through an extruder circular die, coating or laterally wrapping and coating the outer surface of the steel pipe with the powder to form an anti-corrosion layer, extruding PE through another plastic extruder circular die, coating or laterally wrapping and coating the modified asphalt anti-corrosion layer with a layer of PE to form a protecting layer, thereby forming a complete modified asphalt and polyethylene steel pipeline anti-corrosion structure, wherein the raw materials are matched in parts by weight. By means of the process, the technical problems that existing anti-corrosion processes are serious in environmental pollution, large in energy consumption, bad in anti-corrosion effect, short in anti-corrosion life and the like are solved.

Owner:秦皇岛秦鼎高新环保科技开发有限公司

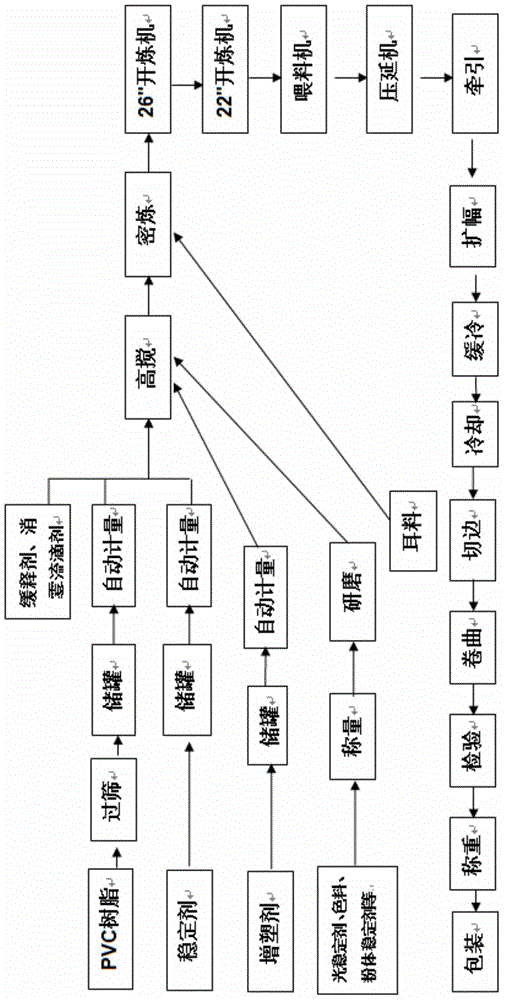

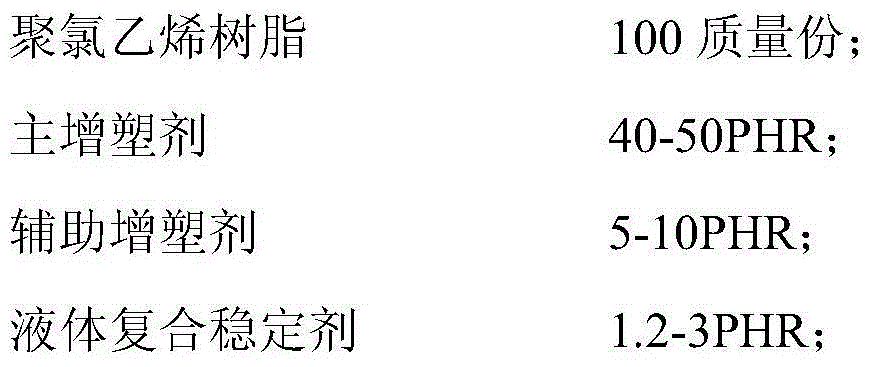

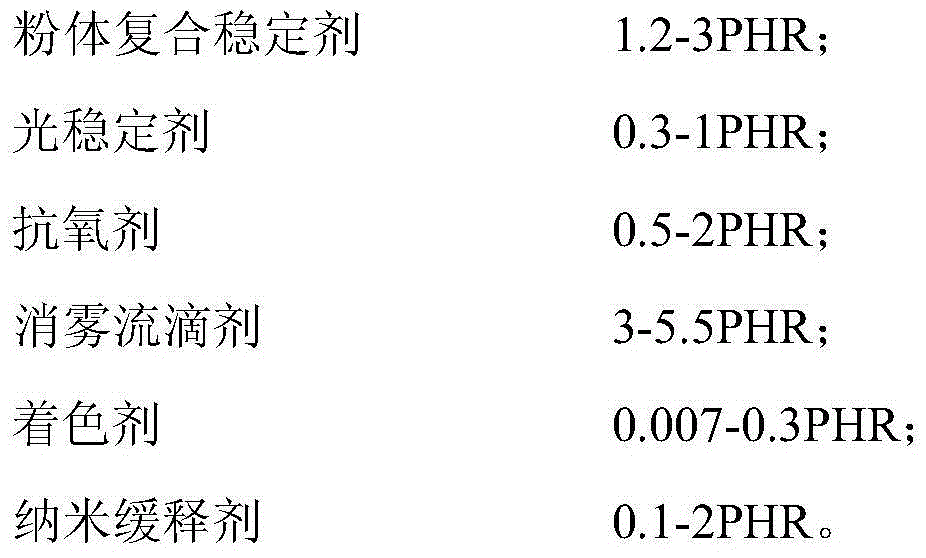

Polyvinyl chloride long-acting fog-dispersal dripping agricultural film with slow-release function and preparation method thereof

The invention relates to a polyvinyl chloride long-acting fog-dispersal dripping agricultural film with slow-release function and a preparation method thereof, belonging to the technical field of agricultural films. The agricultural film is composed of the following components in parts by mass: 100 parts of polyvinyl chloride resin, 40-50 PHR of primary plasticizer, 5-10 PHR of secondary plasticizer, 1.2-3 PHR of liquid composite stabilizer, 1.2-3 PHR of powder composite stabilizer, 0.3-1 PHR of light stabilizer, 0.5-2 PHR of antioxidant, 3-5.5 PHR of fog-dispersal dripping agent, 0.007-0.3 PHR of colorant and 0.1-2 PHR of nano slow-release agent. The preparation method comprises the following steps: (1) grinding: grinding the secondary plasticizer, powder composite stabilizer, light stabilizer, antioxidant and colorant into slurry; (2) feeding of high-speed mixer: simultaneously feeding the slow-release agent and fog-dispersal dripping agent; when the high-speed mixer is at high speed, feeding the plasticizer, mixing, and feeding the ground slurry; and (3) film preparation: banburying, plastifying, calendering, setting and coiling. The agricultural film has the advantages of simple technique, favorable light transmittance, synchronous dripping fog-dispersal function period with service life of the film, and the like.

Owner:TIANJIN TIANSU SCI & TECH GROUP

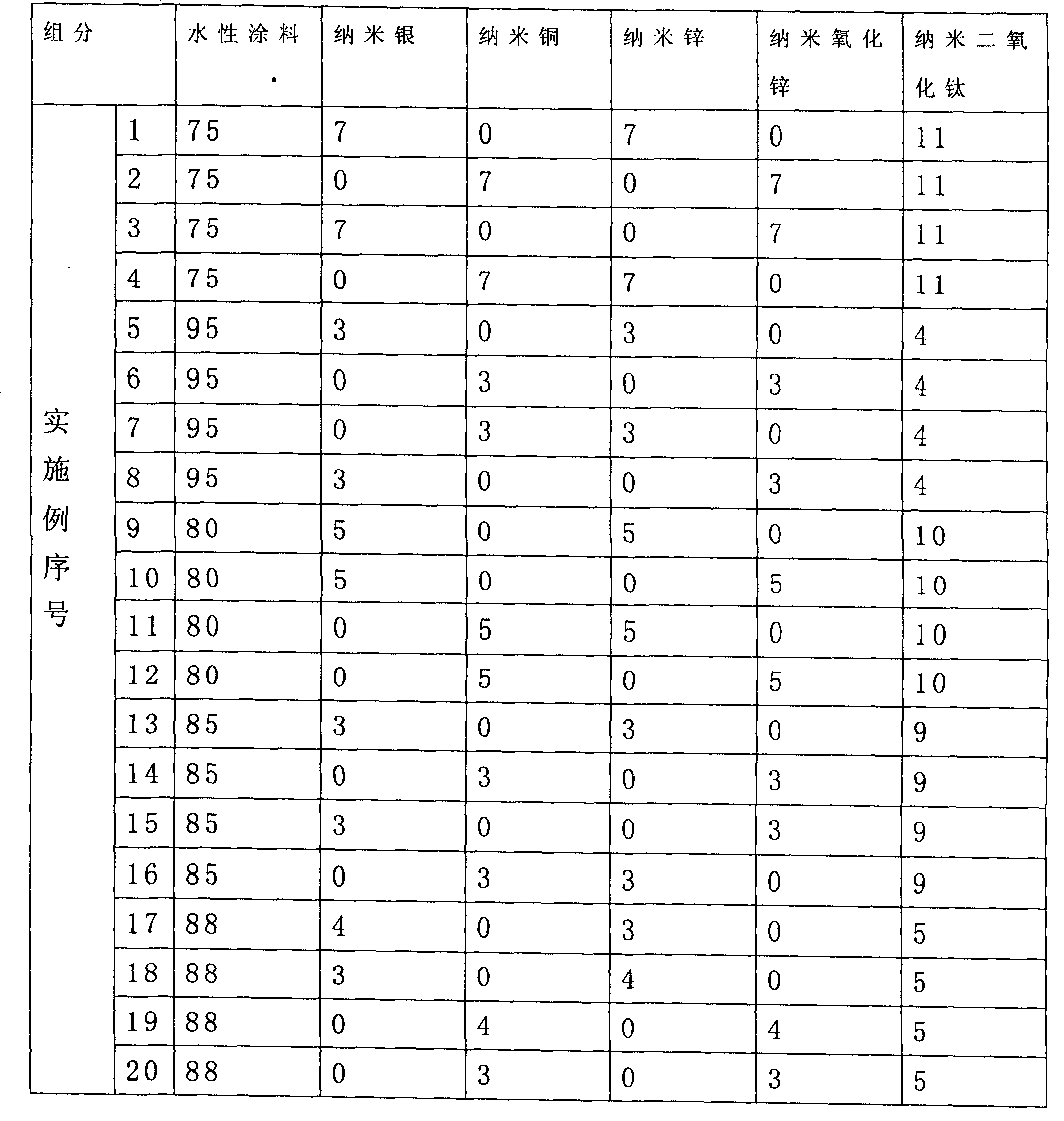

Nano-antimicrobial fungus-resisting paint

ActiveCN101195719BAchieve the perfect combinationNo resistanceAntifouling/underwater paintsPaints with biocidesWater basedIon

The invention discloses nanometer antibacterial mildewproof coating. The invention comprises the following components according to the weight percentage of The invention of water-based coating, 3 to 7 percent of nanometer silver, 3 to 7 percent of nanometer copper or nanometer zinc occupies, and 4 to 11 percent of nanometer zinc oxide or nanometer titanium dioxide. The application of the nanometer antibacterial mildewproof coating is as follows: the nanometer antibacterial mildewproof coating is evenly painted on the medical instruments, the medical furniture and the indoor wall bodies of a hospital, such as hospital beds, bedside cabinets, hospital carts, office tables and chairs of a hospital, so as to ensure the surfaces of the articles to be covered through the coating, when harmful microorganisms in air or at the parts of human hands are contacted with the articles, the harmful microorganisms left on the articles are captured and killed through the metallic ions with positive charge in the nanometer antibacterial mildewproof coating, and therefore the invention prevents the cross spreading of the harmful microorganisms in the hospital.

Owner:东莞市绿萱环保建材有限公司

Technology for reduction of beam section height by use of unbonded steel strand prestress

InactiveCN105569265AEasy constructionNo need to uninstallGirdersJoistsPre stressBuilding construction

Owner:项剑锋

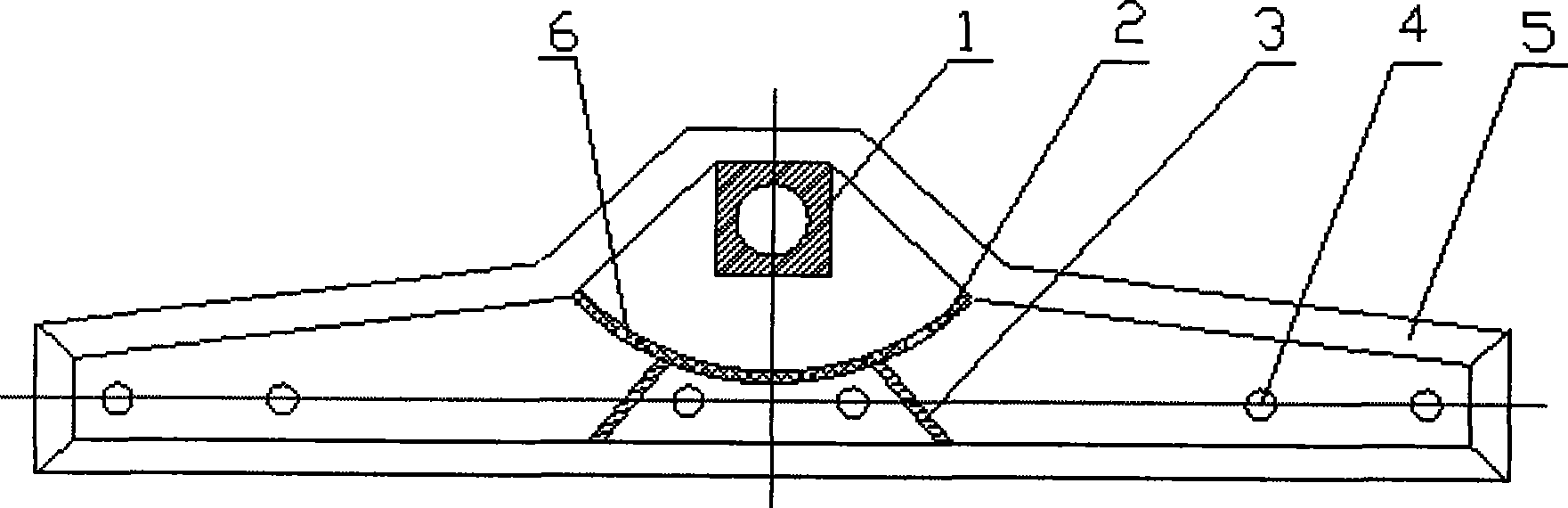

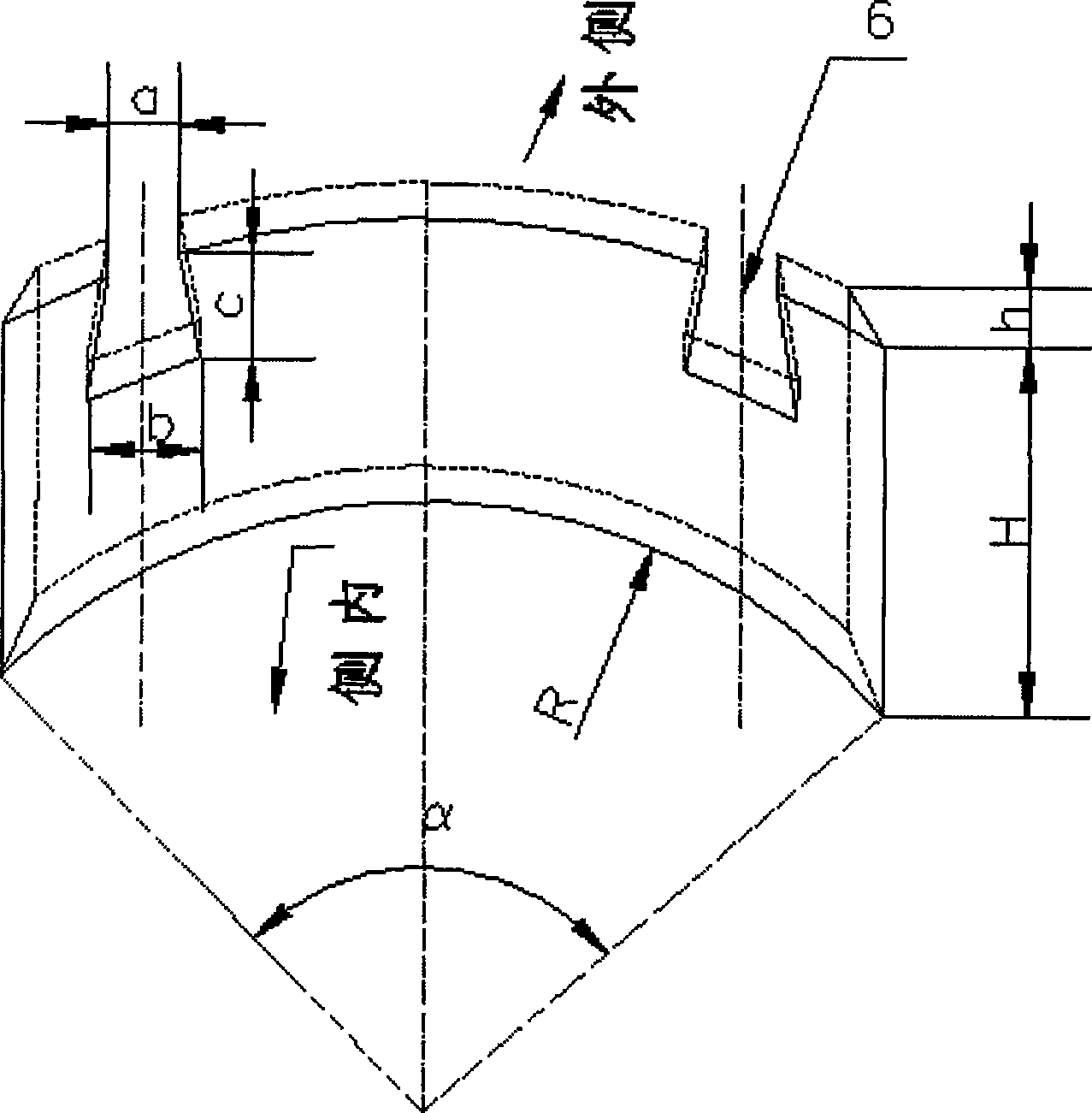

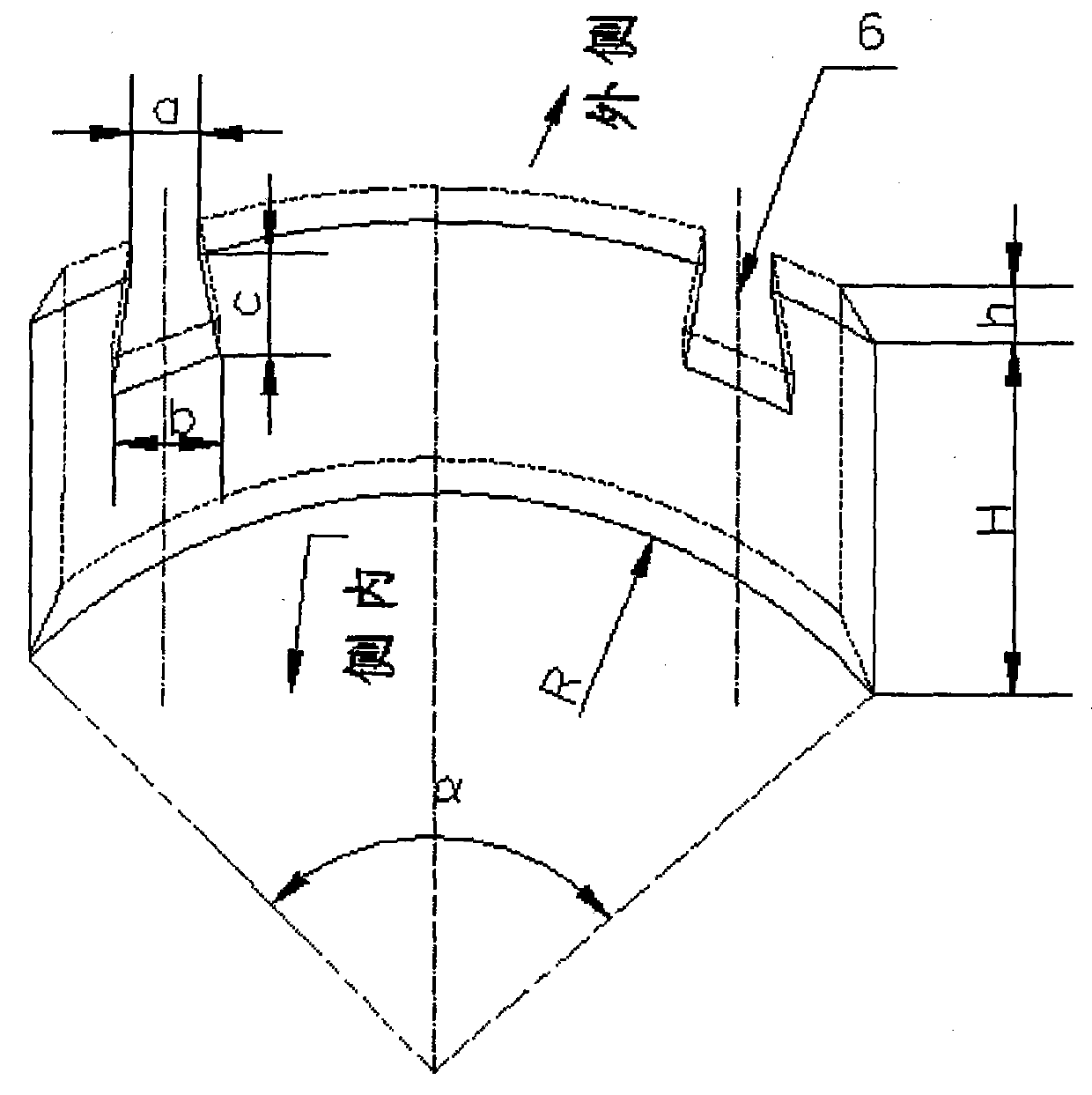

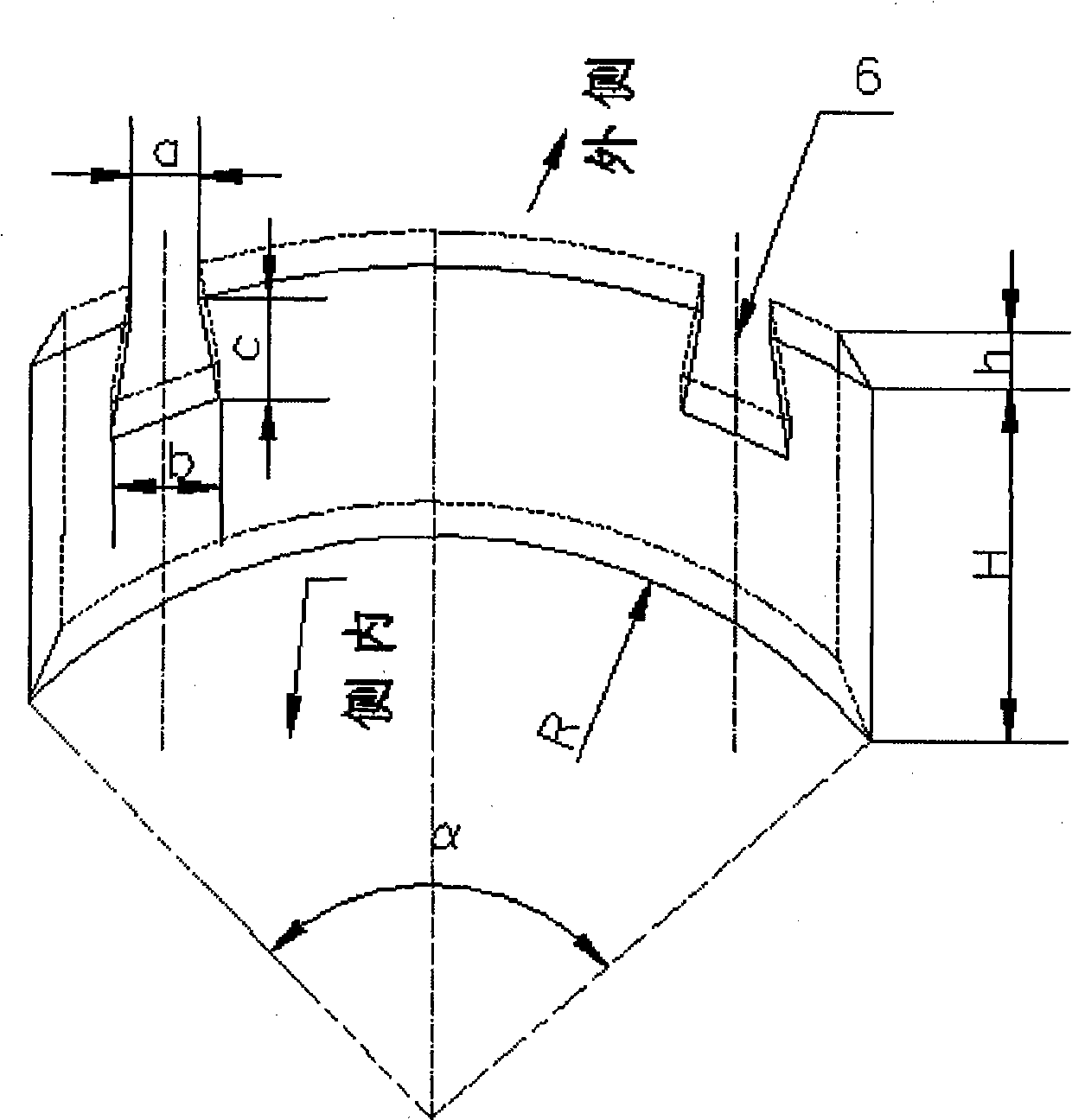

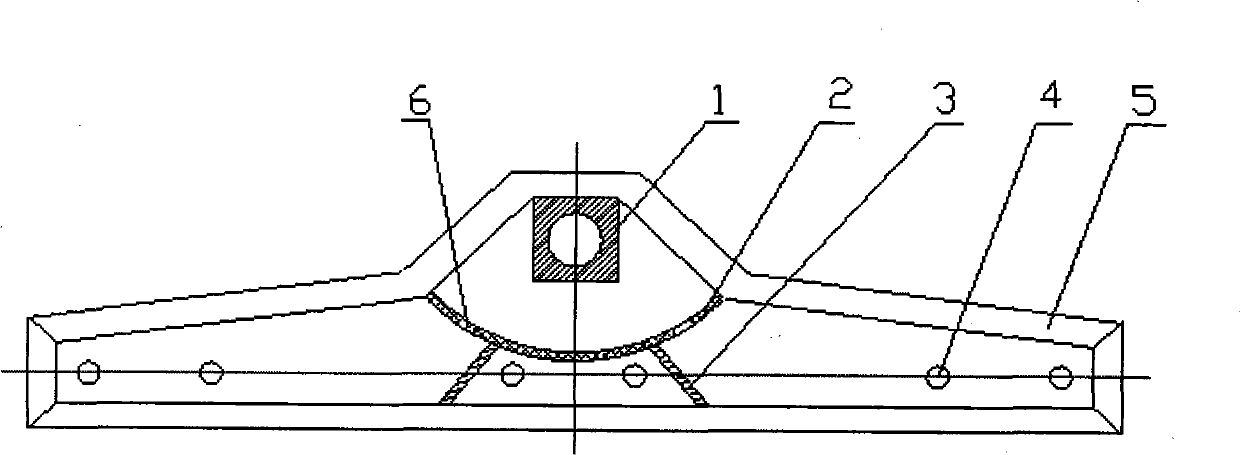

Baffle for special-shaped blank continuous casting machine tundish and preparation method thereof

InactiveCN101502877AImprove corrosion resistanceImprove thermal shock resistanceMelt-holding vesselsSlagTemperature difference

The invention relates to a baffle applied to a tundish of a profiled blank conticaster and a preparing method thereof, belonging to the technical field of the profiled blank continuous casting tundish process in ferrous metallurgy. A guide plate (2) adopts magnesium preformed unit. The baffle is of arc monolithic structure, the arc degree alpha is 90-95 degrees, and a dovetail groove (6) is arranged on the two sides. The guide plate (2) is arranged on the external side of a current stabilizer (1). The upper edge of the guide plate (2) is 120-150mm higher than the upper edge of the current stabilizer (1). Slag blocking dams (3) are respectively arranged between the external side of the dovetail groove (6) of the guide plate (2) and the external side of two sizing nozzles (4) of a middle casting flow. By the shunting function of the guide plate, the compositions and the temperature of molten steel in the tundish of the profiled blank are uniformed. The temperature difference of three casting flows of the profiled blank is lowered from 12 DEG C to 4 DEG C. Casting blank quality defects and steel breakout accidents caused by high molten steel temperature of the middle casting flow are solved. Simultaneously, the upward floating elimination of inclusions is promoted. The qualified rate of the profiled blank is improved and reaches more than 99.7 percent.

Owner:SHANDONG IRON & STEEL CO LTD

Zirconia coating layer for saggar and preparation method of saggar

The invention discloses a zirconia coating layer for a saggar; the zirconia coating layer includes the following components in parts by mass: 4-6 parts of 60-mesh fused zirconia, 1-4 parts of 100-mesh fused zirconia, 1-3 parts of 200-mesh fused zirconia, 0.1-0.5 part of sodium hexametaphosphate, 0.1-0.5 part of polyvinyl alcohol, and 1-5 parts of water. At the same time, the invention also discloses a preparation method of the zirconia coating layer saggar. The product has the advantages of low cost, stable quality and long service life, and is more convenient to use than a traditional product.

Owner:无锡顺佳特种陶瓷有限公司

Prefabricated integrated lining of continuous casting pouring basket and its preparing method

InactiveCN1473677AEasy to manage on siteReduce security risksMelt-holding vesselsMaterials scienceContinuous casting

The prefabricated integrated lining of continuous casting pouring basket is produced with the materials including magnesium material 85-90 wt%, chromium iron ore powder 2-6 wt%, binding agent 4-10 wt% and urotropine 0.4-1 wt%. The production process includes following steps: pouring with magnesium material and chromium iron ore powder in the mold of the permanent lining, vibration to form, heat treatment, and installing hoisting rings. The present invention can prolong the life of the lining, raise productivity of continuous casting and lower production cost.

Owner:王有志

Prestress wall removing technology implemented by aid of non-binding steel strands

InactiveCN105178624ASimple constructionShort construction periodBuilding repairsEngineeringPre stress

The invention discloses a prestress wall removing technology implemented by the aid of non-binding steel strands. The prestress wall removing technology includes an external prestress wall removing technology implemented by the aid of the non-binding steel strands and an internal prestress wall removing technology implemented by the aid of the non-binding steel strands. The external prestress wall removing technology implemented by the aid of the non-binding steel strands is implemented when bearing walls to be removed are short in span or low in borne load and ring beams are arranged on the tops of the walls; the internal prestress wall removing technology implemented by the aid of the non-binding steel strands is implemented when the bearing walls to be removed are large in span or high in borne load, more than six steel strands are required by each bearing wall, end anchoring is difficult to handle or the ring beams are unavailable on the tops of the walls. The prestress wall removing technology has the advantages that the prestress wall removing technology is safe and simple in construction, short in construction period and low in cost, detachment or additional temporary bracing can be omitted, good effects can be realized, and the service lives are synchronized with those of original structures.

Owner:项剑锋

Converter heat replacement hearth bottom circular seam packing method

InactiveCN1609237AReduce erosion rateReduce the number of replacementsManufacturing convertersNitrogenHearth

The hot converter bottom replacing and ring seam filling process includes the following steps: heating the converter lining with burning gun burning gas and oxygen to 600-1000 deg.c and taking down the old converter bottom; spreading the newly laid converter bottom with ring seam powder, installing the newly laid converter bottom, blowing with nitrogen blowing gun the powder into the seam and roasting and sintering the ring seam powder with the burning gun; heating certain amount of ring seam powder in a barrel to 200-350 deg.c to make it melt and become paste poured into the converter; oscillating the converter for the paste to flow into ring seam and heating to cure. The said process has raised tightness or the ring seam and can avoid accident of leaking molten steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

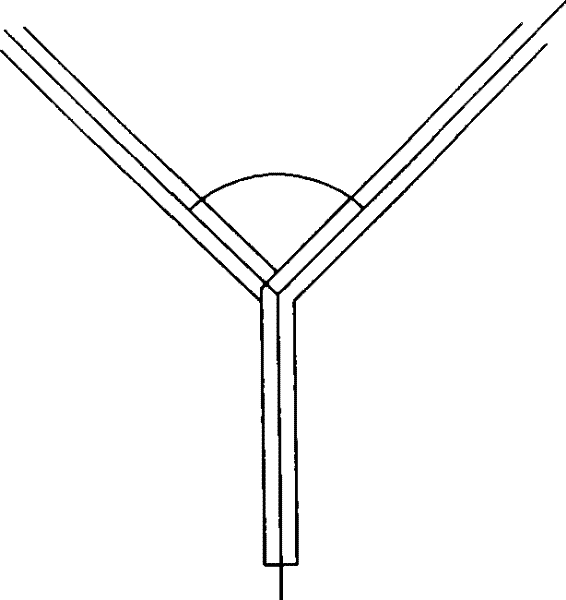

Flow-controllable orifice with three uniformly distributed holes for high-temperature liquid slag

InactiveCN104567428AExtended service lifeLifetime SynchronizationCharge manipulationManufacturing technologyLiquid slag

The invention discloses a flow-controllable orifice with three uniformly distributed holes for high-temperature liquid slag. The flow-controllable orifice is characterized in that three uniformly distributed slag orifices are arranged on an end surface of the inner middle of a nozzle inner bushing made of isostatic graphite materials, only one hole is utilized in each procedure, the other two standby slag orifices are filled with identical isostatic graphite, and stopper rods at the upper ends of the slag orifices can be finely adjusted and lifted, so that the flow of each slag orifice can be controlled. The flow-controllable orifice has the advantages that the service life of the flow-controllable orifice for the high-temperature liquid slag can be prolonged and can be identical to the service lives of graphite crucibles, and the replacement frequency can be reduced; blockage of liquid slag flow can be effectively prevented, the flow-controllable orifice is reliable and is long in service life, and the running cost can be effectively reduced; requirements of short-process mineral wool manufacturing technologies can be met; the flow-controllable orifice is favorable for meeting market requirements on broad development prospects of mineral wool and products of the mineral wool.

Owner:朱兴发

A kind of ceramic or enamel sterilization glaze material and its preparation method and application

Owner:曹文

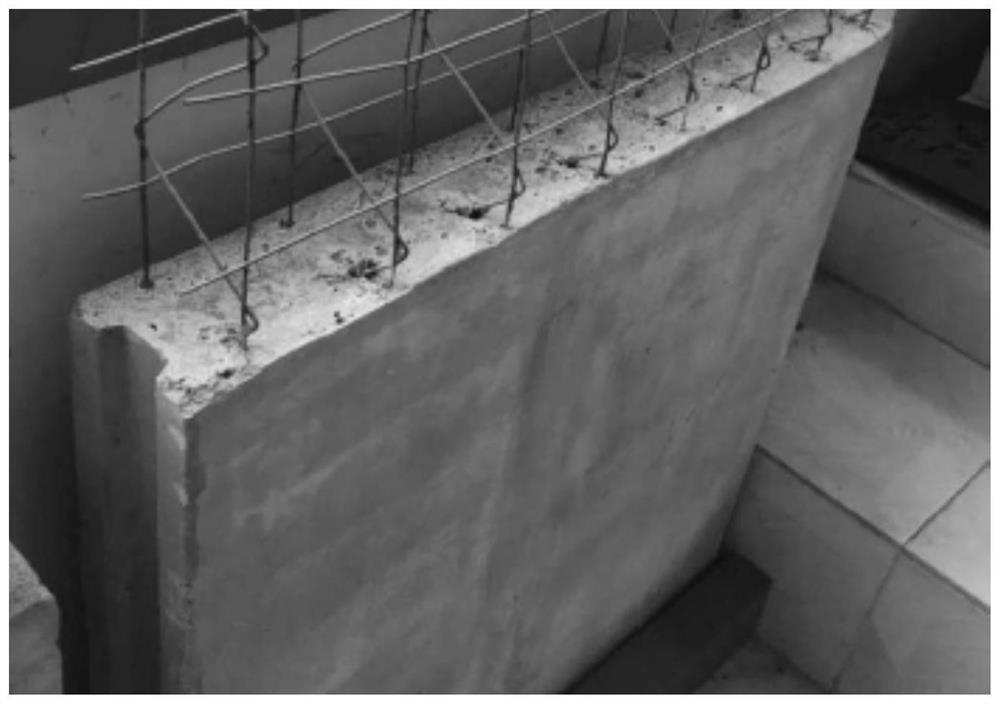

Graphite modified polystyrene solid lightweight concrete wallboard and preparation method thereof

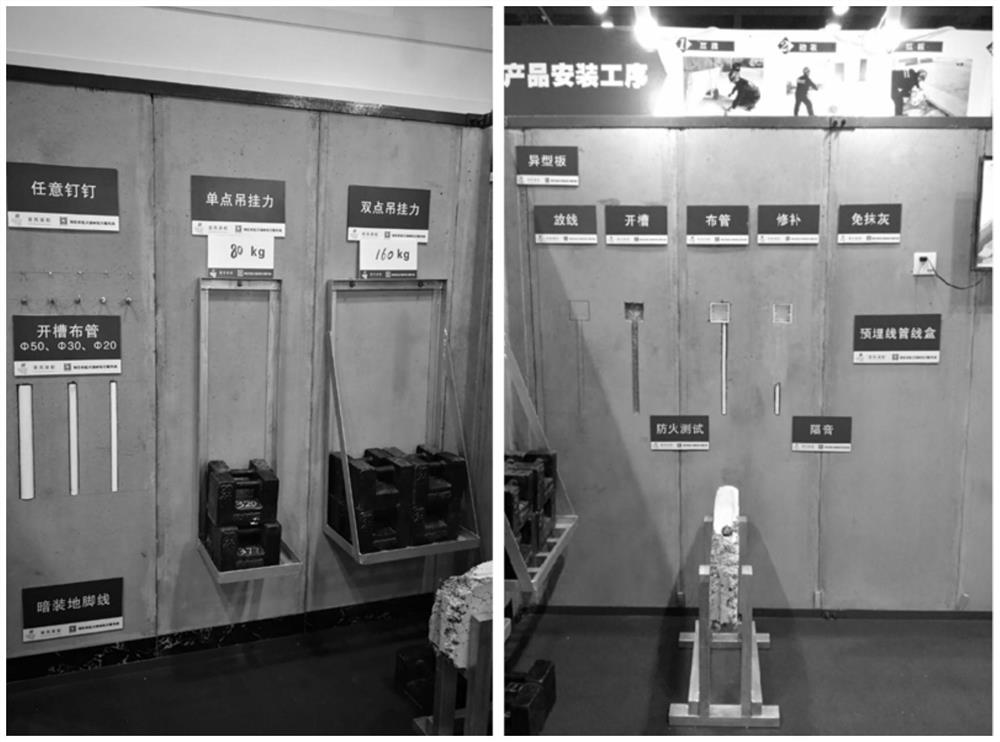

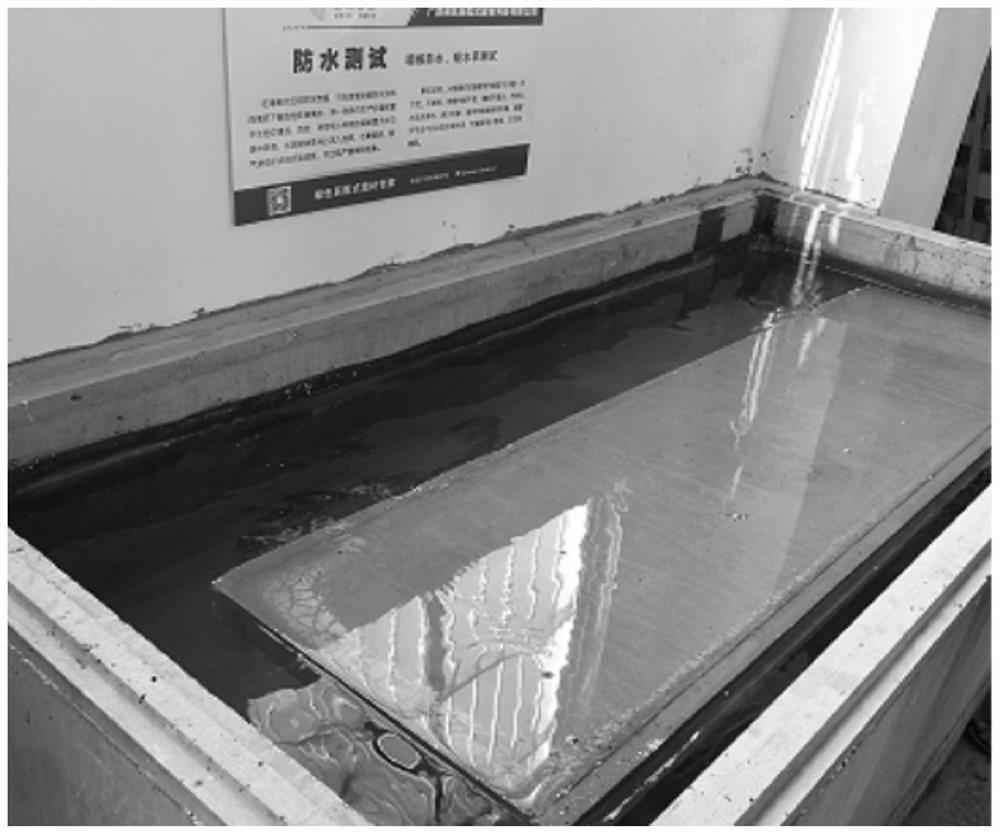

The invention discloses a graphite modified polystyrene solid lightweight concrete wallboard and a preparation method thereof, the wallboard is prepared by taking a steel wire net rack and glass fiber gridding cloth as a framework, pouring a mixture and then solidifying, and the mixture is composed of cement, lightweight aggregate, a filler, a compound additive, graphite modified polystyrene and water. The graphite modified polystyrene is formed by foaming graphite polystyrene twice under specific conditions. The graphite modified polystyrene solid lightweight concrete wallboard can meet the requirements of light weight and high strength at the same time, is formed through one-time pouring, is good in overall gelling and curing effect, free of panel compounding, free of shelling and separation, good in integrity and stability, and synchronous with a building in service life; and secondary decoration is facilitated, slotting and pipe arrangement can be carried out at will, and cracking is avoided. The fire resistance is good, the combustion grade of the wallboard is grade A, and the fire endurance is more than 4 hours.

Owner:广西易筑科技服务有限公司

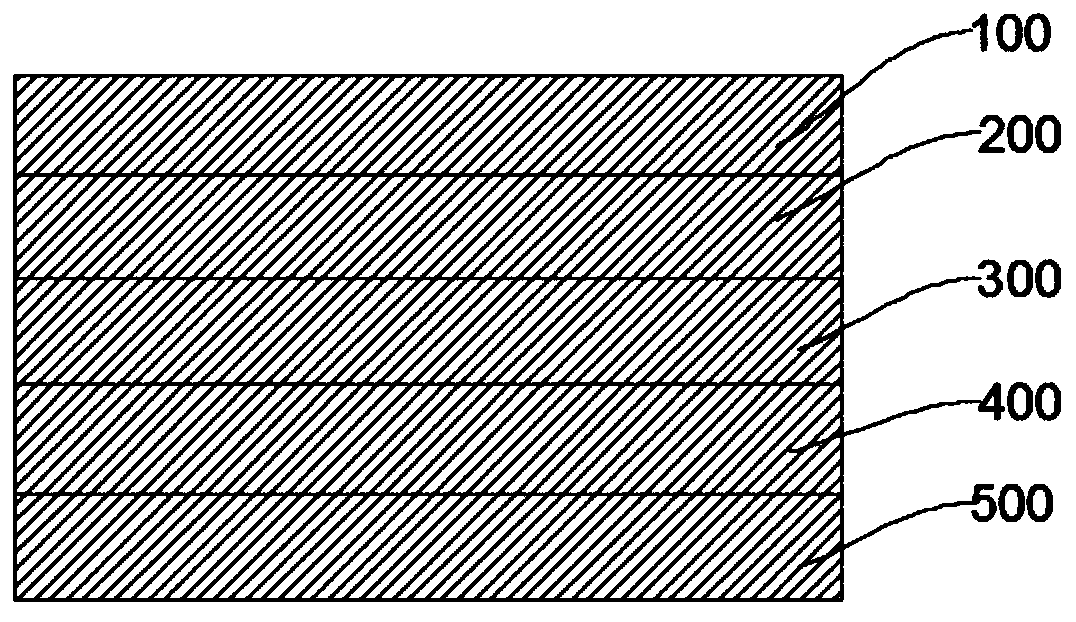

Light conversion film, multilayer light conversion film and preparation method of multilayer light conversion film

InactiveCN111002682APromote absorptionIncreased content of photosynthesis productsClimate change adaptationSynthetic resin layered productsUltraviolet lightsInsect pest

The invention relates to a thin film and a preparation method thereof, in particular to a light conversion film, a multilayer light conversion film and a preparation method of the multilayer light conversion film. The light conversion film comprises a film body and a light conversion film layer, and the light conversion film layer comprises, by weight, 18%-22% of a light conversion agent, 55%-60%of an organic carrier, 13%-15% of a light stabilizer and 9%-12% of an antioxidant, wherein the film body comprises 60%-75% of a film matrix, 12%-20% of a light stabilizer and 10%-20% of an antioxidant; according to the method provided by the invention, by adding the light conversion agent, ultraviolet light in sunlight can be converted into red light, absorption of plants on nutrient elements suchas nitrogen, phosphorus, potassium and zinc is promoted, the content of photosynthesis products in leaves is increased, crop growth is promoted, and meanwhile, the effect of reducing diseases and insect pests is achieved.

Owner:徐蕾

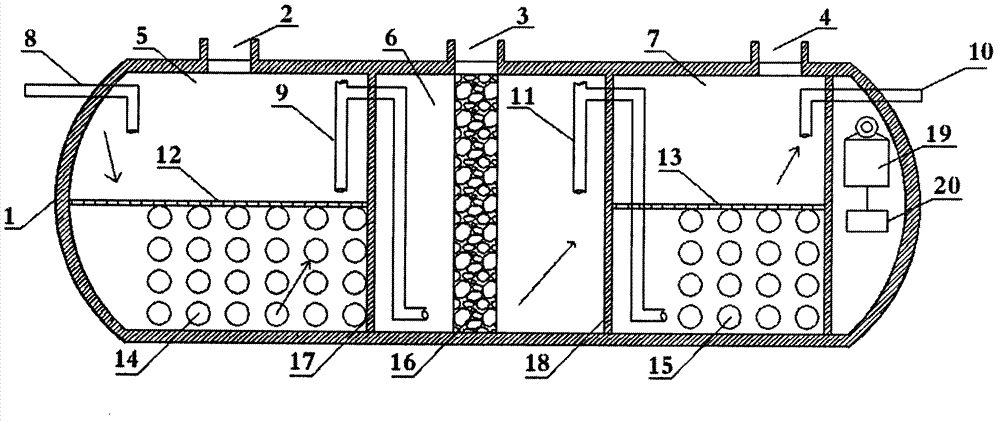

Multistage municipal sewage biological purification integrated device

InactiveCN102849892ASolve the problem of polluted groundwaterImprove tightnessMultistage water/sewage treatmentAeration systemAutomatic control

The invention relates to a multistage municipal sewage biological purification integrated device. The device comprises a pool body; a water inlet, a water outlet, a cleaning port, a microbe feeding port, and a viewing port are disposed on the pool body; a mixed biofilm formation clapboard is disposed in the pool body; the clapboard partitions the pool body into three chambers; the three chamber comprise a deposition separation pool, a biological reaction pool, and an SBR treatment pool which are connected orderly. An axial grating is disposed in the middle of the deposition separation pool, and partitions the pool into an upper layer and a lower layer; stereo elastic fillers are disposed at the lower layer. Microbe fillers are disposed in the biological reaction pool. The SBR treatment pool is provided with an aeration system and stereo elastic fillers. the aeration system is automatically controlled and operated through a PLC device. The device of the invention is high in treatment efficiency, good in discharged water quality, automatic in device operation, convenient for maintenance, and suitable for popularization and application.

Owner:上海新张卫生用品有限公司

Production method of building peripheral guard board with multi-layer bamboo lattice board as inner framework

PendingCN114683396AEmission reductionHigh strengthConstruction materialWallsFiberArchitectural engineering

The invention relates to a production method of a building peripheral guard board with multiple layers of bamboo blank plates as an inner framework, which comprises the following steps of: manufacturing the bamboo blank plates by using bamboo chips, overlapping the multiple layers of bamboo blank plates in a staggered manner and bonding by using glue, fixing steel wire meshes on two surfaces of the multiple layers of bamboo blank plates, and filling foaming materials or cement mortar by using the multiple layers of bamboo blank plates as the inner framework. Bamboo fiber composite polymer cement or gypsum slurry is used as a surface layer to manufacture a building peripheral guard board; according to the production method of the building peripheral guard board with the multi-layer bamboo lattice board as the inner framework, the bamboo is internally and externally sealed through modern building materials, the bamboo is isolated from air, and therefore it is guaranteed that the service life of the bamboo is synchronous with that of a building, energy is saved, carbon emission is reduced, and the production method is suitable for manufacturing the large building peripheral guard board.

Owner:白建国

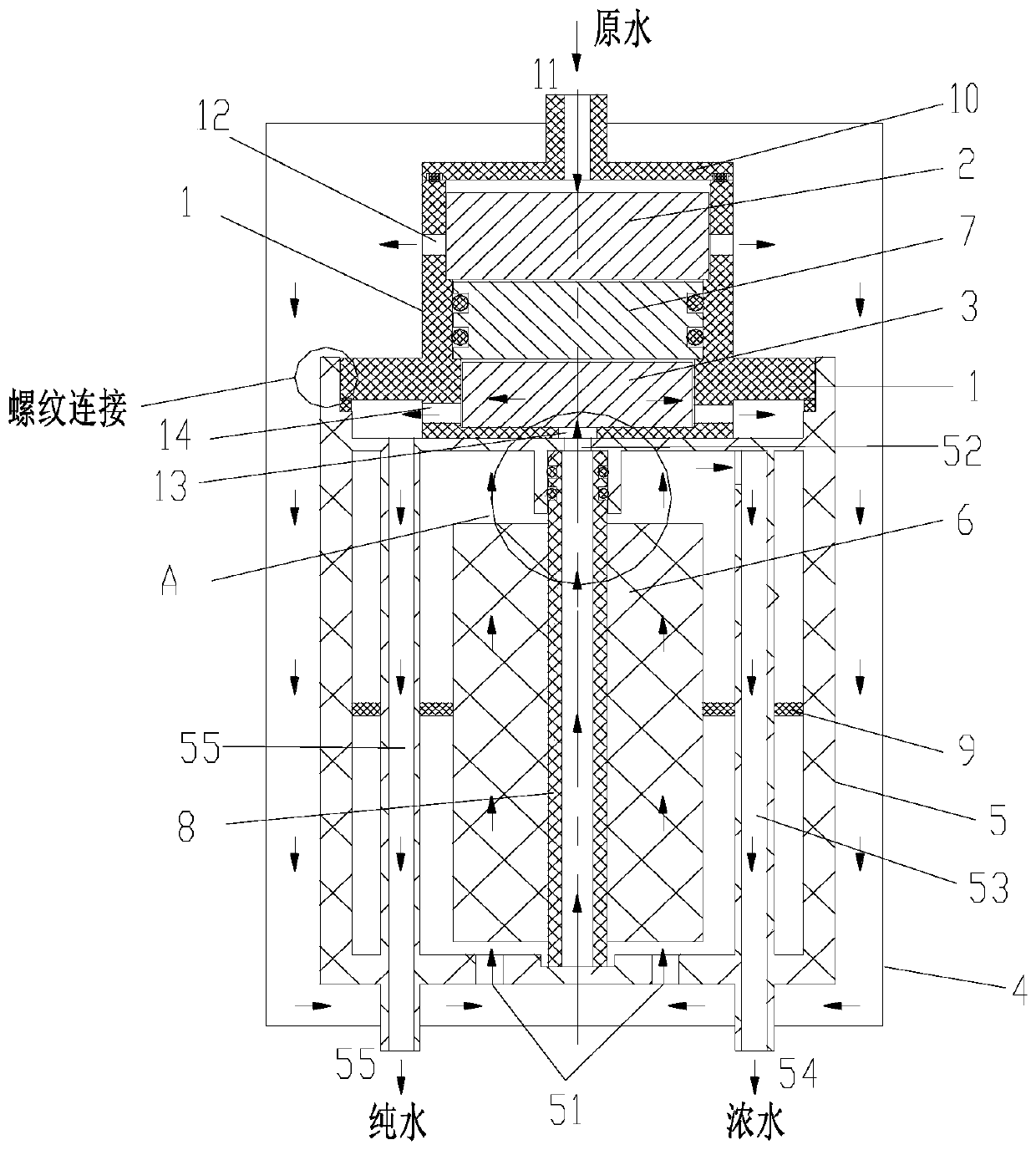

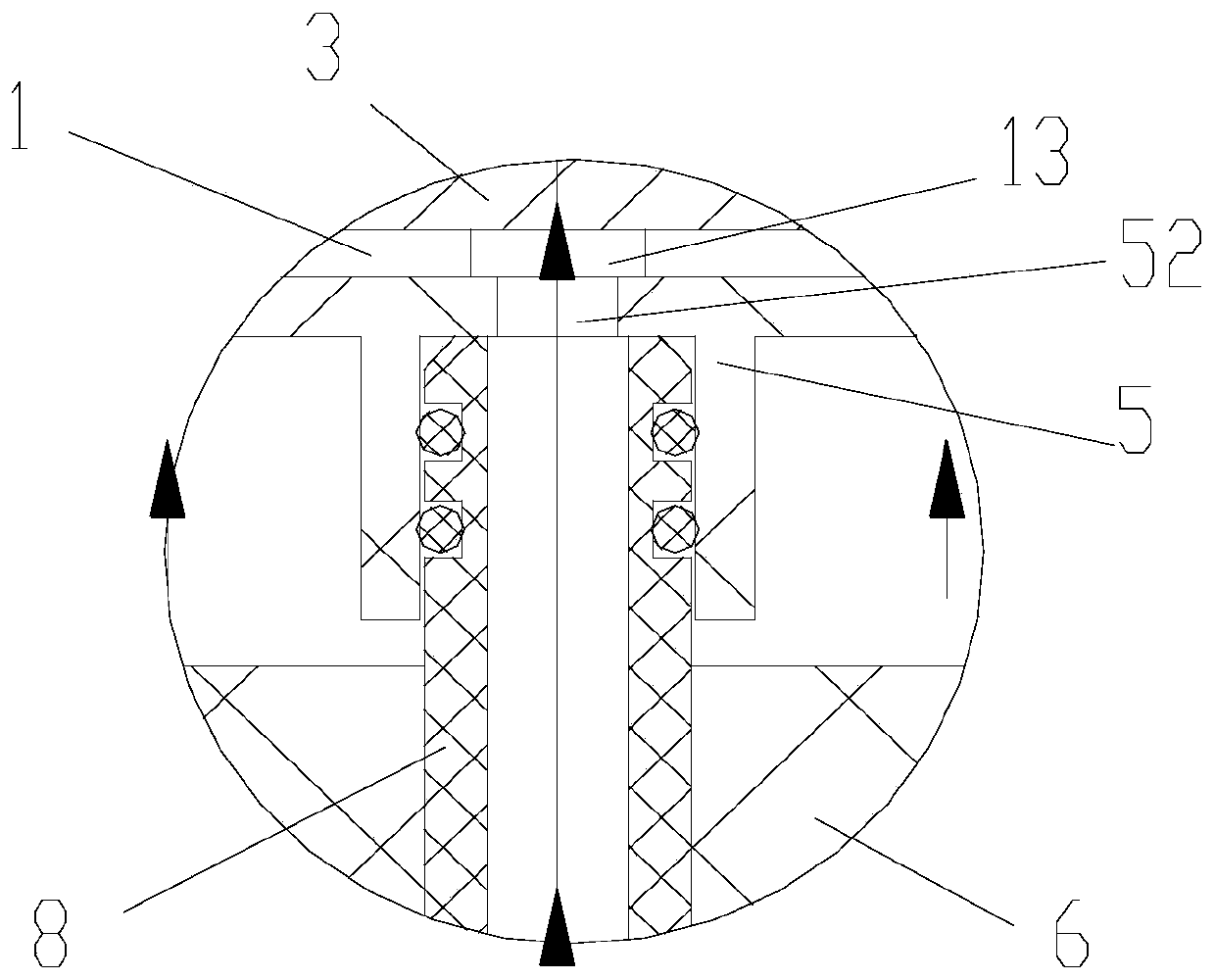

Composite filter element assembly and water purification system

PendingCN111252924ALifetime SynchronizationMaximize UtilizationWater treatment parameter controlSpecific water treatment objectivesReverse osmosisProcess engineering

The invention provides a composite filter element assembly and a water purification system, the composite filter element assembly comprises a first shell, and a front filter element and a rear filterelement are arranged in the first shell at the same time; the composite filter element assembly comprises a filter bottle, the first shell is provided with a raw water inlet and a first-stage filter outlet which are respectively communicated with the front filter element, and the first-stage filter outlet is communicated with the interior of the filter bottle; the composite filter element assemblyfurther comprises a second shell, a reverse osmosis membrane is arranged in the second shell, and the second shell is provided with a front filtered water inlet communicated with the interior of thefilter bottle and a second outlet communicated with the rear filter element in the first shell. According to the invention, the service lives of the two filter elements can be effectively ensured tobe synchronous, and the front filter element and the rear filter element can both reach the service life when the service life reaches the service life limit and are disassembled and replaced, so thatthe utilization rate of the front filter element and the rear filter element can be maximized, the filtering effect is improved, and the cost is effectively reduced.

Owner:GREE ELECTRIC APPLIANCES INC

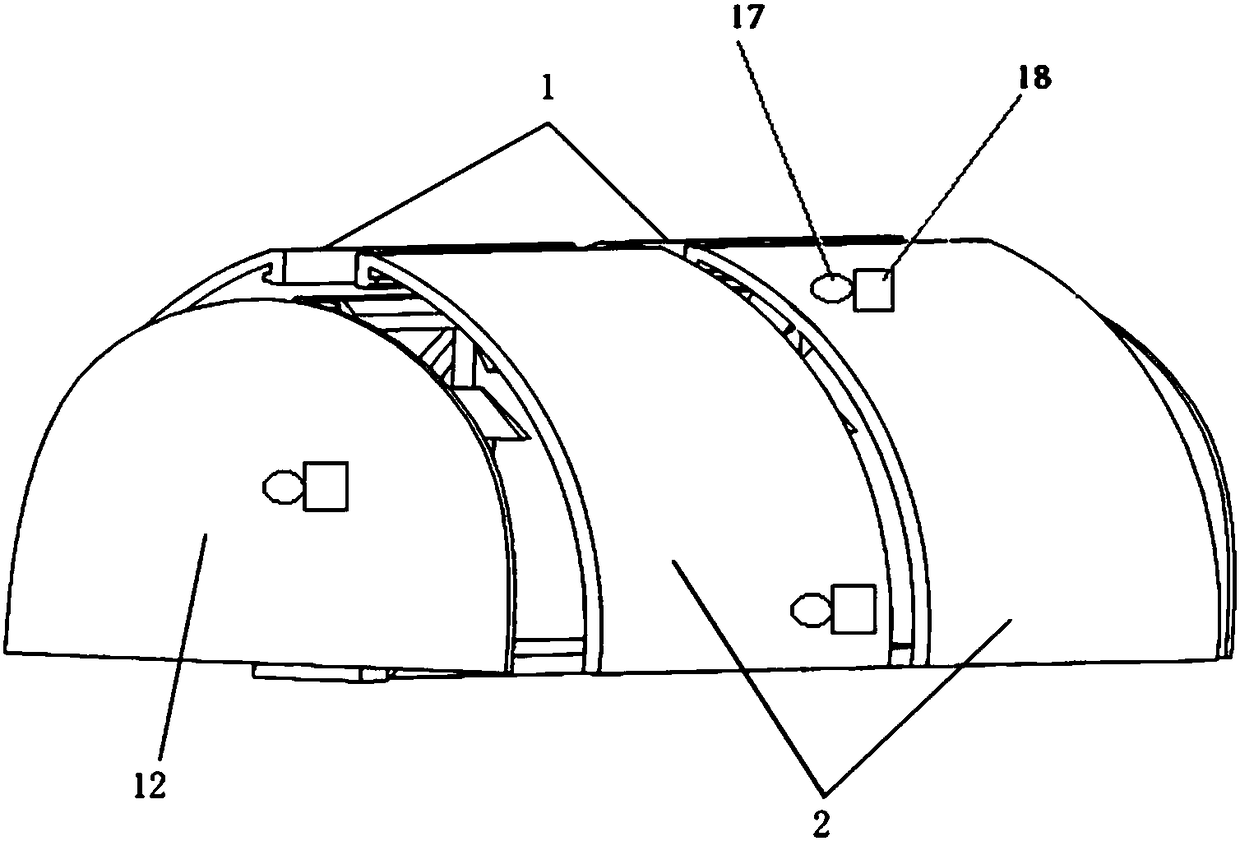

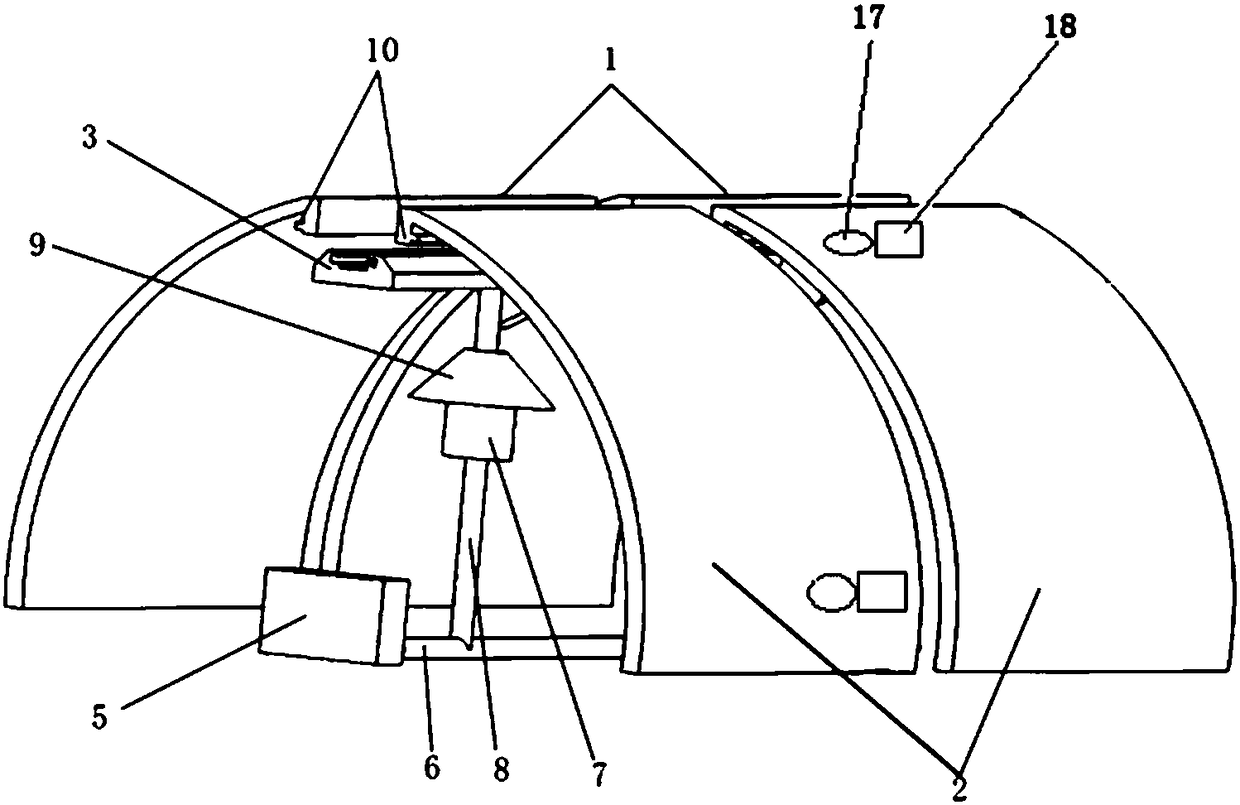

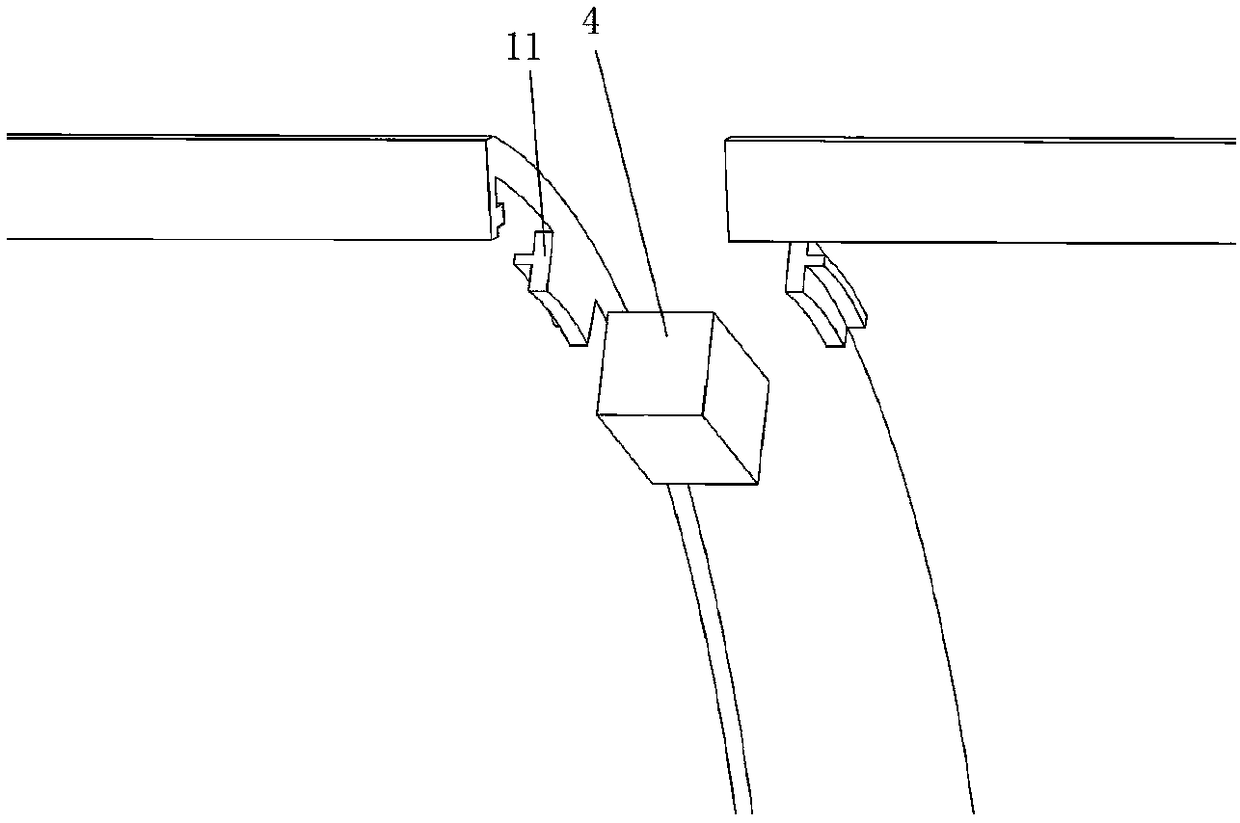

Temperature regulation shield for controlling growth period of peach trees

InactiveCN108076916ALower heat transfer coefficientReduce heat lossClimate change adaptationGreenhouse cultivationAmygdalus persicaEngineering

The invention discloses a temperature regulation shield for controlling a growth period of peach trees. The temperature regulation shield comprises an arc-shaped shield body and a support frame for supporting the shield body, and further comprises a temperature control device, wherein the shield body is provided with a through hole and a hole lid for opening or closing the through hole; a drip fogdispersal layer covers the side, which is close to the peach trees, of the inner side of the shield body; and a PET reflective film covers the outer side of the shield body. The temperature regulation shield has the characteristics of good insulating effect, a function of drip fog dispersal and capability of controlling the growth period of the peach trees. The temperature regulation shield is suitable for culture of the peach trees.

Owner:河北田康农业科技有限公司

Baffle for special-shaped blank continuous casting machine tundish and preparation method thereof

InactiveCN101502877BImprove corrosion resistanceImprove thermal shock resistanceMelt-holding vesselsSlagTemperature difference

The invention relates to a baffle applied to a tundish of a profiled blank conticaster and a preparing method thereof, belonging to the technical field of the profiled blank continuous casting tundish process in ferrous metallurgy. A guide plate (2) adopts magnesium preformed unit. The baffle is of arc monolithic structure, the arc degree alpha is 90-95 degrees, and a dovetail groove (6) is arranged on the two sides. The guide plate (2) is arranged on the external side of a current stabilizer (1). The upper edge of the guide plate (2) is 120-150mm higher than the upper edge of the current stabilizer (1). Slag blocking dams (3) are respectively arranged between the external side of the dovetail groove (6) of the guide plate (2) and the external side of two sizing nozzles (4) of a middle casting flow. By the shunting function of the guide plate, the compositions and the temperature of molten steel in the tundish of the profiled blank are uniformed. The temperature difference of three casting flows of the profiled blank is lowered from 12 DEG C to 4 DEG C. Casting blank quality defects and steel breakout accidents caused by high molten steel temperature of the middle casting flow aresolved. Simultaneously, the upward floating elimination of inclusions is promoted. The qualified rate of the profiled blank is improved and reaches more than 99.7 percent.

Owner:SHANDONG IRON & STEEL CO LTD

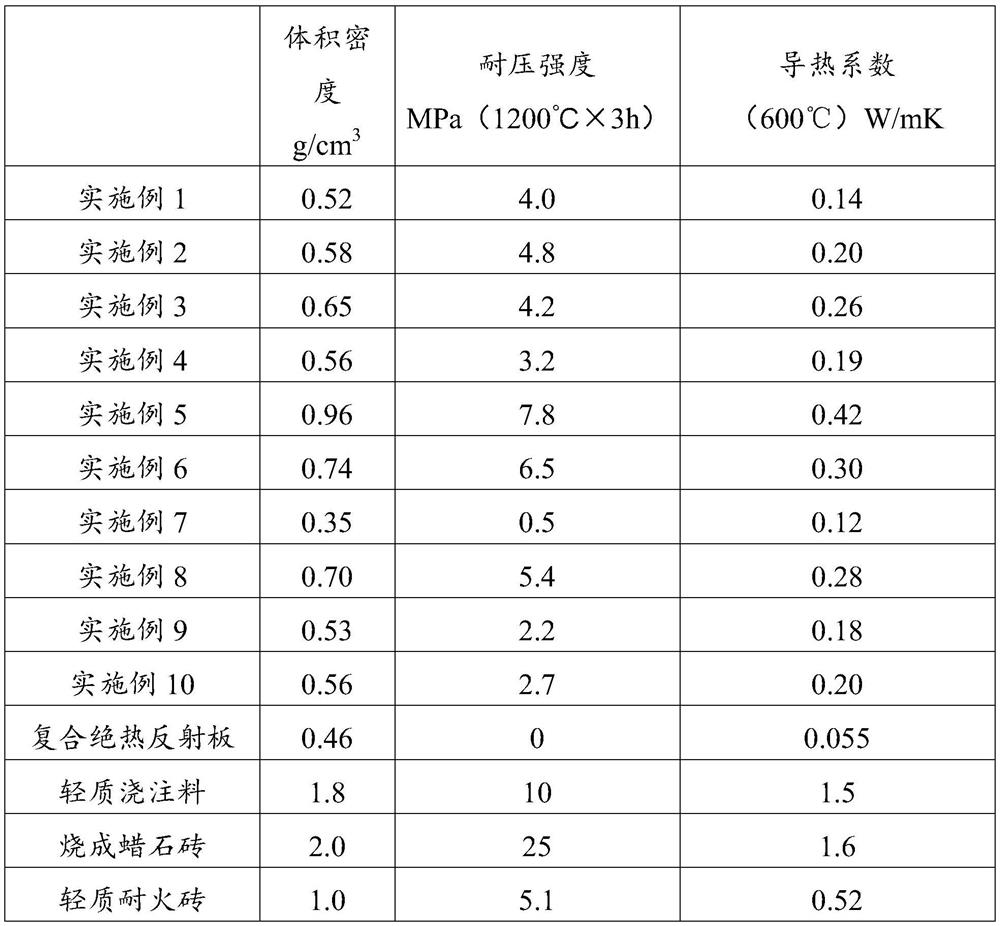

Lightweight high temperature resistant heat insulation board for metallurgy and preparation method thereof

ActiveCN108101554BImprove insulation effectHigh temperature resistance hasSilicon dioxideMold removal

The invention discloses a lightweight high-temperature-resistant heat-insulating board for metallurgy and a preparation method thereof. The board comprises the following raw materials by weight: 10 to70% of vitrified microbeads, 10 to 70% of floating beads, 0 to 30% of magnesia, 0 to 20% bauxite cement, 0 to 8% of Guangxi white clay, 0.02 to 5% of a binder, 0 to 10% silica micropowder, 0 to 15% of pyrophyllite powder and 0 to 3% of quicklime. The preparation method comprises the following steps: uniformly mixing the desired amounts of the raw materials with water in a mixer to obtain a mixture; placing the mixture in a mold for vibrating formation to obtain a molded product; storing the molded product with a mold at room temperature for 8 to 48 h; then putting the molded product with themold into an incubator with a temperature of 50 to 80 DEG C and maintaining the product at the temperature for 8 to 24 h; and then carrying out demolding, and drying the molded product in a drying boxwith a temperature of 120-200 DEG C for 8 to 48 h so as to obtain the lightweight high-temperature-resistant heat-insulating board. The board provided by the invention has the characteristics of light weight, high strength, excellent heat insulation performance and the like.

Owner:WUGANG REFRACTORY CO LTD

Method for prolonging service life of top-bottom composite blowing converter bottom

ActiveCN103290167BExtended service lifeShorten the smelting cycleManufacturing convertersSlagMaterials science

The invention provides a method for prolonging the service life of a top-bottom composite blowing converter bottom. The method for prolonging the service life of the top-bottom composite blowing converter bottom comprises the following steps of: when melting loss of air permeable bricks at the converter bottom achieves 100-150mm, after steel is discharged completely and converter slags are poured away, adding the following repairing mass into the converter in percentage by mass according to the quantity with the shim thickness of 50-150mm each time: 75-85% of MgO, 7-14% of C, 1-3% of CaO, 1-2% of SiO2, 0.5-1.5% of Fe2O3, and 2-10% of bonding agents, and staying for 2-3 seconds; sintering the repairing mass naturally for 40-70 minutes by utilizing temperature in the converter, then sintering for 60-120 minutes again at 700-1,200 DEG C, and inputting for smelting; repeating the step (1) and the step (2) after smelting for 10-30 converters, and shimming repeatedly in the way until the converter bottom rises by 100-300mm. The service lives of the converter bottom bricks of the converter and the air permeable bricks at the converter bottom are prolonged effectively; a top-bottom composite blowing technology requirement is met; the smelting cycle is shortened; the production efficiency is improved.

Owner:红河钢铁有限公司

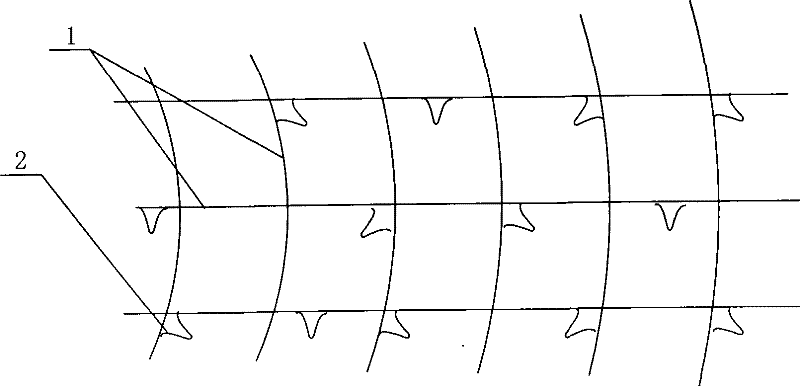

Repairing method of rotary kiln liner fireproof material

The invention relates to the technical field of rotary kiln liner fireproof materials, particularly to a repairing method of a rotary kiln liner fireproof material. The repairing method comprises the following steps of: 1. removing a ring formation layer on the surface of the rotary kiln liner fireproof material to avoid decompacting an unloosed part through excessive mechanical vibration force; 2. welding a metallic network frame structure, and fixing the metallic network frame structure onto a rivet of a kiln burnt brick or a casting strap through a U-shaped nail and a Y-shaped nail; 3. brushing a bond on a working surface, casting a fireproof material on the brushed bond to form a fireproof material casting strap, and arranging a furnace body shrinkage joint plate between the casting straps; 4. after finishing casting, curing for 65-80 hours to achieve the optimal cold strength of the fireproof material; and 5. preserving heat and baking a furnace in segments to the temperature of 600 DEG C. The repairing method of the rotary kiln liner fireproof material can effectively prevent the continuous falling-off of a rotary kiln liner and avoid the influence generated by hot spot accidents; and the high temperature segment and the low temperature segment of a rotary kiln are relatively synchronous, thereby prolonging the service life of the kiln liner.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com