Production method of building peripheral guard board with multi-layer bamboo lattice board as inner framework

A production method and internal framework technology, which can be applied to buildings, building components, building materials, etc., can solve the problems of aggravated carbon emissions, increased steel consumption, and difficulty in making large building panels, and achieve the goal of reducing carbon emissions and improving overall strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

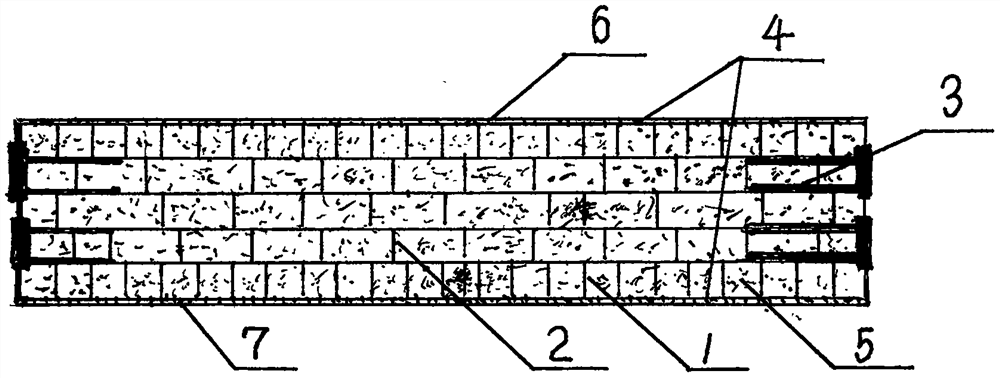

[0009] Use 4-year-old bamboo to break the wall into pieces, and use a mechanical arc cutter to remove the green and yellow according to the shape of the bamboo pieces to make curved bamboo pieces with a length of 3000mm, a width of 30mm and a thickness of 10mm. , Soak the water repellant for 48 hours, use a container with a smoke exhaust device to dry the soaked bamboo chips in the hot smoke in the container to a moisture content of less than 16%, and use a machine to make the bamboo chips at a distance of 50mm and 100mm on one side. Indented bamboo slices, the width of the concave tooth is the thickness of the bamboo slice, and the depth is half the width of the bamboo slice. The concave tooth of the multi-bamboo slices is glued and crossed to form a "field" with a length of 3000mm, a width of 3000mm and a thickness of 30mm. The word grid board, the small hole space board 1, the large hole space board 2, use 12221 five-layer space board glue 222 to be dislocated and stacked, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com