Converter heat replacement hearth bottom circular seam packing method

A filling method and a technology for annular seams, which are applied in the manufacture of converters, etc., can solve the problems of non-dense filling of annular seams and high accident rate of steel leakage, and achieve the effects of reducing thermal shutdown, weakening erosion rate, and synchronizing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

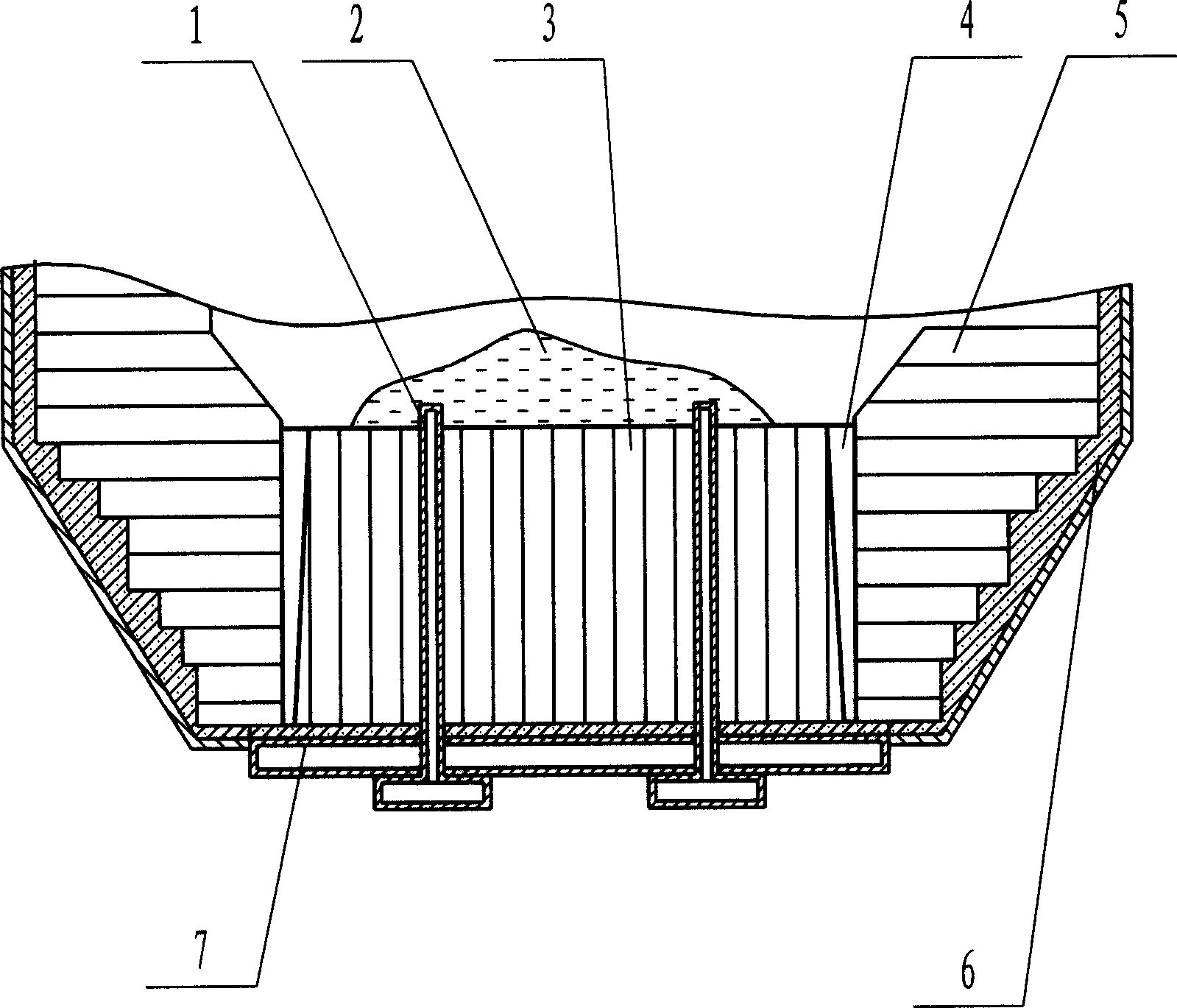

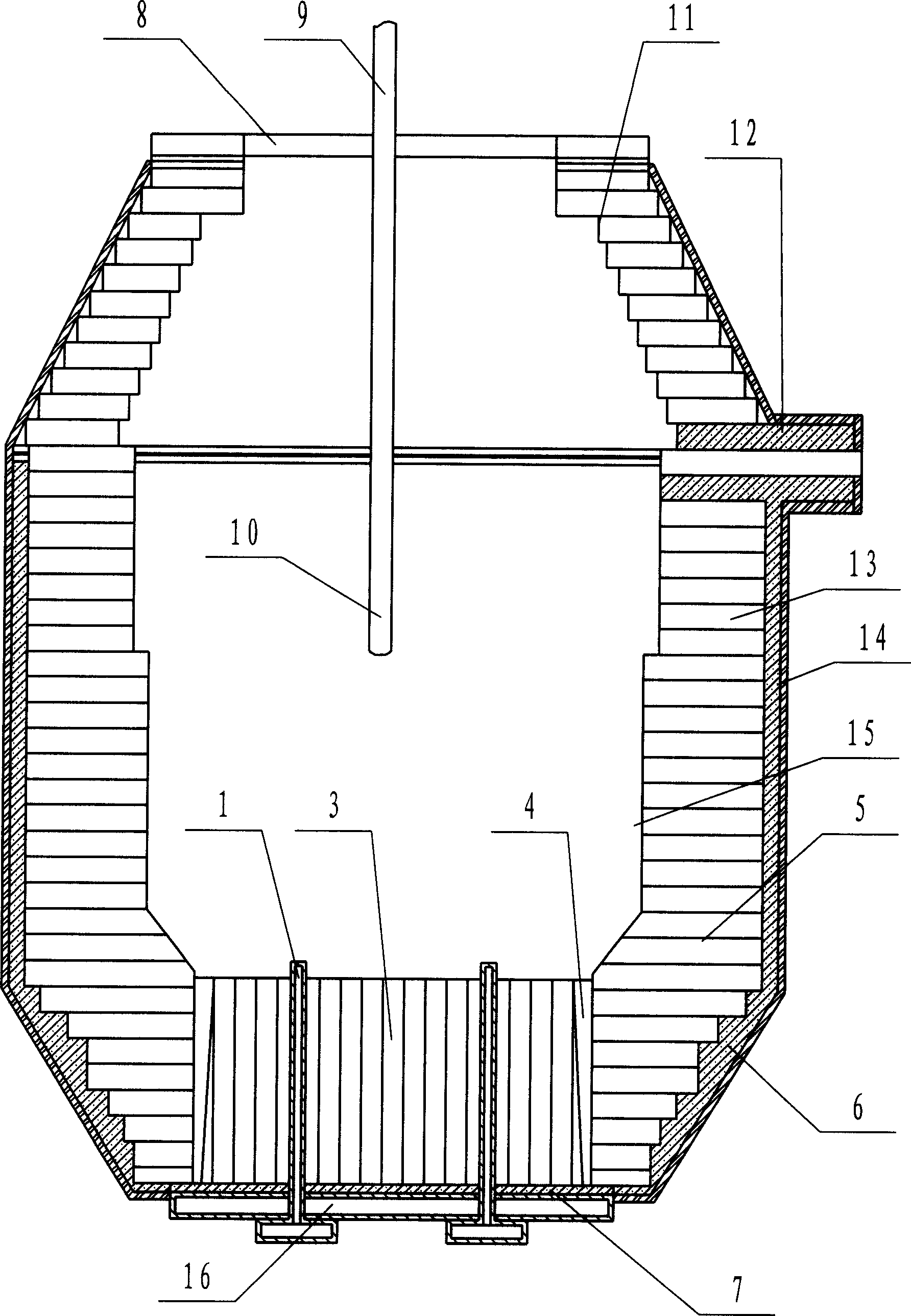

[0038] The method for filling the annular gap at the bottom of the converter heat replacement furnace of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the method for filling the annular gap at the bottom of the converter heat replacement furnace of the present invention is not limited to the following embodiments.

[0039] In this embodiment of the method for filling the ring seam of the bottom of the converter heat exchange furnace, two fillings are implemented in four steps.

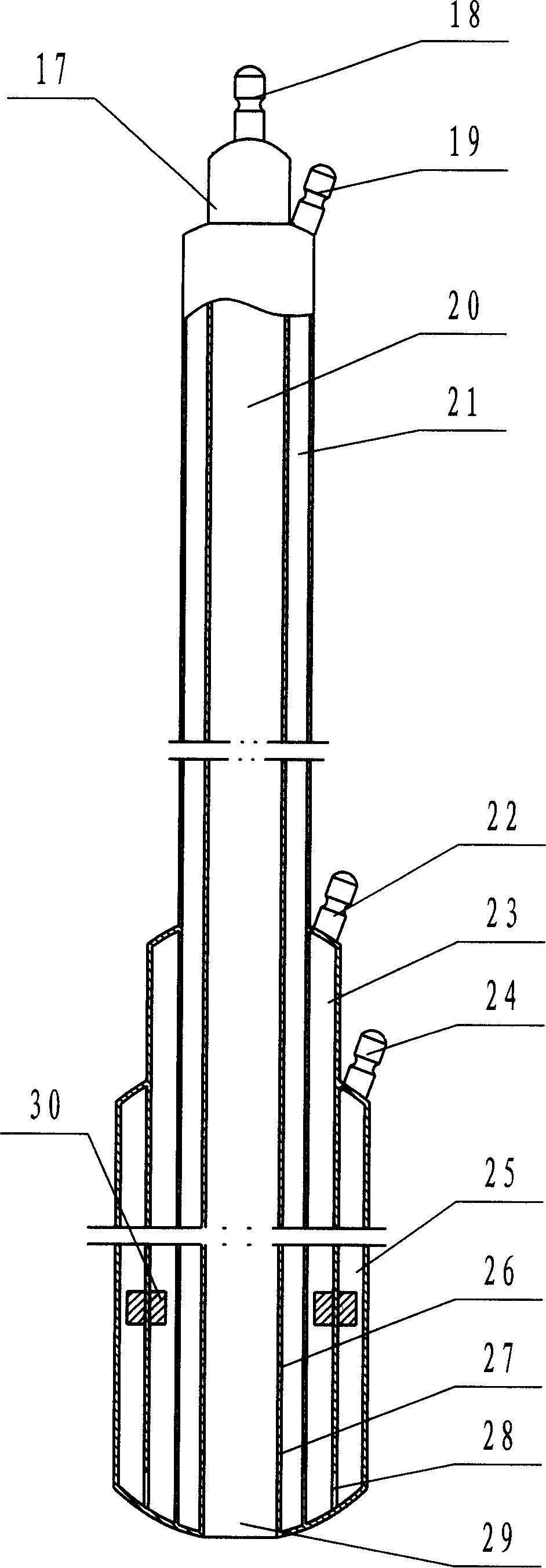

[0040] The first step of insulation: see figure 1 and figure 2 Before the heat replacement of the furnace bottom, first extend the special coal-oxygen lance 9 for burning gas and oxygen into the converter 15 to heat the furnace lining, mainly the furnace body working layer 13 and the hearth working layer 5, to 800°C, and simultaneously heat the working layer The old hearth, eroded to the limits of the craft, was removed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com