Light conversion film, multilayer light conversion film and preparation method of multilayer light conversion film

A light-changing film and light-changing agent technology, applied in botanical equipment and methods, chemical instruments and methods, lamination, etc., can solve problems such as defects in mechanical properties and light-changing effects, achieve good chemical stability, and improve flexibility , The effect of high heat sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

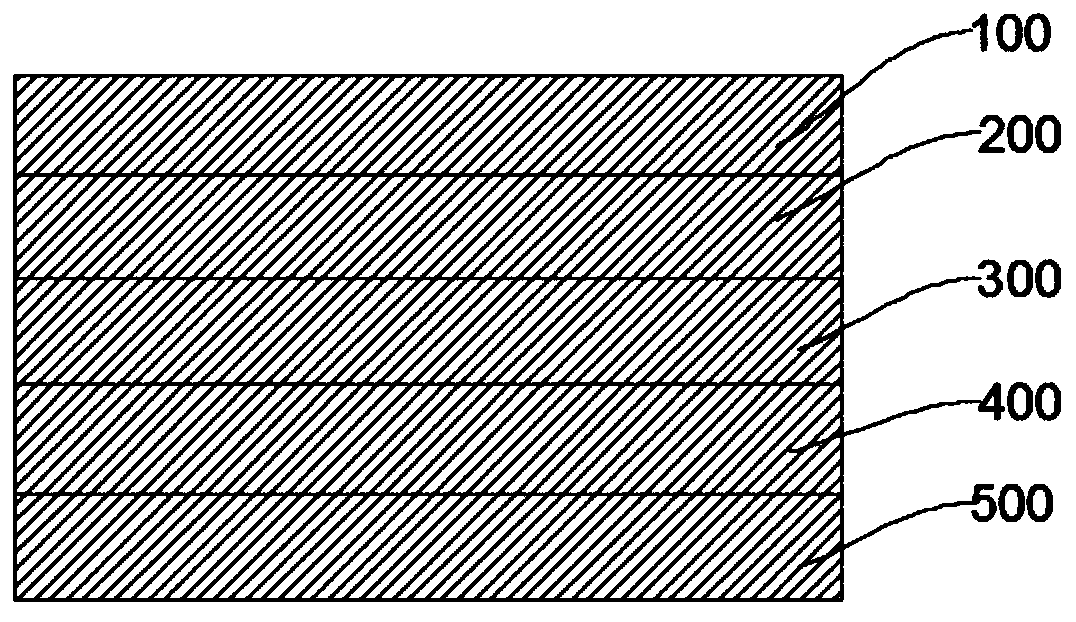

[0030] refer to figure 1 , figure 1 A kind of multi-layer light conversion film provided by the present invention, such as figure 1 as shown,

[0031] The film has a five-layer structure, including the film body, that is, the outer layer, and the film inner layer, and three light-transfer film layers are arranged between the film body and the film inner layer.

[0032] In this embodiment, the film body includes 75% of the film matrix by weight percentage, 12% of light stabilizer and 20% of antioxidant, wherein the film matrix is low density polyethylene, the light stabilizer is phenyl salicylate, and the light stabilizer is phenyl salicylate. The oxidizing agent is Antioxidant 168.

[0033] In this embodiment, the components of the three light conversion film layers are the same, mainly composed of 55% organic vehicle by weight percentage, 18% light conversion agent, 13% light stabilizer, and 9% antioxidant; wherein the organic vehicle It is low-density polyethylene, the...

Embodiment 2

[0036] The film has a five-layer structure, including the film body, that is, the outer layer, and the film inner layer, and three light-transfer film layers are arranged between the film body and the film inner layer.

[0037] In this embodiment, the film body includes 65% of the film matrix by weight percentage, 15% of light stabilizer and 20% of antioxidant, wherein the film matrix is linear polyethylene, and the light stabilizer is p-tert-butylbenzene salicylate Esters, the antioxidant is Antioxidant 330.

[0038] In this embodiment, the components of the three light conversion film layers are the same, mainly composed of 57% organic vehicle by weight percentage, 20% light conversion agent, 14% light stabilizer, and 11% antioxidant; wherein the organic vehicle It is linear polyethylene, the light conversion agent is fluorescent yellow YG-51, the light stabilizer is 2,4-dihydroxybenzophenone, and the antioxidant is antioxidant 330.

[0039]According to the above formula,...

Embodiment 3

[0041] The film has a five-layer structure, including the film body, that is, the outer layer, and the film inner layer, and three light-transfer film layers are arranged between the film body and the film inner layer.

[0042] In this embodiment, the film body includes 60% of the film matrix by weight percentage, 20% of the light stabilizer and 20% of the antioxidant, wherein the film matrix is high-density polyethylene, and the light stabilizer is resorcinol but benzene Ester, the antioxidant is antioxidant 3114.

[0043] In this embodiment, the components of the three light conversion film layers are the same, mainly composed of 60% organic vehicle by weight percentage, 22% light conversion agent, 15% light stabilizer, and 12% antioxidant; wherein the organic vehicle It is high-density polyethylene, the light conversion agent is fluorescent yellow YG-51, the light stabilizer is resorcinol but benzoate, and the antioxidant is antioxidant 3114.

[0044] According to the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com