Patents

Literature

43results about How to "Improve acupuncture effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

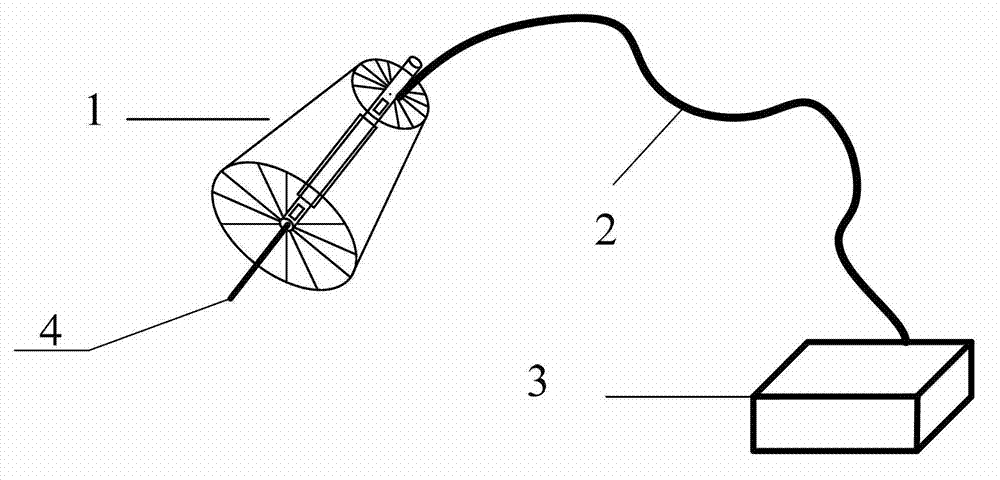

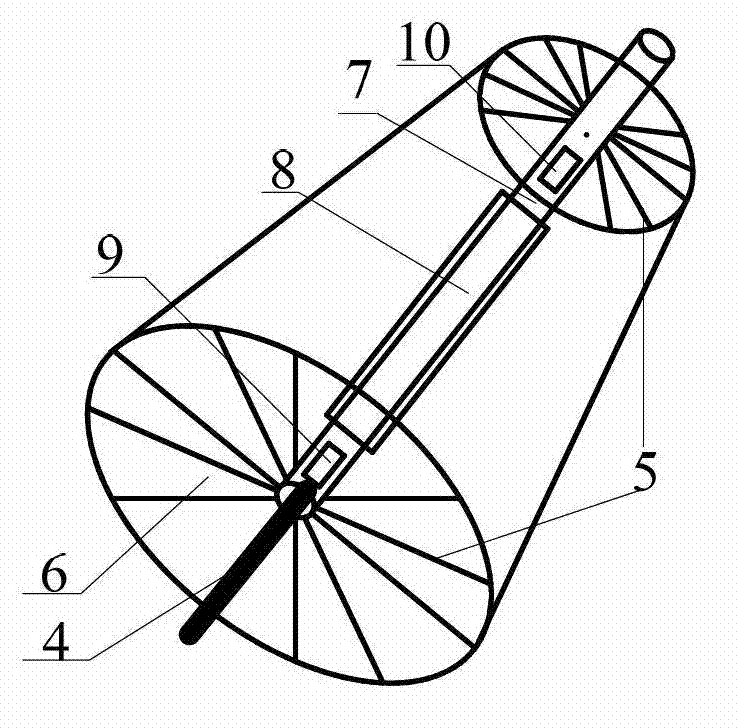

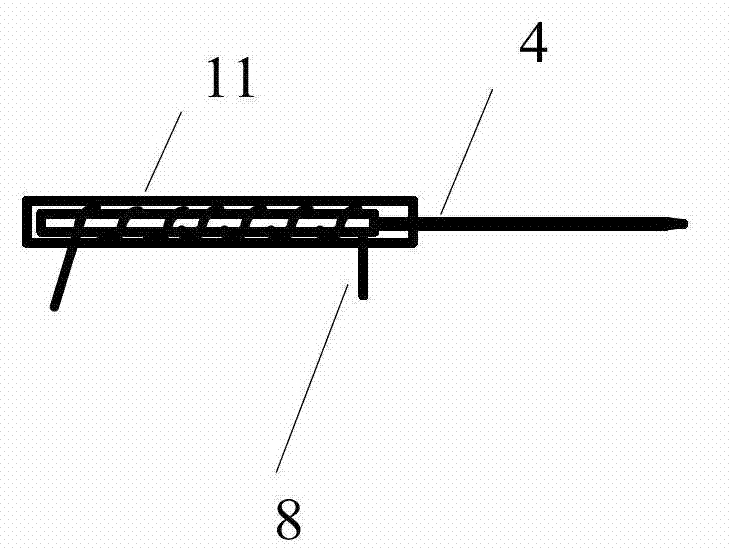

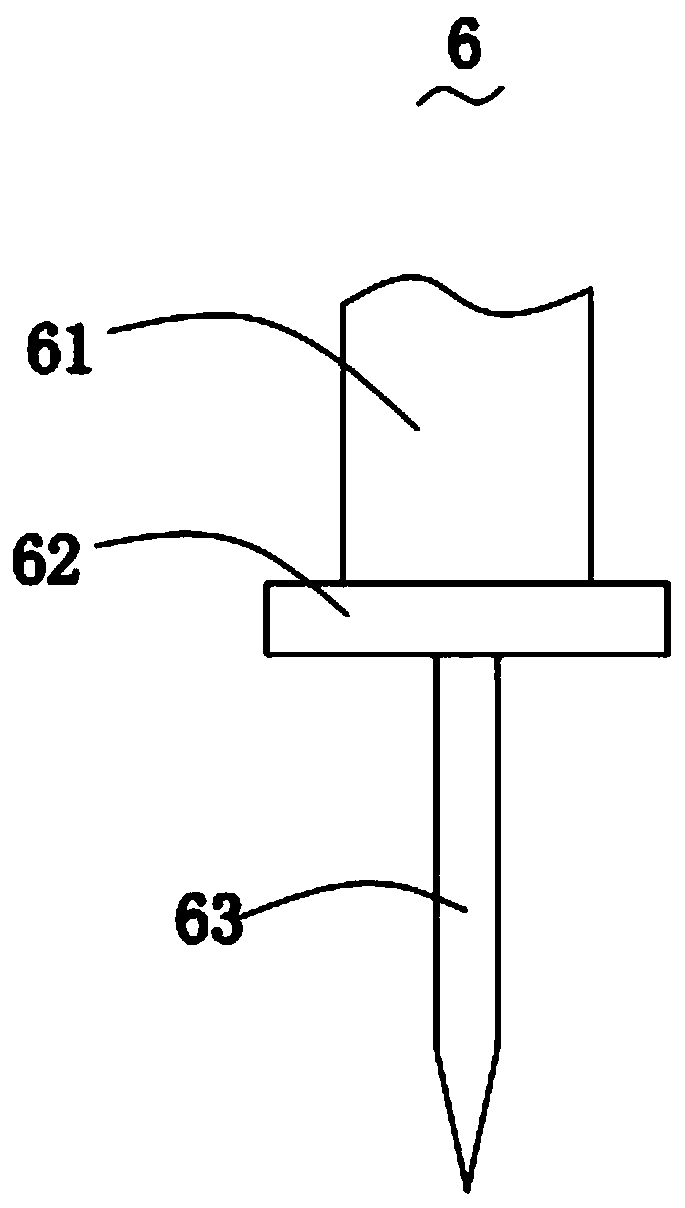

Electric heating acupuncture vibration therapeutic apparatus

ActiveCN103169612AAdjustable and controllable temperatureAccurate and reliable temperatureDevices for heating/cooling reflex pointsAcupunctureAcupuncture treatmentDisplay device

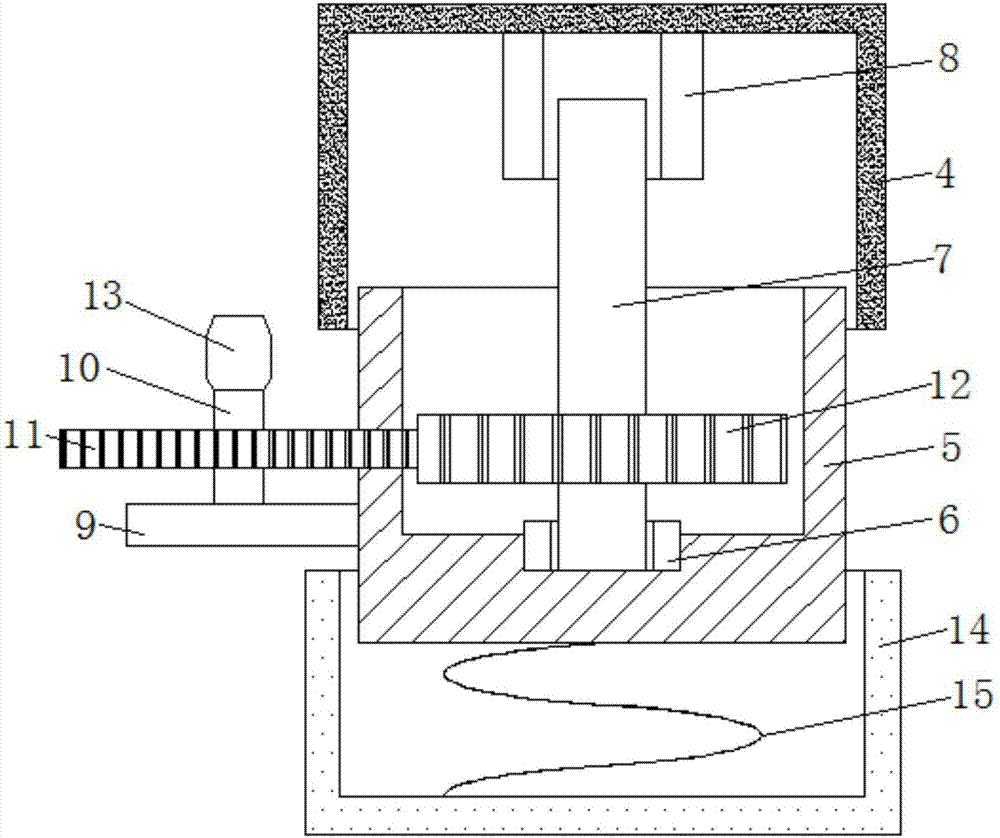

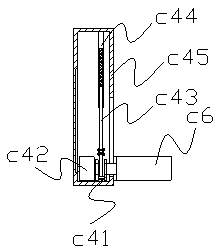

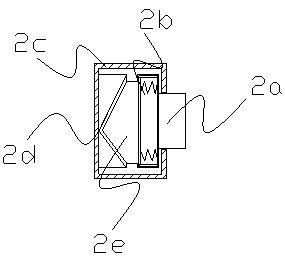

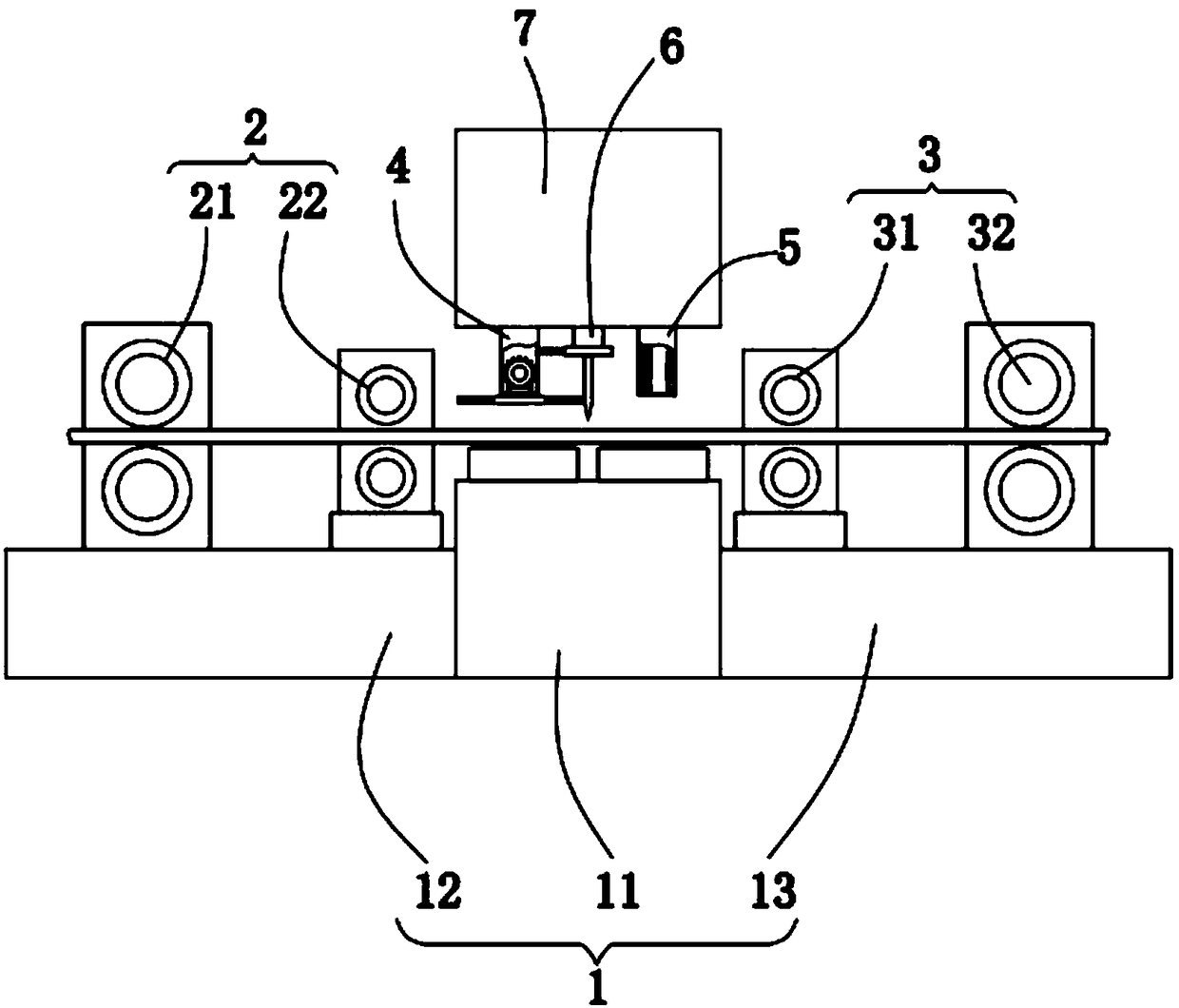

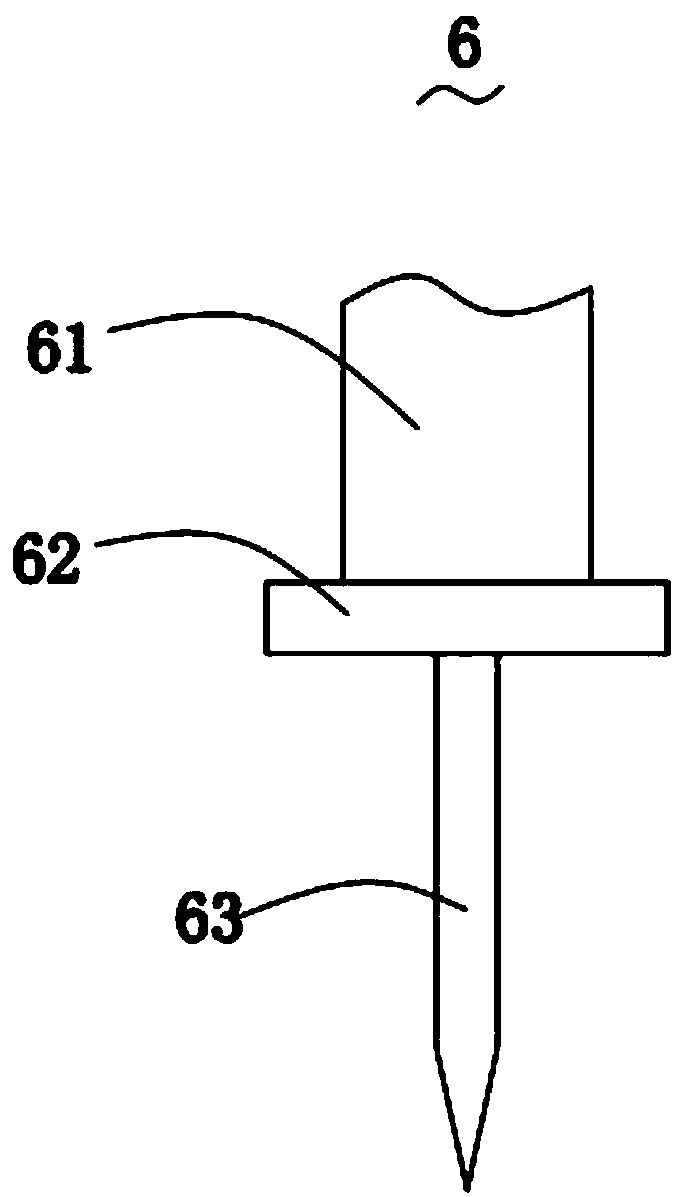

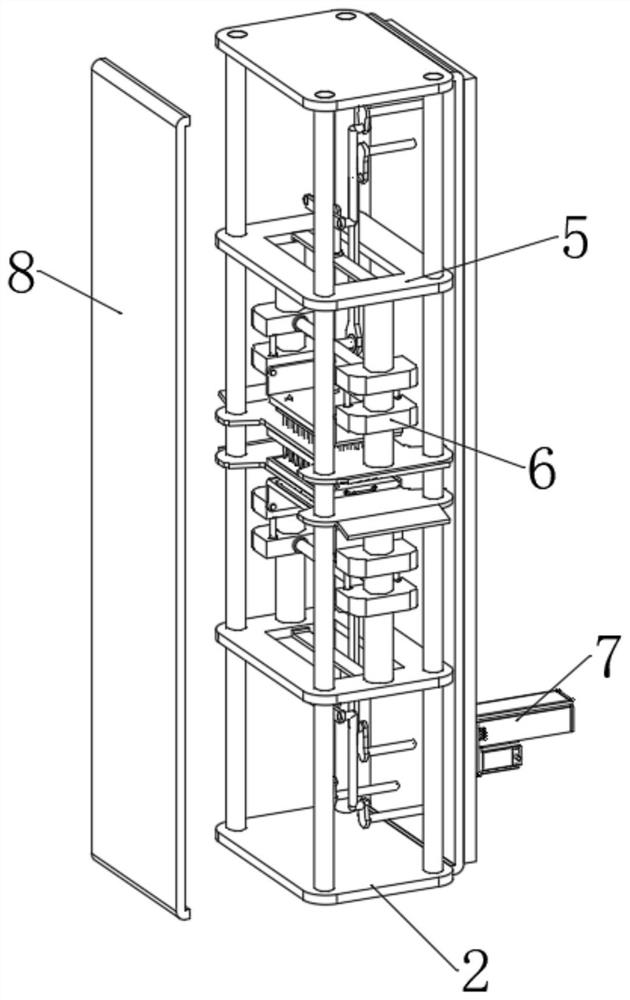

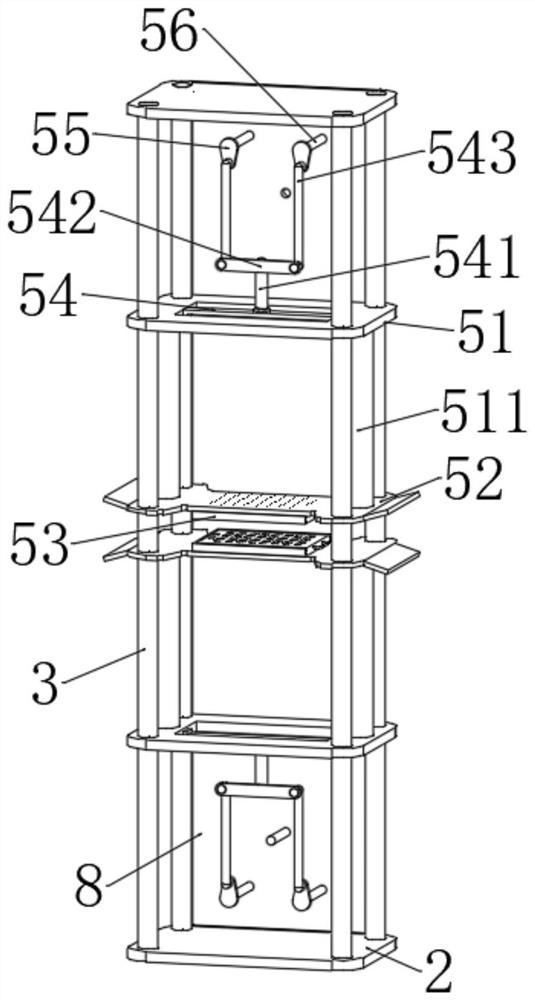

The invention discloses an electric heating acupuncture vibration therapeutic apparatus and relates to acupuncture therapeutic equipment. The electric heating acupuncture vibration therapeutic apparatus is provided with a heater, a controller, a silver needle and a power source; the heater is provided with a support frame, a heat radiating fin, a silver needle sleeve, a sleeve heating part, a temperature sensor and a micro motor; the silver needle sleeve is arranged on the support frame, the heat radiating fin is fixed at the bottom of the support frame, the sleeve heating part is arranged on the silver needle sleeve, the temperature sensor is arranged at the lower part of the silver needle sleeve, the tail part of the silver needle is connected with the silver needle sleeve, and the micro motor is connected with the silver needle sleeve; the sleeve heating part, the temperature sensor and the micro motor are respectively connected with the controller; the sleeve heating part and the micro motor are eclectically connected with the power source through leads, and the temperature sensor is connected with the input end of the controller through a signal line; and the controller is provided with a microprocessor, a vibration time selector button, a vibration time indicating lamp, a vibration strength adjusting knot, a photoelectronic isolator, an environment temperature display driving circuit, a current heating temperature display driving circuit, an environment temperature display and a current heating temperature display.

Owner:XIAMEN UNIV

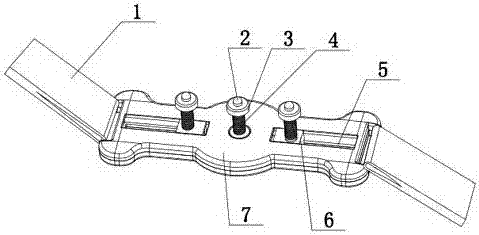

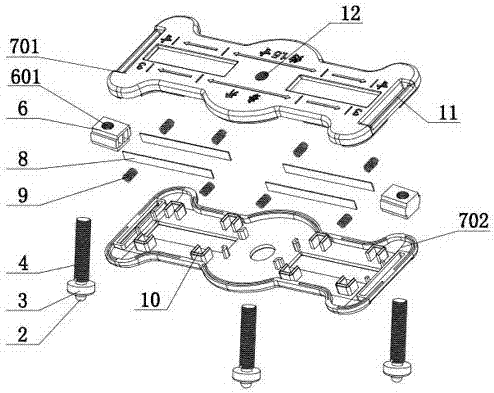

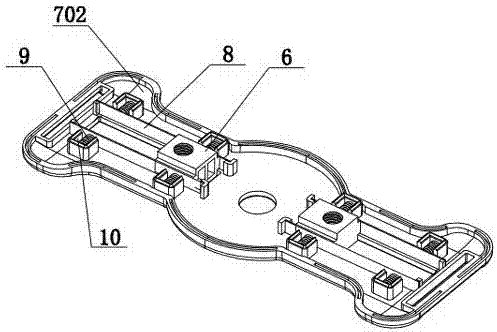

Bandage type acupoint pressing instrument

PendingCN107213013AImprove acupuncture effectEasy to useDevices for pressing relfex pointsBandageBiomedical engineering

The invention discloses a bandage type acupoint pressing instrument, and belongs to the technical field of health maintenance and health protection tools. The bandage type acupoint pressing instrument comprises an acupoint pressing instrument. The acupoint pressing instrument comprises an acupoint pressing instrument body and bandages, the bandages are fittingly connected with the acupoint pressing instrument body, the acupoint pressing instrument body comprises a mounting plate and an acupoint pressing rod, the acupoint pressing rod comprises a threaded rod and an acupoint pressing head at the front end of the threaded rod, a threaded groove is correspondingly formed in the middle of the mounting plate, and the threaded rod of the acupoint pressing rod is matched with the threaded groove in a threaded connection manner. The bandage type acupoint pressing instrument has the advantages that single-acupoint pressing or double-acupoint and triple-acupoint simultaneous pressing can be carried out by the aid of the bandage type acupoint pressing instrument, and good acupoint pressing effects can be realized; labor and the time can be saved by the bandage type acupoint pressing instrument with a bandage type structure, and the bandage type acupoint pressing instrument is free of influence on rest or activities of people, is easy to use and is comfortable and convenient.

Owner:朱乐志 +1

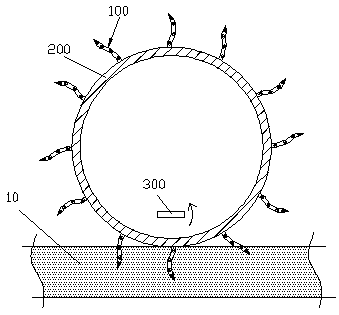

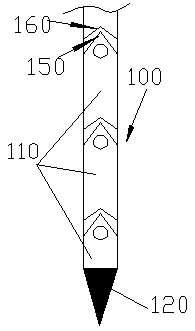

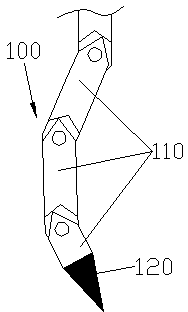

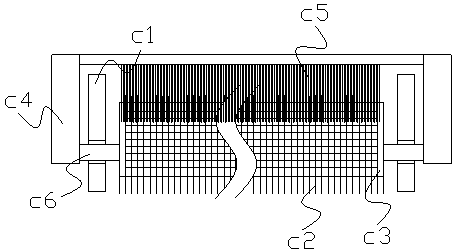

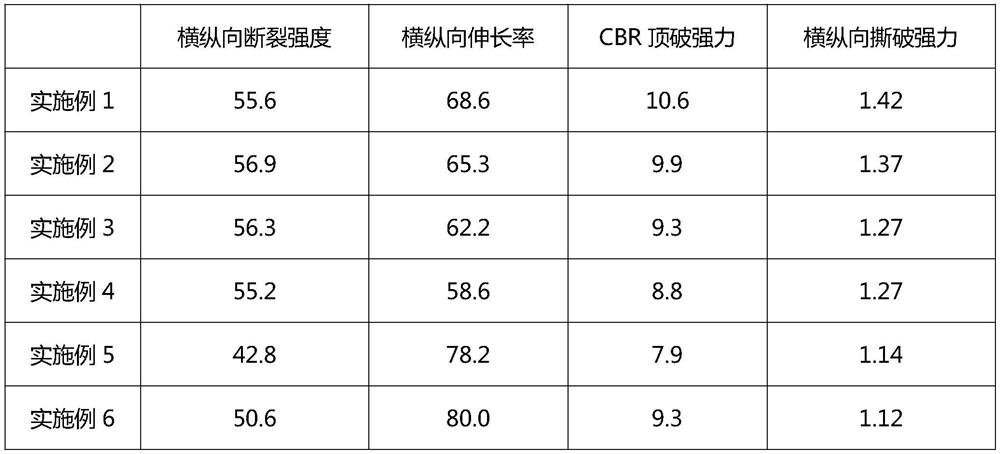

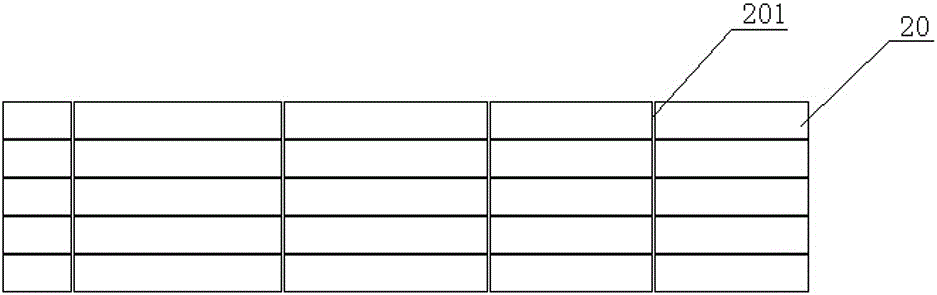

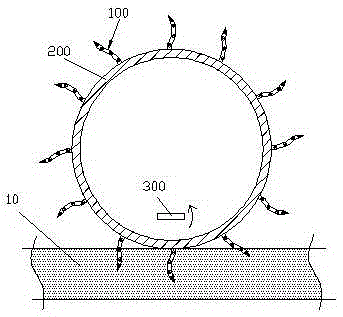

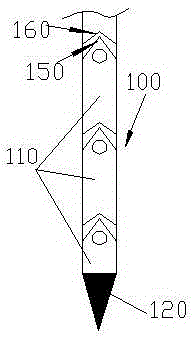

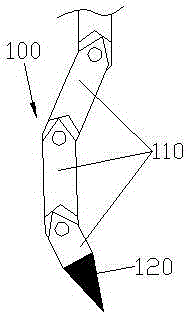

Disorderly needling device for non-woven fabric

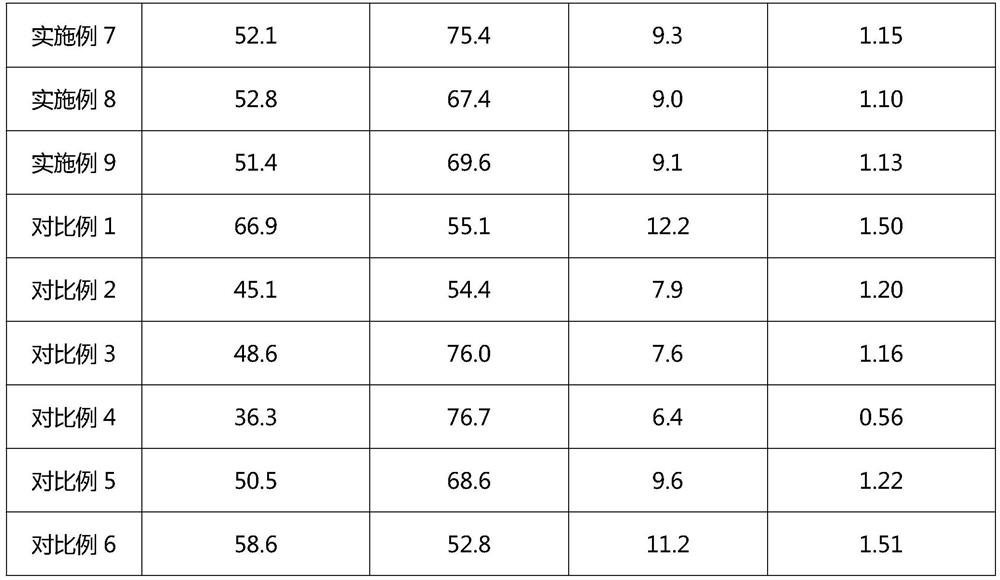

ActiveCN103409944AAcupuncture effect is goodImprove acupuncture effectNeedling machinesNonwoven fabricUltimate tensile strength

The invention provides a disorderly needling device for a non-woven fabric. The device comprises a hollow cylinder body, wherein the cylinder body is driven by a drive device to rotate; felting needles are uniformly distributed on the cylinder body; each felting needle is divided into at least three needle sections which are mutually hinged; a structure for limiting the swing amplitude of the needle sections is arranged at a hinge joint of every two adjacent needle sections; a magnet is arranged on the needle section where a needle point of each felting needle is arranged; a second magnet for influencing the magnet is arranged inside or outside the cylinder body; and the magnet pole pointing direction or the magnetic strength of the second magnet changes consistently. According to the disorderly needling device for the non-woven fabric, the magnet pole pointing direction or the magnetic strength of the second magnet changes consistently, so that shapes of the felting needles change disorderly due to the fact that the felting needles are under the action of different angles and different forces, and the needling effect to the non-woven fabric is better.

Owner:SUZHOU HAOJIAN TEXTILE

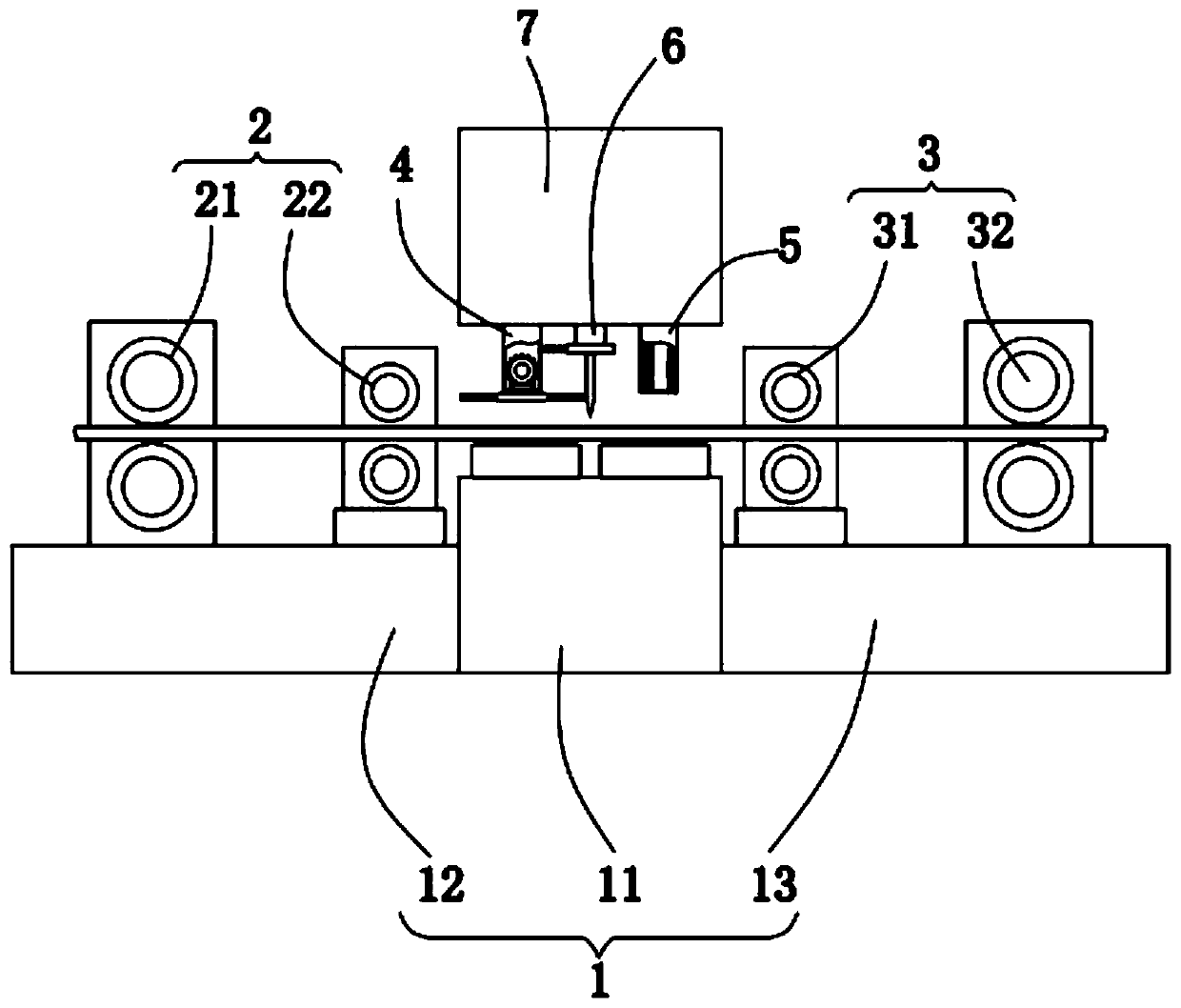

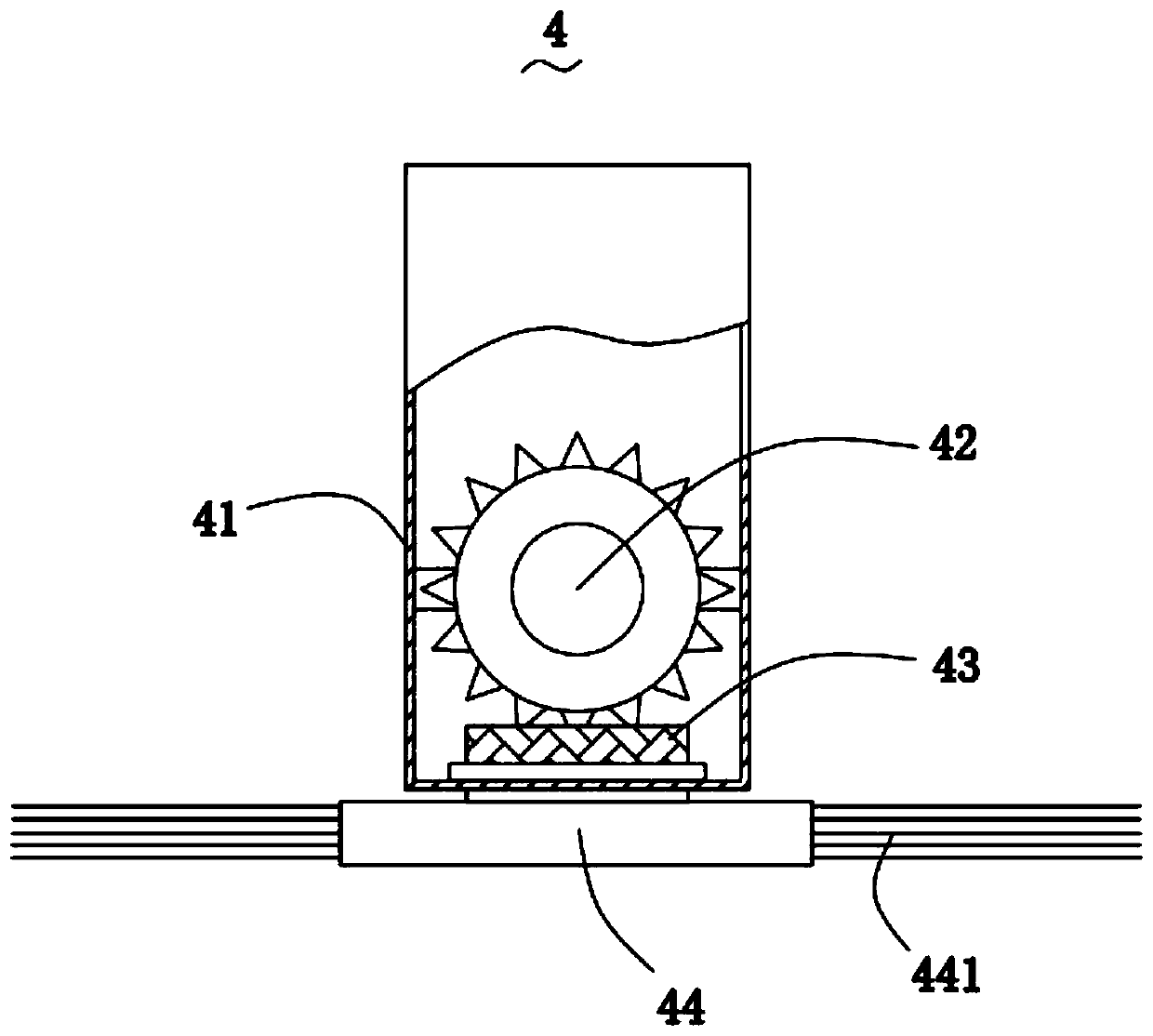

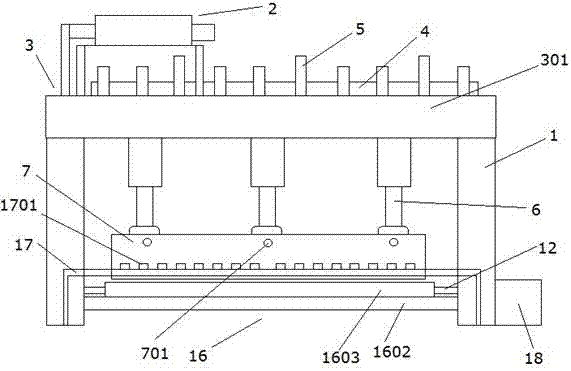

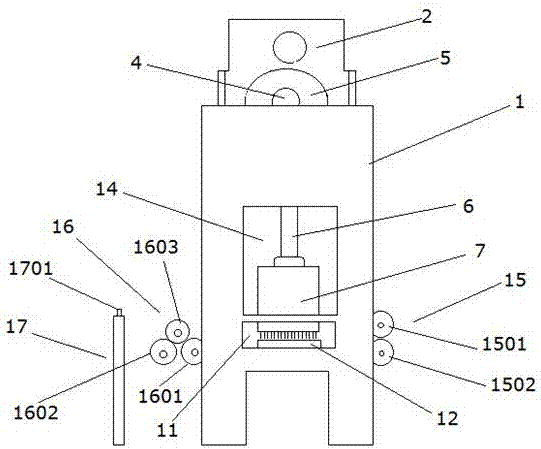

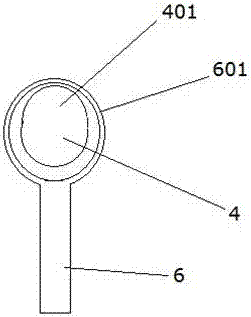

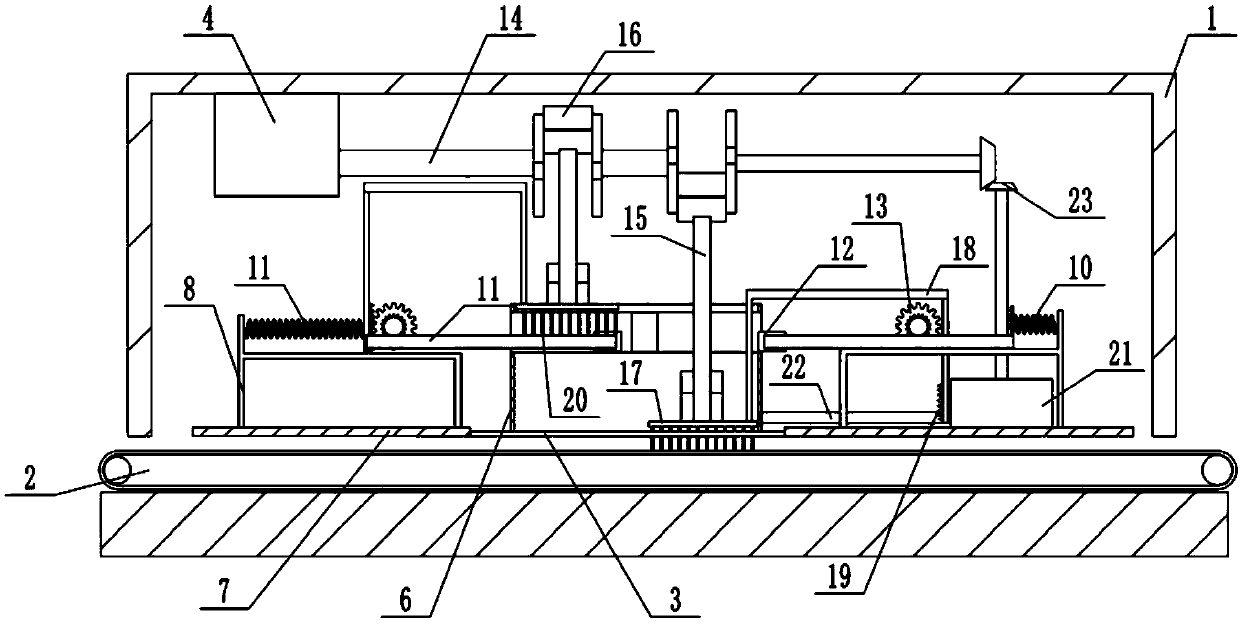

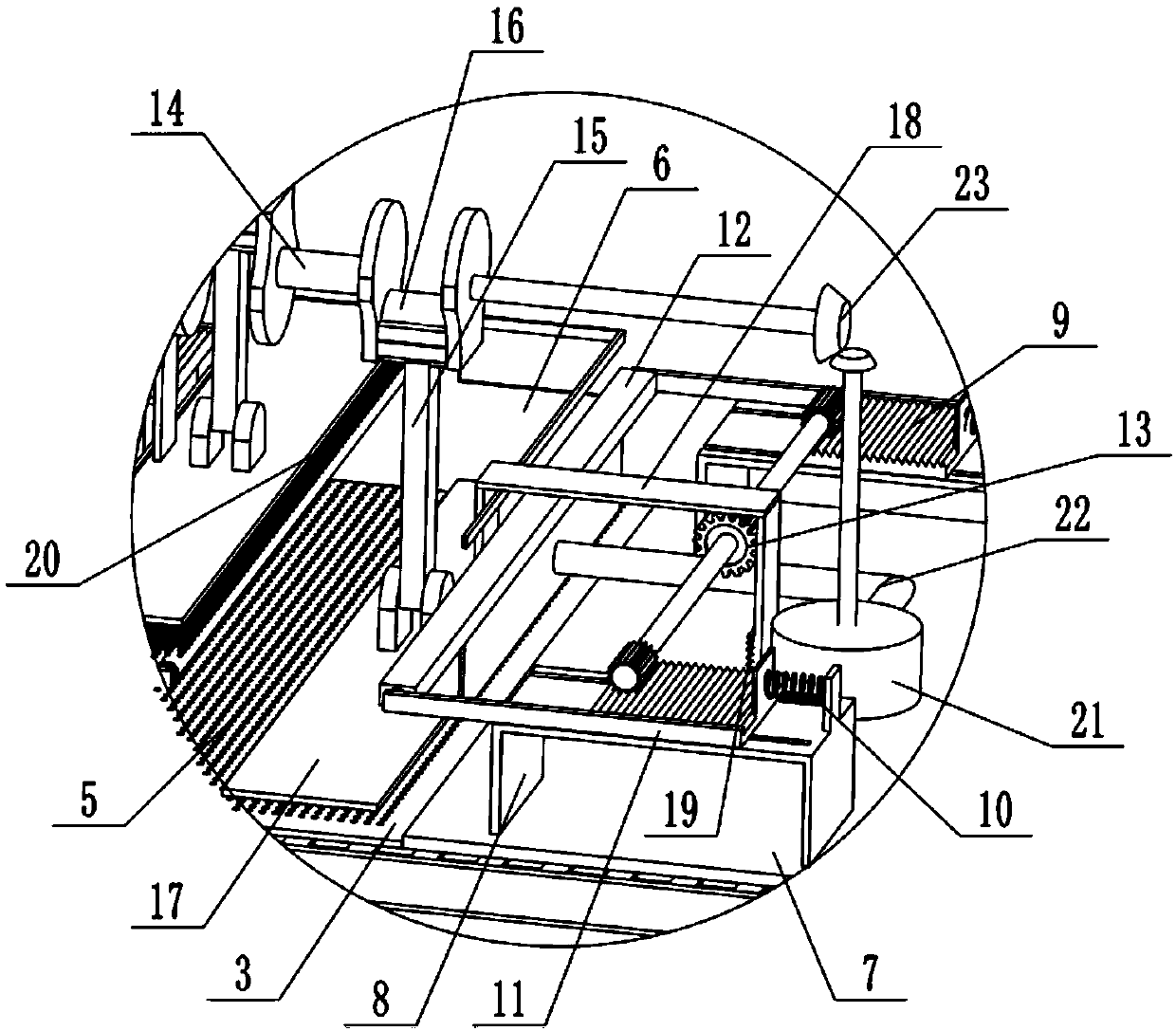

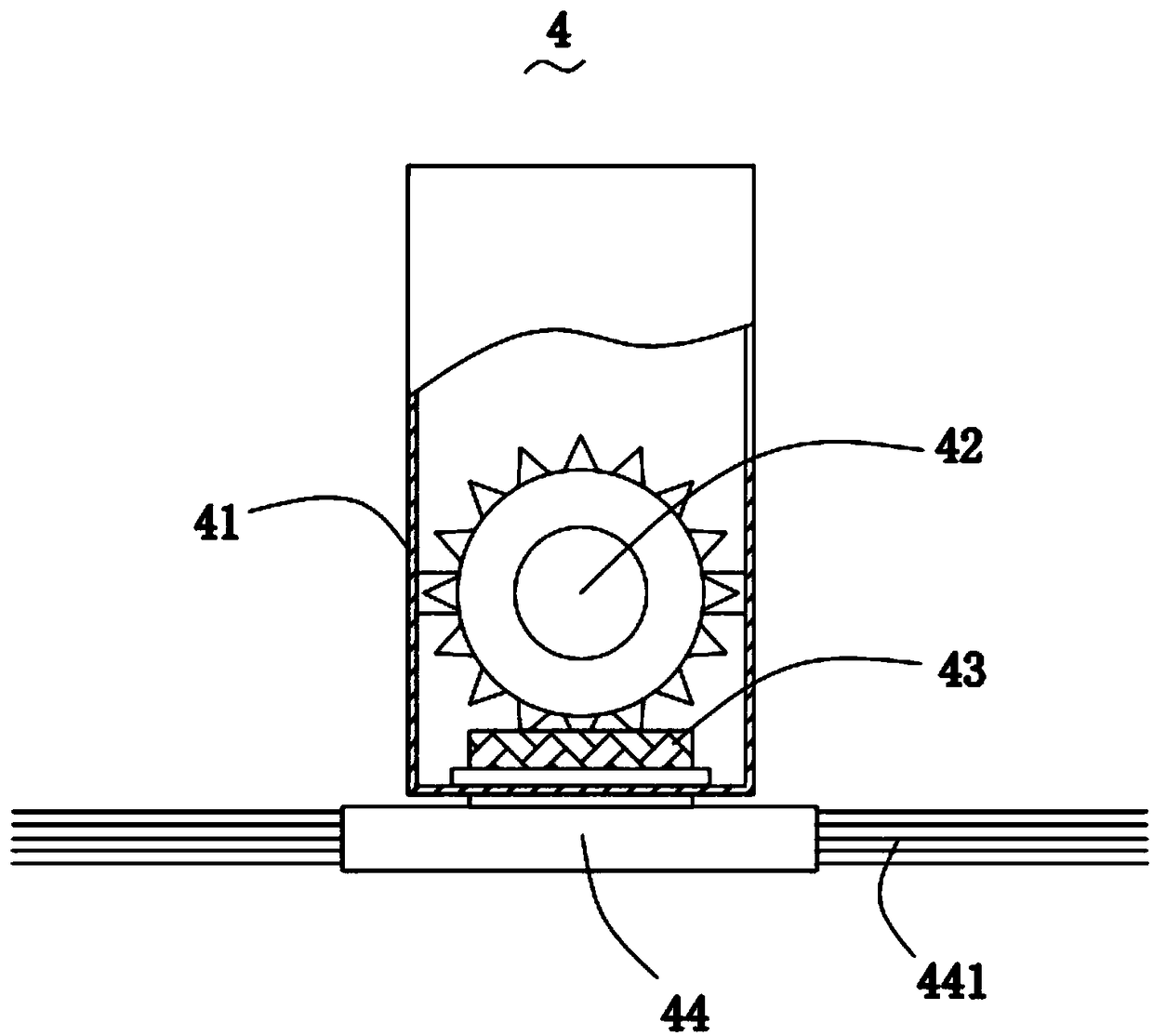

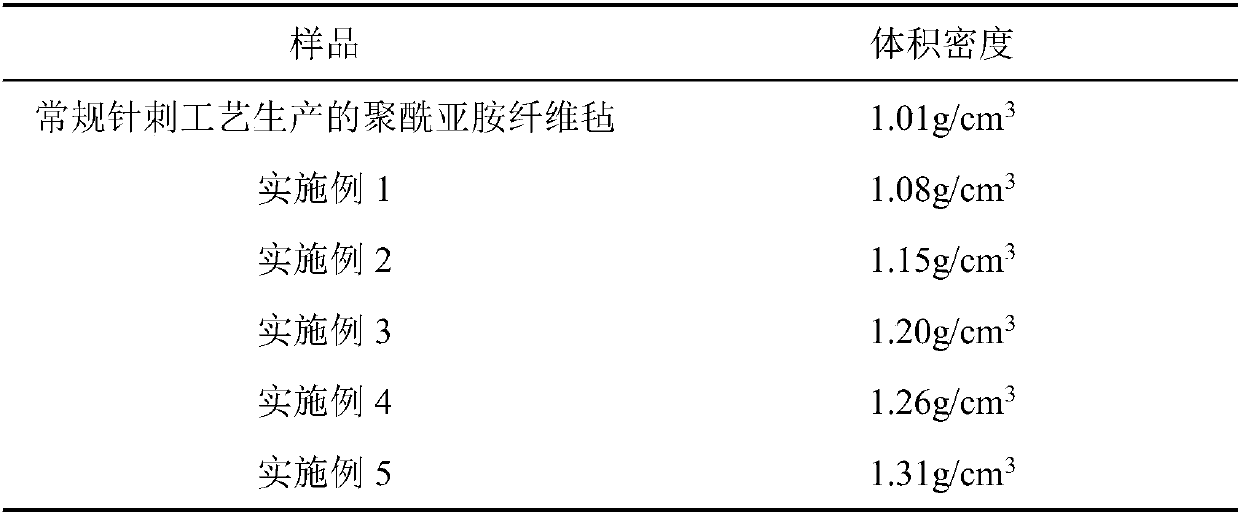

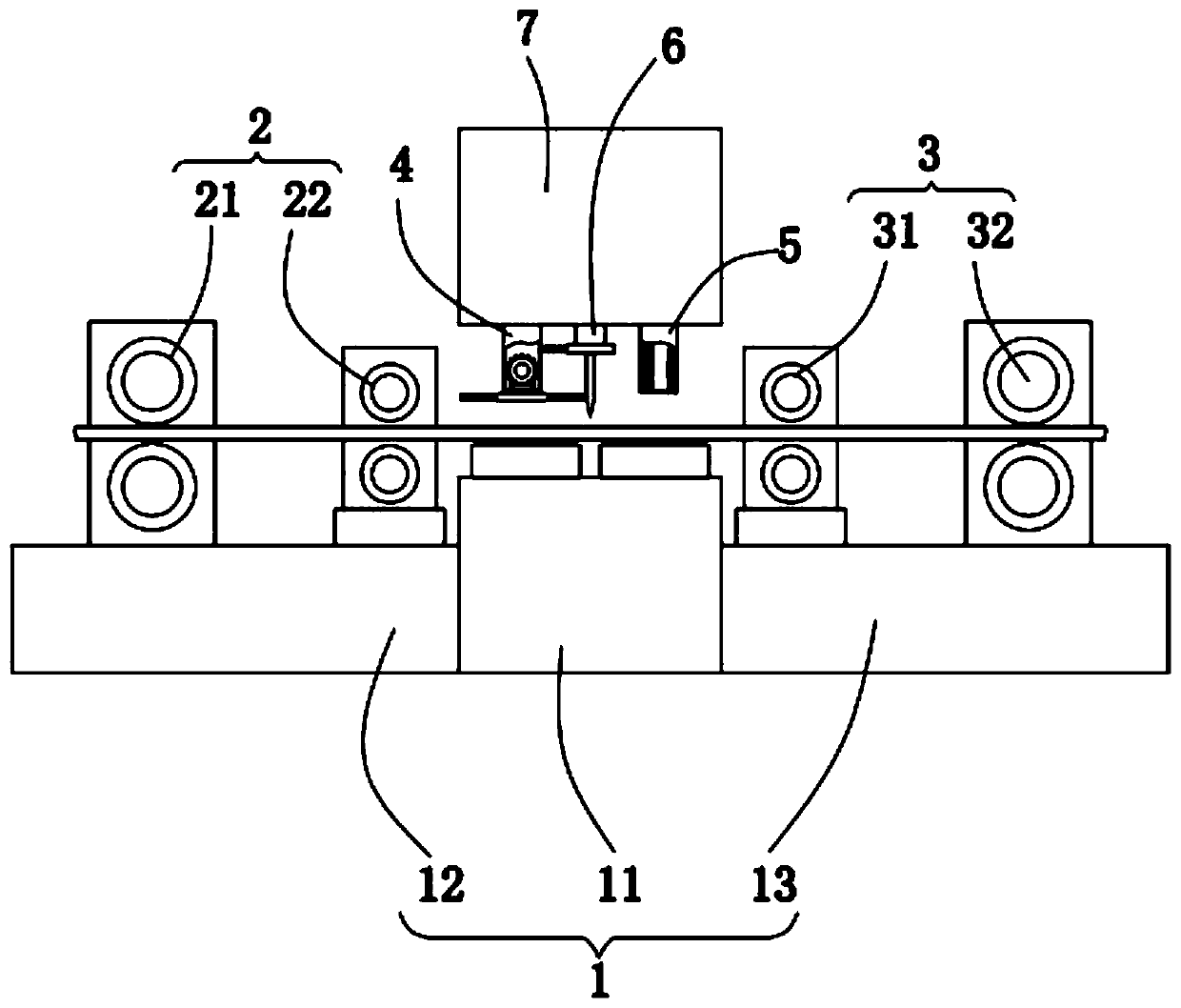

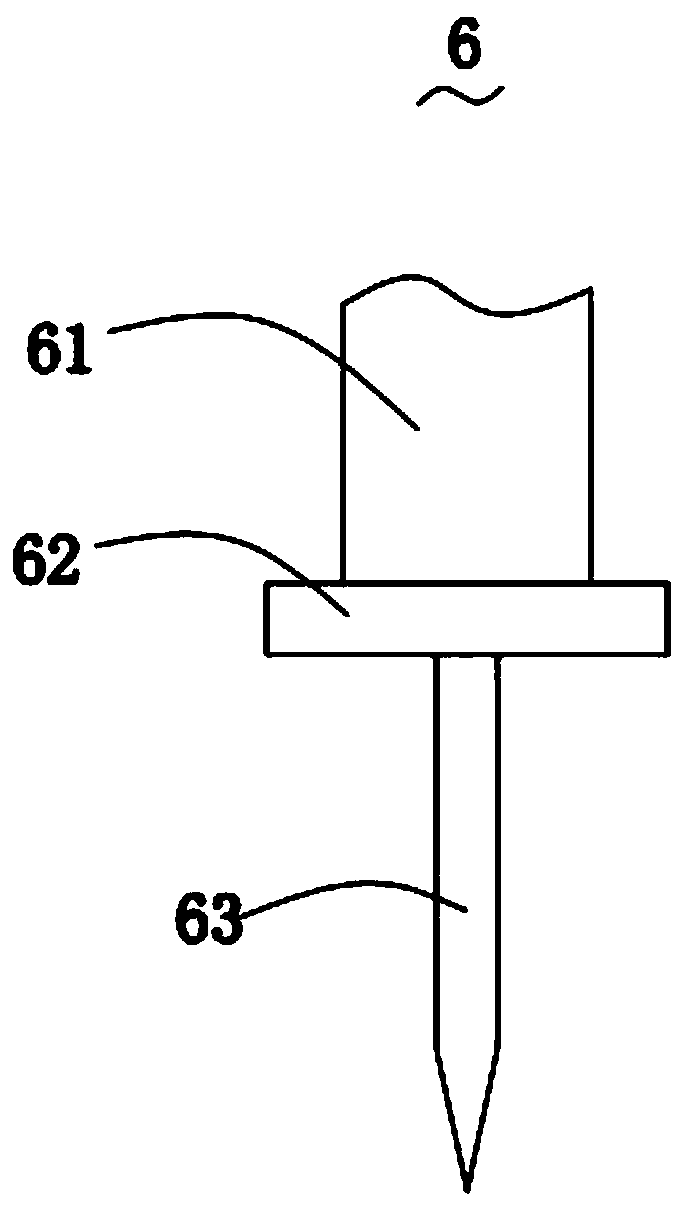

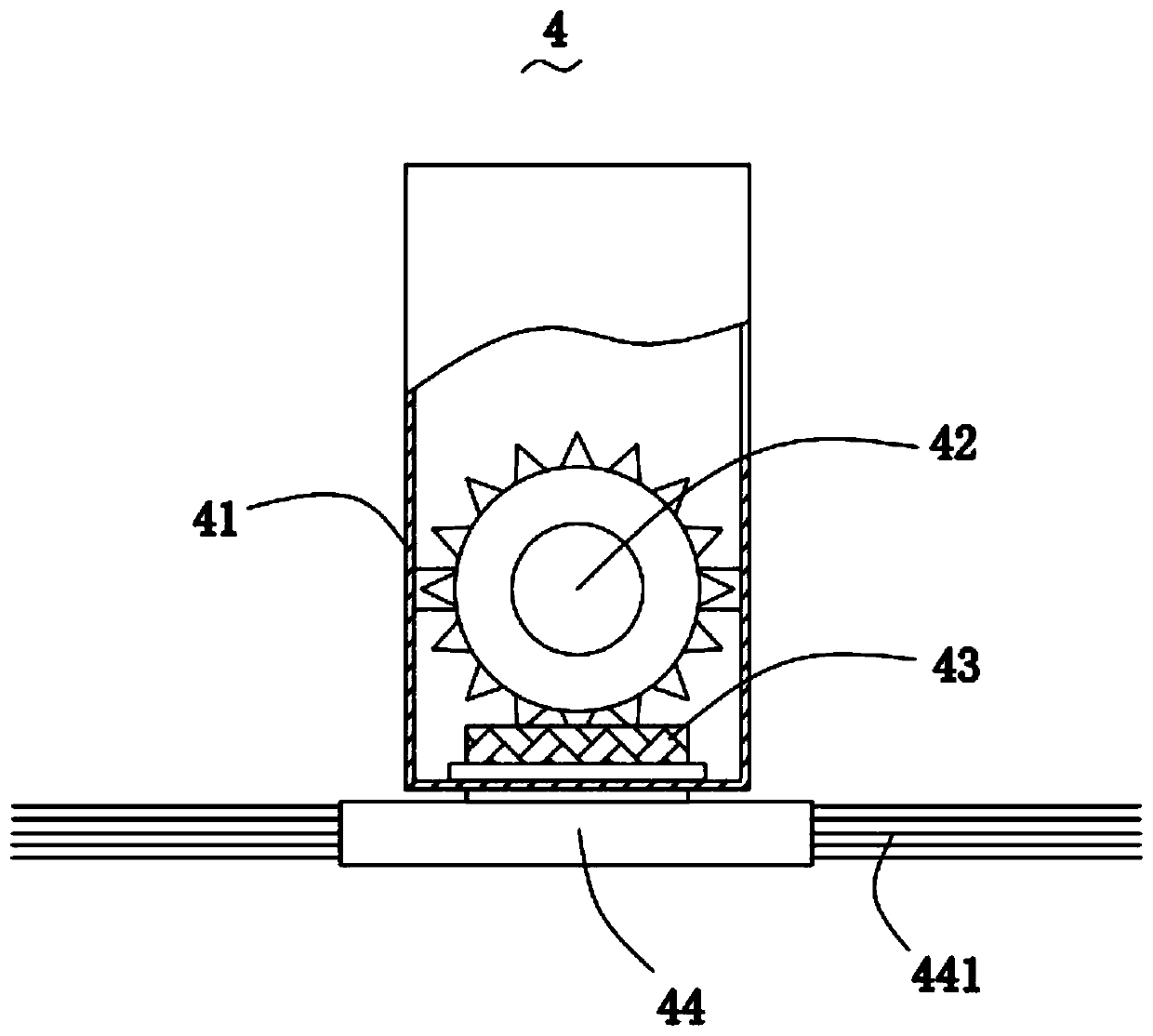

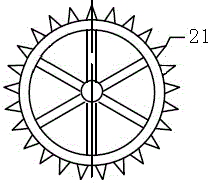

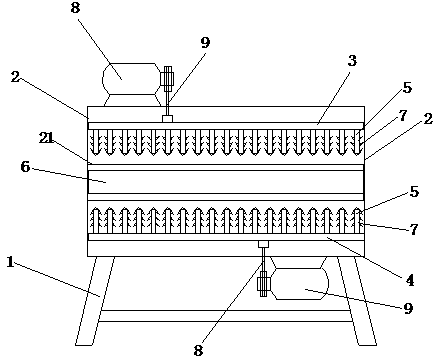

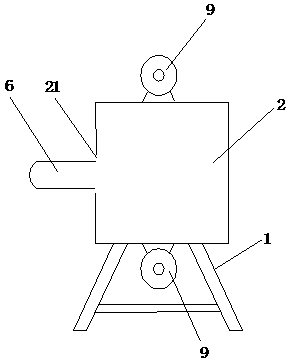

A kind of double-shaft needling machine for textile

ActiveCN108625044BImplement automatic cleanupImprove acupuncture effectNeedling machinesSpinningGear wheel

The invention relates to the technical field of textile processing, in particular to a twin-shaft needle machine for spinning. The twin-shaft needle machine comprises a supporting mechanism, a needling mechanism, a gear case, a feeding mechanism and a discharging mechanism, and further comprises a dust removal mechanism, a dust collection mechanism and a linkage mechanism. The twin-shaft needle machine for the spinning has the advantages that the linkage mechanism can move vertically with the needling mechanism synchronously, thereby driving a drive gear to rotate through a toothed plate, so that a transmission gear and a rotary table rotate synchronously, a hairbrush can constantly scrape a needle body to scrape off the dust, cotton wool, thread residue and the other waste attached on thesurface of the needle body, thereby achieving automatic cleaning of the needle body; during the vertical movement of the needling mechanism, the rotary table can be driven to rotate clockwise and anticlockwise, the hairbrush can sweep the needle body from two directions, thereby effectively preventing the thread residue from winding on the needle body and improving the sweeping effect; the removed dirt is collected to a filter plate through the dust collection mechanism, thereby avoiding that the dirt wafts to the air or falls onto the product, so that the collecting and cleaning of the dirtare more convenient.

Owner:宁夏大斌家纺科技有限公司

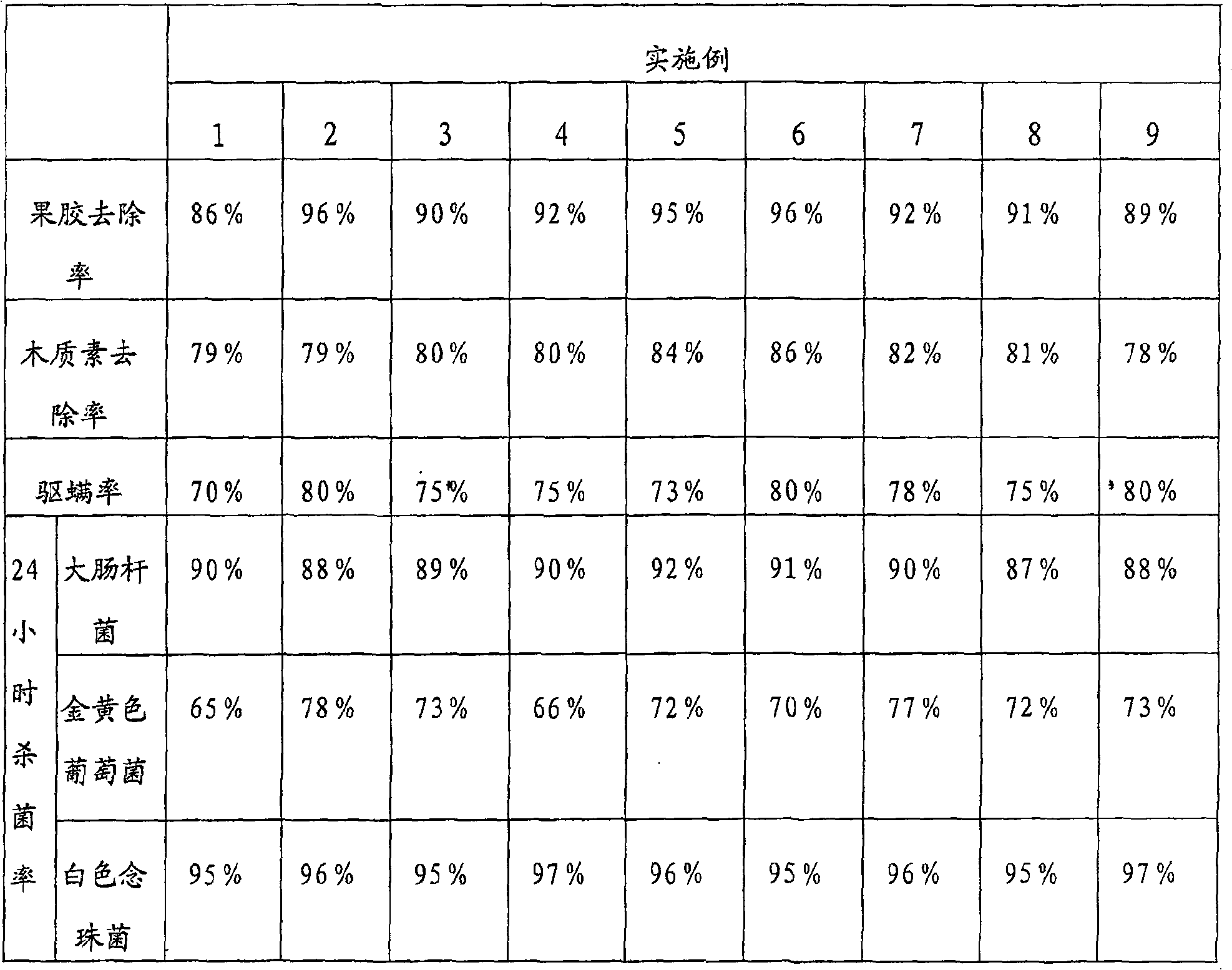

Method for manufacturing insole with jute fiber

ActiveCN101167606AEfficient removalWeaken joint forceInsolesFibre treatment to obtain bast fibreFiberPectinase

A method for manufacturing insoles by jute fibers comprises treating jute fibers with the complex enzyme de-gelatinizing, wherein, the complex enzyme de-gelatinizing treatment uses complex enzyme aqueous solution which is formulated by pectase and laccase to provide the de-gelatinizing treatment to jutes, adjusting the pH value of the complex enzyme aqueous solution to be more than or equal to 4.0 but less than 5.0 when the complex enzyme de-gelatinizing treatment is carried out, elevating the temperature to 35 DEG C to 65 DEG C for 20-120 minutes, and then adjusting the pH value of the solution to be 7.5 to 9.5, keeping the temperature under 40 DEG C to 70 DEG C for 20-120 minutes, enzyme-devitalizating the jutes which are treated by the complex enzyme, mixing the de-gelatinized jute fibers with the chemical fibers, carding, net-spreading, and needling the mixed fibers, hot-pressing the needled mixed fibers and molding. The insole manufactured by the method of the invention is very comfortable when in use, and is not urticant in feeling when in use, good in bacteria repellency, not easily wormy, and strong in air permeability, hygroscopicity, and moisture character.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Needle machine

ActiveCN106958080AQuality improvementAvoid stabbingNeedling machinesElectric machineryBiomedical engineering

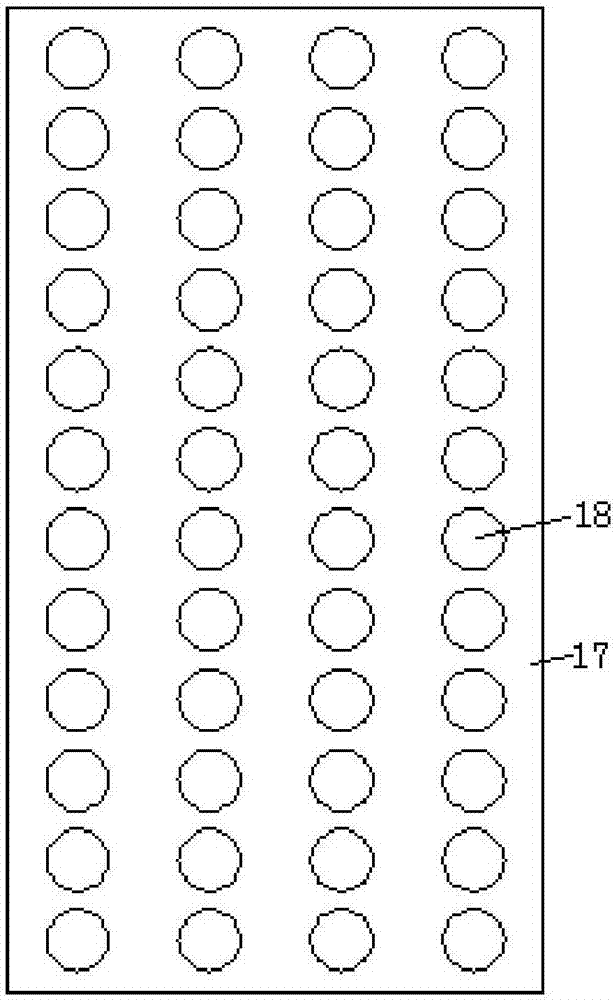

The invention discloses a needle machine. The needle machine comprises a rack and a main motor, wherein the rack is provided with a crossbeam frame, and the crossbeam frame comprises a first beam rod and a second beam rod; a rotating shaft which is in transmission connection with the main motor is arranged between the first beam rod and the second beam rod; a semicircular weight block is mounted on the rotating shaft; the rotating shaft is connected with a needle cloth shell through a linkage shaft, the inside of the needle cloth shell is hollow and the needle cloth shell is embedded with a needle inserting board, and detachable pressing pieces are placed on the needle inserting board in a stacked mode; a plurality of regularly arrayed circular holes are densely distributed on the needle inserting board, the apertures of the circular holes are 1 to 2.5mm; a plug-in mounting port is formed in one side of the needle cloth shell; a needle plate is arranged right below the needle cloth shell, a plurality of regularly arrayed bottom holes are densely distributed in the needle plate, and the bottom holes and the circular holes are in one to one correspondence; the needle plate and the rack are detachably connected. The needle machine is novel in structure, good in needling effect and less in broken needles.

Owner:威海市和谐汽车内饰有限公司

Method for manufacturing seat cushion with jute fibre

ActiveCN101172571AGood puffing effectImprove acupuncture effectUpholstery fillingFibre treatment to obtain bast fibrePectinaseAntibiosis

The invention relates to a manufacturing method of a seat cushion made of jute fiber. The method comprises the following steps: firstly, the soaking is performed to jute in compound enzyme water solution prepared by pectase and laccase, and the weight ratio of the compound enzyme water solution and the jute is 12 : 1 to 40 : 1; the pH value of the compound enzyme water solution is firstly adjusted into 4.0 to 6.5, and the compound enzyme water solution is warmed up to 35 to 65 DEG C, and the temperature is kept for 20 to 120 minutes; and then pH value of the compound enzyme water solution is adjusted to more than 8.0 and less than and equal to 9.5, and the compound enzyme water solution is kept for 20 to 120 minutes at 14 to 70 DEG C; then the enzyme inactivation process is performed to the jute processed through the compound enzyme; secondly, jute fiber after being degumed is mixed with chemical fiber, and carding, mesh placement and needling are performed to the chemical fiber; thirdly, the mixed fiber after being needled is thermally pressed and molded; fourthly, a sleeve body is coated. The seat cushion manufacuted by the invention is soft and comfortable, has no urtication feeling when being used by people, and has good antibiosis and anti-acarine performance.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

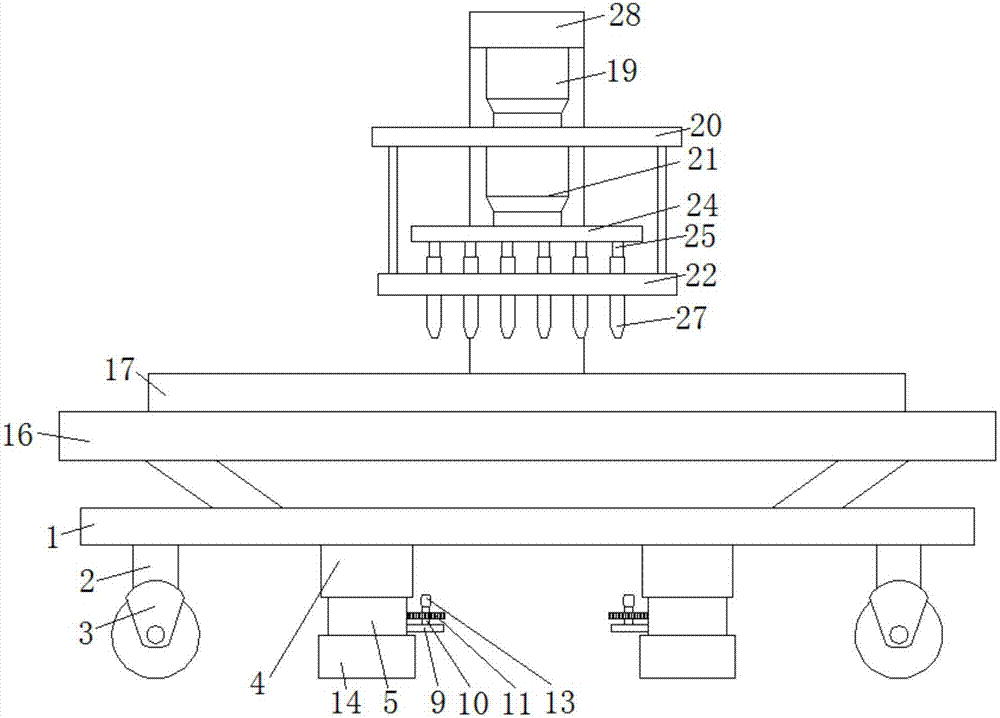

High-napping-efficiency needling machine

The invention discloses an acupuncture machine with high napping efficiency, comprising a base, the lower surface of the base is fixedly connected with supporting legs, the bottom end of the supporting legs is fixedly connected with universal wheels, the lower surface of the base A sleeve is also fixedly connected, and a fixed leg is inserted into the sleeve. The bottom of the inner wall of the fixed leg is clamped with a first bearing, and a threaded rod is inserted into the first bearing. The top of the inner wall of the sleeve The fixed connection has a threaded sleeve. In the present invention, the second hydraulic cylinder, the mounting plate, the mounting column, the frame, the threaded hole, the connecting body and the thread are provided, so that the second hydraulic cylinder drives the mounting plate to press down, so that the needle goes down for acupuncture. During the process, because the thread on the surface of the connecting body is engaged with the threaded hole, the needle will rotate, so that the needle will rotate during the lifting process, so that there will be greater friction between the needle and the fiber, so that the hooking efficiency will be higher. high.

Owner:梅明会

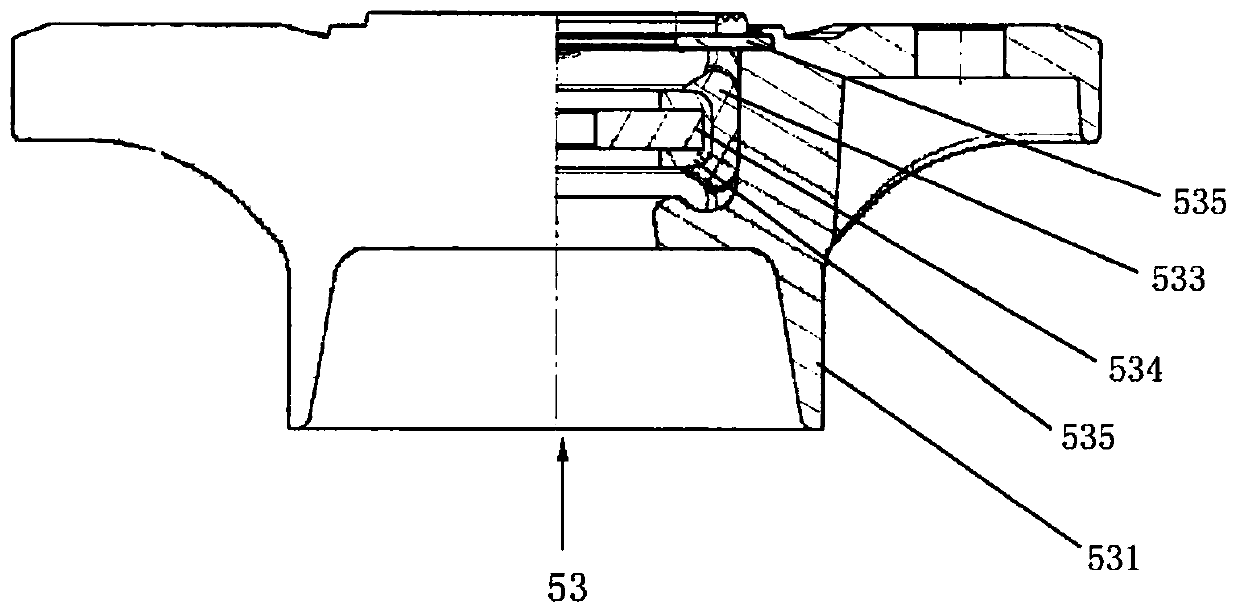

Blueberry punching machine

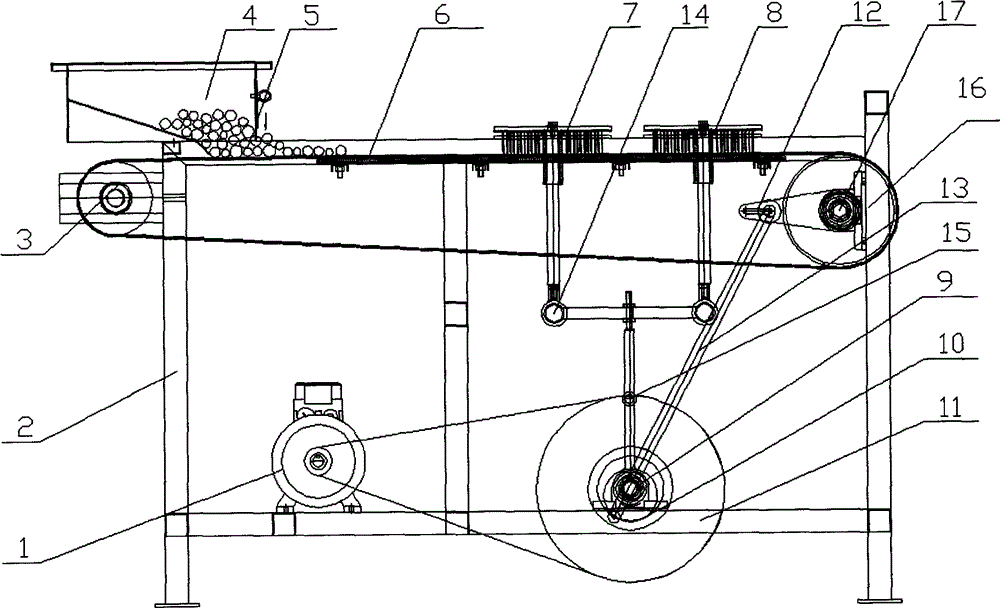

InactiveCN104921275AImprove acupuncture effectIncrease productivityFood treatmentClutchCherry tomato

The invention relates to a blurry punching machine comprising a rack, a transmission motor, a belt wheel, an eccentric wheel and a belt conveying device, and further comprising a puncturing device and an eccentric device. The puncturing device and the eccentric device are connected with each other via an adjusting rod; the belt conveying device is connected with the eccentric wheel via a cranked rod; the belt conveying belt is fixed over the rack; the transmission motor is connected with the belt wheel via a belt; and the belt wheel, the eccentric device and the eccentric wheel are connected to the same connection shaft; plenty of stainless steel and steel material is employed, so the blueberry punching machine possesses long service life; an edible PP type belt is employed for the conveying belt, so the machine is healthy, safety and durable; besides, with the first puncture rack and the second puncture rack as well as cooperation between the clutch and the eccentric wheel, and rational control on conveying speed of the conveying belt, production efficiency can be improved; the blueberry punching machine is rationally designed and multi-purposed; and the machine can be suitable for processing of fruits such as cherry tomatoes and large scale promotion.

Owner:NINGBO YIHONG FOOD MACHINERY CO LTD

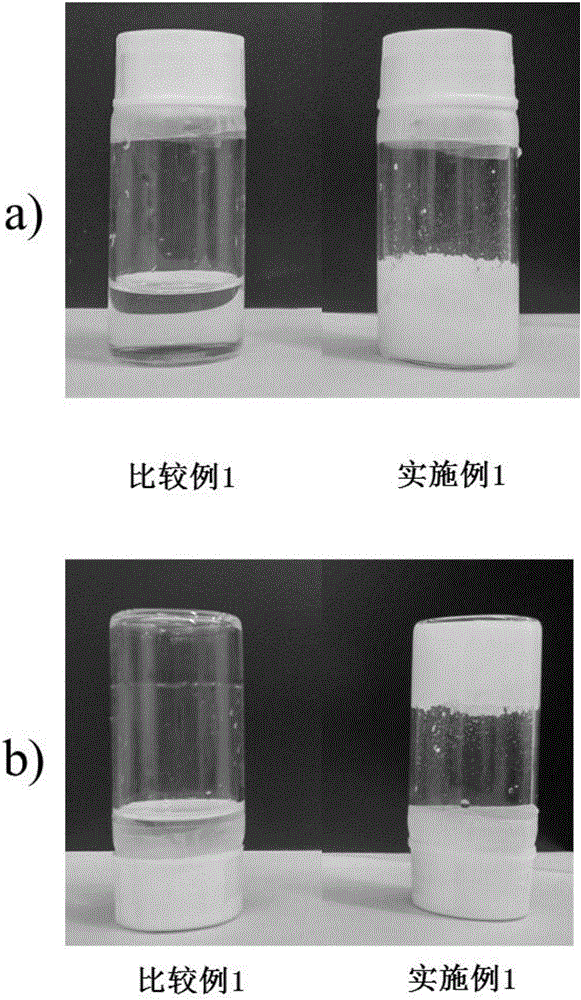

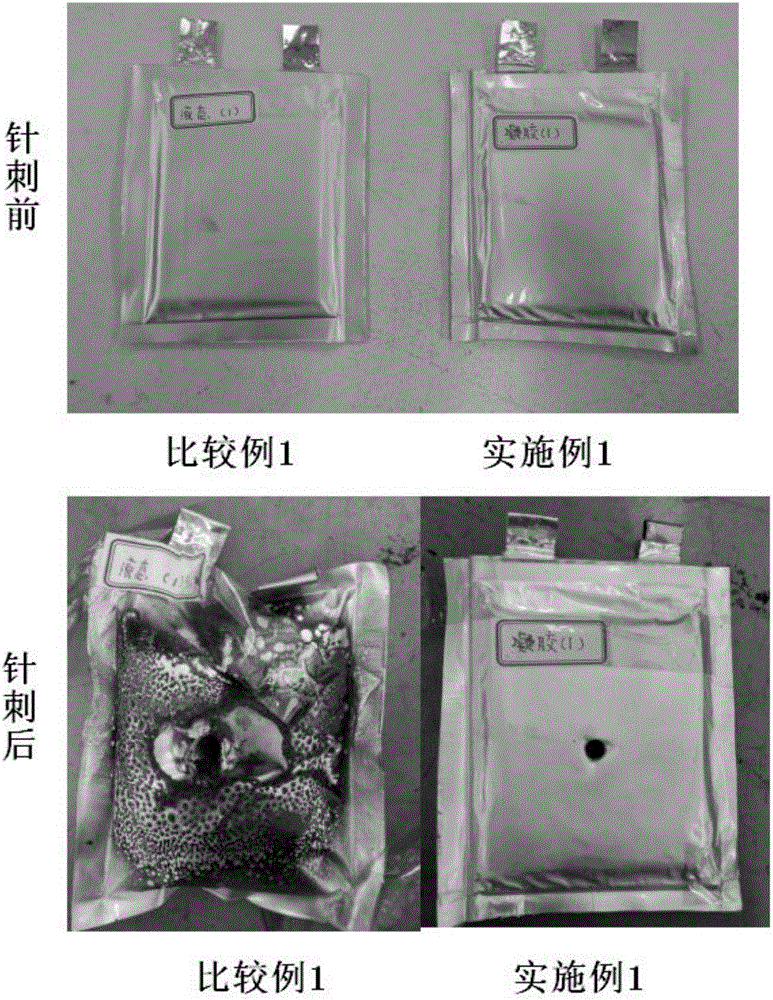

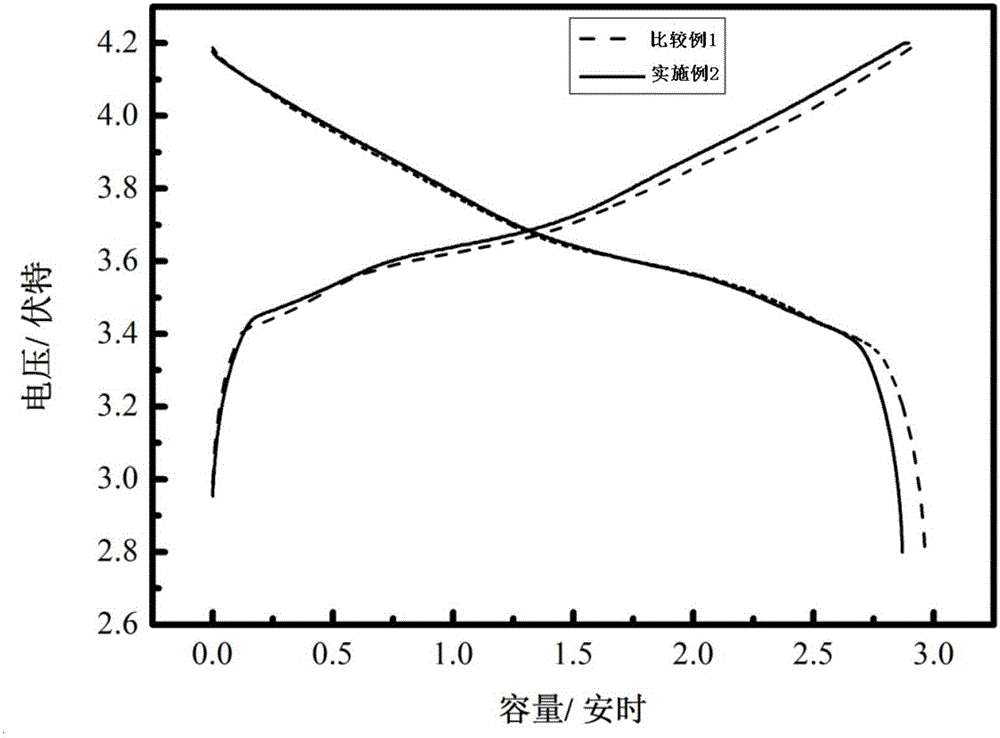

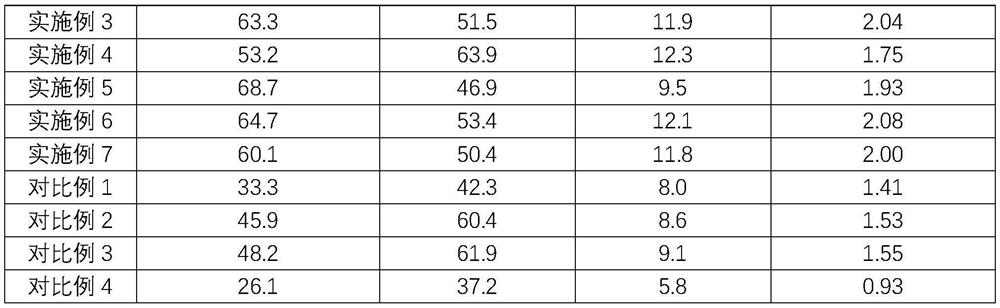

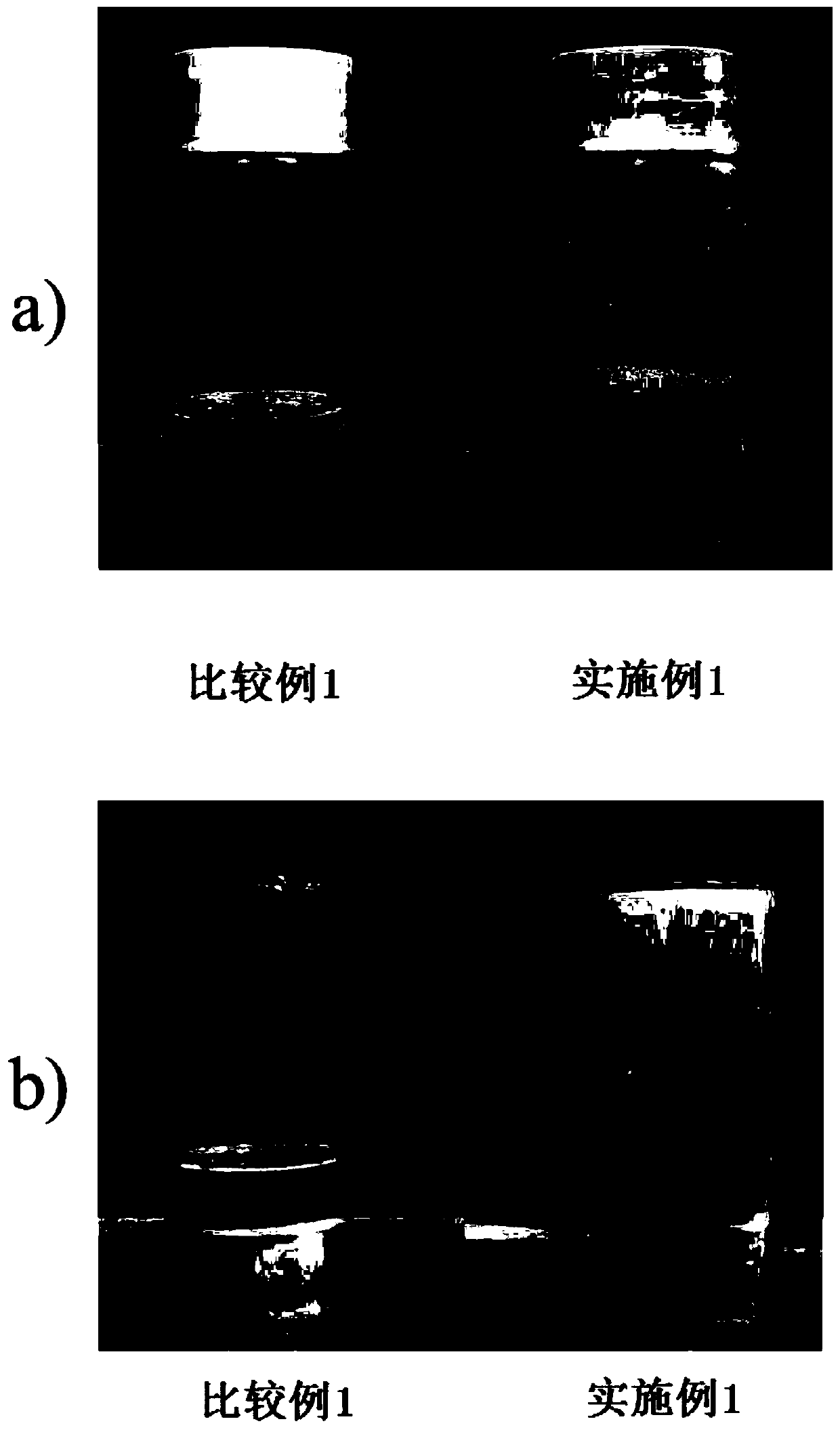

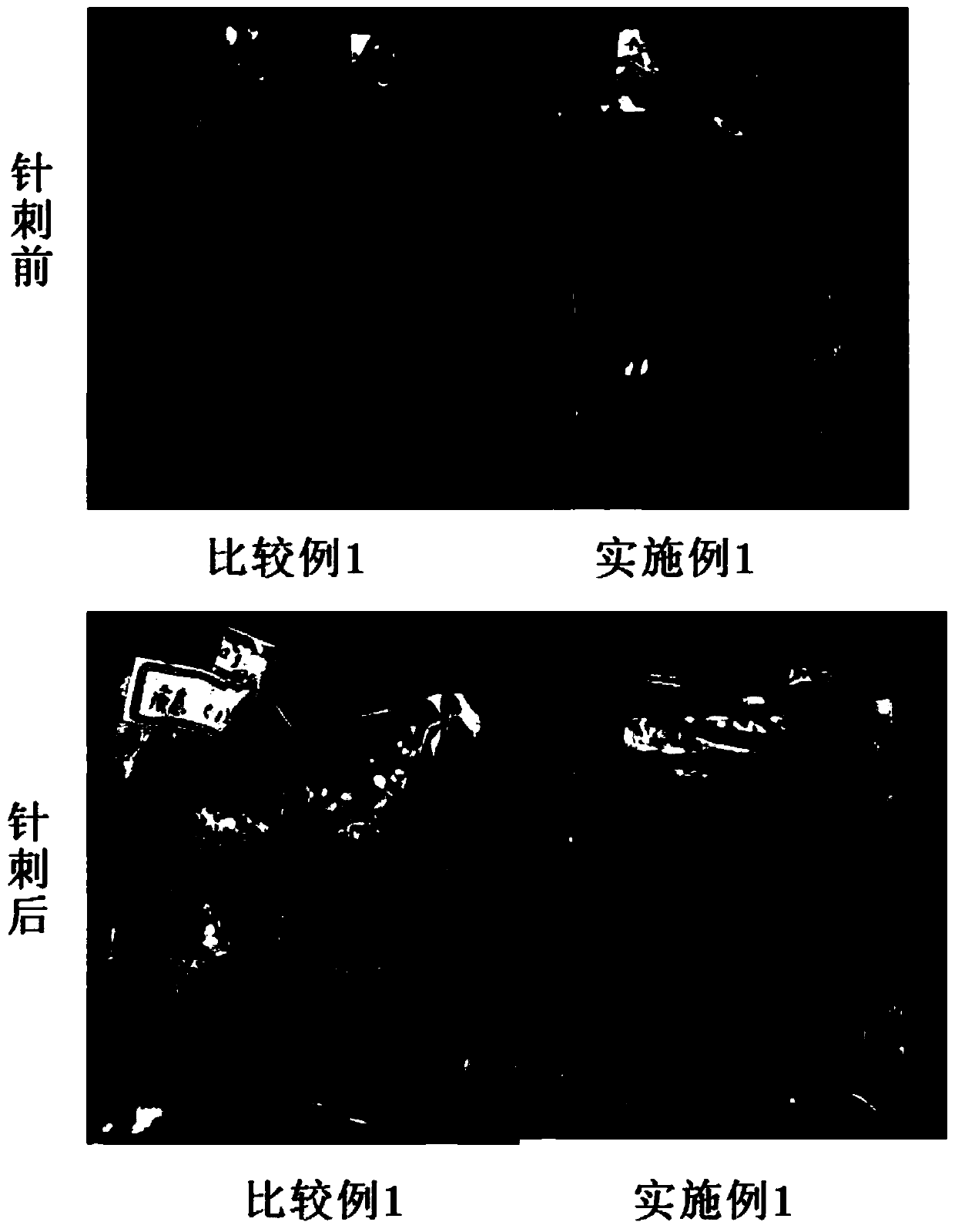

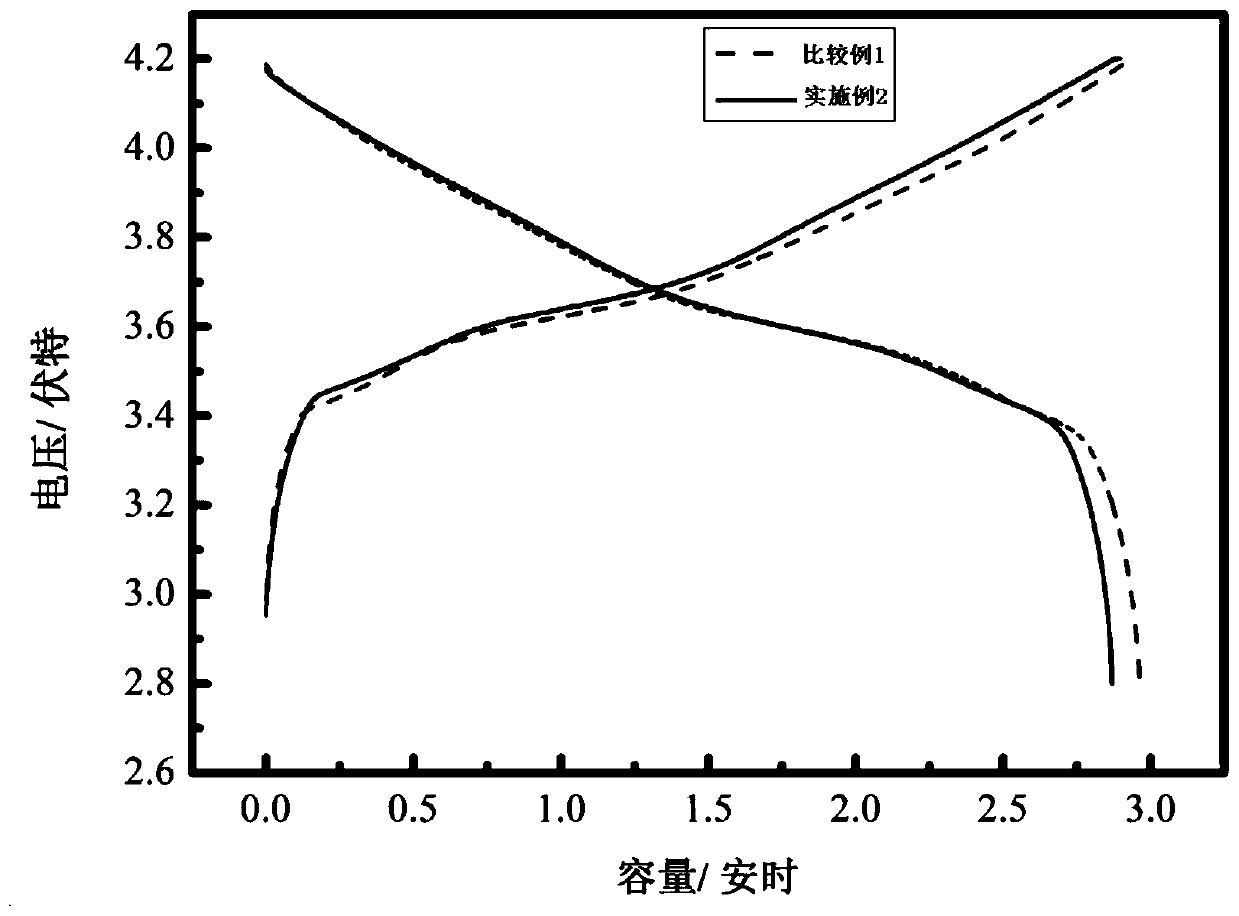

Electrolyte and lithium-ion battery

ActiveCN107180998AIncrease viscosityAvoid potential leaksSecondary cellsSolid state electrolyteSilanes

The invention provides electrolyte which is prepared from 0.5 to 4mol / L inorganic lithium salt, 3 to 15wt% of silane modified inorganic filler and solvent, wherein silane used by the silane modified inorganic filler is YSiX3, the Y is chosen from alkyl, oxo alkyl, amino or phenyl, and the X is chosen from alkyl or alkoxy; inorganic filler used by the silane modified inorganic filler is chosen from one or several of silicate, carbonate, carbide, sulfate, sulfide, titanate, oxide, hydroxide and metal inorganic filler. The electrolyte disclosed by the invention is semi-solid state or quasi-solid state electrolyte. Silane modified aluminum oxide is added into the electrolyte disclosed by the invention to improve viscosity of liquid state electrolyte, reduce solution fluidity and avoid the hidden danger that liquid state solution is prone to leaking; furthermore, battery safety is improved; the electrolyte can bear higher voltage. The invention further provides a lithium ion battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Anti-blockage needle machine

ActiveCN109629120AImprove acupuncture effectEasy to moveDirt cleaningCleaning using toolsFiberEngineering

The invention relates to the field of non-woven fabrics, in particular to an anti-blockage needle machine. The anti-blockage needle machine comprises a rack, a conveying belt, a screen stripping plateand a motor are arranged on the rack, and the screen stripping plate is provided with needle holes, an operation box and a supporting plate; a supporting platform, a sliding groove, a first rack anda spring are arranged on the supporting plate, a supporting arm is arranged on the first rack, and a hairbrush is arranged on the supporting arm; the first rack is meshed with a first gear, the firstgear is coaxially connected with a rotary shaft, and the rotary shaft is coaxially connected with a second gear; an output shaft of the motor is coaxially connected with a crank shaft, the crank shaftis provided with a first connecting rod and a second connecting rod, and a first pressing plate is arranged on the first connecting rod; a second pressing plate is arranged on the second connecting rod, an L-shaped plate is fixedly connected with the top of the pressing plate and provided with a connecting plate, a second rack is arranged on the connecting plate, and puncture needles are arrangedon the first pressing plate and the second pressing plate. By adopting the anti-blockage needle, the problems in the prior art that fiber flocks on the puncture needles cannot be effectively removed,therefore through holes of the screen stripping plate are blocked, and the effect of puncturing cloth by the needles is poor are solved.

Owner:象山平悦环保科技有限公司

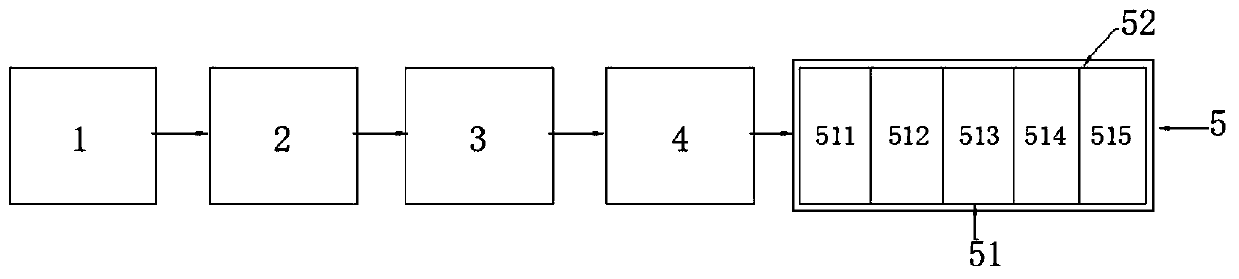

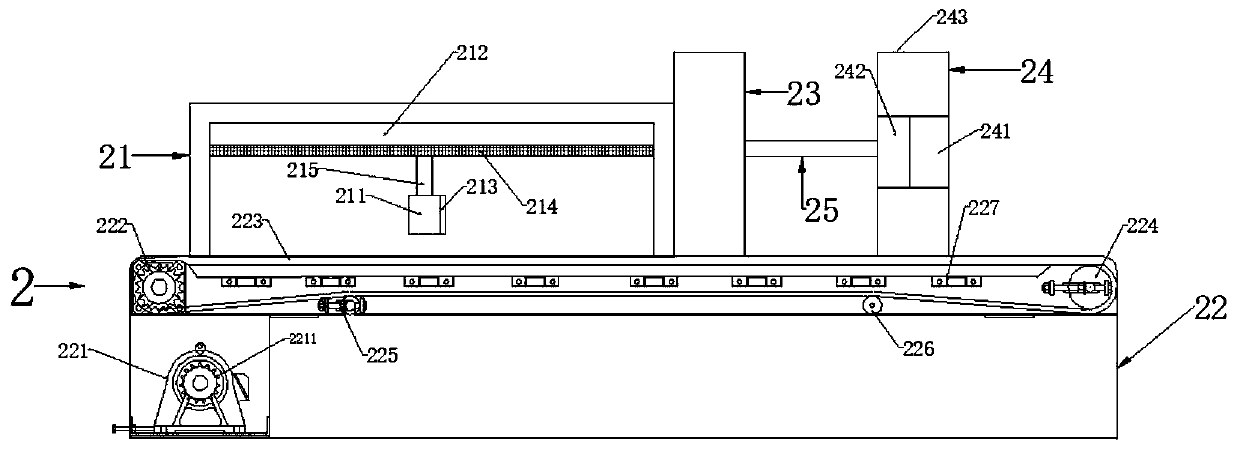

Needle punching production line equipment and production process thereof

InactiveCN110438667AHigh degree of automationSimple structureMeasurement devicesSevering textilesProduction linePunching

The invention relates to needle punching production line equipment and a production process thereof. The needle punching production line equipment comprises a pre-needle punching machine, a detectingmachine, a longitudinal cutting machine, a web turning machine and a main needle punching unit which are sequentially connected, wherein the detecting machine comprises a scanning mechanism, a transmission mechanism, a motor mechanism and a control mechanism, the transmission mechanism is arranged below the scanning mechanism, the motor mechanism is arranged on one side of the scanning mechanism,and the motor mechanism is connected with the control mechanism through an RS data line. The needle punching production line equipment and the production process thereof have the advantages that the equipment integrating pre-needle punching, detecting, cutting, web turning and main needle punching is high in automation level, simple in structure, convenient to mount and debug, high in system operating flexibility, stable, reliable and good in needle punching effect; the production process is simple, capable of achieving online composite one-step production, capable of saving cost, capable of increasing economic benefits and capable of effectively increasing needling punching efficiency and quality.

Owner:苏州鸿源特种纤维制品有限公司

Non-woven fabric needling machine

PendingCN110552116AReduce accumulationQuality improvementCleaning using toolsNeedling machinesNonwoven fabricWoven fabric

The invention discloses a non-woven fabric needling machine which structurally comprises transverse frames, machine bodies, a transmission box, a motor and a needling structure. The transverse framesare horizontally installed between the machine bodies and welded to the machine bodies. The transmission box is horizontally installed between the transverse frames and mechanically connected with thetransverse frames. The motor is installed at the upper end of the transmission box and matched and connected with the transmission box through a chain. The needling structure is arranged on the lowerside of the transmission box and mechanically connected with the transmission box. The needling structure comprises lower buffer cylinders, a fixed needling mechanism, upper buffer cylinders, a connecting frame and a driving rod. The lower buffer cylinders are installed at the lower end of the fixed needling mechanism at equal intervals. The upper buffer cylinders are vertically installed at theupper end of the fixed needling mechanism. The connecting frame is horizontally installed at the upper end of the fixed needling mechanism and welded to the fixed needling mechanism. By arranging a movable needling structure at the upper end of a limiting structure, multi-station circulating needling work is realized, fiber is cleaned up in the transferring process, fiber accumulation is reduced,the needling effect is improved, and the quality of a whole non-woven fabric is improved.

Owner:冯家富

Method for improving fiber textile product quality

ActiveCN108611768AImprove product qualityImprove acupuncture effectCleaning using toolsNeedling machinesFiberEngineering

The invention relates to the technical field of textile, in particular to a method for improving fiber textile product quality. The method comprises the steps of S1-S3, and a needling machine adoptedby the method comprises a supporting mechanism, a needling mechanism, a gear box, a feeding mechanism and a discharging mechanism, and further comprises a dust removal mechanism, a dust collecting mechanism and a linkage mechanism. The method for improving the fiber textile product quality has the advantages that the linkage mechanism can vertically move synchronously with the needling mechanism,thereby driving a driving gear to rotate through a toothed plate, so that a transmission gear and a rotary disk rotate synchronously, a hairbrush can continuously scrap a needle body to scrap off dust, cotton wools, thread residues and other waste adhered on the surface of the needle body, thereby achieving the automatic cleaning of the needle body; when the needling mechanism vertically moves, the rotary disk can be driven to rotate clockwise and anticlockwise, so that the hairbrush can clean the needle body from two directions; the dust collecting mechanism can collect the removed waste onto a filter plate, thereby avoiding the waste from drifting in air or falling onto a product, so that the collection and cleaning of the waste are more convenient and fast.

Owner:海安海顺化纤有限公司

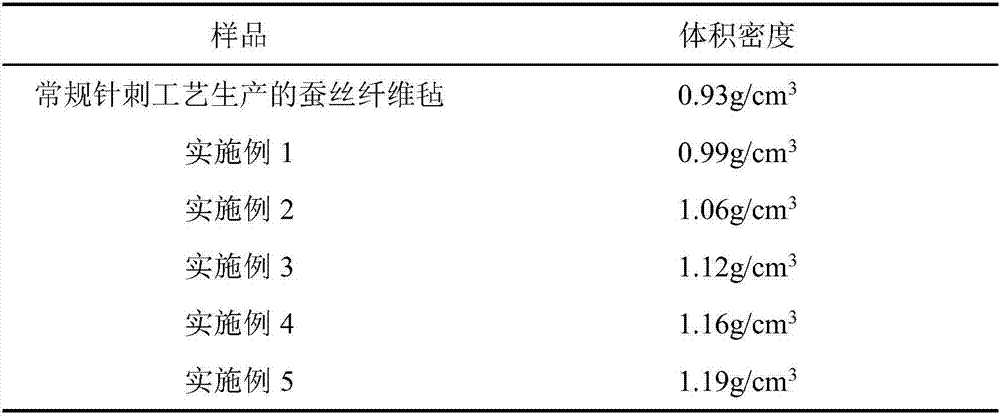

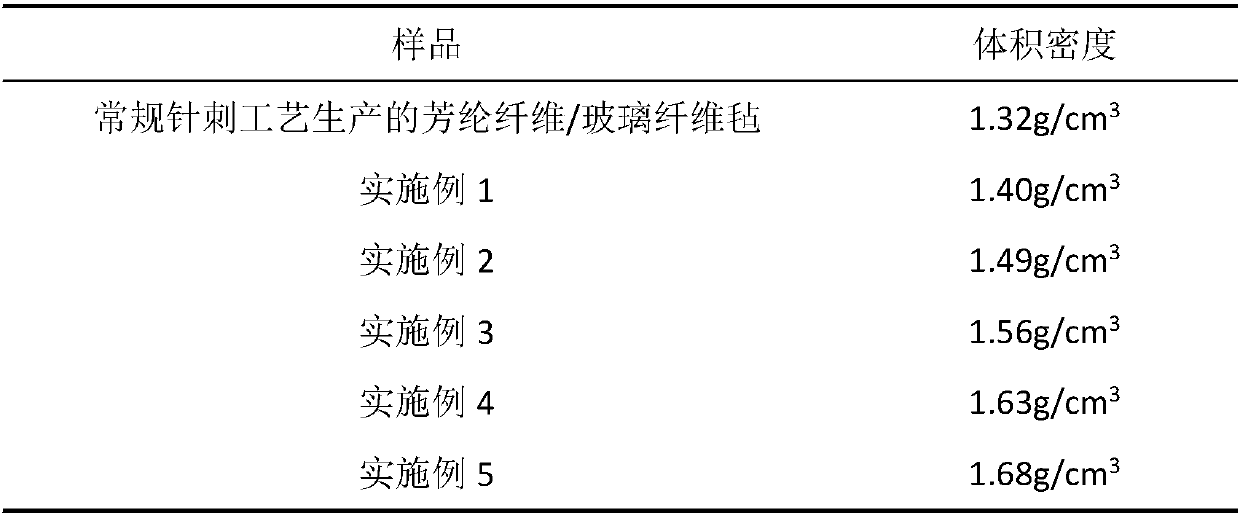

Method for decreasing needling density of silk fiber mats

InactiveCN107574573AReduce voidsFitting effect is obviousNon-woven fabricsCardingVolumetric Mass Density

The invention belongs to the technical field of textile processing and relates to a method for decreasing needling density of silk fiber mats. The method includes: under a negative pressure condition,performing negative-pressure adsorption on a fluffy silk fiber net, subjected to opening, carding and lapping, passing through a needling platform, wherein the adsorbed silk fiber net is contracted towards a negative-pressure operating direction to make the silk fiber net compact; enabling needles on an upper needling plate above the needling platform to perform needling on the silk fiber net. Bythe negative-pressure adsorption effect on silk fiber bundles under the negative-pressure condition, the problem of fluffiness of the silk fiber net due to softness and low density of silk fibers issolved, needling density is decreased on the premise of equal silk fiber mat volume density, silk fiber net conveying speed and needling frequency, and accordingly silk fiber mat needling efficiency and finished product quality are improved, and production cost is reduced.

Owner:WUHAN TEXTILE UNIV

Method for reducing needling density of polyimide fiber felt

ActiveCN107558001AOvercoming fluffy problemsImprove acupuncture efficiencyNon-woven fabricsFiber bundleNeedle position

The invention relates to a method for reducing the needling density of a polyimide fiber felt, and belongs to the technical field of textile processing. According to the method, a fluffy polyimide fiber mesh after opening, combing and lapping is subjected to negative pressure adsorption when passing a needling table under the condition of negative pressure, and the adsorbed polyimide fiber mesh retracts in a negative pressure running direction, so that the polyimide fiber mesh is compact. Besides, an upper needling plate needle positioned on the needling table performs needling on the retracted polyimide fiber mesh. The negative pressure adsorption action on polyimide fiber bundles by the negative pressure solves the problem of fluffy property of the polyimide fiber mesh due to low moisture regain and poor static electricity resistance of polyimide fibers, on the premise of similarity of the volume density of the polyimide fiber felt and the conveying speed and the needling frequency of the polyimide fiber mesh, the needling density is reduced, so that the needling efficiency and the final product quality of the polyimide fiber felt are improved, and production cost is reduced.

Owner:WUHAN TEXTILE UNIV

Anti-blocking needling machine capable of avoiding influence of fiber flock

InactiveCN113550080AReduce needling timeImprove acupuncture effectNeedling machinesFiberStructural engineering

The invention discloses an anti-blocking needling machine capable of avoiding influence of fiber flock, and belongs to the field of needling machines. The anti-blocking needling machine comprises a support; a bottom plate is fixedly mounted in the middle of the top end of the support; guide vertical rods are fixedly mounted at four corners of the top end of the bottom plate; a top plate is fixedly mounted at the top ends of the guide vertical rods; the guide vertical rods are provided with anti-blocking mechanisms which are symmetrically distributed up and down; the anti-blocking mechanisms are provided with needling mechanisms; the two sets of needling mechanisms are of a symmetrical distribution structure; and the two sides of the bottom plate and the two sides of the top plate are fixedly provided with U-shaped protection frames. According to the invention, the two sets of needling mechanisms which are symmetrically distributed up and down are arranged, and a driving assembly is used in cooperation; multiple sets of needling needles in two sets of needling assemblies distributed up and down are distributed in a staggered mode; materials are needled at the same time through the two sets of needling assemblies, so that the needling time of the materials is shortened; and the materials can be needled up and down in a staggered mode, so that the needling effect of the needling machine on the materials is effectively improved.

Owner:合肥经新科技有限公司

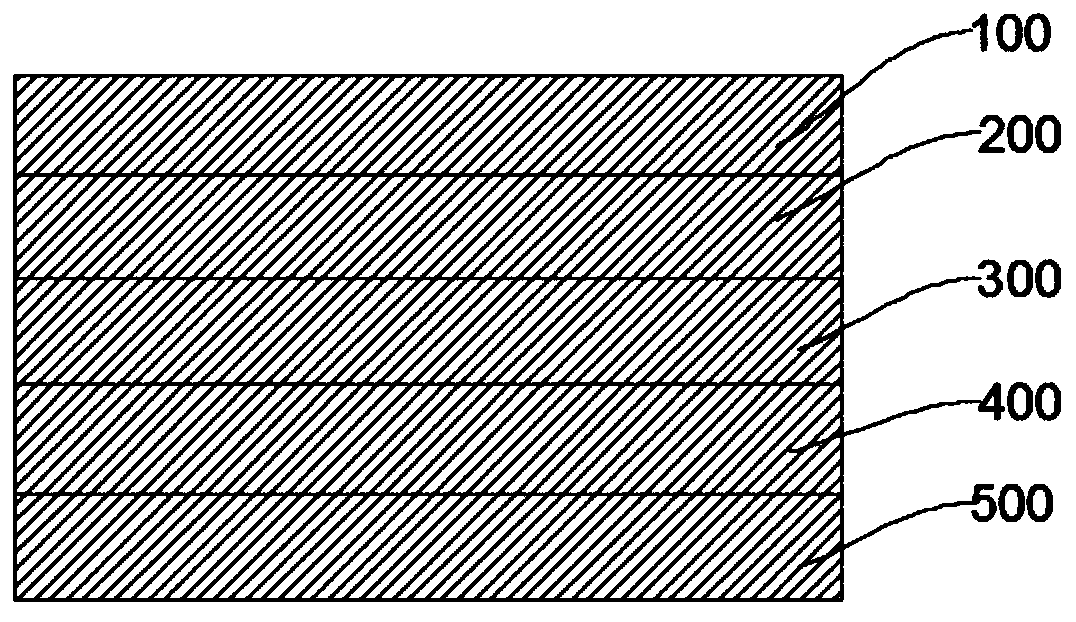

Light conversion film, multilayer light conversion film and preparation method of multilayer light conversion film

InactiveCN111002682APromote absorptionIncreased content of photosynthesis productsClimate change adaptationSynthetic resin layered productsUltraviolet lightsInsect pest

The invention relates to a thin film and a preparation method thereof, in particular to a light conversion film, a multilayer light conversion film and a preparation method of the multilayer light conversion film. The light conversion film comprises a film body and a light conversion film layer, and the light conversion film layer comprises, by weight, 18%-22% of a light conversion agent, 55%-60%of an organic carrier, 13%-15% of a light stabilizer and 9%-12% of an antioxidant, wherein the film body comprises 60%-75% of a film matrix, 12%-20% of a light stabilizer and 10%-20% of an antioxidant; according to the method provided by the invention, by adding the light conversion agent, ultraviolet light in sunlight can be converted into red light, absorption of plants on nutrient elements suchas nitrogen, phosphorus, potassium and zinc is promoted, the content of photosynthesis products in leaves is increased, crop growth is promoted, and meanwhile, the effect of reducing diseases and insect pests is achieved.

Owner:徐蕾

Tough needle-punched non-woven fabric

ActiveCN112064148APrevent clogging of drawing nozzleGood strengthConjugated synthetic polymer artificial filamentsArtifical filament manufactureProtein proteinPeptide

The invention belongs to the technical field of non-woven fabrics, and particularly relates to a tough needle-punched non-woven fabric. The tough needle-punched non-woven fabric comprises PET slices,polyhexamethylene adipamide, gum rosin, protein additives, amino silicon oil, a polymerizing agent and a polycarboxyl carboxylic acid compound. Thetough needle-punched non-woven fabric is prepared through the steps of S1, drying, S2, melting, S3, yarn drawing, S4, yarn swaying and S5, needle punching. According to the invention, the protein additives are added into a PET / PA66 blended system, so that the compatibility is improved, and blended fibers are better in toughness and strength; and meanwhile, the gum rosin and the amino silicon oil are added, the gum rosin and the amino silicon oil canbe used as bridges for connecting short peptides, more double bonds exist in the gum rosin and can react with sulfydryl, the difficulty of mutual connection between the short peptides is greatly reduced, the amino silicon oil is relatively long in molecular chain and large in effect taking range, and the spraying speed can be increased under the condition of keeping a filament body state, so thatthe yield is increased.

Owner:恒兆(湖北)新材料科技股份有限公司

A method for improving the quality of fiber fabric products

ActiveCN108611768BImprove product qualityImprove acupuncture effectCleaning using toolsNeedling machinesFiberEngineering

The invention relates to the field of textile technology, specifically a method for improving the quality of fiber fabric products, including S1 to S3. The acupuncture machine used in this method includes a support mechanism, acupuncture mechanism, gearbox, feeding mechanism and discharging mechanism. The mechanism also includes a dust removal mechanism, a dust collection mechanism and a linkage mechanism; the linkage mechanism of the present invention can move up and down synchronously with the acupuncture mechanism, thereby driving the driving gear to rotate through the tooth plate, thereby causing the transmission gear and the turntable to rotate synchronously, and the brush can continuously Scrape the needle body to remove dust, lint, thread and other waste attached to the surface of the needle body to realize automatic cleaning of the needle body; during the up and down movement of the acupuncture mechanism, it can drive the turntable to rotate forward and reverse, making the brush The needle body can be cleaned from two directions; the removed dirt can be collected on the filter plate through the dust collection mechanism to prevent it from flying into the air or falling on the product, making the collection and cleaning of dirt more convenient.

Owner:海安海顺化纤有限公司

Self-healing non-woven fabric

ActiveCN112030356BHigh tensile strengthIncrease stickinessSpinning solution de-aeratingFibre typesPolymer scienceSpinning

The invention belongs to the technical field of non-woven fabrics, in particular to self-repairing non-woven fabrics, including PET slices, acrylamide-maleic anhydride-acrylic acid copolymer, turpentine, cuprous chloride, melamine, through S1. drying, S2. Processing, S3. Melting, S4. Drawing, S5. Swinging, S6. Acupuncture to make self-healing non-woven fabric. The present invention has the following advantages: 1. by adding acrylamide-maleic anhydride-acrylic acid copolymer and cuprous chloride, the non-woven fabric made has self-repairing properties; 2. adding turpentine and melamine simultaneously can reduce the Melt viscosity makes spinning smoother, on the other hand, it can make the combination between acrylamide-maleic anhydride-acrylic acid copolymer and PET better, making the final spinning consistency stronger; 3. Add cementation The binder and the toughening agent, the cementing agent improves the internal mutual bonding force of the fiber web, and the toughening agent can improve the tensile effect of the thread.

Owner:恒兆(湖北)新材料科技股份有限公司

Method for manufacturing seat cushion with jute fibre

ActiveCN101172571BGood puffing effectImprove acupuncture effectUpholstery fillingFibre treatment to obtain bast fibrePectinaseAntibiosis

The invention relates to a manufacturing method of a seat cushion made of jute fiber. The method comprises the following steps: firstly, the soaking is performed to jute in compound enzyme water solution prepared by pectase and laccase, and the weight ratio of the compound enzyme water solution and the jute is 12 : 1 to 40 : 1; the pH value of the compound enzyme water solution is firstly adjusted into 4.0 to 6.5, and the compound enzyme water solution is warmed up to 35 to 65 DEG C, and the temperature is kept for 20 to 120 minutes; and then pH value of the compound enzyme water solution is adjusted to more than 8.0 and less than and equal to 9.5, and the compound enzyme water solution is kept for 20 to 120 minutes at 14 to 70 DEG C; then the enzyme inactivation process is performed to the jute processed through the compound enzyme; secondly, jute fiber after being degumed is mixed with chemical fiber, and carding, mesh placement and needling are performed to the chemical fiber; thirdly, the mixed fiber after being needled is thermally pressed and molded; fourthly, a sleeve body is coated. The seat cushion manufacuted by the invention is soft and comfortable, has no urtication feeling when being used by people, and has good antibiosis and anti-acarine performance.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Flame-retardant explosion-proof solid-state battery with stable polymer and ceramic electrolyte components

PendingCN113725486AImprove dispersion uniformityImprove acupuncture effectFire rescueLi-accumulatorsElectrical batteryPhysical chemistry

The invention relates to a flame-retardant explosion-proof solid-state battery with stable polymer and ceramic electrolyte components, and belongs to the technical field of lithium batteries. An electrolyte mixed solution added with nano aluminum oxide particles is prepared into a mixed solution which is uniformly dispersed and is high in stability through a high-speed dispersion method of a high-end battery pole piece pulping project. The innovative and practical method greatly improves the dispersity of the slurry after the nano aluminum oxide particles are added into the electrolyte to form the mixed solution with uniformly dispersed aluminum oxide particles, and the mixed solution is stable and does not precipitate. Under the condition that the electrical performance of the lithium battery is not influenced, the safety flame-retardant problems of full-power acupuncture, extrusion, thermal abuse and the like can be greatly improved and solved.

Owner:慈溪斯昂尼电池有限公司

A sealing material that blocks the passage of rodents and vermin

ActiveCN104542568BSo as not to damageImprove toughnessLamination ancillary operationsLaminationMetal fiberCarding

The invention provides a sealing material for preventing rodents and pests from passing through and a manufacturing process of the sealing material. The sealing material comprises metal and chemical fiber mixture textile fabric and through holes, wherein stainless steel velvet cotton and flame-retardant chemical fibers are disorderly interwoven together to form the metal and chemical fiber mixture textile fabric. The manufacturing process comprises the steps that opening, carding, layer stacking, needling, baking and hot pressing are conducted on the metal and chemical fiber mixture textile fabric so that the finished sealing material can be obtained. The metal and chemical fiber mixture non-woven textile fabric manufactured through the manufacturing process is easy and convenient to install, operation can be conducted under the condition that no professional staff are required, and the metal and chemical fiber mixture non-woven textile fabric can be repeatedly used, and is free of waste and convenient to maintain.

Owner:SUZHOU DANGEWEI IND

A disorderly needling device for non-woven fabrics

The invention provides a disorderly needling device for a non-woven fabric. The device comprises a hollow cylinder body, wherein the cylinder body is driven by a drive device to rotate; felting needles are uniformly distributed on the cylinder body; each felting needle is divided into at least three needle sections which are mutually hinged; a structure for limiting the swing amplitude of the needle sections is arranged at a hinge joint of every two adjacent needle sections; a magnet is arranged on the needle section where a needle point of each felting needle is arranged; a second magnet for influencing the magnet is arranged inside or outside the cylinder body; and the magnet pole pointing direction or the magnetic strength of the second magnet changes consistently. According to the disorderly needling device for the non-woven fabric, the magnet pole pointing direction or the magnetic strength of the second magnet changes consistently, so that shapes of the felting needles change disorderly due to the fact that the felting needles are under the action of different angles and different forces, and the needling effect to the non-woven fabric is better.

Owner:SUZHOU HAOJIAN TEXTILE

Three-layer co-extrusion high heat preservation light conversion po film

ActiveCN108099326BHigh elongation at breakLow melting pointAgricultural articlesClimate change adaptationEngineeringHeat conservation

The invention discloses a three-layer co-extruded high-heat-preservation light-conversion PO film, and belongs to the field of agricultural greenhouse films. According to the invention, on the basis of a previous product, ethylene-vinyl acetate copolymer (EVA) is added into metallocene polyethylene (mPE), a light-conversion master batch is added into a middle layer, the formulas of an outer layer,the middle layer and an inner layer are different, the formulas of the outer layer, the middle layer and the inner layer are mixed uniformly respectively, master batches are prepared by using a two-thread worm double-screw extruder, a three-layer film extrusion is formed through a co-extrusion die head to prepare a PO agricultural greenhouse film, and water-based dripping fog-eliminating coatingliquid is coated outside the PO film. The film is anti-aging and free of fog drops, and excellent in puncture resistance and has a service life of 3 years or more. After inspection and testing by an authoritative department, all quality and technical indexes reach or exceed a national standard, some of which are more than twice as good as the national standard. The PO film is good in light-conversion effect, has a light conversion rate reaching 13% or more, is very beneficial to the growth of crops and shortens the growth period of the crops at the same time.

Owner:HENAN YINFENG PLASTIC

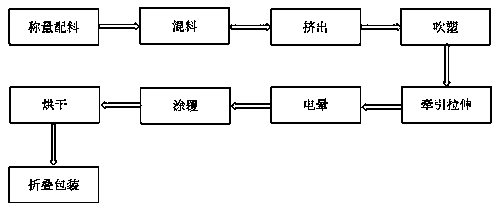

Negative-pressure needling method of aramid fiber/glass fiber mat

The invention relates to a negative-pressure needling method of an aramid fiber / glass fiber mat and belongs to the technical field of textile processing. The negative-pressure needling method of the aramid fiber / glass fiber mat comprises the steps that negative-pressure suction is conducted on a fluffy aramid fiber / glass fiber net undergoing opening, carding and lapping under the negative-pressurecondition when the fiber passes through the upper surface of a needling table, the sucked aramid fiber / glass fiber net shrinks in the negative-pressure operation direction, and an upper needling plate located above the needling table needles the shrunk aramid fiber / glass fiber net while the aramid fiber / glass fiber net shrinks. By adding a negative-pressure device, the needling times are decreased, and fiber damage caused by needling is decreased. Under the suction effect of negative pressure on aramid fiber / glass fiber bundles, the problem of low needling efficiency caused by fluffing of thefluffy aramid fiber / glass fiber net is solved, accordingly the needling efficiency and finished product quality of the fluffy aramid fiber / glass fiber mat are improved, and the production cost is reduced.

Owner:WUHAN TEXTILE UNIV

Needle machine for gigging non-woven fabric

InactiveCN104032488AImprove acupuncture effectTo achieve the fleece effectNeedling machinesNonwoven fabricUltimate tensile strength

The invention discloses a needle machine for gigging non-woven fabric. The needle machine comprises a frame, a case, a first needle plate, a second needle plate, needle bars, a conveying curtain, a plurality of barbs and telescopic rods. An opening slot is formed in the middle of the front end of the case. The conveying curtain is arranged in the opening slot and protrudes from the front end of the case by 30-60 cm. The telescopic rods are respectively arranged at the upper end of the first needle plate and the lower end of the second needle plate. The first needle plate and the second needle plate vertically move up and down through the telescopic rods. The barbs are uniformly obliquely distributed on the outer surfaces of the needle bars respectively. According to the arrangement, the needle bars and the barbs pierce the non-woven fabric to achieve effective and uniform needling effect of the non-woven fabric during needling, and leave the non-woven fabric to gig the same through the barbs. Thus working efficiency is greatly improved, labor intensity of workers is reduced, and requirement of company is met.

Owner:常熟市振泰不织布有限公司

A kind of electrolyte and lithium ion battery

ActiveCN107180998BIncrease viscosityAvoid potential leaksSecondary cellsSolid state electrolyteSilanes

The invention provides electrolyte which is prepared from 0.5 to 4mol / L inorganic lithium salt, 3 to 15wt% of silane modified inorganic filler and solvent, wherein silane used by the silane modified inorganic filler is YSiX3, the Y is chosen from alkyl, oxo alkyl, amino or phenyl, and the X is chosen from alkyl or alkoxy; inorganic filler used by the silane modified inorganic filler is chosen from one or several of silicate, carbonate, carbide, sulfate, sulfide, titanate, oxide, hydroxide and metal inorganic filler. The electrolyte disclosed by the invention is semi-solid state or quasi-solid state electrolyte. Silane modified aluminum oxide is added into the electrolyte disclosed by the invention to improve viscosity of liquid state electrolyte, reduce solution fluidity and avoid the hidden danger that liquid state solution is prone to leaking; furthermore, battery safety is improved; the electrolyte can bear higher voltage. The invention further provides a lithium ion battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for manufacturing insole with jute fiber

ActiveCN100591234CEfficient removalWeaken joint forceInsolesFibre treatment to obtain bast fibrePectinaseFiber

A method for manufacturing insoles by jute fibers comprises treating jute fibers with the complex enzyme de-gelatinizing, wherein, the complex enzyme de-gelatinizing treatment uses complex enzyme aqueous solution which is formulated by pectase and laccase to provide the de-gelatinizing treatment to jutes, adjusting the pH value of the complex enzyme aqueous solution to be more than or equal to 4.0but less than 5.0 when the complex enzyme de-gelatinizing treatment is carried out, elevating the temperature to 35 DEG C to 65 DEG C for 20-120 minutes, and then adjusting the pH value of the solution to be 7.5 to 9.5, keeping the temperature under 40 DEG C to 70 DEG C for 20-120 minutes, enzyme-devitalizating the jutes which are treated by the complex enzyme, mixing the de-gelatinized jute fibers with the chemical fibers, carding, net-spreading, and needling the mixed fibers, hot-pressing the needled mixed fibers and molding. The insole manufactured by the method of the invention is very comfortable when in use, and is not urticant in feeling when in use, good in bacteria repellency, not easily wormy, and strong in air permeability, hygroscopicity, and moisture character.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com