Needle punching production line equipment and production process thereof

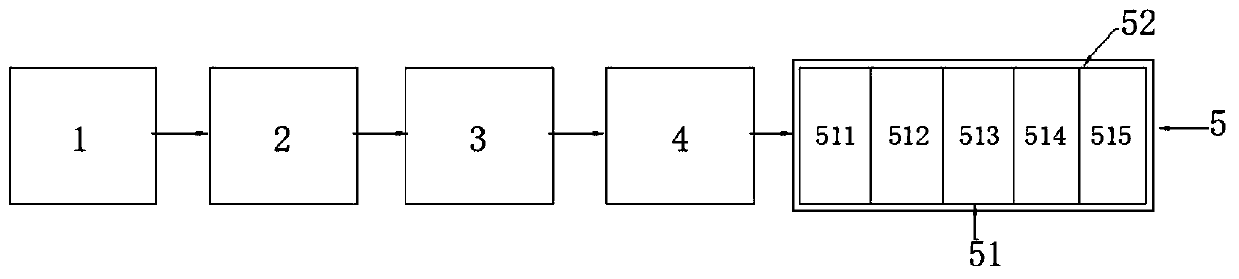

A technology of production line equipment and production process, which is applied in the field of acupuncture production line equipment and its production process, can solve the problems of incompleteness and perfection, and achieve the effects of reasonable equipment setting, cost saving and good acupuncture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] (1) Preliminary preparation: conduct a comprehensive and detailed inspection of the acupuncture production line equipment to confirm that there is no abnormality in the equipment;

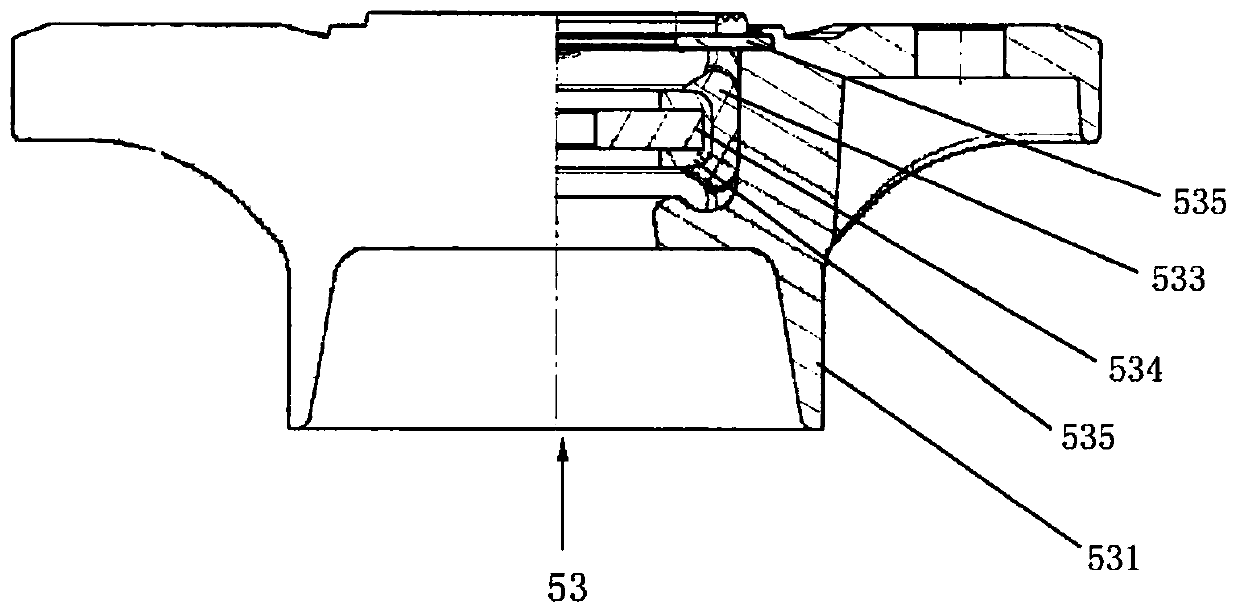

[0057] (2) Pre-acupuncture: The fiber web obtained by laying the web by the upstream web-laying machine enters the pre-acupuncture machine 1 for pre-acupuncture. The working width of the pre-acupuncture machine 1 is 5.3m, the acupuncture frequency is 1200 times / min, the needle plate density is 5000 / m, and the needles are 3.5-inch tapered needles;

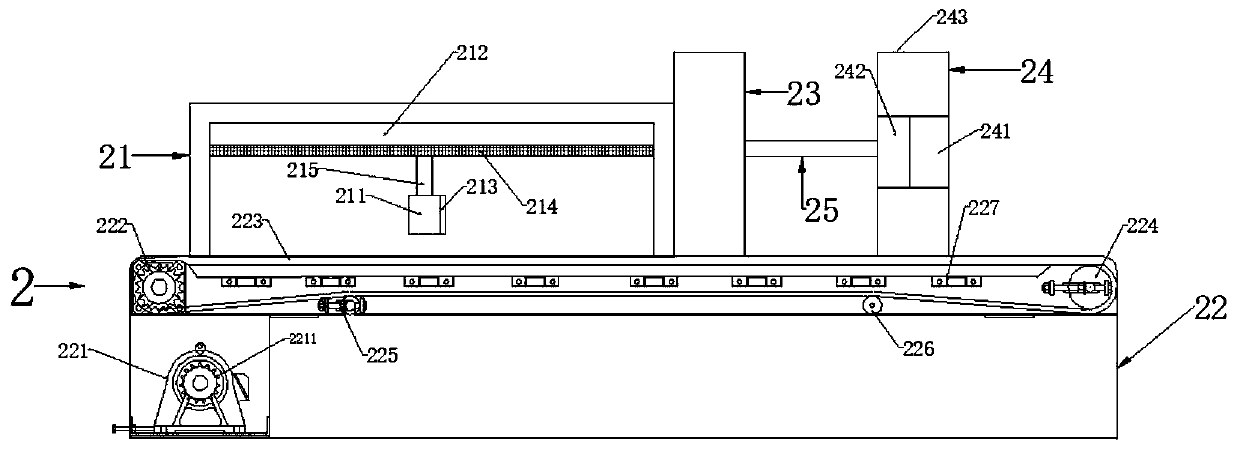

[0058] (3) Automatic detection: the fiber web reinforced in step (2) is transmitted by the transmission mechanism 22, and when the fiber web reaches the scanning mechanism 21, the fiber web is scanned, collected and scanned by the scanning mechanism 21. Process the thickness signal of the fiber web, and send it to the control mechanism 24 by the motor mechanism 23 through the RS data line 25, and the control mechanism 24 executes the vertical and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com