Needle machine

An acupuncture machine and acupuncture technology, applied in the direction of acupuncture machines, textiles, papermaking, non-woven fabrics, etc., can solve the problems of inconsistency in the speed of cotton feeding and cotton output, and the frequency of acupuncture, so as to avoid stab wounds and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the improvement made by the present invention compared with the prior art, the specific embodiments of the present invention will be described in detail below.

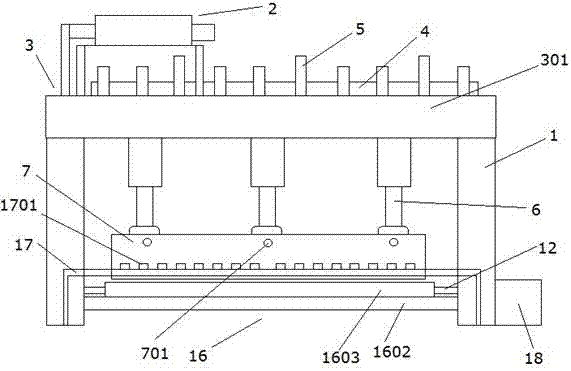

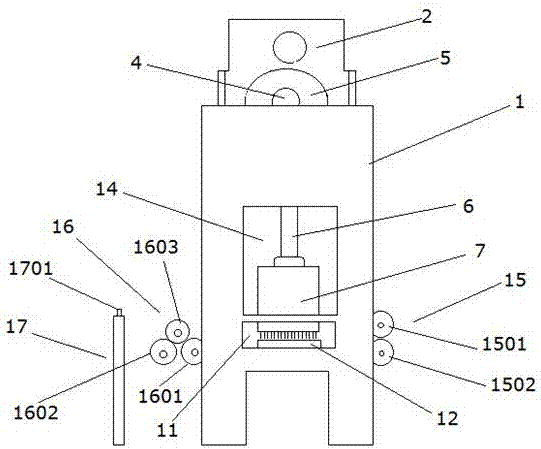

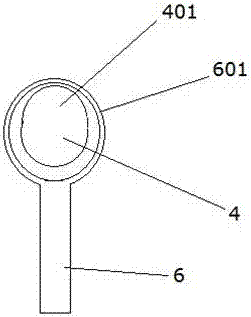

[0031] Such as figure 1 As shown, the acupuncture machine of the present invention includes a frame 1 and a main motor 2, the frame 1 is provided with a beam frame 3, and the beam frame 3 is composed of a first beam bar 301 and a second beam bar 302; Between the first beam bar 301 and the second beam bar 302, a rotating shaft 4 connected to the main motor 2 is provided; a semicircular weight 5 is installed on the rotating shaft 4; the rotating shaft 4. The card clothing shell 7 is connected with the connecting shaft 6, and the inside of the card clothing shell 7 is hollow, and a needle insertion plate 8 is embedded in it, such as Figure 6 As shown, the pin board 8 is stacked with detachable pressed parts 9, such as Figure 7 As shown; the pin plate 8 is densely covered with a pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com