Tough needle-punched non-woven fabric

A needle-punched non-woven fabric, tough technology, applied in textiles and papermaking, conjugated synthetic polymer artificial filament, fiber chemical characteristics, etc., can solve PET-wrapped PA66 pellets, difficult blending of modified resin, PET modification Difficulty and other problems, to achieve the effect of large effective range, prevent clogging of the drawing nozzle, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

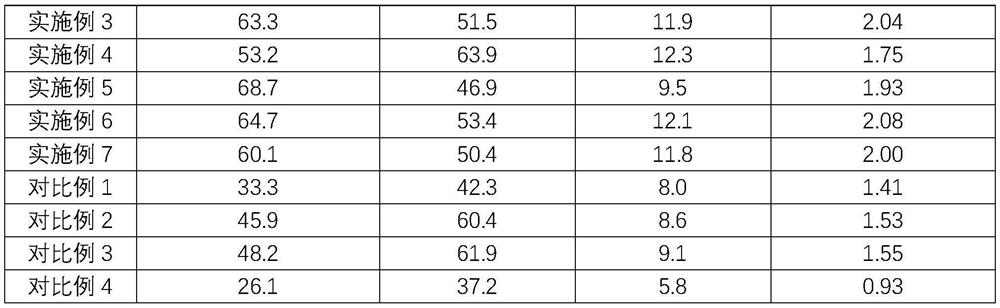

Examples

Embodiment 1

[0040] A preparation process for tough needle-punched non-woven fabrics, comprising the following steps:

[0041] S1. Drying: drying all raw materials until the final moisture content is less than 35ppm;

[0042] S2. Melting: Put 110 parts of PET chips, 26 parts of polyhexamethylene adipamide and 7.2 parts of gum rosin into the melting equipment to melt, add 2.5 parts of protein additives, 8.5 parts of amino silicone oil, and 1.3 parts of tetratitanate Butyl ester and maleic anhydride equivalent to 4.5 parts of acetic acid are stirred quickly evenly, and then filtered through a melt filter, and the filtration accuracy of the melt filter is 40 μm;

[0043] S3. Wire drawing: the melt obtained in the melting of S2 is drawn through the spinning box, and the filament bundle is cooled by side blowing while drawing, and the air humidity of the side blowing is controlled to be less than 50%;

[0044] S4. Spinning wire: break up the tow obtained in S3. drawing, and lay it on the trans...

Embodiment 2

[0051] A preparation process for tough needle-punched non-woven fabrics, comprising the following steps:

[0052] S1. Drying: drying all raw materials until the final moisture content is less than 35ppm;

[0053]S2. Melting: Put 100 parts of PET slices, 28 parts of polyhexamethylene adipamide and 5 parts of gum rosin into the melting equipment to melt, add 3 parts of protein additives, 6 parts of amino silicone oil, and 2.5 parts of tetratitanate Butyl ester and maleic anhydride equivalent to 3 parts of acetic acid are then filtered through a melt filter with a filtration accuracy of 40 μm;

[0054] S3. Wire drawing: the melt obtained in the melting of S2 is drawn through the spinning box, and the filament bundle is cooled by side blowing while drawing, and the air humidity of the side blowing is controlled to be less than 50%;

[0055] S4. Spinning wire: break up the tow obtained in S3. drawing, and lay it on the transmission mesh curtain;

[0056] S5. Acupuncture: the mesh...

Embodiment 3

[0062] A preparation process for tough needle-punched non-woven fabrics, comprising the following steps:

[0063] S1. Drying: drying all raw materials until the final moisture content is less than 35ppm;

[0064] S2. Melting: Send 120 parts of PET slices, 20 parts of polyhexamethylene adipamide and 8 parts of gum rosin into the melting equipment to melt, add 1.5 parts of protein additives, 18 parts of amino silicone oil, and 2 parts of tetratitanate Butyl ester and maleic anhydride equivalent to 5 parts of acetic acid are then filtered through a melt filter, and the filtration accuracy of the melt filter is 40 μm;

[0065] S3. Wire drawing: the melt obtained in the melting of S2 is drawn through the spinning box, and the filament bundle is cooled by side blowing while drawing, and the air humidity of the side blowing is controlled to be less than 50%;

[0066] S4. Spinning wire: break up the tow obtained in S3. drawing, and lay it on the transmission mesh curtain;

[0067] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com