A sealing material that blocks the passage of rodents and vermin

A sealing material and rodent technology, applied in the field of non-woven metal fabric sealing materials, can solve the problems of environmental pollution, metal fiber pilling, insufficient strength, etc., and achieve simple process flow, uniform thickness, and enhanced tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Cut the loose No. 3 434 stainless steel velvet cotton into 18cm long pieces;

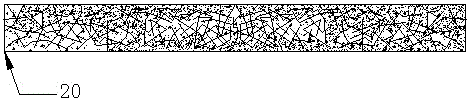

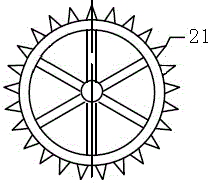

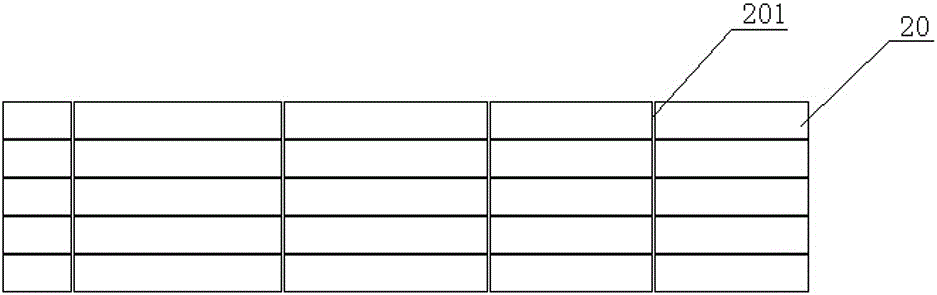

[0042] Step 2: Select a flat tendon belt with a thickness of 3mm and a width of 60mm to be placed on the conveyor 1. The ratio of stainless steel velvet cotton to flame-retardant chemical fiber is 6:2.5, and the conveyor belt 11 is driven by the conveyor 1 to cut into small pieces. No. 3 434 stainless steel velvet cotton and flame-retardant chemical fiber are sent into the opener 2 and opened for 5 minutes to obtain a mixed fabric 20 of metal and chemical fiber, such as figure 1 As shown, the tooth profile of the hob 21 on the opener 2 is adjusted to be conical, as figure 2 shown;

[0043] Step 3: send the mixed fabric 20 of metal and chemical fiber after opening and mixing into the cotton box 4 through the suction machine 3, the suction diameter of the suction machine 3 is 3.81cm, and the suction speed is 300kg / h;

[0044] Step 4: The metal and chemical fiber mixed fabric 20 outpu...

Embodiment 2

[0050] Step 1: Cut the loose No. 3 434 stainless steel velvet cotton into 19cm long pieces;

[0051] Step 2: Select a flat tendon belt with a thickness of 3mm and a width of 60mm to be placed on the conveyor 1. The ratio of stainless steel velvet cotton to flame-retardant chemical fiber is 6.5:2.8, and the conveyor belt 11 is driven by the conveyor 1 to cut into small pieces. No. 3 434 stainless steel velvet cotton and flame-retardant chemical fiber are sent into the opener 2 and opened for 8 minutes to obtain a mixed fabric 20 of metal and chemical fiber, such as figure 1 As shown, the tooth profile of the hob 21 on the opener 2 is adjusted to be conical, as figure 2 shown;

[0052] Step 3: send the mixed fabric 20 of metal and chemical fiber after opening and mixing into the cotton box 4 through the suction machine 3, the suction diameter of the suction machine 3 is 5cm, and the suction speed is 350kg / h;

[0053] Step 4: The metal and chemical fiber mixed fabric 20 output...

Embodiment 3

[0059] Step 1: Cut the loose No. 3 434 stainless steel velvet cotton into 20cm long pieces;

[0060] Step 2: Select a flat tendon belt with a thickness of 3mm and a width of 60mm to be placed on the conveyor 1. The ratio of stainless steel velvet cotton to flame-retardant chemical fiber is 7:3, and the conveyor belt 11 is driven by the conveyor 1 to cut into small pieces. No. 3 434 stainless steel velvet cotton and flame-retardant chemical fiber are sent into the opener 2 and opened for 10 minutes to obtain a mixed fabric 20 of metal and chemical fiber, such as figure 1 As shown, the tooth profile of the hob 21 on the opener 2 is adjusted to be conical, as figure 2 shown;

[0061] Step 3: send the mixed fabric 20 of metal and chemical fiber after opening and mixing into the cotton box 4 through the suction machine 3, the suction diameter of the suction machine 3 is 6.35cm, and the suction speed is 400kg / h;

[0062] Step 4: The metal and chemical fiber mixed fabric 20 output...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com