Graphite modified polystyrene solid lightweight concrete wallboard and preparation method thereof

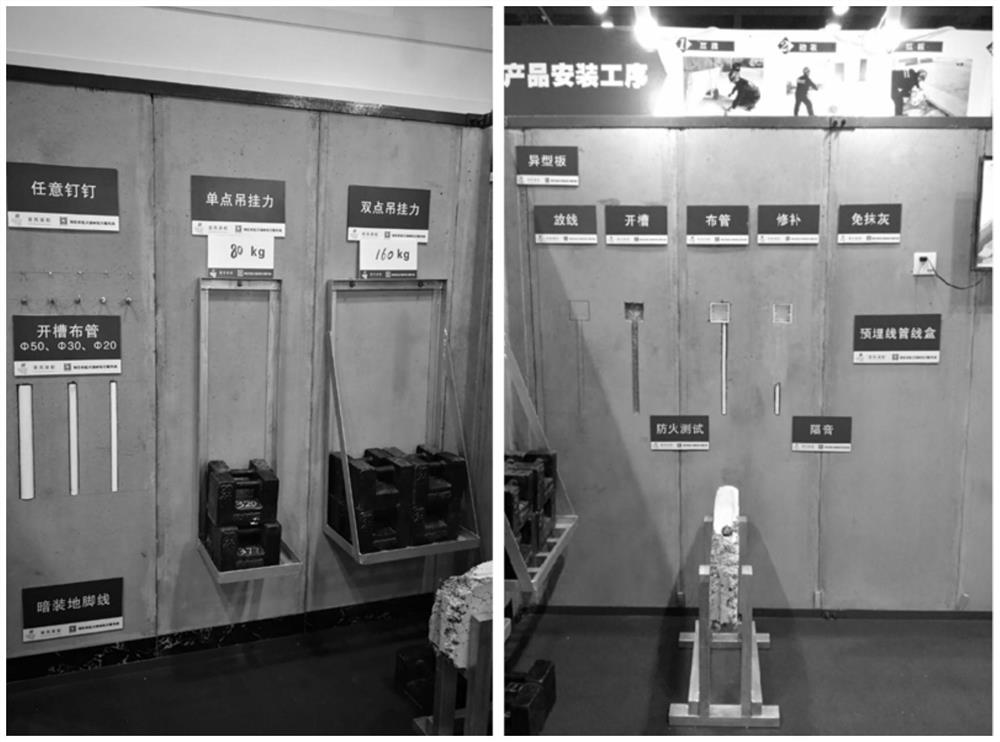

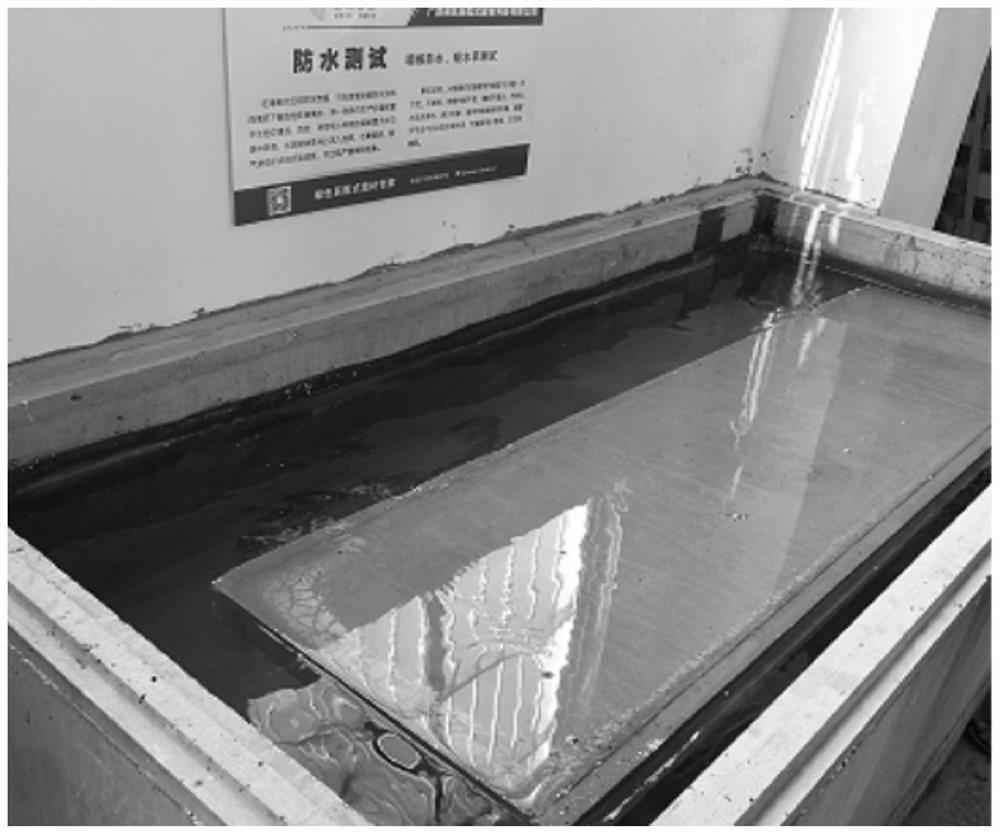

A technology of lightweight concrete and polystyrene, applied to walls, building components, buildings, etc., can solve problems such as mechanical property degradation, poor surface flatness, and insufficient nail-holding force, achieving good results, solving poor sound insulation, and solving problems The effect of bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the inventive concept and specific application of the present invention, the technical solutions of the present invention are explained and illustrated in detail below in conjunction with preferred embodiments. Of course, the listed embodiments do not limit the protection scope of the present invention. To limit.

[0041] Part I Preparation of Graphite Modified Polystyrene

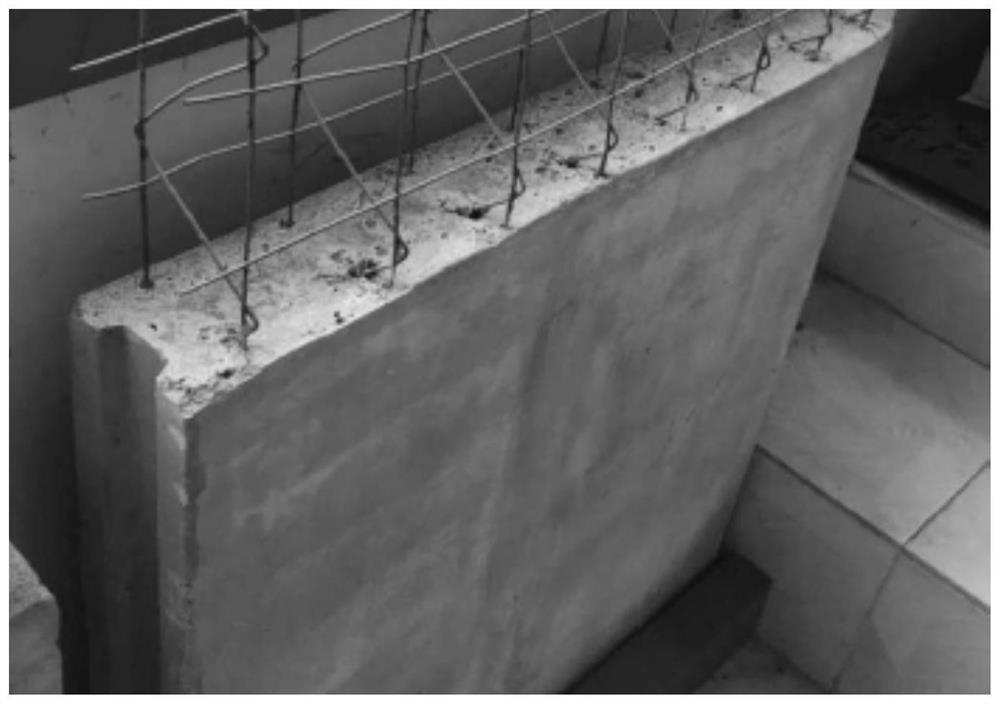

[0042] By heating and pressing, under the action of steam and foaming agent (contained in the raw material), the steam condenses in the internal tissue space after encountering graphite polystyrene, releasing heat to soften graphite polystyrene and make it foam It expands, increases in volume, and changes in density accordingly. After curing and shaping, graphite-modified polystyrene suitable for wallboards is obtained. The specific preparation method is as follows:

[0043] Step 1, prepare raw materials: pull the commercially availa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com