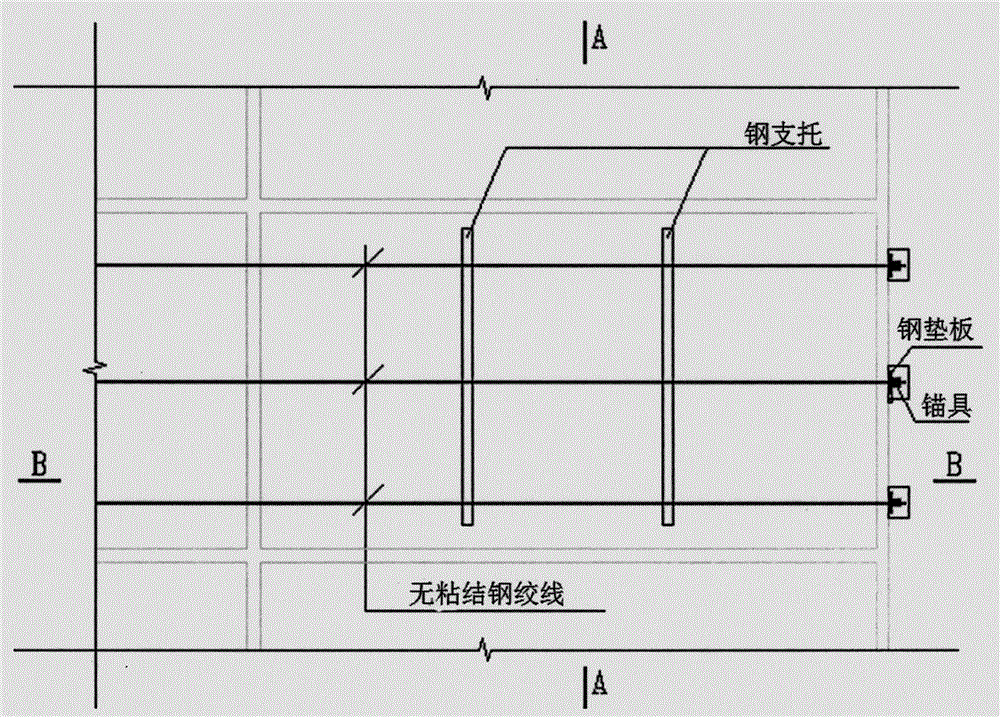

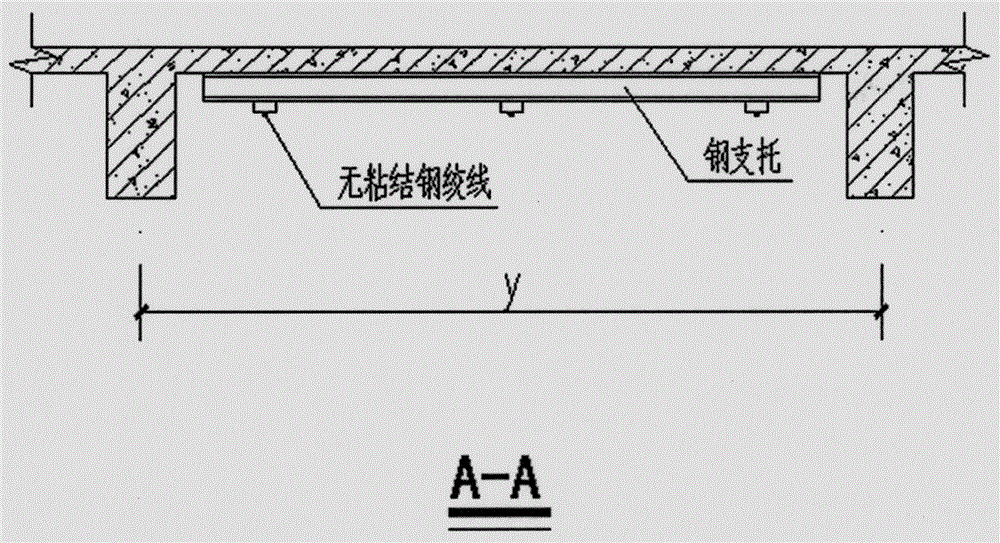

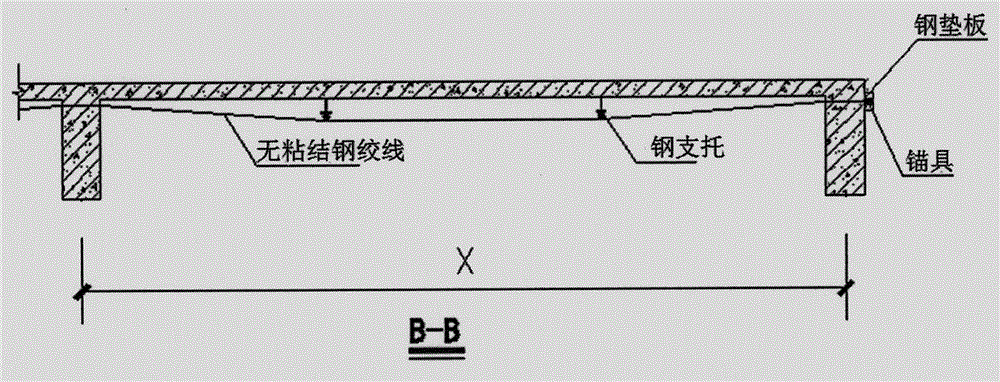

Steel-support non-cohesive steel strand lower support type prestress floor reinforcing method

A non-bonded, steel strand technology, used in building maintenance, construction, building construction, etc., can solve problems such as waste of resources, asynchronous service life, mismatch, etc., to achieve low construction costs, reduced deflection, and construction. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Applying the present invention to the reinforcement of the archives of the urban construction building in Yongkang City, Zhejiang Province

[0030] The floor of the archives of the Yongkang Urban Construction Building was originally a general-purpose perforated board floor. After being used as an archive, it will increase by 600kg / m 2 use load. The floor beams and slabs are reinforced by the external prestressing technology of unbonded steel strands.

Embodiment 2

[0031] Embodiment 2 Applying the present invention to the floor reinforcement of the monitoring room at the housing management office in Ninghai County, Zhejiang

[0032] The floor of the monitoring room of the Ninghai County Housing Management Office is a perforated plate floor, which was originally used as an office. Now it has been changed to a monitoring room. After the use of the monitoring room, the floor live load has increased significantly. The owner entrusted to provide a reinforcement plan and is responsible for the reinforcement construction. The method of the present invention is adopted to reinforce its floor panels and floor beams. After the unbonded steel strand is stretched, the anchors at both ends and the iron parts in the middle of the span are sealed with C25 fine stone concrete, and the unbonded steel strand in the middle of the span is covered with a white flame-retardant PVC pipe.

Embodiment 3

[0033] Embodiment 3 The present invention is applied to the reinforcement of floor slabs when facilities such as cold storage and fish ponds are added on the floor of the pedestrian street shopping mall in Yongkang City, Zhejiang

[0034] The floor of the third-phase project of Yongkang Pedestrian Street was originally designed as the floor of a general shopping mall. Later, loads such as cold storage will be added, and the technology of the present invention will be used to reinforce the floor beams and slabs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com