Treatment process for desulfurized wastewater

A technology for desulfurization wastewater and treatment process, which is applied in gaseous effluent wastewater treatment, water/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. The effect of less secondary pollution and less electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

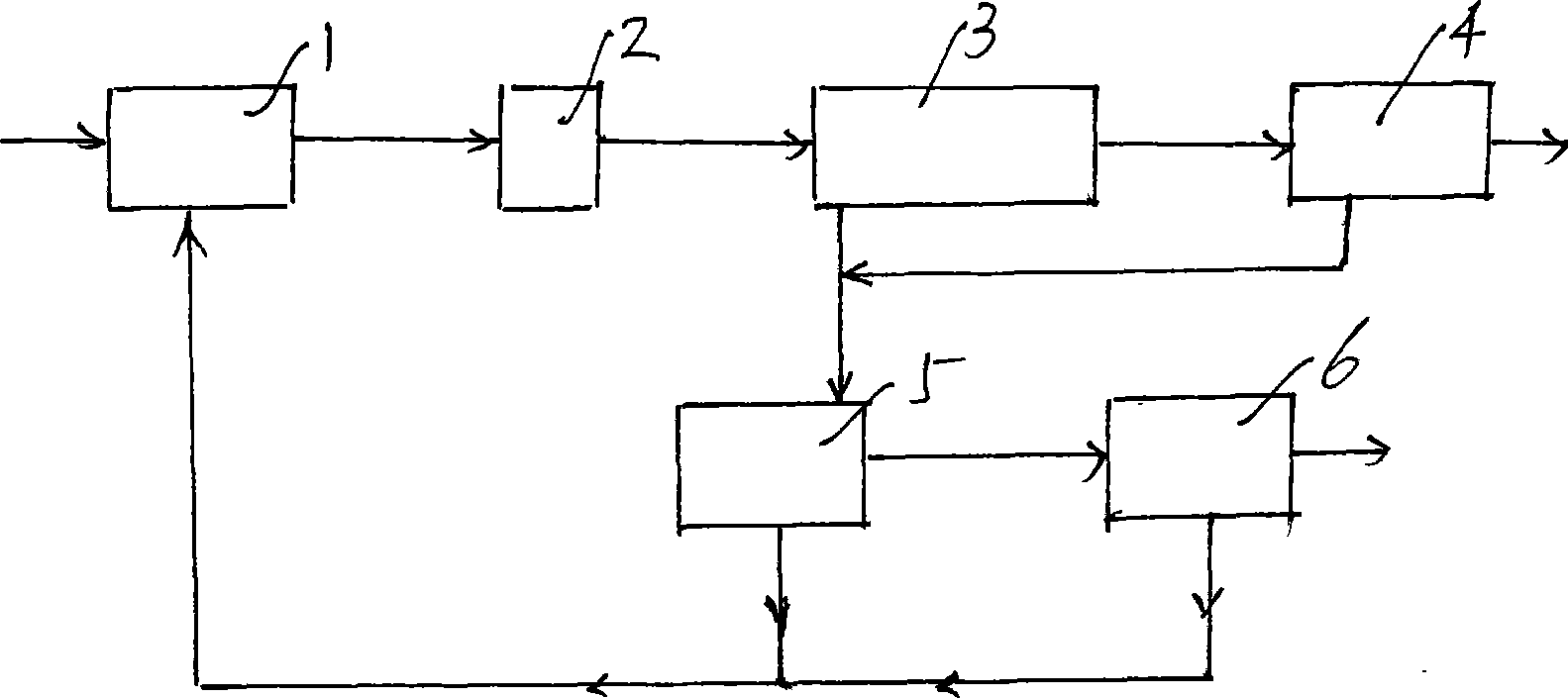

[0017] A treatment process for desulfurization wastewater, first adding NaOH or milk of lime to the acidic desulfurization wastewater in the adjustment pool 1 to adjust the pH to 8-9, and then pumping the desulfurization wastewater to the electrocoagulation treatment device 3 with the pump 2, and then undergoing electrocoagulation treatment The final effluent enters the inclined tube clarifier 4 for further treatment, and the treated waste water up to the standard is discharged or reused; the scum discharged from the electrocoagulation treatment device and the sedimentation sludge discharged from the inclined tube clarifier enter the sludge thickening tank 5 for further concentration and concentration. The final sludge is poured into the sludge dehydrator 6 for drying, and the dried sludge is transported outside for disposal, and the supernatant of the concentration tank and the press filtrate of the dehydrator are returned to the regulating tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com