Flow-controllable orifice with three uniformly distributed holes for high-temperature liquid slag

A uniformly distributed and liquid technology, applied in the field of slag melting equipment, can solve the problems of difficulty in guaranteeing the quality of slag cotton and low investment, and achieve the effects of improving service life, reducing operating costs and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

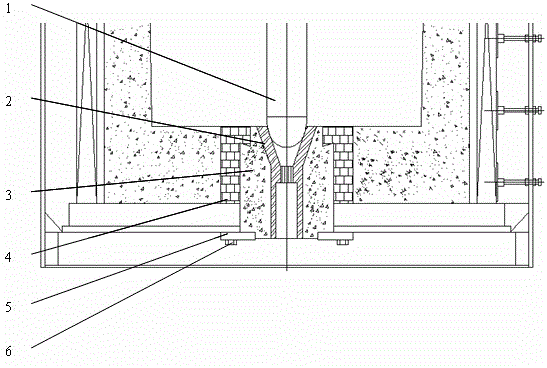

[0030] as attached figure 1 As shown in the figure, the three-hole evenly distributed orifice with controllable flow of high-temperature liquid slag used to meet the short-process production of mineral wool is characterized by a nozzle inner bush made of isostatic graphite, and the inner middle of the nozzle inner bush is There are three evenly distributed slag outlets on the end face, one of which is the currently used hole, and the other two slag outlets are spare slag outlets, and the same isostatic pressure is filled in the spare slag outlets. Graphite, the upper end of the slag outlet is provided with a fine-tuning lift control stopper.

[0031] When working, the currently used hole is used for a period of time, and it cannot be used due to the enlarged hole diameter. After being blocked, the second slag outlet will be drilled for use. After the second hole is used for a period of time, it cannot be used due to the enlarged hole diameter. After the use is blocked, the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com