Patents

Literature

55results about How to "Meet the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based mechanical microcellular foaming paint and application process thereof in synthetic leather

InactiveCN102757718AFeel plumpGood hygroscopicity and air permeabilityFibre treatmentPolyurea/polyurethane coatingsChemistryFiber

The invention discloses a water-based mechanical microcellular foaming paint which comprises the following components in percentage by mass: 10-95% of water-based polyurethane resin, 0.01-5% of foaming agent, 1-40% of pigment, 0-10% of packing, 0-5% of assistant and the balance of deionized water. The invention also discloses an application process of the water-based mechanical microcellular foaming paint in synthetic leather, which comprises the following steps: well stirring and dispersing the water-based polyurethane resin, the packing, the assistant and the foaming agent, and spreading the slurry on release paper on the premise of mechanically and uniformly stirring to prepare superfine fiber synthetic leather or spreading the slurry on synthetic leather to serve as a coating. The water-based mechanical microcellular foaming paint provided by the invention has the advantages that production raw materials are environment-friendly materials which are harmless to the environment, no three wastes are generated in the slurry preparation and production processes, the requirement of the current production process is met, and the economic and environment benefits are remarkable.

Owner:NANTONG HONGTU MATERIAL TECH

High-flow, high-modulus, flame-retarding polypropylene composite material for LFT-D production process

The invention discloses a high-flow, high-modulus, flame-retarding polypropylene composite material for an LFT-D production process. The composite material is composed of following components, by weight, 70-90 parts of polypropylene, 3-10 parts of a compatilizer, 0-0.5 parts of a lubricant, 0-5 parts of an anti-glass fiber exposure agent, 0.1-0.5 parts of an antioxidant, 0-0.5 parts of a photo-stabilizer, 5-25 parts of a flame retardant and 0-5 parts of other additives. The polypropylene composite material has high flowability and modulus and is suitable for a full-automatic LFT-D production process. A product can have a complex structure, is large in breadth and has good size stability.

Owner:HEFEI GENIUS NEW MATERIALS

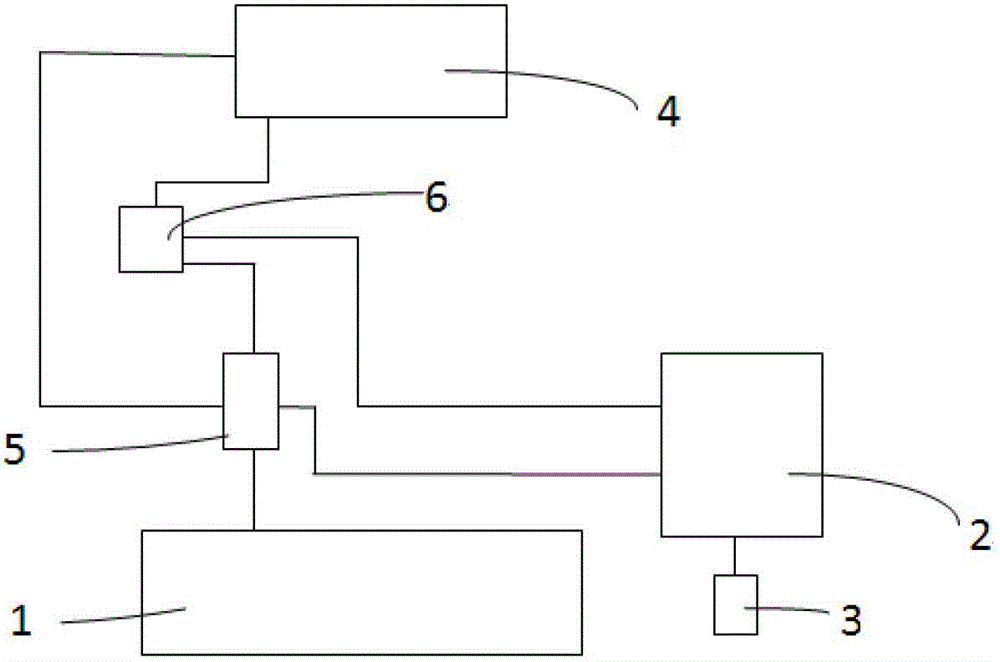

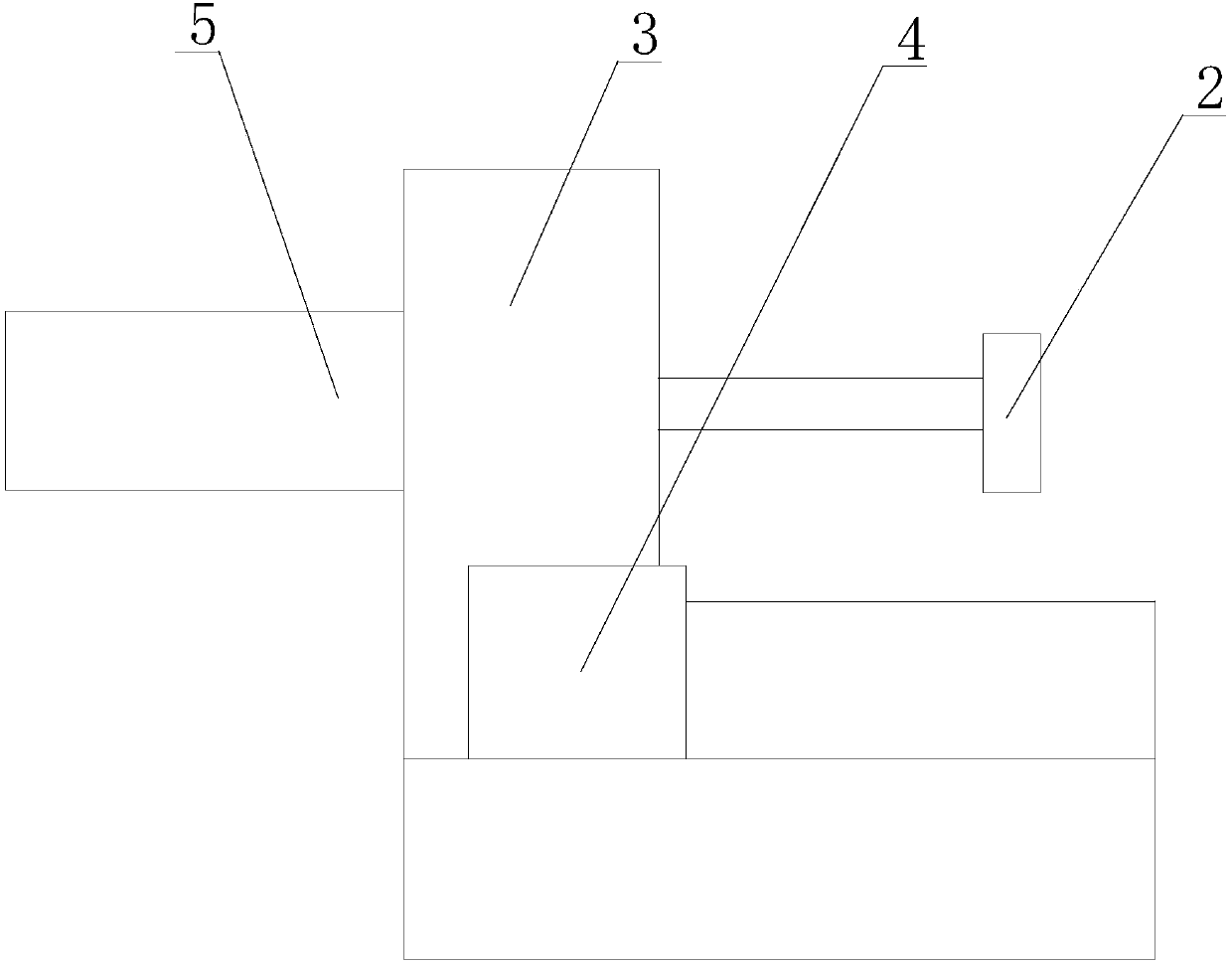

Automatic quantitative adding system

The invention provides an automatic quantitative adding system. The system comprises an electroplating auxiliary cylinder, a PLC controller, a timer, an automatic charging pump, an quantitative cup and an assistant storage tank, the PLC controller is connected with the automatic charging pump, the timer and the quantitative cup through a line respectively, the quantitative cup is connected with the electroplating auxiliary cylinder, the assistant storage tank and the automatic charging pump through a pipeline respectively, and the automatic charging pump is connected with the assistant storage tank through a pipeline. The system has the advantages of realization of the quantitative addition of an assistant, guarantee of the same charging amount each time, high adding precision, electroplating quality guarantee, adjusting convenience, good stability, production technology satisfying, and production efficiency increase.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Internal foaming rubber of dual density Goodyear outsole and preparation method thereof

An internal foaming rubber of a dual density Goodyear outsole and a preparation method thereof. The internal foaming rubber of a dual density Goodyear outsole is prepared by the method of: weighing 800-1000 weight parts of natural rubber, 500-700 weight parts of styrene butadiene rubber, 1100-1300 weight parts of reclaimed rubber, 50-70 weight parts of activated zinc oxide, 40-50 weight parts of stearic acid, 20-30 weight parts of antioxidant, 700-800 weight parts of N330 carbon black, 400-500 weight parts of light calcium carbonate, 80-120 weight parts of machine oil, 200-250 weight parts of phenolic resins, 15-20 weight parts of vulcanizing agent, 35-45 weight parts of promoter, 10-20 weight parts of foaming agent and 10-20 weight parts of foaming agent; plasticating the natural rubber, mixing the natural rubber with styrene butadiene rubber and reclaimed rubber, uniformly dispersing and storing for one day; adding the rubber compound into an internal mixer, adding carbon black, light calcium carbonate and phenolic resins, pressing a ram piston, lifting the ram piston 40-100s later; adding activated zinc oxide, stearic acid, antioxidant, foaming agent and machine oil, pressing the ram piston and discharging the materials after load stabilization of the internal mixer; adding the obtained materials into an open mill, pulling out three channels and adding promoter, vulcanizing agent and urea; making five triangle packages after rubber mixing, removing a sheet and hanging; detecting; putting qualified mixed stock in the open mill for thermal aging and processing the mixed stock into a required prescribed shape.

Owner:JIHUA 3515 LEATHER & SHOES

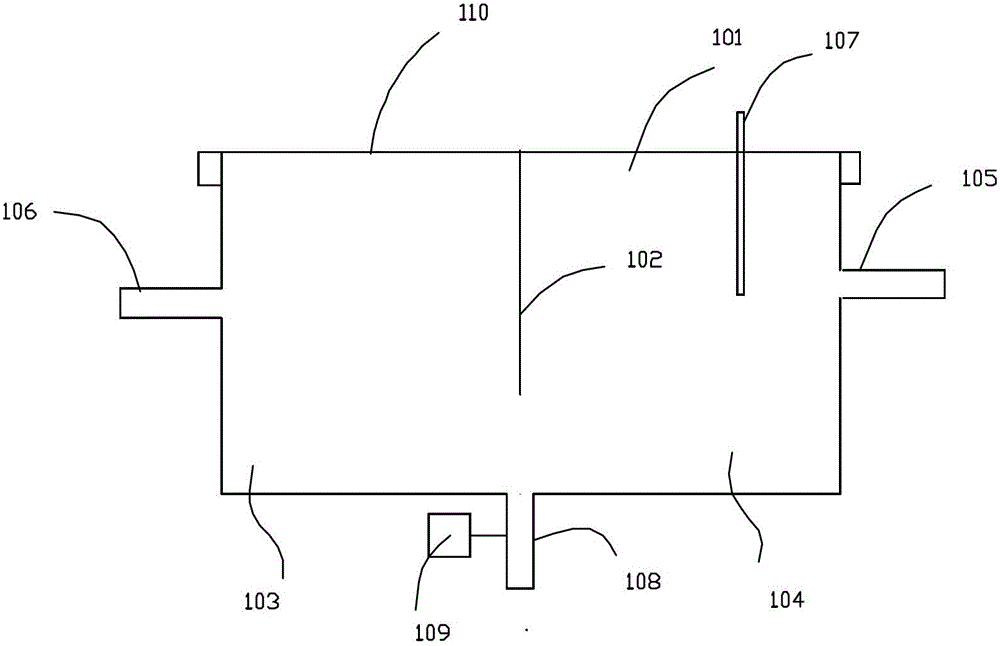

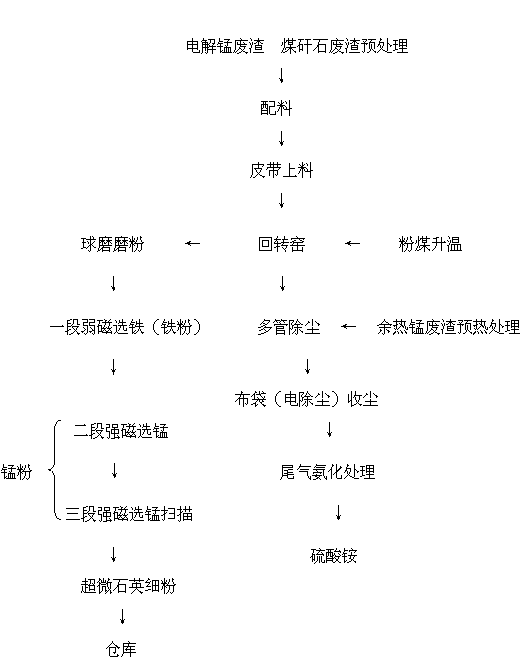

Method for restoring, roasting, purifying, and extracting manganese and iron by utilizing electrolytic manganese slag rotary kiln

The invention discloses a method for restoring, roasting, purifying, and extracting manganese and iron by utilizing an electrolytic manganese slag rotary kiln. The method comprises the following steps of: adding manganese slag and coal gangue slag into a rotary kiln, wherein the adding quantity of the coal gangue slag is 5-10%; carrying out high-temperature roasting under a high-temperature environment inside the rotary kiln and the condition of negative pressure, so that sulphur, ammonia and nitrogen compound is decomposed into gaseous state, feeding the gases into a multi-pipe dedusting and tail gas treatment system to be removed along with the smoke; and carrying out the scavenging processes of ball-milling, first-stage low-intensity magnetic separation, second-stage high-intensity magnetic separation and third-stage high-intensity magnetic separation on the material restored by high temperature of the rotary kiln to obtain an iron product, a manganese product and a novel ultra-fine quartz powder, wherein the iron product is obtained after first-stage low-intensity magnetic separation, the manganese product is obtained after the second-stage high-intensity magnetic separation and third-stage high-intensity magnetic separation, and the final tailing is the ultra-fine quartz powder. The manganese and iron are extracted by the process disclosed by the invention; detrimental impurities are moved; the gas containing sulphur, ammonia and nitrogen is prepared into an ammonium sulfate fertilizer; and the tailing is prepared into the superfine powder as a building material. The afterheat is utilized; the energy is saved, and the environment friendliness is achieved.

Owner:陈建湘

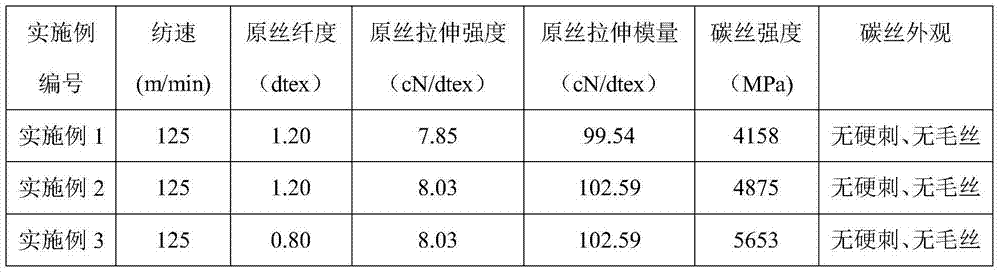

Preparation method of precursor fibers for wet-process spinning PAN-based carbon fibers

InactiveCN104846464AReduce manufacturing costMeet the production processMonocomponent synthetic polymer artificial filamentWet spinning methodsPolymer scienceCarbon fibers

The invention discloses a preparation method of precursor fibers for wet-process spinning PAN-based carbon fibers. The preparation method comprises the following steps: (1) preparation of a polyacrylonitrile raw solution; (A) dissolving raw materials; (B) carrying out polymerization reaction; (C) obtaining the polyacrylonitrile raw solution; and (2) a spinning process: carrying out a condensation and molding process, a water washing process, an oil applying process, a drying and densifying process, a high-pressure steam drafting process, secondary oil application and a loosening hot molding process on the prepared polyacrylonitrile raw solution to obtain the precursor fibers. The residual amount and gel of the raw solution prepared by the method are less and the hydrophily is great; primary fibers obtained by the raw solution in a spinning and condensation molding process are dense and have high transparency, so that the operation in a spinning process is stable when the spinning speed is increased to be more than 125m / min; the solvent residual amount of the precursor fibers is small, and no broken fibers and parallel fibers are formed; the single-path yield is greatly improved and the production cost of the precursor fibers is greatly reduced; and under a high-speed spinning condition, a production process of T700-grade and T800-grade precursor fibers is met.

Owner:HENGSHEN

Automatic blowing mechanism on mold

The invention relates to an automatic blowing mechanism on a mold. The mechanism comprises a supporting frame, and is characterized in that: a hole and a first cylinder are arranged above the supporting frame; a guide sliding rod is arranged in the hole, and can slide up and down in the hole under the driving action of the first cylinder; a gas needle fixing rod is erected above the guide sliding rod; a blowing needle is arranged at one end of the gas needle fixing rod; a first guide rail is arranged below the supporting frame; a transverse limiting block is arranged on one side of the supporting frame; a second cylinder is arranged on the transverse limiting block; the supporting frame can slide on the first guide rail under the driving action of the second cylinder; and a height limiting block is arranged below the supporting frame, is arranged on the second guide rail, is connected with a piston rod of a third cylinder and can slide on the second guide rail under the driving action of the third cylinder. The mechanism has a simple, compact and reasonable structure, is easy to operate, and can meet the requirement of the production process of a special automobile interior trim part product on the basis of not changing the structure of the mold.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

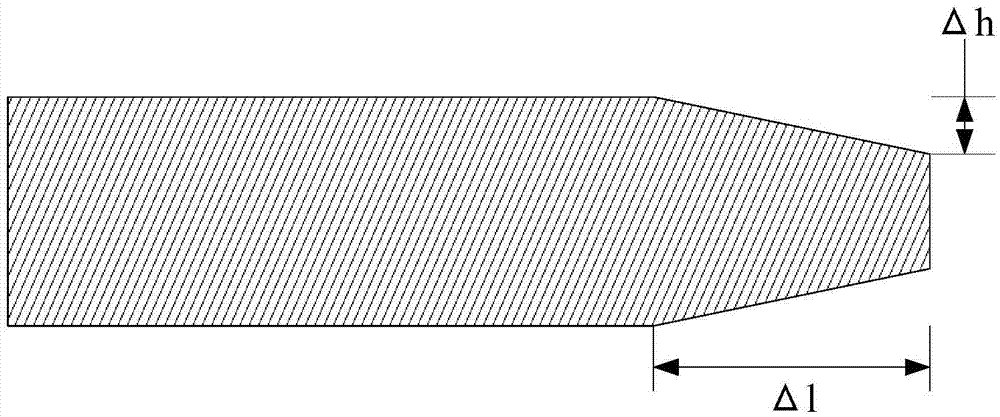

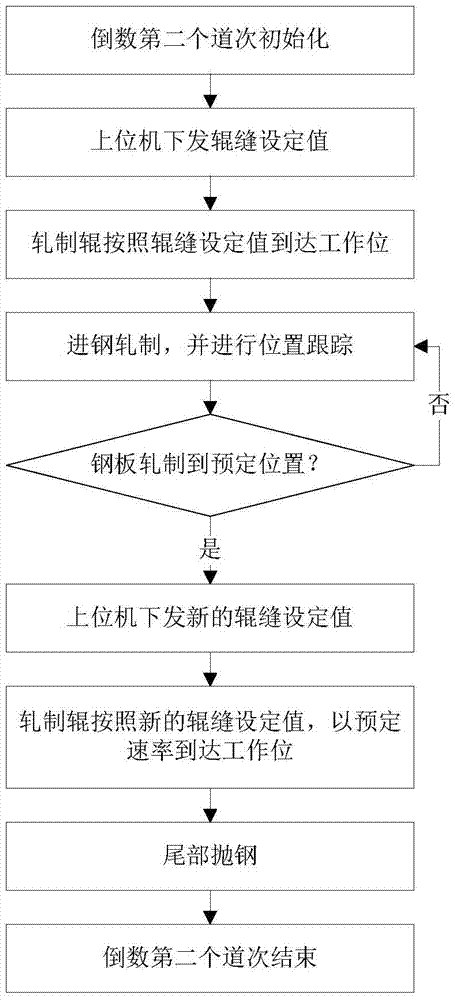

Method for reducing finish mill steel biting impact

InactiveCN106890852AReduce shockProtection worksRolling equipment maintainenceMetal rolling arrangementsMaterials scienceBiting

The invention relates to a method for reducing the steel bite impact of a finishing mill. In the rough rolling process set before the finishing rolling process: in the penultimate pass, when the slab is rolled to the set position, the The reduction increases by the set value; in the penultimate pass, the reduction of the rolling rolls is set to zero. The method for reducing the steel bite impact of the finishing mill in the present invention effectively reduces the impact of the finishing mill's steel bite without changing the control logic of the finishing mill, protects the work rolls and main shafts of the finishing mill, and ensures the smoothness of the rolling line. The production runs smoothly, which can meet the production process and ensure the safety of the finishing rolling equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

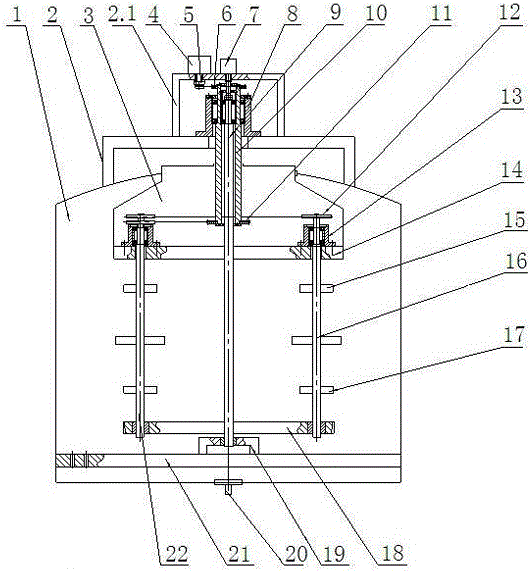

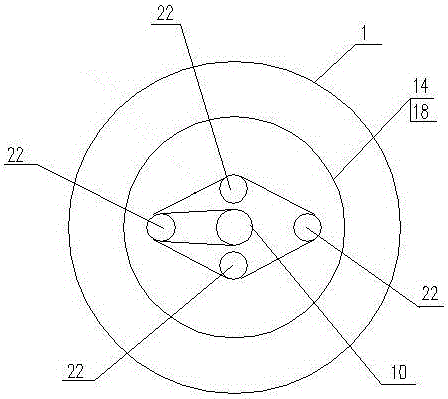

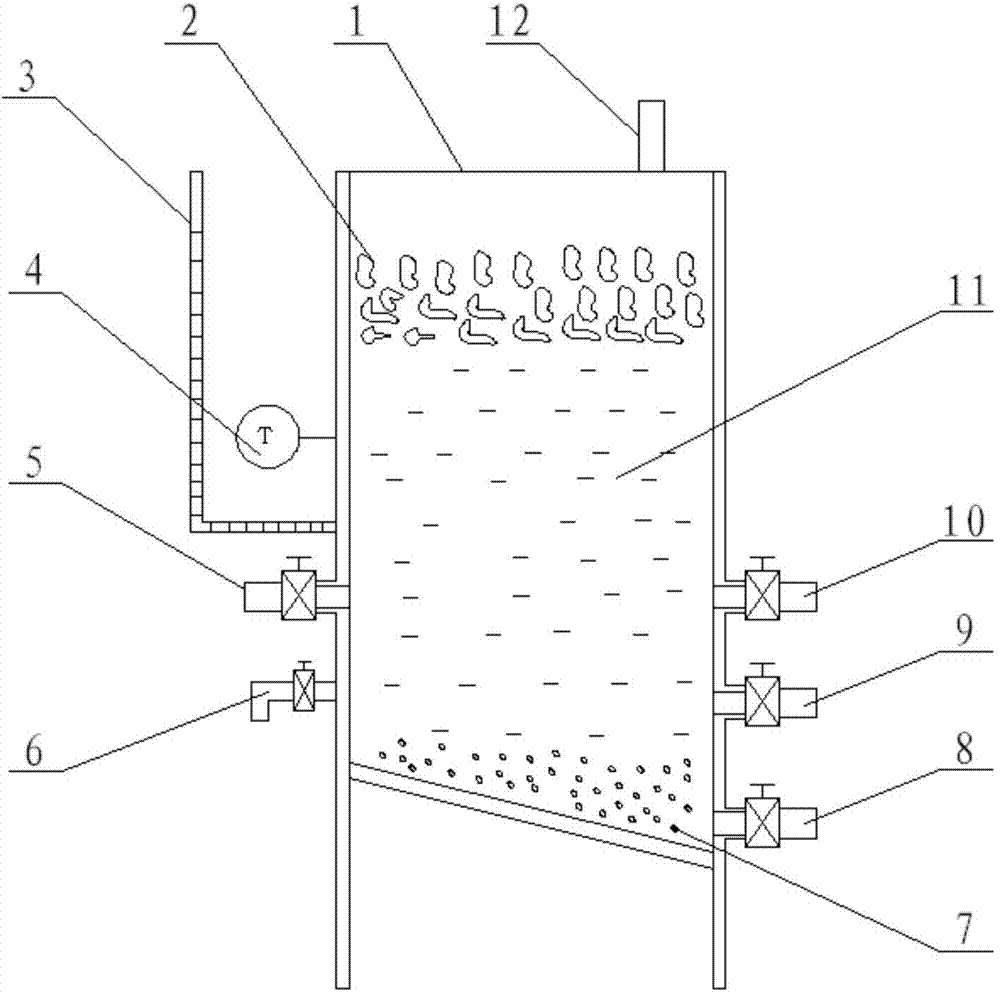

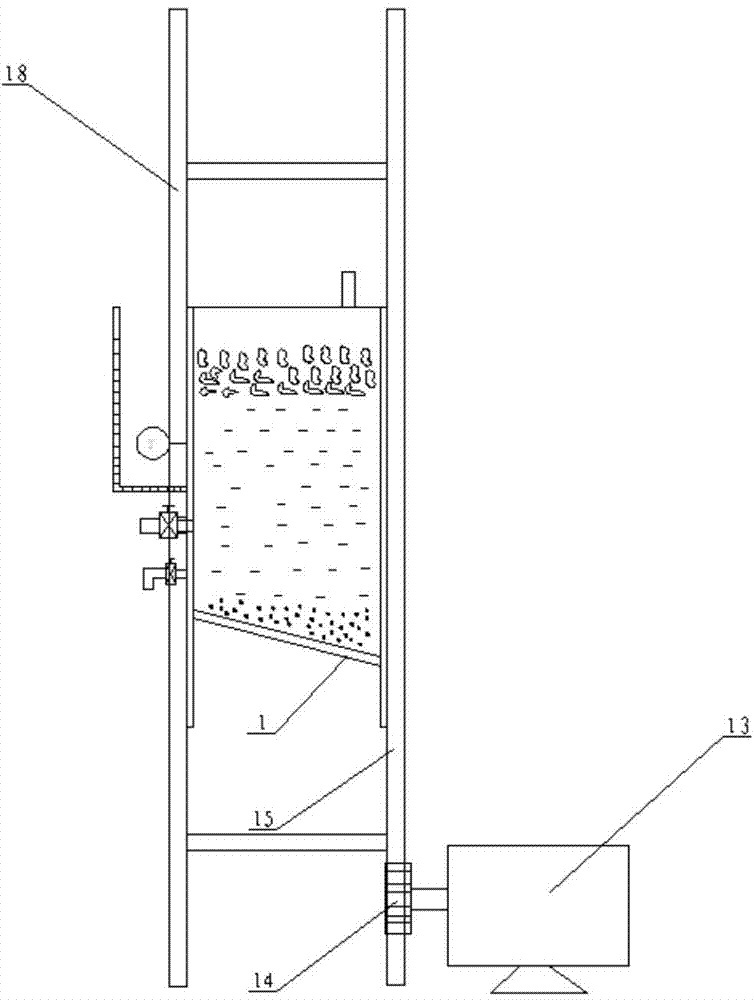

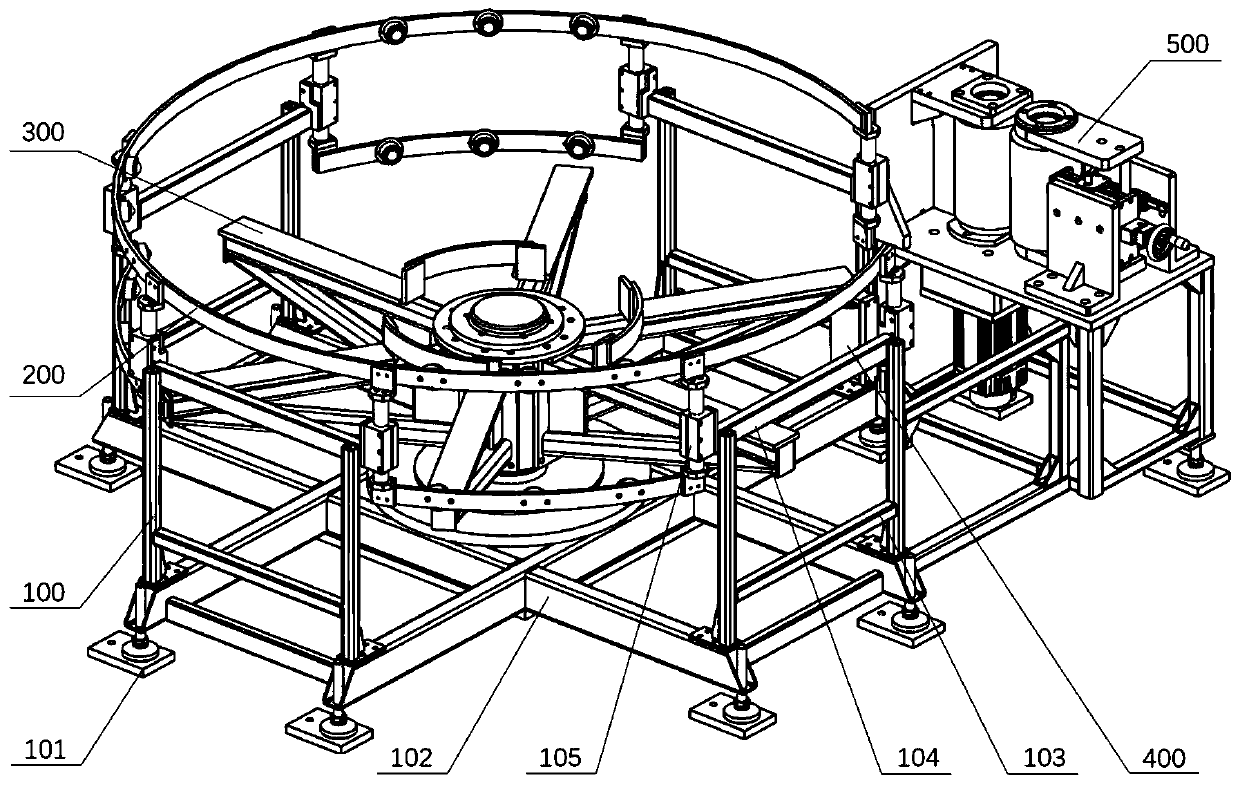

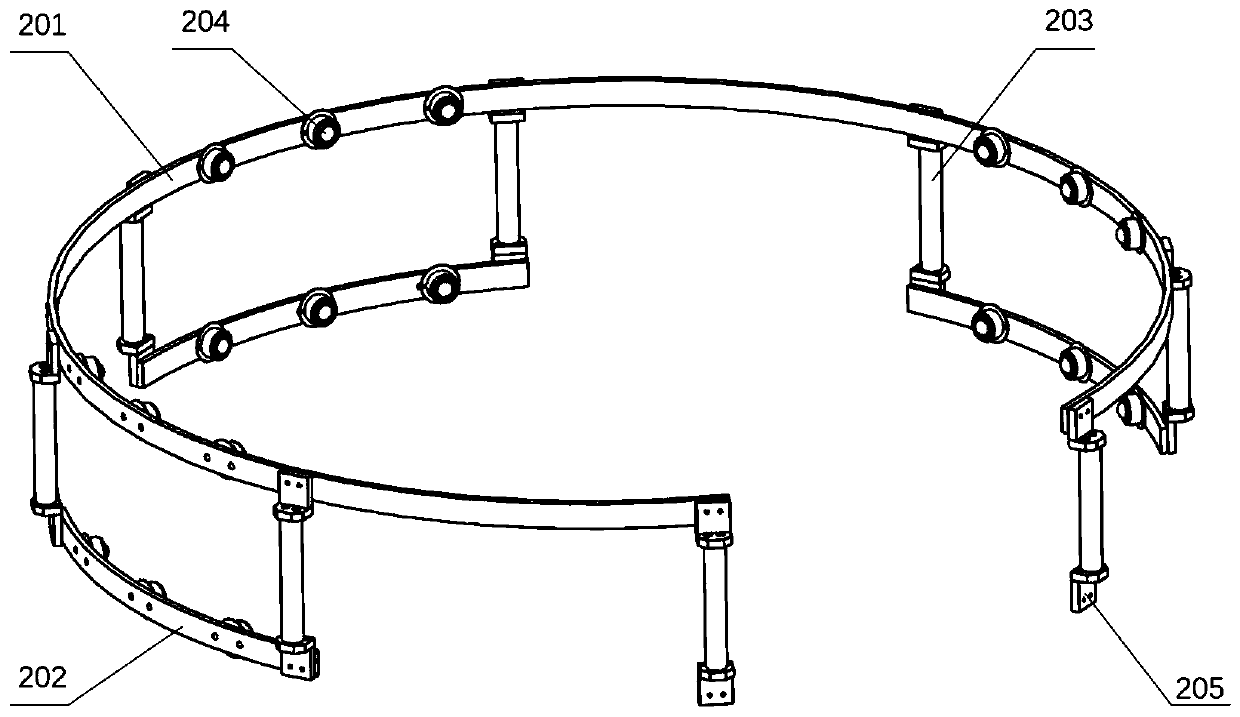

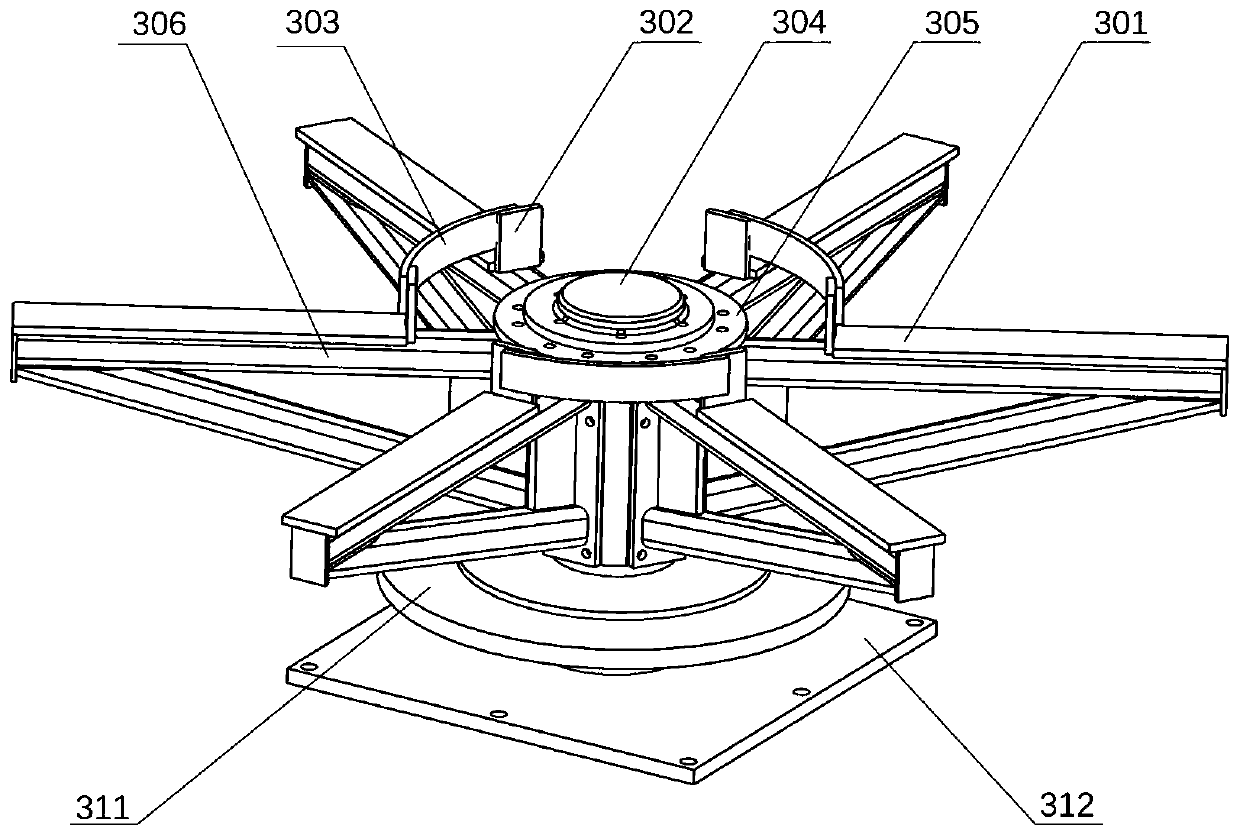

Large fermentation tank stirring device and stirring method

ActiveCN105695305AWide range of design diametersLower the altitudeBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemDrive motor

The invention provides a large fermentation tank stirring device and a stirring method. The large fermentation tank stirring device comprises a tank body, a stirring device body in the tank body and a control system. The large fermentation tank stirring device is characterized in that the stirring device body comprises a central shaft and at least two blade shafts, the central shaft is vertically arranged in the middle of the tank body, a rotary disc is arranged on the central shaft, the central shaft is driven by a central shaft movement driving motor and drives the rotary disc to rotate, the blade shafts are arranged on the rotary disc, stirring blades are arranged on each blade shaft, and each blade shaft is driven by a blade shaft driving motor to be in autorotation while being along with revolution of the rotary disc. The control system controls linkage and rotating speed of the central shaft movement driving motor and the blade shaft driving motor and rotating direction of the blade shafts to realize autorotation and revolution of the blade shafts, and materials in the tank body are stirred by the blades on the blade shafts. By using the large fermentation tank stirring device, fermentation liquid can be fully stirred, fermentation quality can be improved, and stirring energy consumption and power consumption in delivering filtered air into the bottom of the tank body can be lowered.

Owner:吴文宇 +1

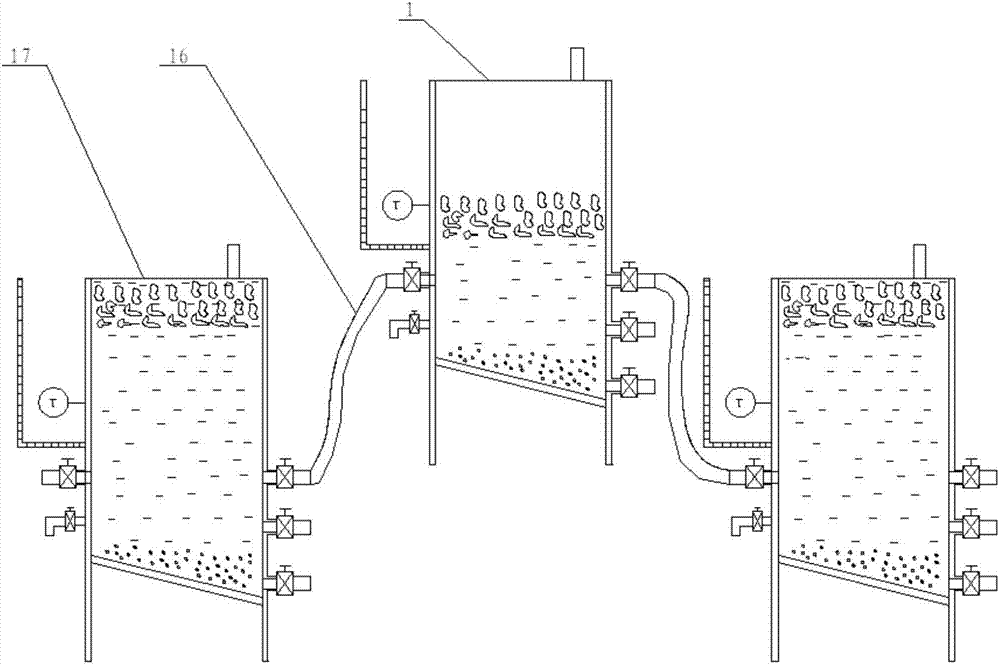

Tandem-type fermentor group and use method thereof

ActiveCN103666900AMeet the production processIncrease production capacityWine preparationProcess engineeringGrape wine

The invention discloses a tandem-type fermentor group. The fermentor group comprises one or more fermentors and one or more movable fermentors, wherein connecting pipes are arranged between the fermentors and the movable fermentors; the fermentors and the movable fermentors are mutually communicated through the connecting pipes; the movable fermentators can be externally driven to move up and down; a fermentation liquid flows into / out of the fermentors and the movable fermentors via the connecting pipes under the gravity action generated by height differences between the fermentors and the movable fermentors. The tandem-type fermentor group disclosed by the invention not only adopts the air current agitation principle of fermentors in an invention 97182142.9, but also enables the fermentation liquid to circulate during the fermentation; moreover, the tandem-type fermentor group not only satisfies the production processes of various kinds of wines, but also is used as aging storage pots during fermentation; compared with the fermentators provided by the invention 97182142.9, the tandem-type fermentor group has the advantages of simpler process, wider use range, lower manufacturing cost, higher output and the like, and is simple in the maintenance of equipment and suitable for large-scale production.

Owner:ZHENJIANG FENGZE BIOTECH EQUIP MFG

Method for detecting moisture content, vanadium pentoxide content and carbon content in hexamine vanadium

ActiveCN109596454AMeet the production processSatisfy production qualityWeighing by removing componentChemical analysis using titrationAmmonium ferrous sulfateSulfur

The invention discloses a method for detecting moisture content, vanadium pentoxide content and carbon content in hexamine vanadium. The method comprises the following steps: sample pretreatment withnitrogen protection, moisture determination, determination of vanadium pentoxide content with ammonium ferrous sulfate standard solution drop method, and determination of carbon content with an infrared carbon-sulfur analyzer. A drying method for moisture determination of a hexamine vanadium sample, a sample dissolving method for vanadium pentoxide determination, and an equivalent correction method for carbon determination are established, thereby realizing accurate detection of the moisture content, the vanadium pentoxide content and the carbon content in hexaamine vanadium. The method is easy to operate and can meet the requirements of production process, quality judgment and business settlement of hexamine vanadium.

Owner:HEBEI IRON AND STEEL

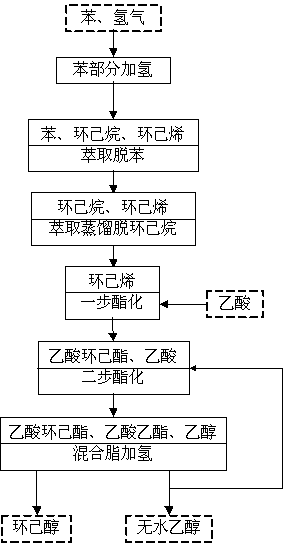

Method for co-production of cyclohexanol and absolute ethyl alcohol

InactiveCN104193583AAchieve full utilizationAvoid azeotrope formationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsExtractive distillationCyclohexene

The invention discloses a method for co-production of cyclohexanol and absolute ethyl alcohol. The method comprises the steps of: (1) benzene hydrogenation; (2) debenzolization by extraction of a mixture; (3) cyclohexane removal by extractive distillation; (4) first esterification; (5) second esterification; and (6) mixed ester hydrogenation. The method has the characteristics that as a two-step esterification method is adopted, acetic acid which does not react in the first esterification process reacts with excess ethyl alcohol in the second esterification process so as to be converted to ethyl acetate, thus avoiding corrosion to equipment in the subsequent acetic acid distillation separation process, lowering the equipment requirement and the production energy consumption and saving the cost. According to the method disclosed by the invention, cyclohexene has a high conversion rate (no less than 99 percent), and acetic acid is not needed to be separated in the middle process and is completely converted to absolute ethyl alcohol with a higher additional value finally. The cyclohexanol prepared by the method satisfies the high-speed caprolactam spinning production process.

Owner:河北美邦工程科技股份有限公司

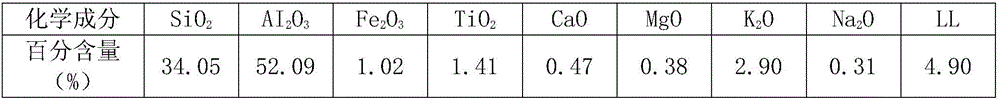

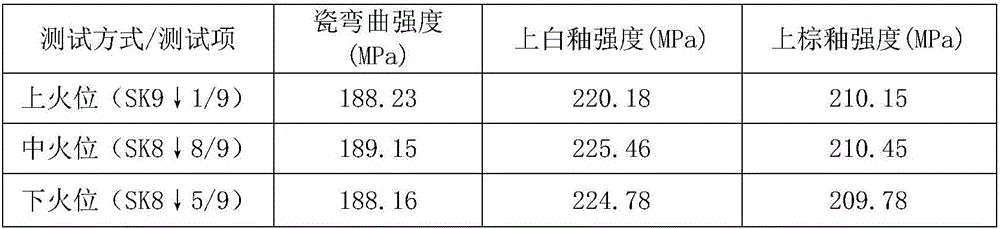

High-intensity direct current electrical porcelain formula

The invention relates to a high-intensity direct current electrical porcelain formula, which is prepared from the following substances in parts by mass: 25 to 30 parts of Dongshengtu, 20 to 26 parts of Jingyangtu, 22 to 28 parts of low-titanium alumina, 6 to 10 parts of Jiangjintu clay, 1.5 to 3 parts of barium carbonate and 12 to 18 parts of alpha-Al2O3. The performance of the high-intensity direct current electrical porcelain formula completely reaches the formula design requirement and the product performance requirements; the current production process can be met; the drying bending intensity is higher than or equal to 5.0MPa; the porcelain bending intensity is higher than or equal to 150 MPa; the glazing bending intensity is higher than or equal to 200 MPa.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

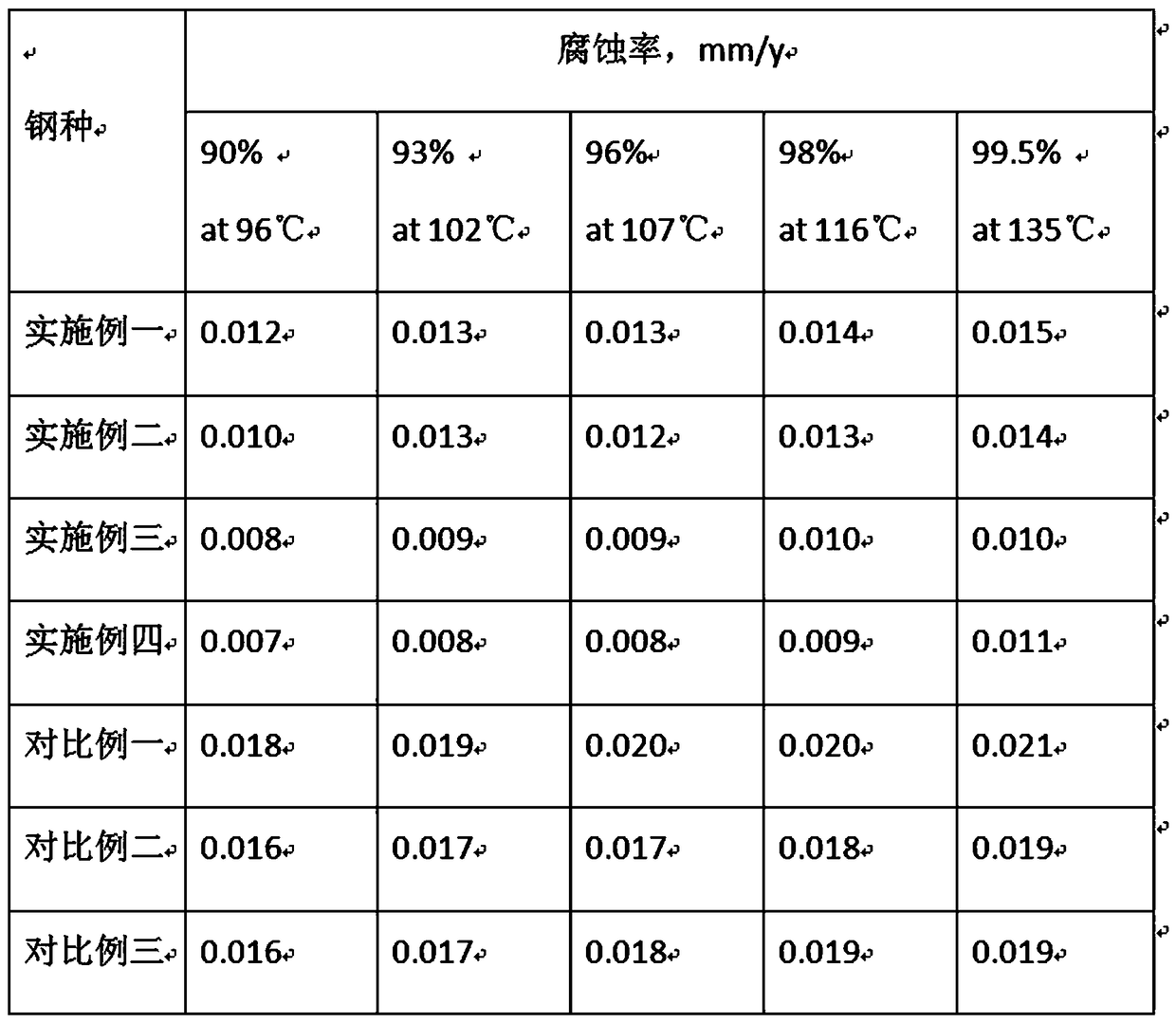

Austenitic stainless steel resistant to high temperature and high-concentration sulfuric acid

The invention relates to an austenitic stainless steel resistant to high temperature and high-concentration sulfuric acid and belongs to the technical field of austenitic stainless steel. The austenitic stainless steel resistant to high temperature and high-concentration sulfuric acid comprises, by weight, 13-19.5% of Cr, 13-22% of Ni, 4.5-6.5% of Si, 0.30-1.5% of Cu, 0.75-2.5% of Mo, 0.07% or less of C, 2% or less of Mn, 0.015% or less of S, 0.03% or less of P, 0.3% or less of Al, inevitable impurities, and the balance Fe. Among steel varieties in the prior art, Zecor, Saramet35 and sandvik SX developed by foreign companies are similar to the austenitic stainless steel on the aspects of material design and overall performance, and compared with the steel of foreign countries, the austenitic stainless steel has more obvious advantages on the aspects of material manufacturing process, yield improvement, corrosion resistance and the like.

Owner:YONGXING SPECIAL STAINLESS STEEL

Manufacturing technology of PBT used for loose tube of optical cable

InactiveCN104109351AImprove flexibilityFast crystallizationManufacturing technologyMolecular materials

A manufacturing technology of PBT used for a loose tube of an optical cable. The invention relates to the technical field of high molecular materials and provides a manufacturing technology of PBT used for a loose tube of an optical cable. The PBT is stable in shape, good in flexibility and high in processing efficiency. The manufacturing technology includes following steps: 1) preliminary treatment; 2) a primary stirring process; 3) a secondary stirring process; and 4) dust removal. According to the invention, a viscosity-increasing process is carried out to a PBT raw material and 5# white oil is added during the primary stirring process. By means of the white oil, flexibility of the material can be enhanced effectively, thereby increasing smoothness of a surface of the loose tube and being beneficial to cabling. A polypropylene nucleating agent is added during the secondary stirring process. By means of the polypropylene nucleating agent, a crystallization speed of the material can be effectively increased, thereby significantly reducing a production time of the material and improving a processing efficiency. The PBT material, after being processed, can satisfy a production requirement and a technical standard of the loose tube.

Owner:YANGZHOU JINSEN OPTOELECTRONICS

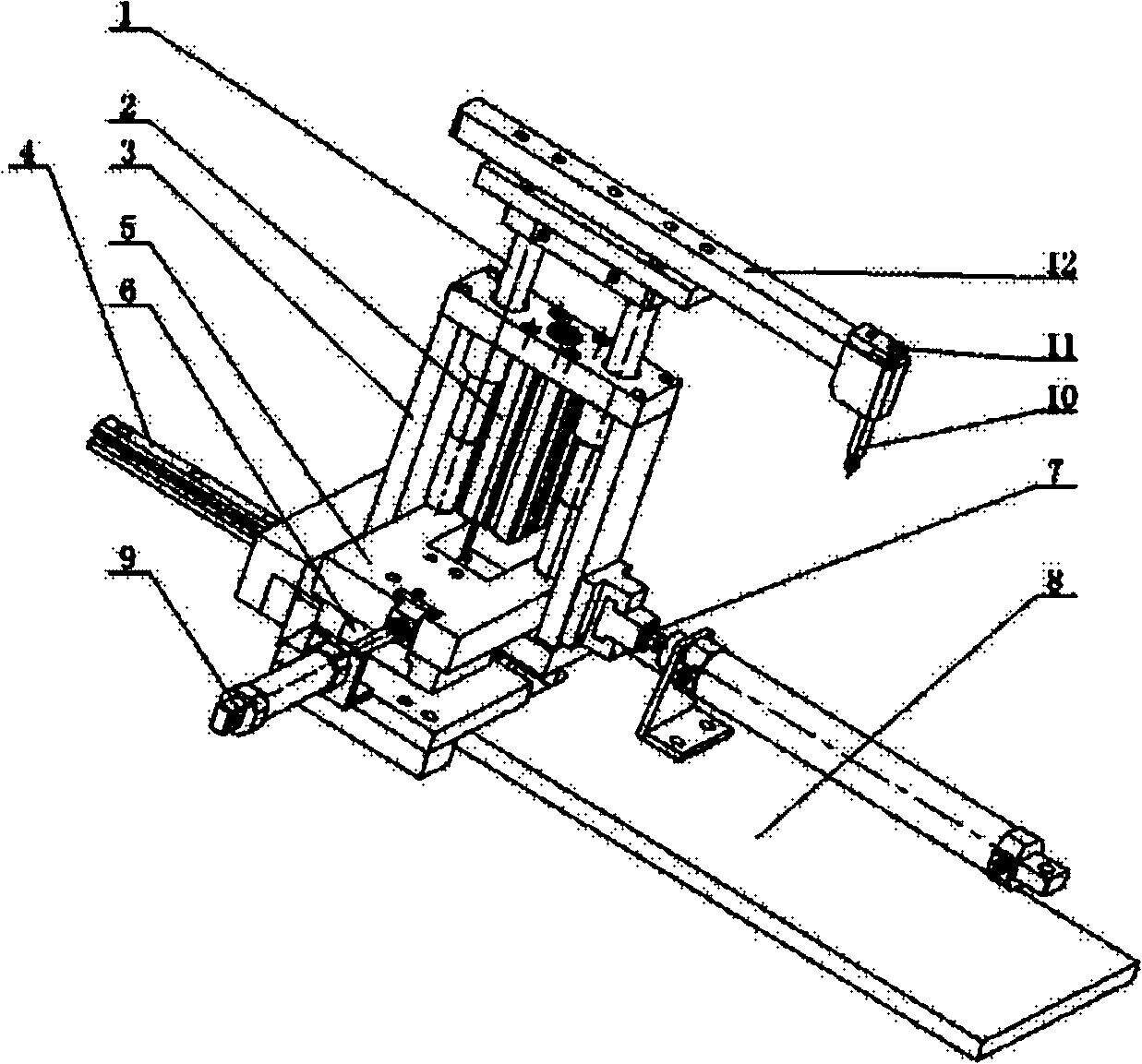

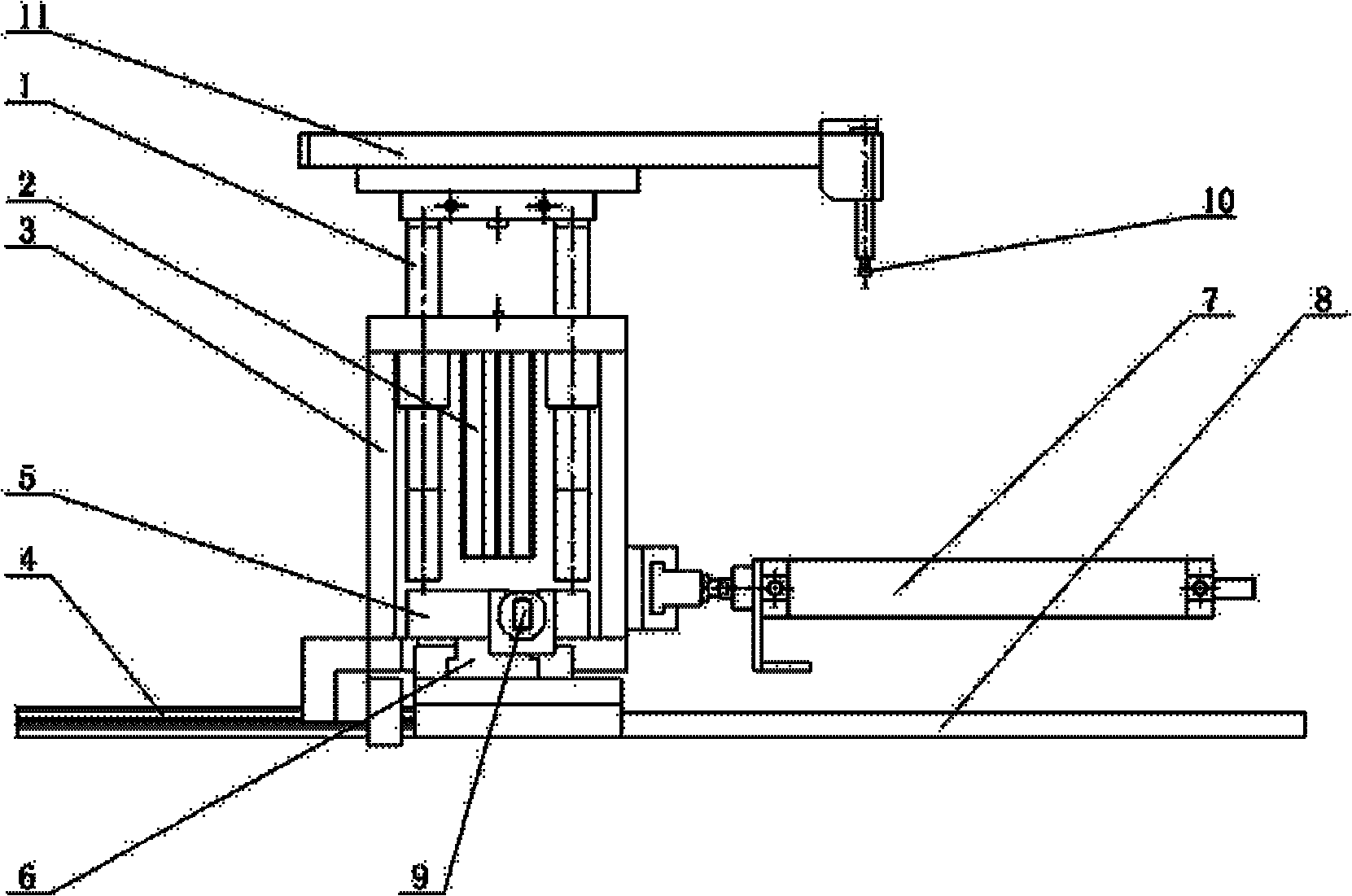

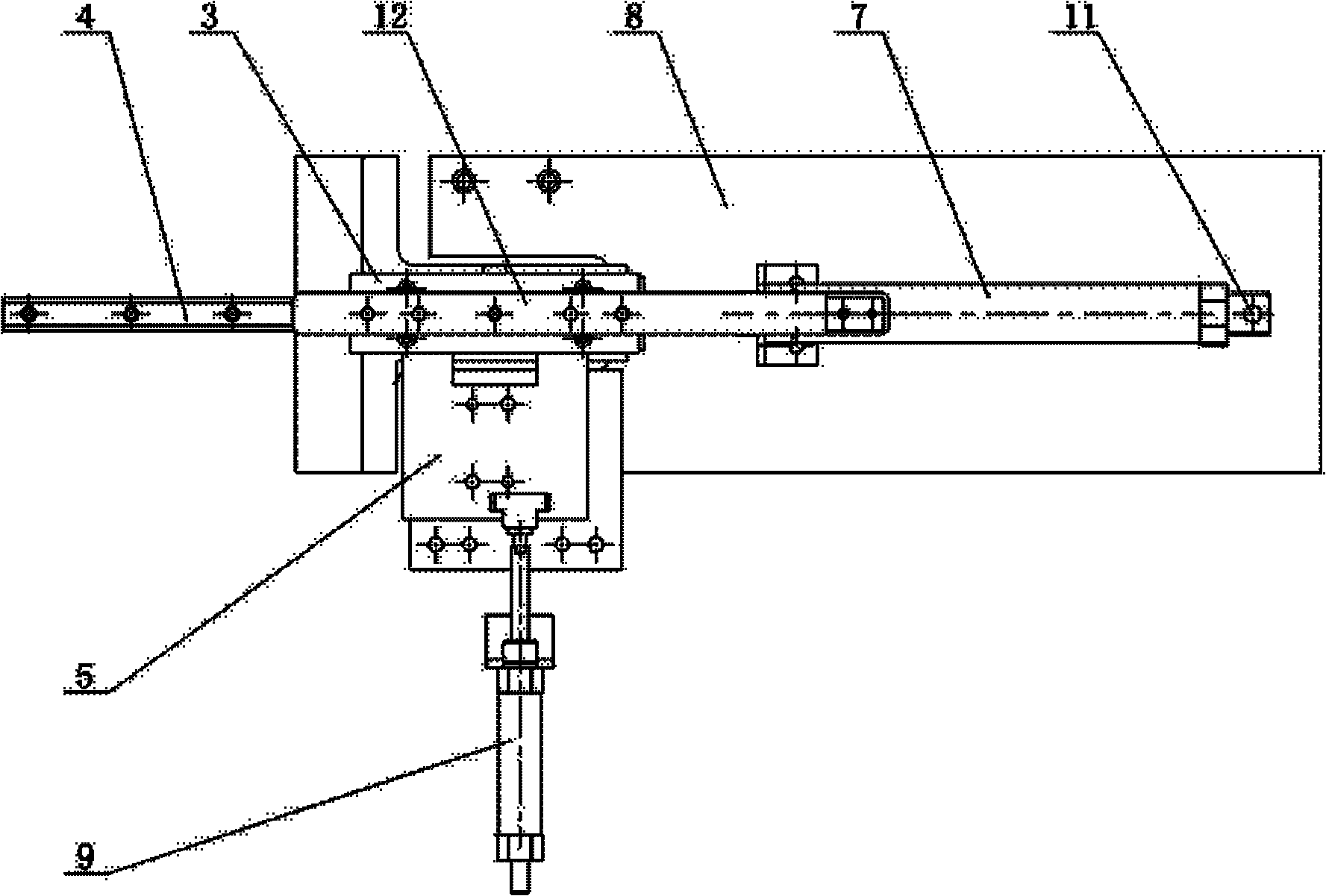

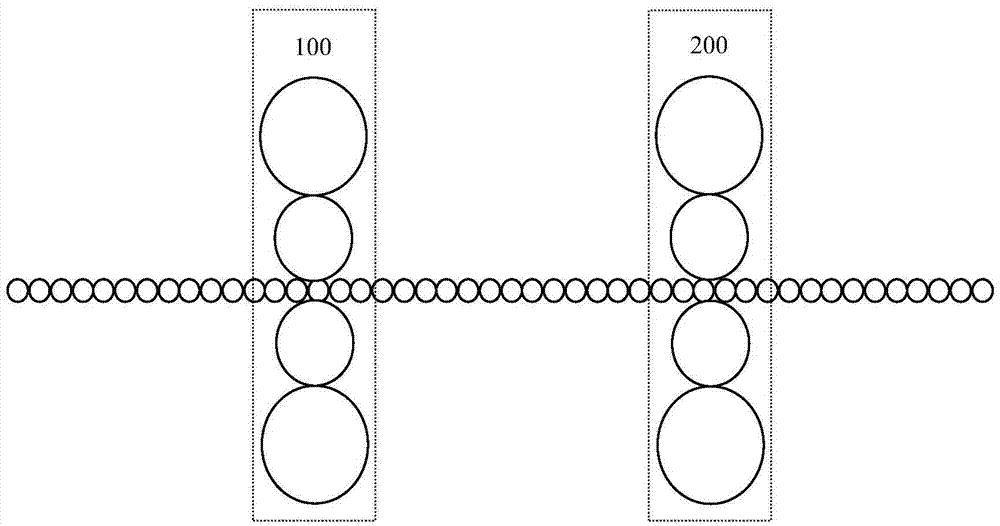

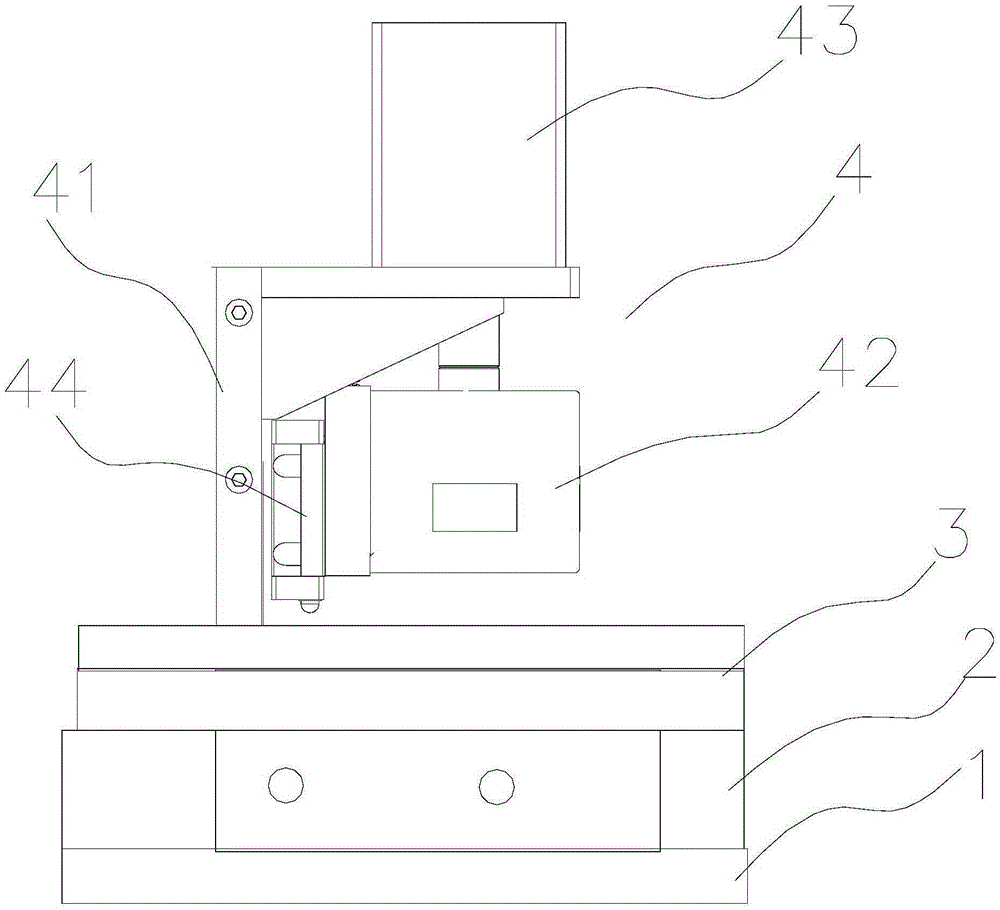

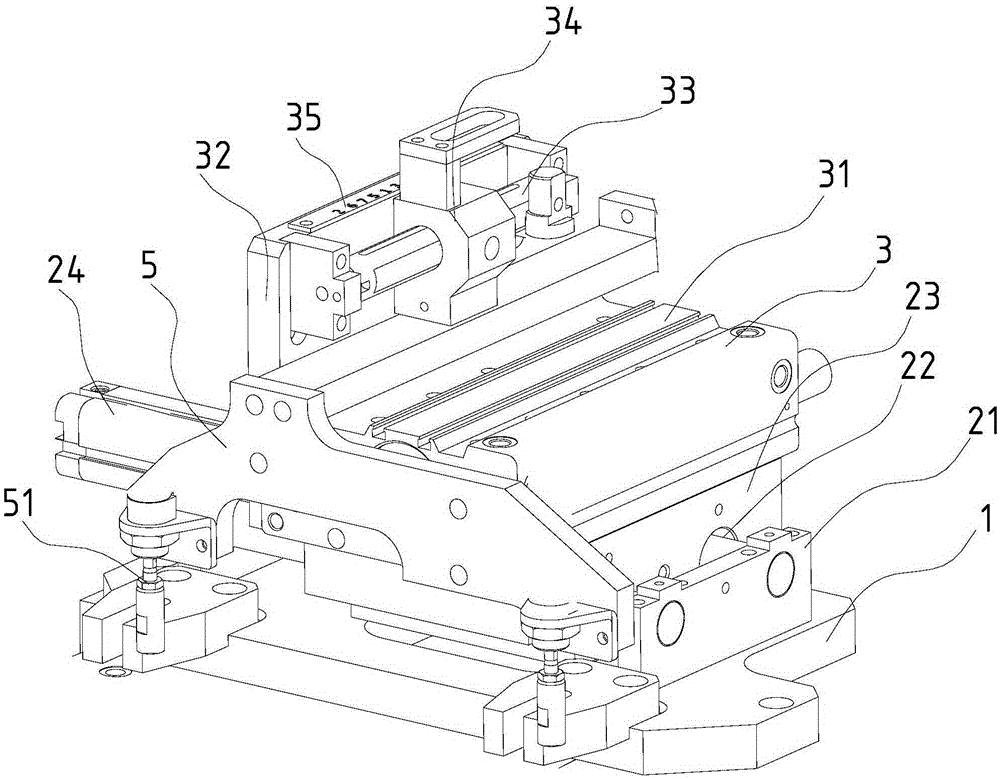

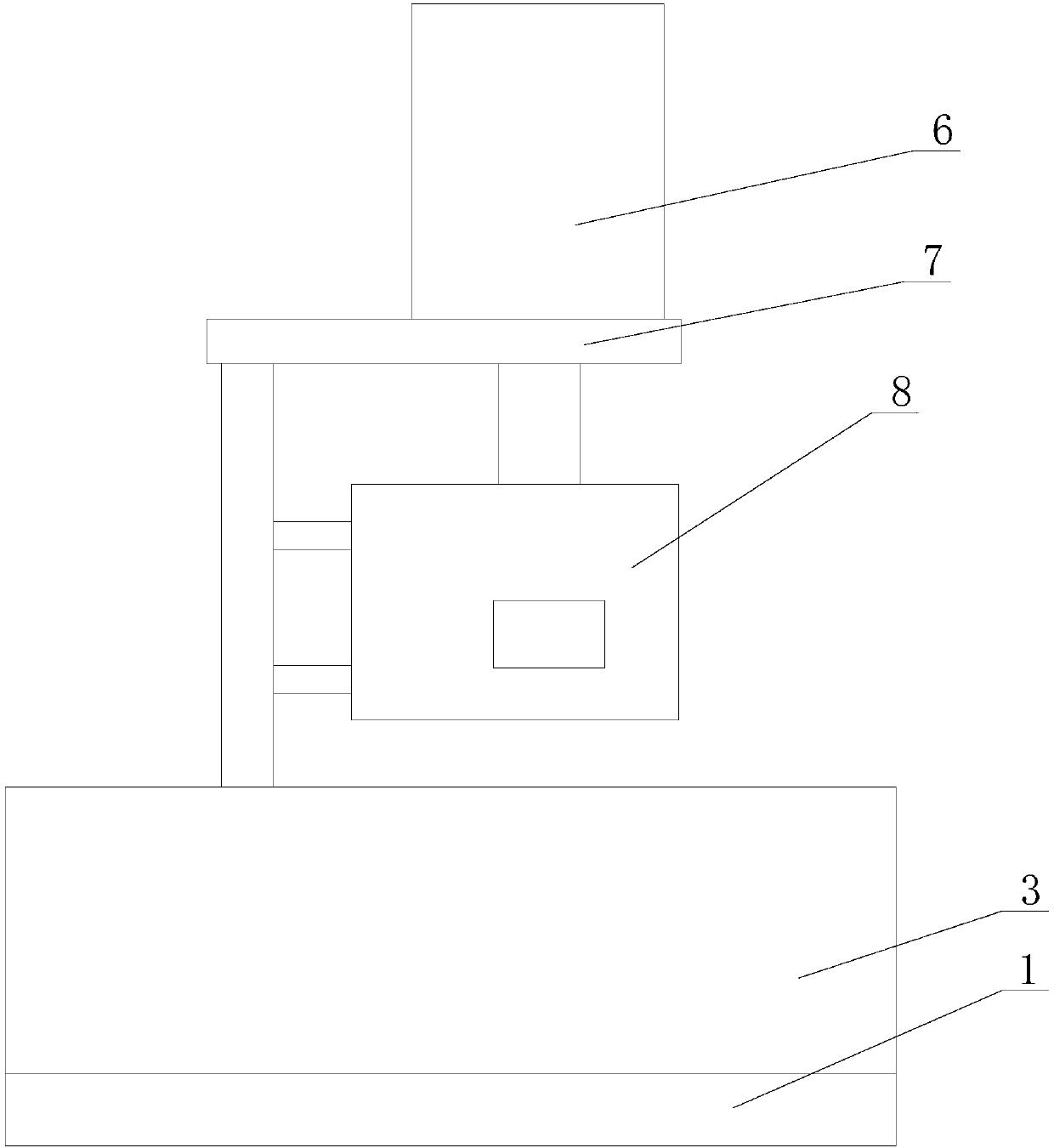

Ultrasonic welding machine for welding of aluminum foil end surfaces of lithium batteries

ActiveCN105414735AMeet the production processQuality improvementNon-electric welding apparatusUltrasonic weldingAluminum foil

The invention provides an ultrasonic welding machine for welding of aluminum foil end surfaces of lithium batteries. The ultrasonic welding machine comprises a bottom plate, a clamping seat, a fixed seat and an ultrasonic welding machine body, wherein the clamping seat is fixed on the bottom plate, a first clamping block is arranged on the clamping seat, a first air cylinder is arranged on one side of the clamping block, a clamping plate is arranged on the other side of the clamping block, and a piston rod of the first air cylinder penetrates through the clamping block to be connected with the clamping plate; the fixed seat is located above the clamping seat and provided with slide rails; a rack and an ultrasonic welding head assembly are arranged on the ultrasonic welding machine body, and the rack of the ultrasonic welding machine body is in slide connection with the slide rails. The ultrasonic welding machine can be used for welding the aluminum foil end surfaces very conveniently, the production technology of the lithium batteries is met, and the quality of the lithium batteries is improved.

Owner:SUZHOU RECEN PRECISION MACHINERY CO LTD

Polypropylene wood-plastic composite material and preparation method thereof

The invention relates to preparation and research of a polypropylene wood-plastic composite material. The polypropylene wood-plastic composite material is prepared from the following raw materials inparts by weight: 40-60 parts of wood powder, 20-50 parts of polypropylene, 0.2-1 part of surface treatment agent, 0.2-0.8 part of lubricant, 0.2-1 part of modifier, 01- 1 part of flame retardant and 0.2-1 part of compatibilizer. The invention also provides a preparation method of the polypropylene wood-plastic composite material. The polypropylene wood-plastic composite material prepared by the method has greatly improved impact strength, tensile strength, modulus and flame retardant performance, thus meeting the requirements of multiple occasions for the productioni technique and the usability.

Owner:JINLING INST OF TECH

Vertical active uncoiling device for spiral steel plate bin forming

The invention relates to a strip steel cold bending forming machining manufacturing technology, in particular to a vertical active uncoiling device for spiral steel plate bin forming. The device comprises a bracket, a rotating device, a vertical guide roller device, a circumference fixing device and a steel coil driving device, the inner wall of the rotating device is provided with a universal ball, the steel coil driving device is provided with two driving wheels driven by a positive displacement straight gear, power is provided by a servo motor, and the gap between the two driving wheels isadjusted by moving the driving wheels through a manual linear module and a linear guide rail. A steel coil for manufacturing a spiral steel plate bin is placed on the rotating device, a steel plate isdriven to advance through the steel coil driving device, whether the steel plate exists within a calibrated distance or not is judged according to a photoelectric sensor, an analog output signal is sent to a servo motor control system, the speed difference between the driving speed and the forming speed of the steel plate is controlled, and steel plates with different thicknesses of 3mm-5mm can be machined and manufactured. The device better protects the outer surface of the steel plate, reduces the load of a motor of a steel plate forming unit, and improves the working efficiency.

Owner:JIANGSU HENGXIN SILO EQUIP CO LTD

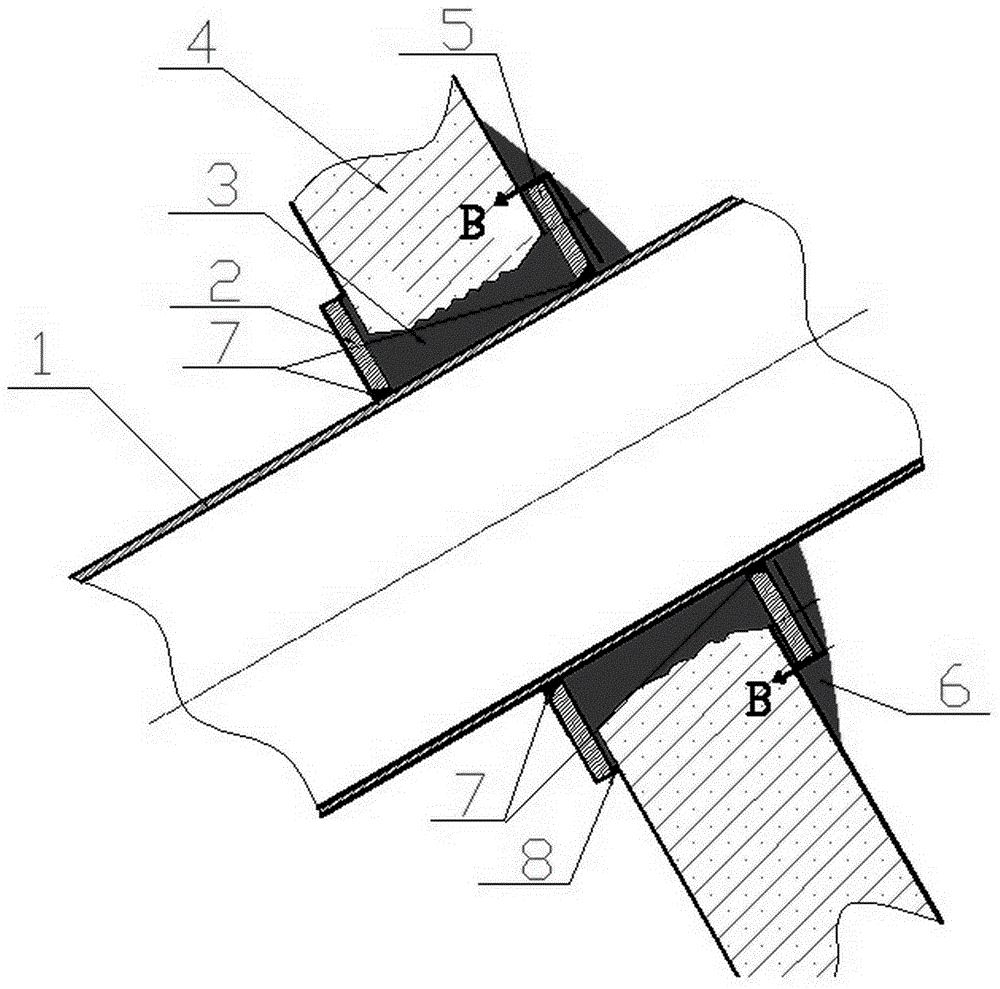

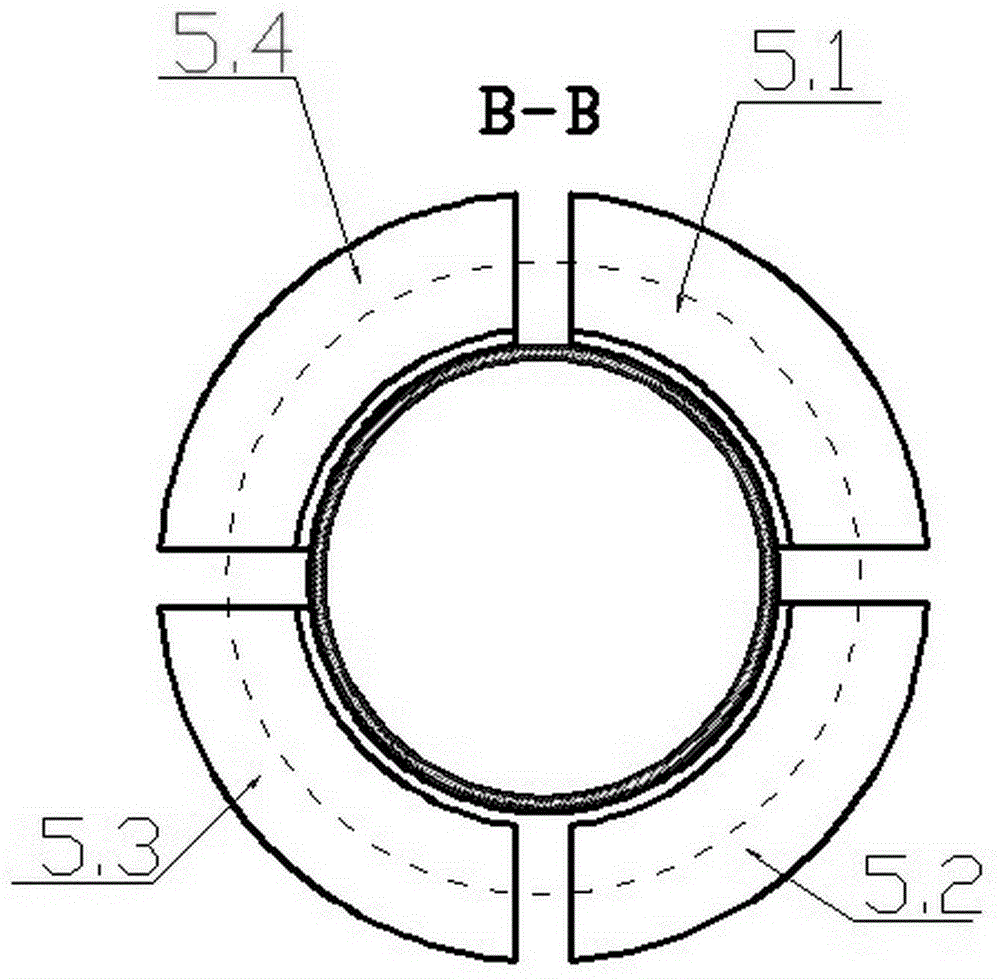

Flow-controllable orifice with three uniformly distributed holes for high-temperature liquid slag

InactiveCN104567428AExtended service lifeLifetime SynchronizationCharge manipulationManufacturing technologyLiquid slag

The invention discloses a flow-controllable orifice with three uniformly distributed holes for high-temperature liquid slag. The flow-controllable orifice is characterized in that three uniformly distributed slag orifices are arranged on an end surface of the inner middle of a nozzle inner bushing made of isostatic graphite materials, only one hole is utilized in each procedure, the other two standby slag orifices are filled with identical isostatic graphite, and stopper rods at the upper ends of the slag orifices can be finely adjusted and lifted, so that the flow of each slag orifice can be controlled. The flow-controllable orifice has the advantages that the service life of the flow-controllable orifice for the high-temperature liquid slag can be prolonged and can be identical to the service lives of graphite crucibles, and the replacement frequency can be reduced; blockage of liquid slag flow can be effectively prevented, the flow-controllable orifice is reliable and is long in service life, and the running cost can be effectively reduced; requirements of short-process mineral wool manufacturing technologies can be met; the flow-controllable orifice is favorable for meeting market requirements on broad development prospects of mineral wool and products of the mineral wool.

Owner:朱兴发

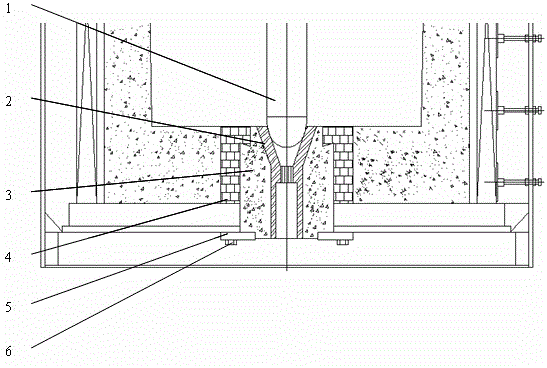

Technology for preventing seepage of suspended water cooling pond wall of corex furnace by means of reaming, pipe penetrating and blocking

The invention discloses a technology for preventing seepage of a suspended water cooling pond wall of a corex furnace by means of reaming, pipe penetrating and blocking. The technology comprises the steps that firstly, an original pipe penetrating hole in the pond wall is reamed, and after reaming is finished, a pipe is sleeved with an inner flange piece in advance, the inner flange piece is closely attached to the pond wall, and then the inner ring of the inner flange piece and the outer wall of the pipe are fully welded; grouting at the initial stage is carried out, grouting and tamping are firstly carried out in a cavity formed by the pipe and the lower portion of the pond wall, the weight ratio of components, namely, high-strength quick-dry contraction-free cement mortar to small gravel to alkyd enamel to water, of grout during grouting at the initial stage is 4:1:1:8, outer flange pieces are used for blocking, then the pipe wall is beaten every other 20 min to 30 min to generate vibration, gaps are filled till the cavity is thoroughly full, and the outer flange pieces are covered with wool felt; and secondary smearing is carried out, after 3 days to 5 days, coating is smeared to the outer surfaces of the outer flange pieces, the weight ratio of components, namely, high-strength quick-dry contraction-free concrete mortar to washed-out sand to paint to water, of the coating is 4:1:1:4, and water can be injected for testing after standing is carried out for 2-3 days and impurities in a pond are cleared away.

Owner:XINJIANG BAYI IRON & STEEL

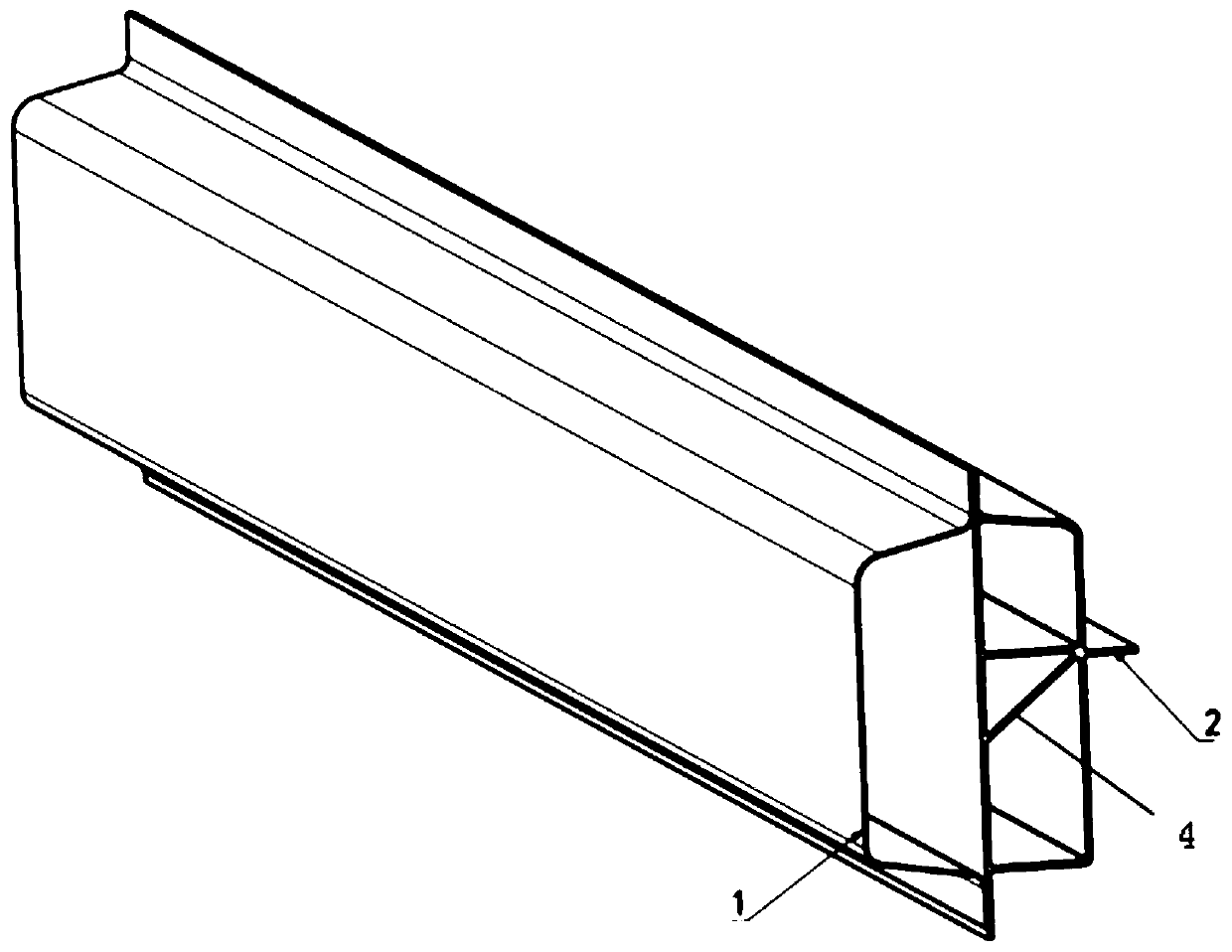

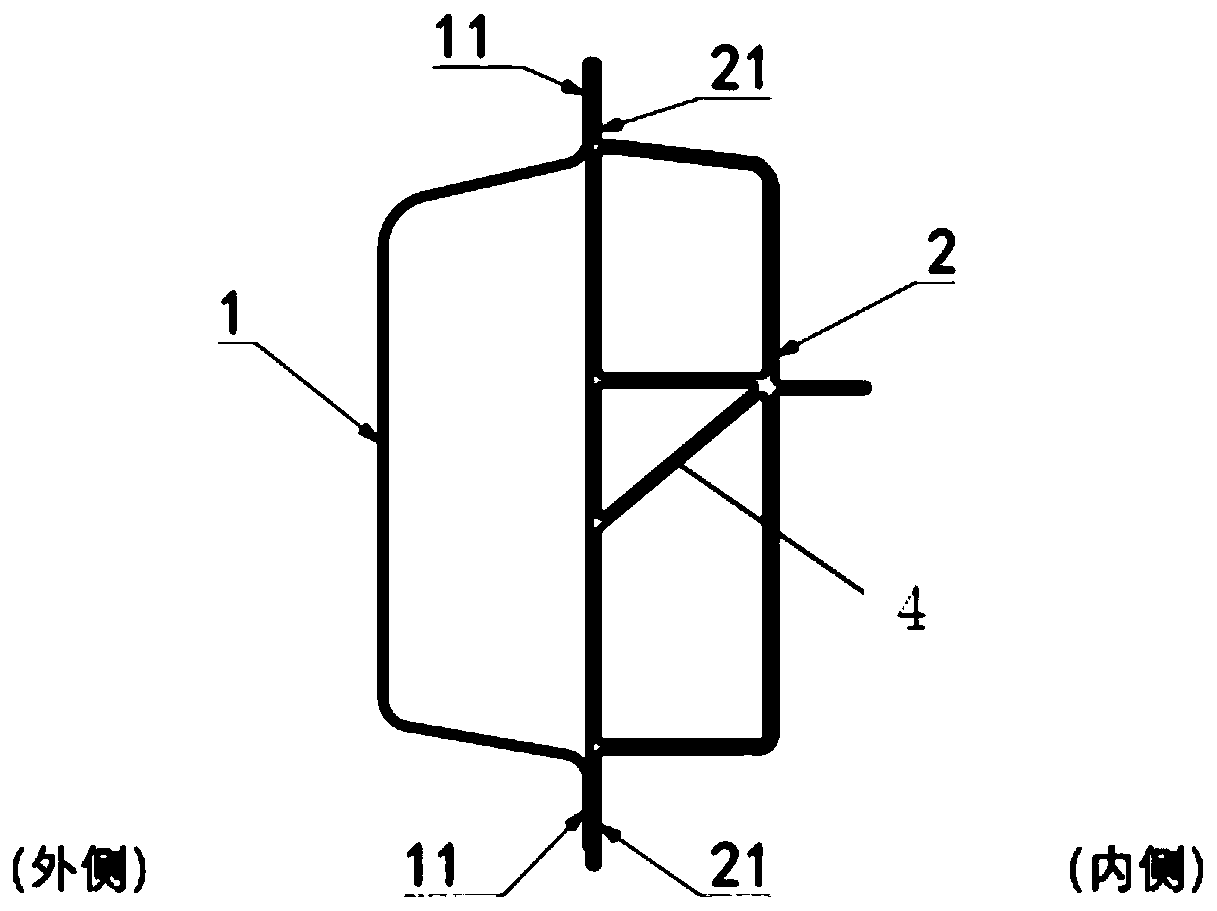

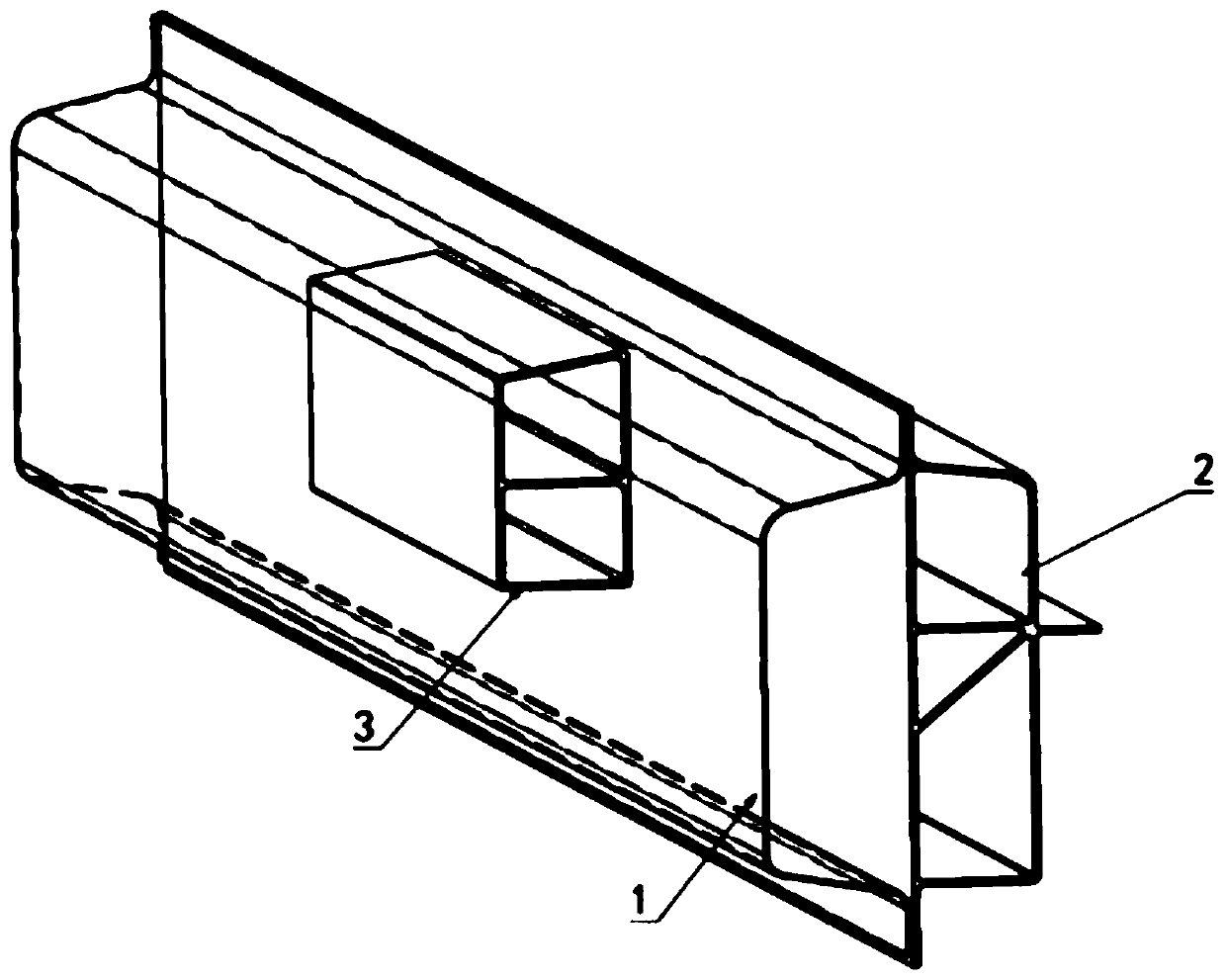

Improved automobile threshold structure

PendingCN111216809AIncrease stiffnessHigh strengthSuperstructure subunitsEnergy absorptionEngineering

The invention relates to an improved automobile threshold structure. The improved automobile threshold structure comprises a doorsill outer side plate and a doorsill inner side plate, the doorsill outer side plate is a stamping part made of steel or aluminum. The section of the doorsill outer side plate is C-shaped; and the upper end and the lower end of the threshold outer side plate extend in the vertical direction to form first flange faces. The doorsill inner side plate is an extruded section made of aluminum; the section of the threshold inner side plate is square, the interior of the threshold inner side plate is divided into at least two cavity structures, the upper end and the lower end of the threshold inner side plate extend in the vertical direction to form second flange faces,the first flange faces and the second flange faces are connected in a matched mode, and the threshold outer side plate and the threshold inner side plate are oppositely arranged and fixedly connectedto form a cavity structure. Compared with the prior art, the doorsill outer side plate can be placed into the vehicle body side wall structure, so that the side wall structure has good rigidity and strength, some unnecessary precision and quality problems cannot be generated, and the doorsill inner side plate structure is provided with a plurality of cavity structures, is high in rigidity and goodin energy absorption effect and can bear large side impact.

Owner:麦格纳卫蓝新能源汽车技术(镇江)有限公司

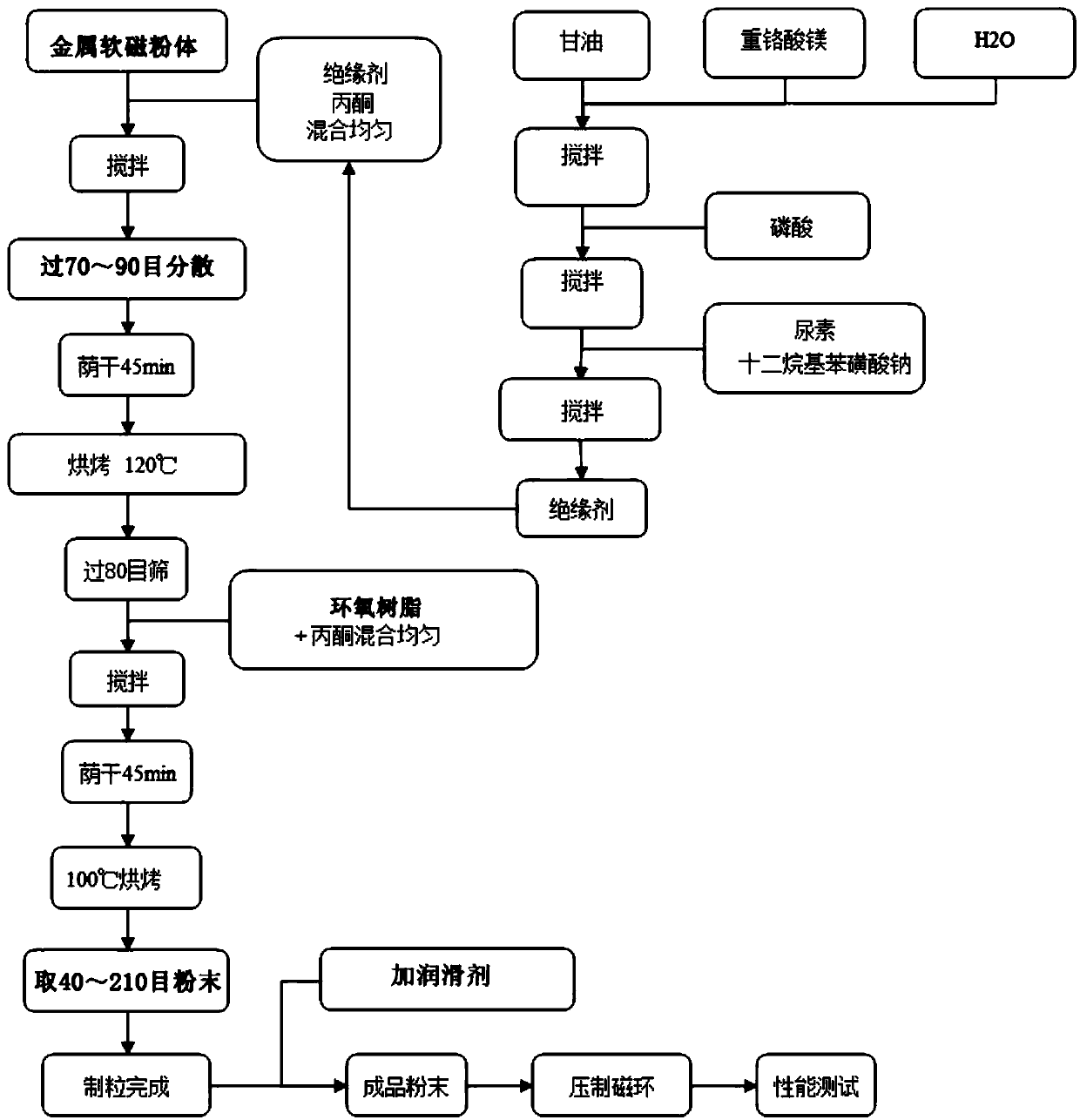

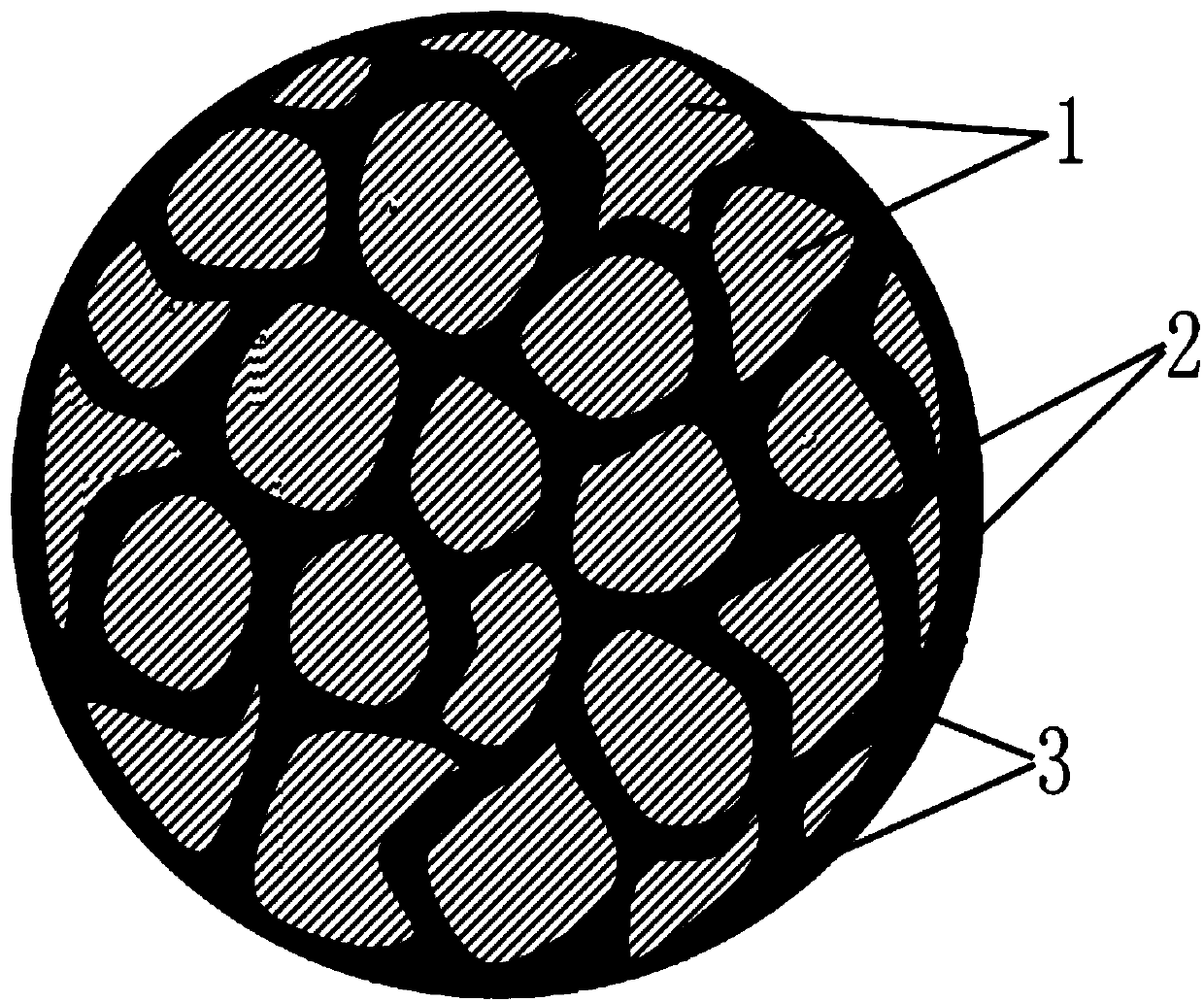

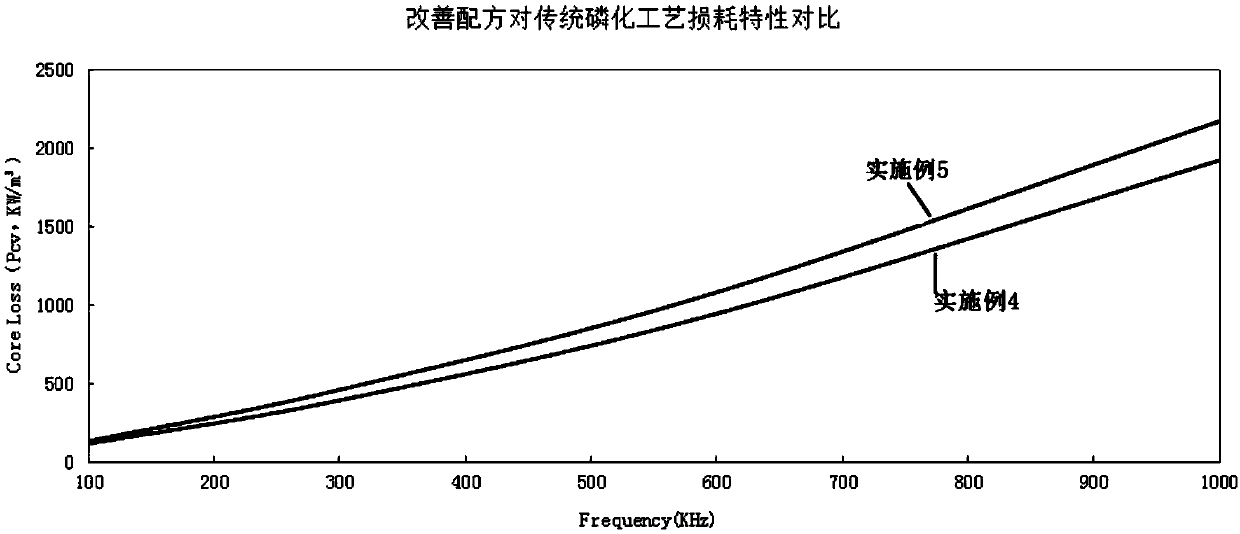

Manufacturing method for metal soft magnetic powder insulating particles

InactiveCN109663908AReduce eddy current lossHigh saturationTransportation and packagingMetal-working apparatusViscous liquidEpoxy

The invention discloses a manufacturing method for metal soft magnetic powder insulating particles. The manufacturing method comprises the following steps of adding magnesium dichromate in glycerol, performing stirring until a solution becomes viscous liquid with a uniform color, adding phosphoric acid for mixing, and adding urea and sodium dodecyl benzene sulfonate for mixing to prepare an insulating agent; (2) diluting the insulating agent with acetone, and adding metal soft magnetic powder in the insulating agent, performing stirring until a dry state, dispersing the powder with a sieve, drying the dispersed powder in a shallow, and performing baking to obtain primary processing powder; (3) diluting epoxy resin with the acetone, adding the diluted epoxy resin in the primary processing powder, performing screening, granulating, shadow drying and baking after stirring to obtain secondary processing powder; and (4) adding the secondary processing powder in a lubricant, and performing uniform mixing to obtain the metal soft magnetic powder insulating particles. A power inductor provided by the invention has high-saturation, large-current and low-eddy current loss power inductance performance; and compared with a traditional inductor, by adopting the method, the stability and the characteristics of a product are improved on the aspects of materials and processes.

Owner:深圳市迈翔科技有限公司

Method for preparing three-layer plastic compound film used for packaging food

InactiveCN101746100APaste firmlyNo pollution in the processFlexible coversWrappersPolyvinyl alcoholMoisture resistance

The invention provides a method for preparing a three-layer plastic compound film used for packaging food. The method is characterized by comprising the following steps of: spreading a polypropylene film, spraying aqueous solution of polyvinyl alcohol and making the aqueous solution of polyvinyl alcohol uniformly coated on the polypropylene film by using a supersonic machine, pressing another polypropylene film on the aqueous solution of polyvinyl alcohol to form the three-layer film, and making the three-layer film pass through a film pressing machine at the temperature of 120 DEG C to obtain the three-layer plastic compound film. The three-layer plastic compound film has the characteristics of low cost, high strength, no toxin, easy heat sealing, high oxygen insulation and moisture resistance and the like, and is suitable to be used for packaging sausages, preserved pork and hot pickled mustard tuber, particularly peanuts and deep fried crispy foods; and the food packaged by the three-layer plastic compound film can be stored for over half a year without going bad, the raw materials and equipment are based on domestic markets, and the cost is low, so that the three-layer plastic compound film is suitable to be produced by small- and medium-sized enterprises.

Owner:哈达

Halogen-free flame-retardant resin composition as well as bonding sheet and copper clad laminate with same

ActiveCN106751821AImprove liquidityHigh glass transition temperatureSynthetic resin layered productsMetal layered productsVitrificationHeat resistance

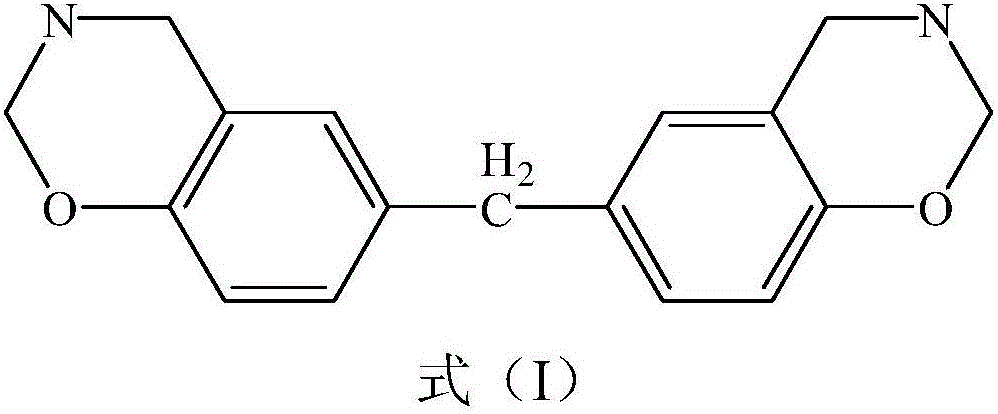

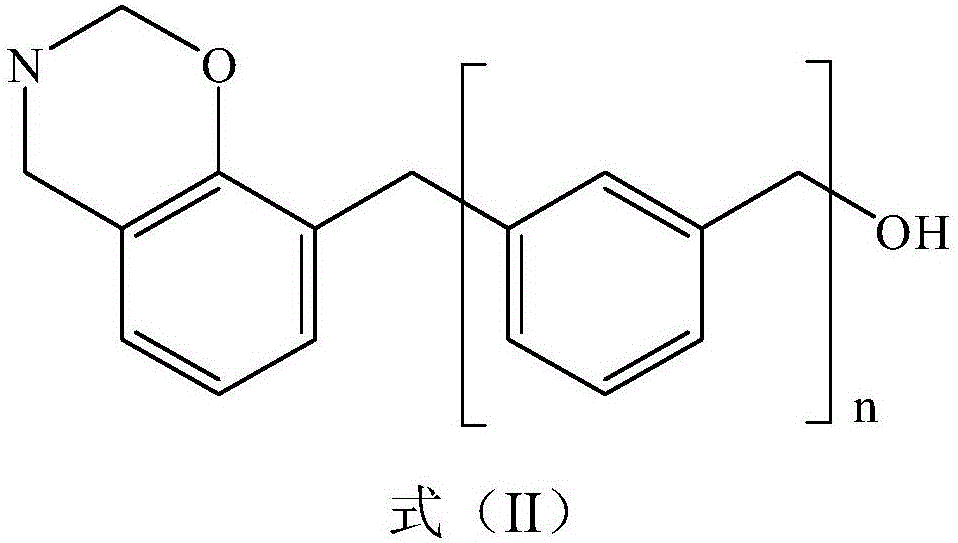

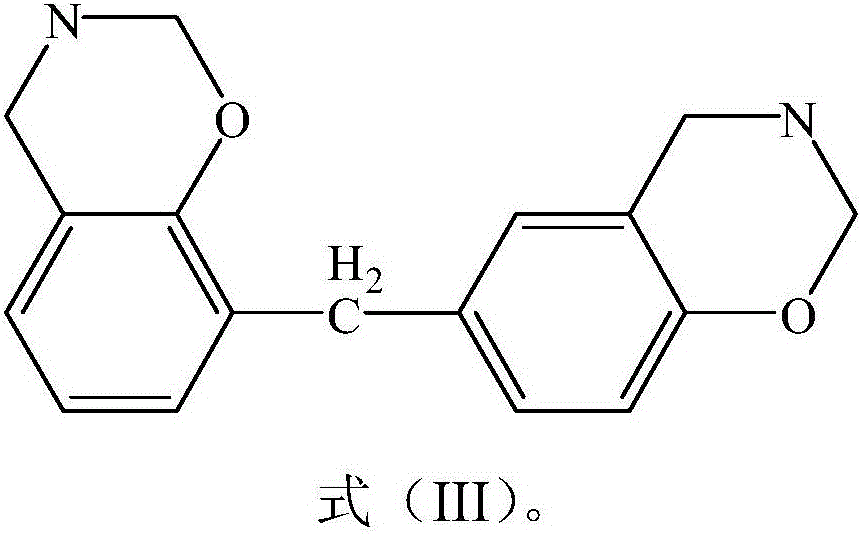

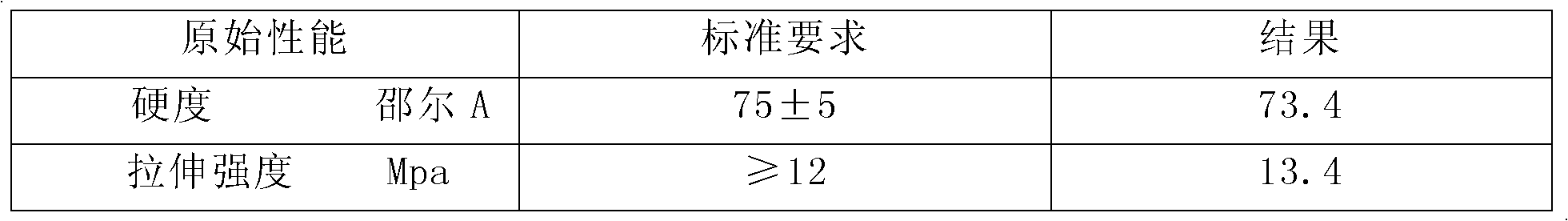

The invention relates to a halogen-free flame-retardant resin composition as well as a bonding sheet and copper clad laminate with same. By the weight parts of organic solids, and the sum of weight parts of (A), (B) and (C) is 100, the halogen-free flame-retardant resin composition comprises the following components: (A) 50-80 parts of benzoxazine resin, (B) 10-40 parts of a polyepoxy compound, (C) 1-15 parts of a phenolic aldehyde curing agent, (D) 0-20 parts of a phosphorus-containing flame retardant, and (E) a curing promoter and (F) packing as well, wherein the benzoxazine resin at least comprises 35-65% by weight of 4,4-bisphenol F benzoxazine resin and 15-35% of phenolic aldehyde benzoxazine resin. The prepreg and the laminate made of the halogen-free flame-retardant resin composition provided by the invention have relatively high glass-transition temperature, good thermal resistance, low water absorption capacity and relatively good resin flowability, and conventional preparation processes of electronic circuit base materials and downstream PCBs (Printed Circuit Boards) can be met.

Owner:GUANGDONG SHENGYI SCI TECH

Preparation method for ultra-pure nitric acid

The invention discloses a preparation method for ultra-pure nitric acid. The method comprises the steps of: (1) subjecting electronic grade nitric acid to electric heating rectification, and controlling the temperature at 100-120DEG C; (2) employing nitrogen to remove nitrogen dioxide from the fraction obtained in step (1) by a bleaching reaction kettle to make the fraction colorless and transparent; (3) putting the product obtained in step (2) into a mixing tank, adding an appropriate amount of ultrapure water, and performing stirring for 30min; and (4) filtering the product obtained in step (3) by a 0.2micrometer filter to remove harmful particles with a particle size larger than 0.2 micrometer from the mixture, thus obtaining the nitric acid. According to the preparation method, under original production process conditions, through further rectification purification and precise mixing, impurities in the product can be removed, so that the nitric acid can have purity reaching the PPt grade, and can meet the production process requirement of ultra large scale integrated circuits.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

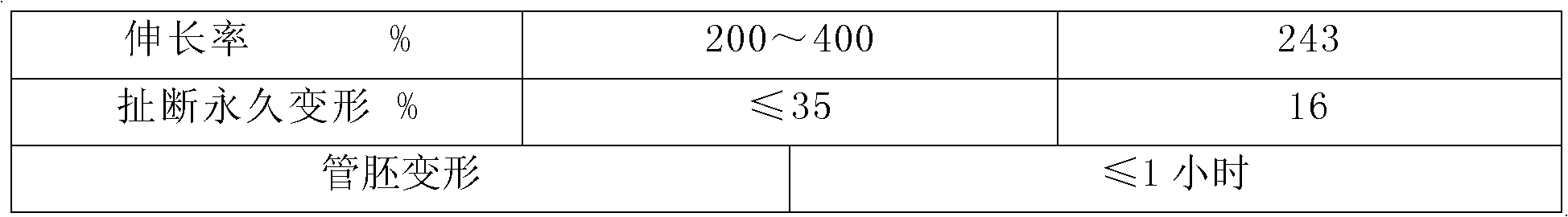

Turbocharger tube rubber

The invention relates to turbocharger tube rubber, which consists of ethylene-methyl acrylate G, ethylene-methyl acrylate IP, a reinforcing agent N774, a reinforcing agent N330, a plasticizer TP-759, an internal release agent 18D and a vulcanizing agent DIAK number 1, wherein the sum of the ethylene-methyl acrylate G and the ethylene-methyl acrylate IP is 100 parts. On one hand, by adopting a method for mixing the ethylene-methyl acrylate G with more excellent processability with raw rubber ethylene-methyl acrylate IP in a traditional formula, the ethylene-methyl acrylate IP adapts to various production environments, has good stiffness, does not deform and can effectively improve the production processability; on the other hand, due to high reinforcing property of carbon black N300, the hardness of the mixed making rubber is adjusted to the high-limit of tolerance by matching the N774, and the production processability also can be improved by properly improving the rubber hardness. The productive technology performance of the mixed making rubber is improved by the two aspects, pipe blanks do not fall or deform within 24 hours in the process of standing, the requirement of production technology is met, the rubber is more suitable for continuous production under different conditions, and the production efficiency is improved.

Owner:TIANJIN PENGYI GRP CO LTD

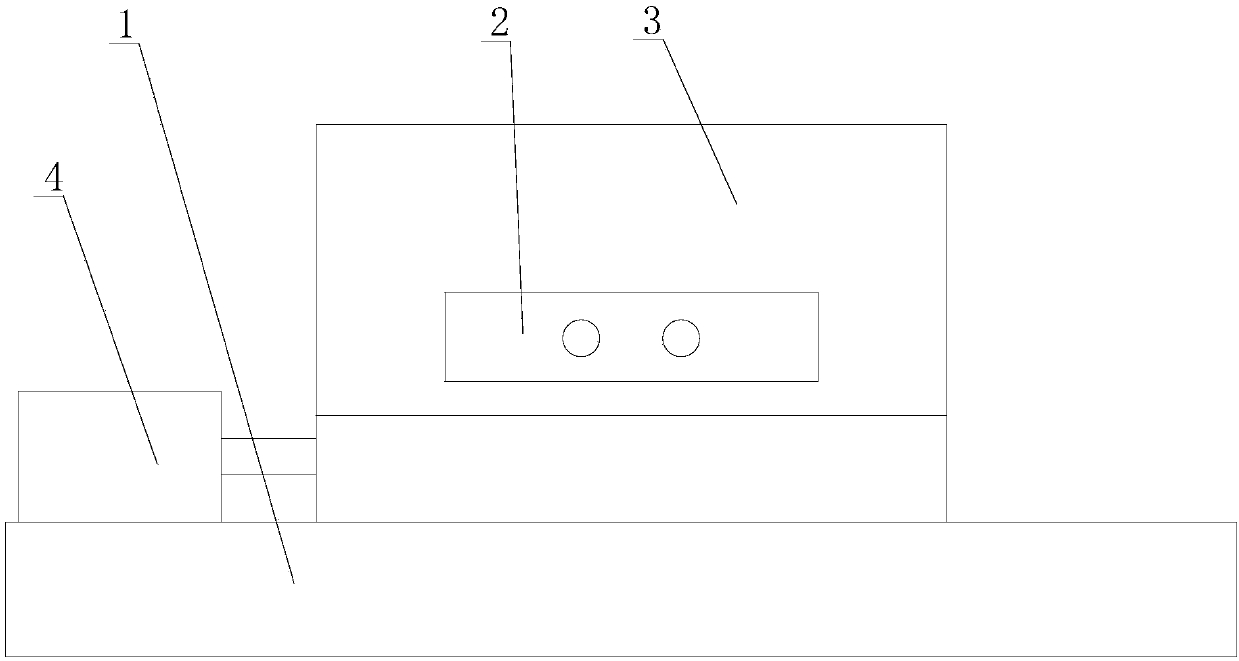

Ultrasonic aluminum foil welding machine

InactiveCN107803582AEasy to weldMeet the production processNon-electric welding apparatusEngineeringMechanical engineering

The invention discloses an ultrasonic aluminum foil welding machine. The ultrasonic aluminum foil welding machine comprises a welding head assembly, a base and a clamping assembly. The welding head and the clamping assembly are mounted on the base; the welding head assembly lifts relative to the base; the clamping assembly comprises a clamping plate, a mounting seat and a driving assembly; and theclamping plate clamps an aluminum foil or loosens the aluminum foil through the driving assembly and the mounting seat. The ultrasonic aluminum foil welding machine disclosed by the invention has theadvantages of being simple in structure, convenient to operate and wide in application range.

Owner:ZHAOQING HI TECH ZONE GUOZHUAN TECH CO LTD

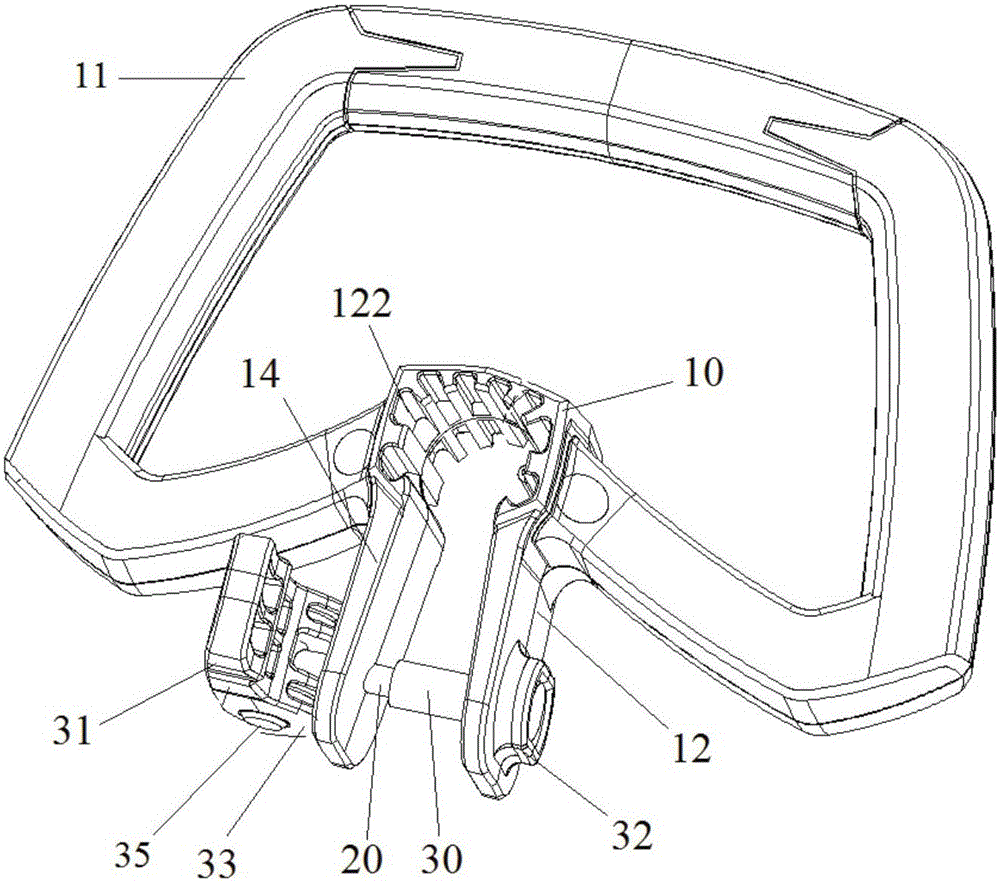

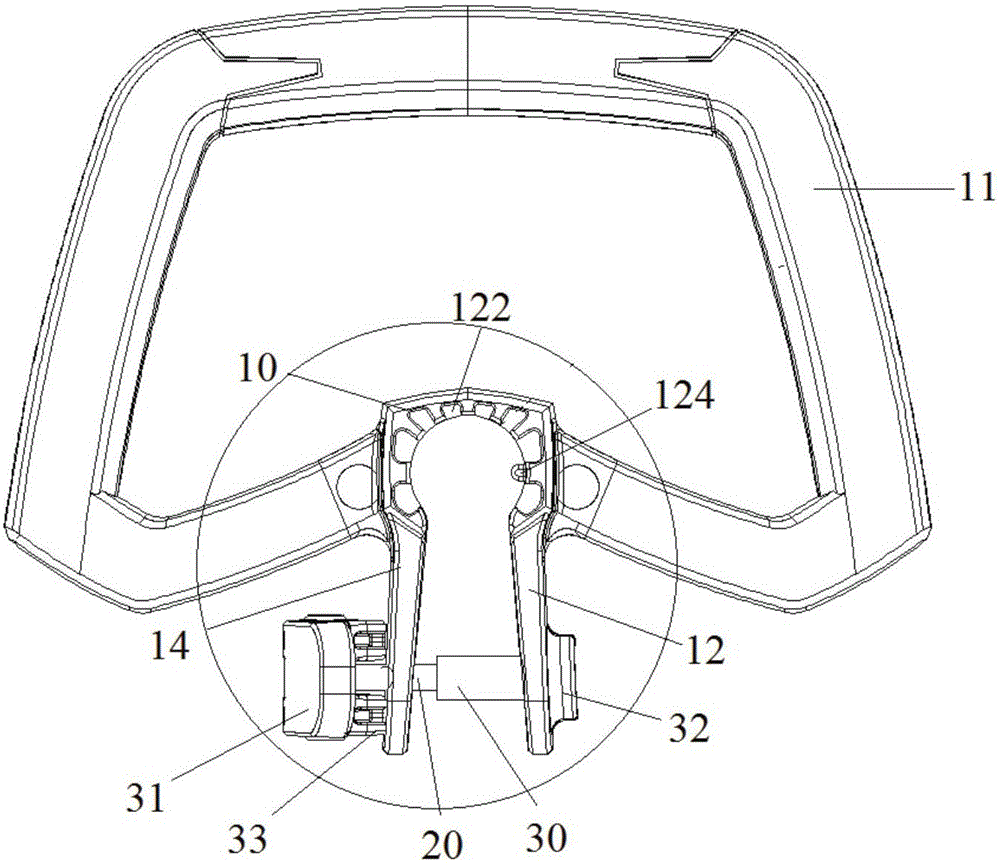

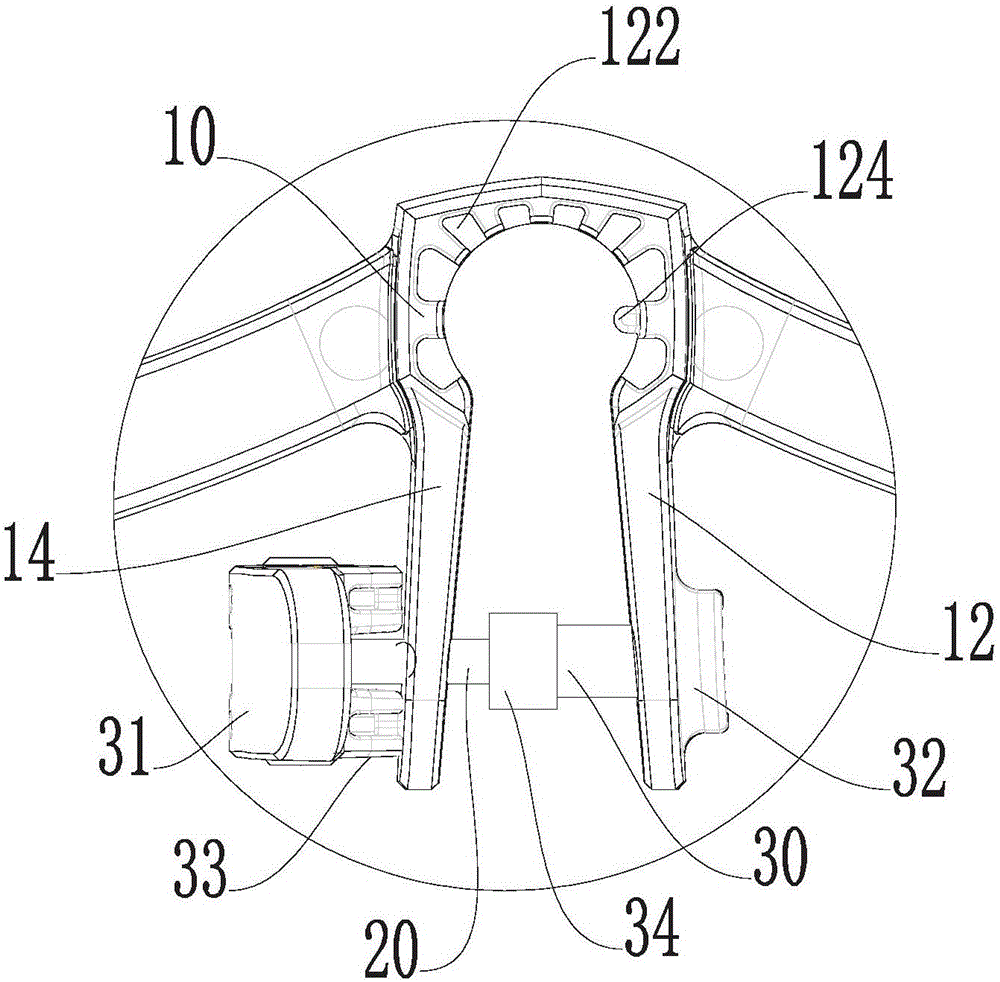

Auxiliary handle

InactiveCN106041841ACost controlMeet the production processPortable power-driven toolsMetal-working hand toolsEngineeringMechanical engineering

The invention discloses an auxiliary handle which comprises a loop bar part (10) provided with an opening, and a clamping part. The clamping part comprises a first clamping arm (12) and a second clamping arm (14) which are connected with the two ends of the opening of the loop bar part (10). A limiting part (30) is arranged between the first clamping arm (12) and the second clamping arm (14). The minimum distance, between the first clamping part (12) and the second clamping arm (14), at the position of the limiting part (30) is limited by the limiting part (30). By means of the auxiliary handle, the problems that the clamping arms are locally whitened and fractured due to deformation generated by excessive clamping and approaching can be effectively solved.

Owner:SKYBEST ELECTRIC APPLIANCE SUZHOU CO LTD

Silicon dioxide etching solution and preparation method thereof

InactiveCN104164237AImprove etching precisionAccelerateSurface treatment compositionsUltrapure waterAmmonium fluoride

The invention discloses a silicon dioxide etching solution and a preparation method thereof. The silicon dioxide etching solution comprises the following compositions by weight: 20%-30% of an ammonium fluoride solution, 3%-6% of hydrofluoric acid, and the balance ultrapure water. The preparation method of the silicon dioxide etching solution provided by the invention includes: weighing certain amount of an ammonium fluoride solution, adding hydrofluoric acid under stirring, fully stirring the mixture for 15min; then adding the ultrapure water, and conducting stirring for 45min; and then filtering the prepared mixture by a 0.5micrometer filter to remove harmful particles with a particle size larger than 0.5micrometer from the mixture, thus obtaining the silicon dioxide etching solution. Through precise blending, impurities are removed from the etching solution product provided by the invention, the etching precision is high, and the speed is fast.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com